Gas ultrasonic flowmeter based on TDC-GP30 and dual-channel and using method thereof

An ultrasonic and flowmeter technology, which is applied in liquid/fluid solid measurement, flow measurement/mass flow measurement, measurement devices, etc., can solve the problems that the measurement accuracy cannot meet the trade settlement, cannot accurately reflect the pipeline flow field distribution, and the accuracy is not high. , to achieve data communication and instrument alarm function, good application prospects, and improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is a further explanation with examples.

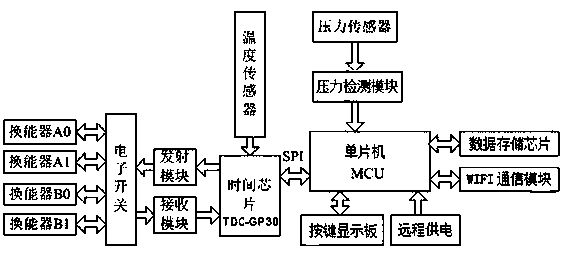

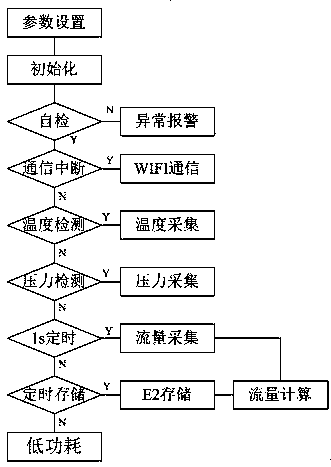

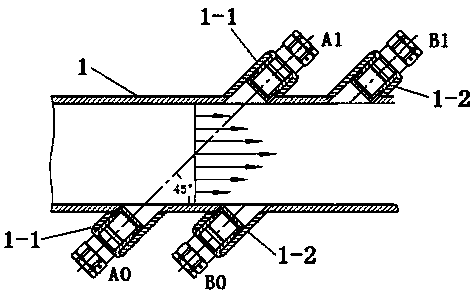

[0044] Such as figure 1 As shown, based on the TDC-GP30 dual-channel gas ultrasonic flowmeter, including dual paired transducer A0 and transducer A1, transducer B0 and transducer B1, and electronic switches, transmitting modules, receiving modules, and temperature sensors , Pressure sensor, time chip, pressure detection module, single-chip microcomputer MCU, data storage chip, WIFI communication module, remote power supply, key display board; dual paired transducer A0 and transducer A1, and transducer B0 and transducer The device B1 is connected to the electronic switch in two directions. The electronic switch is connected to the time chip through the receiving module, the time chip is connected to the electronic switch through the transmitting module, the temperature sensor is connected to the time chip, and the pressure sensor is connected to the single-chip microcomputer through the pressure detection module. MCU ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com