Predictive maintenance method and system for high-speed bearing of wind driven generator

A technology for wind turbines and high-speed bearings, applied in computer-aided design, special data processing applications, geometric CAD, etc., can solve problems such as unrealistic prediction, high threshold for use, and high difficulty in promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

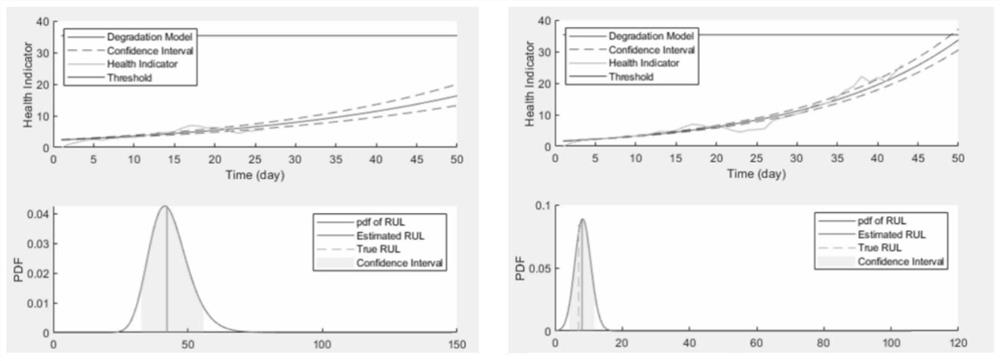

[0136] The dataset for this example was collected on a high speed shaft of a 2MW wind turbine driven by a 20 tooth pinion. The vibration signal is collected for 6 seconds every day and continuously collected for 50 days. Inner race failure occurred on day 50 and resulted in bearing failure.

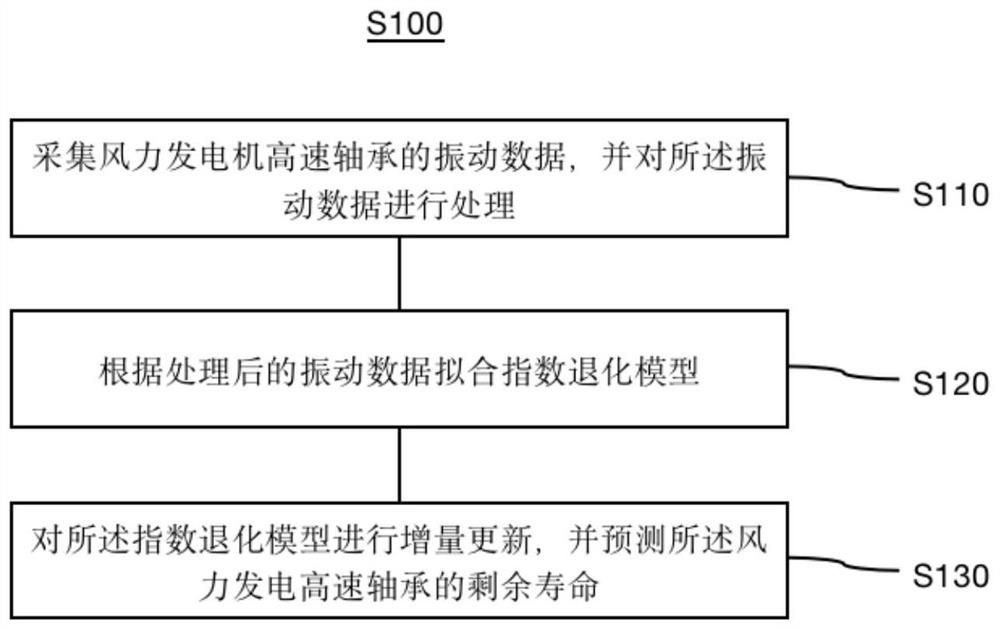

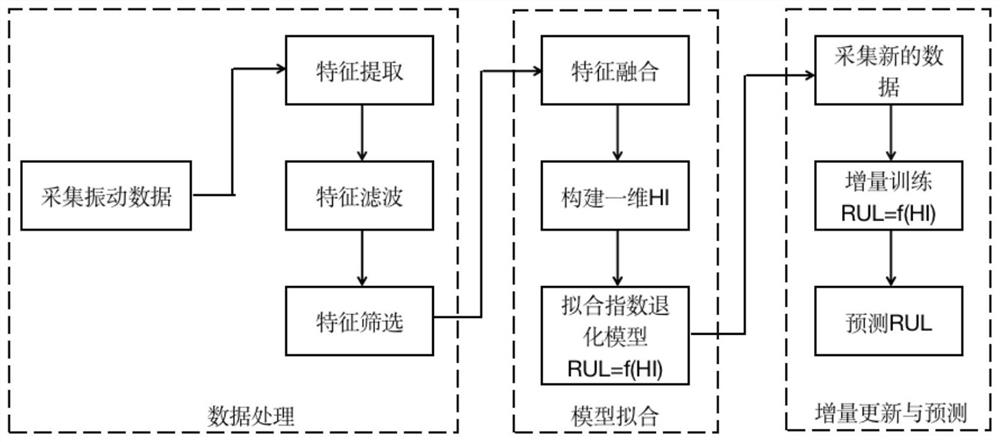

[0137] The specific implementation steps are as follows:

[0138] S1. Collect the vibration data of the high-speed bearing of the wind power generator, and process the vibration data.

[0139] Specifically, the first step, data organization, cleaning and reading into the memory, wherein, the waveform of the vibration signal in the time domain is as follows Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com