Halogen gas removing agent, method for producing same, removal device, monitoring method and removal method

A technology of halogen gas and remover, which is applied in the field of consumables, can solve problems that have not been raised, and achieve the effects of preventing major failures, reducing maintenance costs, and reducing the cost of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0160] Remover samples were prepared as follows. Bromophenol blue powder and pseudo-boehmite powder (specific surface area: 340 m 2 / g) and sodium thiosulfate pentahydrate powder were mixed using a crushing machine (manufactured by Ishikawa Works Co., Ltd., model 18) while adding water to obtain a kneaded cake (cake). The kneaded cake was made into a granular shaped body with a diameter of about 2 mm and a length of about 6 mm using a plunger extruder. The obtained molded body was dried overnight in an electric dryer kept at 110° C., and then placed in a desiccator for more than 1 hour, thereby cooling down to room temperature to obtain a remover sample of Example 1. The obtained samples were subjected to a color tone evaluation test. The color tone of the remover changed from blue to yellow before and after chlorine treatment.

Embodiment 2

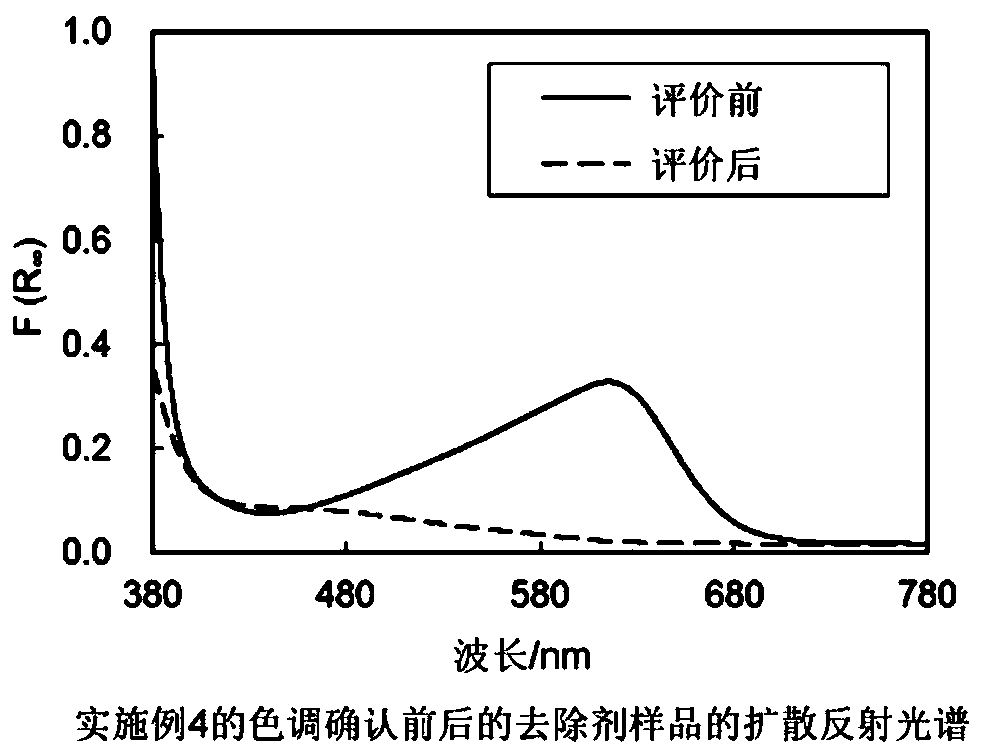

[0162] Using the same method and conditions as in Example 1, bromothymol blue is 0.01% by weight, pseudo-boehmite is 81.99% by weight, and sodium thiosulfate pentahydrate is the remover of Example 2 of 18.00% by weight. Sample (tap density 0.85 g / ml). The obtained samples were evaluated for chlorine removal at 25°C. After the inflow of chlorine gas started, discoloration was observed gradually from near the inlet, and the discoloration range increased over time. Sulfurous acid gas was first detected after 150 minutes of chlorine gas aeration, at the same time the range of discoloration reached the outlet. Then, hydrogen chloride gas was detected after 240 minutes. If the earliest gas breakthrough time is defined as the remover capacity, the remover capacity is 14Lkg -1 . In addition, a color tone evaluation test was performed on the prepared samples. Before and after the color tone evaluation test, the color tone of the remover changed from blue to red. The reason why th...

Embodiment 3

[0164] Using the same method and conditions as in Example 1, the remover sample of Example 3 was prepared with 0.01% by weight of phenolphthalein, 81.99% by weight of pseudoboehmite, and 18.00% by weight of sodium thiosulfate pentahydrate. The obtained samples were subjected to a color tone evaluation test. Before and after the color tone evaluation test, the color tone of the remover changed from red to white.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com