Method for forecasting residual service life of steel-cored aluminum strand overhead conductor

An overhead wire and life prediction technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve the problems that there is no prediction of the remaining life of the overhead wire running state, and achieve the effect of improving safety management and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the specific implementation, the conductor fretting simulation experiment device disclosed in the publication number CN 101017715A is used.

[0024] Taking the LJ / G1A-150 / 20 steel-reinforced aluminum-strand overhead conductor that has been in service for 45 years in a certain place as an example, the prediction of the remaining life of the steel-reinforced aluminum-strand overhead conductor is carried out as follows:

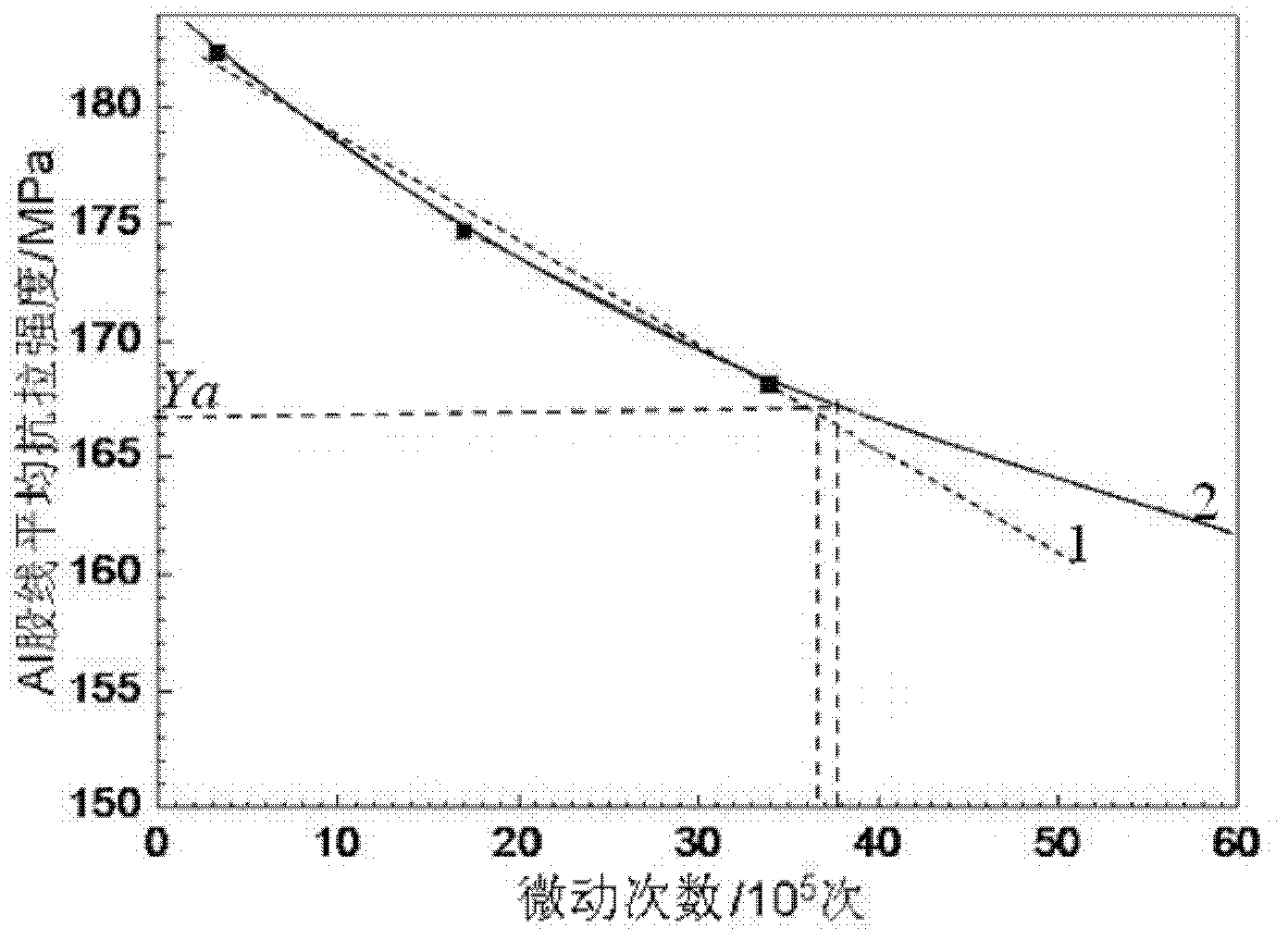

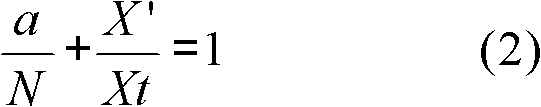

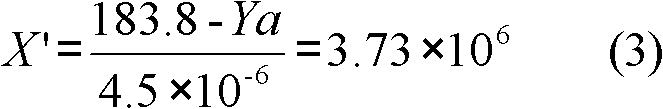

[0025] 1. Take a new wire of the same type that has not been put into use, and conduct a fretting simulation experiment on the new wire on a multi-parameter adjustable fretting experimental device, and obtain the same fretting frequency, fretting amplitude and wire axial load of the new wire. Below, the tensile strength Y of aluminum strands corresponding to different fretting times X; set the fretting frequency to 10Hz, the fretting amplitude to 1.0mm, and the axial load of the wire to be 25% of the rated tensile strength of the wire; measure The numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com