Concentrating photo-thermal electric coupling hydrogen production reaction system based on direct solar gradient utilization

A technology of reaction system and solar energy, which is applied in the field of concentrating photothermal and electric coupling hydrogen production reaction system, can solve the problems of no experimental device system and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

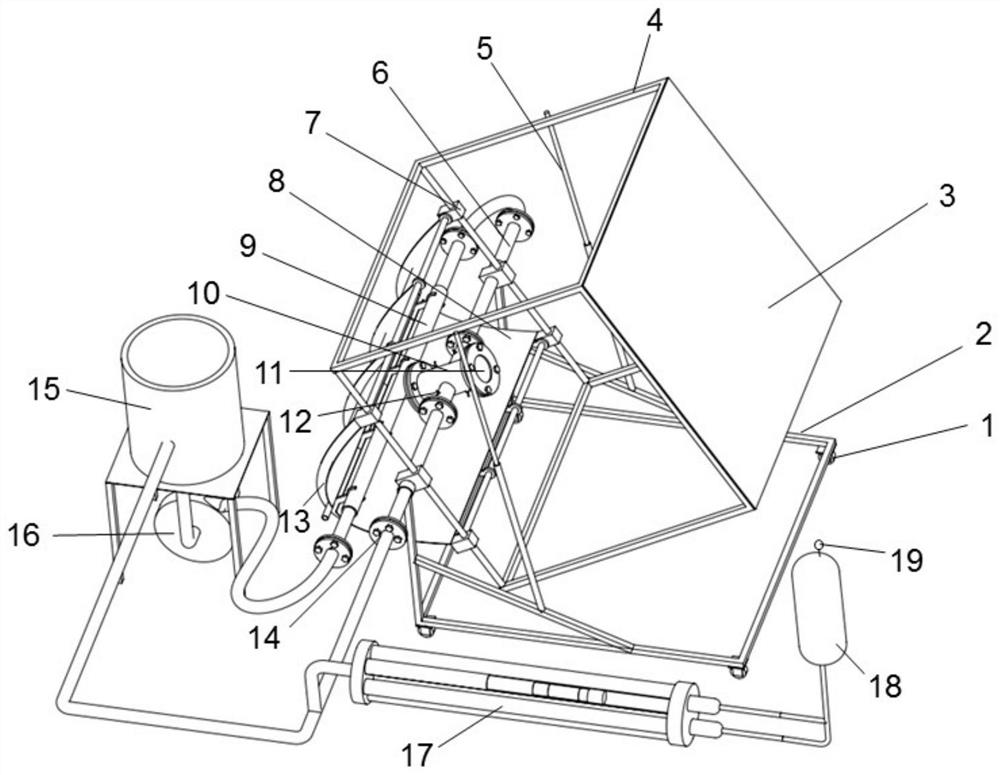

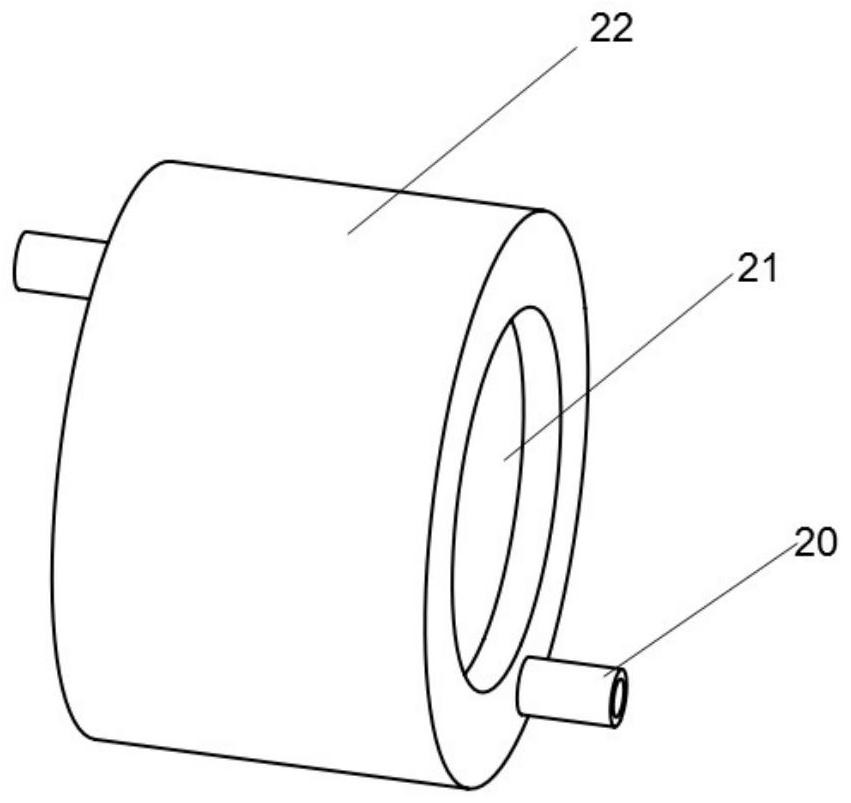

[0029] Such as figure 1 As shown, the process of the present invention provides a concentrating light thermoelectric coupling hydrogen production reaction system based on direct solar cascade utilization. Part of the mid-infrared light passes through the high-transmittance and pressure-resistant glass 11 and is absorbed by the mixed liquid nanofluid to make the temperature higher. The part of the ultraviolet light and infrared light is absorbed by the photothermal catalytic reaction module 22 and used to catalyze hydrogen production. The fluid reversely heats the photothermal catalytic reaction module 22, and the generated hydrogen is separated and collected through the gas-liquid separation device connected to the outside through the opening 12. The transmitted light and part of the scattered light passing through the cross-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com