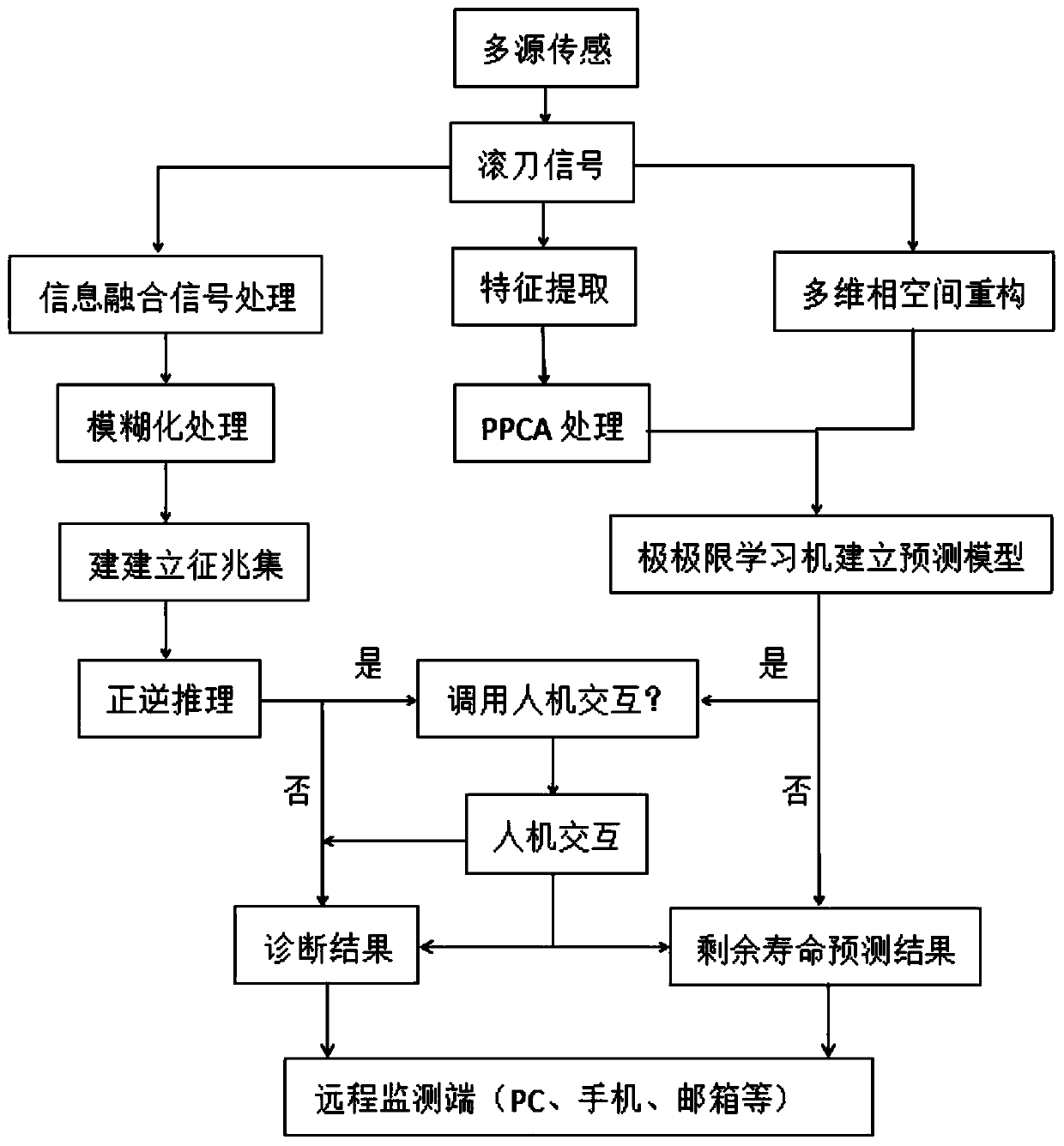

Tool state monitoring and life predicting system based on multi-source information fusion

A multi-source information fusion and life prediction technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the impact of construction efficiency and construction economy, cannot know the working state of the hob, and observe the cutting tool. wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

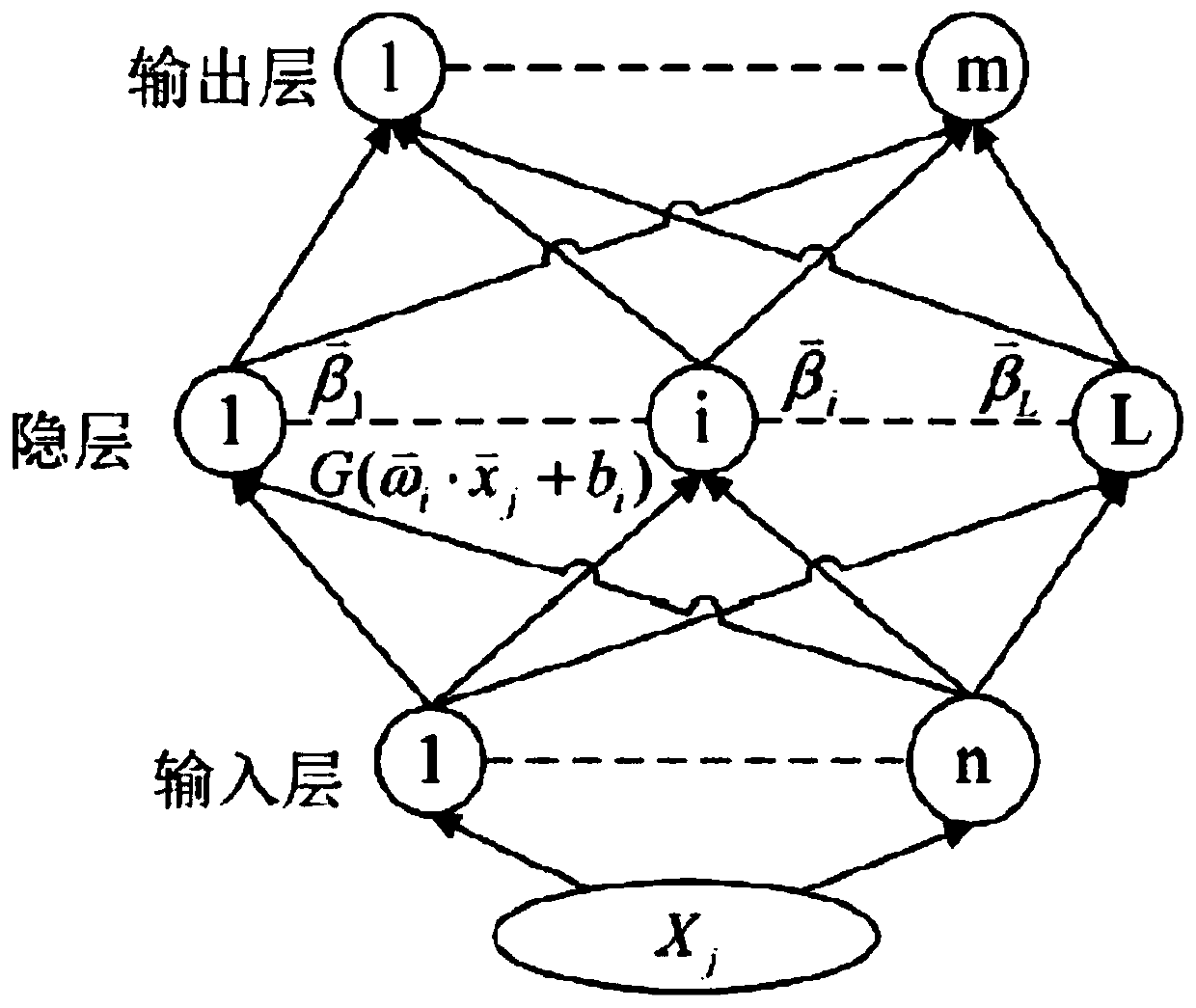

[0069] Embodiment 1: A tool state monitoring and life prediction system based on multi-source information fusion, including an information collection module, a signal preprocessing module, a state monitoring module, a life prediction module and a remote monitoring module; the information collection module collects the hob The parameter information is sent to the state monitoring module and / or life prediction module after being preprocessed by the signal preprocessing module. The state monitoring module receives the hob parameter information and processes it to output the state of the hob. Output the remaining life of the hob, the output results of the status monitoring module and the life prediction module can be directly viewed on site, and can also be sent to the remote monitoring module through the wireless communication module for remote project management personnel to view through mobile phones, remote PCs, etc. .

[0070] Specifically, the hob parameter information inclu...

Embodiment 2

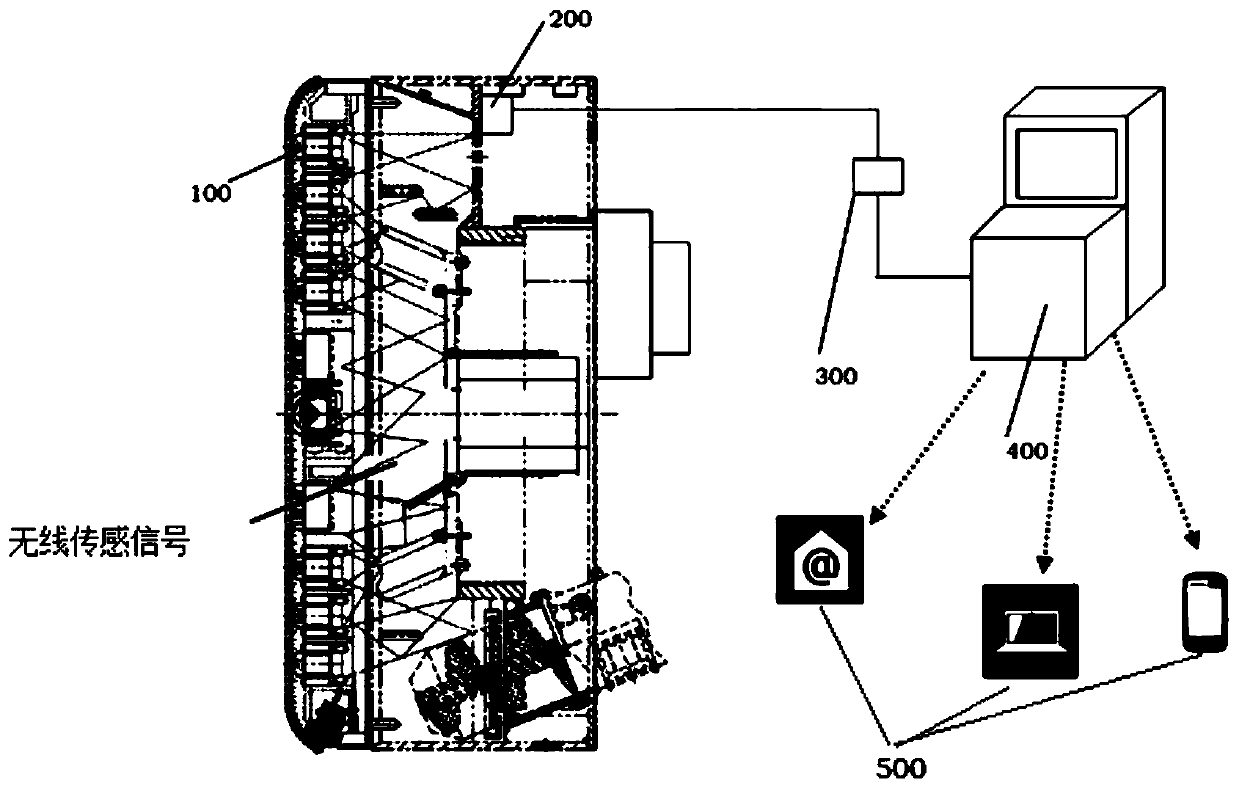

[0130] Embodiment 2: A hob information monitoring device, such as Figure 3-4 As shown, including the hob tool holder 100, a laser distance sensor 1 is installed on the inner side of the slider end cover 101 of the hob knife holder 100, and a temperature sensor 2 and a sensor are installed on the outer end surface of the hob 102 of the hob cutter holder. Sensor 3, an eddy current sensor 6 is installed on the outer wall of the hob 102 of the hob knife seat; a six-dimensional force sensor 4 and an acceleration sensor 5 are installed on the C-shaped block 103 of the hob knife seat; A battery 8 is installed on the driving slider 104 of the seat, and a wireless signal transmitter 7 is installed on the screw rod 105 on the driving slider 104; a laser distance measuring sensor 1, a temperature sensor 2, a Hall sensor 3, a six-dimensional force sensor 4, The acceleration sensor 5 and the eddy current sensor 6 are all sent to the signal receiver 200 in the shield body through the wirel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com