Industrial equipment remaining useful life prediction model and construction method and application thereof

A technology of life prediction model and industrial equipment, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve the problems that the data set processing method cannot effectively denoise, the prediction accuracy of the model is not high, and improve the prediction accuracy , the effect of improving the predictive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

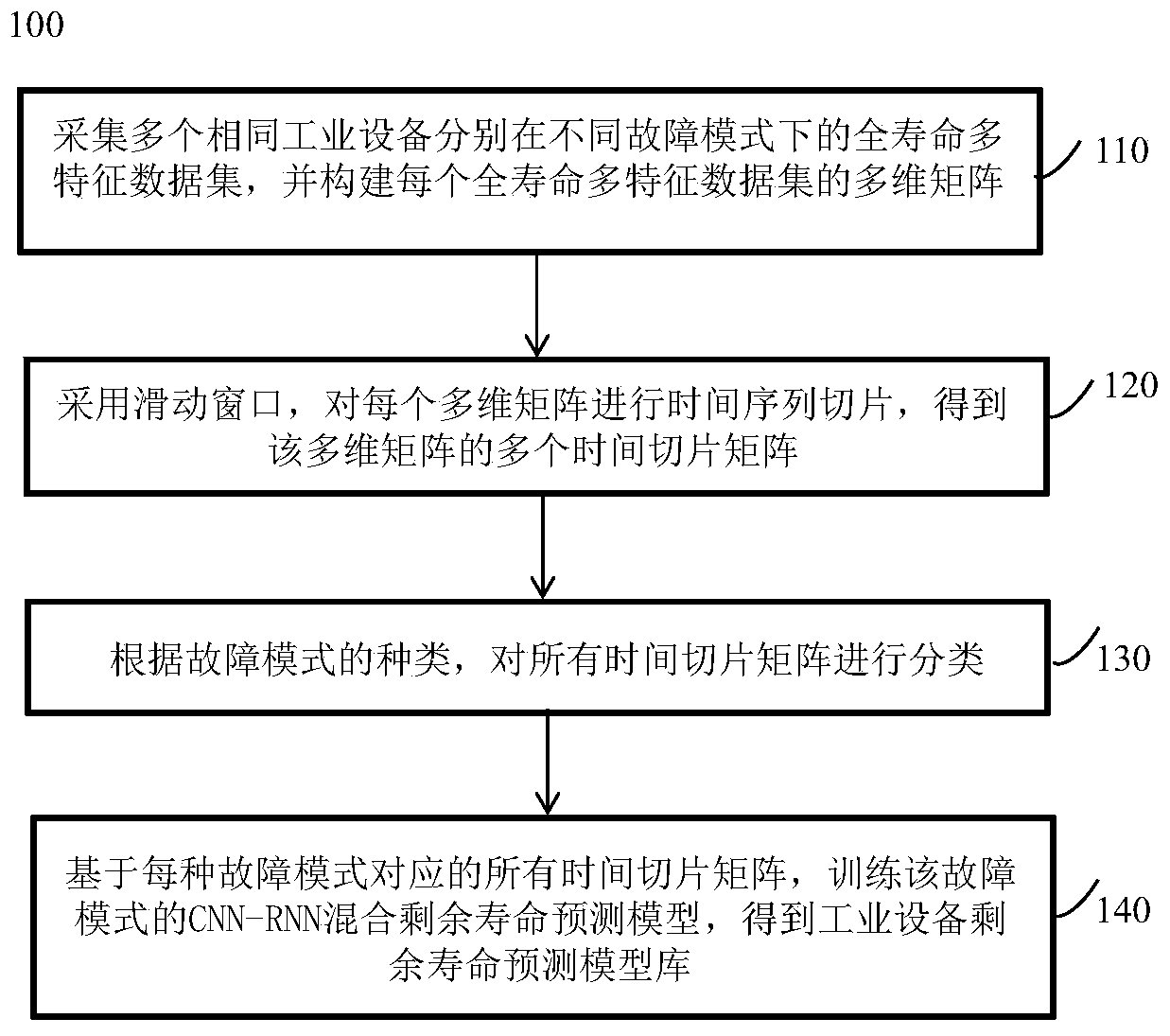

[0044] A construction method 100 of a remaining life prediction model for industrial equipment, such as figure 1 shown, including:

[0045] Step 110, collecting a plurality of full-life multi-feature data sets of the same industrial equipment under different failure modes, and constructing a multi-dimensional matrix of each full-life multi-feature data set;

[0046] Step 120, using a sliding window to slice each multi-dimensional matrix in time series to obtain multiple time-sliced matrices of the multi-dimensional matrix;

[0047] Step 130, classify all time slice matrices according to the type of failure mode;

[0048] Step 140 , based on all the time slice matrices corresponding to each failure mode, train the CNN-RNN hybrid remaining life prediction model of the failure mode, and obtain the remaining life prediction model library of industrial equipment.

[0049] The distributed sensor network is used to collect and record the data changes in multiple dimensions such a...

Embodiment 2

[0113] An industrial equipment remaining life prediction model library is constructed by using any method for constructing an industrial equipment remaining life prediction model described in the first embodiment above.

[0114] The relevant technical solutions are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

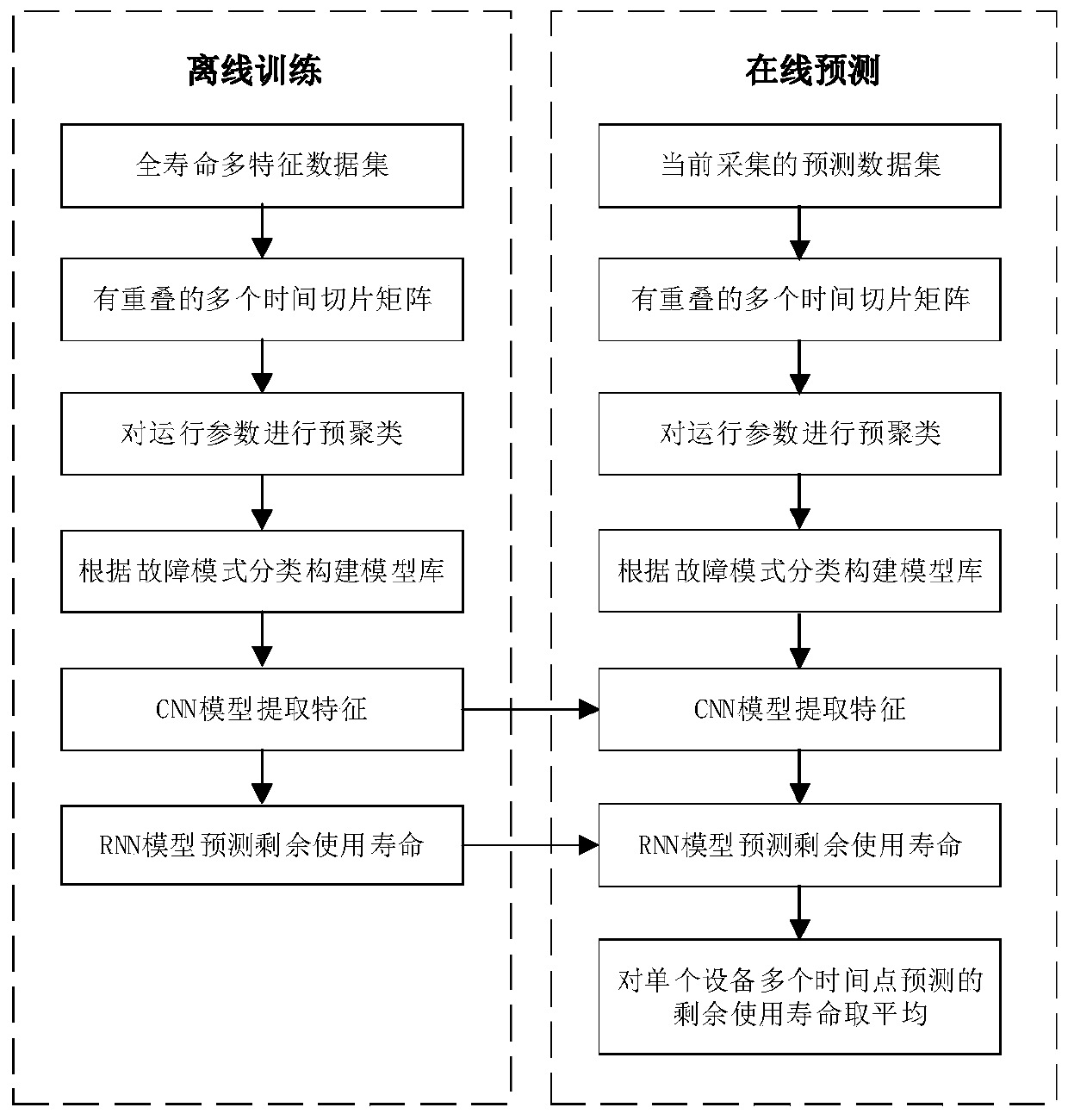

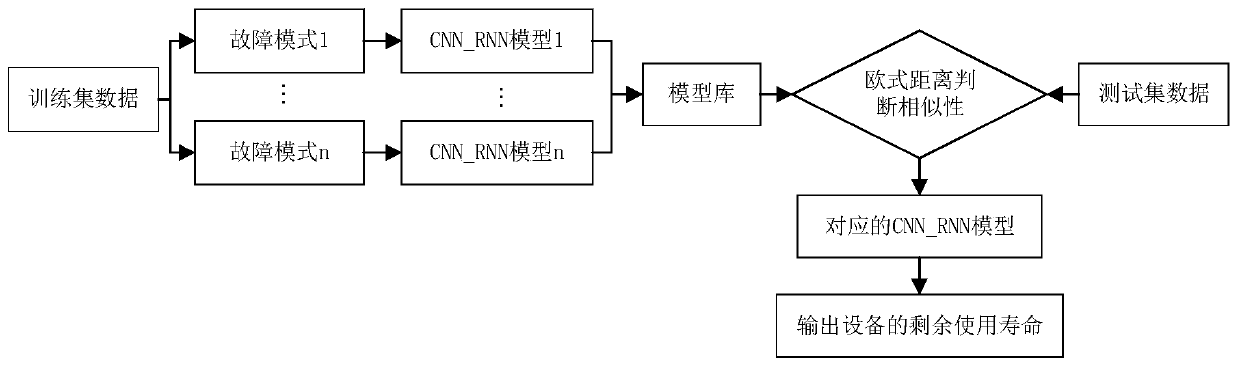

[0116] A remaining life prediction method 200 of industrial equipment, such as figure 2 and image 3 shown, including:

[0117] Step 210, obtain the test data set of the industrial equipment to be tested and the above-mentioned predictive model library, and determine the construction method of the predictive model library;

[0118] Step 220, according to the processing operation of the full-life multi-feature data set in the construction method, process the test data set to obtain multiple time slice matrices;

[0119] Step 230, calculate the Euclidean distance between multiple time slice matrices and all time slice matrices required for training each prediction model in the prediction model library, and determine the prediction model with the closest distance;

[0120] Step 240: Based on multiple time slice matrices, use the prediction model with the closest distance to predict the remaining life of the industrial equipment under test under the test data set.

[0121] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com