Expert system for measurement of vacuum degree and life management of vacuum arc extinguish chamber and application method

A technology of vacuum interrupter and expert system, which is applied in the field of vacuum degree measurement and life management expert system of vacuum interrupter, which can solve the problems of loss of monitoring function, limitation of popularization and application, lack of data building and analysis and processing, etc.

Inactive Publication Date: 2010-03-03

HEBEI UNIV OF TECH

View PDF2 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The use of the first type of online vacuum monitoring system, even if it is not electrically connected to the power grid, increases the complexity of the power system and reduces the reliability of the power grid. Therefore, the actual application of various online monitoring methods in the p

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

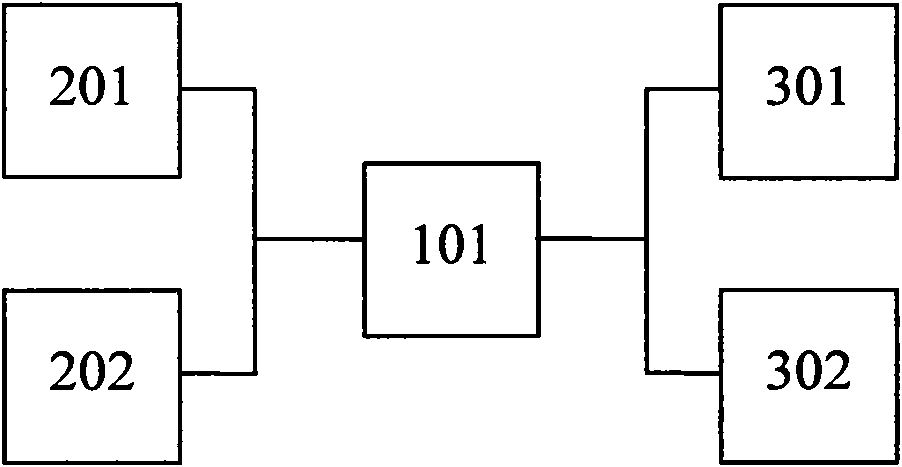

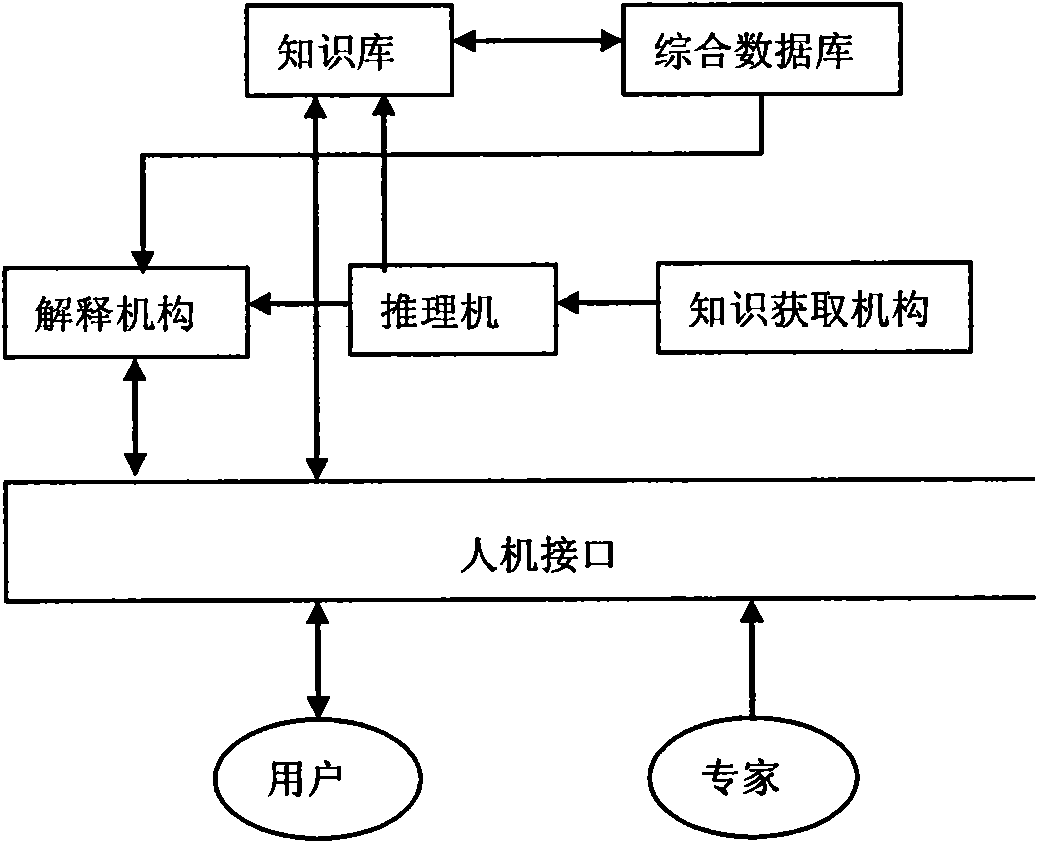

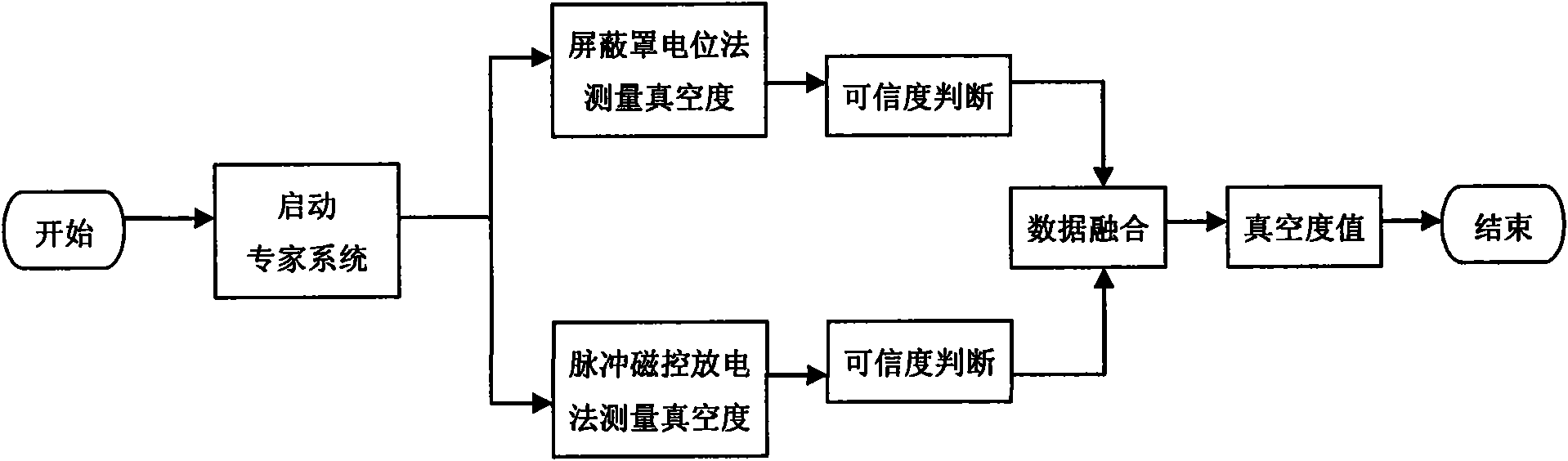

The invention relates to a method for vacuum degree measurement and life management of a vacuum arc extinguish chamber, which is based on an expert system in electric grid. The invention comprises anexpert system main module, a residual life predicating module and a life management module, a vacuum degree measurement device by a magnetic control method, and a vacuum degree measurement device by ashielding case potential method, wherein the expert system main module is respectively connected with the residual life predicating module and the life management module, and the vacuum degree measurement device by the magnetic control method and the vacuum degree measurement device by the shielding case potential method. The data measured on line by the vacuum degree measurement device by the magnetic control method and the vacuum degree measurement device by the shielding case potential method is provided to the expert system which provides results and outputs life management information based on a reliability knowledge base of the measured data. In the invention, the vacuum degree in the vacuum arc extinguish chamber can be measured in the power grid, and also the residual life can bepredicated and off-line monitoring can be realized so as to avoid the reduction of reliability coefficient of a powder system due to the access of on-line measurement equipment, thereby meeting the requirement of switch electrical applicance state examination, and realizing the intelligentizing of a vacuum switch.

Description

technical field [0001] The invention relates to an expert system for vacuum degree measurement and life management of a vacuum interrupter and a method for using it, in particular to a method for vacuum degree measurement and life management of a vacuum interrupter based on the expert system in a power grid. Background technique [0002] At present, the vacuum interrupter in the power grid has reliable vacuum measurement methods during the production process, so the factory parameters of the products are reliable, but these measurement methods cannot be used for the products after they leave the factory. Accurate measurement of vacuum degree after leaving the factory has always been a problem. Domestic and foreign researchers, including the applicant, have devoted themselves to the research on the vacuum degree monitoring of the vacuum interrupter installed in the switchgear. Kerr electro-optic conversion method, shielding cover potential method, discharge acoustic emission...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06N5/04G01L21/00H01H33/668

Inventor 赵智忠王丽君

Owner HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com