A Creep-Fatigue Life Prediction Method for Materials

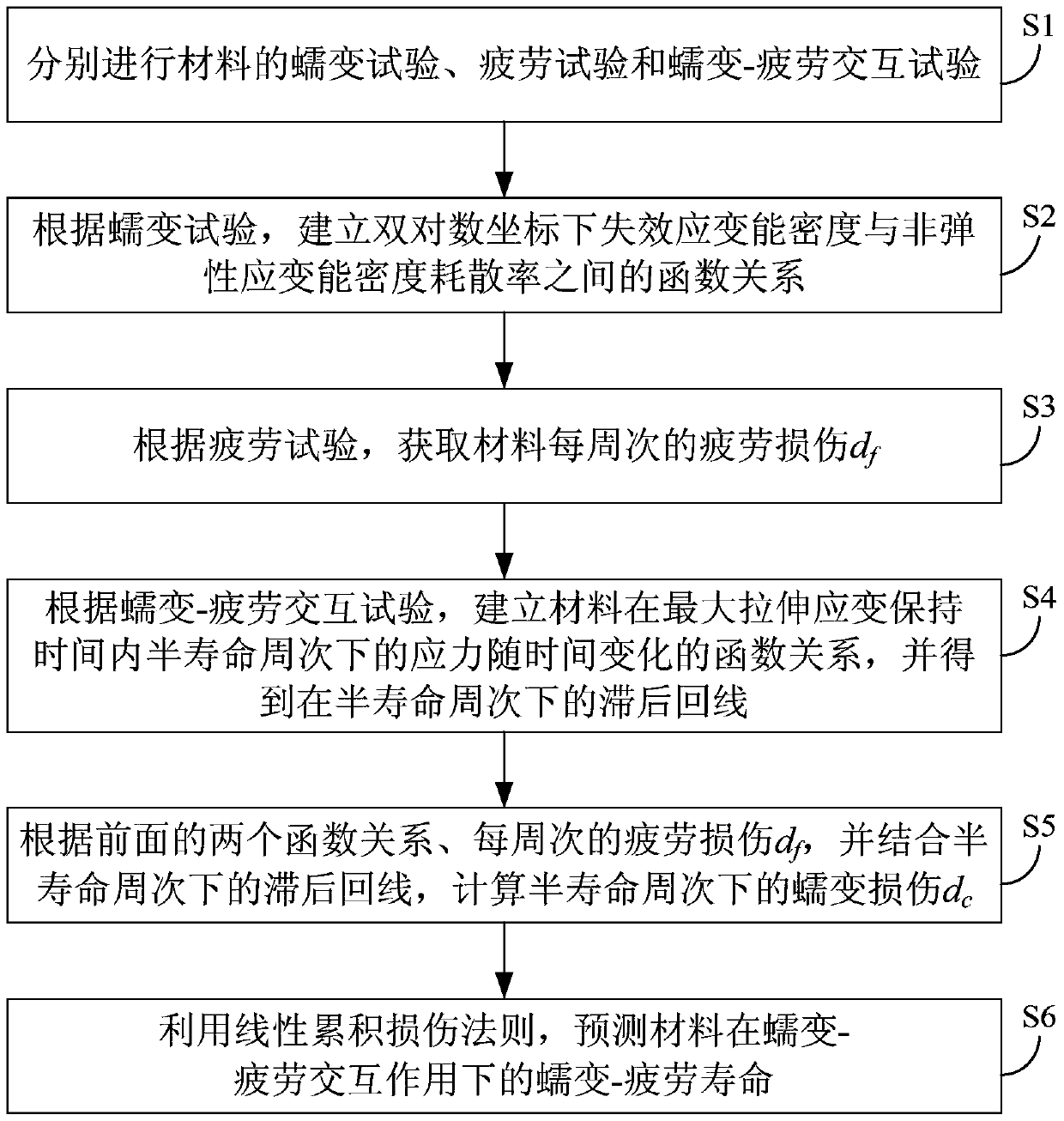

A fatigue life prediction and creep technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of conservative ductility exhaustion model, non-conservative life prediction results of time fraction model, lack of physical meaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

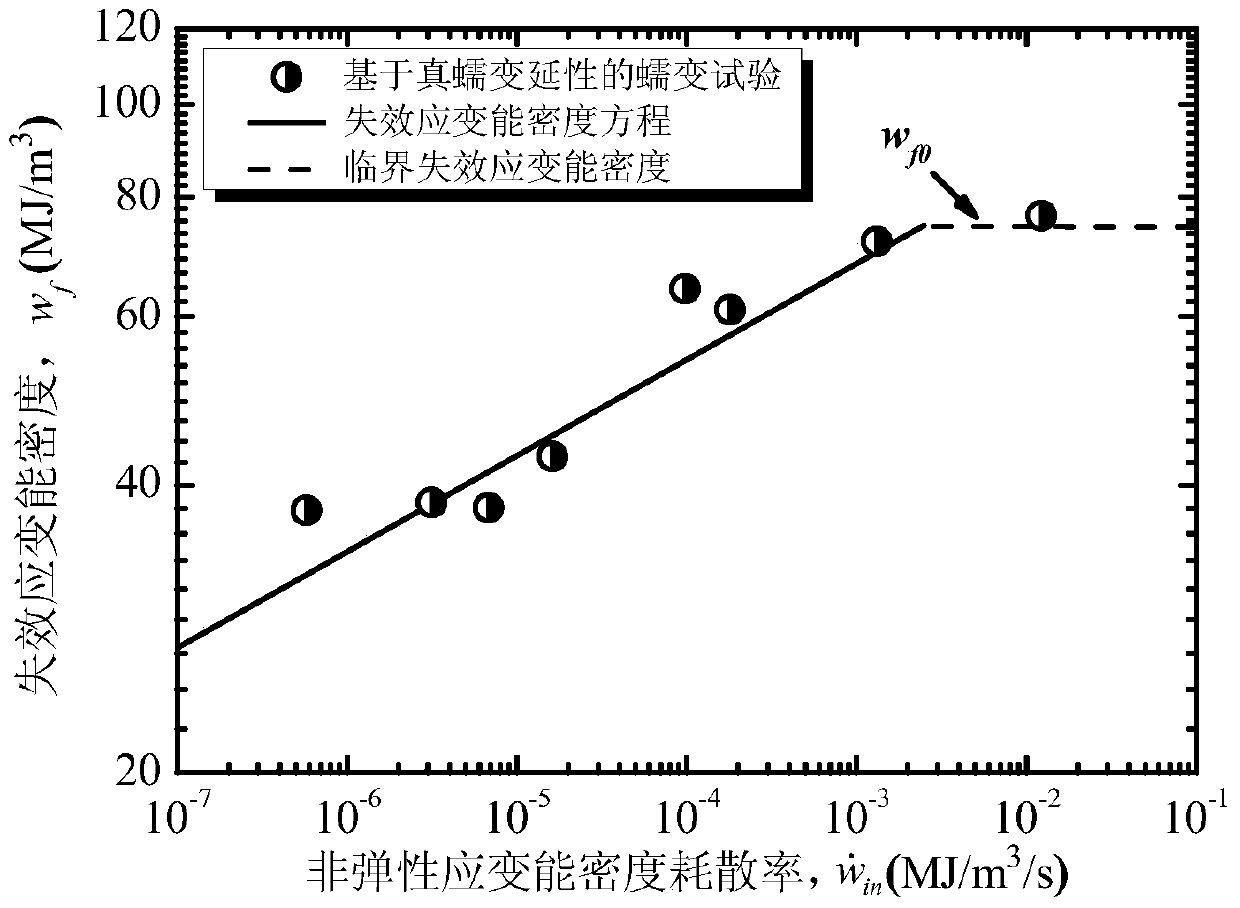

[0130] The selected data are three papers published by Takahashi and Yaguchi [Y. Takahashi, Study on creep-fatigue evaluation procedures for high-chromium steels-Part I: Test results and life prediction based on measured stress relaxation, International Journal of Pressure Vessels and Piping.85 (2008)406-422], 【Y.Takahashi, B.Dogan, D.Gandy, Systematic evaluation of creep-fatigue life prediction methods for various alloys, Proceedings of the ASME 2009 Pressure Vessels and Piping Division Conference. (2009) 1-10】 , [K.Taguchi, E.Kanno, S.Ozaki, Application of the overstress concept to inelastic behavior and evaluation of creep-fatiguedamage for modified 9Cr-1Mo steel International Journal of Pressure Vessels and Piping.44(1990)99-115] and Asayama [T.Asayama, Update and ImproveSubsection NH-Alternative Simplified Creep-Fatigue Design Methods, STP-NU-041.(2011)]. First of all, these documents give the creep test data of Grade91 at 550 °C, 600 °C and 650 °C, that is, the linear ma...

example 2

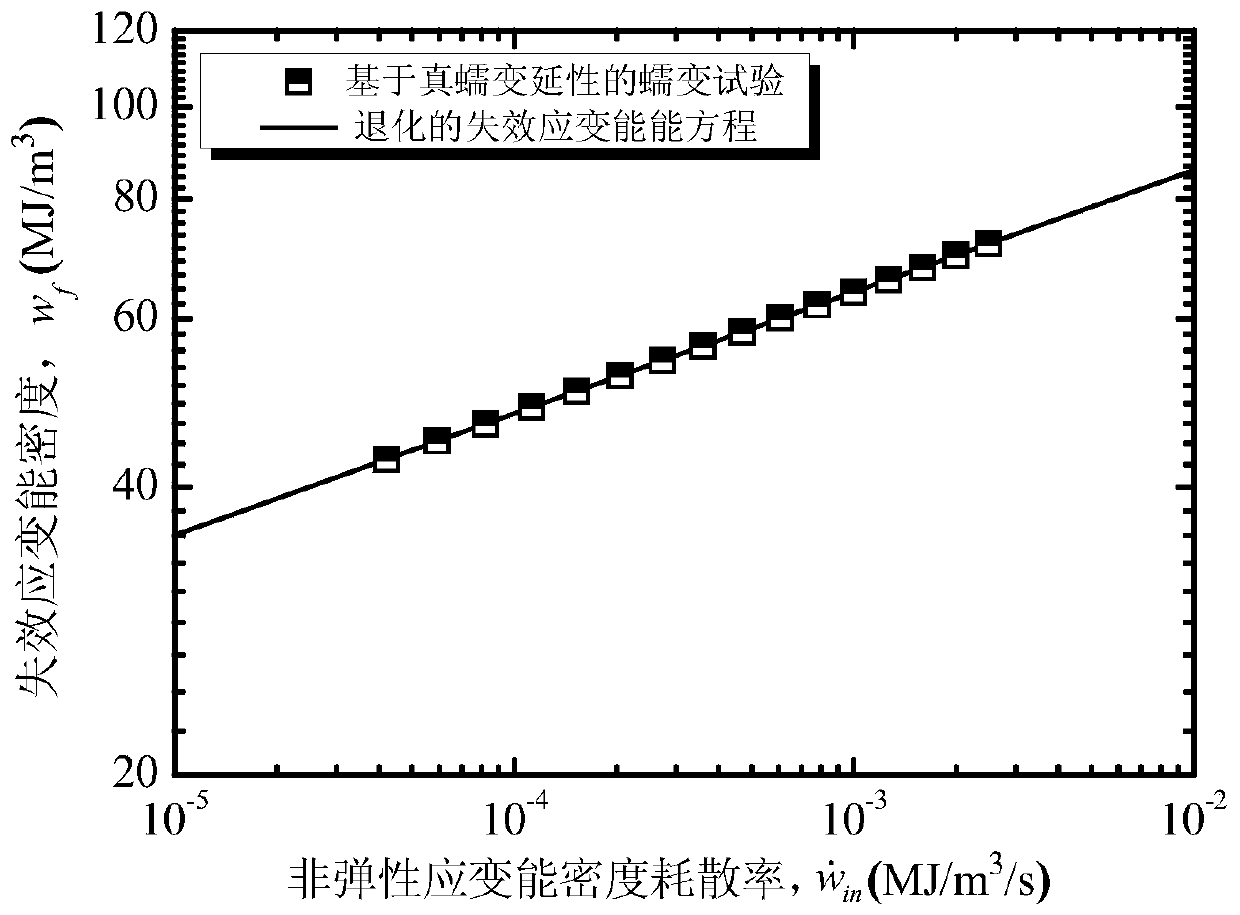

[0134] The selected data are three papers published by Chen, Pritchard and Kim [X.Chen, High temperature creep-fatigue behavior of alloy 617 and alloy 230, University of Illinois at Urbana-Champaign.(2012)], [P.G.Pritchard, L.Carroll, T .Hassan,Constitutivemodeling of high temperature uniaxial creep-fatigue and creep-ratcheting responses of Alloy 617,ASME 2013Pressure Vessels and PipingConference.American Society of Mechanical Engineers.(2013)],【W.G.Kim,J.Y.Park,G.G.Leeect,T creep behavior of alloy 617 in air and helium environments. Nuclear Engineering and Design. 271(2014) 291-300]. First of all, these documents give Alloy creep test data at 850°C. Since only the material life at 850°C is studied, that is, using the degeneration formula (4), the temperature-related material constant D = 464.111 can be obtained; analysis 850 The functional relationship between the failure strain energy density and the inelastic strain energy density dissipation rate at ℃, it is found that the...

example 3

[0138] The selected data are two papers published by Conway and Kim [J.B.Conway, R.H.Stentz, J.T.Berling.Fatigue, tensile, and relaxation behavior of stainless steels, Mar-Test, Inc., Cincinnati, Ohio.(1975)], [V.K. Sikka, M.K. Booker. Assessment of tensile and creep data for Types 304 and 316 stainless steel, Journal of Pressure Vessel Technology. 99 (1977) 298-313]. First of all, these documents give the creep test data of 304SS at 650°C. Since only the material life at a temperature of 650°C is studied, that is, using the degeneration formula (4), the temperature-related material constant D=154.12 can be obtained; the analysis of 650 The functional relationship between the failure strain energy density and the inelastic strain energy density dissipation rate at ℃, it is found that there is no critical failure strain energy density; in the creep fatigue test at 650℃, the passing total strain ranges are 0.5% and 2.0%, respectively, Calculate the constants A=45.55 and B=129.19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com