Patents

Literature

46results about How to "Predict remaining life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Predication method of electric vehicle power battery service life

InactiveCN103954913AEvaluate your healthEasy to manageElectrical testingElectric vehicleCollections data

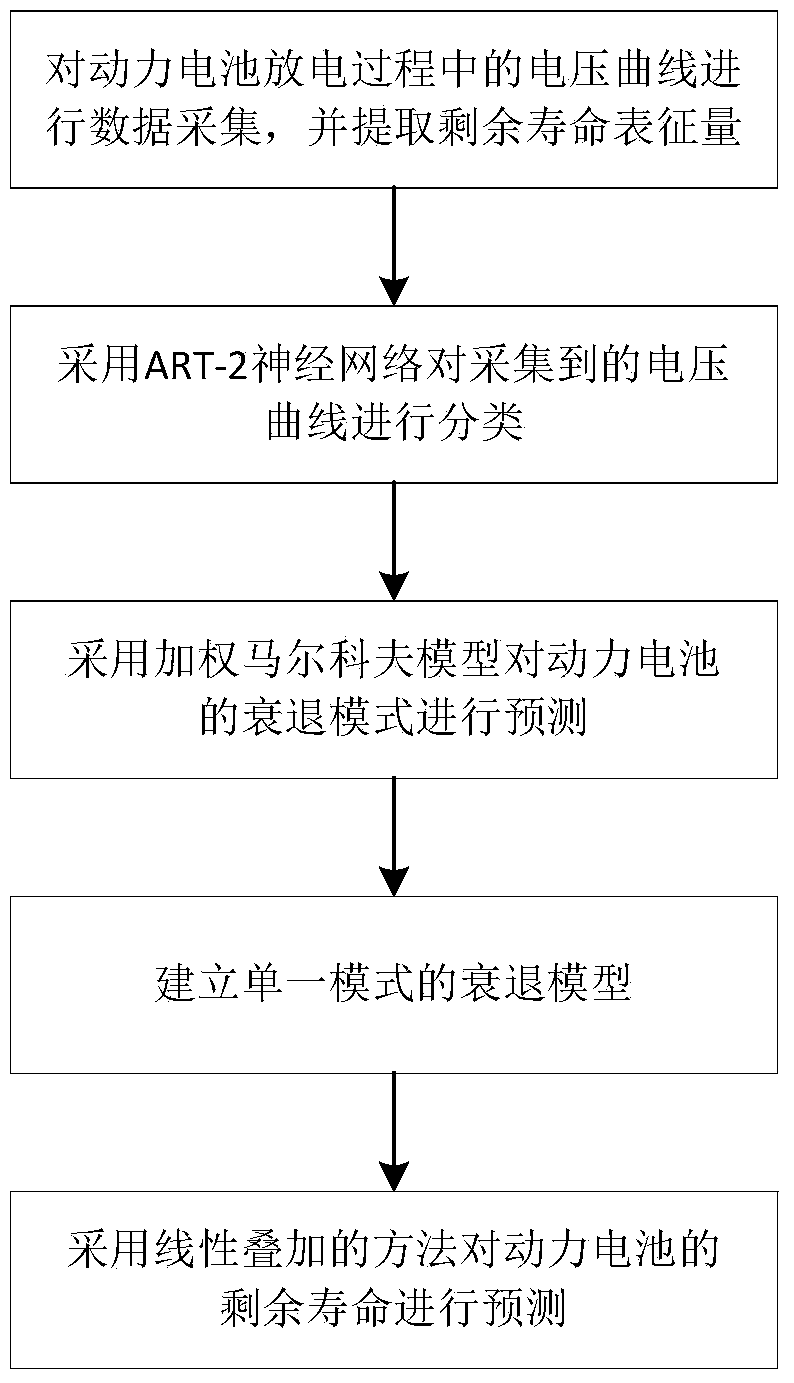

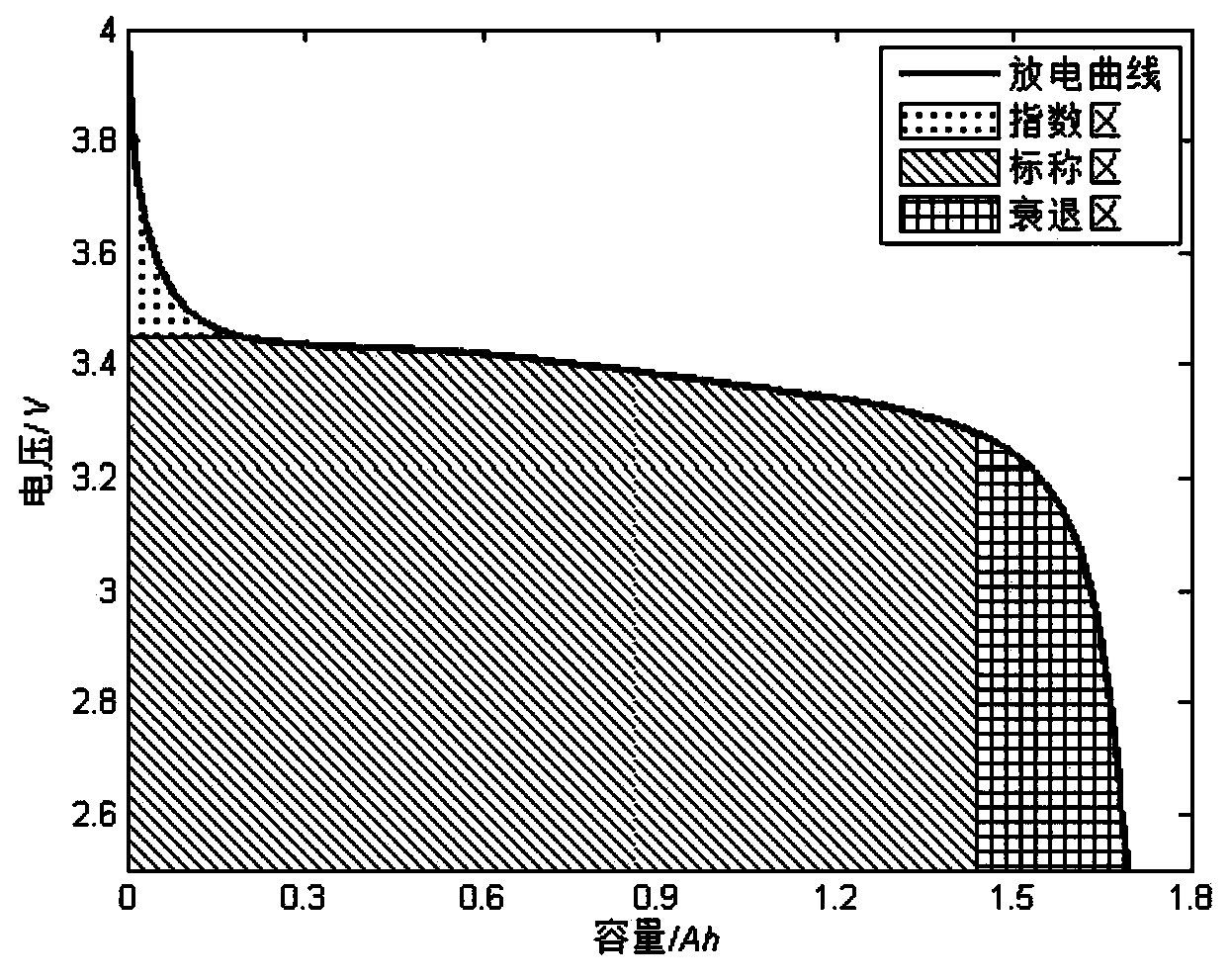

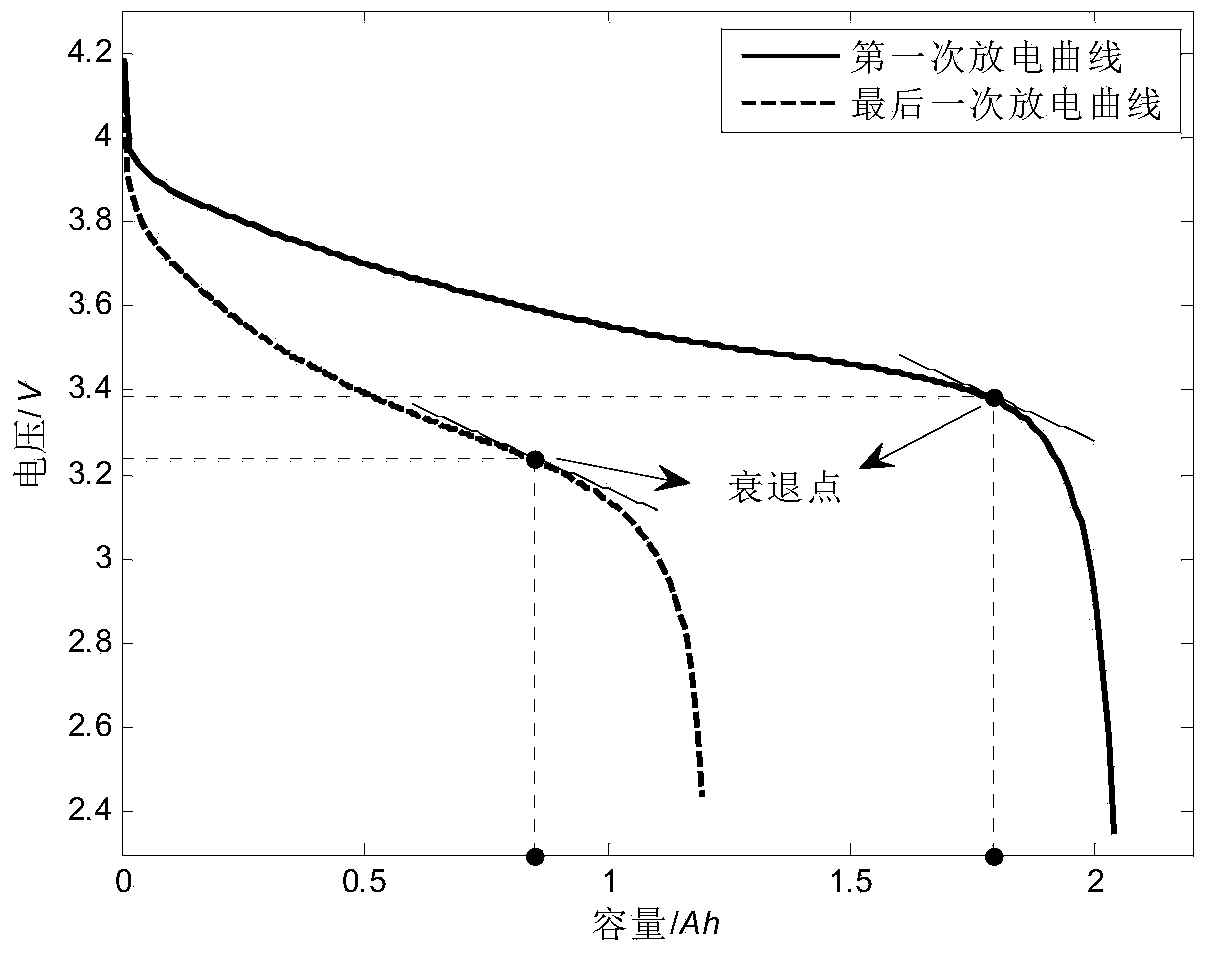

The invention provides a prediction method of electric vehicle power battery service life. The method includes the following steps that (1) data collection is conducted on the voltage curve of a power battery in the process of electro-discharge, battery residual life characterization is extracted, and a recession point is gained; (2) clustering is conducted on the collected voltage curve by the adoption of an ART2 neural network, and recession pattern classification is conducted on the voltage curve; (3) predication is conducted on the recession pattern of the power battery by the adoption of a weighted Markov model; (4) a single mode of recession pattern is built; (5) prediction is conducted on the residual service life of the power battery by the adoption of a linear superposition method. By means of the prediction method of electric vehicle power battery service life, the health condition of batteries can be evaluated conveniently, quickly and accurately, the residual service life of the power battery of an electric vehicle can be accurately predicted aiming to individuals according to different driving habits of different people, and the battery can be better managed, planned and used.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

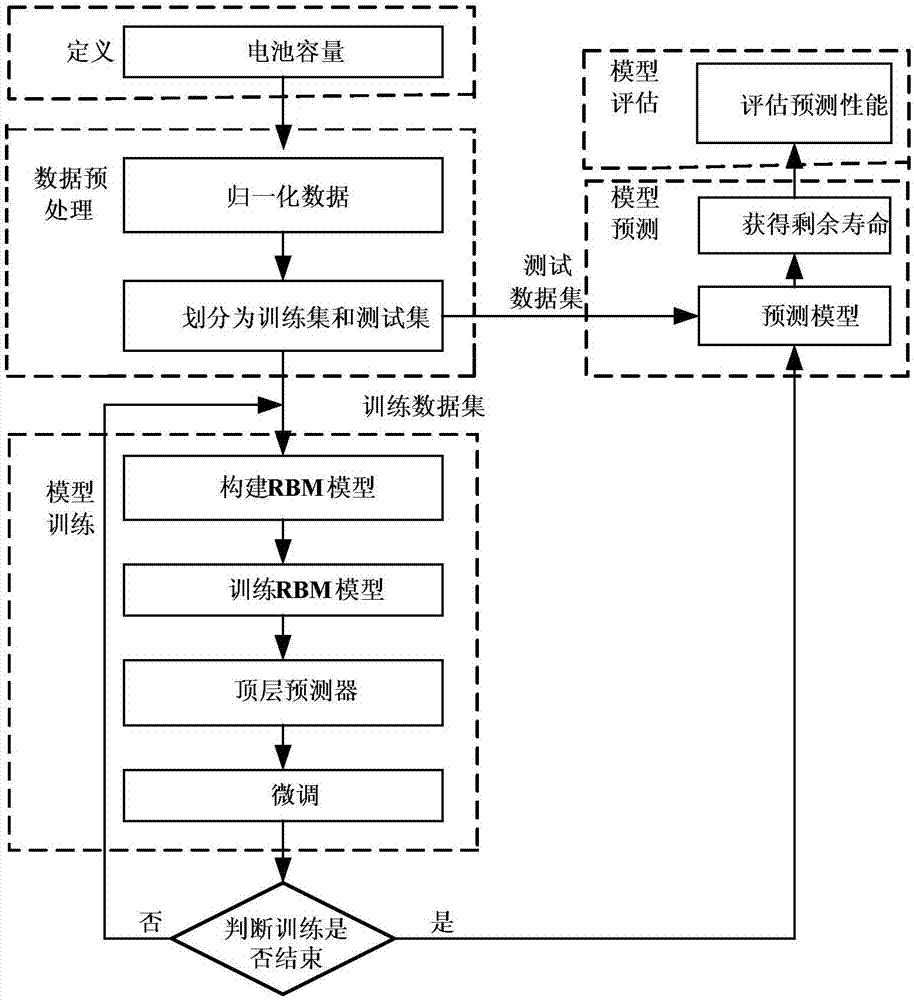

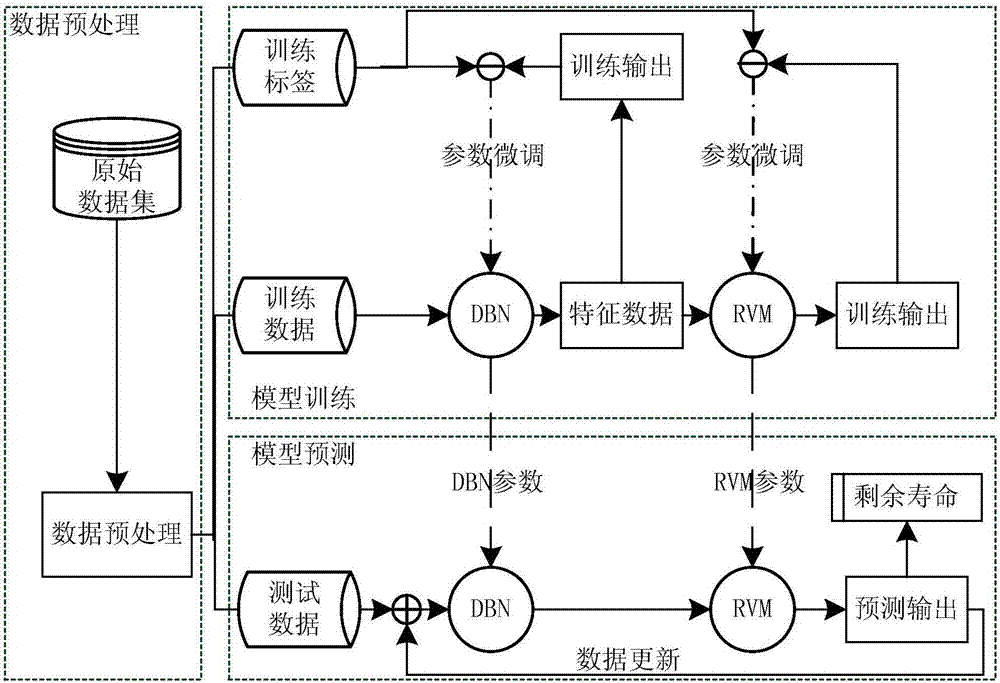

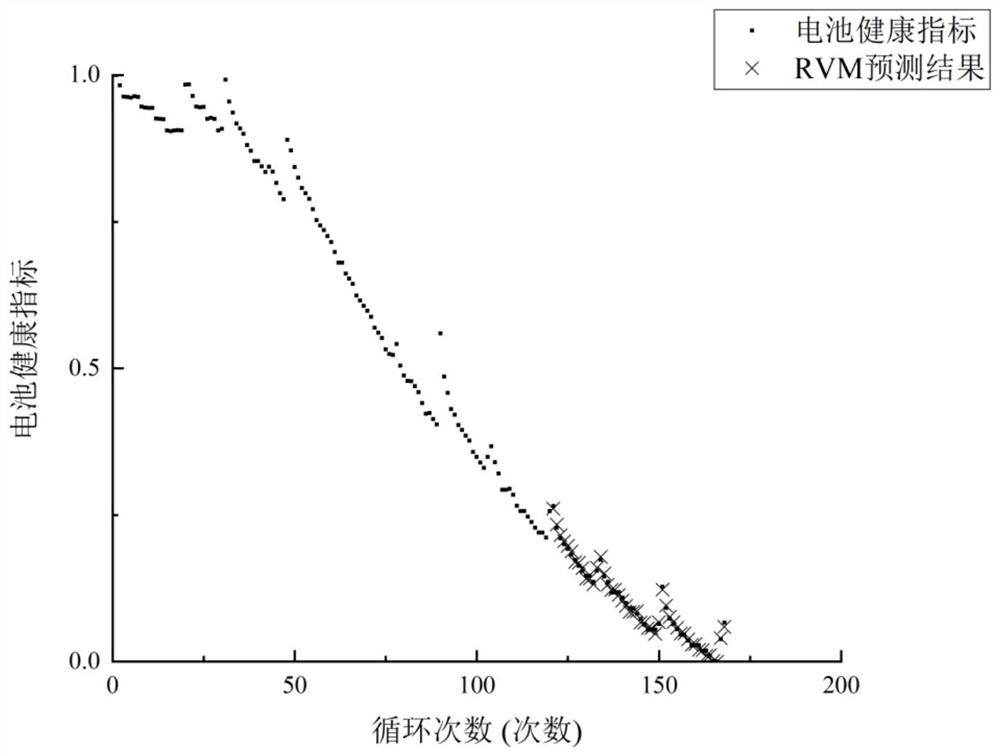

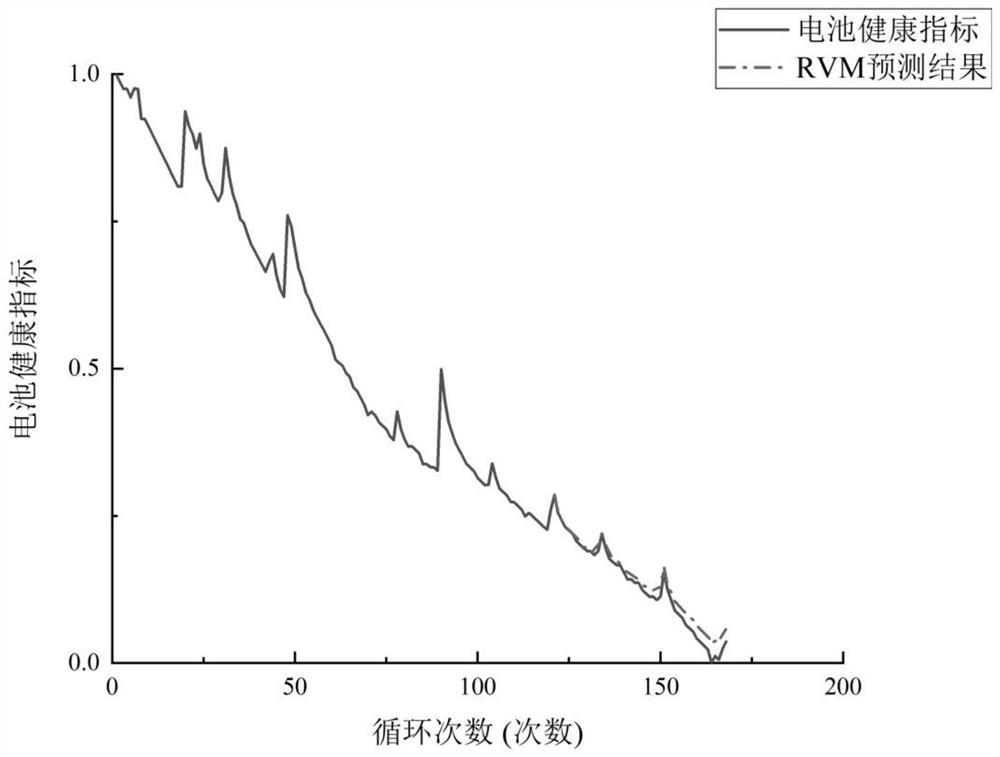

Deep belief network and relevance vector machine fusion-based lithium battery residual life prediction method

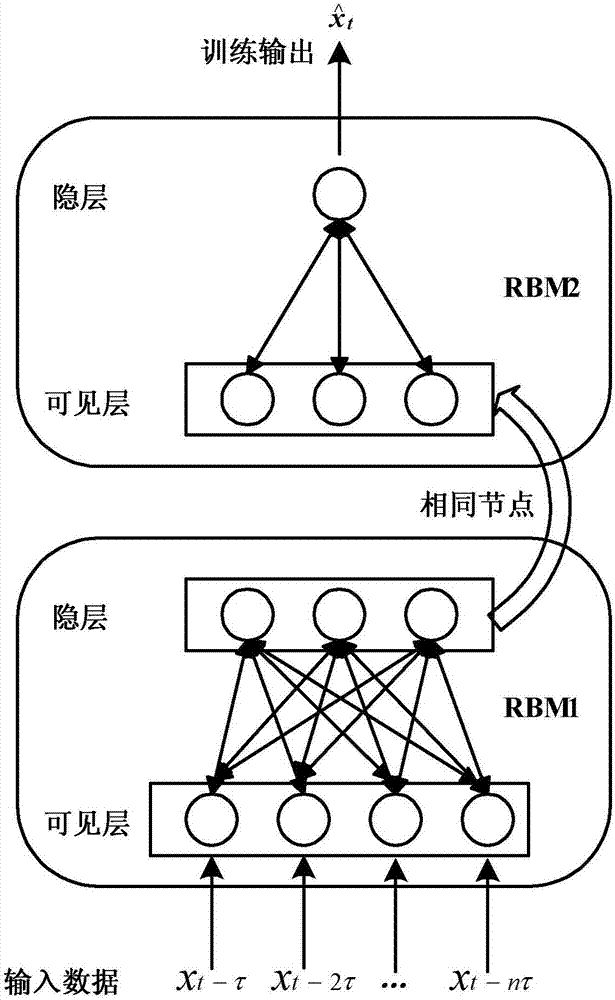

The invention relates to a lithium ion battery cycle life prediction technology, in particular, a deep belief network and relevance vector machine fusion-based lithium battery residual life prediction method. An existing lithium battery residual life prediction method relies on accurate physical models or complex signal processing technologies, as a result, the existing lithium battery residual life prediction method needs heavy investment, or the existing method is based on a shallow structures, as a result, the performance of fault prediction will be limited, and the existing method is vulnerable to curse of dimensionality, while with the method of the invention adopted, the problems of the existing method can be solved. A charging and discharging period-based lithium battery capacity degradation data set is obtained; the data are pre-processed; the fusion models of a DBN (deep belief network) and an RVM (relevance vector machine) are built; a DBN model and a RVM model are trained; and the trained fusion models of the DBN and the RVM is adopted to predict the residual life of a lithium battery. The method of the invention is suitable for predicting the residual life of the lithium battery.

Owner:HARBIN INST OF TECH

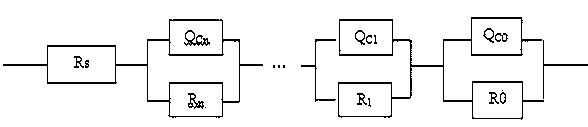

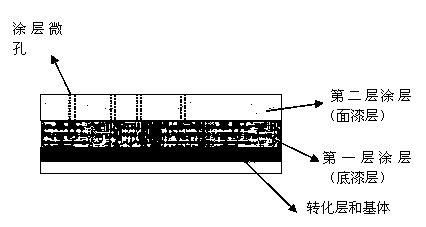

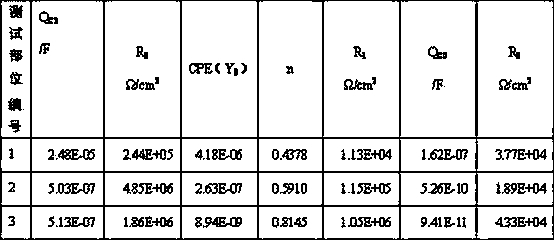

Method for rapidly evaluating critical corrosion damage of multilayer coating system

InactiveCN104076079ASimple technical solutionPractical technical solutionsMaterial analysis by electric/magnetic meansCapacitanceMacroscopic scale

As for a multilayer coating system in use or a multilayer coating system sample for carrying out a natural environment test, the invention provides a method for rapidly evaluating a coating critical corrosion damage value on the basis of macroscopic appearance features and electrochemical features according to the characteristic that the corrosion damage degree of a first coating of the multilayer coating system directly affects the protecting performance of the coating system. According to the method, the macroscopic appearance features of the multilayer coating system are detected visually, the electrochemical impedance spectroscopy of a portion which has an aging failure or is seriously damaged is measured, a multilayer coating system physical model and an electrochemical impedance spectroscopy CM equivalent circuit model are established according to the preparation mode of the multilayer coating system and the characteristic that the thickness is large, the capacitance and the resistance of each coating of the multilayer coating system are obtained by carrying out analysis through an electrochemical feature analysis system, and the critical corrosion damage value of the multilayer coating system is rapidly evaluated according to the impedance value of the first coating. The method is simple, data are reliable, and an evaluating result is accurate and practical.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

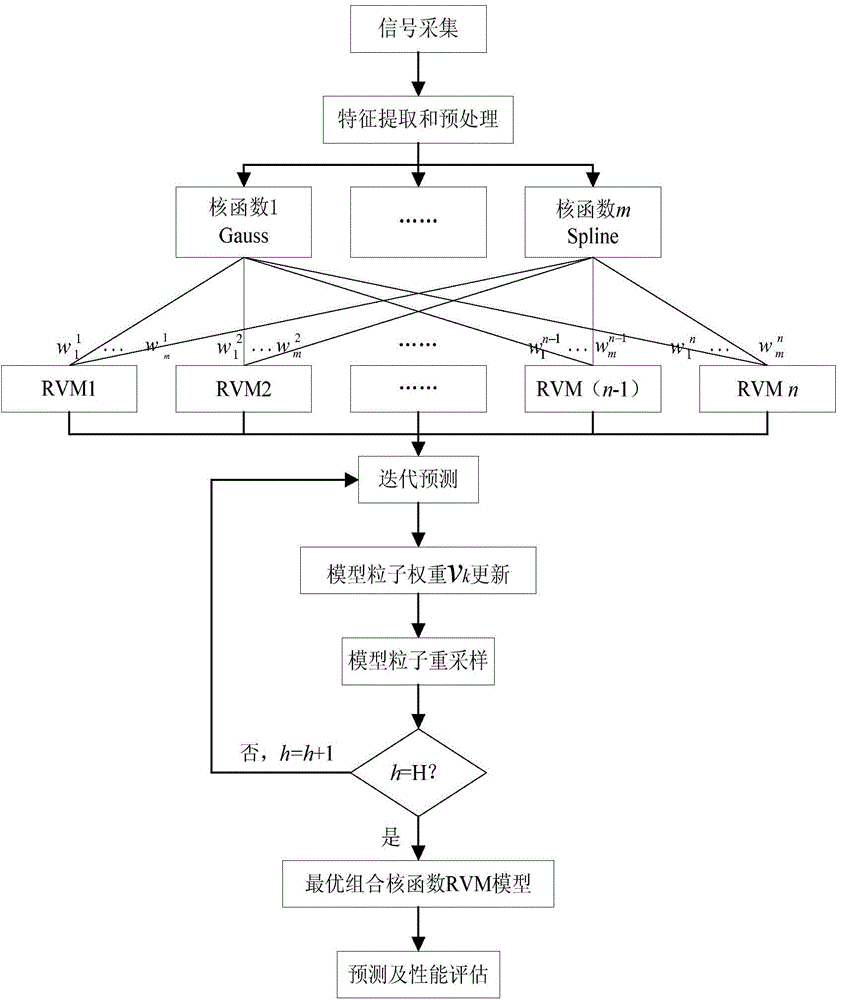

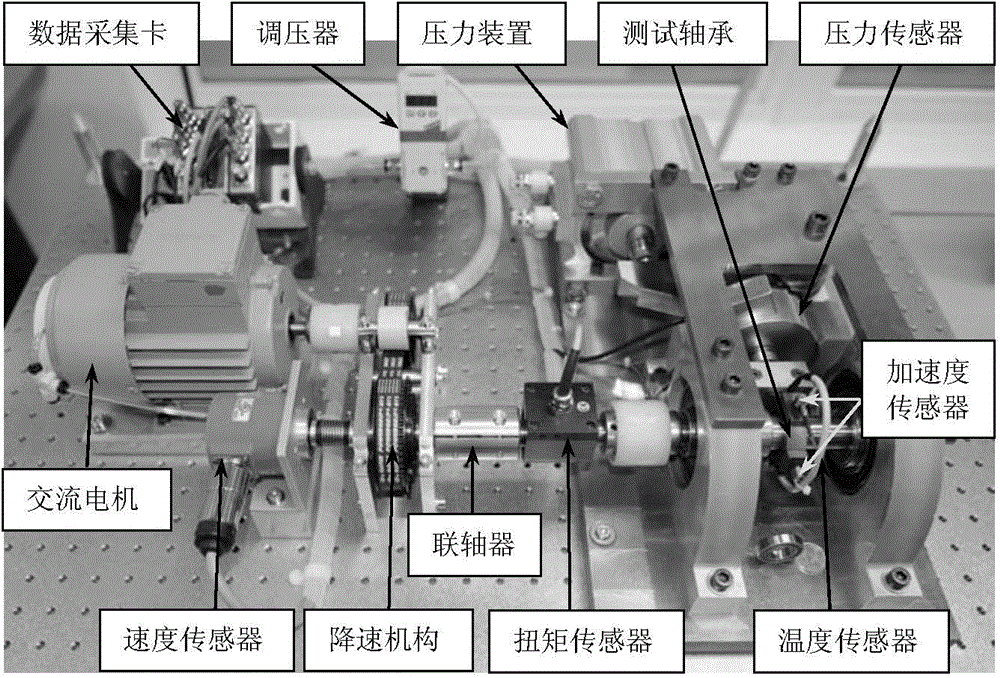

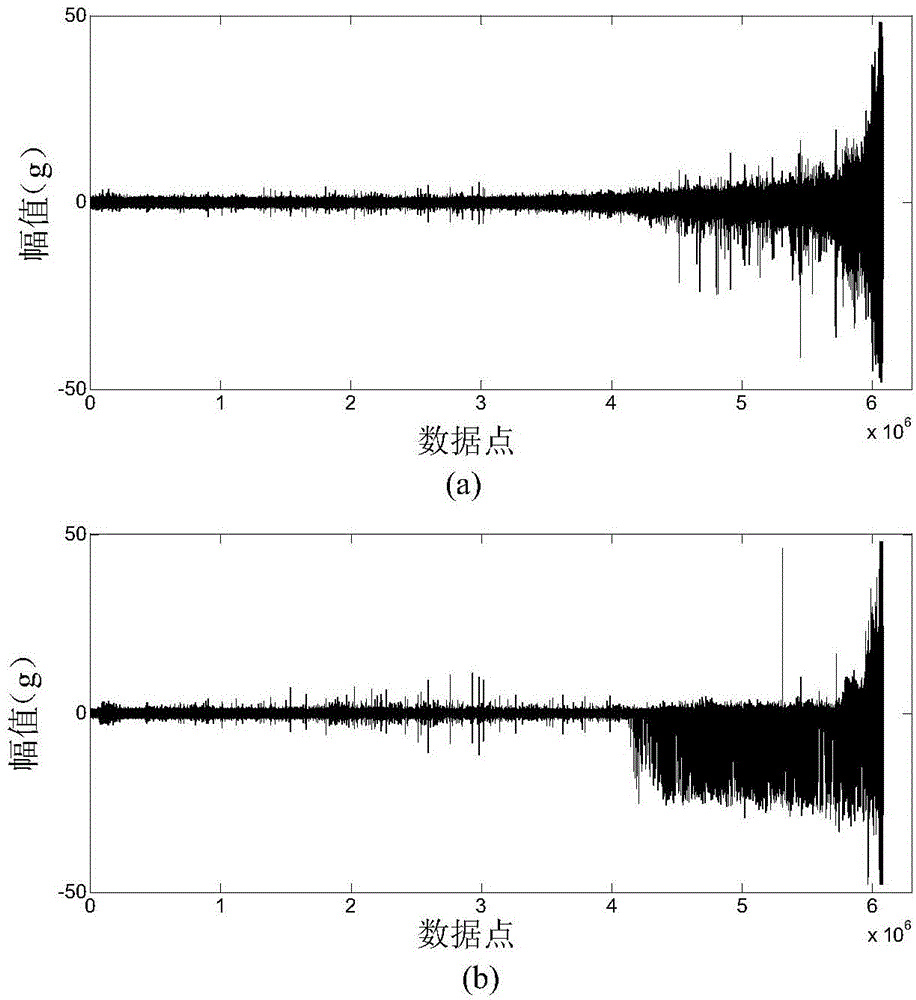

Roller bearing service life predicting model of self-adaptive multi-kernel combination relevance vector machine

ActiveCN104598736AAvoid redundancyDiversity guaranteedSpecial data processing applicationsEngineeringSelf adaptive

The invention relates to a roller bearing service life predicting model of a self-adaptive multi-kernel combination relevance vector machine. The roller bearing service life predicting model comprises the following steps of utilizing particle filter to initialize a combination kernel function weighting matrix, so as to obtain a combination kernel function set; establishing a multi-kernel combination relevance vector machine set; performing iteration predicting, weight updating and re-sampling self-adaption to obtain an optimal multi-kernel combination relevance vector machine model; finally, predicting the running state and remaining life of the rolling bearing. The roller bearing service life predicting model has the advantages that the excellent characteristics of a plurality of single kernel functions are adaptively integrated, the reliance of the single kernel function relevance vector machine model on the parameters is reduced, the predicting accuracy is improved, the predicting stability is better, the robustness of the model is higher, and the engineering application value is higher.

Owner:XI AN JIAOTONG UNIV

Tool state monitoring and life predicting system based on multi-source information fusion

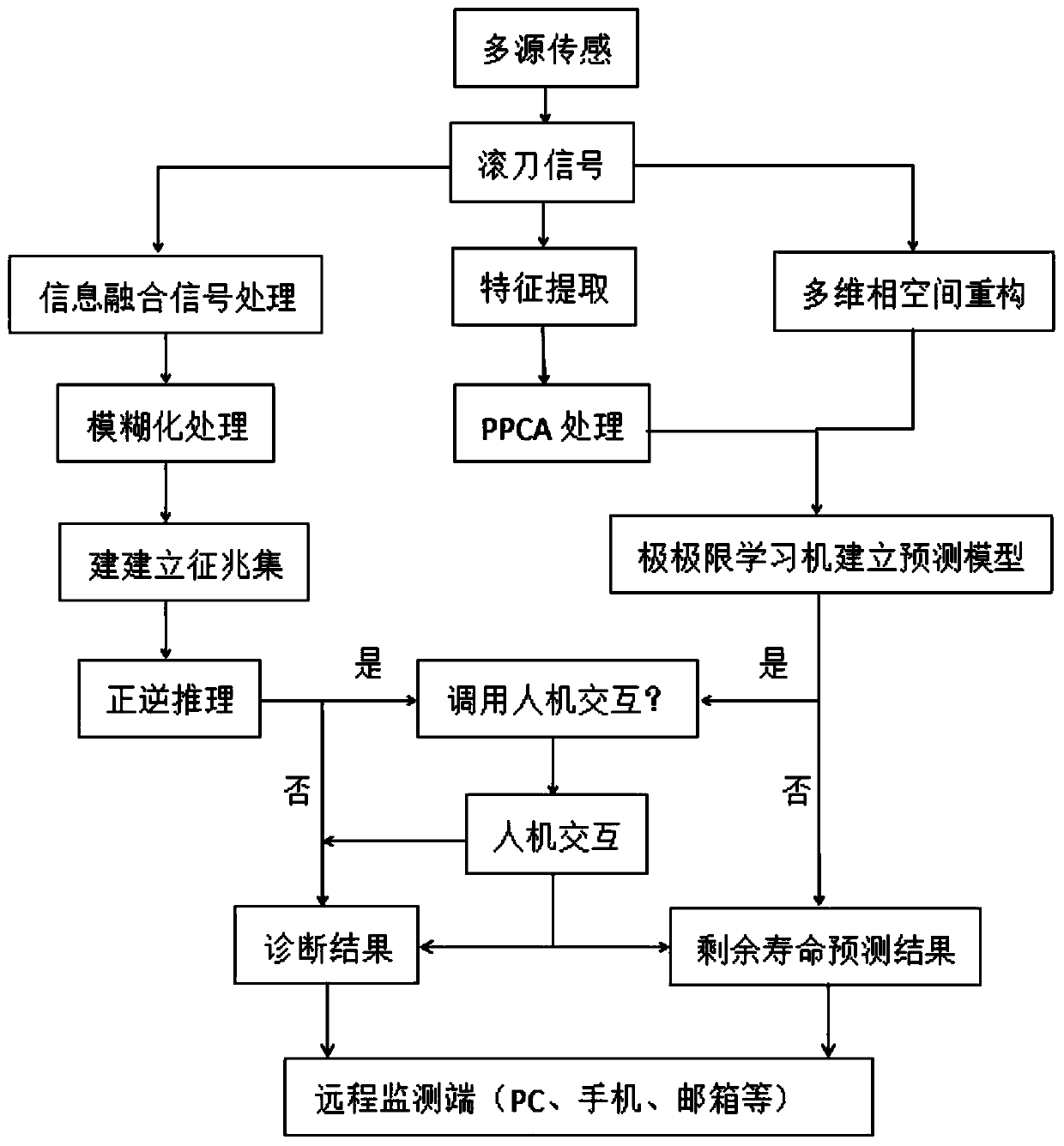

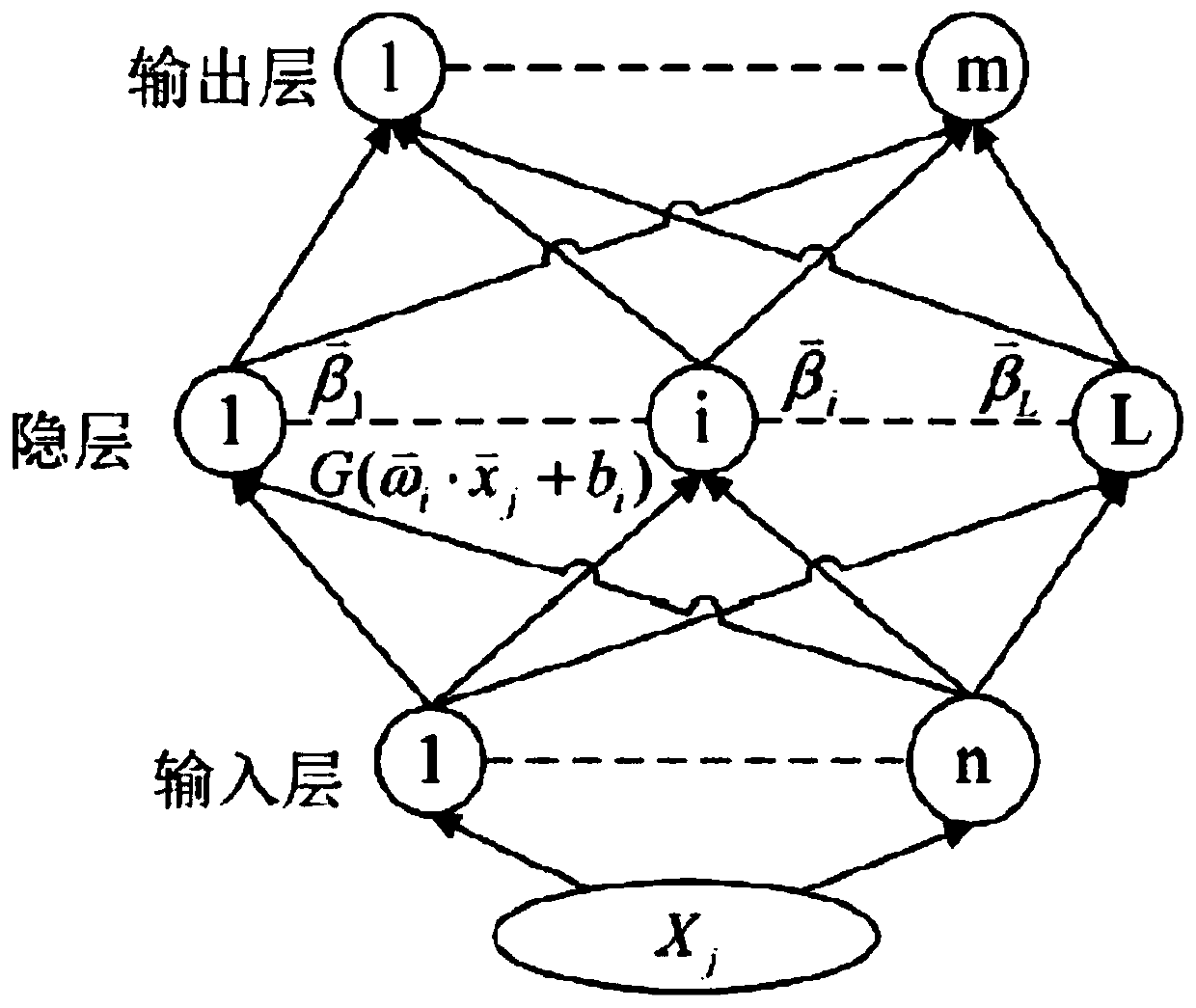

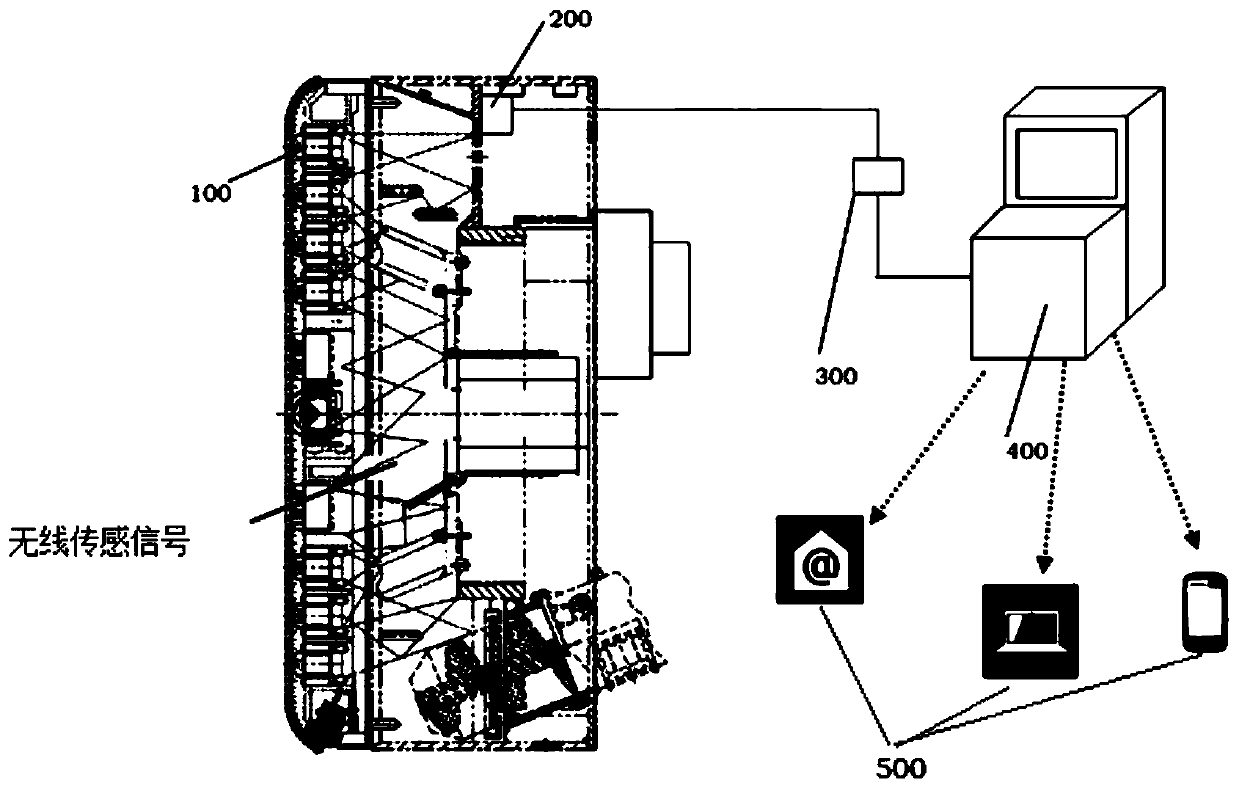

PendingCN109724785AMonitoring forceThe monitoring device monitors the force in real timeMachine part testingProject managementInformation acquisition

The invention discloses a tool state monitoring and life predicting system based on multi-source information fusion, comprising: an information acquisition module, a signal preprocessing module, a state monitoring module, a life predicting module, and a remote monitoring module. The information acquisition module collects the parameter information of the hob, and sending them to the condition monitoring module and / or the life predicting module after preprocessing by the signal preprocessing module; outputting the hob status by the condition monitoring module; outputting the remaining life of the hob by the life prediction module. The output of the status monitoring module and the life predicting module can be directly viewed on the spot and can be viewed remotely. The tool state monitoringand life predicting system based on multi-source information fusion realizes visual management by real-time monitoring the key parameters such as the force, wear amount, rotation speed, and shape ofthe hob by the hob monitoring device, and monitors the state of the hob in real time and predicts the remaining life of the hob by analyzing and processing the relevant signals of the hob. Further, the communication-related project management staff of the remote monitoring module can view through mobile phones, remote PCs, etc, helping humanely determine if the tool is replaced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

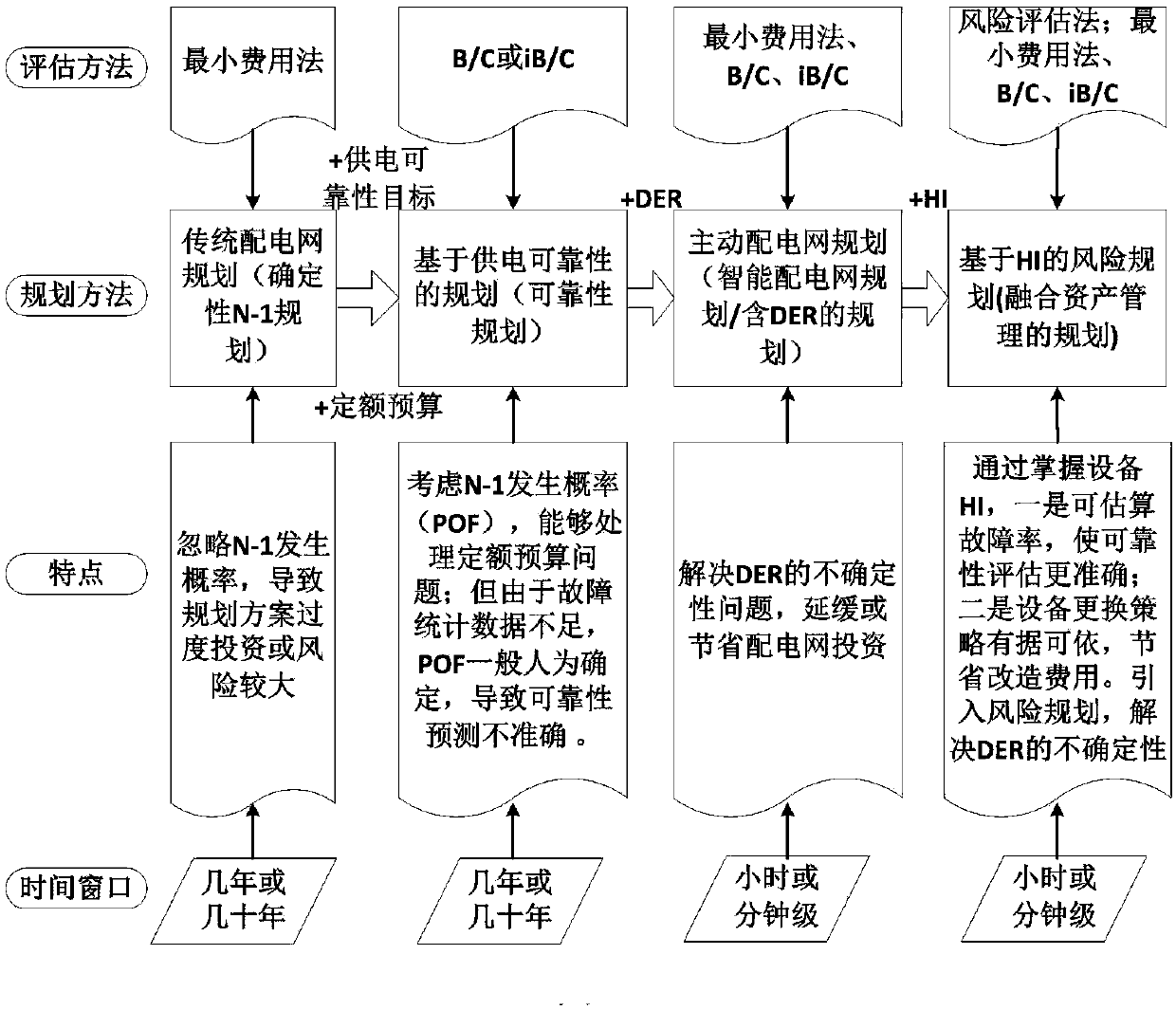

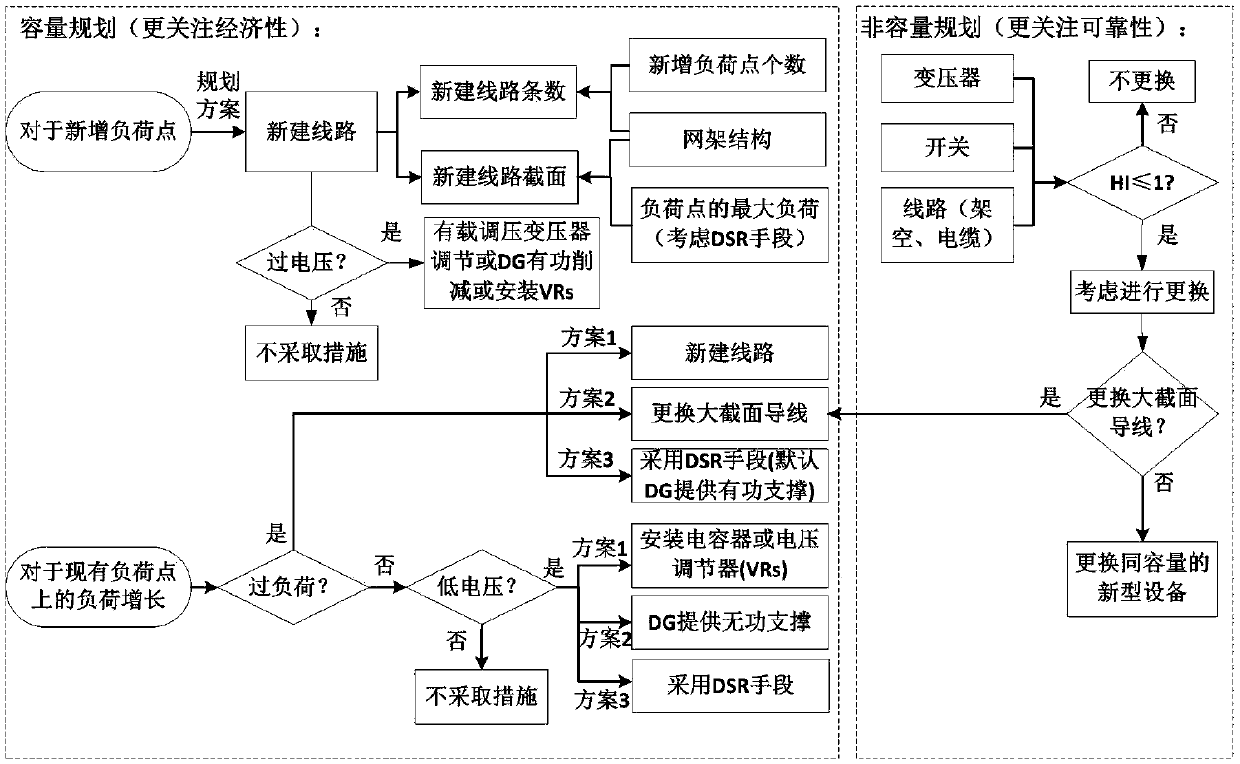

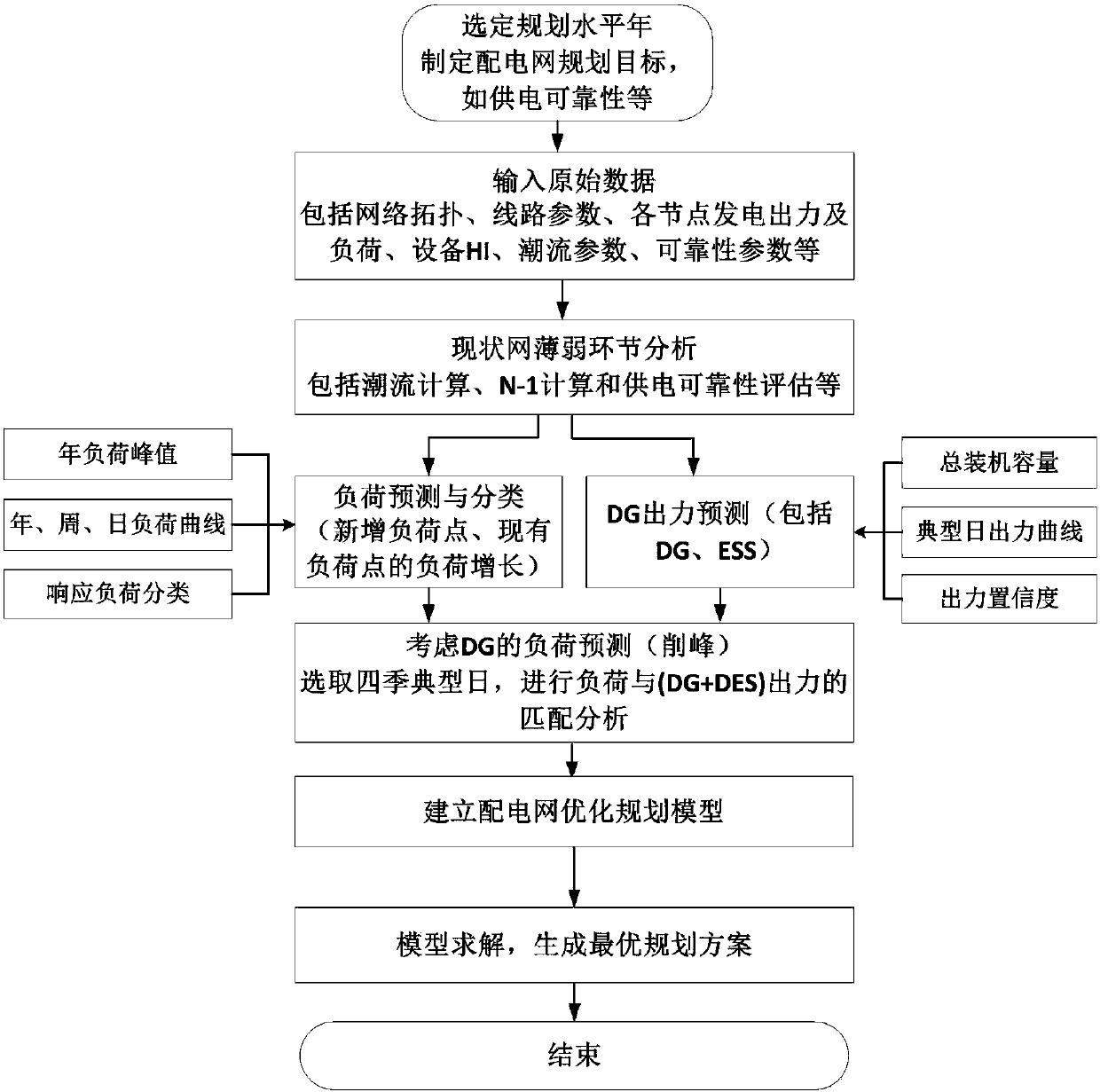

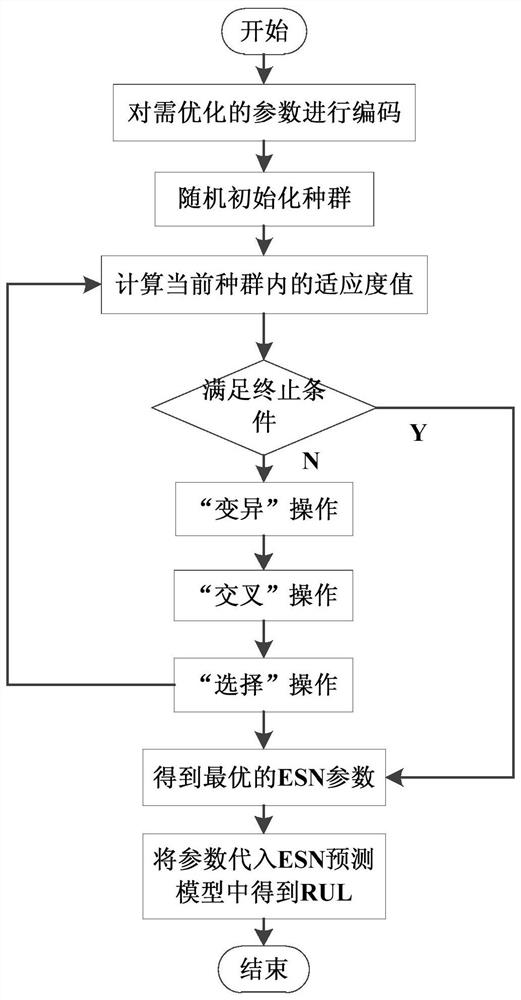

Power distribution network risk planning method and system thereof

InactiveCN108122068ALess investmentAccurate Remaining LifeResourcesGenetic algorithmsSocial benefitsHealth index

The invention relates to a power distribution network risk planning method and a system thereof. The method comprises the steps of acquiring original data of the power distribution network and generating an alternative planning scheme; setting the alternative planning scheme to a chromosome, and solving a pre-established power distribution network multi-target optimization planning model by meansof a genetic algorithm for obtaining an optimal power distribution network risk plan; wherein the power distribution network original data comprise a power distribution network health index. Accordingto the method and the system, on one hand, an asset management concept is combined, thereby realizing a more accurate power supply reliability evaluation result, effectively reducing reconstruction and changing cost of the equipment or postponing the reconstruction and changing time of the equipment, and saving investment of the power distribution network; and on the other hand, output uncertainty of distributed energy DER can be settled, thereby effectively promoting conversion of modern power distribution network planning technology from single-target planning to multi-target optimized planning and asset management integrated planning, reducing power grid investment risk and improving economic and social benefit of the power distribution network.

Owner:CHINA ELECTRIC POWER RES INST +2

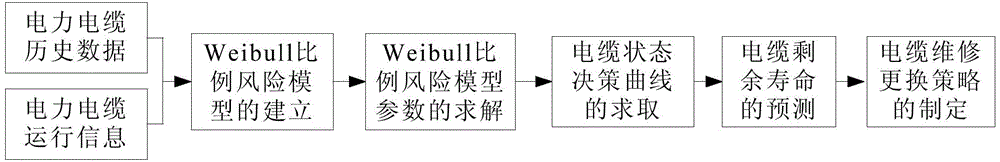

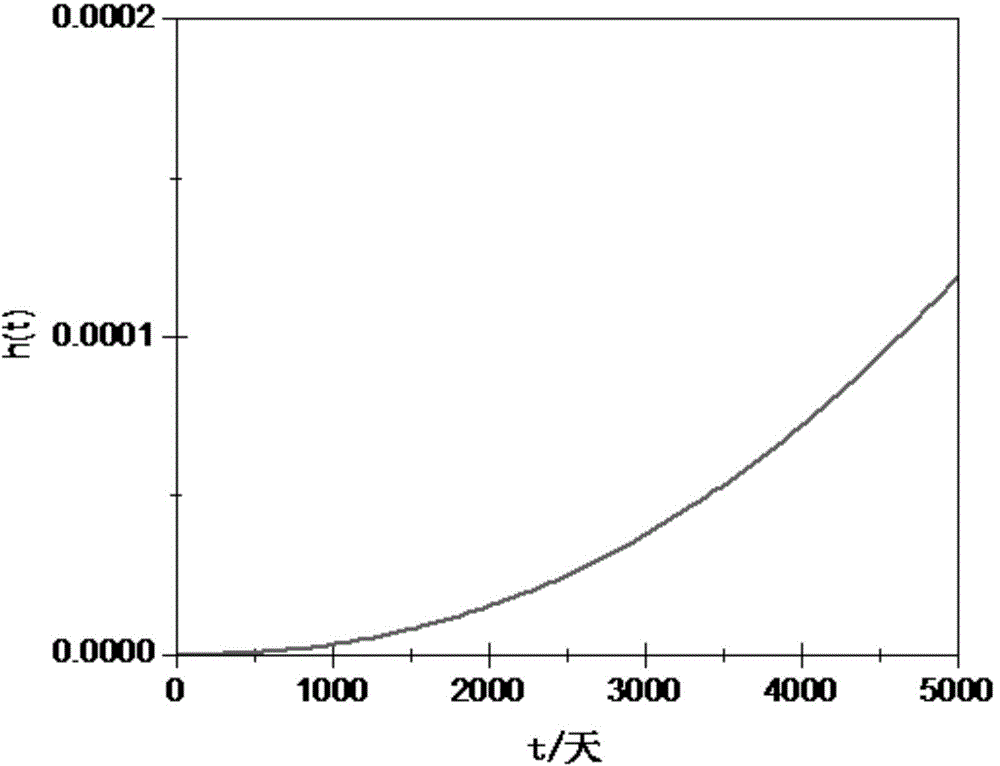

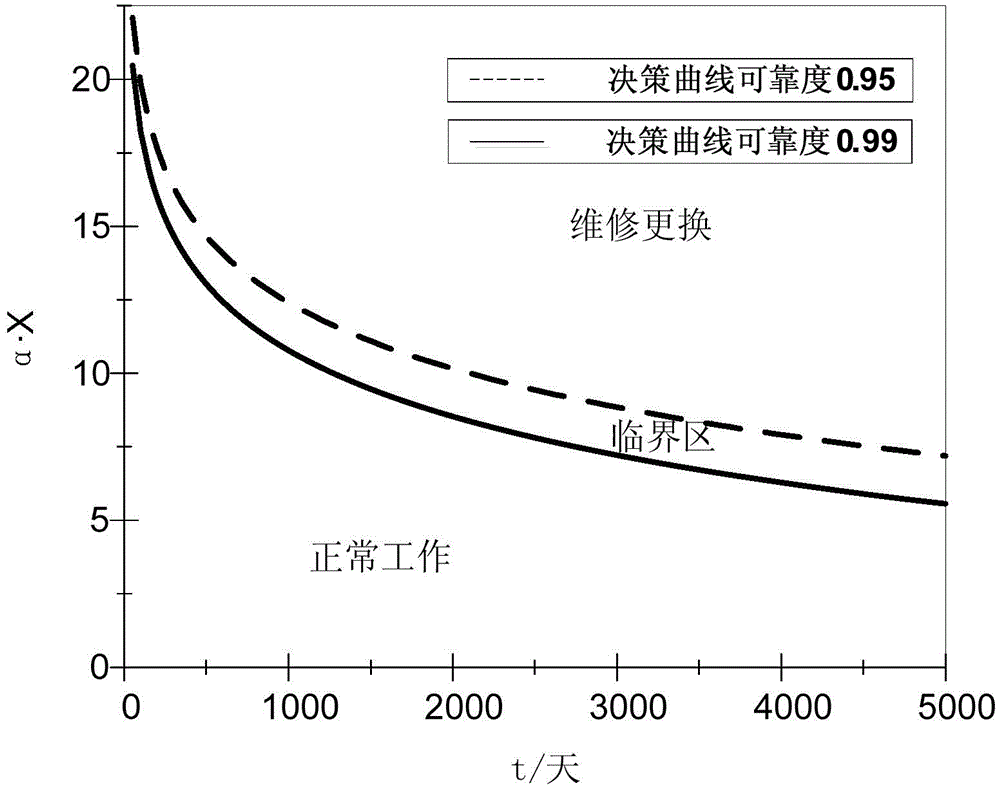

Power cable operation maintenance method based on historical fault information and operating state

InactiveCN104899690AImprove rationalityImprove reliabilityResourcesProportional hazards modelPower cable

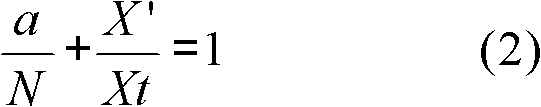

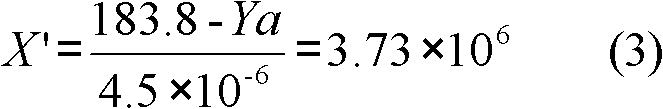

The invention relates to a power cable operation maintenance method based on historical fault information and an operating state, wherein the method is used for predicting the residual life of a power cable and formulating a replacement strategy of the power cable. The method comprises the following steps of establishment of a weibull proportional hazard model, solution to parameters in the weibull proportional hazard model, resolving of a power cable state decision curve, prediction of the residual life of the power cable; and formulation of a maintenance and replacement strategy of the power cable. With the method, reasonability and reliability of cable fault prediction are improved; the operating situation of the cable can be displayed visually and clearly; and a reference can be provided for making a decision of cable maintenance and replacement. A minimum cost method and a maximum availability method are brought forward based on the weibull proportional hazard model; and with consideration of economic factors, a proper strategy of cable maintenance and replacement can be formulated.

Owner:SUZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +3

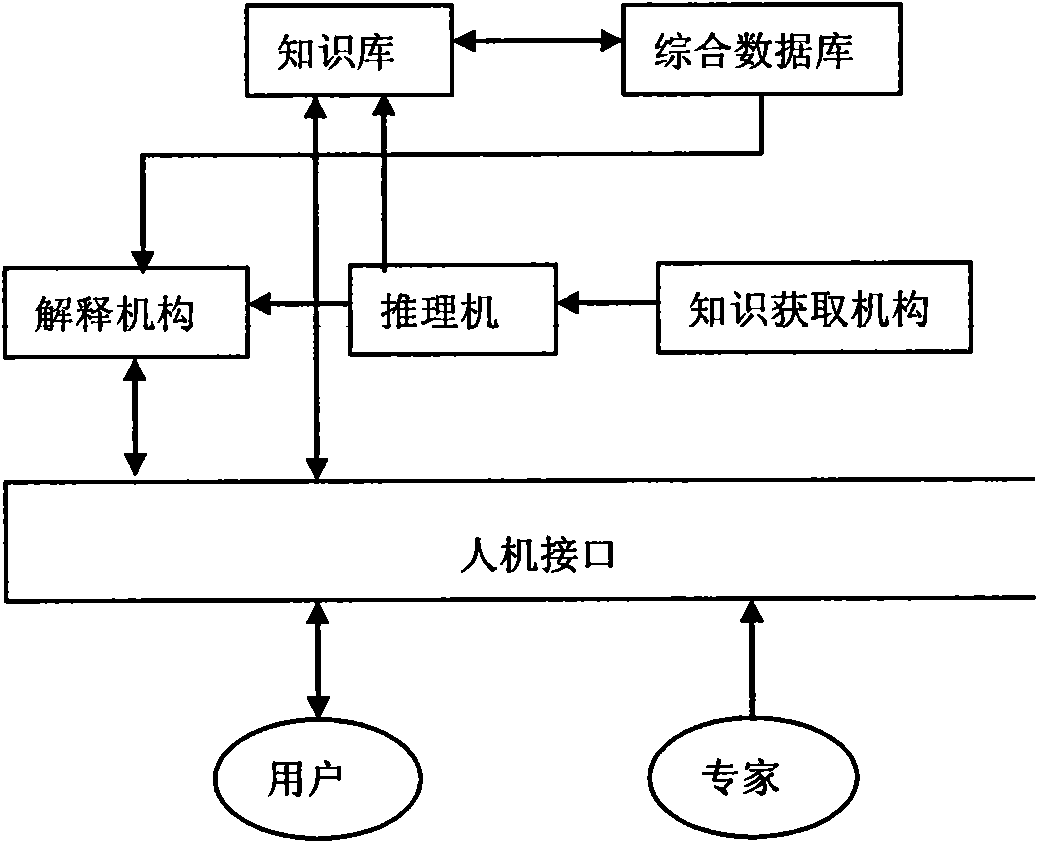

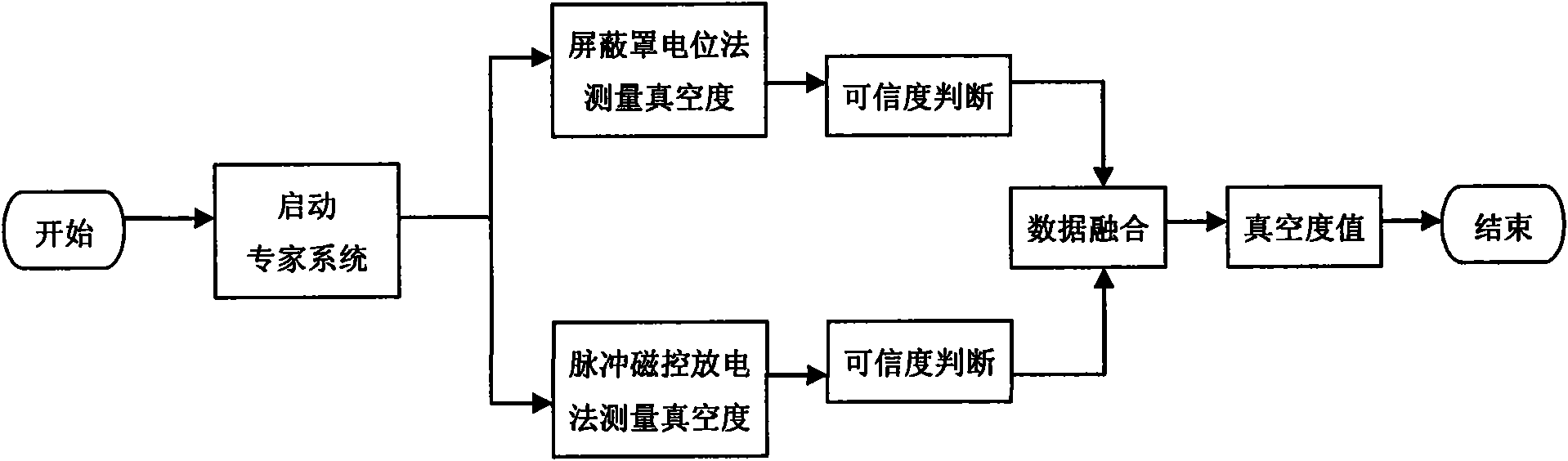

Expert system for measurement of vacuum degree and life management of vacuum arc extinguish chamber and application method

InactiveCN101661570ALife expectancySolve the credibility problemVacuum gaugesHigh-tension/heavy-dress switchesMeasurement devicePower grid

Owner:HEBEI UNIV OF TECH

Method for evaluating remanufacturing access period of engineering mechanical arm rest class structure

InactiveCN103838931AObtain the law of performance degradation and failurePredict remaining lifeSpecial data processing applicationsElement modelExpert evaluation

The invention relates to a method for evaluating the remanufacturing access period of an engineering mechanical arm rest class structure. The method comprises the specific steps of a, formulating an evaluation criteria of a solid web type arm rest failure mode, b, correcting and perfecting a parameterized finite element model and a simulation computing platform, c, setting up the performance under the remanufactured arm rest typical service working condition, namely, a database of the failure form, d, conducting traceability analyzing on the failure form and the main influence factor, and e, predicating the residual service life of an arm rest, and forming the remanufacturing arm rest access period evaluating method. The computer virtual simulation technology is utilized by the method, an expert evaluation system of an arm rest class structure part is set by processing related measured data, and the system is used for evaluating the residual life and the related technical index of the arm rest class structure.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

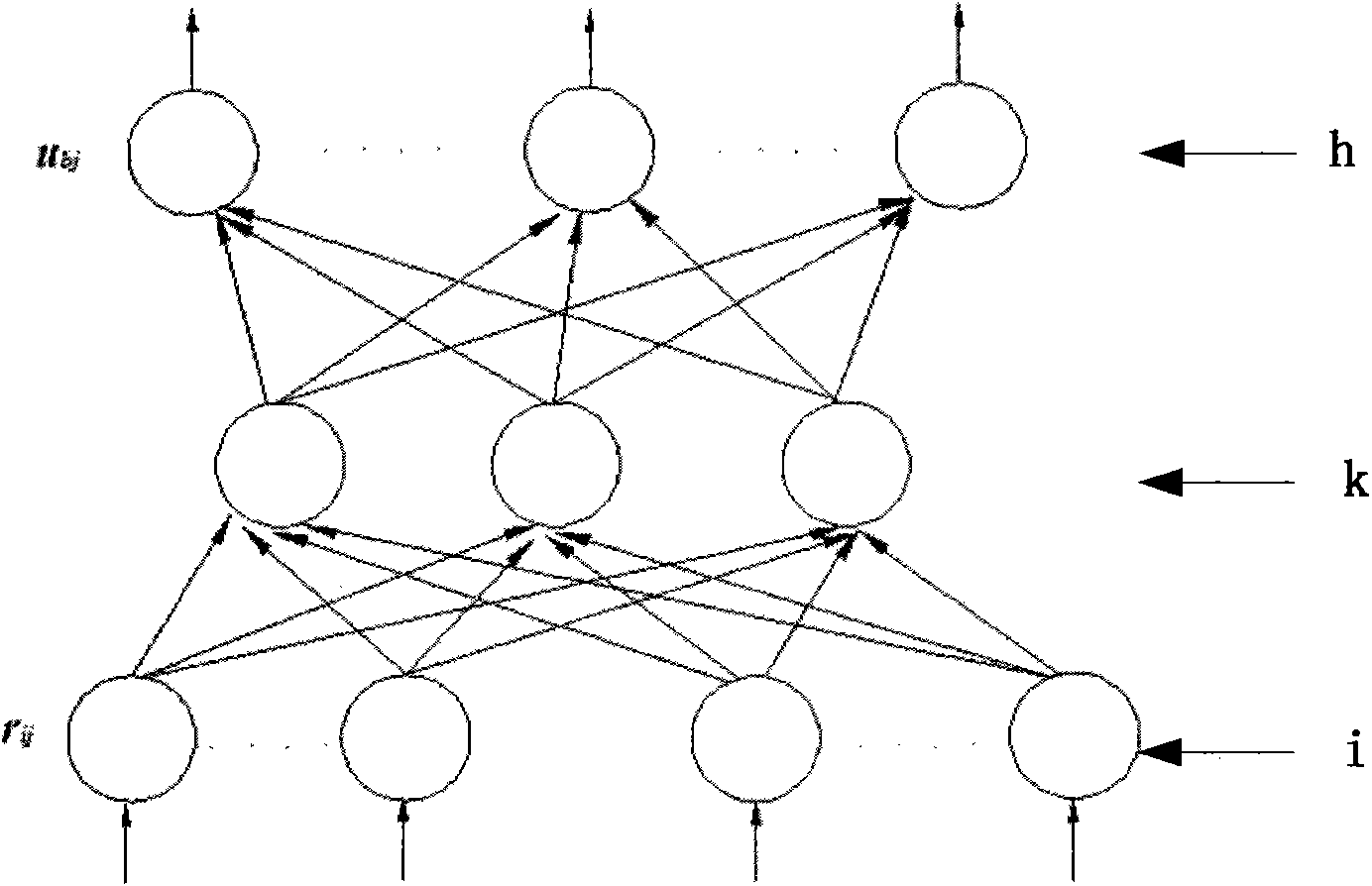

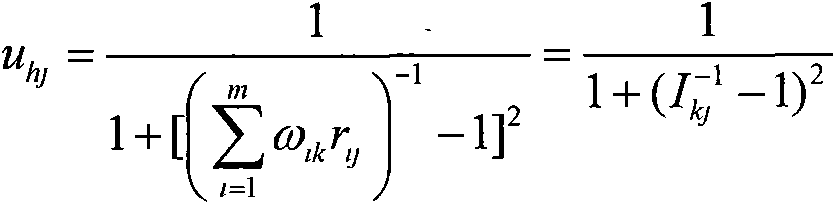

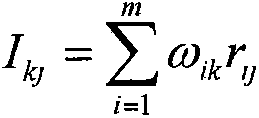

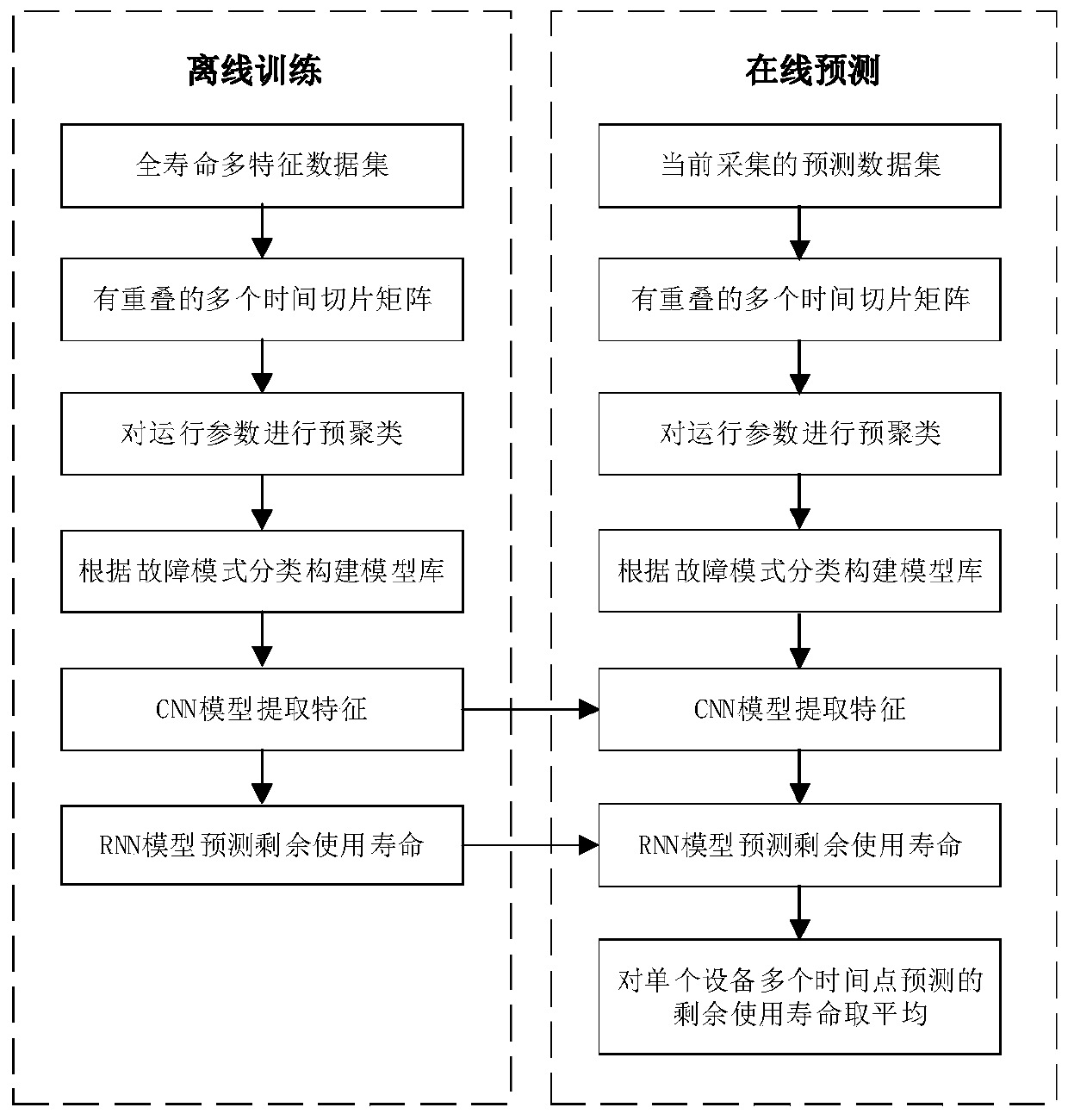

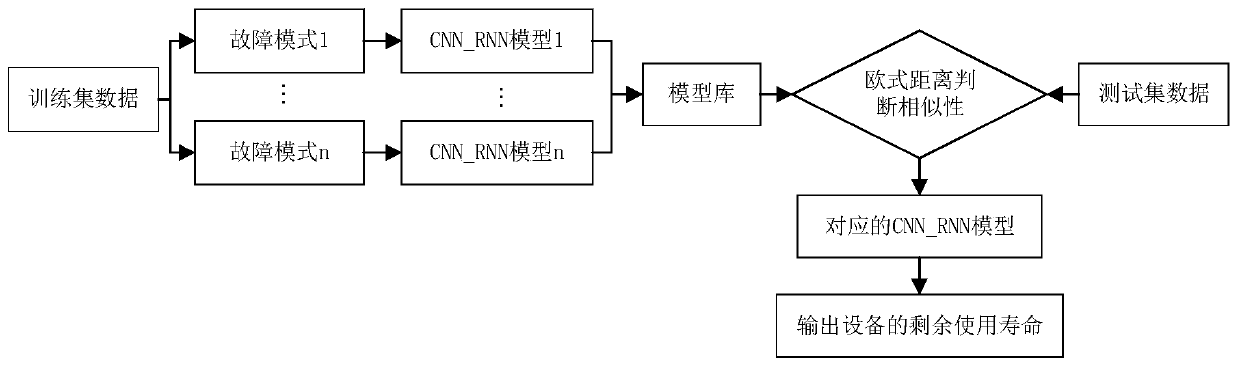

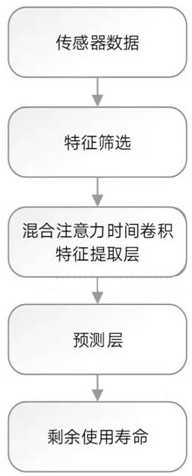

Industrial equipment remaining useful life prediction model and construction method and application thereof

ActiveCN110609524AHigh precisionChoose accuratelyTotal factory controlProgramme total factory controlFeature DatasetResidual service life

The invention discloses an industrial equipment remaining useful life prediction model and a construction method and application thereof. The method comprises the steps that full-life multi-feature datasets of multiple sets of identical industrial equipment under different fault modes are collected, and a multidimensional matrix of each full-life multi-feature dataset is constructed; a sliding window is adopted to perform time sequence slicing on each multidimensional matrix, and multiple time slice matrixes of each multidimensional matrix are obtained; according to the types of the fault modes, all the time slice matrixes are sorted; and based on all the time slice matrixes corresponding to each fault mode, a CNN-RNN (Convolutional Neural Network-Recurrent Neural Network) hybrid prediction model of each fault mode is trained to obtain the remaining useful life of the industrial equipment. According to the prediction model, by using the sliding window to perform time sequence slicing on multidimensional data, the diversity of hybrid model input is improved; a model base is constructed by use of pre-sorting, and the datasets containing the multiple fault modes are processed to improve the model prediction precision; and by constructing a CNN-RNN hybrid network, the end-to-end remaining useful life prediction model without self-definition of a failure threshold is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

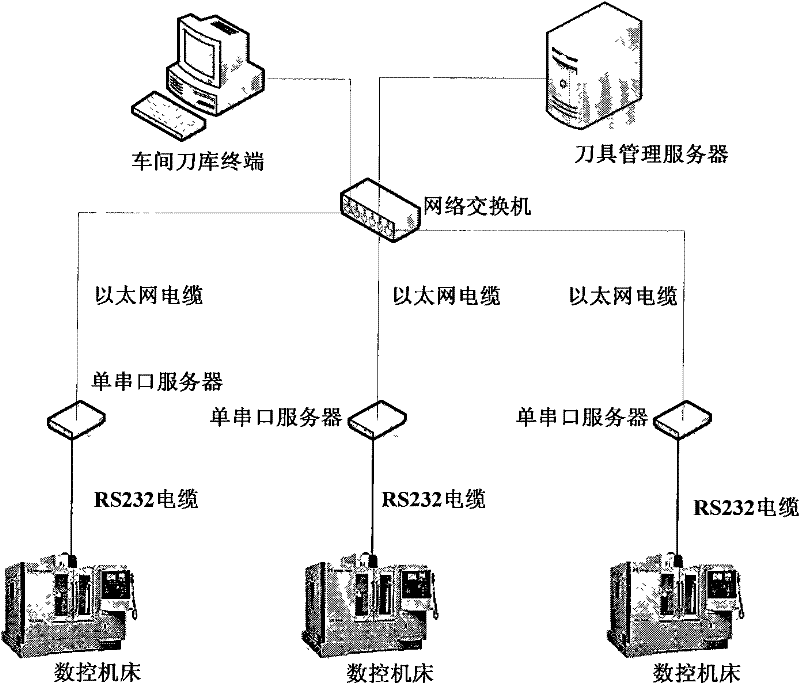

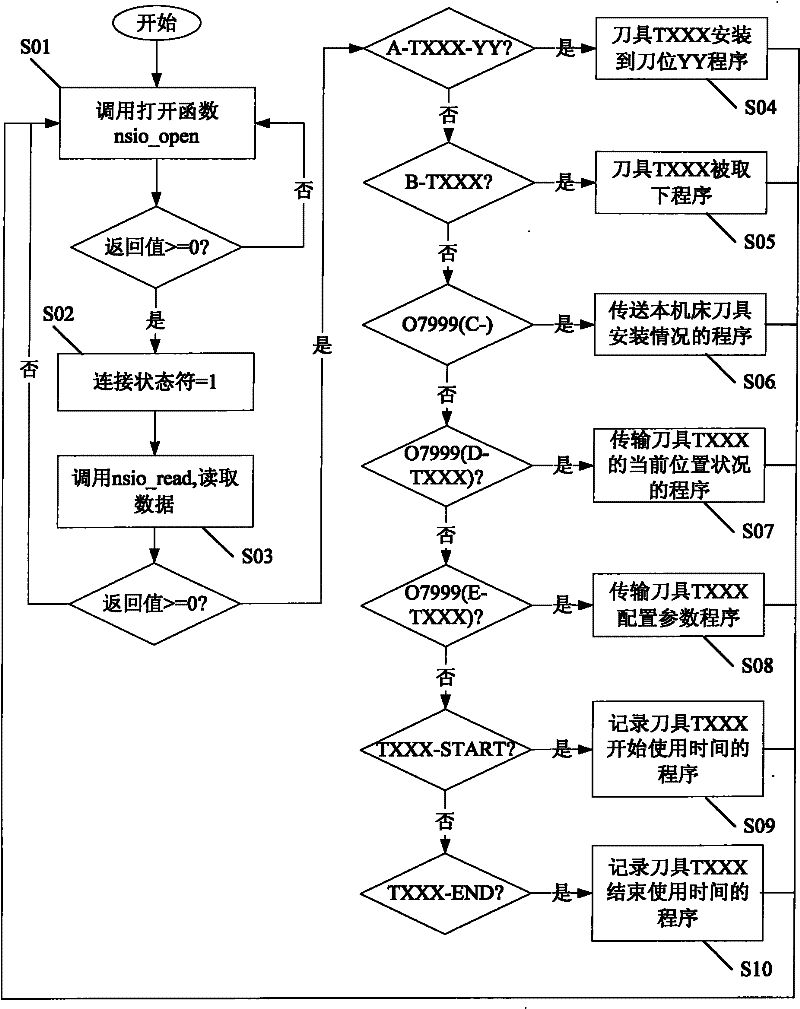

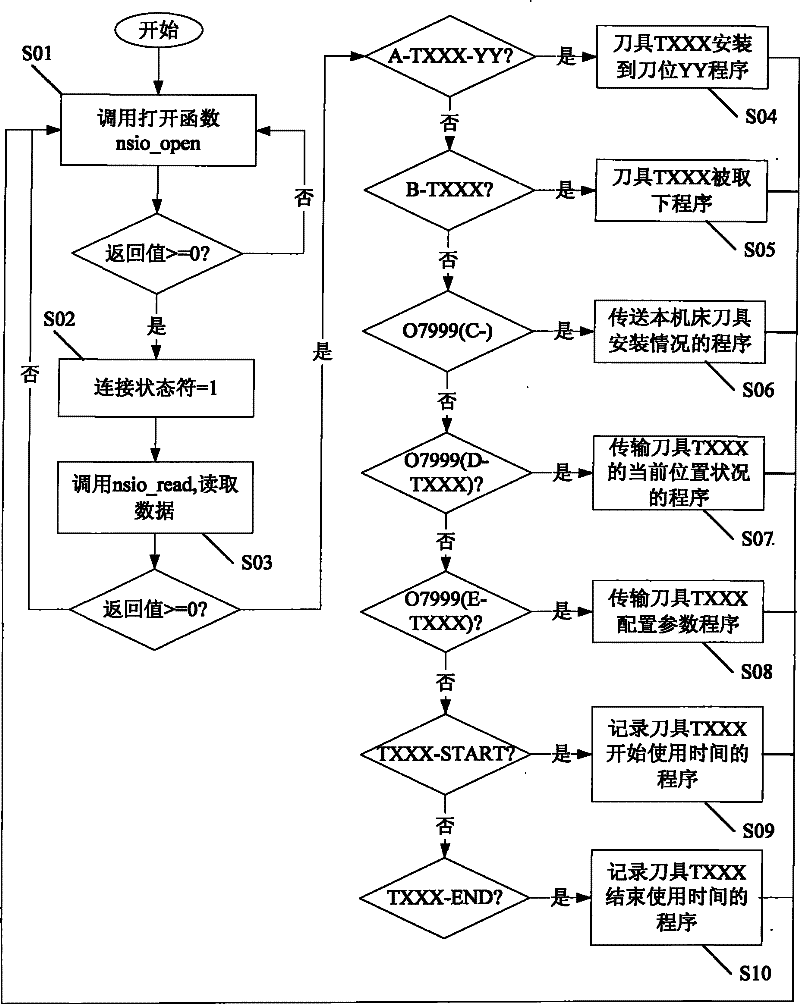

Online management method of numerical control machine tool cutter

InactiveCN107861473AAccurately record usage timePredict remaining lifeProgramme controlComputer controlComputer terminalExchange time

The invention discloses an online management method of a numerical control machine tool cutter. The method comprises the steps of firstly establishing a numerical control machine tool cutter online management system, establishing a database in a cutter management server, developing a corresponding functional module interface on a workshop tool magazine terminal, programming a sub-program on the numerical control machine tool according to an adopted numerical control system programming rule, receiving and transmitting information between a machine tool and the cutter management server by the cutter management server through calling a function in a serial-port server, performing processing according to the read program data, rewriting or searching the database, and transmitting the searchedinformation to the corresponding numerical control machine tool. Through networking all machining centers and workshop tool magazine terminals, the online management method has advantages of realizingaccurate recording and searching for cutter information, reducing cutter exchange time, sufficiently utilizing the residual service life of the cutter, saving manpower resource and improving production efficiency.

Owner:NANTONG OUKE CNC EQUIP CO LTD

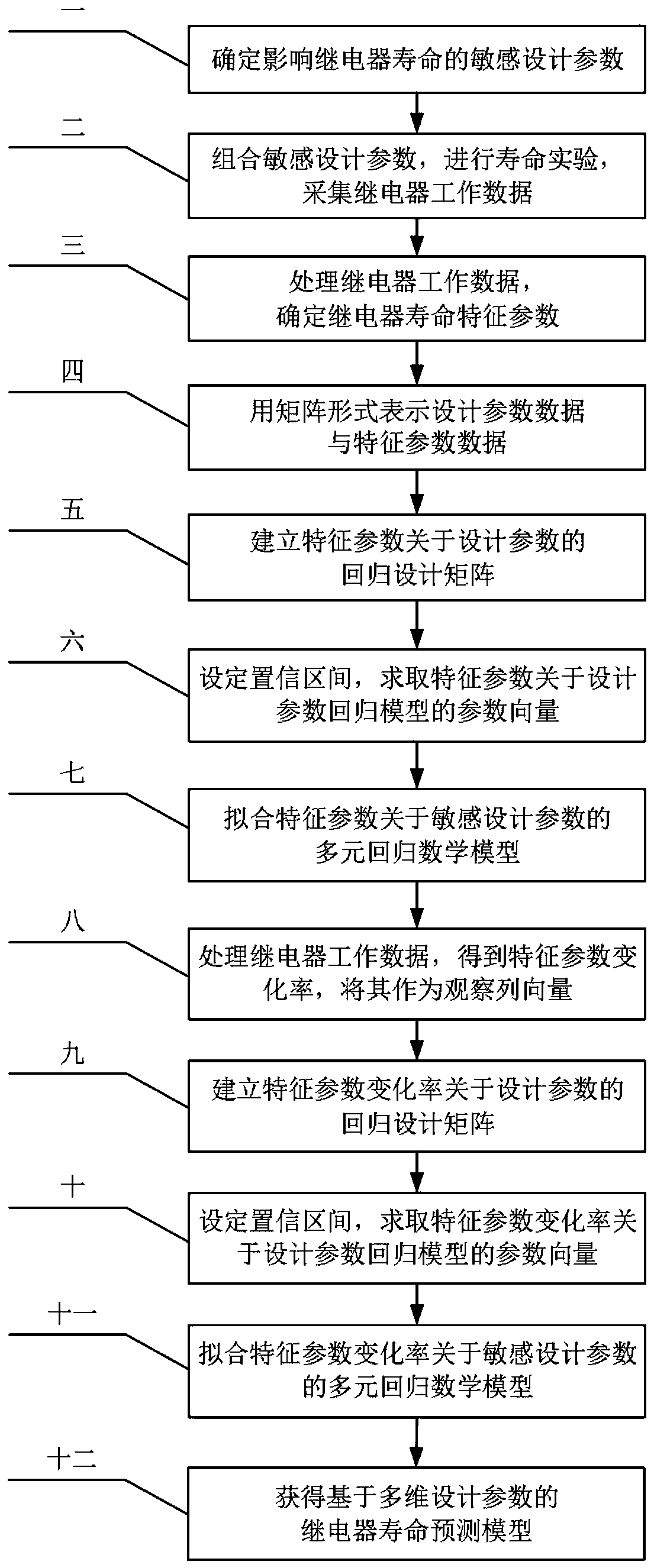

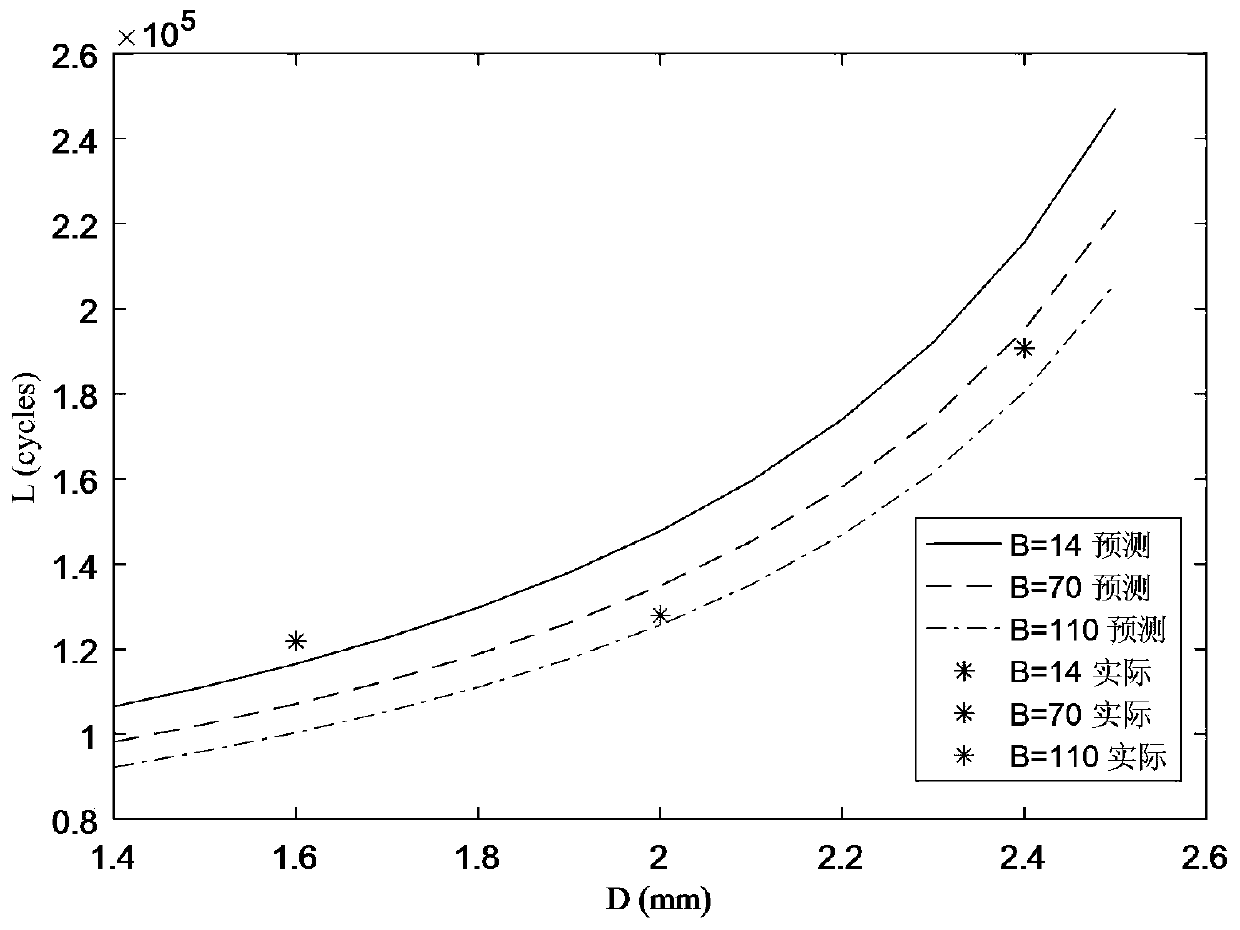

Relay life prediction method based on multidimensional design parameters

ActiveCN110795863AExtend your lifePredict remaining lifeElectrical testingDesign optimisation/simulationDesign matrixMathematical model

The invention discloses a relay service life prediction method based on multidimensional design parameters, and the method comprises the steps: firstly analyzing the working principle of a relay product, and obtaining relay service life experiment data under different design parameter conditions through a variable control method; then analyzing and determining sensitive design parameters influencing the service life of the relay; in the process of carrying out the service life experiment, collecting the working data of the relay, and determining characteristic parameters representing the service life of the relay; establishing a regression design matrix, taking the relay life characteristic parameters as observation vectors, solving parameter vectors, and obtaining a mathematical model ofthe characteristic parameters about the design parameters; taking the change rate of the characteristic parameters as an observation vector, and fitting to obtain a mathematical model of the change rate of the characteristic parameters relative to the design parameters; and finally, combining the two models to obtain a life prediction model. The relation between the relay service life and the multi-dimensional design parameters can be determined through modeling, and relay design can be guided to further prolong the relay service life.

Owner:HARBIN INST OF TECH

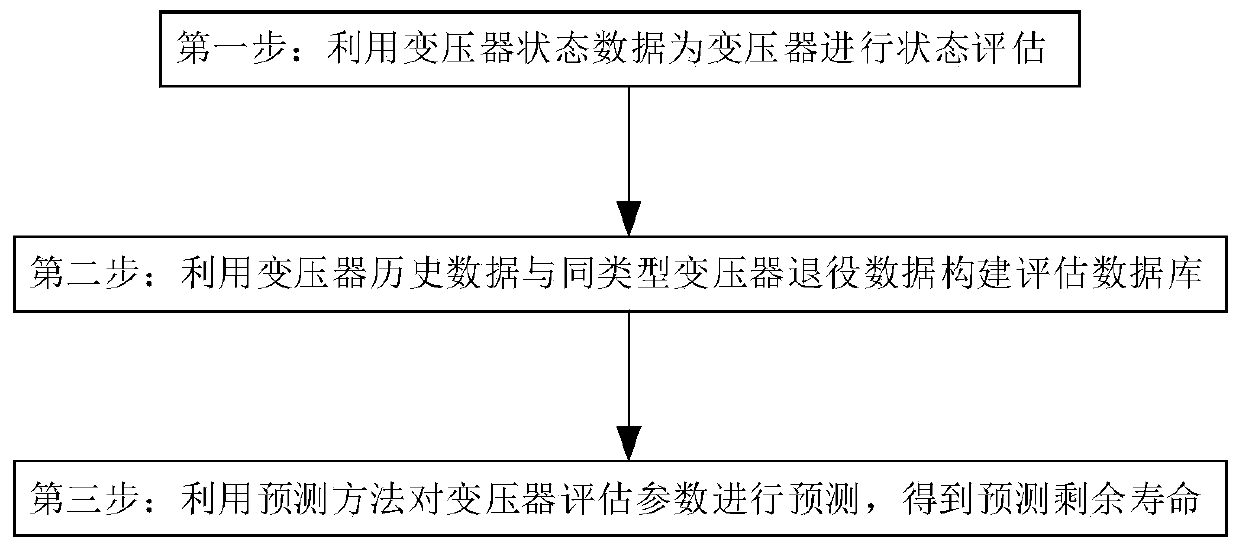

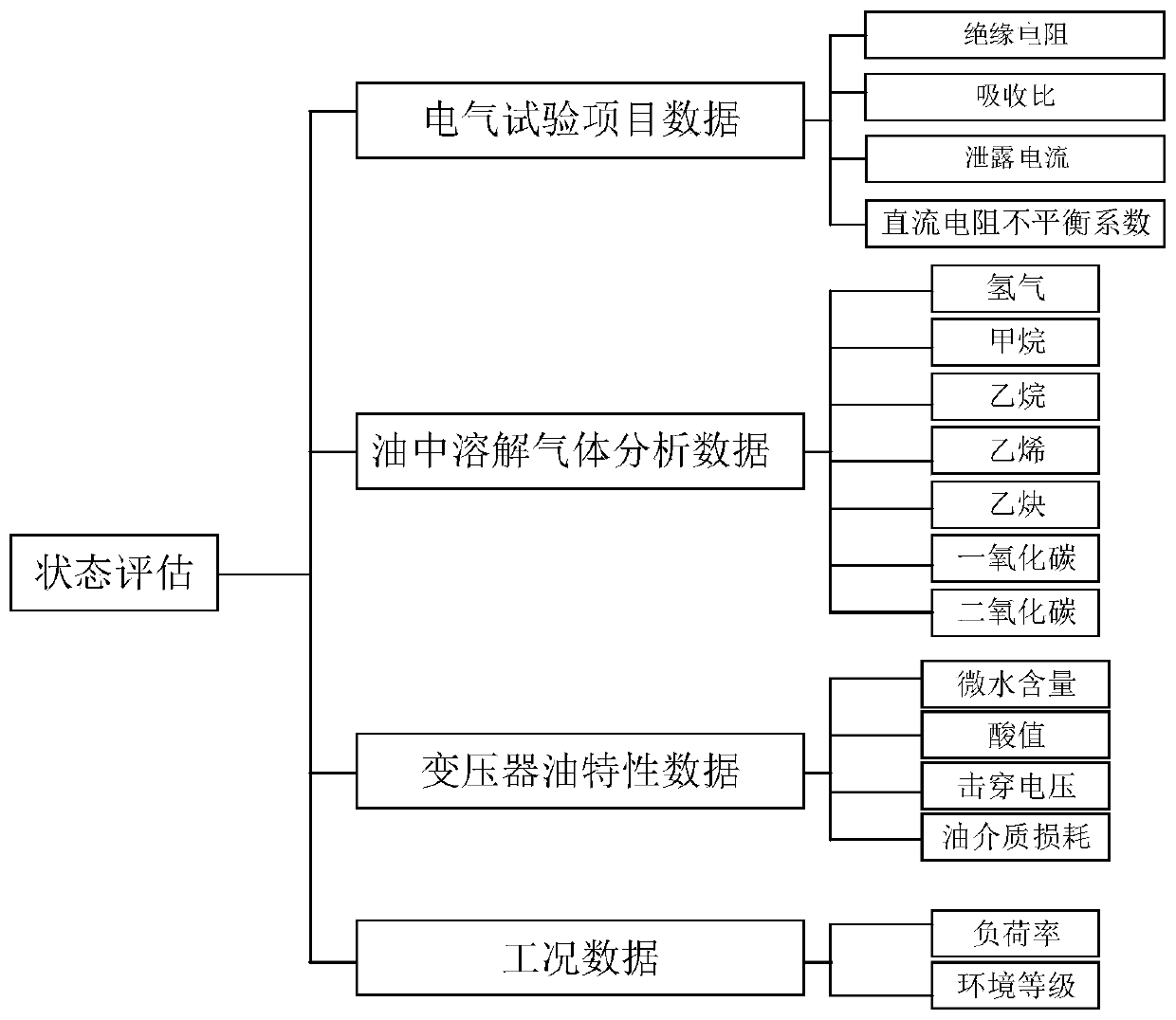

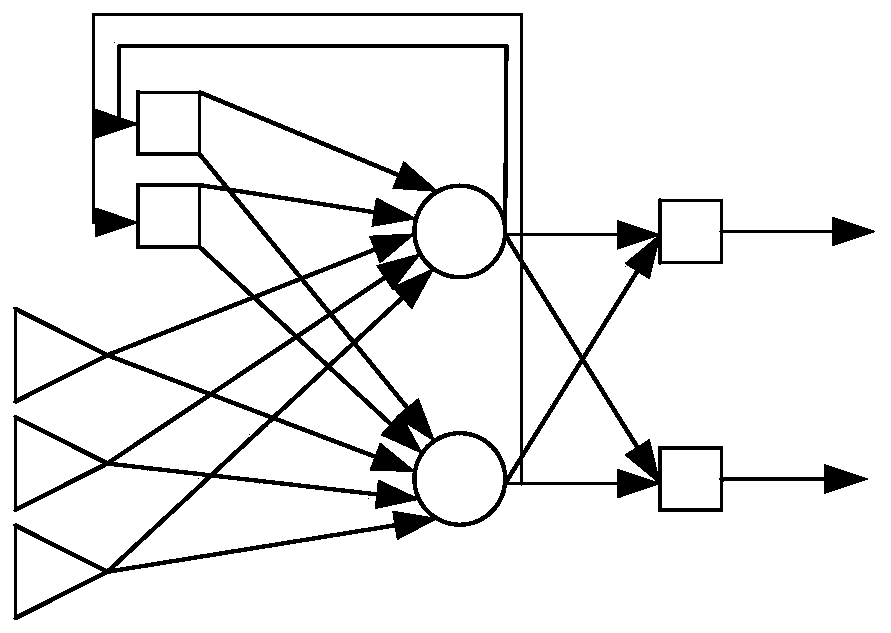

Method for predicting service life of transformer by using multiple parameters

PendingCN111460727APredict remaining lifeImprove forecast accuracyDesign optimisation/simulationNeural architecturesThermodynamicsEvaluation data

The invention discloses a method for predicting the service life of a transformer by using multiple parameters. The method comprises the following steps of S1, performing state evaluation on the transformer by using state data of the transformer; S2, constructing an evaluation database by utilizing the historical data of the transformer and the retirement data of the same type of transformer; andS3, predicting the transformer evaluation parameters by using an Elman network prediction method to obtain a predicted residual life. The transformer state data comprises transformer electrical test project data, analysis data of dissolved gas in oil, transformer oil characteristic data and working condition data, wherein the analysis data of the dissolved gas in the oil comprises hydrogen, methane, ethane, ethylene, acetylene, carbon monoxide and carbon dioxide, the transformer oil characteristic data comprises micro-water content, acid value, breakdown voltage and oil dielectric loss. The method can be used for predicting the service life of the transformer, accurately replacing the transformer and guaranteeing healthy operation of the transformer.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

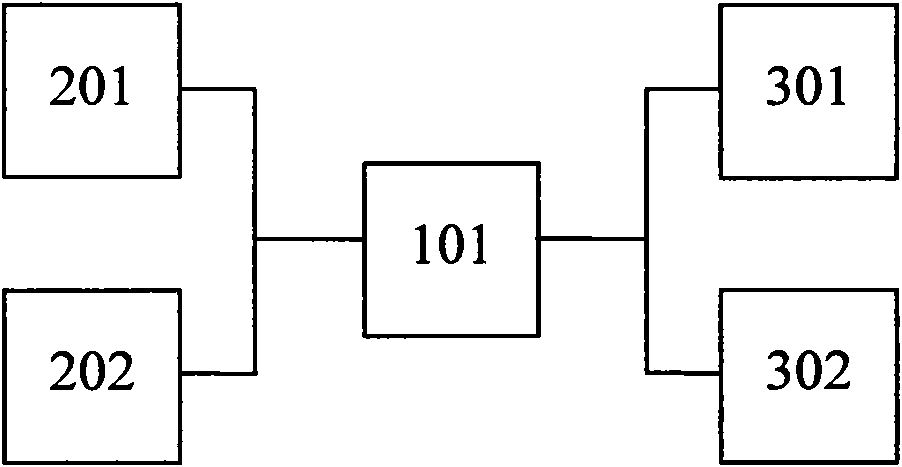

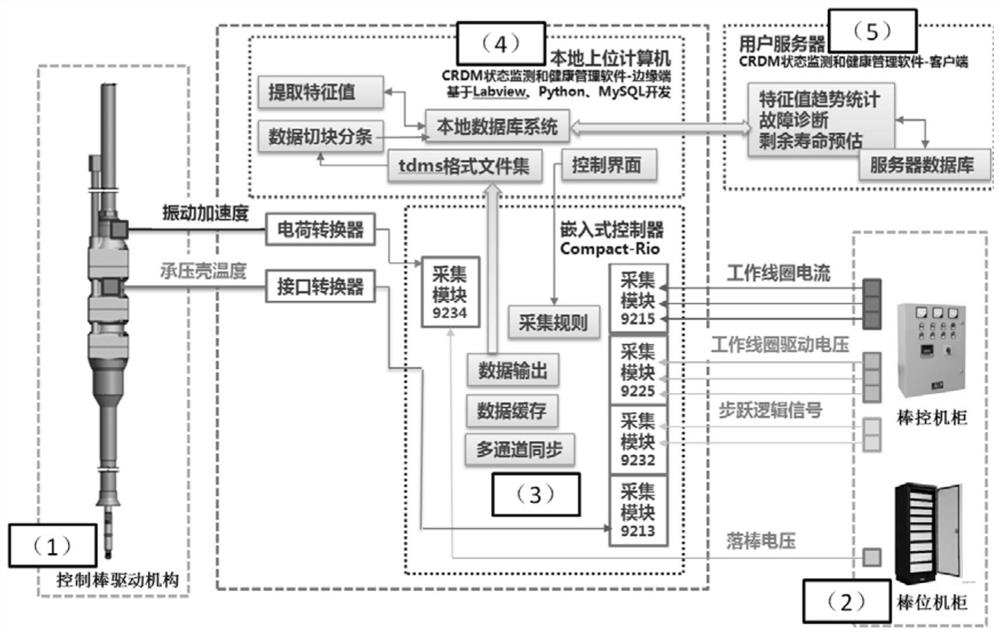

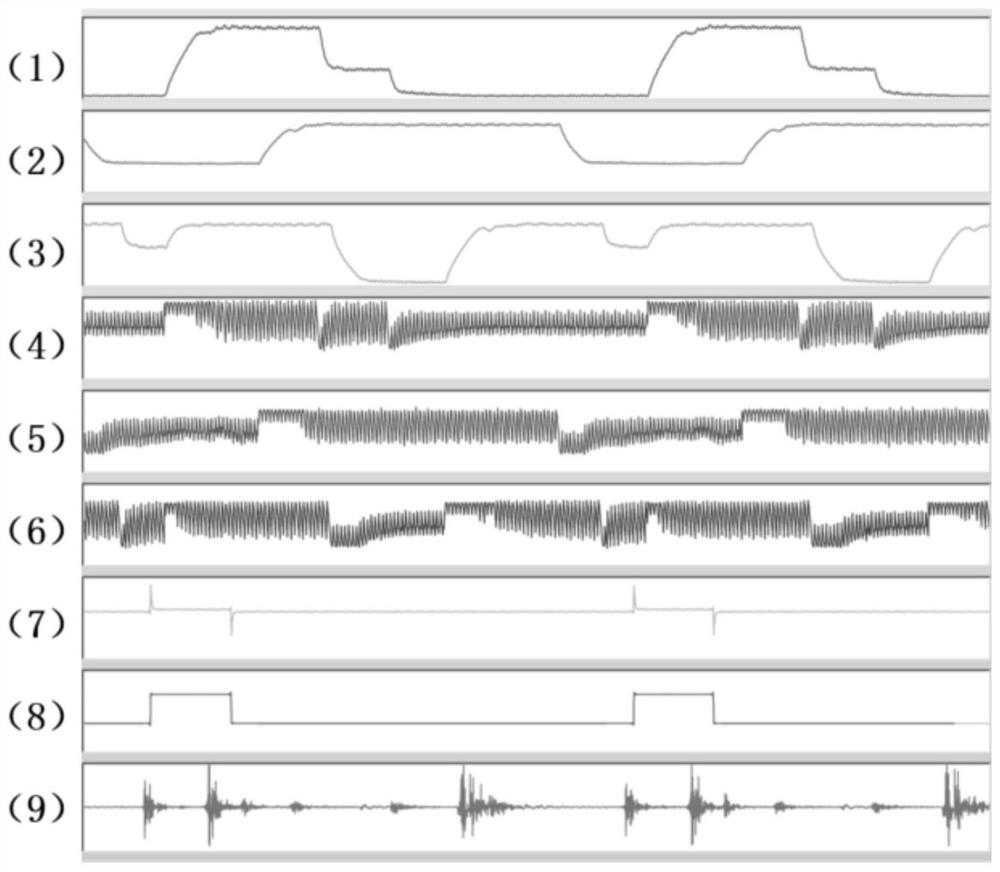

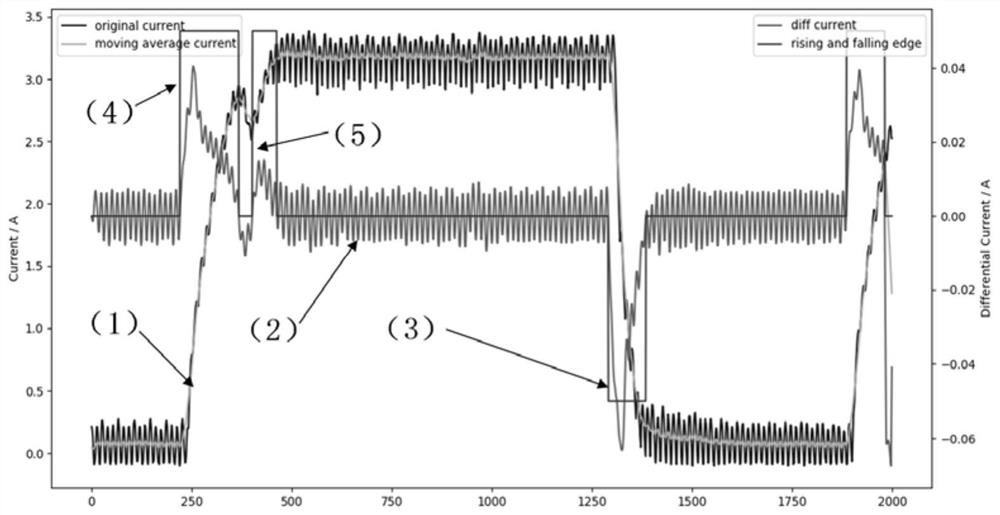

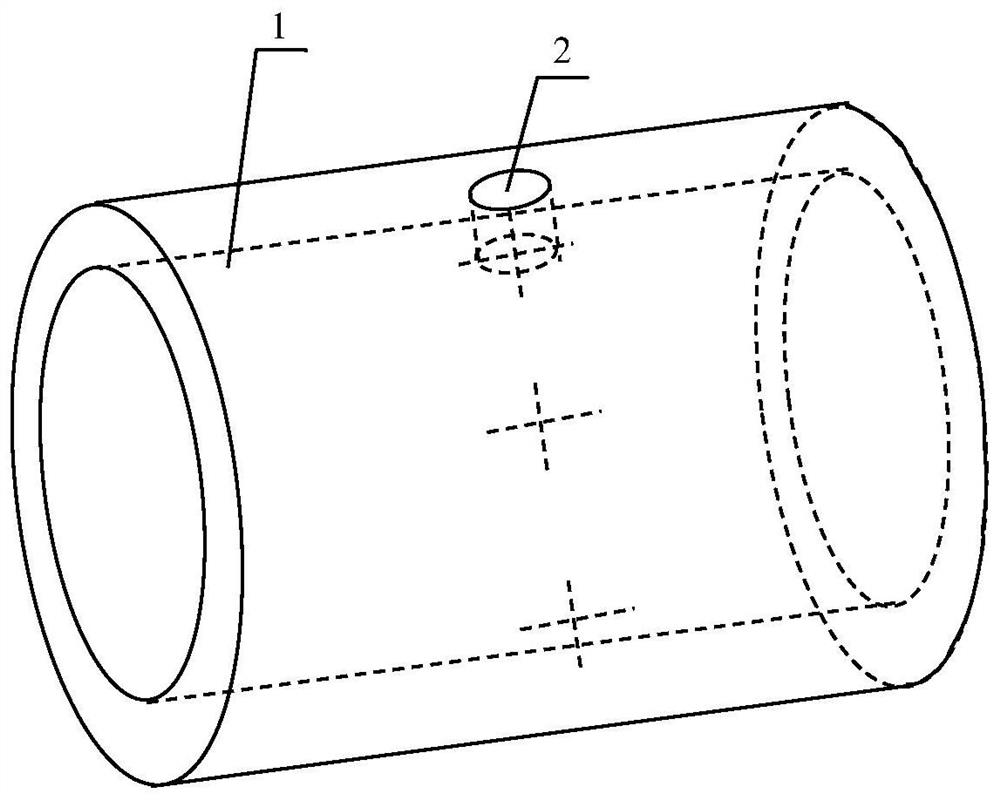

Control rod driving mechanism state monitoring and health management method and system

PendingCN111696692APredict remaining lifeLife expectancyNuclear energy generationNuclear monitoringNuclear reactorNuclear power plant

The invention discloses a nuclear reactor control rod driving mechanism monitoring and management system and method. The system comprises sensors (1 and 2), a data acquisition module (3), a data storage module (4), a local upper computer (5) and a server computer (6); the local upper computer (4) communicates with an embedded controller, completes data preprocessing and feature value extraction, and stores and manages the data in the two modes of an offline file and a local database; and the server computer (5) communicates with the local upper computer (4), calls standardized signal data entries, and completes characteristic value trend statistics and residual life calculation. A small number of sensors are additionally arranged on the basis of existing maturely-applied rod control rod position and control rod driving mechanism equipment of a nuclear power plant, and a feasible, accurate and reliable state monitoring and health management method and system meeting engineering requirements are provided for four component objects.

Owner:上海核工程研究设计院股份有限公司

Lithium ion battery residual life detection method based on relevance vector regression

The invention provides a lithium ion battery residual life detection method based on relevance vector regression, which comprises the following steps of (1) data feature extraction: extracting the data of the discharge voltage of a lithium battery along with time change according to the charge and discharge data of the lithium battery, and extracting the voltage change time as the data feature according to the voltage change gradient, (2) data feature normalization: carrying out normalization processing on the data, (3) building a model: selecting a Gaussian kernel function according to a relevance vector machine (RVM) algorithm model, building mapping from a data set sample to high-dimensional data, and performing data training to obtain the RVM algorithm model, and (4) prediction: predicting the residual capacity of the lithium battery by using a relevance vector machine (RVM) algorithm model so as to effectively detect the residual life of the battery.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

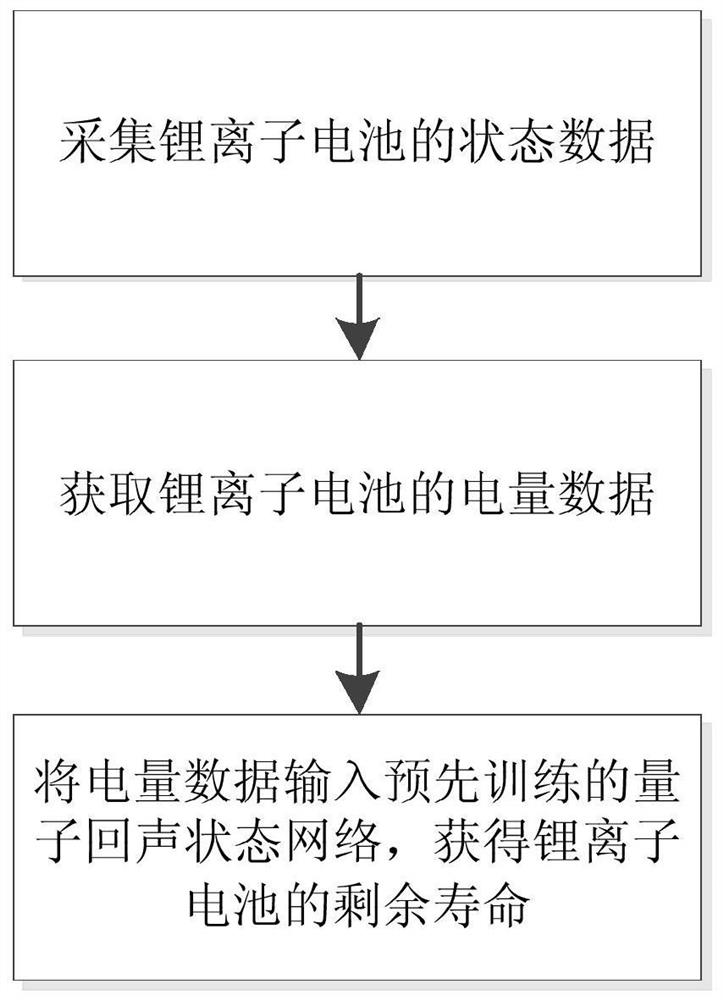

Lithium ion battery residual life prediction method and system

PendingCN111831955APredict remaining lifeFast convergenceQuantum computersElectrical testingEngineeringLithium-ion battery

The invention discloses a lithium ion battery residual life prediction method and system. The method comprises the steps of collecting state data of the lithium ion battery; acquiring electric quantity data of the lithium ion battery according to the state data; and inputting the electric quantity data into a pre-trained quantum echo state network to obtain the residual life of the lithium ion battery. The invention further discloses a corresponding system. Through the quantum echo state network, the residual life of the lithium ion battery is effectively predicted, and the method has important significance for guaranteeing safe and reliable operation of equipment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

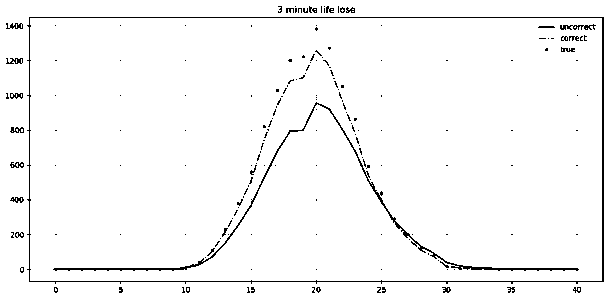

Residual life prediction method of electromechanical system based on two-time-scale particle filter

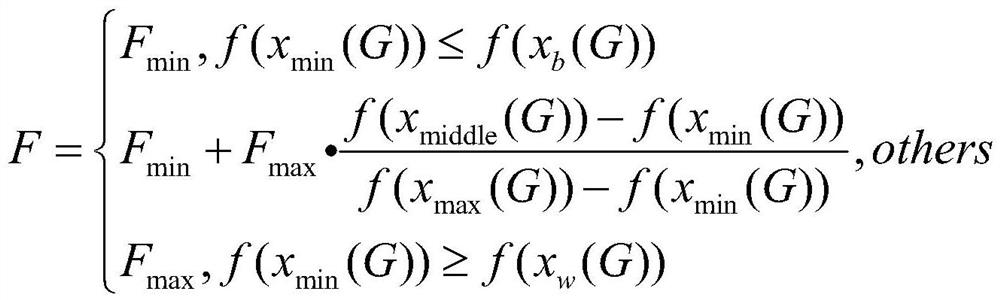

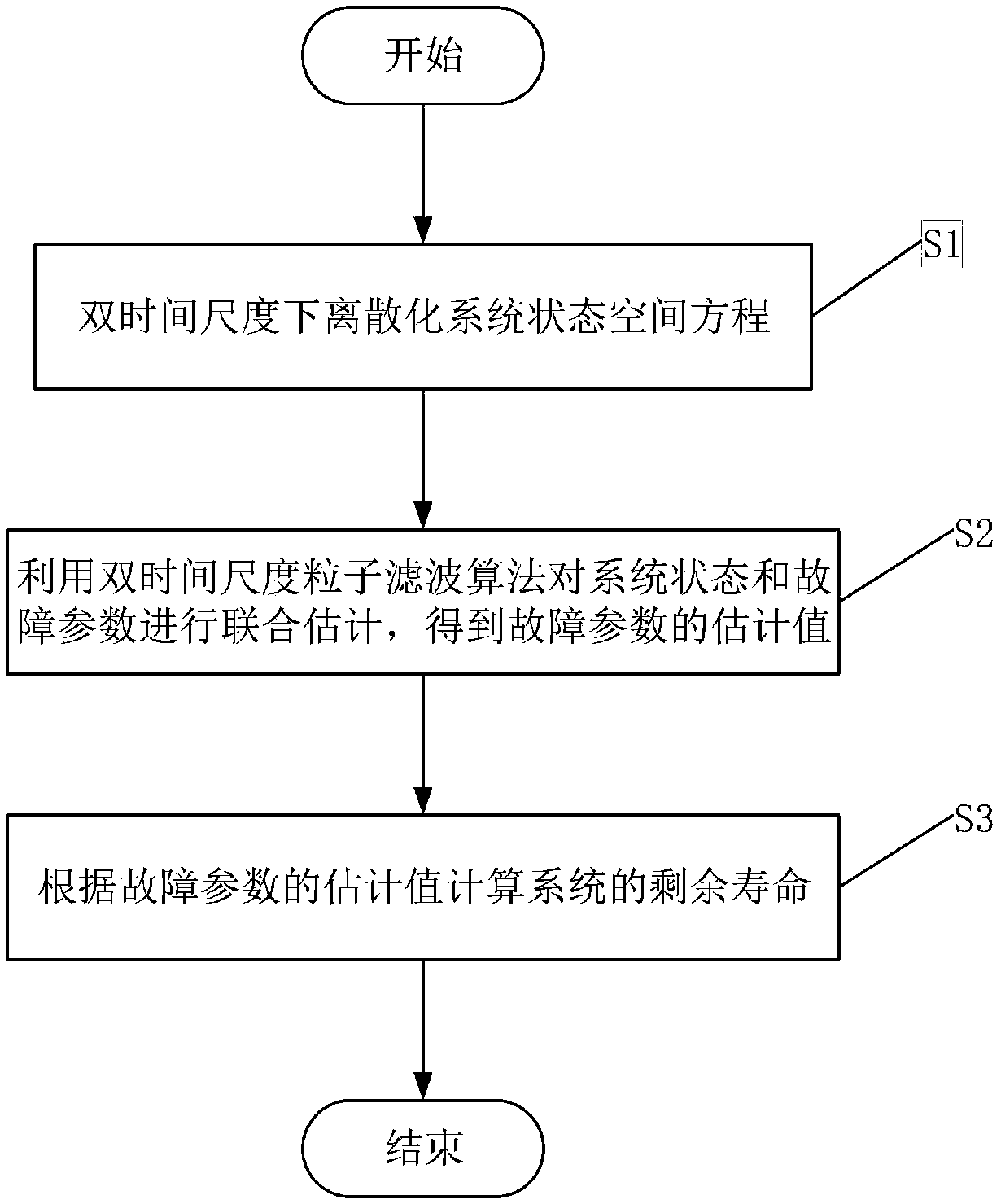

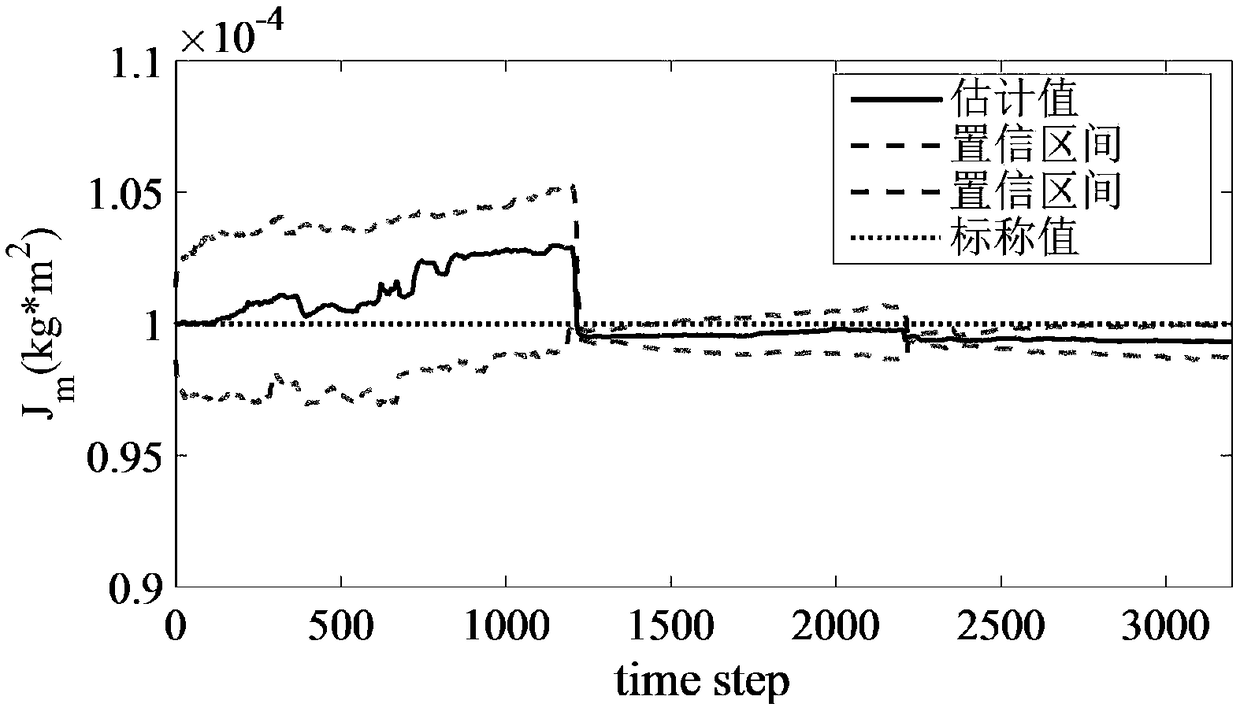

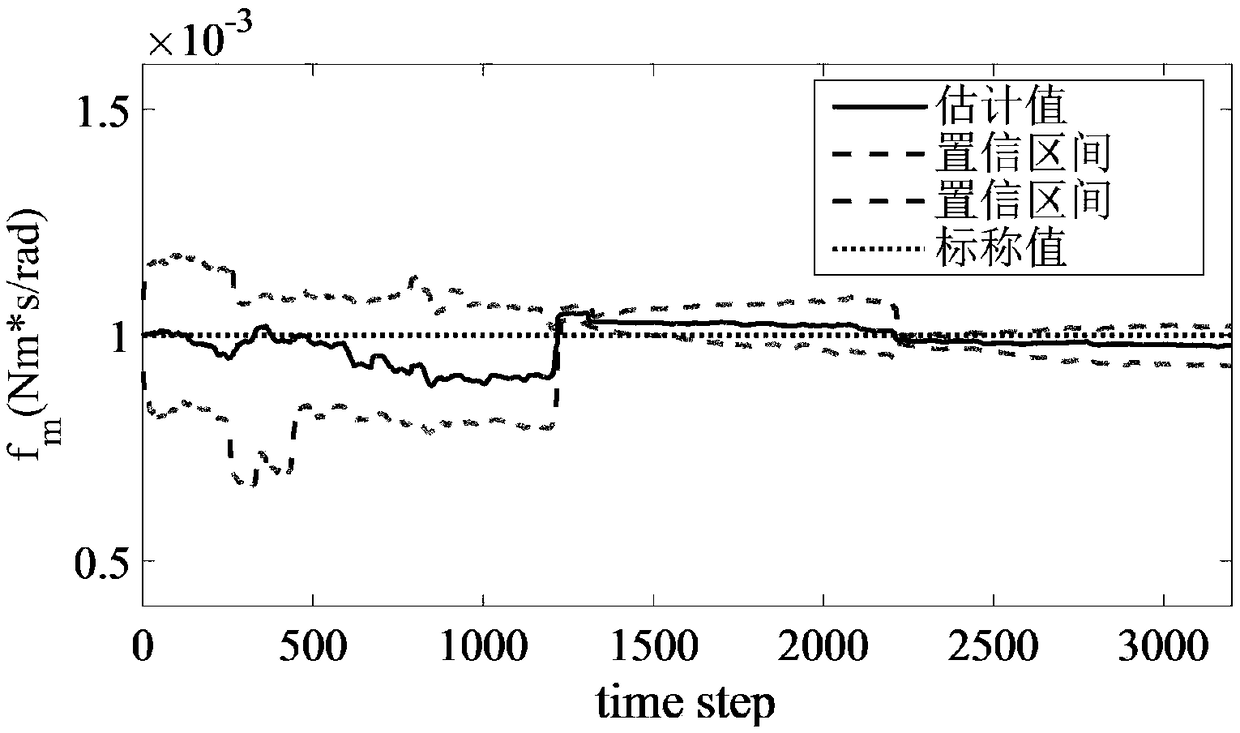

ActiveCN109241639AImproving the Efficiency of Joint EstimationAvoid wastingDesign optimisation/simulationSpecial data processing applicationsEuler discretizationPrediction methods

The invention discloses a residual life prediction method of an electromechanical system based on a dual-time scale particle filter, which comprises the following steps of: a continuous system state space equation is discretized by adopting an Euler discretization method to obtain a discrete system state space equation under the dual-time scale; The state and fault parameters of the system are estimated by using the dual-time-scale particle filter algorithm, and the fault source is identified by the estimated value of the fault parameters; A degradation model of system parameters is predicted,and the residual life of the system is calculated by using the estimated value of the fault parameters and the fault failure threshold. The invention solves the problem that a large amount of computational resources are wasted during the joint estimation of the system state and the fault parameters in the time period when the fault parameters are basically unchanged, improves the efficiency of the fault diagnosis, and guarantees the real-time performance of the residual life prediction.

Owner:HEFEI UNIV OF TECH

Life prediction method and system based on degradation state of welding spot of IGBT module

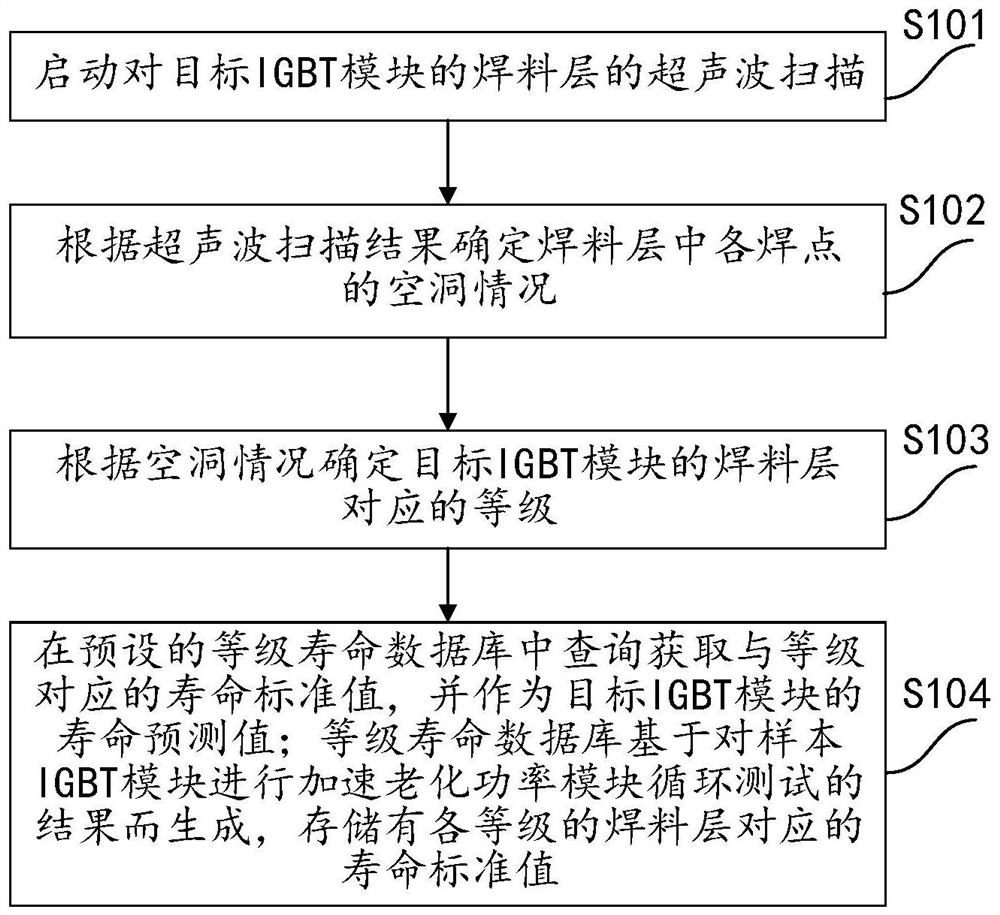

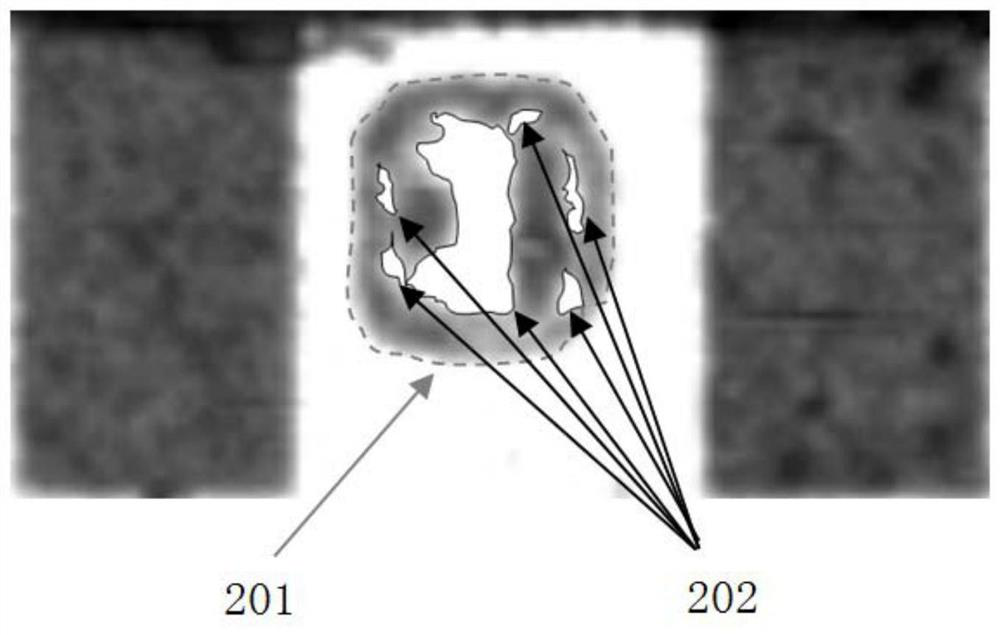

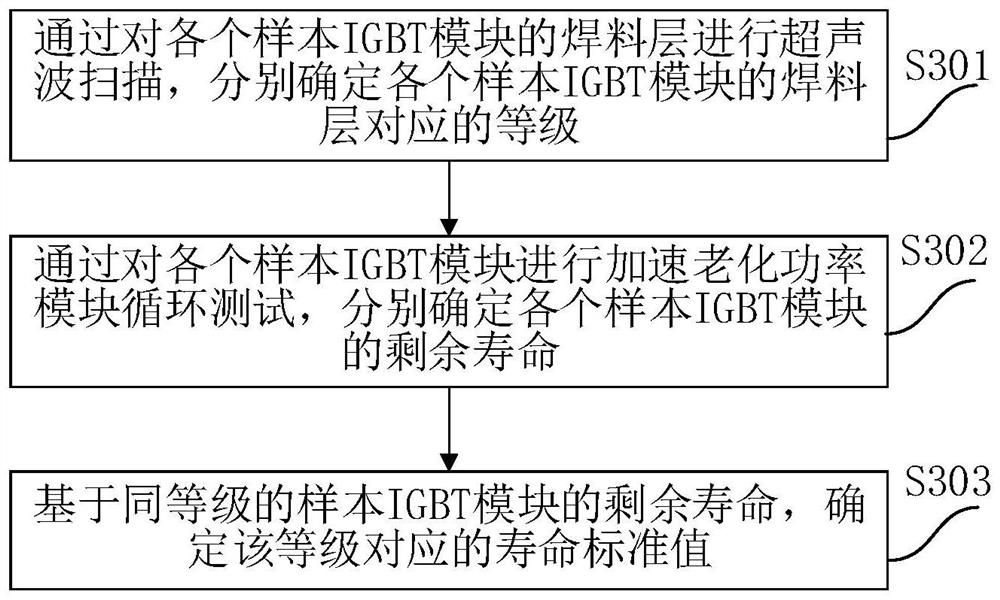

PendingCN113379165APredict remaining lifeDetect remaining lifeForecastingResourcesAccelerated agingEconomic benefits

The invention discloses a life prediction method and system based on the degradation state of a welding spot of an IGBT module. The method comprises the following steps: starting ultrasonic scanning of a welding flux layer of a target IGBT module; determining the cavity condition of each welding spot of the welding flux layer according to the ultrasonic scanning result; determining a level corresponding to a solder layer of the target IGBT module according to the void condition; querying in a preset grade life database to obtain a life standard value corresponding to the grade, and taking the life standard value as a life prediction value of the target IGBT module; and generating a grade life database based on the result of the accelerated aging power module cycle test on the sample IGBT module and storing the life standard value corresponding to the solder layer of each grade. The cavity problem of the solder layer is detected by adopting a simple and easy-to-operate ultrasonic detection technology, so that the residual life of the IGBT module can be efficiently and accurately predicted, the efficiency and rationality of equipment operation and maintenance are improved, and the economic benefits of products are effectively improved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

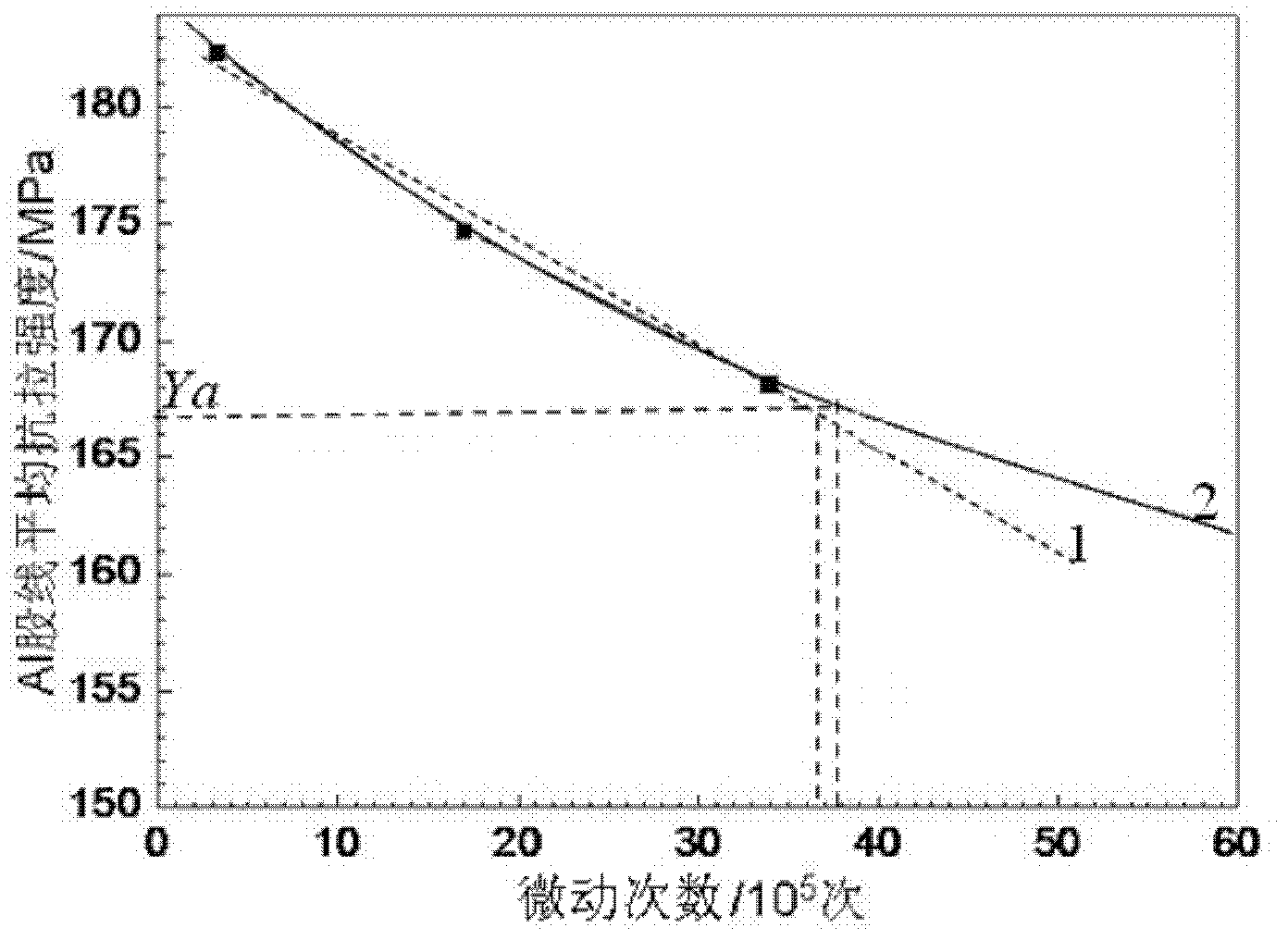

Method for forecasting residual service life of steel-cored aluminum strand overhead conductor

InactiveCN102589992AImprove safety management levelImprove reliabilityMaterial strength using repeated/pulsating forcesVibration basedPower grid

The invention discloses a method for forecasting the residual service life of a steel-cored aluminum strand overhead conductor, wherein the method is characterized by forecasting the residual service life Nr of the serviced steel-cored aluminum strand overhead conductor under the condition of aeolian vibration based on the final motion simulation test and the cumulative damage criterion of the steel-cored aluminum strand overhead conductor of a laboratory. The method in the invention has important meanings for improving the safety management level of a transmission line of a power supply unit, and improving the running reliability of a power grid.

Owner:HEFEI UNIV OF TECH

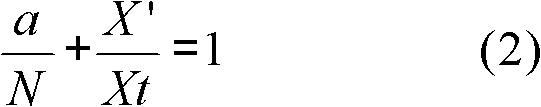

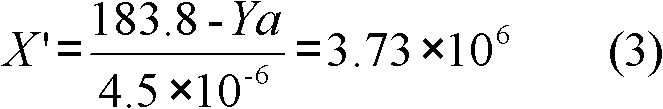

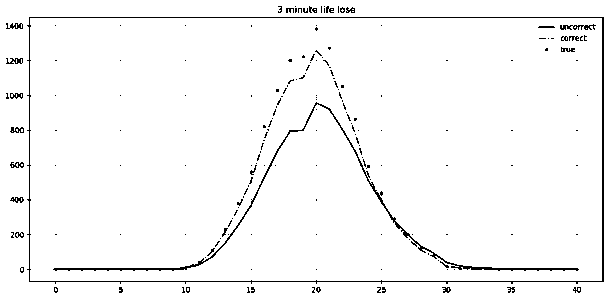

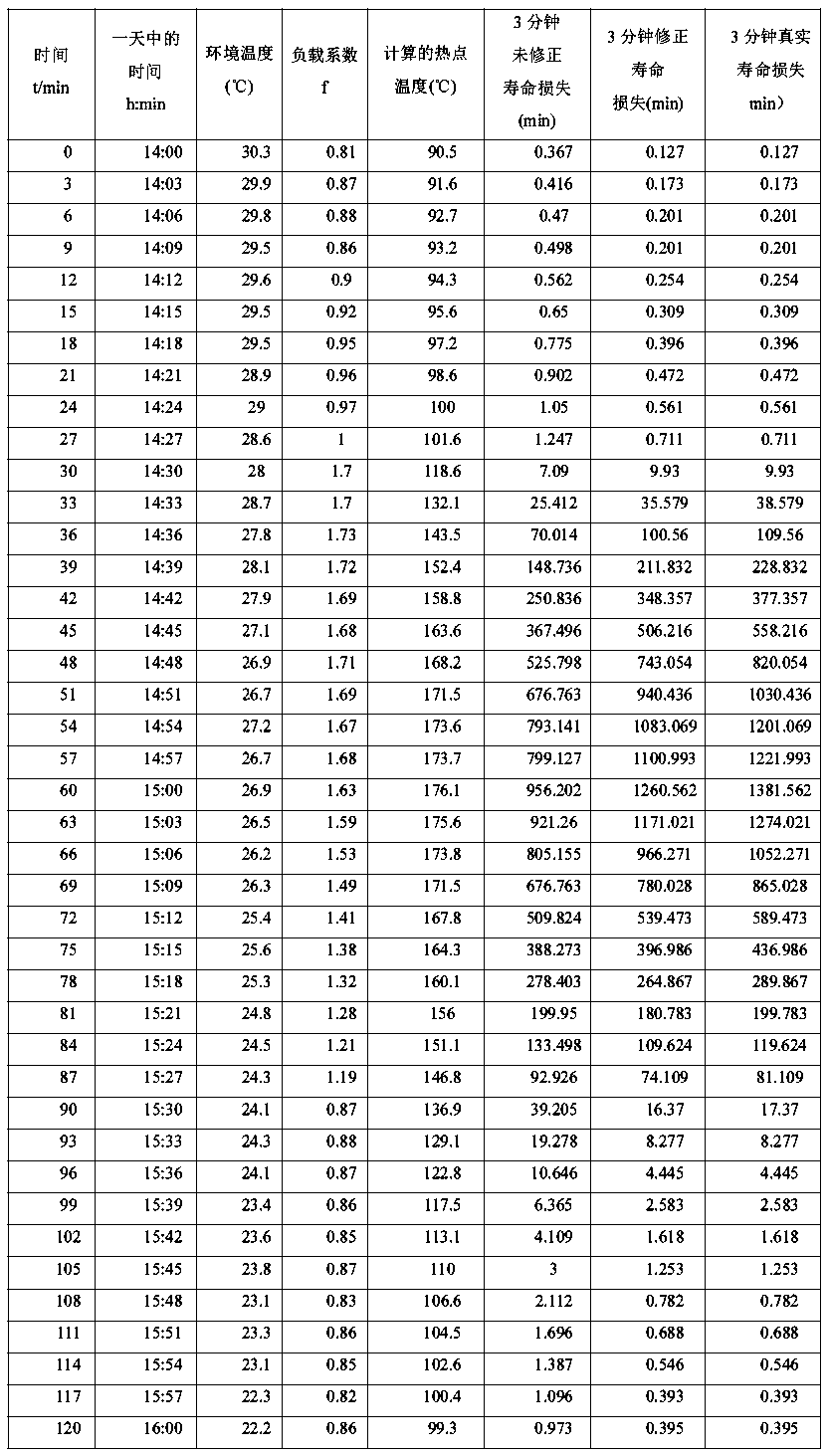

Transformer insulation life loss calculation method

PendingCN111125915APredict remaining lifePredictive runabilityDesign optimisation/simulationInformation technology support systemTransformerIndustrial engineering

The invention discloses a transformer insulation life loss calculation method, and belongs to the technical field of transformers. The method comprises two steps of correcting an insulation life agingfactor of the transformer and calculating the insulation life loss of the transformer. The method has the advantages that by monitoring the key data of the running state of the transformer, the insulation life loss can be accurately calculated, and then the remaining life and the overall running state of the transformer are predicted; operation and maintenance personnel are helped to make accurate and efficient decisions in time, customers are helped to arrange product maintenance in a planned mode, the number of products needing to be replaced is accurately provided, and product inventory isreduced; potential hazards are effectively eliminated through timely judgment, downtime is shortened, and power supply is ensured.

Owner:SHIJIAZHUANG KE IOT TECH CO LTD +1

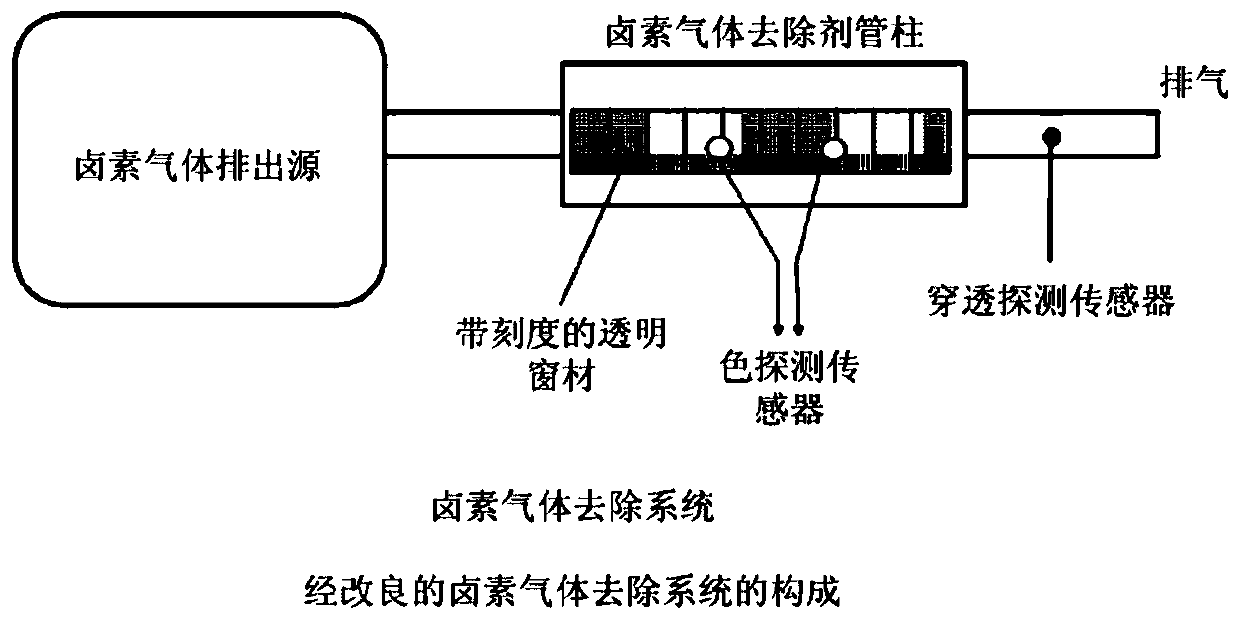

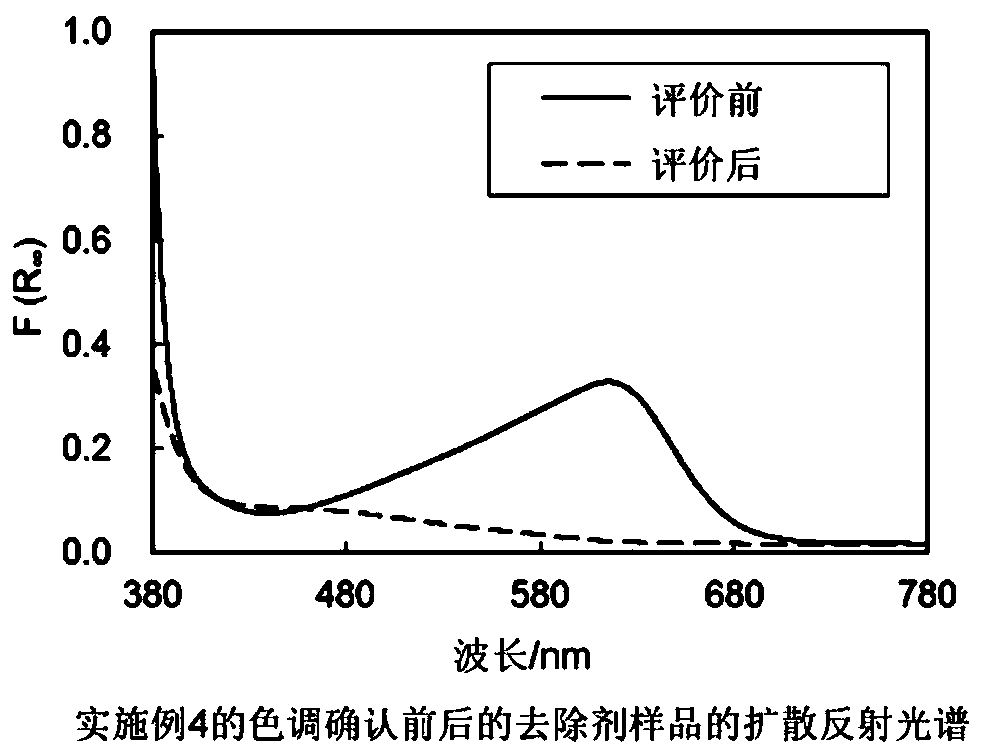

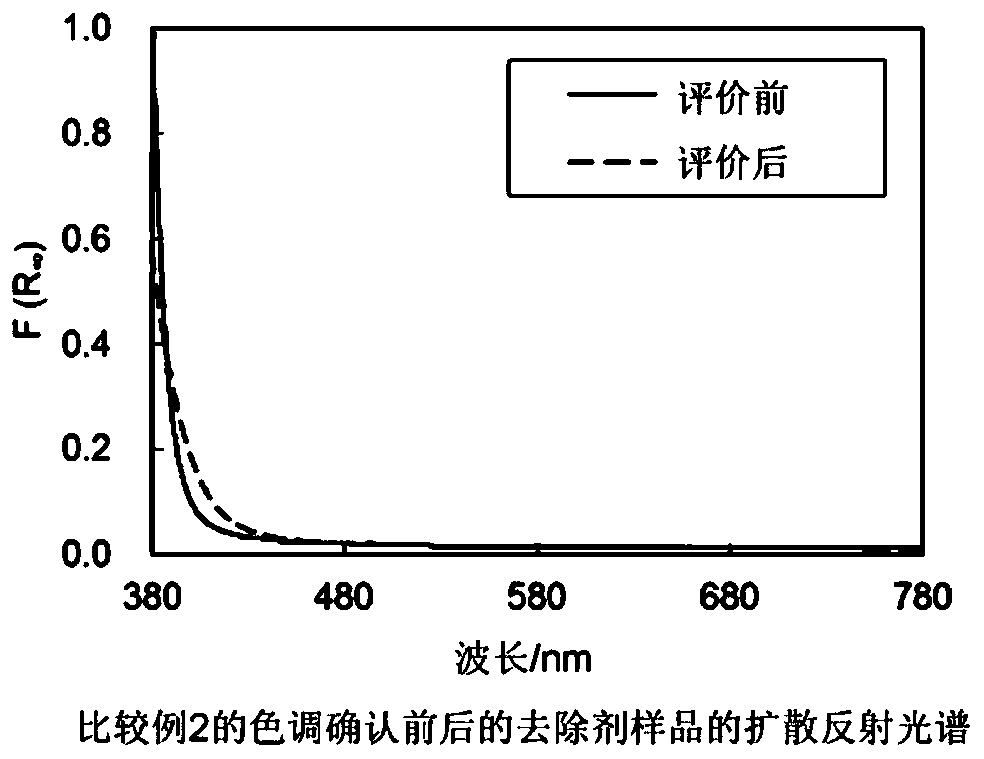

Halogen gas removing agent, method for producing same, removal device, monitoring method and removal method

InactiveCN110772947ALarge decomposition capacityMonitor consumption statusGas treatmentAnalysis using chemical indicatorsPseudoboehmiteHalogen

The invention provides a halogen gas removing agent and a manufacturing method thereof. The halogen gas removing agent for removing halogen gas from a gas flow, which reduces the risk of leakage of the halogen gas exhausted from a semiconductor production process by treating the gas flow with the removing agent and a process for producing the removing agent. Also provided are an apparatus for removing the halogen gas using the removing agent, and a method for monitoring the state of consumption of the halogen gas. The halogen gas removing agent includes an inorganic compound base material, a sulfur-containing reducing compound and a color indicator, preferably using a pseudoboehmite as the base material, adding a pH indicator having a transition range in a pH range of 3 to 8 as the color indicator, and adding a basic metal compound such as zinc oxide. Thus, the halogen gas removing agent which is high in halogen gas treatment capacity and capable of monitoring the consumption state ofthe halogen gas removing agent can be obtained.

Owner:CLARIANT CATALYSTS JAPAN

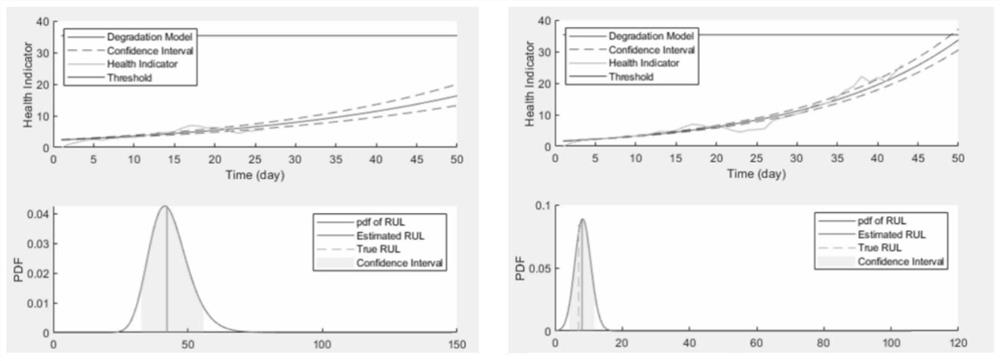

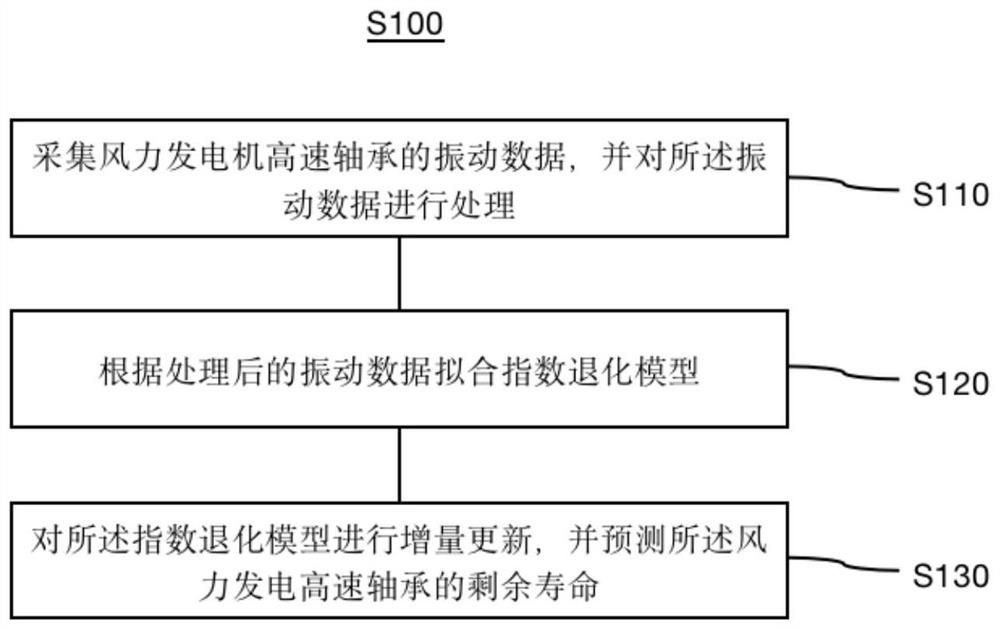

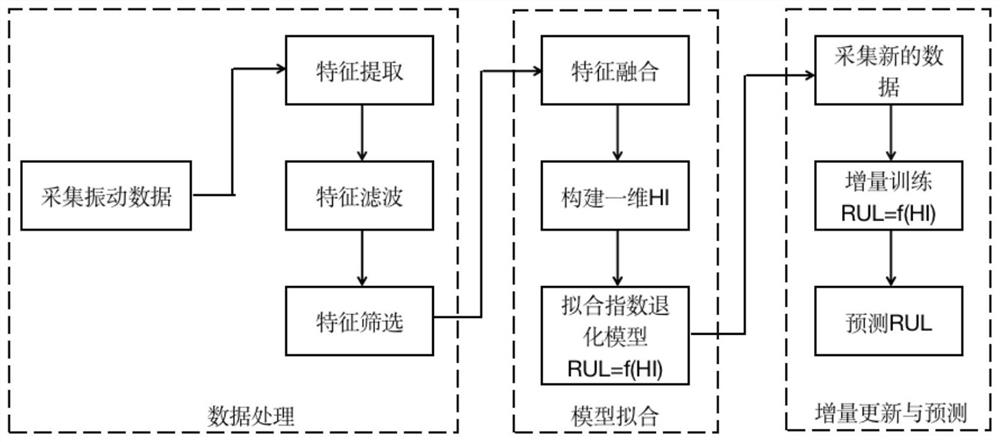

Predictive maintenance method and system for high-speed bearing of wind driven generator

PendingCN112597607APredict remaining lifeReal-time prediction of remaining lifeGeometric CADSpecial data processing applicationsWind drivenControl engineering

The invention provides a predictive maintenance method and system for a high-speed bearing of a wind driven generator, and belongs to the technical field of industrial automation. The predictive maintenance method for the high-speed bearing of the wind driven generator comprises the following steps: collecting vibration data of the high-speed bearing of the wind driven generator, processing the vibration data, fitting an index degradation model according to the processed vibration data, carrying out incremental updating on the index degradation model, and predicting the residual life of the wind power generation high-speed bearing. According to the predictive maintenance method, prediction of the residual life of the high-speed bearing of the wind driven generator without historical numbers in the initial stage of production is achieved, and then predictive maintenance is guided. Moreover, the method provided by the invention can update model parameters on line by utilizing newly acquired data along with the operation of equipment, can predict the residual life of the wind power generation high-speed bearing in real time, and can calculate the confidence coefficient of a predictionresult at the same time.

Owner:BEIJING HUANENG XINRUI CONTROL TECH

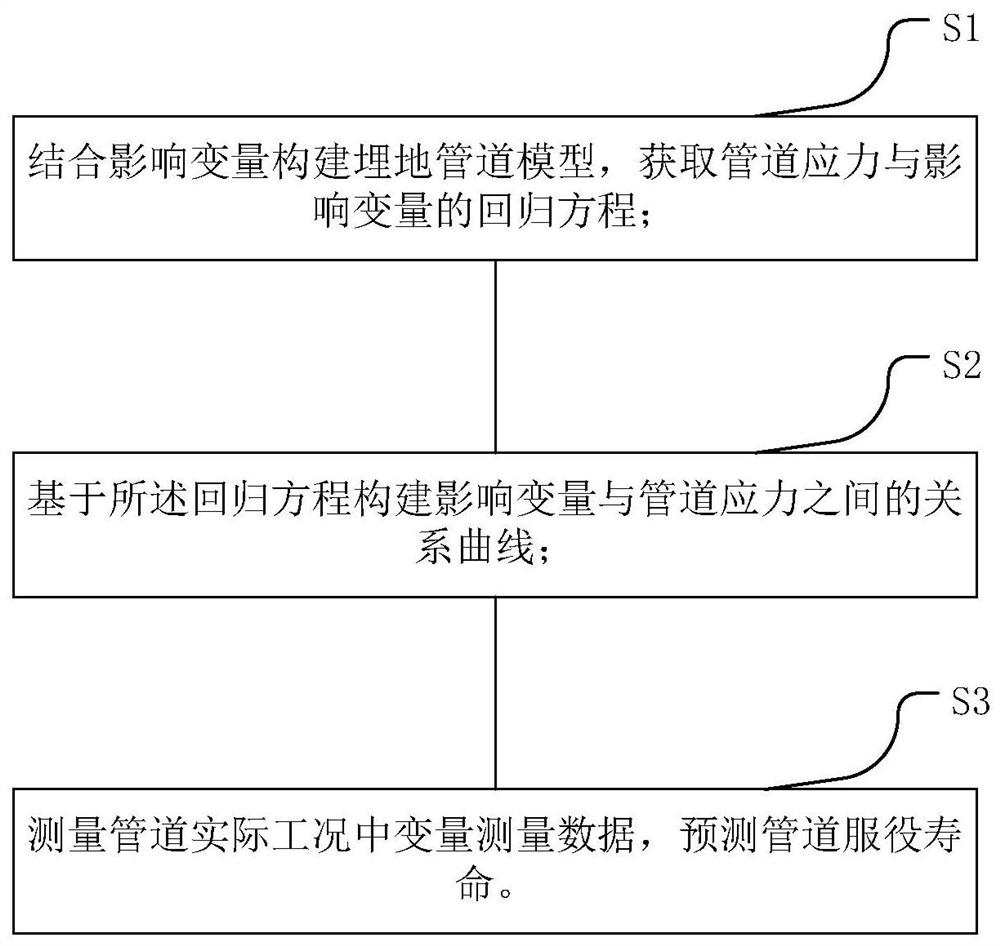

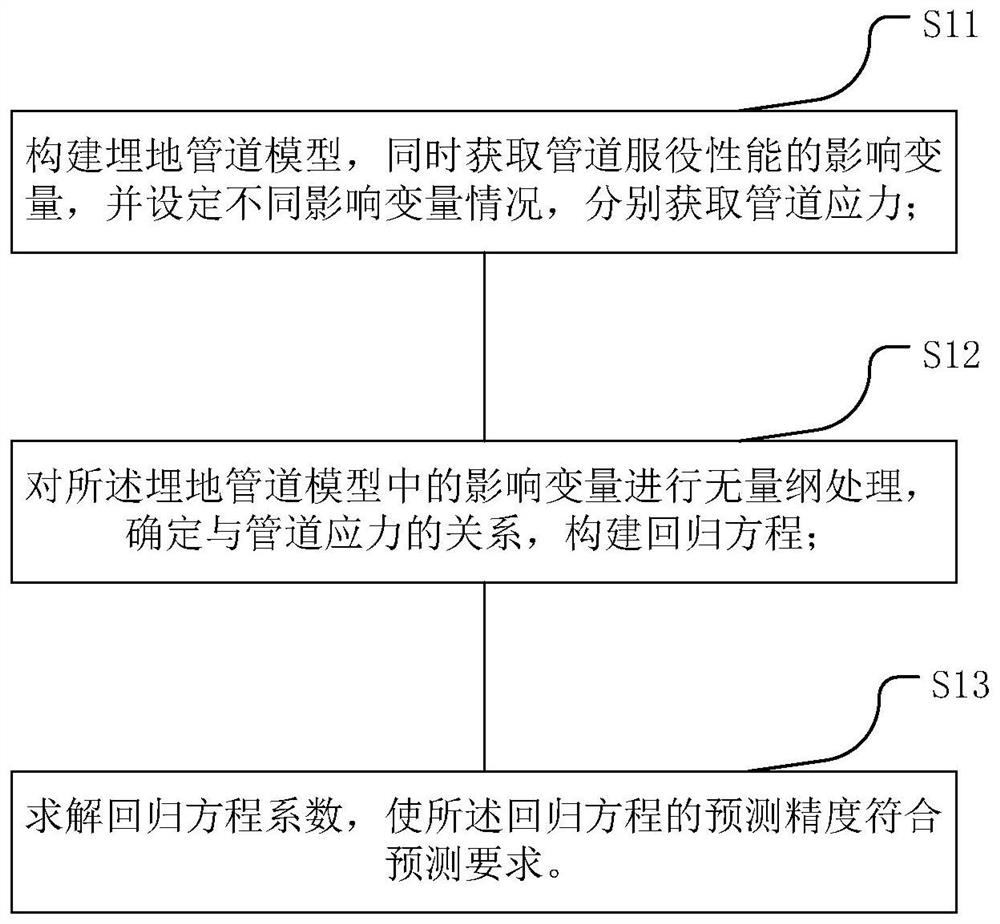

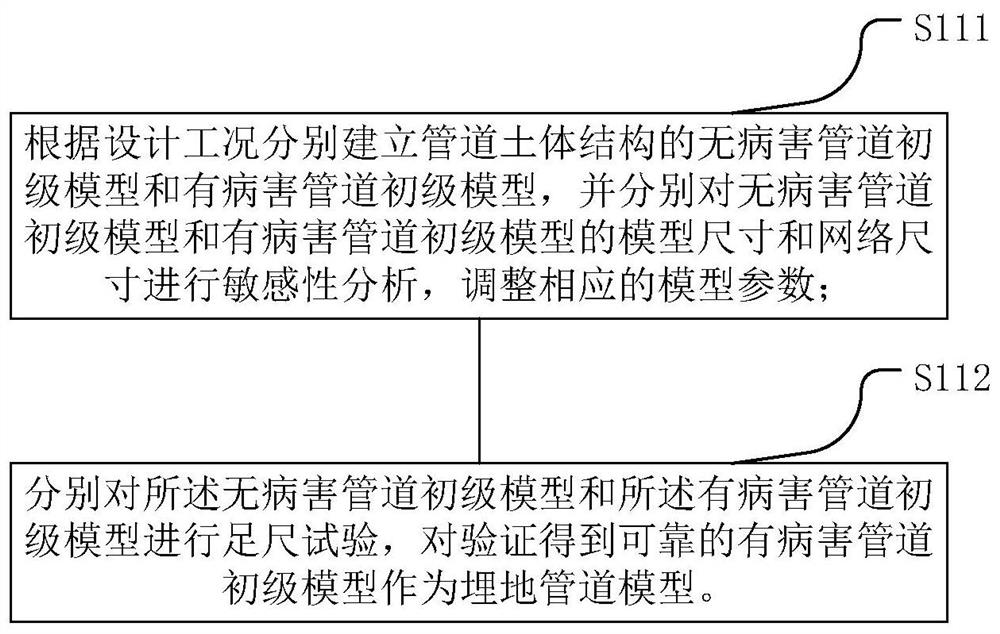

Buried pipeline service performance evaluation method, computer readable medium and equipment

ActiveCN112001104AOvercome the conditionsOvercoming supportForecastingArtificial lifeSimulationIndustrial engineering

Owner:ZHENGZHOU UNIV

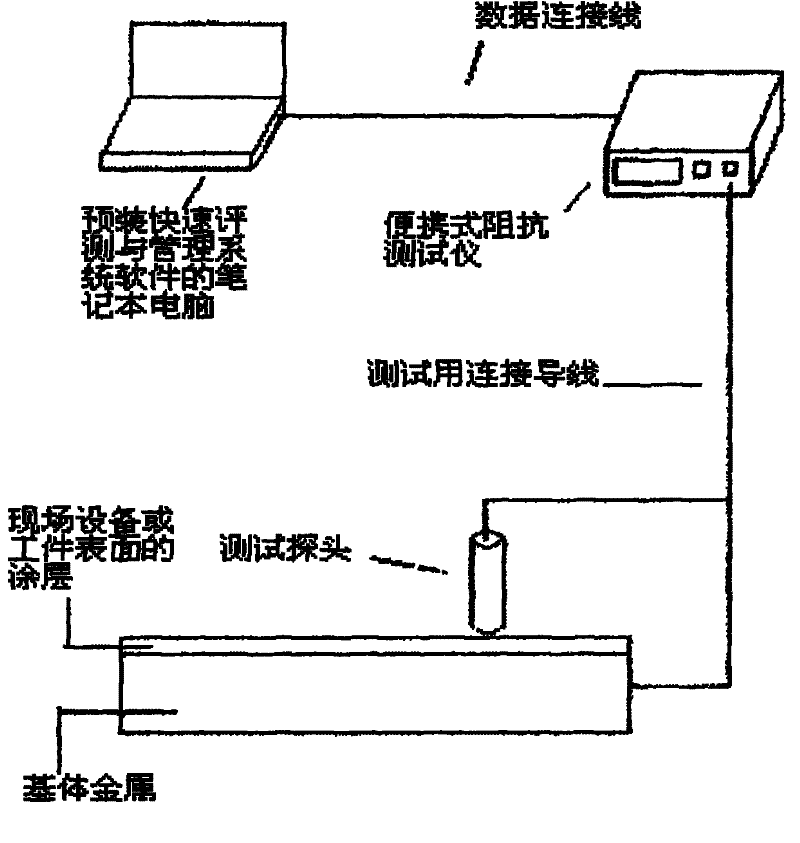

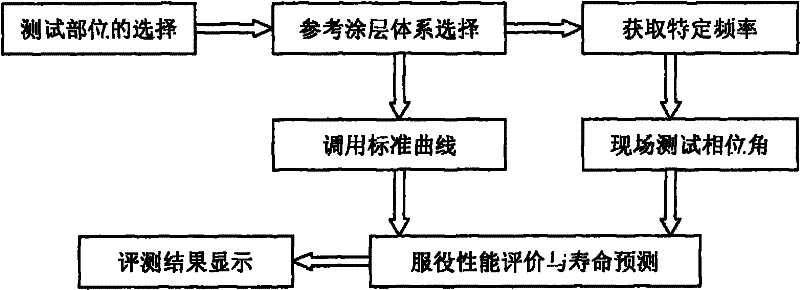

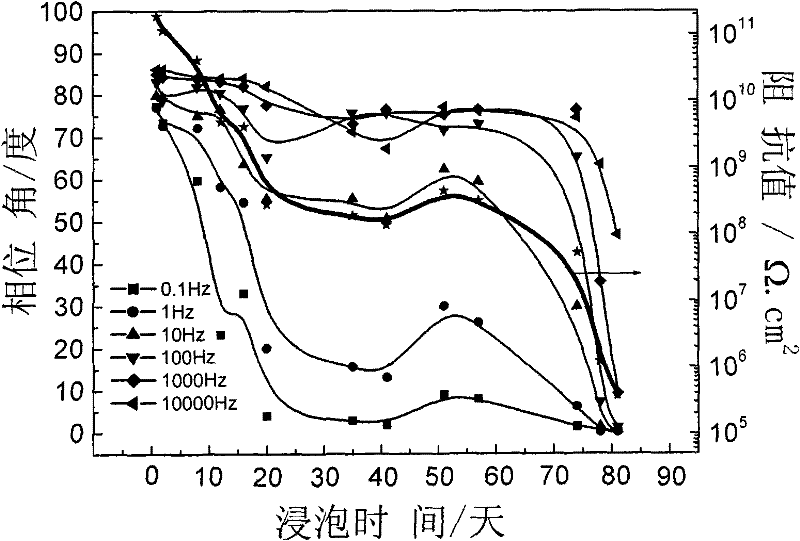

Method and system for rapidly evaluating corrosion resistance of in-service coating

ActiveCN101634623BRapid Evaluation of Corrosion ResistanceSimple technical solutionWeather/light/corrosion resistanceSoftware systemEngineering

The invention relates to an electrochemical method for rapidly evaluating the performance of an in-service coating, which can reflect a change law of impedance in the service process of the coating according to the change of a phase angle in specific frequency of a coating / metal system along with the service time and designs and develops a software system for rapidly evaluating and managing the performance of the in-service coating on the basis, which is suitable for the industrial field. The system is matched with a detection probe, a portable impedance test instrument and a notebook computer. The invention is used for rapidly evaluating the corrosion resistance and predicting the service life of the in-service coating, is particularly applied to the industrial field, has rapid and convenient measurement, reliable data and simple instrument and does not need to analyze impedance data.

Owner:BEIJING UNIV OF CHEM TECH

Nonlinear ultrasonic detection grading evaluation method for performance degradation of heat-resistant steel part

ActiveCN113189199APredict remaining lifeSolving the Quantitative Grading Problem of Nonlinear Ultrasonic TestingAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalNonlinear ultrasoundStructural engineering

The invention discloses a non-linear ultrasonic testing, grading evaluation method for performance degradation of a heat-resistant steel part, which comprises the following steps: manufacturing an initial manual comparison micro sample, obtaining the failure time of a performance degradation acceleration test of the heat-resistant steel part, manufacturing a manual comparison micro sample group for non-linear ultrasonic testing, grading and evaluating, building a nonlinear high-energy ultrasonic testing system, testing ultrasonic nonlinear coefficients of an artificial contrast micro sample group for nonlinear ultrasonic detection grading evaluation, drawing a weighted average ultrasonic nonlinear coefficient-performance degradation damage level reference curve, and performing performance degradation damage level evaluation on the heat-resistant steel part to be detected; predicting the residual life of the heat-resistant steel part to be detected. According to the method, grading evaluation of nonlinear ultrasonic detection of performance degradation of the heat-resistant steel part is realized, the performance degradation degree of the heat-resistant steel part can be measured, the residual life of the detected heat-resistant steel part can be predicted, and the quantitative grading problem of nonlinear ultrasonic detection of the performance degradation of the heat-resistant steel part is solved.

Owner:国能锅炉压力容器检验有限公司

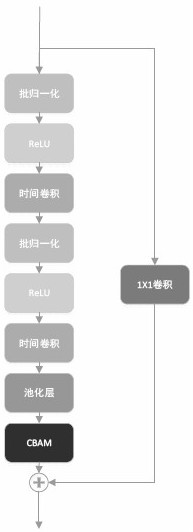

Method for predicting residual life of dynamic filtering compensator

ActiveCN112881518AGood prediction efficiency and prediction accuracyEasy to operateMaterial strength using repeated/pulsating forcesHarmonic reduction arrangementFeature screeningMonitoring data

The embodiment of the invention provides a method for predicting the residual life of a dynamic filtering compensator. The method comprises the following steps of: obtaining monitoring data, and preprocessing of the monitoring data; calculating a Spearman correlation coefficient between the monitoring data and the residual life, and setting a threshold value to perform feature screening so as to obtain feature-screened data related to degradation; constructing a mixed attention time convolutional network according to the feature-screened data; and obtaining a prediction model according to the mixed attention time convolutional network, and obtaining residual life data according to the prediction model. The method can effectively improve the prediction efficiency and precision.

Owner:东冶及策河北能源技术有限公司

Method for online managing cutting tool of numerically controlled lathe

InactiveCN101770222BAccurately record usage timePredict remaining lifeNumerical controlComputer terminalMachine tool

Owner:JIANGNAN UNIV

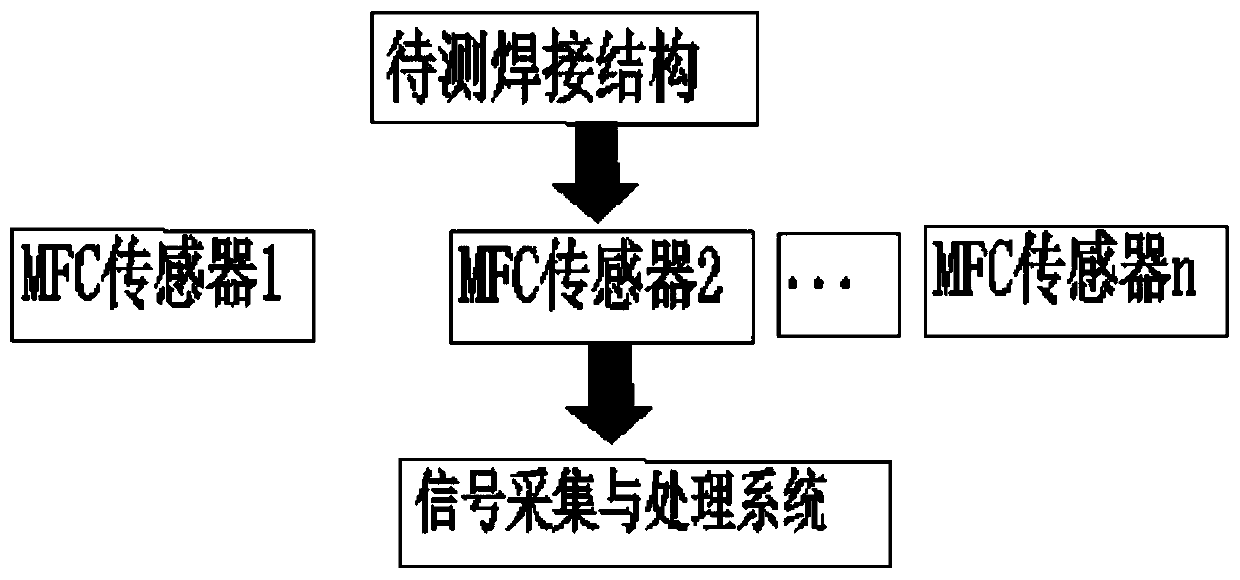

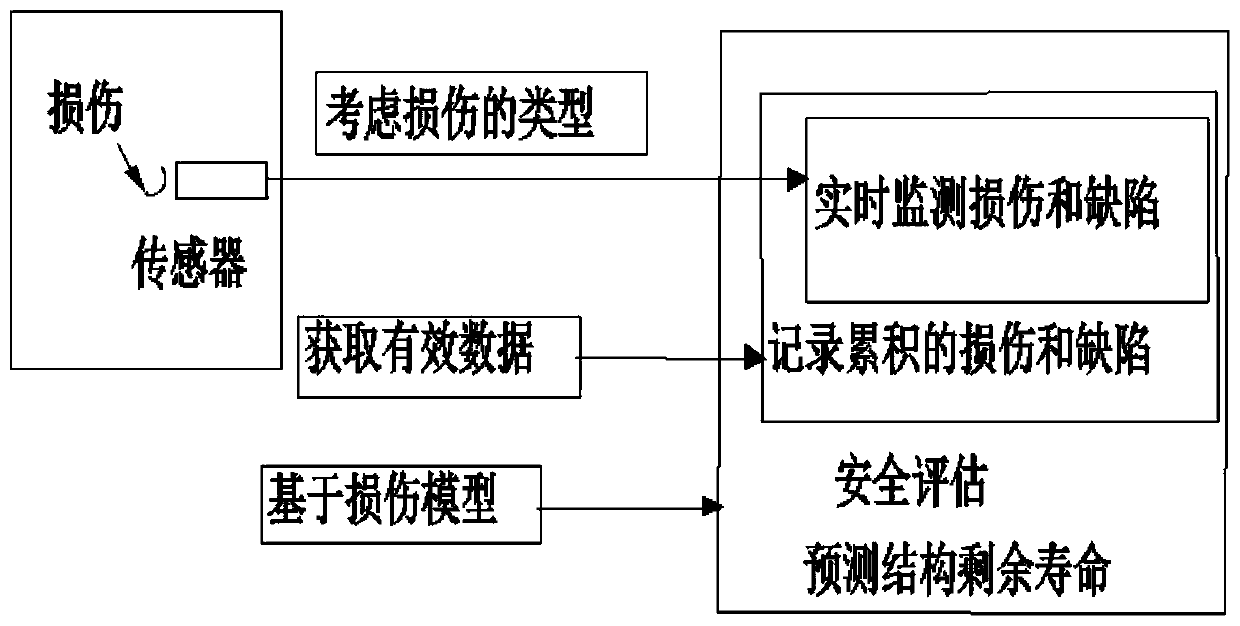

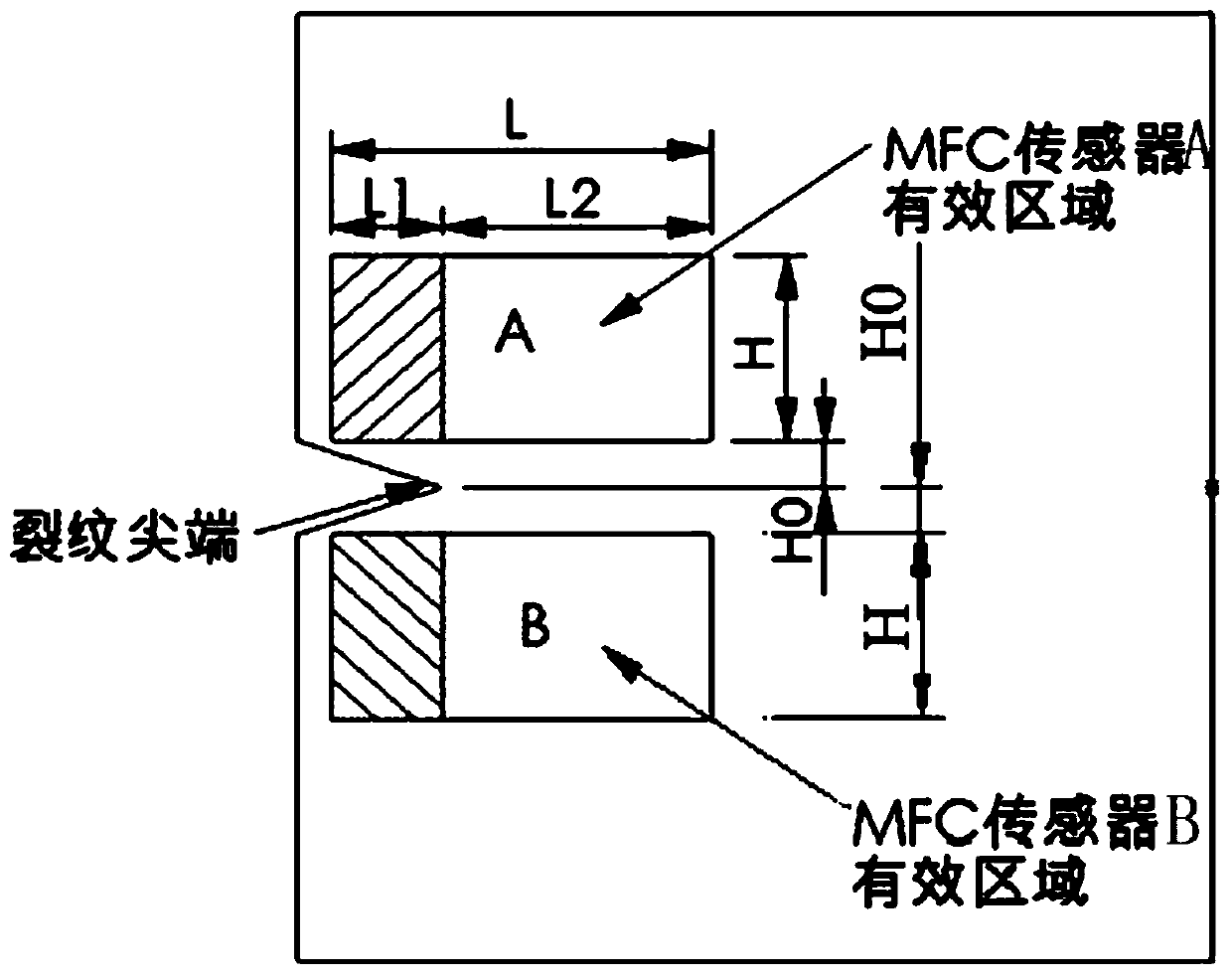

Novel welding structure health monitoring system and method

InactiveCN111007108APredict remaining lifeLong-term and efficient implementation of monitoringMaterial analysis by electric/magnetic meansStructure health monitoringStress intensity factor

The invention discloses a novel welding structure health monitoring system and method, and solves the technical problems that the existing structural design is unreasonable, the structural health monitoring durability of a steel structure in the service process is poor, the accuracy is low, and the stress intensity factor of the crack tip of the welding structure cannot be mastered for a long timein real time. The novel welding structure health monitoring system comprises an MFC sensor and a signal acquisition and processing system which are electrically connected with each other, wherein theMFC sensor is adopted to collect strain data around a welding seam of the welding structure and convert the strain data into a voltage signal, and the signal acquisition and processing system is adopted to collect, record and calculate the voltage signal output by the MFC sensor to obtain a crack stress intensity factor; and safety assessment is carried out by combining the crack stress intensityfactor, and the residual life of the welding structure is predicted. The invention further provides the monitoring method which can be widely applied to the technical field of structural health monitoring.

Owner:HARBIN INST OF TECH AT WEIHAI +1

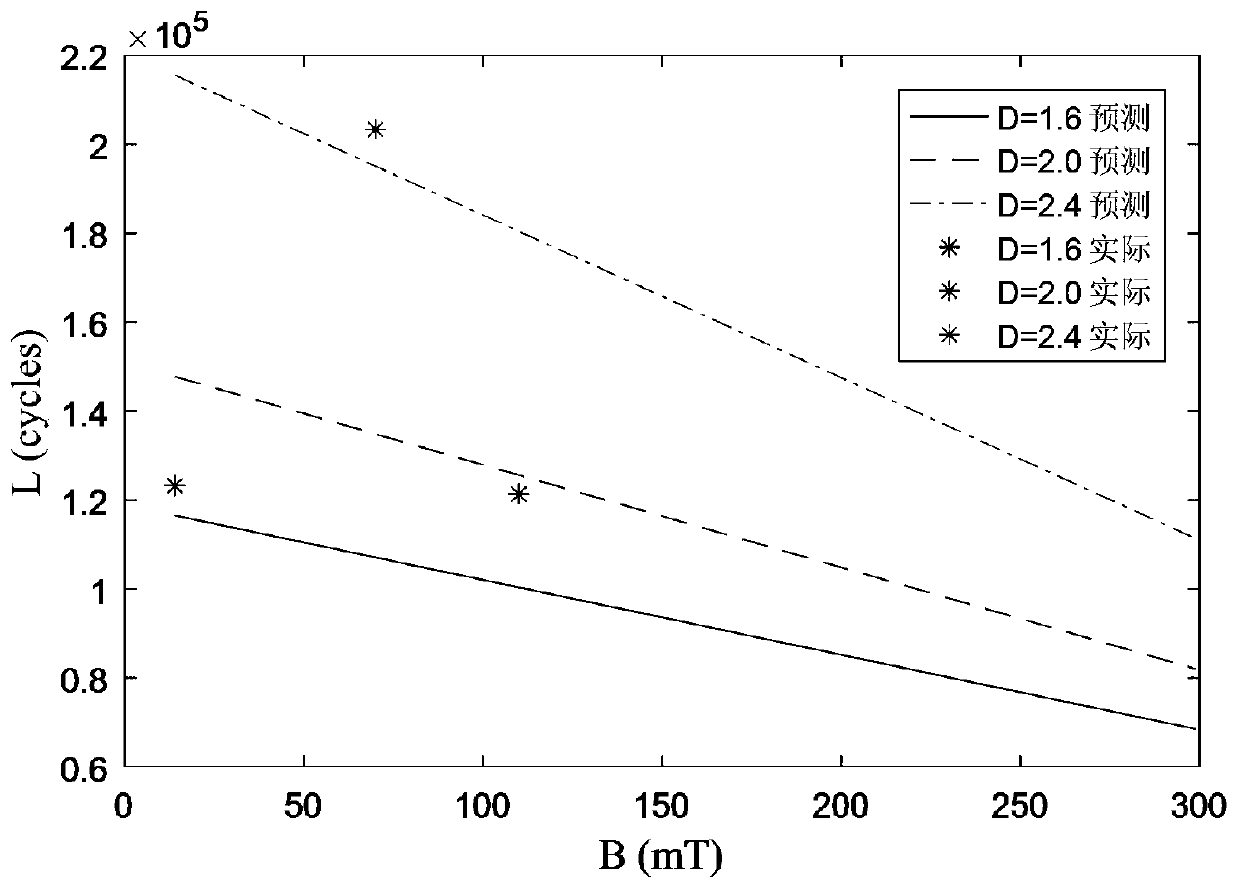

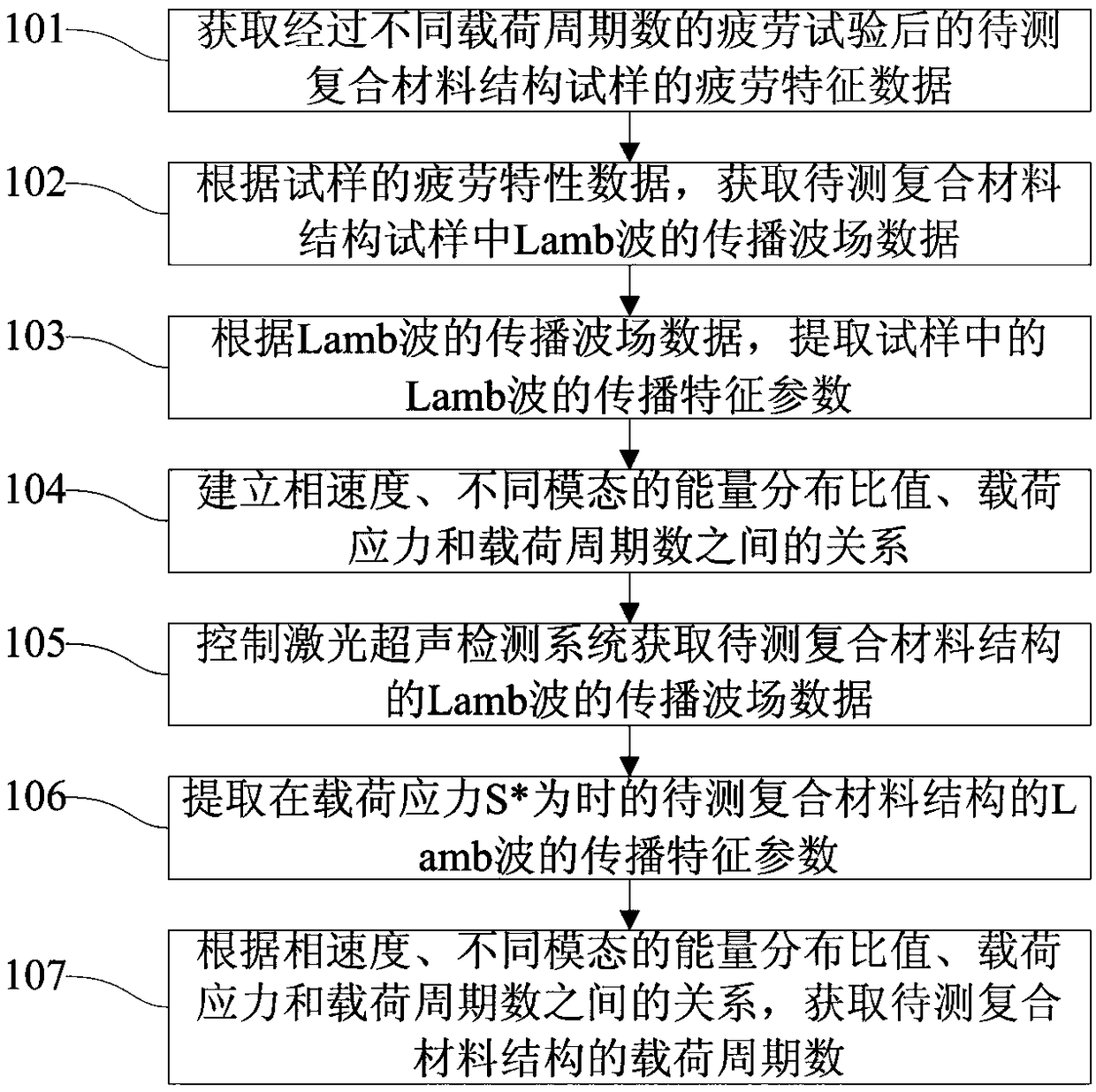

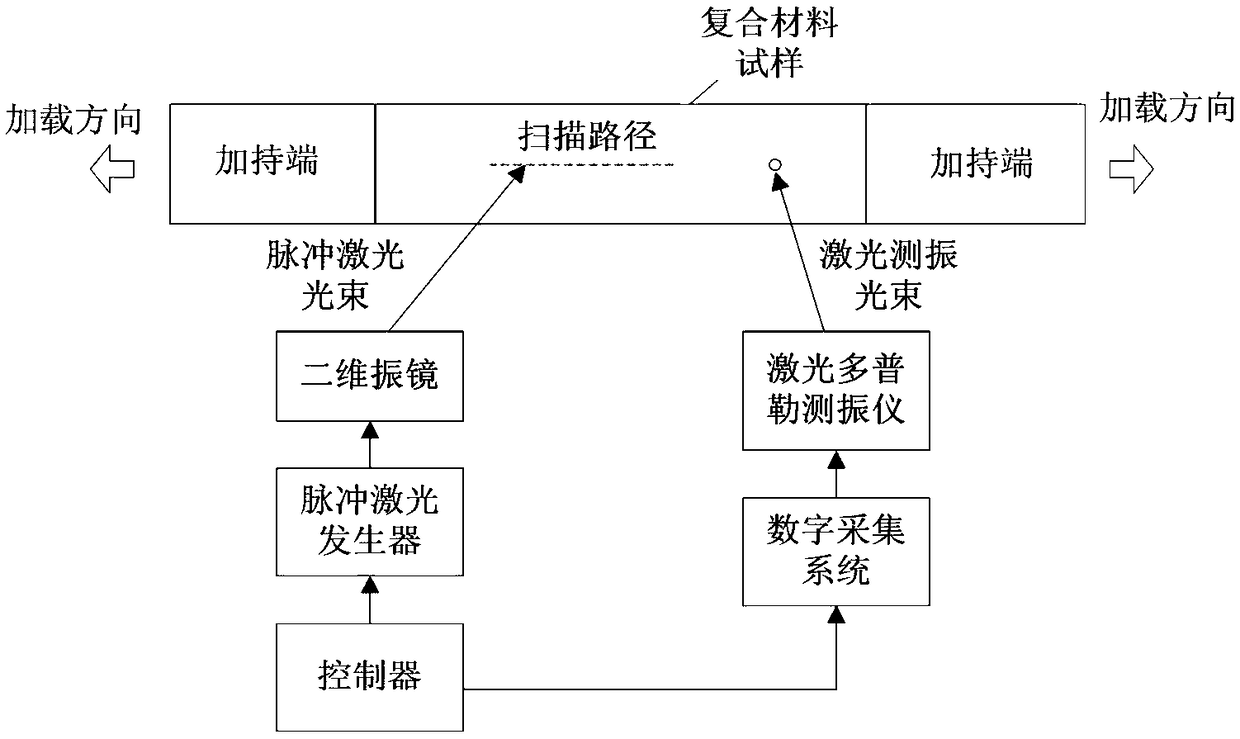

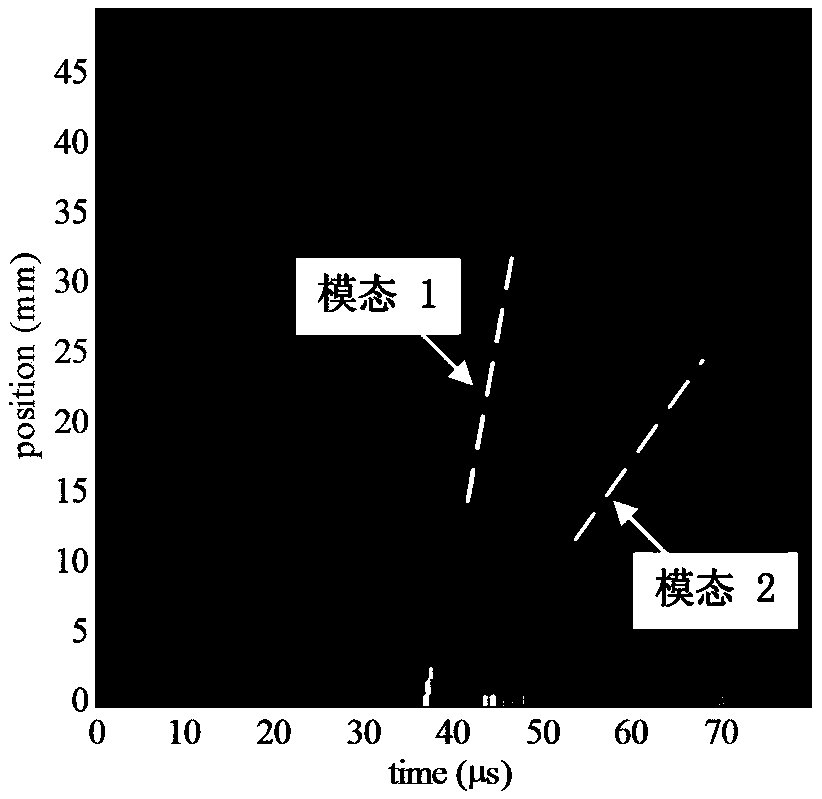

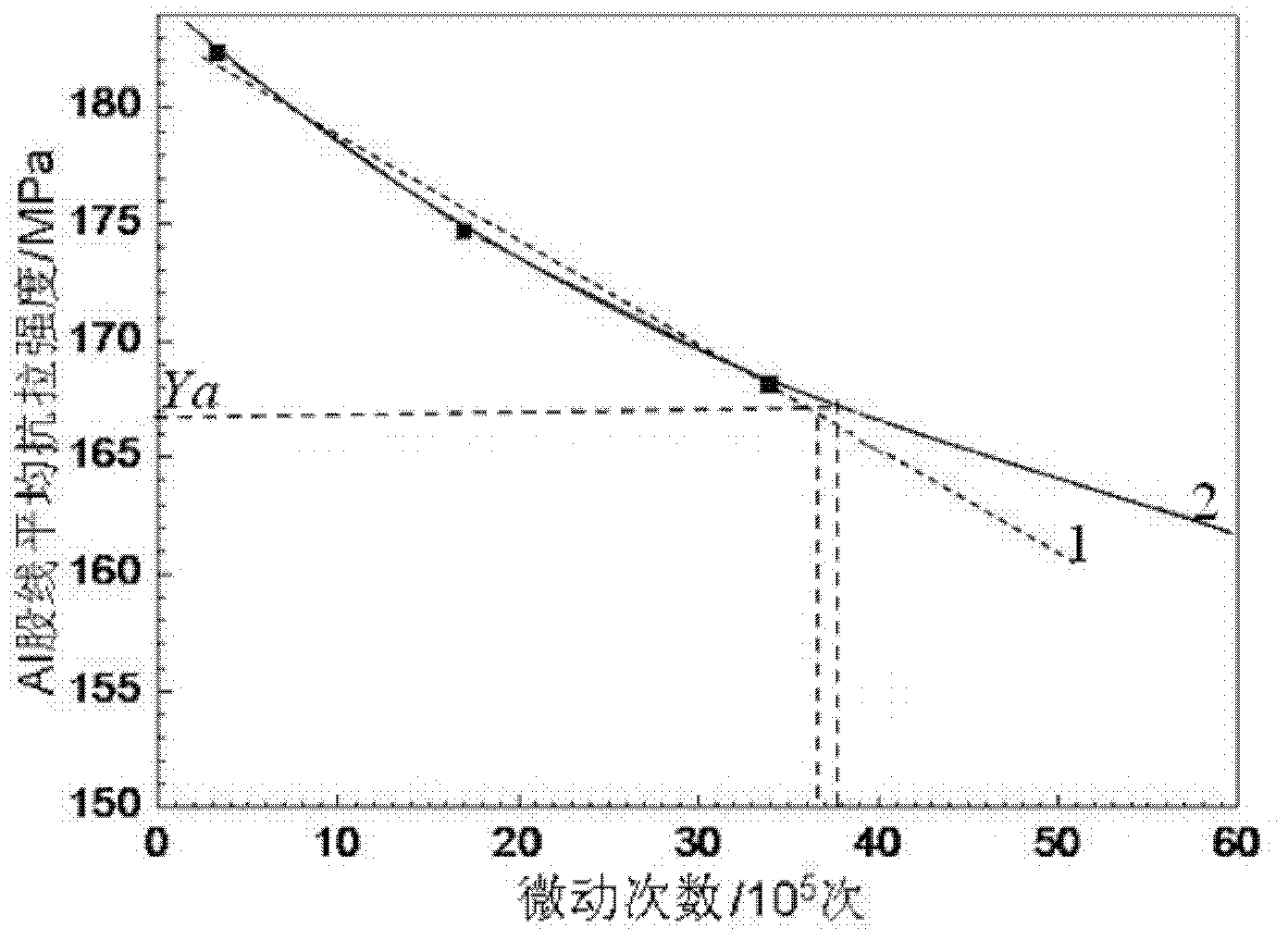

Method and system for non-contact evaluation of fatigue properties of composite structures

ActiveCN106290566BRealize evaluationPredict remaining lifeAnalysing solids using sonic/ultrasonic/infrasonic wavesWave fieldField analysis

The invention discloses a method and a system for non-contact assessing of fatigue property of a compound material structure based on Lamb wave field analysis. The method comprises the following steps: acquiring a fatigue property data of a to-be-measured compound material structure sample; acquiring a propagating wave field data of Lamb wave in the to-be-measured compound material structure sample; extracting a propagating feature parameter of the Lamb wave in the sample; establishing a relationship of phase velocity cp, different modal energy distribution ratio rm, load stress S and load periodicity N; controlling a laser ultrasonic testing system to acquire the propagating wave field data of Lamb wave of the to-be-measured compound material structure; extracting the propagating feature parameter of the Lamb wave of the to-be-measured compound material structure when the load stress is S*; acquiring the load periodicity of the to-be-measured compound material structure; assessing the fatigue property of the to-be-measured compound material structure. According to the assessing method and system, the information of the load periodicity is forecast by measuring the propagating feature parameter of the Lamb wave, so that the assessment for the fatigue property of the compound material is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for forecasting residual service life of steel-cored aluminum strand overhead conductor

InactiveCN102589992BImprove safety management levelImprove operational reliabilityMaterial strength using repeated/pulsating forcesPower gridMotion simulation

The invention discloses a method for forecasting the residual service life of a steel-cored aluminum strand overhead conductor, wherein the method is characterized by forecasting the residual service life Nr of the serviced steel-cored aluminum strand overhead conductor under the condition of aeolian vibration based on the final motion simulation test and the cumulative damage criterion of the steel-cored aluminum strand overhead conductor of a laboratory. The method in the invention has important meanings for improving the safety management level of a transmission line of a power supply unit, and improving the running reliability of a power grid.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com