Bending failure strain measurement method

A strain measurement and bending technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of difficult parts formability, not considering deformation history, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the following, a method for measuring bending failure strain of the present invention will be further described in detail according to the accompanying drawings and specific implementation methods.

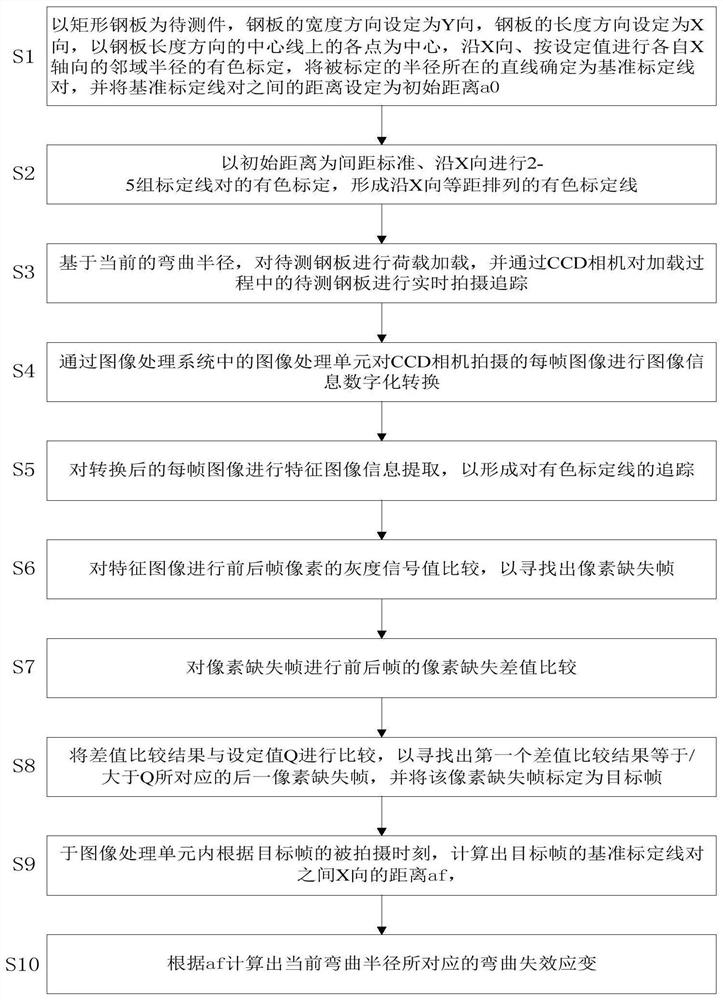

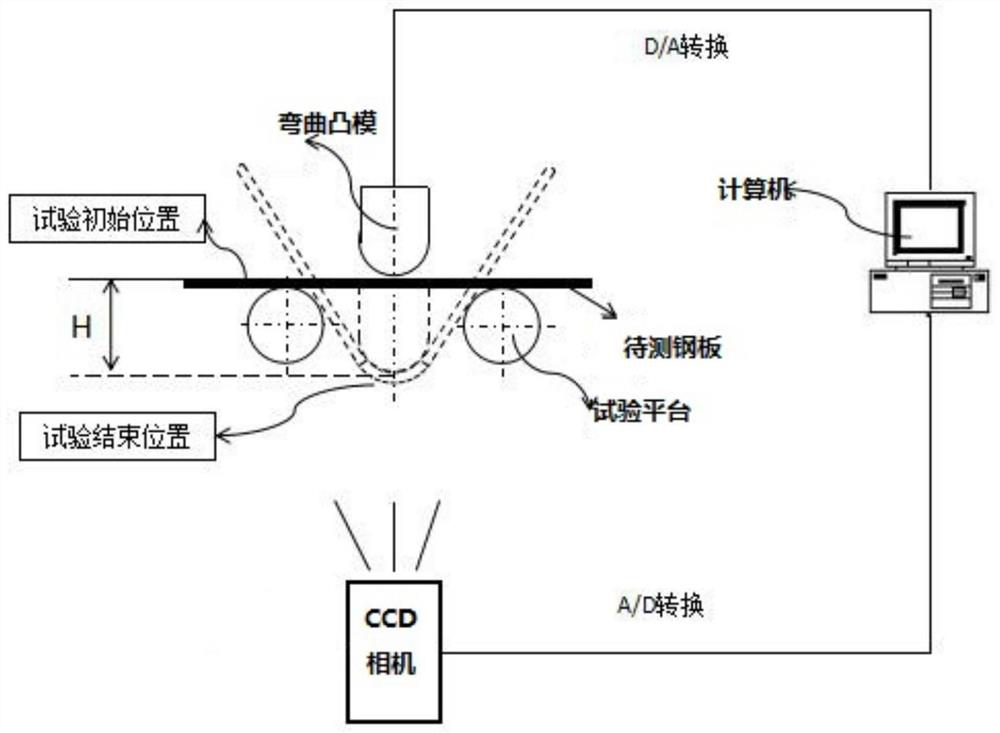

[0048] Such as figure 1 , 2 A bending failure strain measurement method shown in ,

[0049] Through the image processing system based on the CCD camera, the bending failure strain corresponding to different bending radii is found, which specifically includes the following steps:

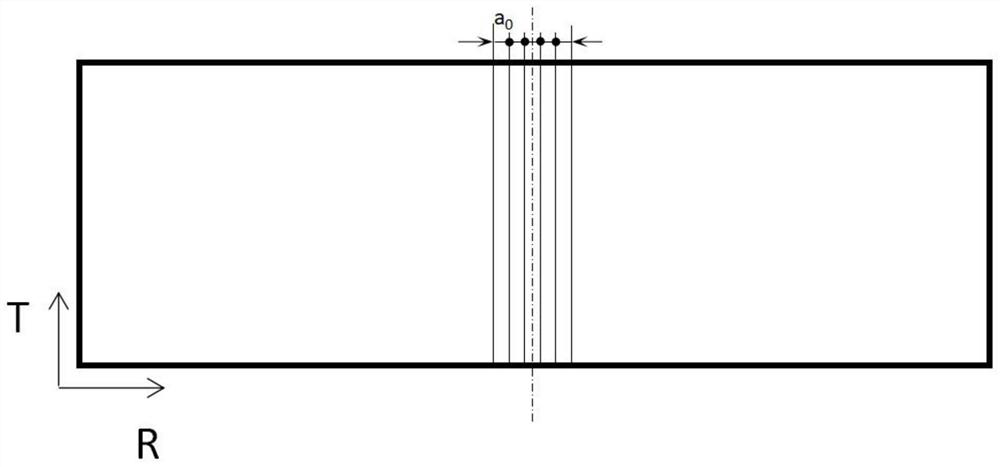

[0050] S1: Take a rectangular steel plate as the object to be tested, set the width direction of the steel plate as the Y direction, set the length direction of the steel plate as the X direction, and take each point on the center line of the steel plate length direction as the center, along the X direction, according to the design Set the value to carry out the colored calibration of the neighborhood radius of each X axis, determine the straight line where the calibrated radius is located as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com