Nonlinear ultrasonic detection grading evaluation method for performance degradation of heat-resistant steel part

A non-linear, heat-resistant steel technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc. Insufficient statistical samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

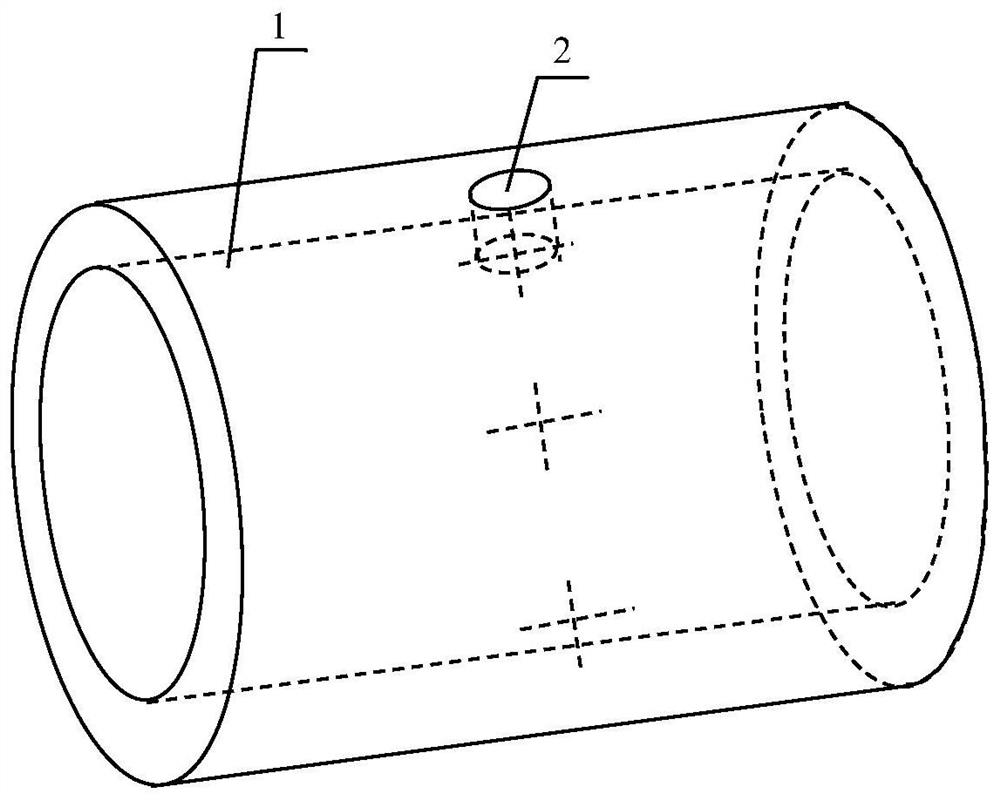

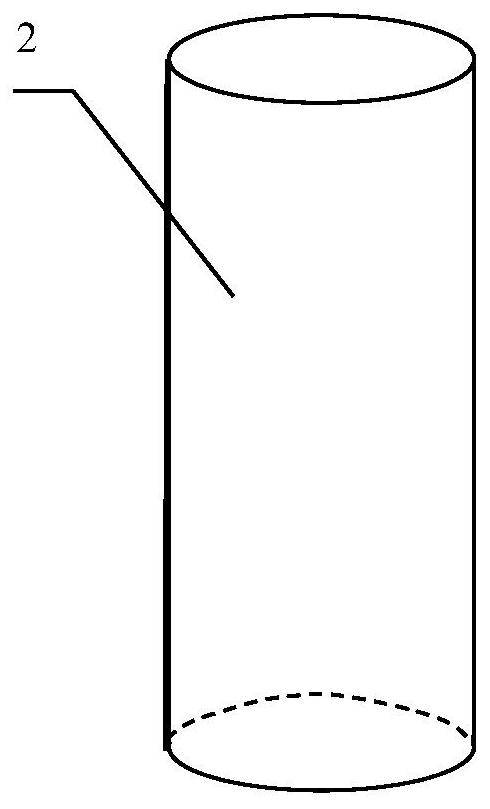

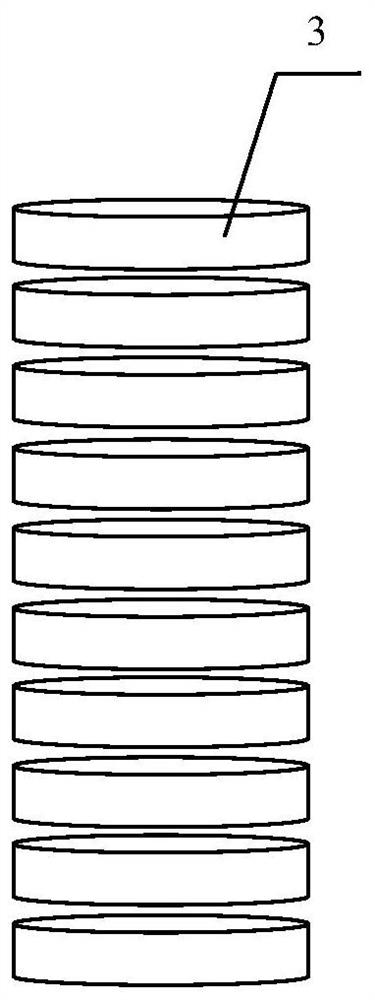

Image

Examples

Embodiment 1

[0096] If the performance degradation damage level of heat-resistant steel parts measured according to step 7 is level 4, then:

[0097] Accelerated test time of performance degradation corresponding to measured heat-resistant steel parts τ′=τ4 / 5

[0098] Substitute into the formula Ts=(20-20τ′ / τ)÷1.5;

[0099] Ts=[20-20(τ4 / 5) / τ]÷1.5=2.67 (ten thousand hours)

[0100] It is concluded that when the measured performance degradation damage level of heat-resistant steel parts is 4, the remaining life predicted by this method is 26,700 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com