Self monitoring DOFS-FRP cloth and monitoring method thereof

A DOFS-FRP and self-monitoring technology is applied in the direction of measuring the change force of the optical properties of the material when it is stressed, which can solve the problems of sticking difficulties and achieve the effect of novel design and real-time force performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described below in conjunction with specific embodiments.

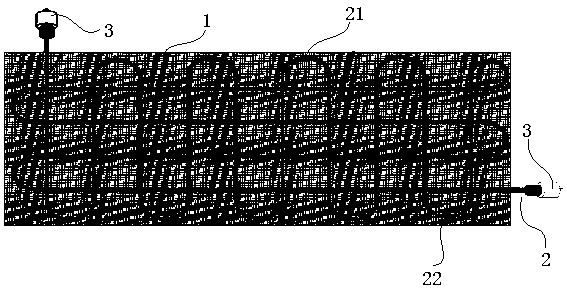

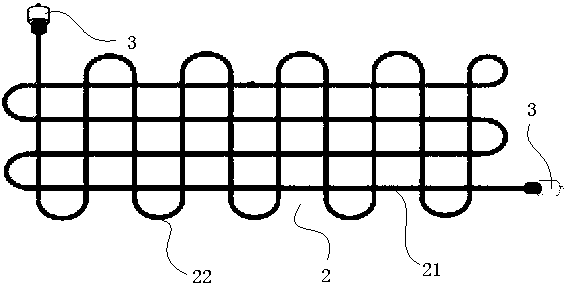

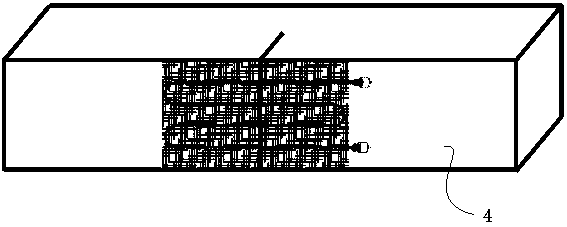

[0039] Such as figure 1 and figure 2 As shown, a self-monitoring DOFS-FRP cloth includes FRP cloth 1 and a distributed optical fiber sensor 2 (referred to as DOFS) in the shape of a long cable and continuously extending. The distributed optical fiber sensor 2 includes a built-in bare optical fiber 21. An outer protective sheath 22 wrapped around the periphery of the built-in bare optical fiber 21 and extending along the length direction of the built-in bare fiber 21 .

[0040]Among them, the FRP cloth 1 is formed by weaving fibers through a loom. During the process of weaving and forming the FPR cloth through the loom, the fibers that make up the FRP cloth 1 are fed into the loom together with the distributed optical fiber sensor 2, and the distributed optical fiber sensor 2 is weaved and embedded in the FRP cloth 1, and the distributed optical fiber sensor 2 and the FRP cloth 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com