Vulcanizing device for collecting pressure at fixed point in tire vulcanizing process and intelligent tire design equipment

A tire vulcanization and pressure technology, applied in the field of tire intelligent design equipment and vulcanization equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

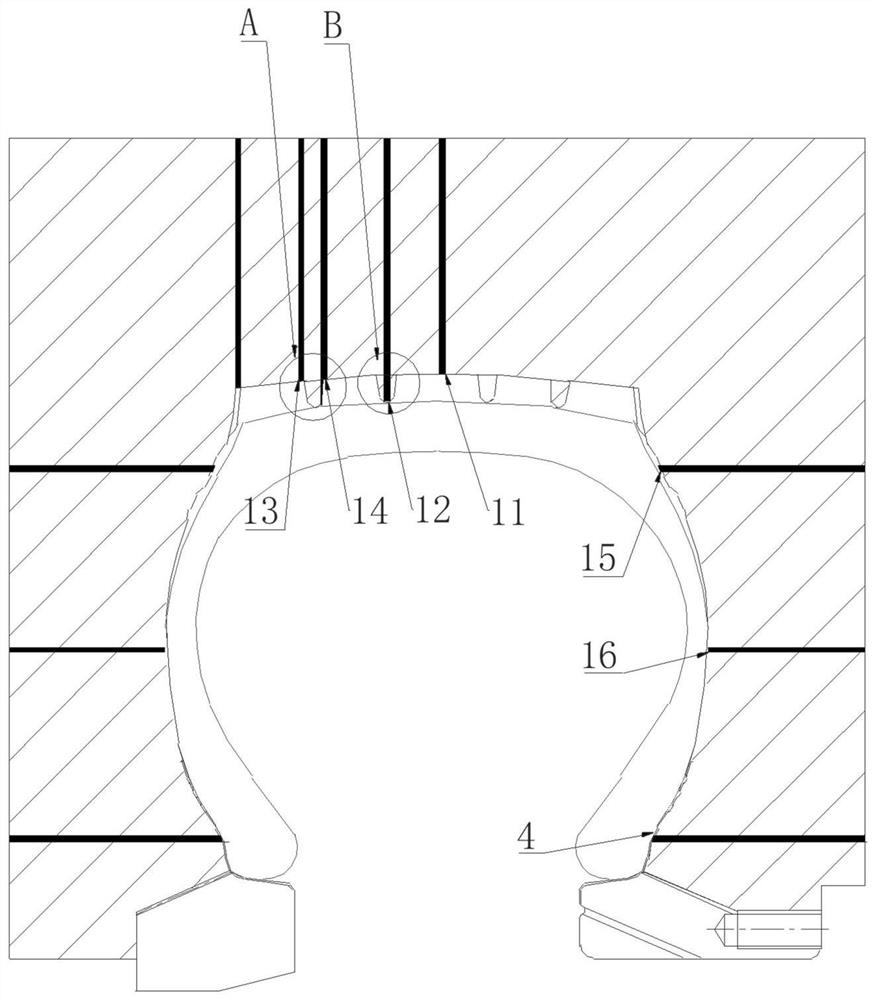

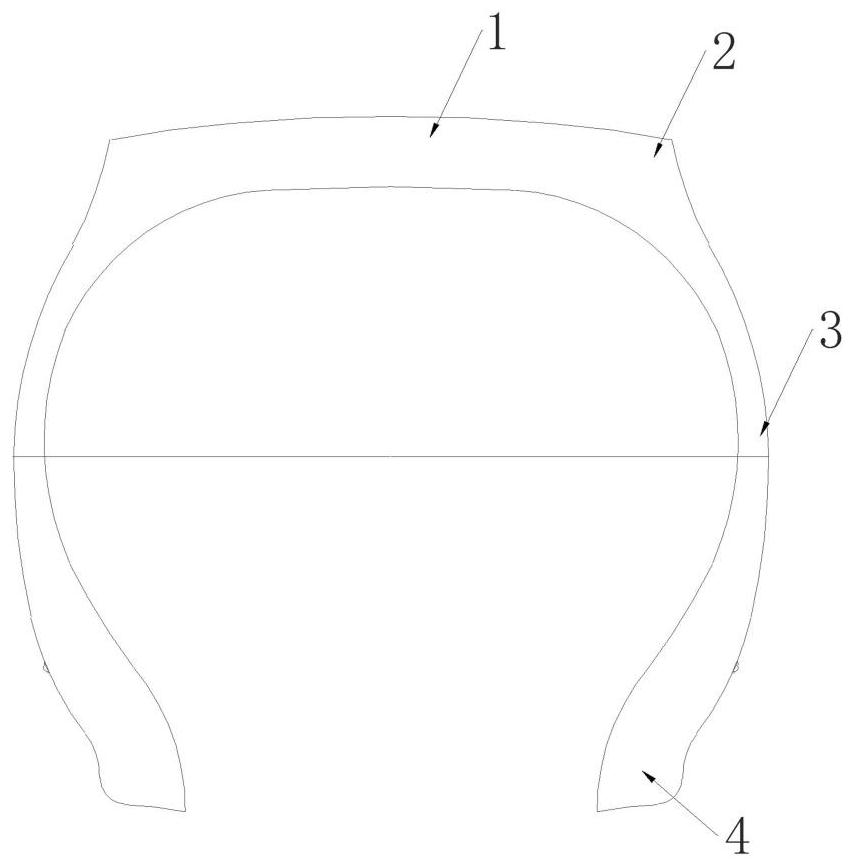

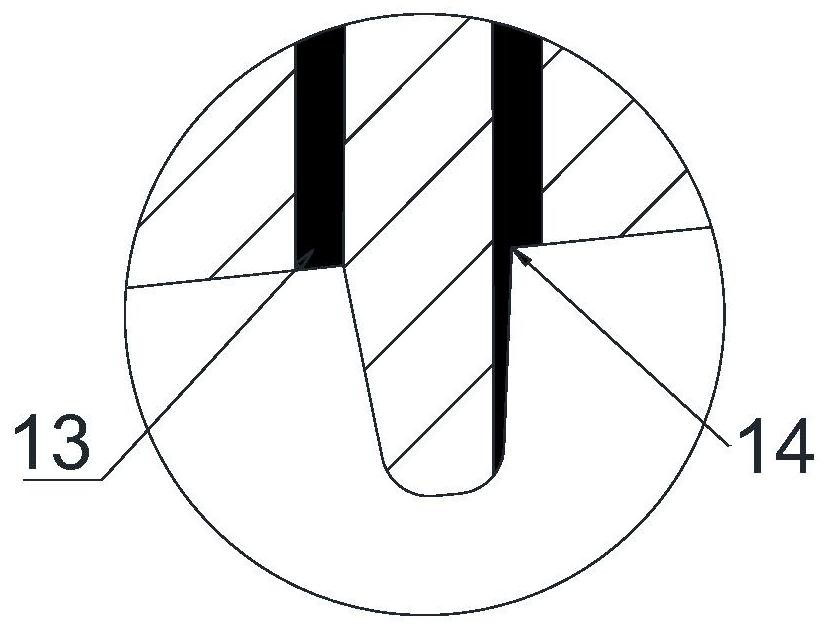

Embodiment 1

[0034] Using the test method described in this application, take the 12.00R20 specification as an example for test analysis. The vulcanization pressure is 2.5 MPa, the vulcanization temperature is 170°C, and the vulcanization time is 50 minutes. Data collection and analysis are carried out to calculate the bond failure force of each part.

Embodiment 2

[0036]Using the test method described in this application, take the 12.00R20 specification as an example for test analysis. The vulcanization pressure is 2.0 MPa, the vulcanization temperature is 170°C, and the vulcanization time is 50 minutes. Data collection and analysis are carried out to calculate the bond failure force of each part.

Embodiment 3

[0038] Using the test method described in this application, take the 12.00R20 specification as an example for test analysis. The vulcanization pressure is 1.5 MPa, the vulcanization temperature is 170°C, and the vulcanization time is 50 minutes. Data collection and analysis are carried out to calculate the bond failure force of each part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com