Patents

Literature

46results about How to "No reduction in reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

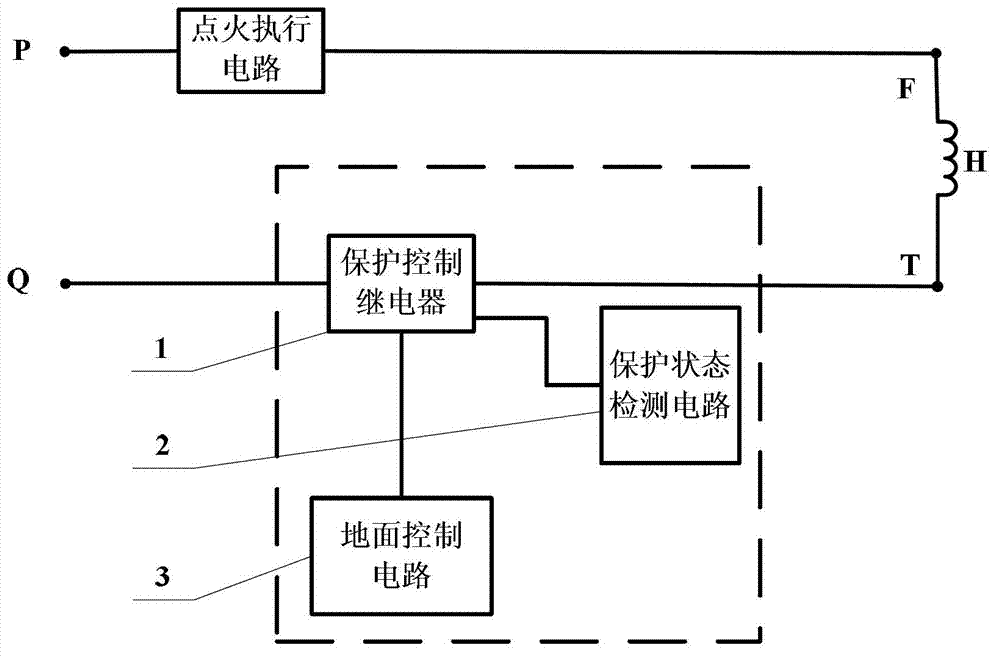

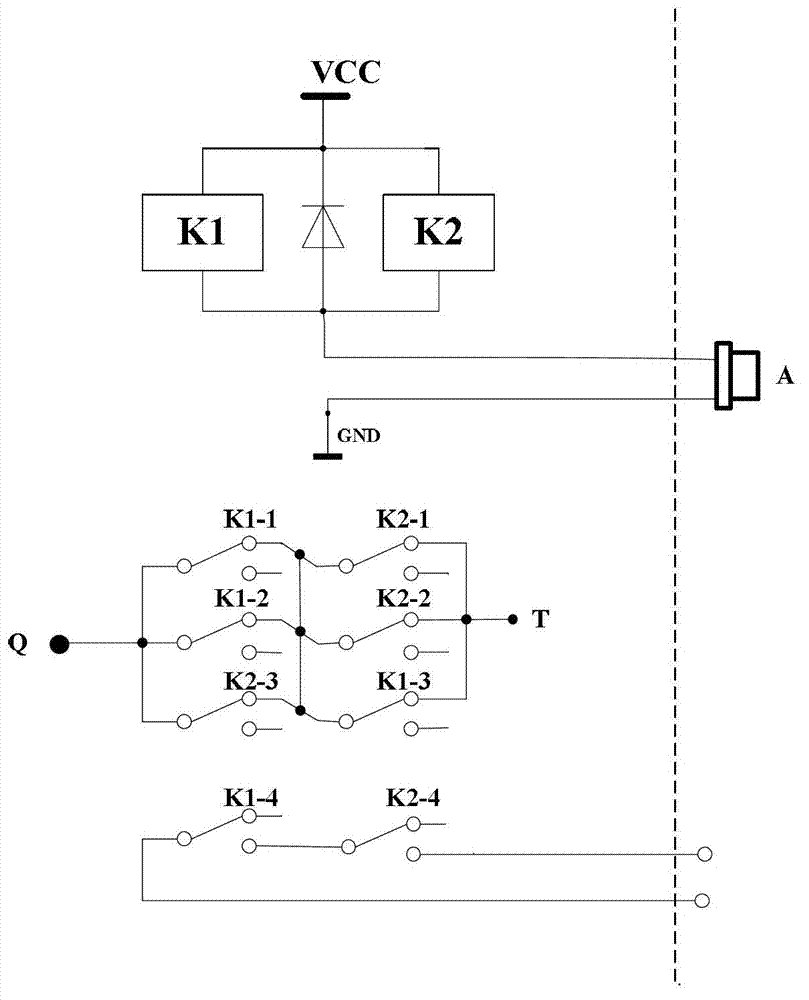

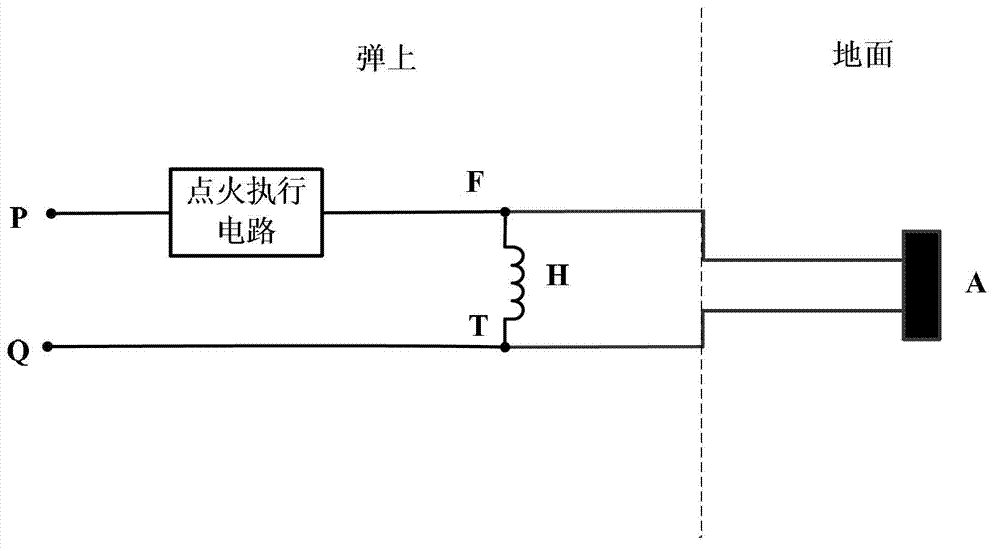

Protection circuit suitable for initiating explosive device on two-stage ignition bomb

ActiveCN102931628AImprove reliabilityImprove securityArrangements responsive to excess currentControl signalNegative power

The invention discloses a protection circuit suitable for an initiating explosive device on a two-stage ignition bomb. The protection circuit belongs to the technical field of safety protection of the initiating explosive device on the bomb, and solves problems of delayed explosion and poor direct protectiveness of the initiating explosive device caused by a safety protection mode of the conventional initiating explosive device on the bomb. The protection circuit comprises a protection control relay, a protection state detection circuit and a ground control circuit; one end of the protection control relay is connected with a negative power supply end Q of an ignition power supply; the other end of the protection control relay is connected with a negative activating end T of the initiating explosive device; a control signal input end of the protection control relay is connected with a control signal output end of the ground control circuit, and the control signal output end of the protection control relay is connected with the control signal input end of the protection state detection circuit. The protection circuit is suitable for safety protection of the initiating explosive device on the two-stage ignition bomb.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

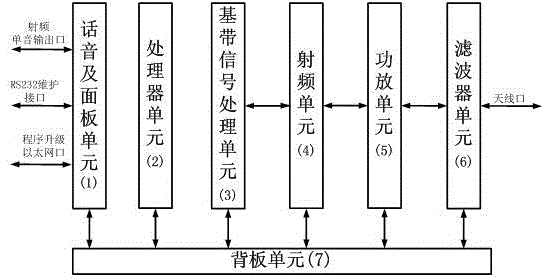

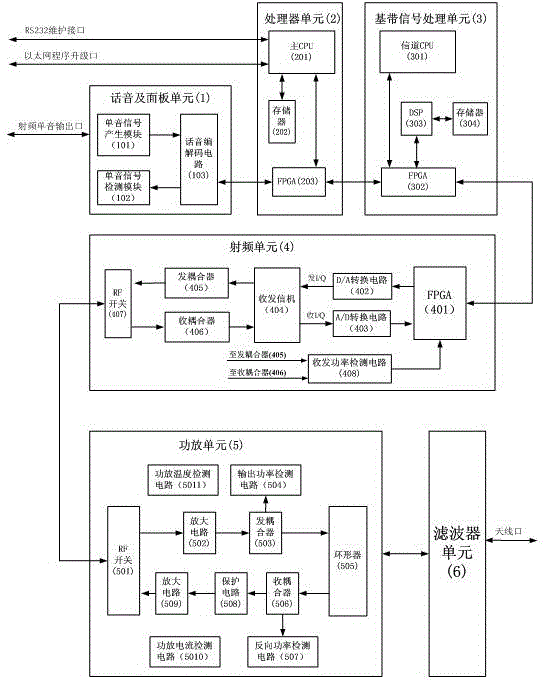

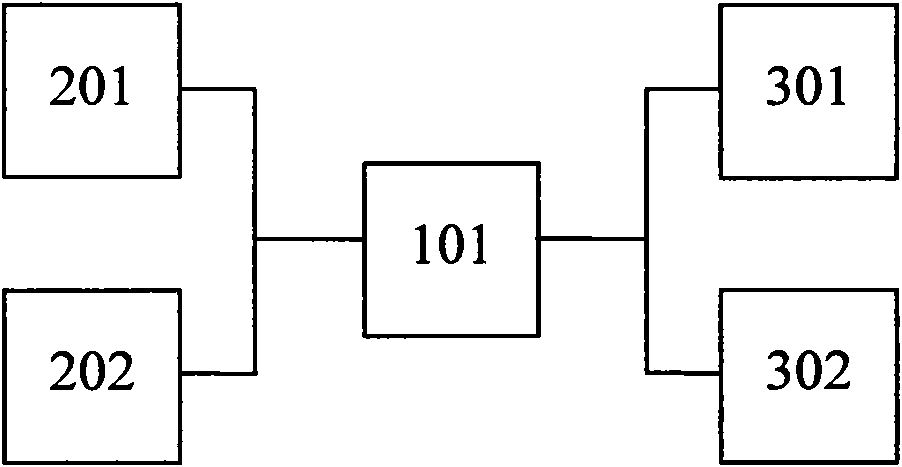

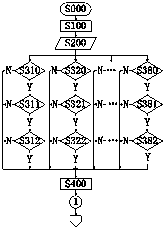

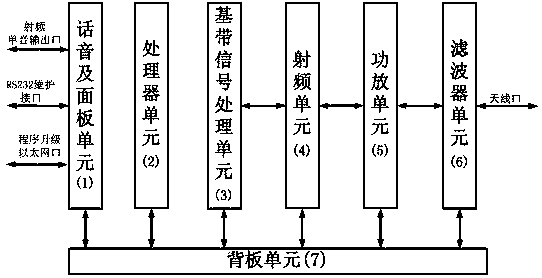

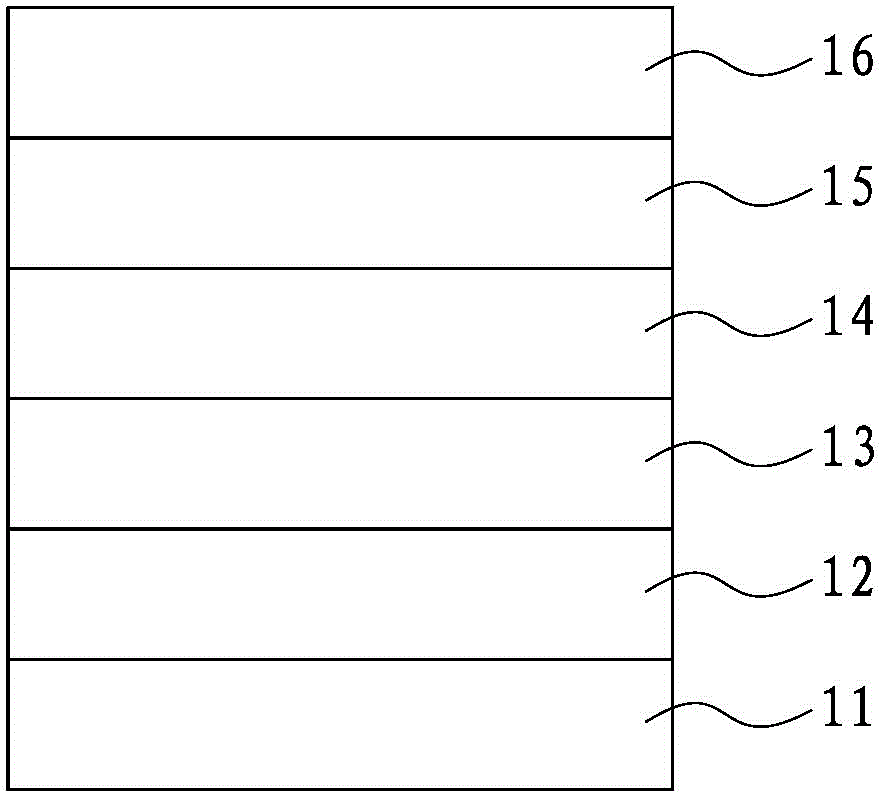

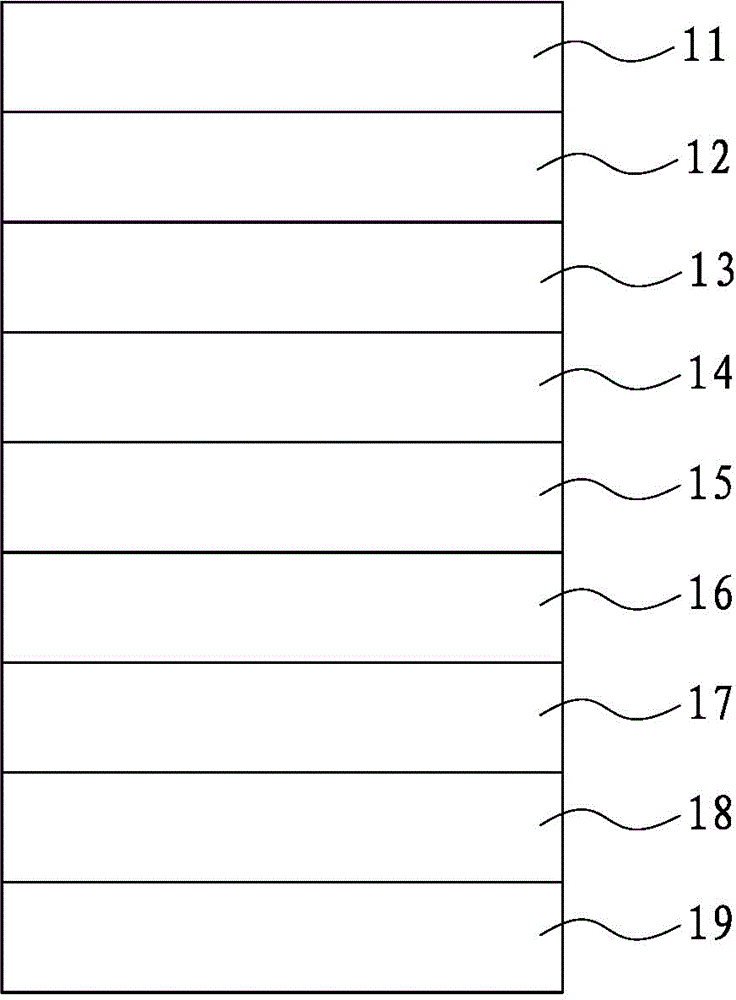

Wireless communication device testability design method

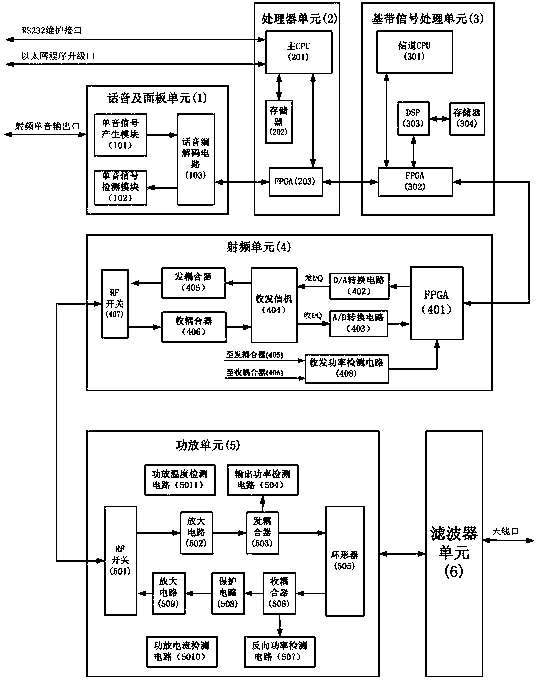

ActiveCN105553754AAchieve control and observabilityAvoid disassembling the whole machine out of the boxData switching networksRadio frequencyUpgrade

The invention discloses a wireless communication device testability design method. The method includes performing functional unit division on a wireless communication device, including a voice and panel unit, a processor unit, a baseband signal processing unit, a radio frequency unit, a power amplifier unit, a filter unit and a backboard unit, wherein the voice and panel unit, the baseband signal processing unit, the radio frequency unit, the power amplifier unit and the filter unit are connected with the processor unit through respective control interfaces and data communication interfaces via the backboard unit, and the voice and panel unit provides a device internal unit program upgrade interface and maintenance interface to the outside. Main faults of each unit are automatically diagnosed when the device is powered on, a test command is input through the maintenance interface when a fault occurs, a test signal passes through each unit inside and realizes loopback gradually, and the faults of each unit are diagnosed automatically. The wireless communication device testability design method has the beneficial effects of utilizing hardware resources of the device itself, increasing test software to realize testability design of the device itself, accurately positioning the faults inside the device, and greatly reducing debugging and testing and maintenance guarantee cost of the device.

Owner:CHONGQING JINMEI COMM

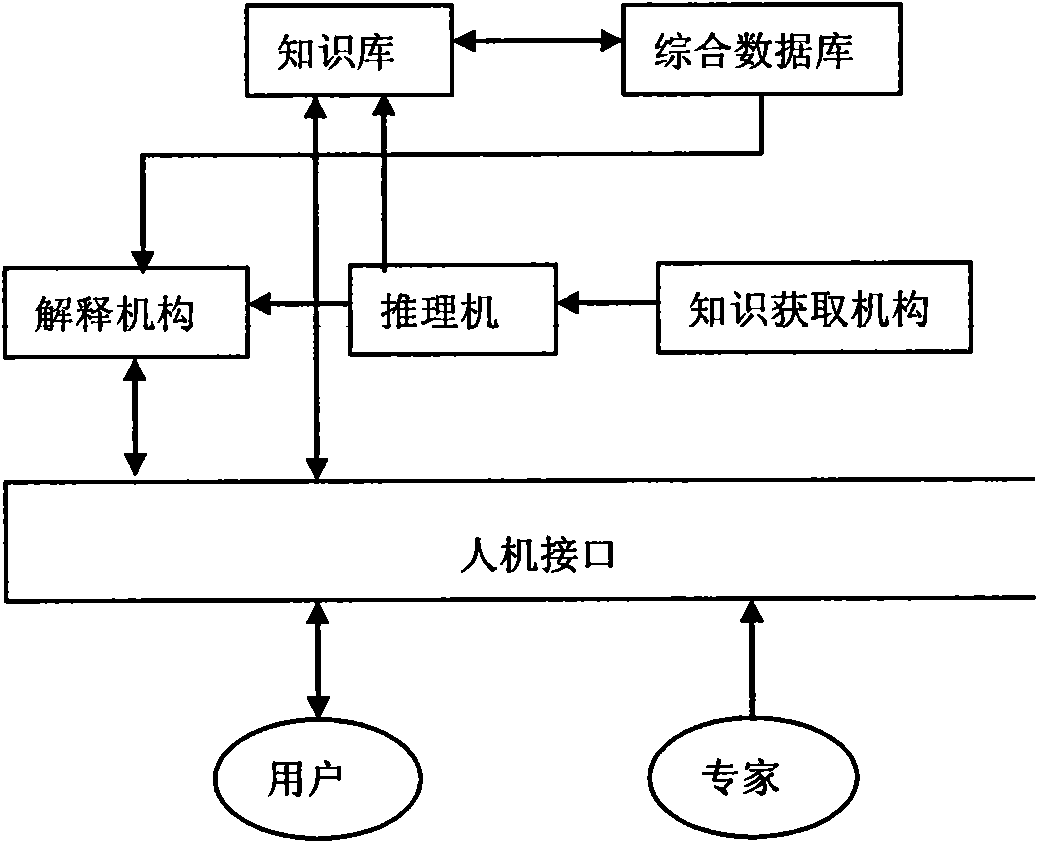

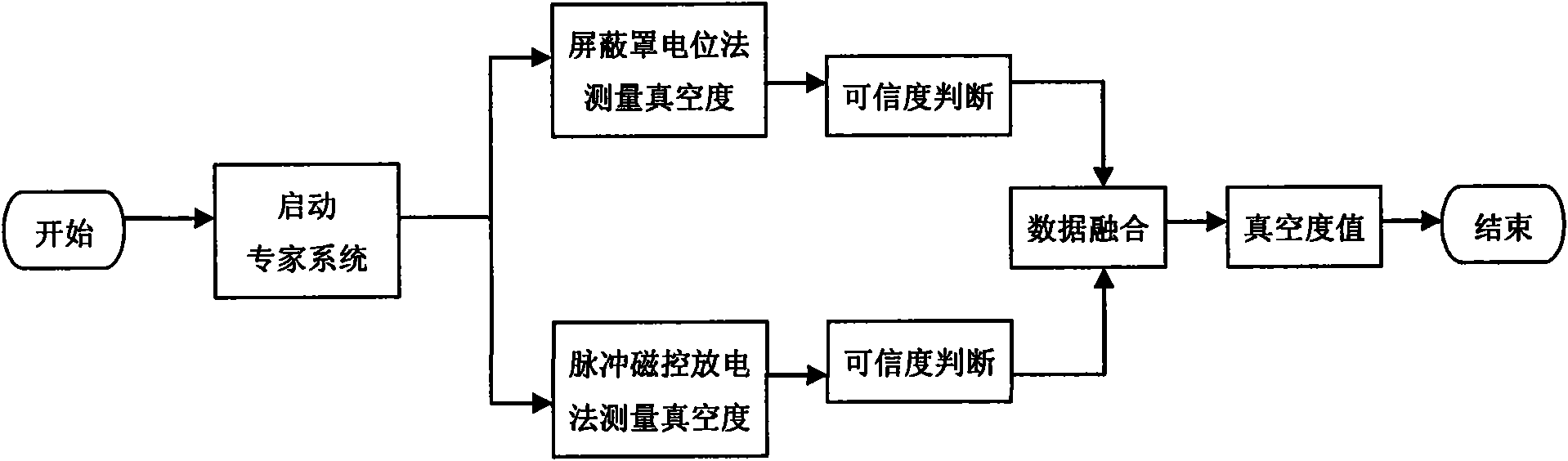

Expert system for measurement of vacuum degree and life management of vacuum arc extinguish chamber and application method

InactiveCN101661570ALife expectancySolve the credibility problemVacuum gaugesHigh-tension/heavy-dress switchesMeasurement devicePower grid

Owner:HEBEI UNIV OF TECH

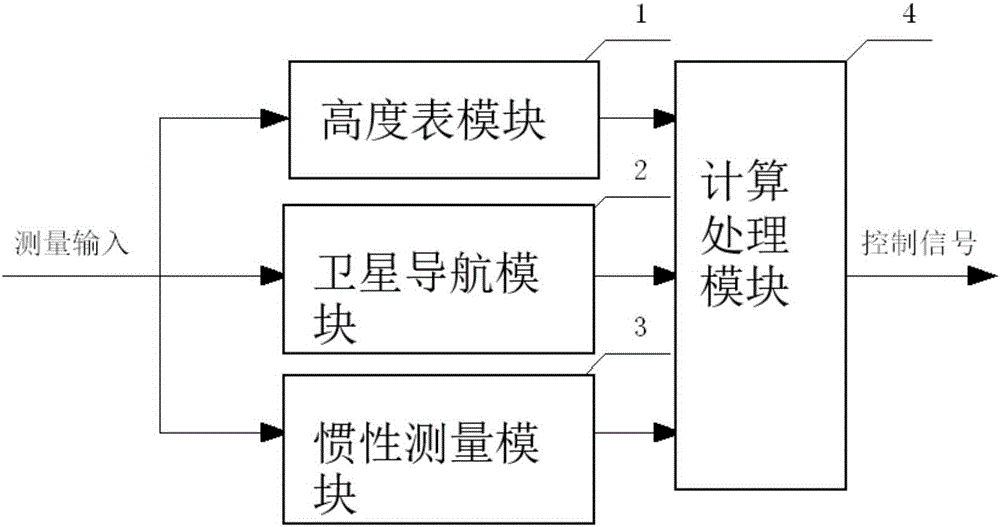

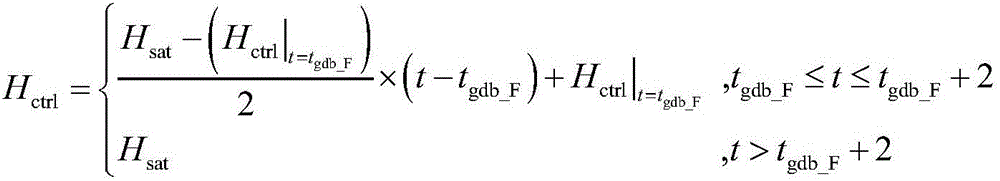

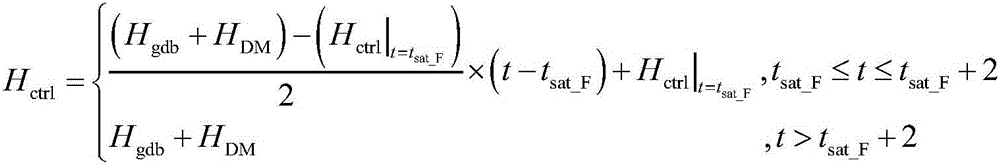

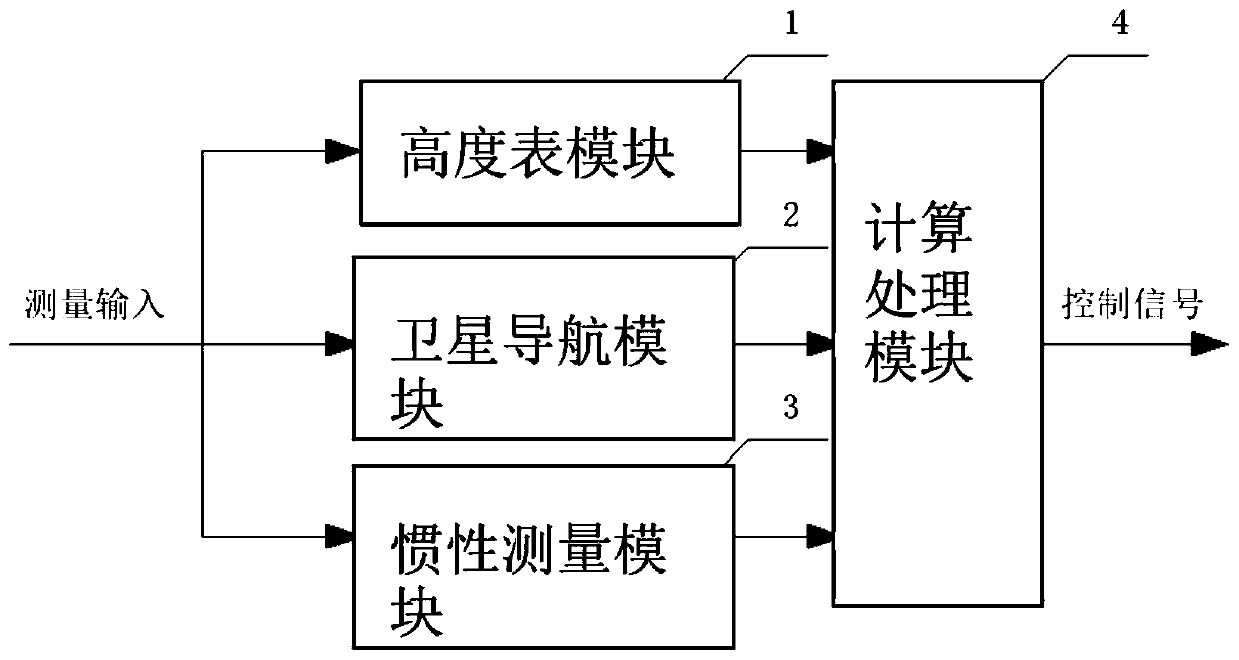

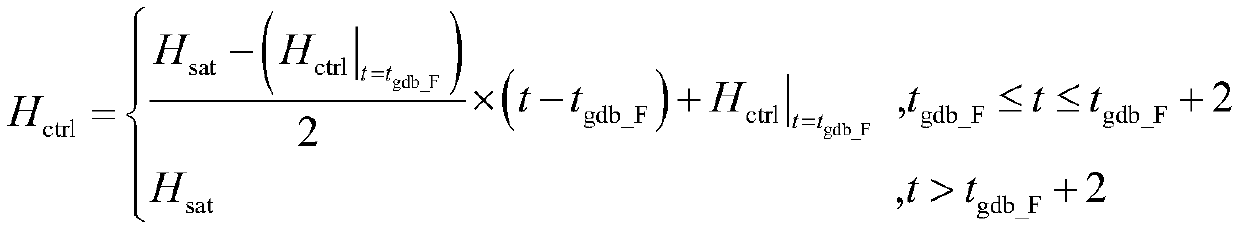

Unmanned-aerial-vehicle height measurement control system based on fault-tolerance processing and control method

ActiveCN106681336AAchieve reliabilityImprove reliabilityNavigation by speed/acceleration measurementsHeight/levelling measurementFault toleranceFlight vehicle

The invention discloses an unmanned-aerial-vehicle height measurement control system based on fault-tolerance processing and a control method. The unmanned-aerial-vehicle height measurement control system comprises a height meter module, a satellite navigation module, an inertial measurement module and a computing and processing module. The height meter module is used for measuring the distance of an unmanned aerial vehicle to the ground in real time; the satellite navigation module is used for receiving and processing satellite signals in real time and measuring the flight position and the direction of the unmanned aerial vehicle; the inertial measurement module is used for measuring the attitude angular velocity and the accelerated velocity of the unmanned aerial vehicle in real time; the computing and processing module is used for receiving data of the height meter module, the satellite navigation module and the inertial measurement module in a parallel mode and computing and obtaining height measurement data. By means of the unmanned-aerial-vehicle height measurement control system based on fault-tolerance processing and the control method thereof, the conditions of the fault of a height meter or the fault of satellite navigation or the faults of a height meter and satellite navigation can be synthetically processed, and the high stability of the unmanned aerial vehicle is guaranteed through the control system to a maximum limit.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

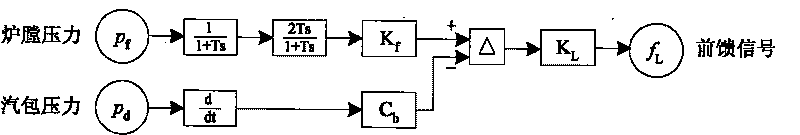

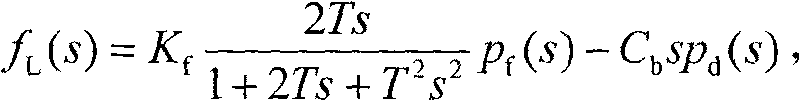

Feedforward signal of drum water level control system of drum boiler

InactiveCN101709868AImprove securityImprove control effectWater feed controlTime domainControl system

A feedforward signal of a drum water level control system of a drum boiler is used for overcoming the adverse impact of false water level on water level control. The feedforward signal fL(s) is specifically formed as follow, wherein s is complex variable of Laplace transform and is equivalent to differential operator in time domain, fL(s) is Laplace transform of feedforward signal fL, pf(s) is Laplace transform of furnace pressure pf, pd(s) is Laplace transform of drum pressure pd, Cb is boiler heat storage coefficient, Kf is furnace pressure gain coefficient and T is furnace pressure filter coefficient. The invention is simple and convenient in implementation, low in cost, good in control effect and high in reliability, can effectively overcome the adverse impact of false water level and greatly improve the control quality.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

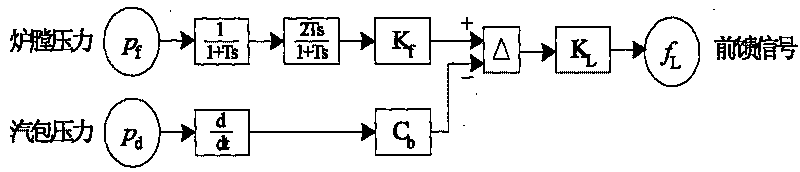

Intelligent management system and method for illegal fee collection cheating of medical imaging equipment

PendingCN107424105AMeet the needs of leakage prevention fee managementLow costData processing applicationsState of artMedical equipment

The invention discloses an intelligent management system and method for illegal fee collection cheating of medical imaging equipment. The system comprises a data acquisition subsystem connected with the medical image equipment, a cloud analysis subsystem connected with the data acquisition subsystem, and a management subsystem connected with the cloud analysis subsystem. According to the system and method, the management need of illegal fee collection cheating prevention of all medical imaging equipment of a hospital can be met only by installing one data acquisition box and the total cost is less than one tenth of those of other plans in the prior art. Moreover, statistics of detailed usage records of the equipment is realized by using working logs of the equipment; the data source is direct and the result is accurate; a phenomenon that the operation of the equipment is limited by cutting of the power or signal is avoided, so that high reliability of the equipment is ensured.

Owner:北京绪水互联科技有限公司

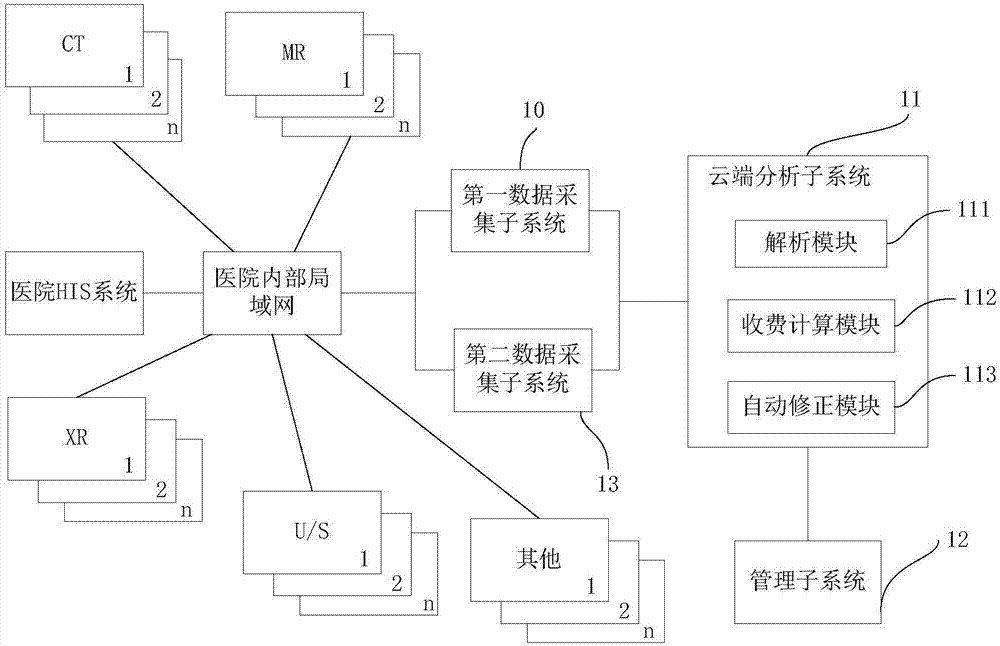

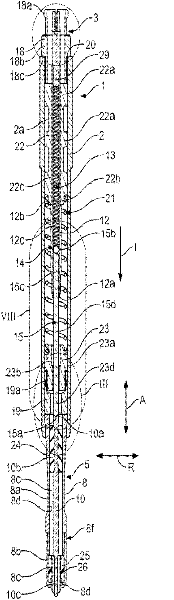

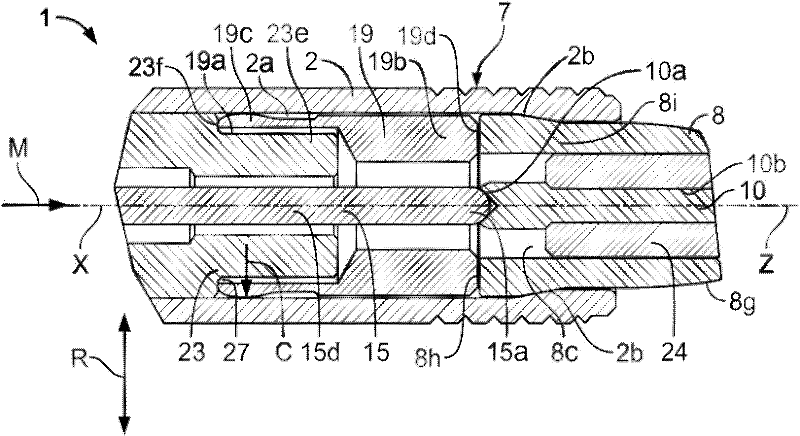

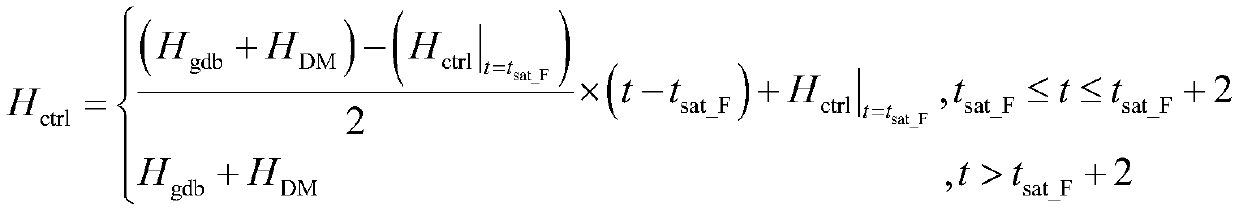

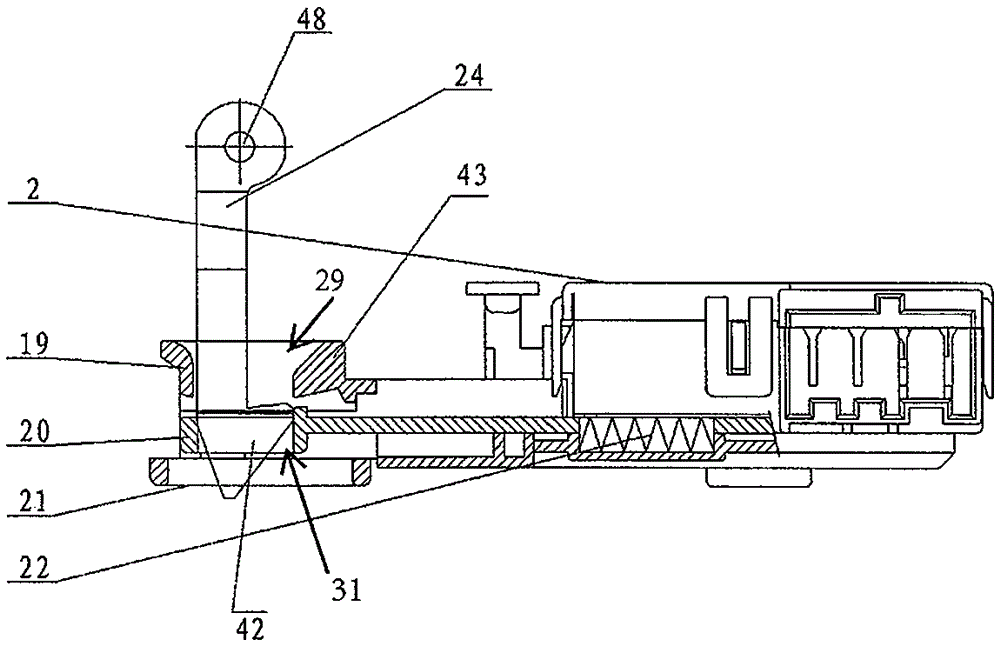

Test probe

ActiveCN102197310ANo reduction in reliabilityTwo pole connectionsElectrical measurement instrument detailsBiomedical engineeringTest probe

The present invention relates to a test probe (1) for mating with a connector (30) in a probe insertion direction (I), comprising a housing (2), an outer contact portion (8), the outer contact portion (8) supported by the housing (2) and extending away from the housing (2), said outer contact portion (8) supported by an elastically deformable outer biasing means (21) and being adapted to be deflected substantially perpendicular to the probe insertion direction (I) and at least one contact assurance means (19), said contact assurance means (19) connecting the outer contact portion (8) electrically conductively to the housing (2). To decrease the number of parts the contact assurance means (19) has at least one contact section (19c), said contact section (19c) pressed conductively against the housing (2) by being elastically deflected.

Owner:泰科电子服务有限责任公司

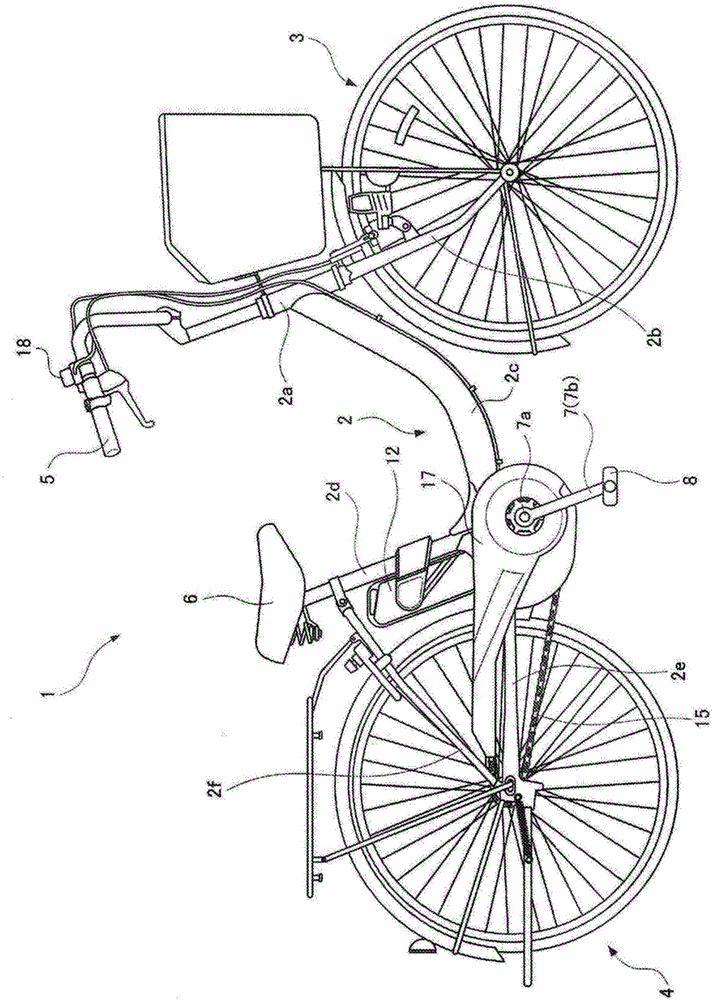

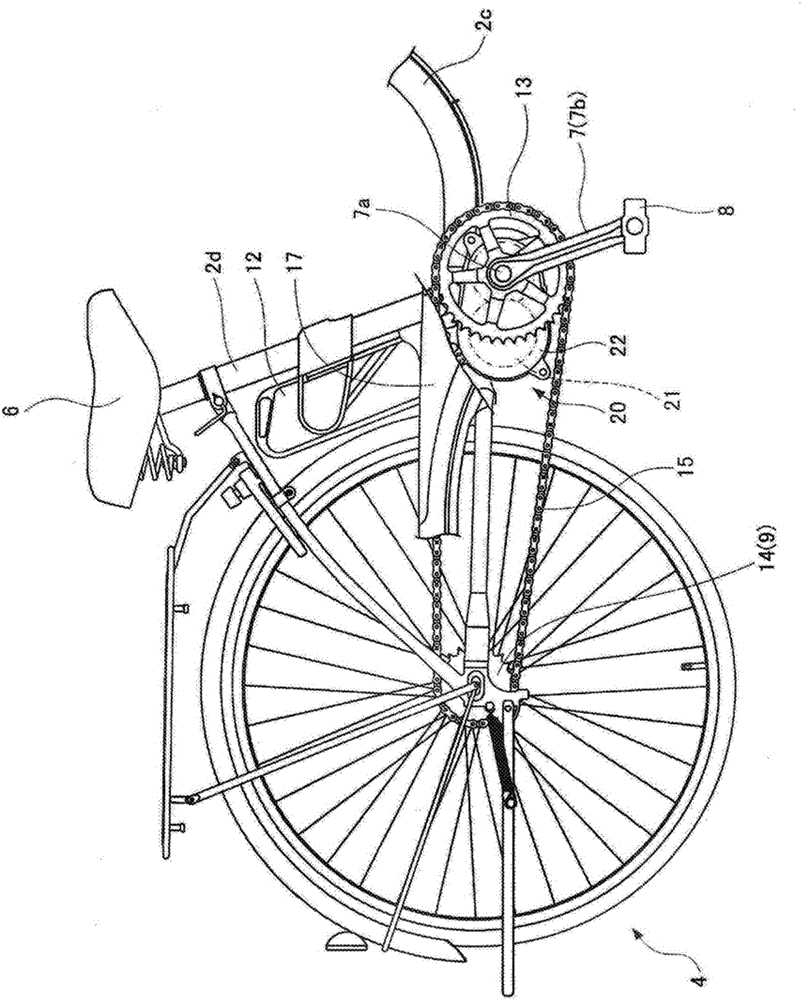

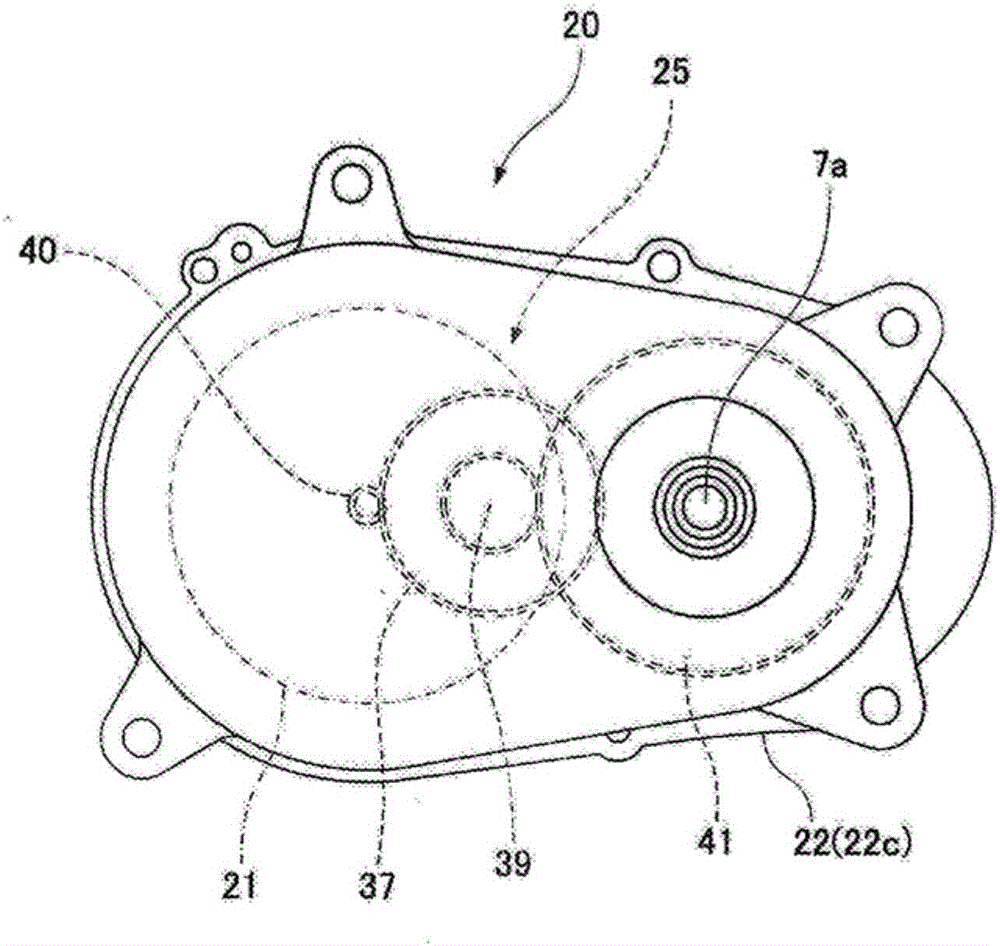

Electric assisted bicycle

Provided is an electric assisted bicycle with a configuration wherein a drive unit for internally combining human powered drive force and auxiliary drive force is fitted with an interior transmission with automatically switchable speed-change stages. A drive unit disposed at an intermediate position between a front wheel and a rear wheel is internally fitted with a transmission mechanism (25) that transmits combined force of human powered drive force and auxiliary drive force from a motor while changing speeds by switching the combined force to a plurality of stages. The transmission mechanism (25) is fitted with a speed-change weight (81) of which the posture is changed in accordance with a centrifugal force when being rotated, and configured such that as the rotation speed of a crank shaft (7a) increases, the posture of the speed-change weight (81) is changed so as to be switched from low speed stage side to high speed stage side.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

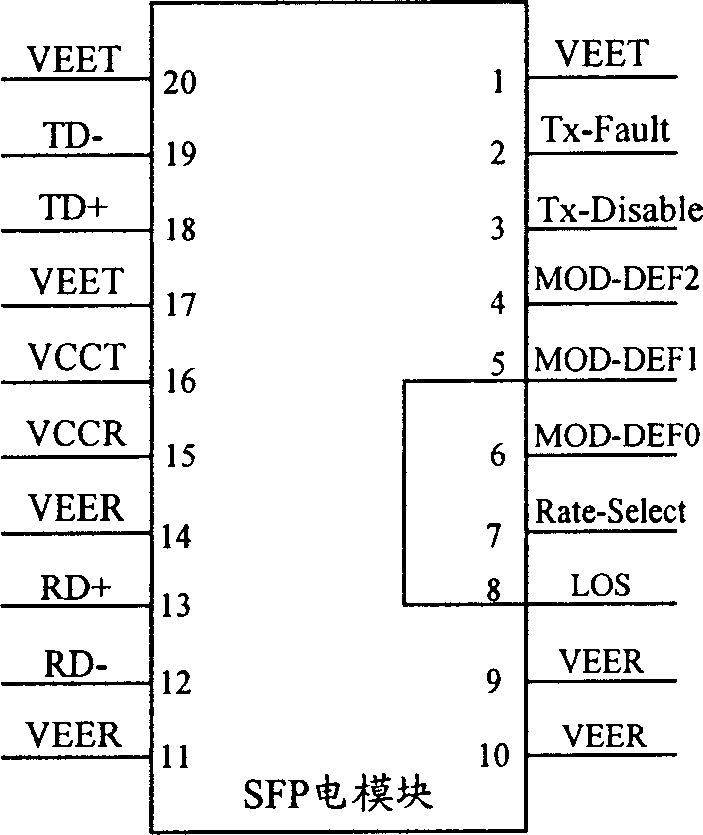

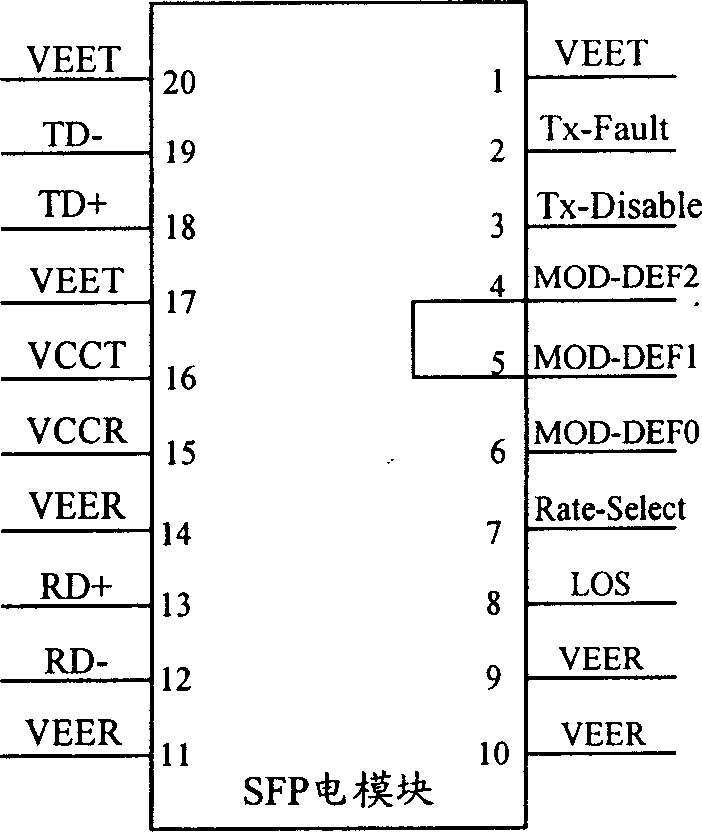

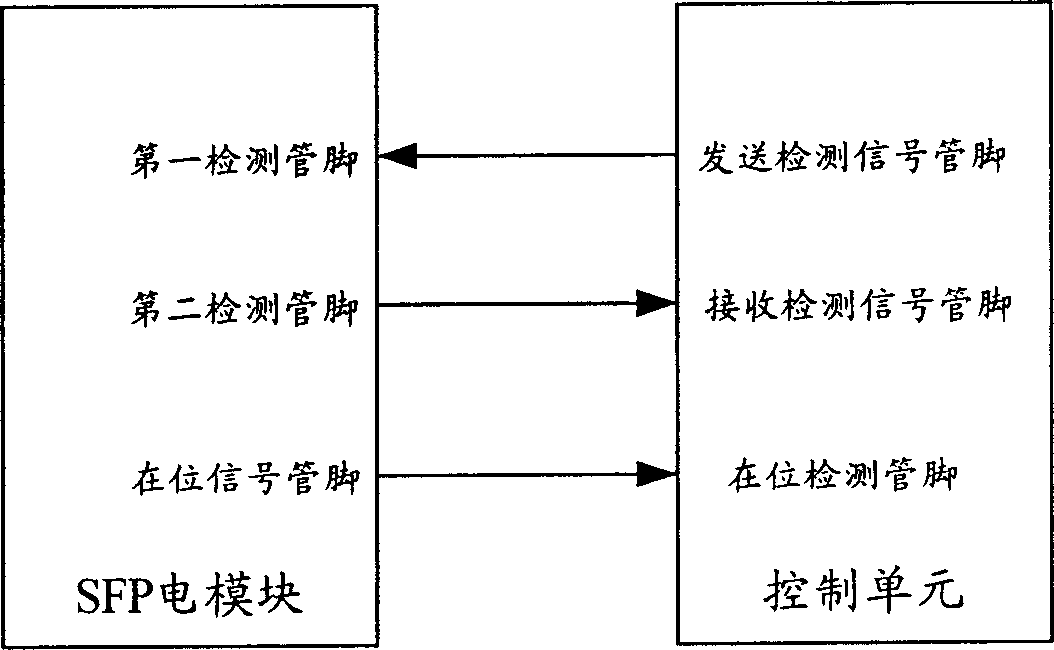

Method for on-line identifying small packaged hot connecting and disconnecting module

InactiveCN1889401ARealize online identificationNo reduction in reliabilityTransmission monitoringLine-transmission monitoring/testingEngineeringMonoboard

This invention discloses a method for identifying on-line SFP electric modules, which connects the first and second test pins of a SFP module in short-circuit, when a control unit of a monoboard the SFP module places tests that the module has been plugged in the monoboard, said method includes the following steps: A, the control unit transmits a preset test signal to the first test pin of the SFP module by the pin of its own transmitting test signals, B, the control unit receives the fed back signals from the second test pin of the module by its pin receiving test signals and judges if said fed back signal is the preset signal, if so, it judges that the SFP module plugged in the monoboard current is an electric module, otherwise, it's not.

Owner:HUAWEI TECH CO LTD

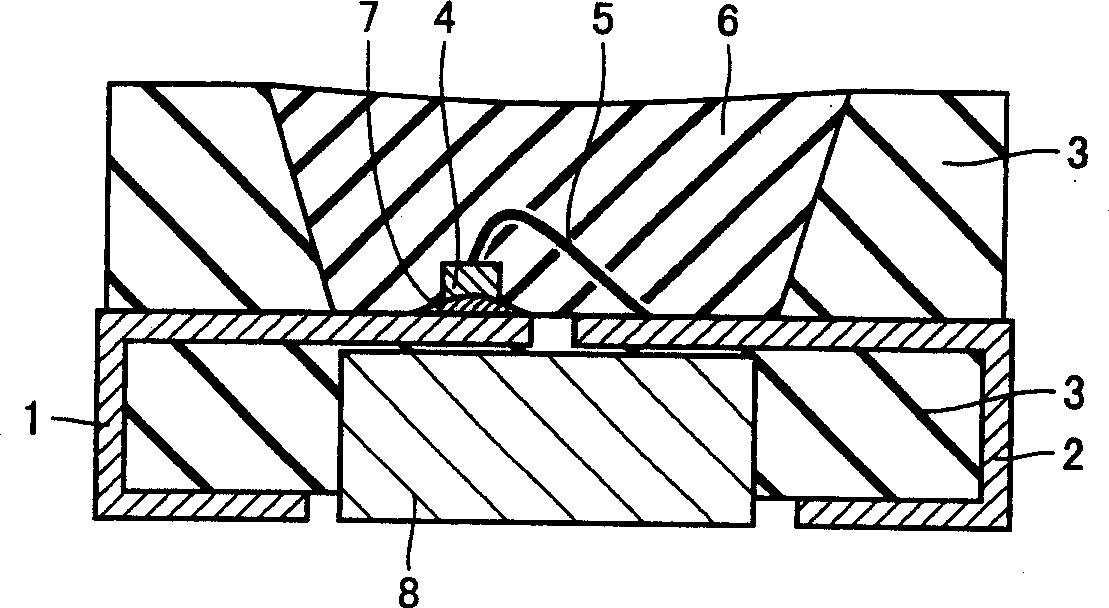

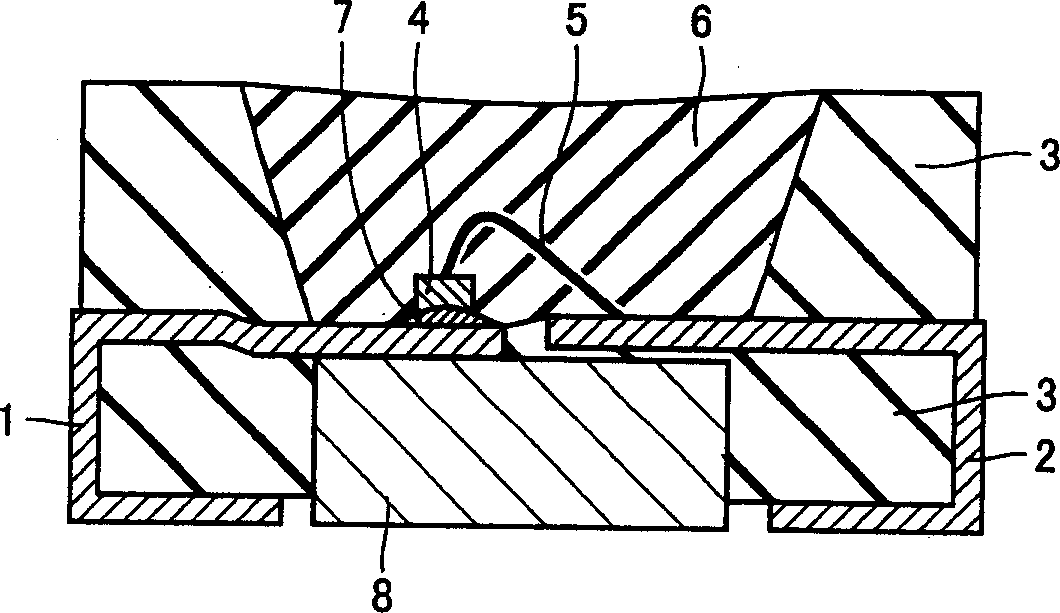

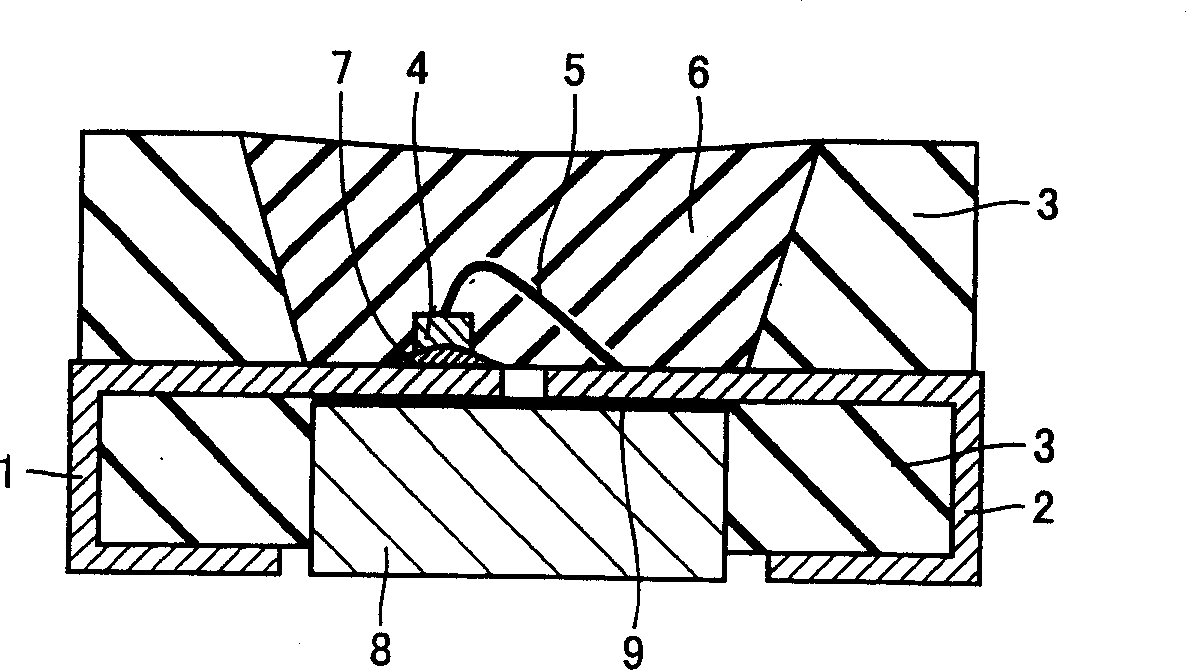

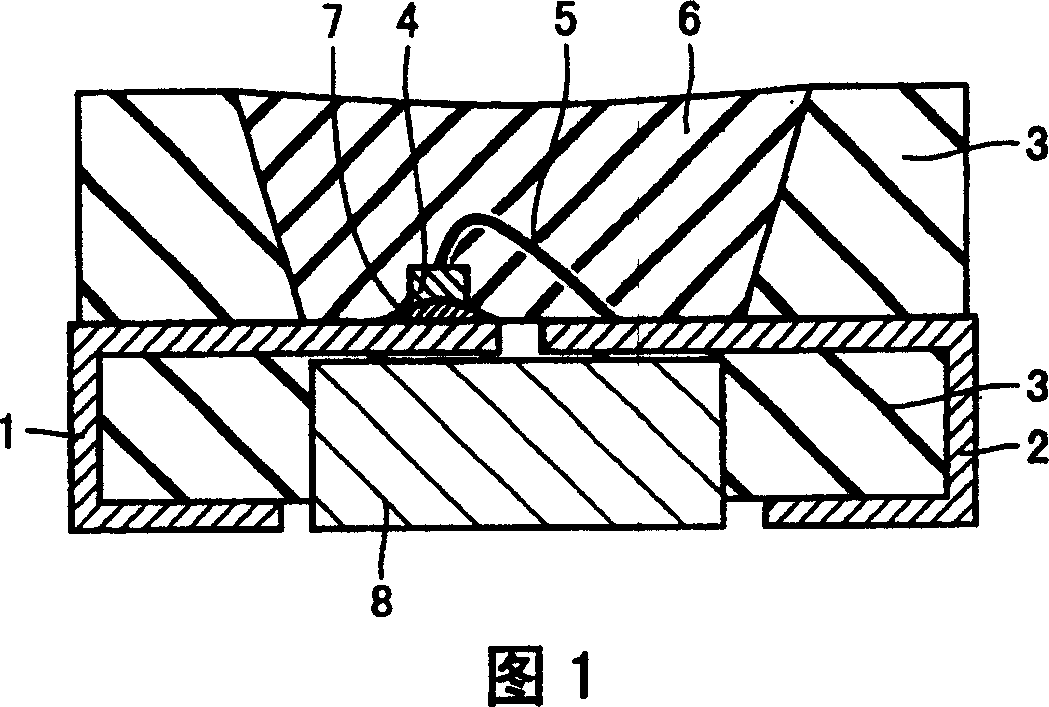

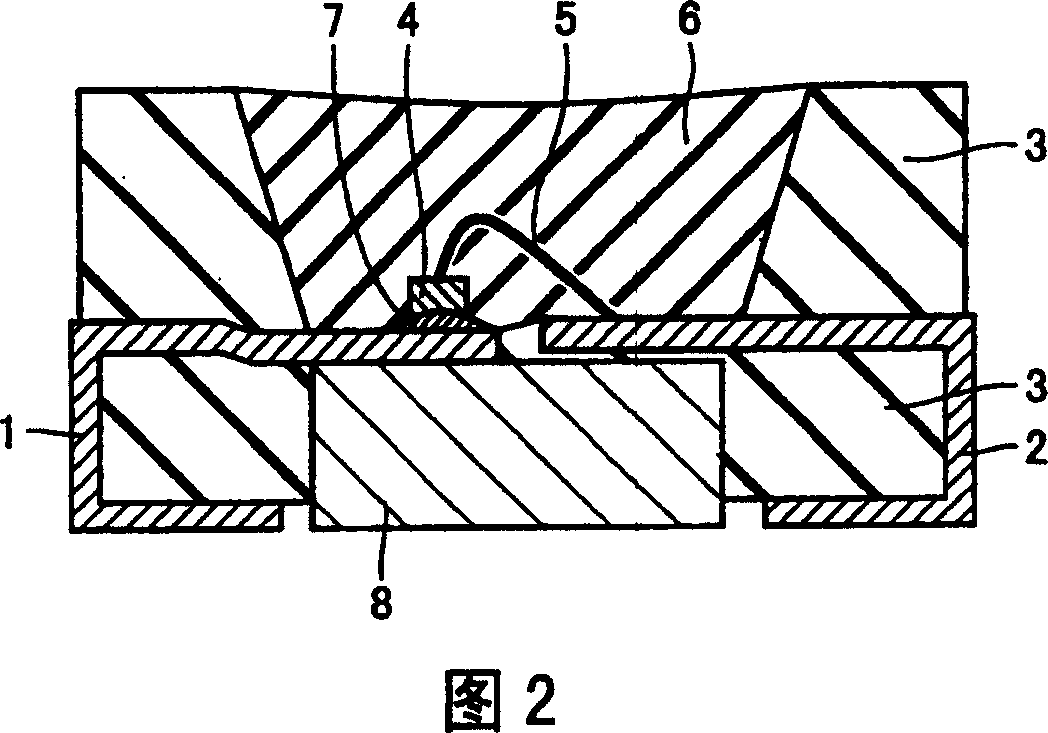

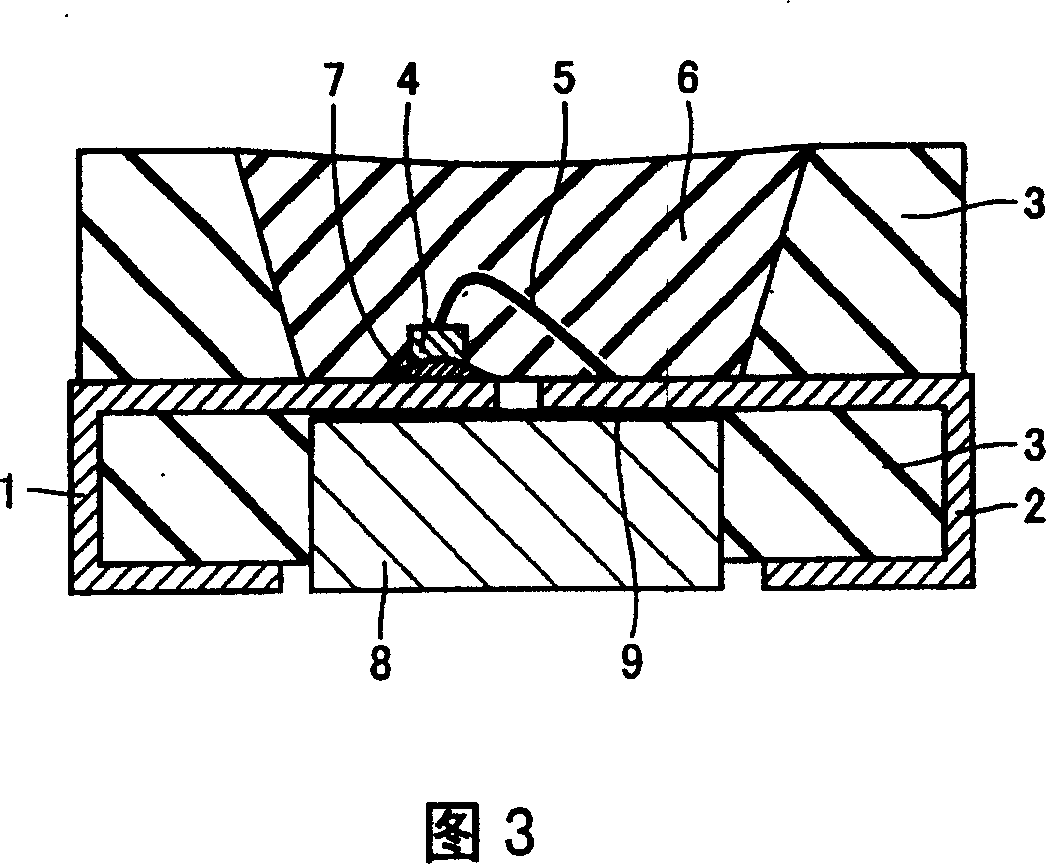

Semiconductor luminescent device and its manufacturing method

InactiveCN1518135AHigh luminous intensityEasy to fixSolid-state devicesSemiconductor devicesEngineeringLead frame

A semiconductor light emitting device includes an LED chip (4), a first lead frame (1) on which the LED chip (4) is mounted, a second lead frame (2) electrically connected to the LED chip (4) via a bonding wire (5), and a resin portion (3) surrounding the circumference of the LED chip (4), and fastening the first and second lead frames (1, 2). A metal body (8) is located under the region of the first lead frame (1) where the LED chip (4) is mounted.

Owner:SHARP KK

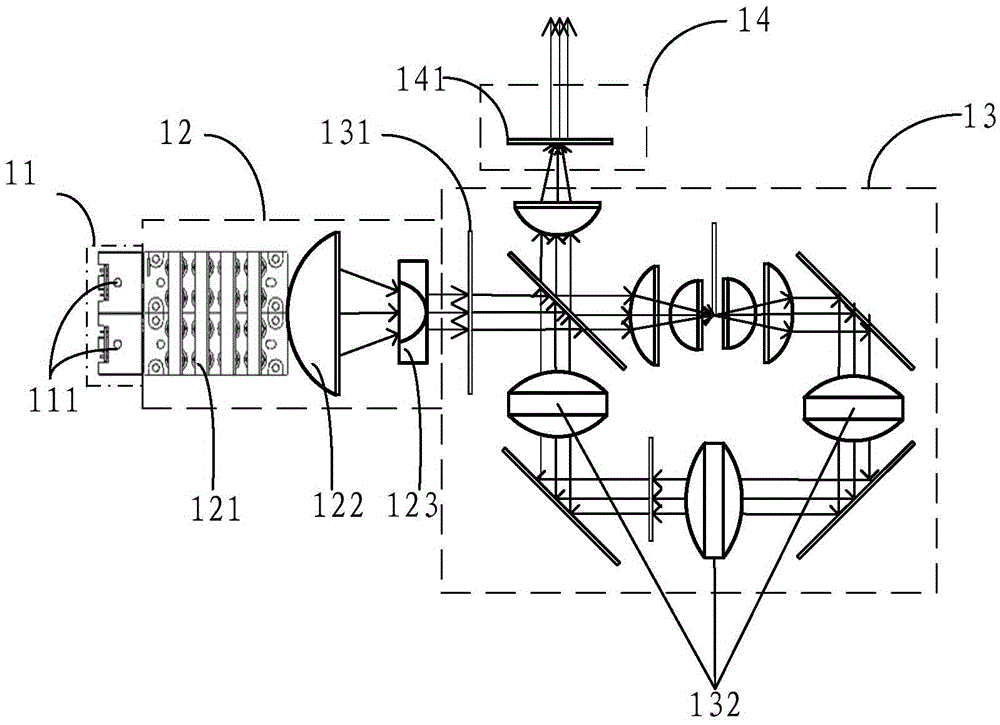

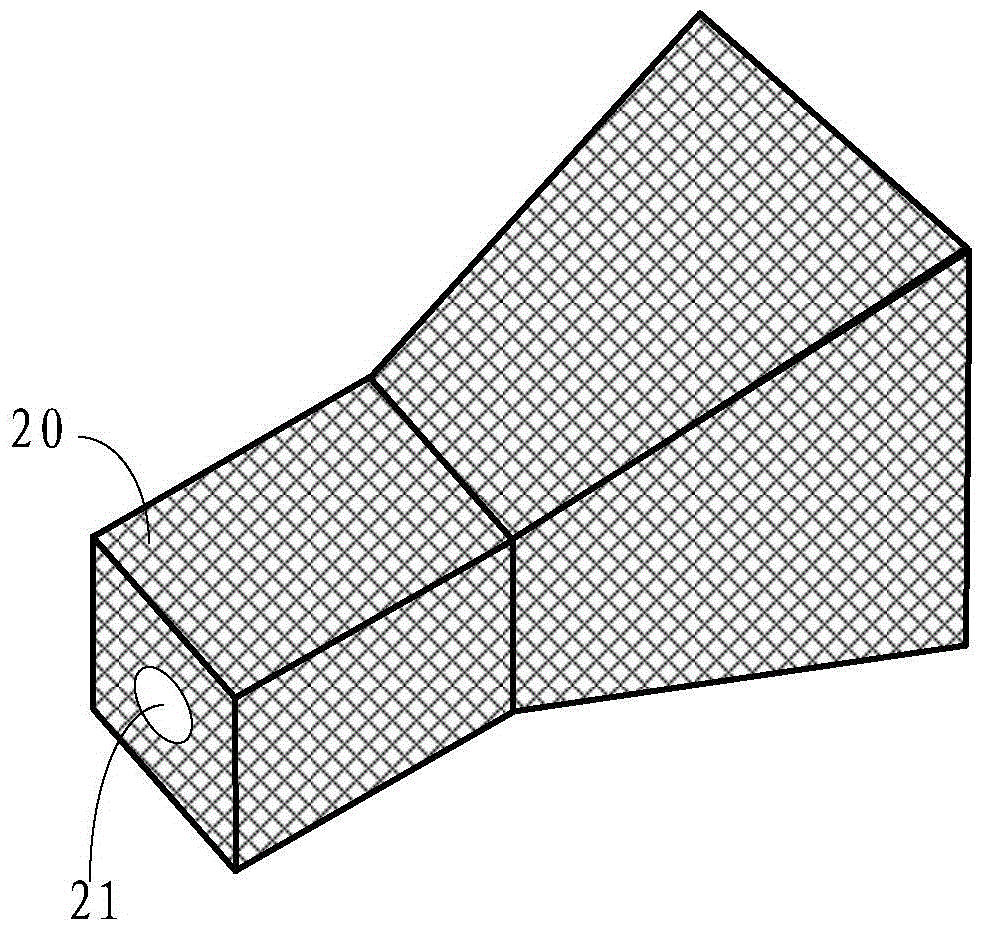

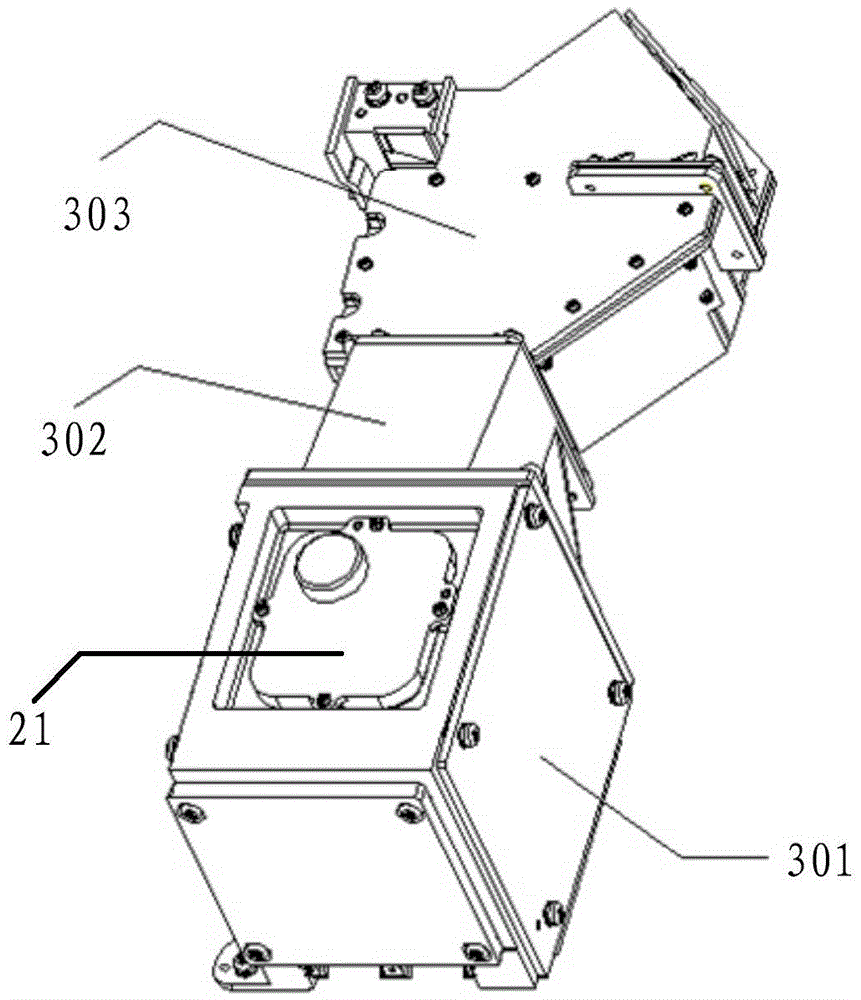

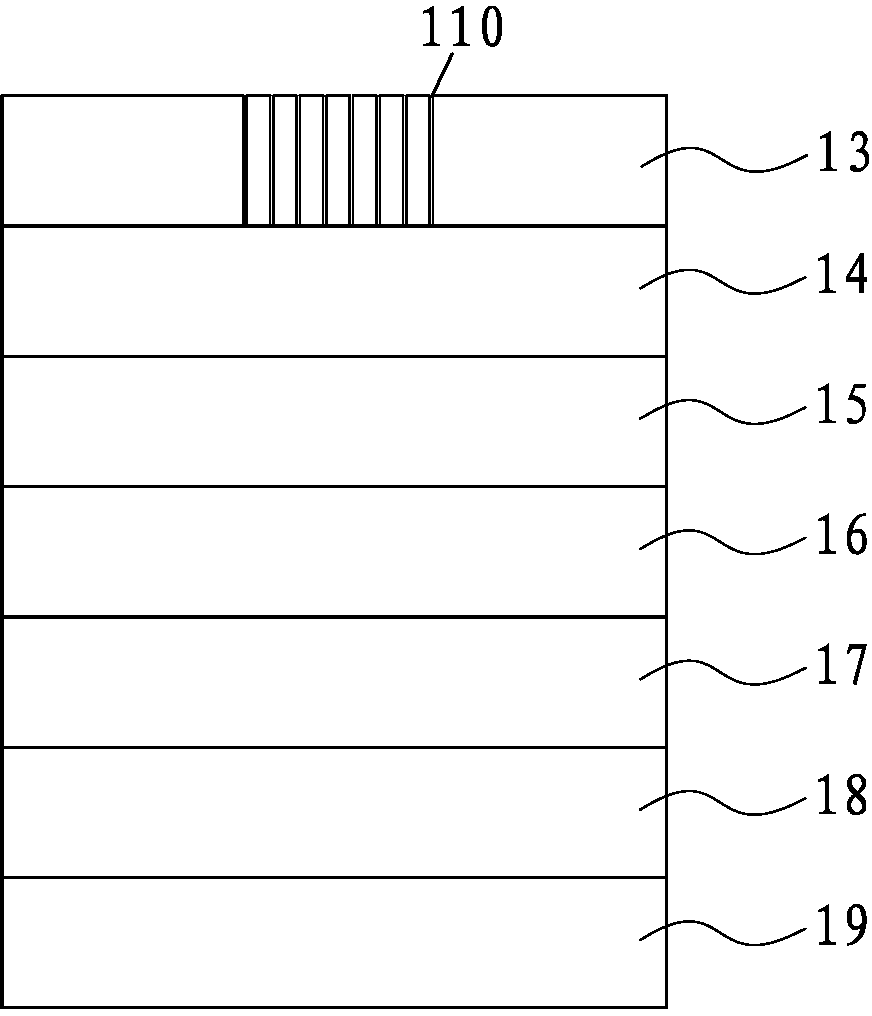

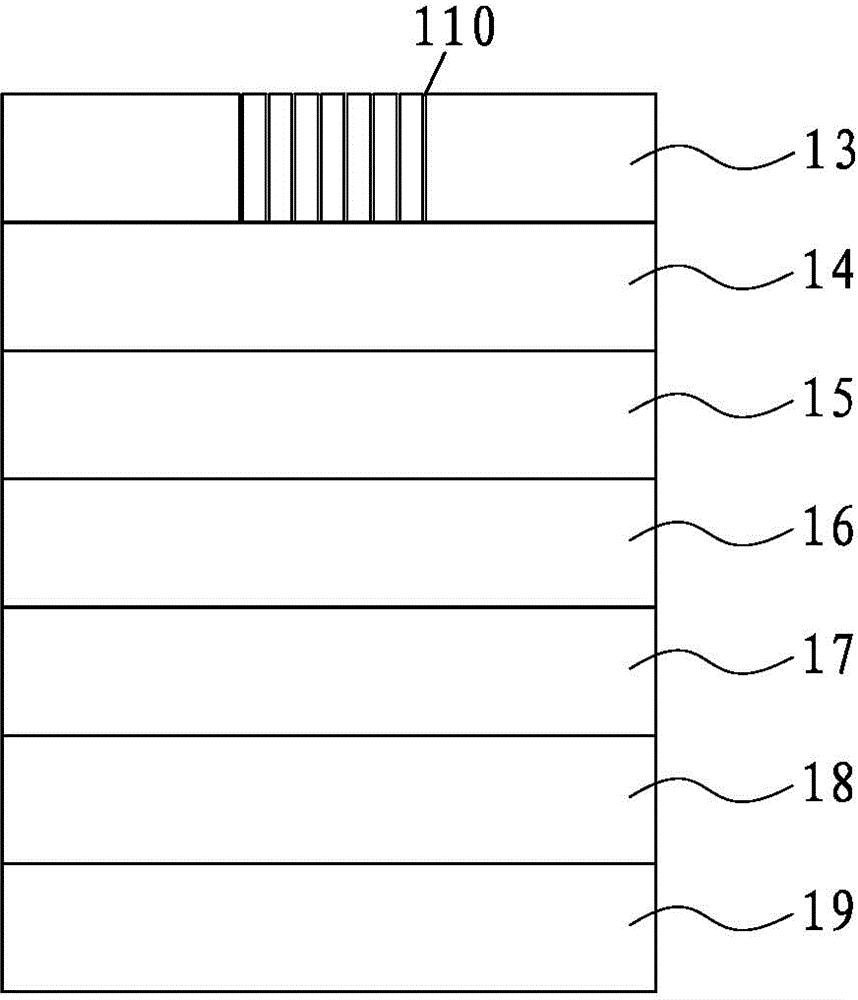

Laser light source and laser projection display device

The invention provides a laser light source and a laser projection display device, relating to the laser technology field, and the invention is used for preventing the interference on the laser source caused by the dust. The laser source comprises a sealing housing and a laser member sealed inside the sealing housing; the laser device comprises a laser array, a light beam shaping module, a fluorescence transition module and a color filter output module which are successively connected; the sealing housing is provided with an exhaust hole which is used for communication between the internal of the housing and the external and is used for balancing the pressure inside and outside the sealing housing. The embodiment of the invention is applied for the dustproof of the laser source.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

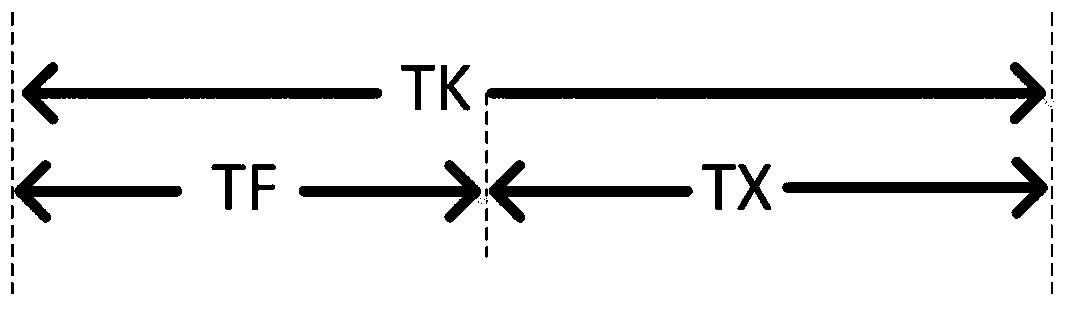

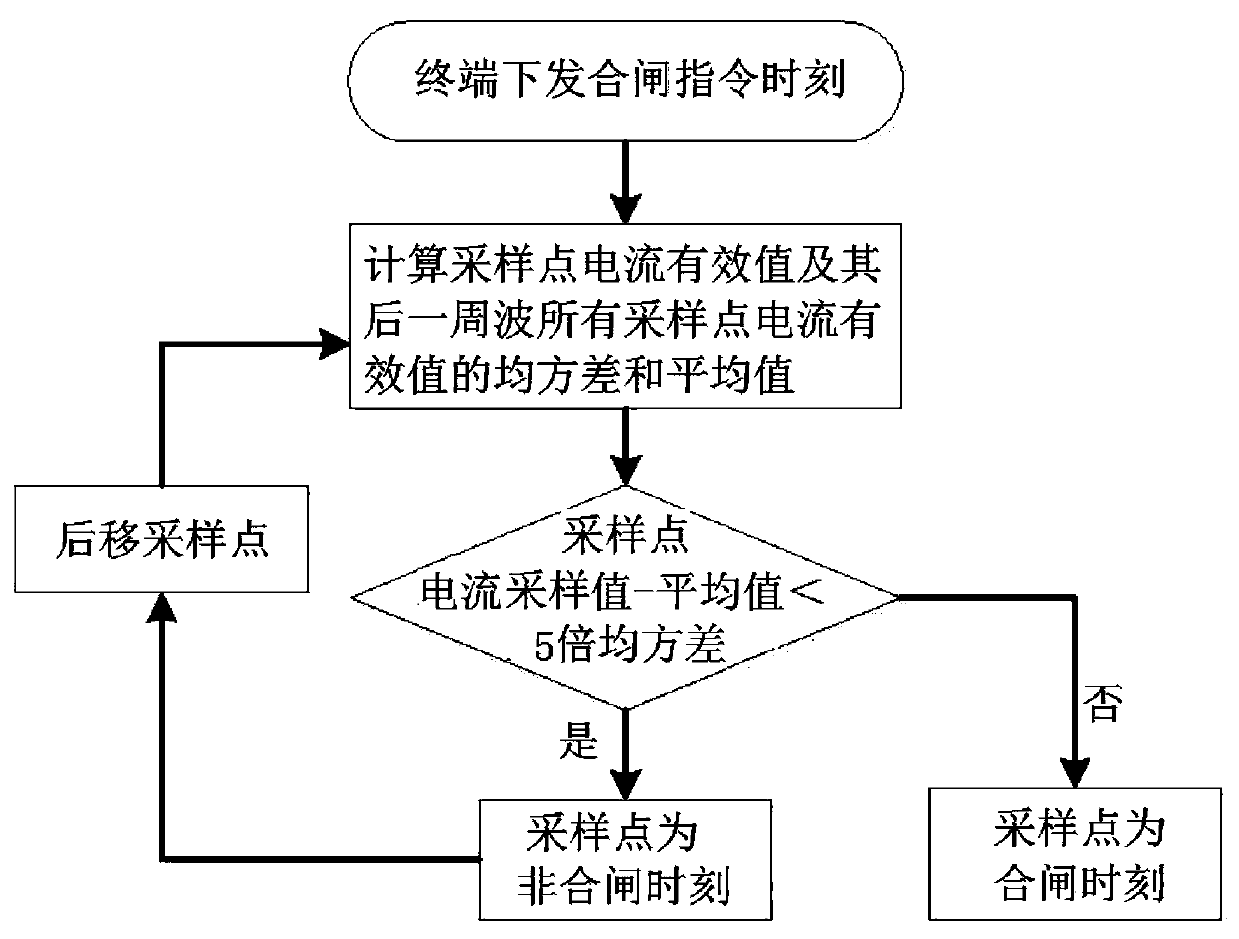

High-voltage circuit-breaker condition monitoring method of distribution automation system

InactiveCN110261768ANo reduction in reliabilityRealize online status monitoringCircuit interrupters testingCondition monitoringLoad following power plant

The invention discloses a high-voltage circuit-breaker condition monitoring method of a distribution automation system. Through the opening / closing command issuing moment recorded by a terminal device of a power distribution station automation system and a load current change process during the opening / closing operation of a high voltage circuit breaker, the load current dynamic data during the opening / closing of the high voltage circuit breaker can be utilized to calculate the opening / closing completion moment of the high voltage circuit breaker, so that the opening / closing time of the high voltage circuit breaker can be determined according to the recorded opening / closing command issuing moment and the opening / closing moment of the high voltage circuit breaker, and the state of the high voltage circuit breaker can be assessed according to whether the opening / closing time of the high voltage circuit breaker reaches the standard. The method can perform state monitoring of the terminal high voltage circuit breaker of the distribution automation system on the existing basis of the distribution automation system without increasing hardware equipment, so that the method is good in economy, and the operation reliability of the high voltage circuit breaker of the distribution automation system can be enhanced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

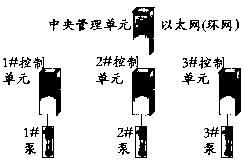

Distributed redundant constant-pressure water supply control system

ActiveCN110764481ASolve industry problemsImprove reliabilityEnergy industryService pipe systemsControl mannerControl cell

The invention discloses a distributed redundant control system. According to the system, pump revolution speed is dynamically adjusted based on the pressure, flow, temperature and other variables of fluid so as to achieve an expected control objective. The product is composed of one central management and coordination unit and n distributed control units which are independent and redundant from one another and can run autonomously, wherein each unit is in whole-network information transmission and modular design; the central management and coordination unit is only responsible for managing andcoordinating the control units, and the right of control is handed over to each control unit; and the central management and coordination unit can perform cascading in the same network segment or across network segments. In a pressure-maintaining standby state based on a multi-variable weight algorithm, the system does not do idle work due to dynamic flow compensation. The system has the advantages of high reliability, high continuity, distributed running, strong extensibility and energy preservation, therefore, the defects that through a traditional central control mode, reliability is poor,and equipment overhaul requires shutdown and water supply cut-off are overcome, and the problems that water supply continuity is not high, and the scale is not large in the industry are solved. In this way, the after-sales service pattern in the current industry is changed, and after-sales cost is greatly lowered.

Owner:许刚

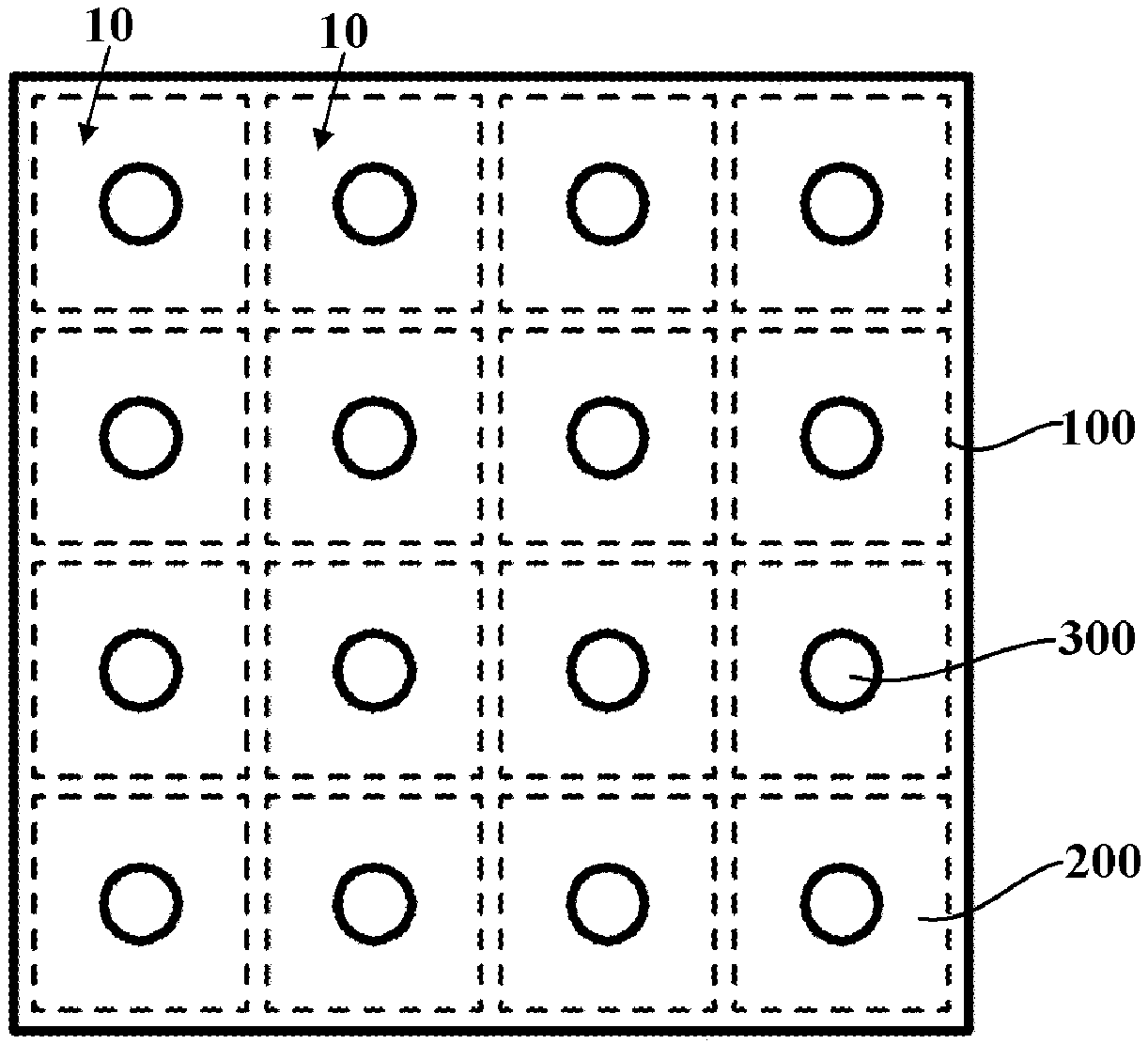

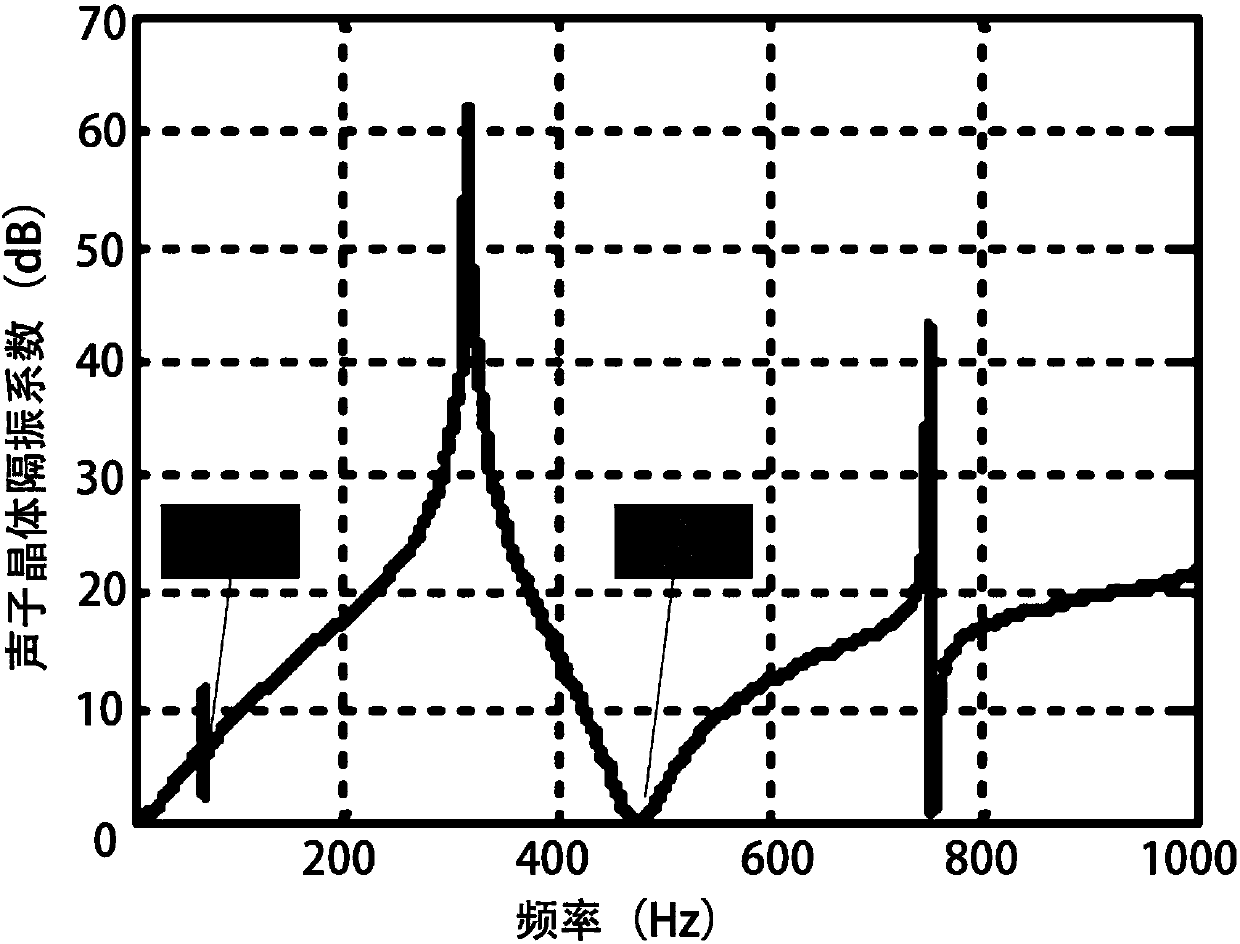

Broadband acoustic metamaterial

ActiveCN110097869AOptimizing key modalsIncrease the effective sound insulation bandwidthSound producing devicesGratingBroadband

The invention provides a broadband acoustic metamaterial. The broadband acoustic metamaterial comprises: a grating plate with a plurality of hollow parts; an elastic film which is tensioned and fixedon the grating plate, wherein the first surface of the elastic film is attached to the grating plate; a plurality of mass blocks fixed on the second surface of the elastic film, each mass block facingone hollow part of the grating plate. The periphery of each mass block is surrounded by multiple rigidity control blocks, and each rigidity control block is fixed to the second surface of the elasticfilm. The problem that an effective sound insulation band of an existing acoustic metamaterial is narrow is solved, and the sound insulation and noise reduction effects of the acoustic metamaterial are improved.

Owner:HAIER SMART HOME CO LTD +1

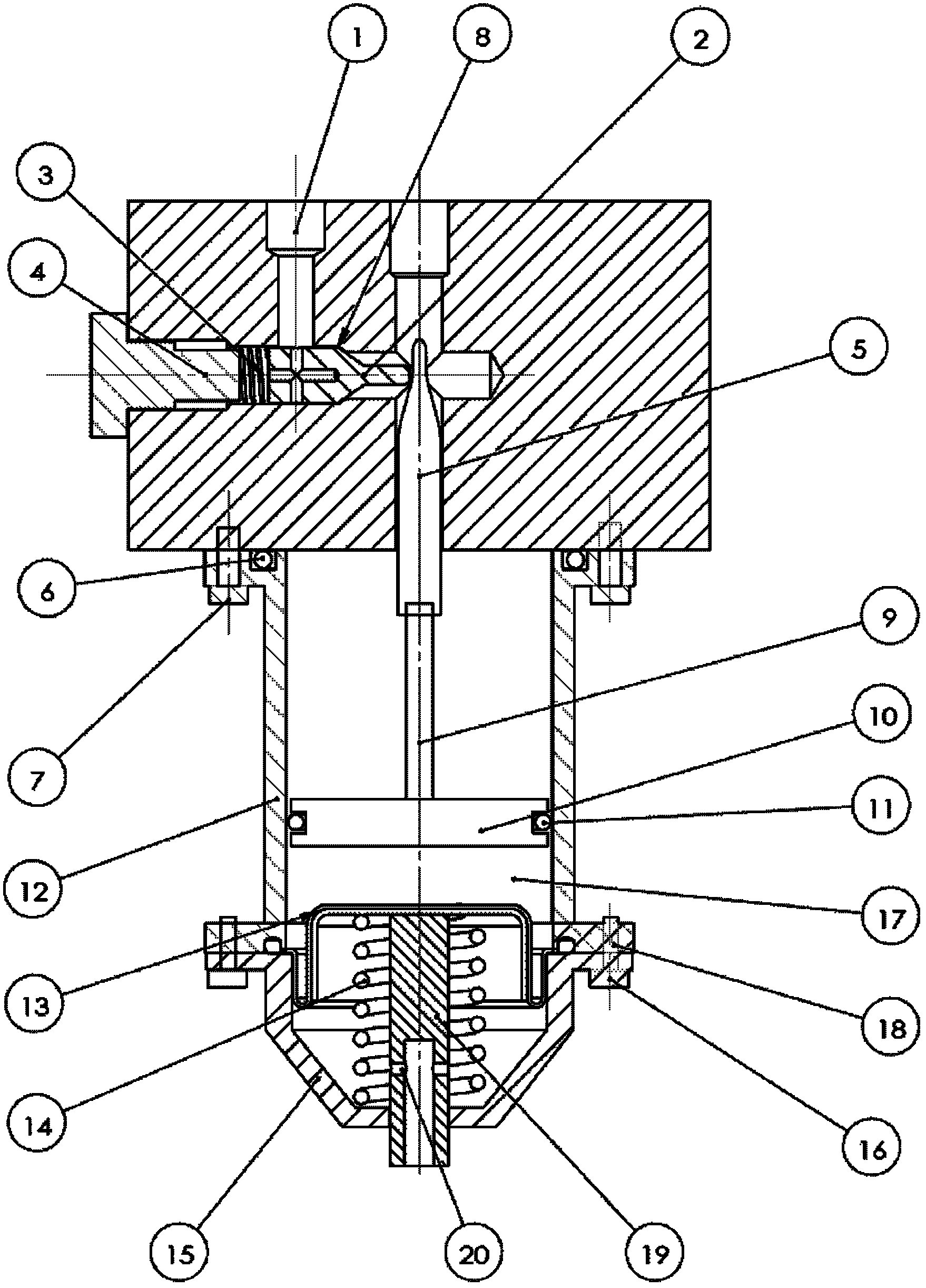

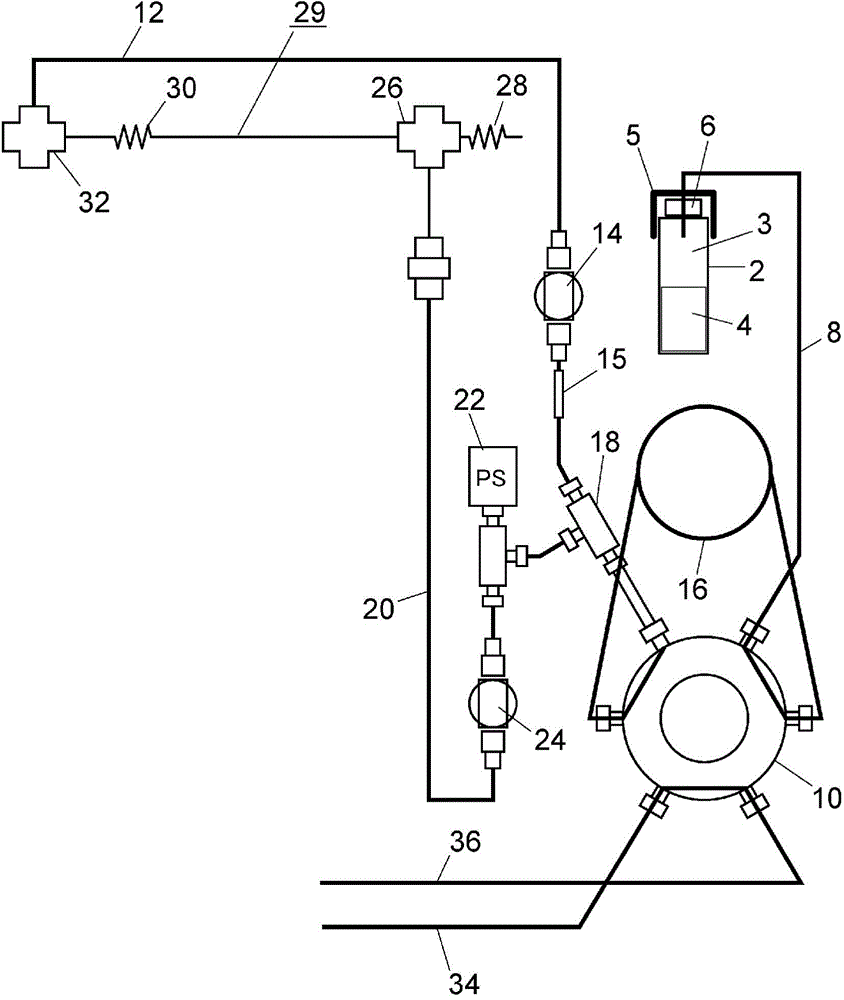

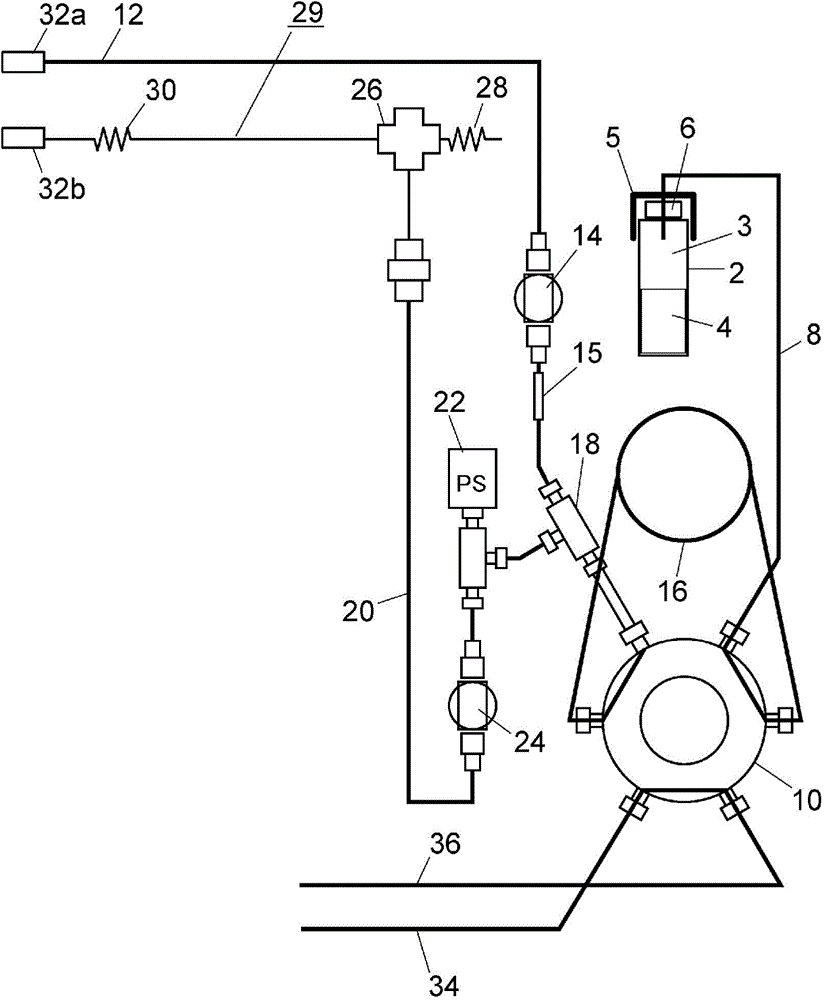

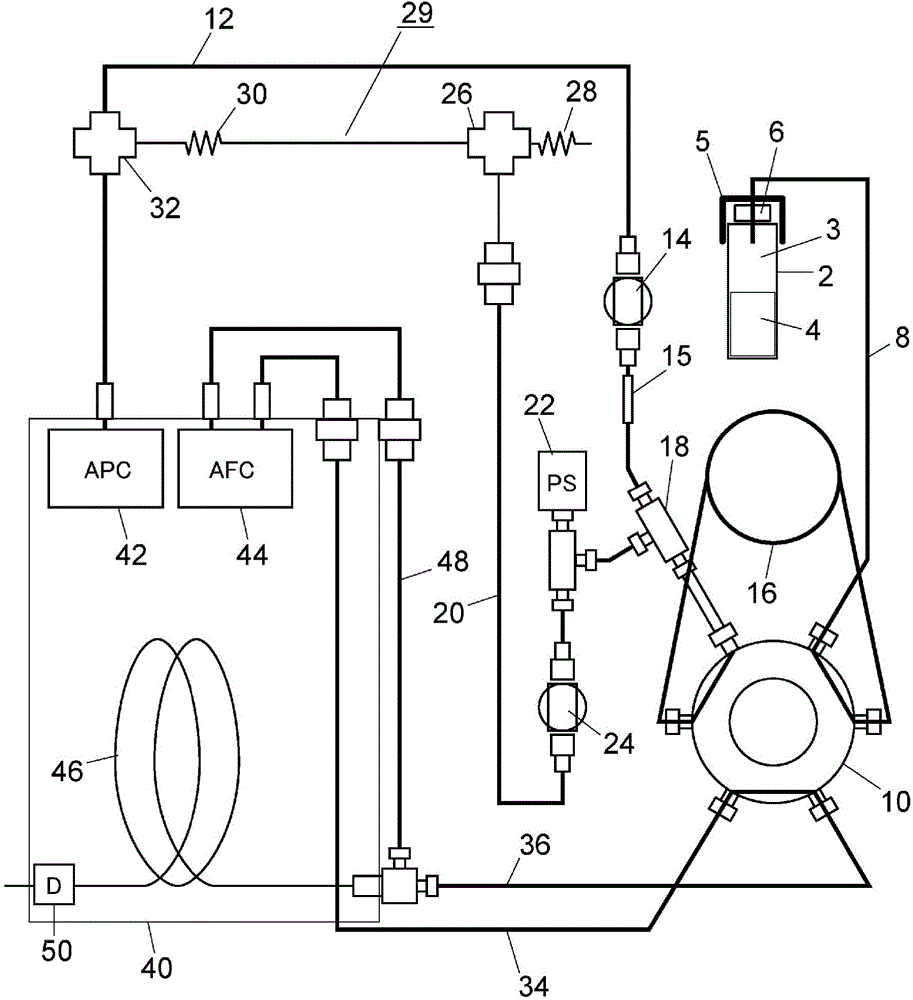

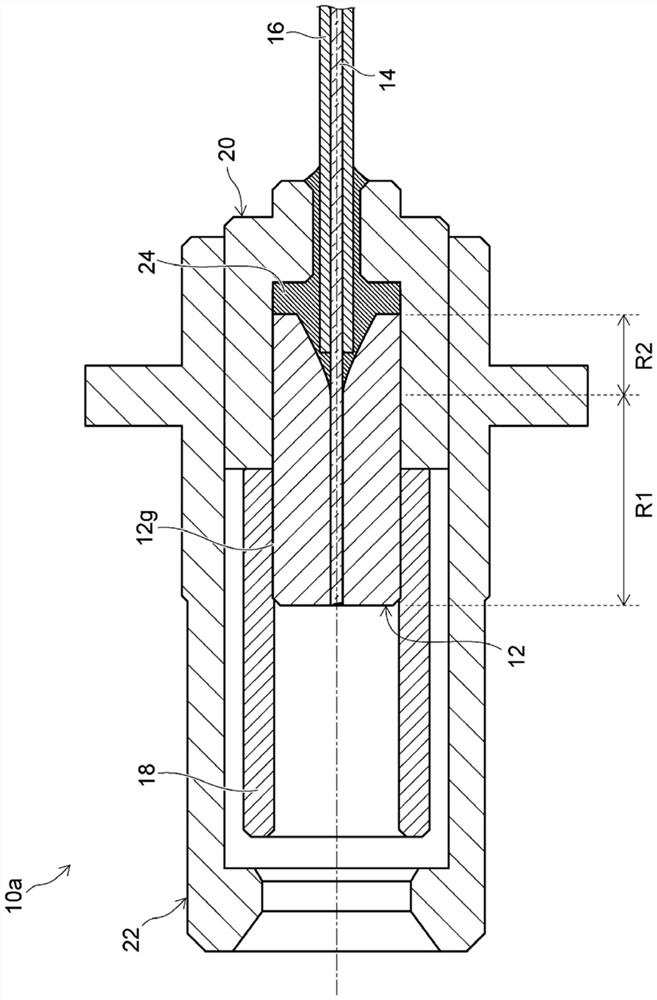

Pressure balance retainer for underwater oil charge system

InactiveCN102862665AReduce weightReduce volumeWave based measurement systemsUnderwater equipmentPressure sensePressure balance

The invention relates to a pressure balance retainer for an underwater oil charge system, comprising a seawater pressure sensing transfer unit and an oil pressure rapid automatic compensation unit, wherein the seawater pressure sensing transfer unit comprises an upper shell, a lower shell, a spring, a rolling membrane, a piston, a piston rod and an oil pressure control rod which are coaxially arranged; the upper shell is fixedly connected with the lower shell, the lower shell is provided with through holes, the rolling membrane is arranged between the upper shell and the lower shell through the spring and a fixed plate, the piston is arranged above the rolling membrane, and the piston rod is lockedly connected with the oil pressure control rod; the top end of the lower shell is hermetically fixed on the oil pressure rapid automatic compensation unit; and the oil pressure rapid automatic compensation unit comprises an oil charge valve for realizing the open and close of an oil charge oil circuit by the movement of the oil pressure control rod. According to the invention, the pressure balance retainer disclosed herein can automatically compensate the oil charge system, and can guarantee the reliability of devices by the multi-layer watertight structure.

Owner:SUZHOU SOUNDTECH OCEANIC INSTR

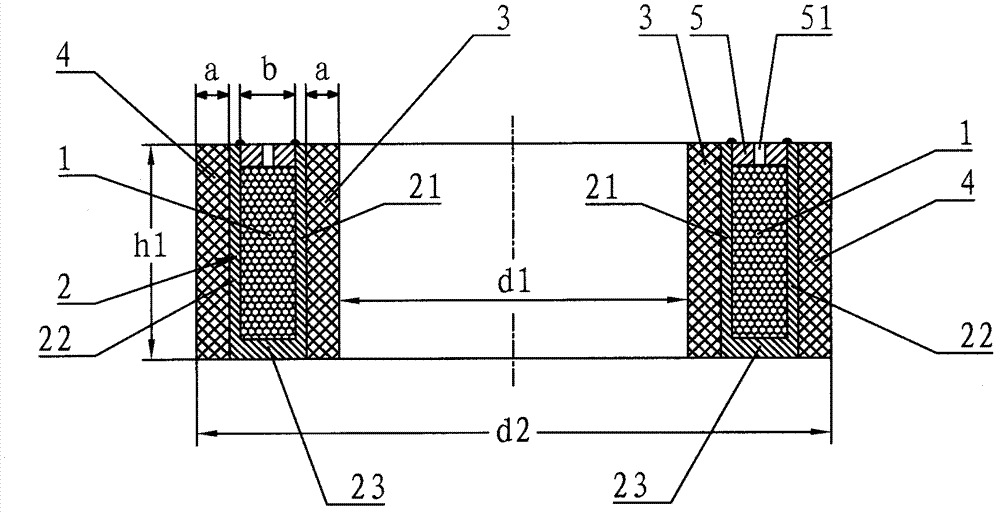

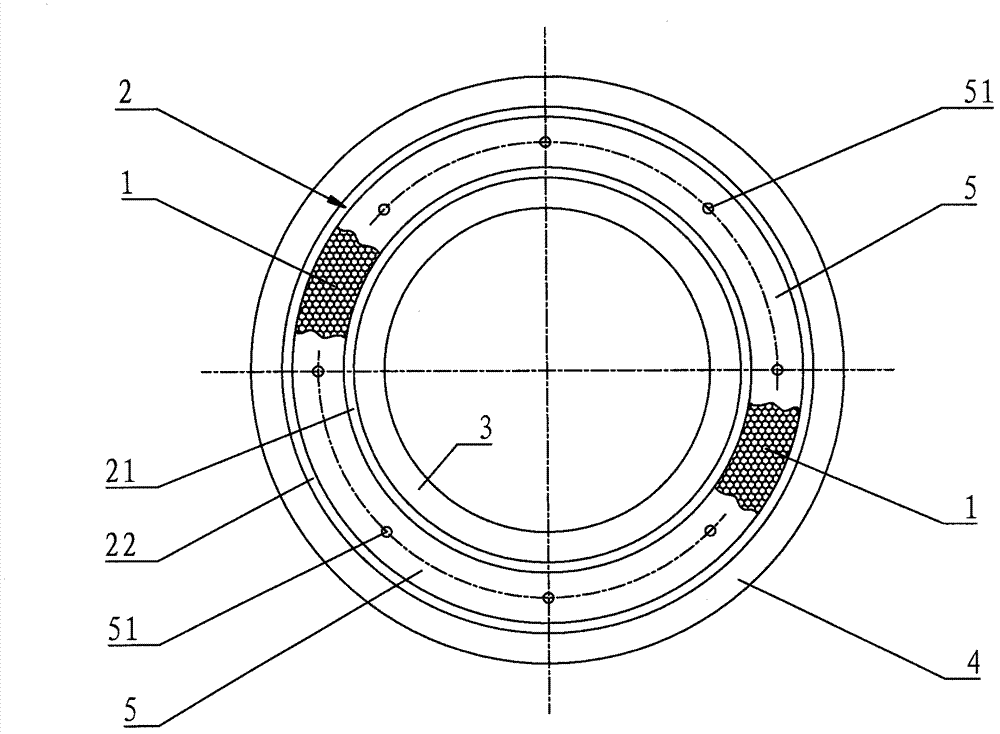

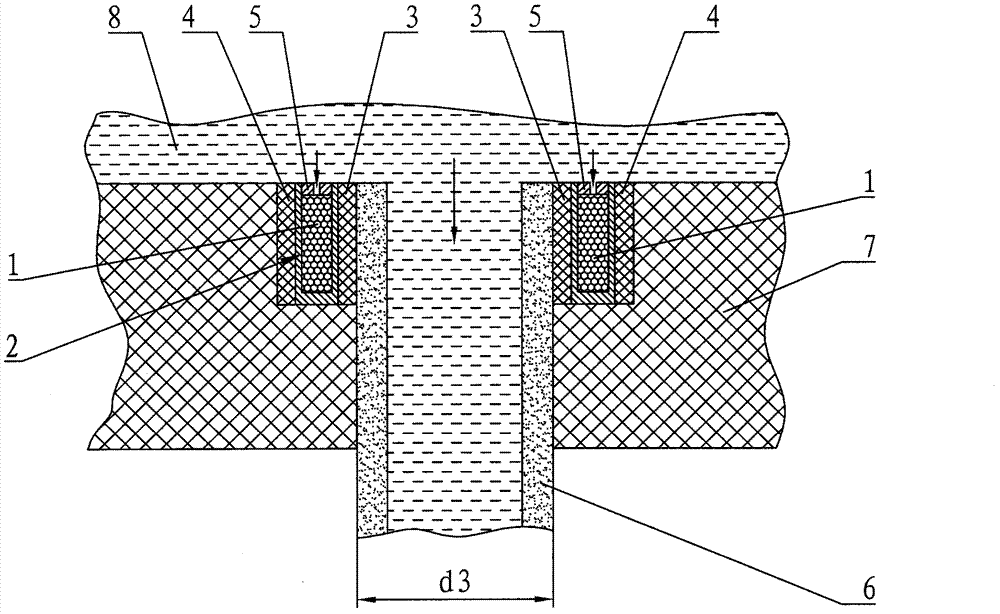

Sealing device for graphite pipe type heat exchanger tube sheet and heat exchange pipe

ActiveCN102901395ASimple structureFit tightlyHeat exhanger sealing arrangementGraphiteCoal chemical industry

The invention discloses a sealing device for a tube sheet and a heat exchange pipe of a graphite pipe type heat exchanger and aims to solve the problems that by an existing sealing device, threads on sealing holes are easy to damage, a sealing structure and a mounting process are complicated, radial gaps cannot be complemented by a sealing ring and the like. The sealing device is provided with an inner sealing ring (3), a metal casing (2) and an outer sealing ring (4) from inside to outside, the metal casing is provided with an inner side plate (21) and an outer side plate (22) from the inside to the outside. An annular bottom plate (23) is arranged at the bottoms of the inner side plate and the outer side plate, an annular cover plate (5) is arranged at the tops of the inner side plate and the outer side plate and provided with holes (51). A cavity is formed by the inner side plate, the outer side plate, the bottom plate and the cover plate, and expansion rubber (1) is arranged in the cavity and is water-absorbable or oil-absorbable rubber. The sealing device for the tube sheet and the heat exchange pipe of the graphite pipe type heat exchanger is mainly used for a graphite type heat exchanger in the petrochemical and coal chemical industries and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Light-emitting diode with electrode light emitting characteristic

ActiveCN104393138AReduce shading areaReduce light blocking areaSemiconductor devicesQuantum efficiencySoldering

Disclosed in the invention is a light-emitting diode with an electrode light emitting characteristic. A first electrode and a second electrode are form at an epitaxial light-emitting structure; and the first electrode or the second electrode is used as a soldering station electrode. A plurality of regular superfine transparent cylinders are arranged inside the first electrode or the second electrode as the soldering station electrode; and the transparent cylinders and the epitaxial light-emitting structure are connected. According to the invention, the electrode light blocking area is reduced and the external quantum efficiency of the light-emitting diode is improved.

Owner:XIAMEN CHANGELIGHT CO LTD

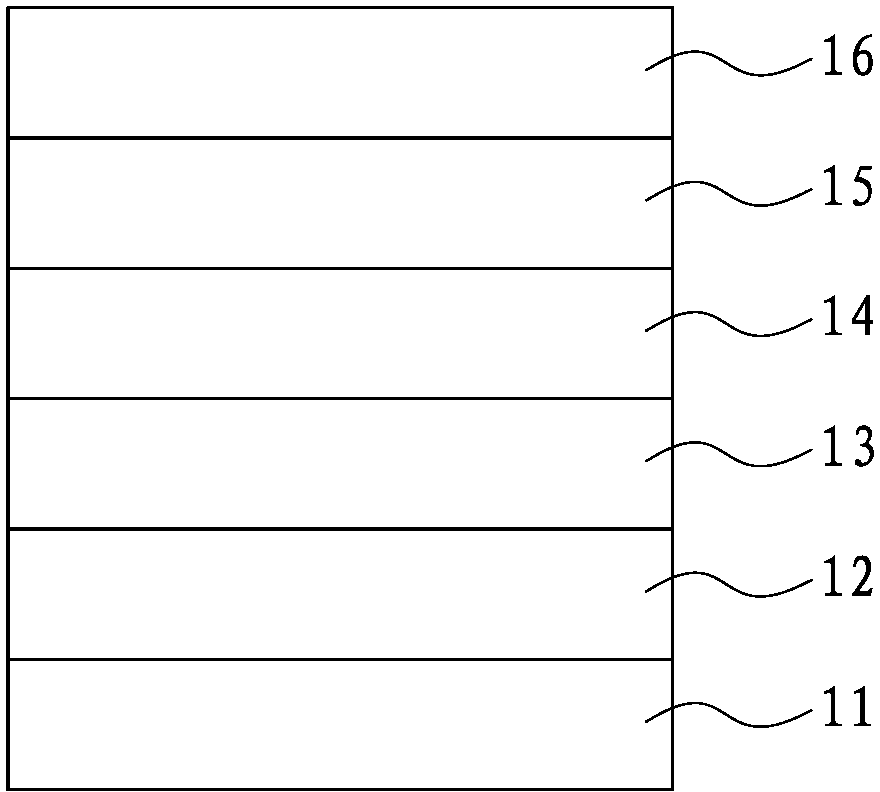

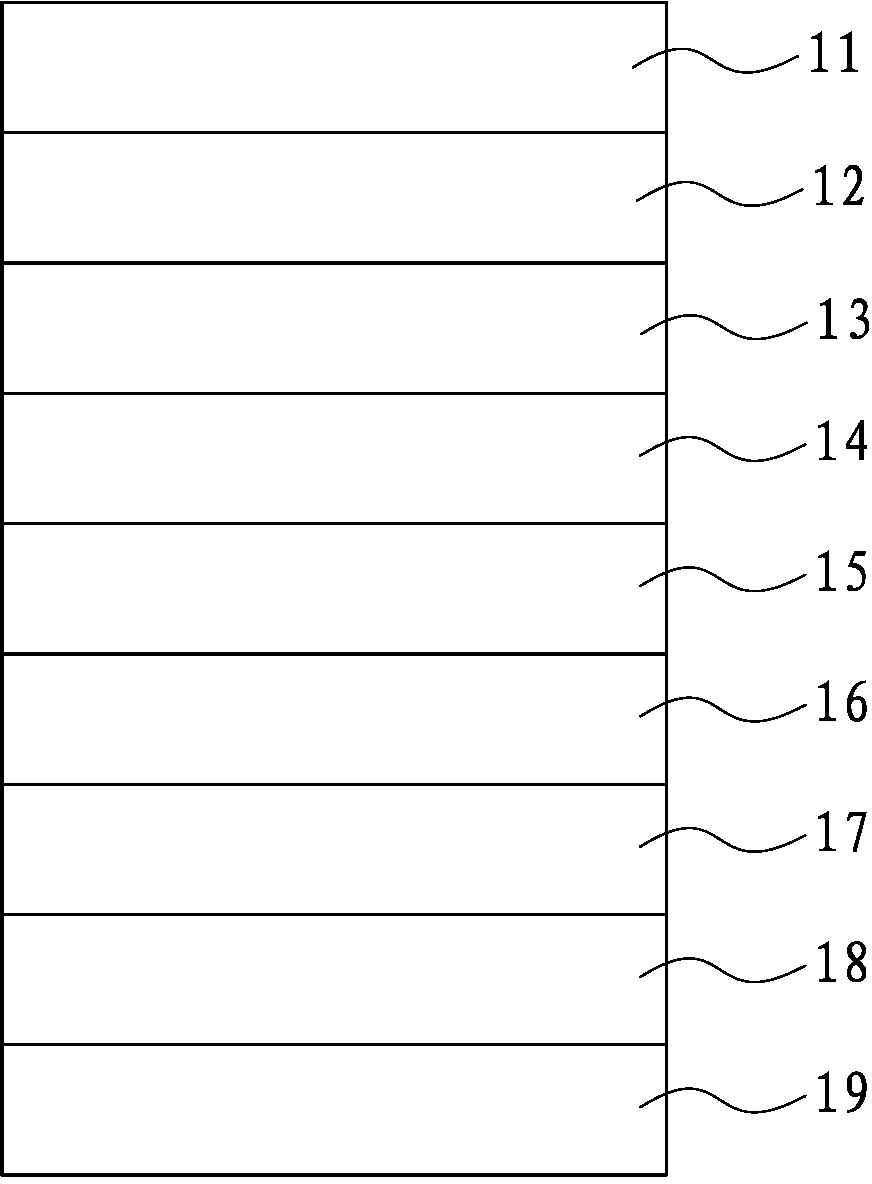

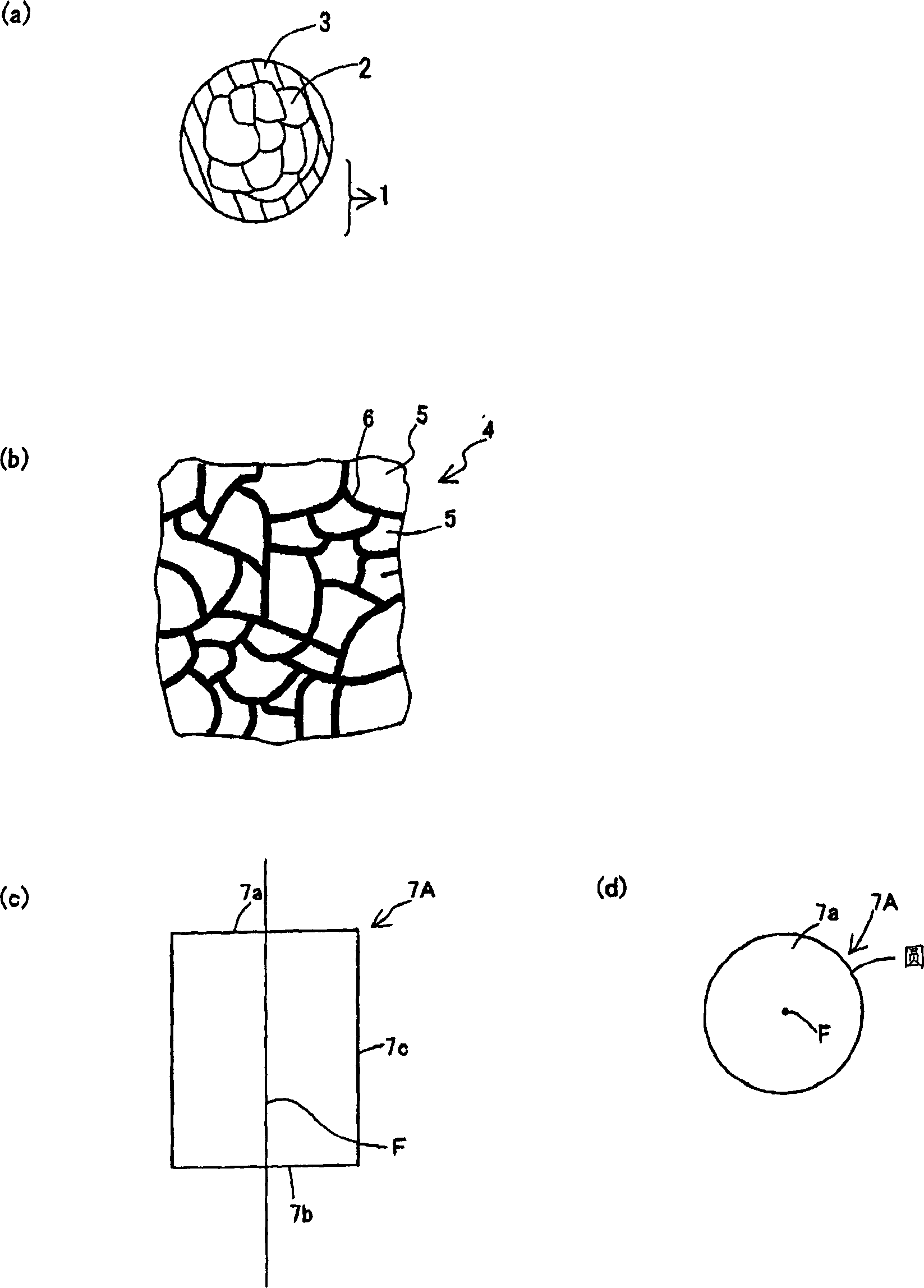

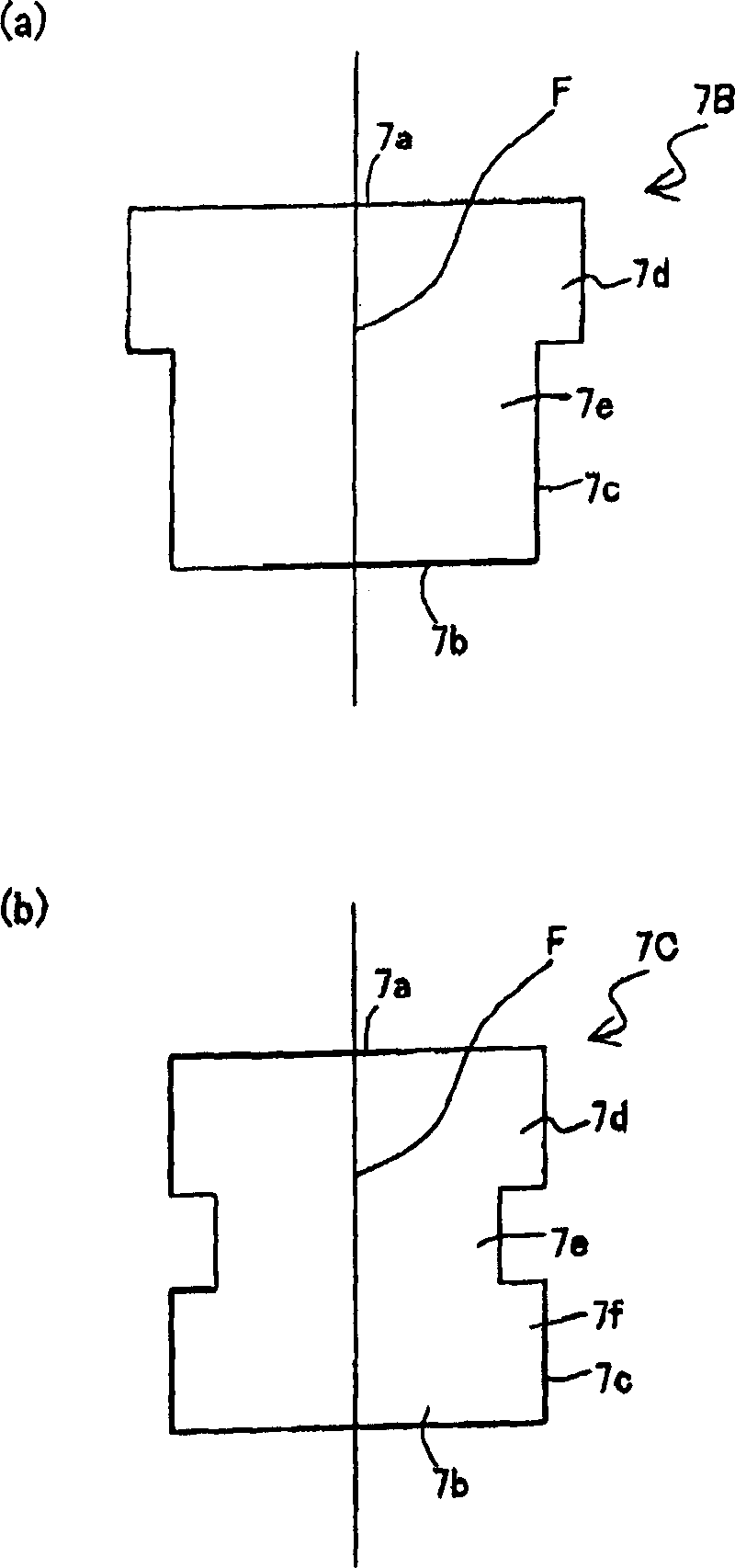

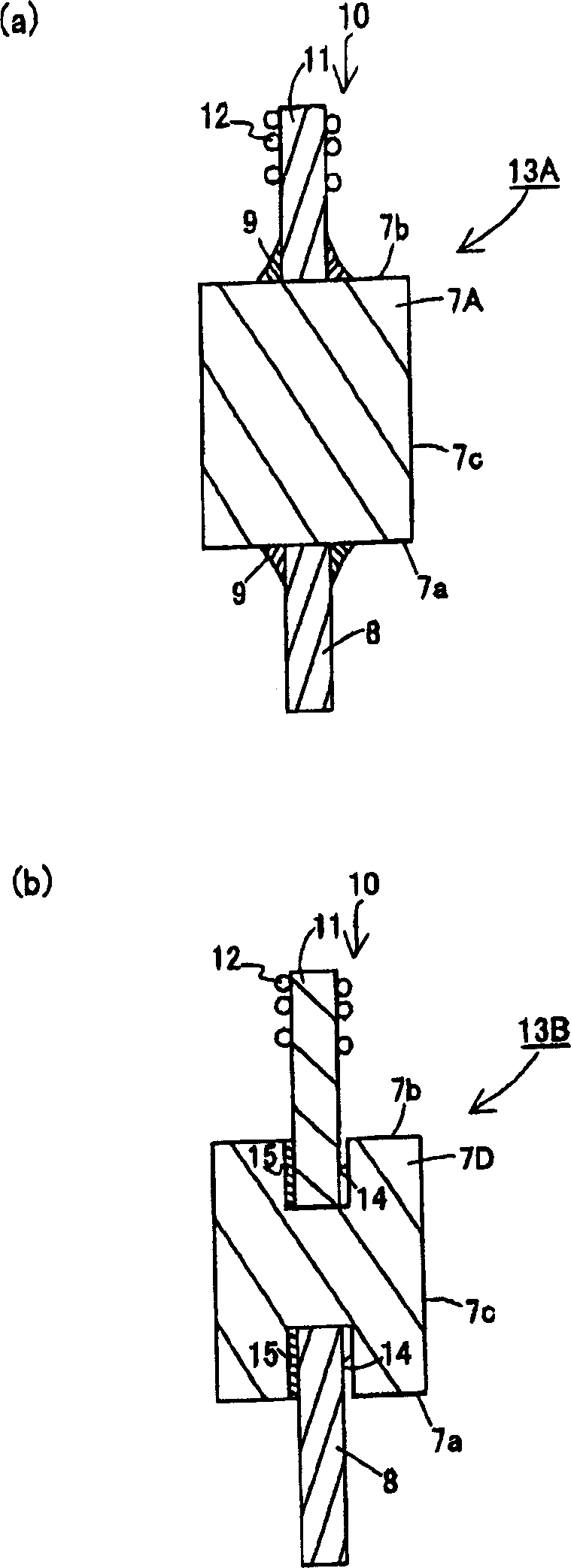

High voltage mercury lamp and sealing material for same

InactiveCN1463028AAlleviate thermal expansion coefficient differencesIncrease internal pressureElectric discharge tubesGas discharge lamp detailsStress concentrationEngineering

An object of the invention is to reduce the adverse effects due to a difference of thermal expansion between a conductive sealing member (7A) and a light-emitting vessel (16) and to provide a reliable high pressure mercury lamp, even when the lamp is operated at a high pressure. The lamp has a light-emitting vessel (16) of quartz and having end portions, an electrode member (10) contained in the vessel (16), and a conductive sealing member (7A). The sealing member (7A) is fixed in the end portion (18) and connected to the electrode member (10). The conductive member (7A) is composed of a sintered body (4) made from silica granules (1) each having a coating (3) of a metal or a metal compound. The sintered body (4) has a conductive network structure made of the metal and having a content of the metal of not higher than 20 volume percent.

Owner:NGK INSULATORS LTD

Head space sample introduction device and gas chromatograph including same

ActiveCN104583770ASimple structureNo reduction in reliabilityComponent separationWithdrawing sample devicesGas liquid chromatographicMechanics

A pressurization passage that divides a constant pressure from a pressure source with passage resistances so as to have a predetermined constant pressure is disposed on a downstream side of a sample loop in order to maintain a back pressure of the sample loop constant when a sample gas is collected to the sample loop.

Owner:SHIMADZU SEISAKUSHO LTD

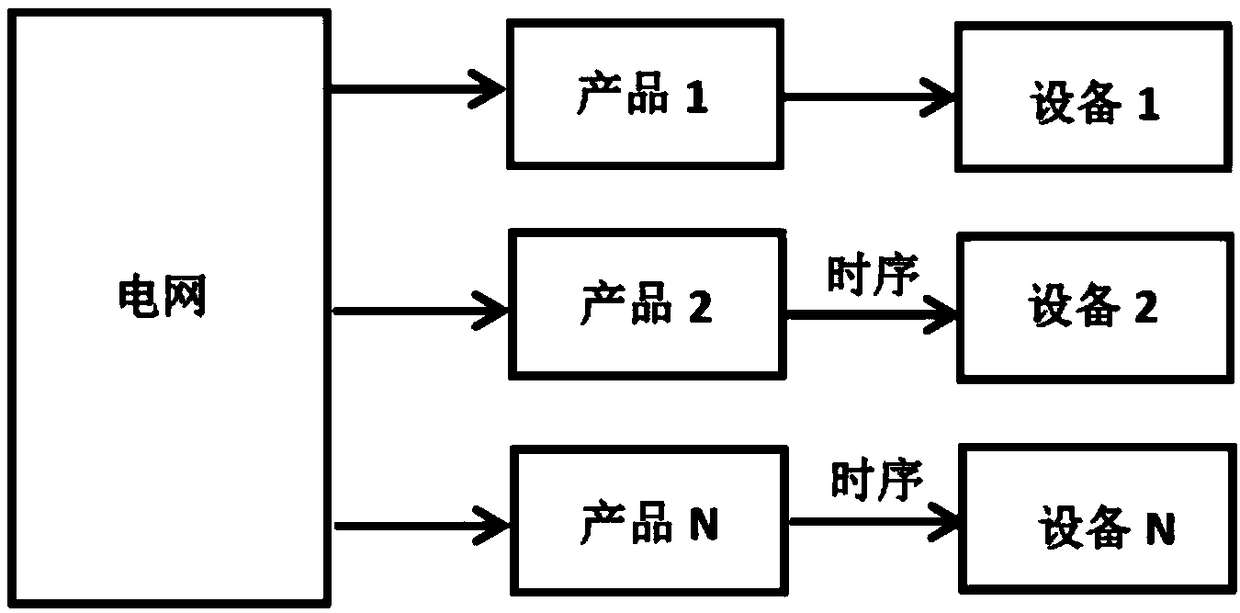

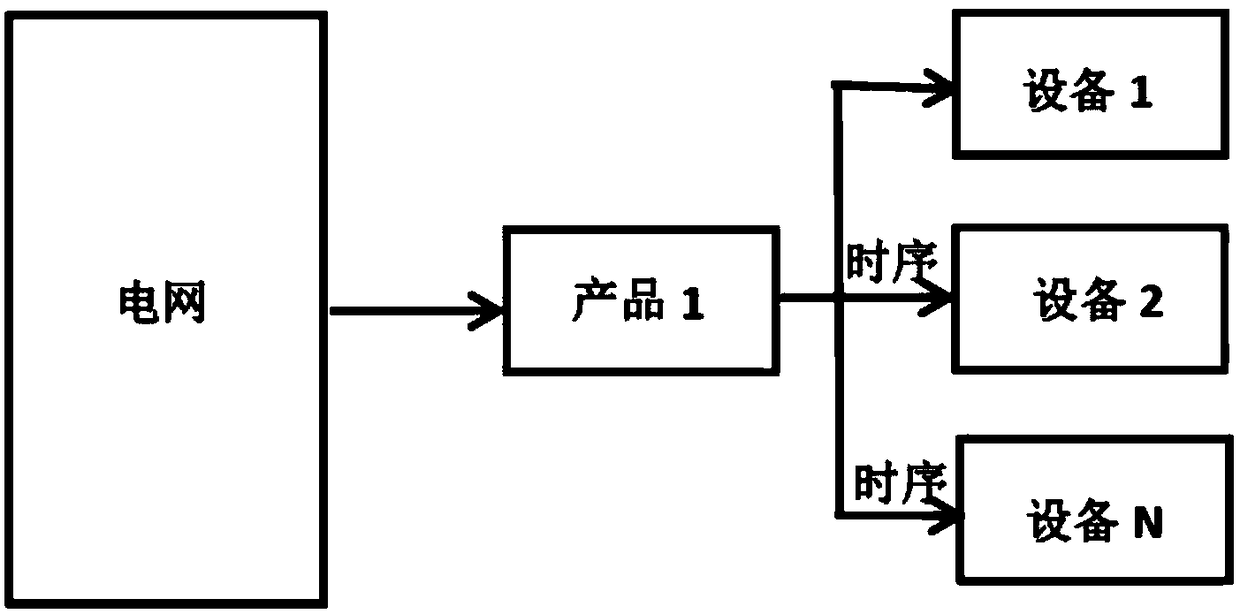

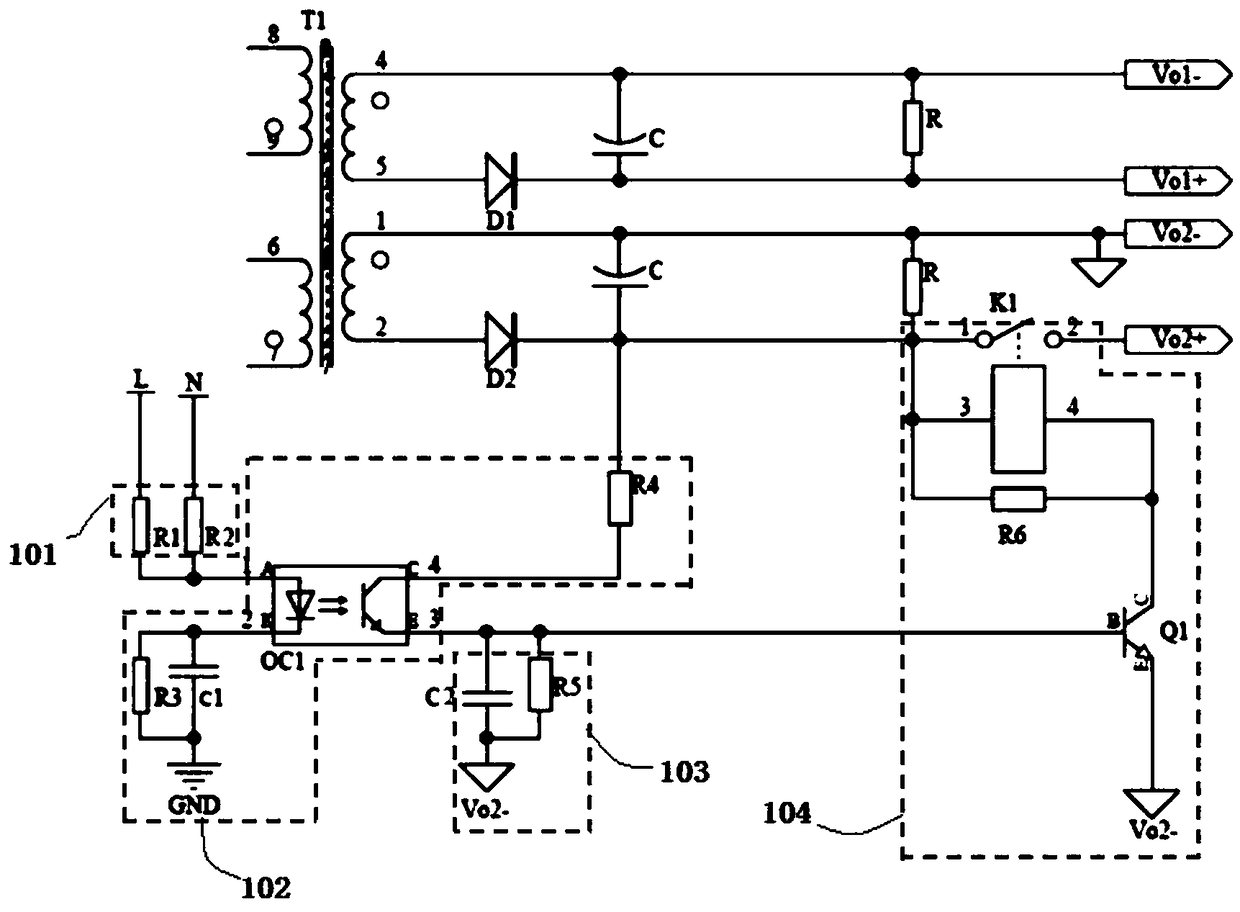

Multi-output power supply

A multi-output power supply includes at least one sequencing control circuit, multiple timing outputs can be achieved. the settling time of each output voltage is set according to the need and is usedto control the auxiliary circuit delay turn-on output of the switching power supply product, so as to solve the sequential power-down application demand of a plurality of equipment of the customer, at the same time, the cost is reduced, and the occupying space is small. When the circuit can be used in the switching power supply with more than two outputs, the effect is most obvious.

Owner:MORNSUN GUANGZHOU SCI & TECH

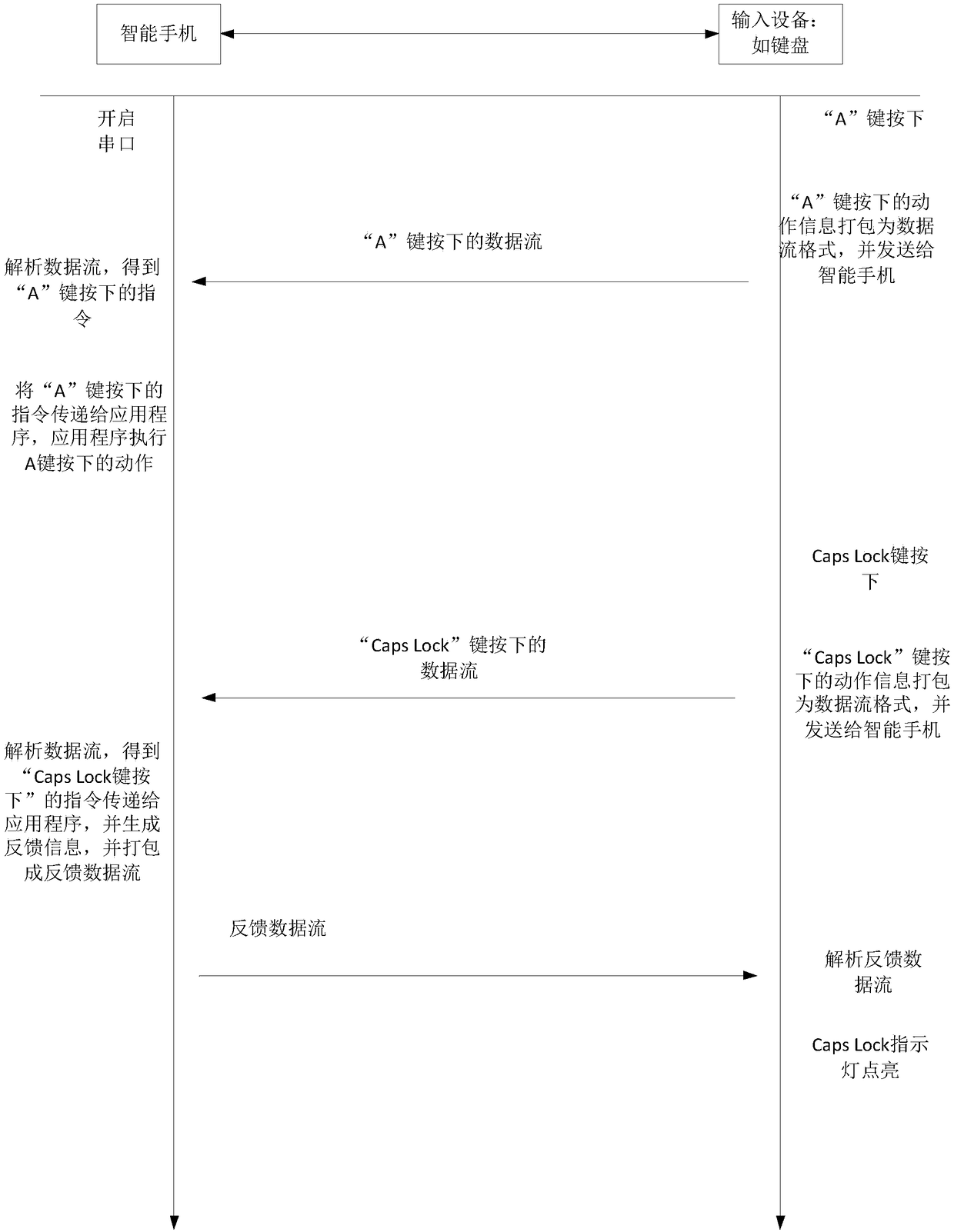

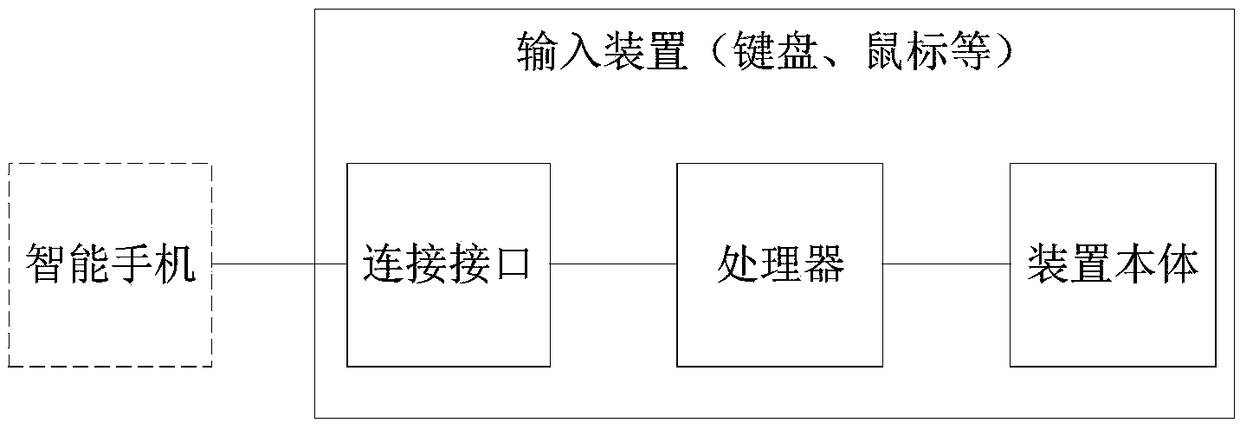

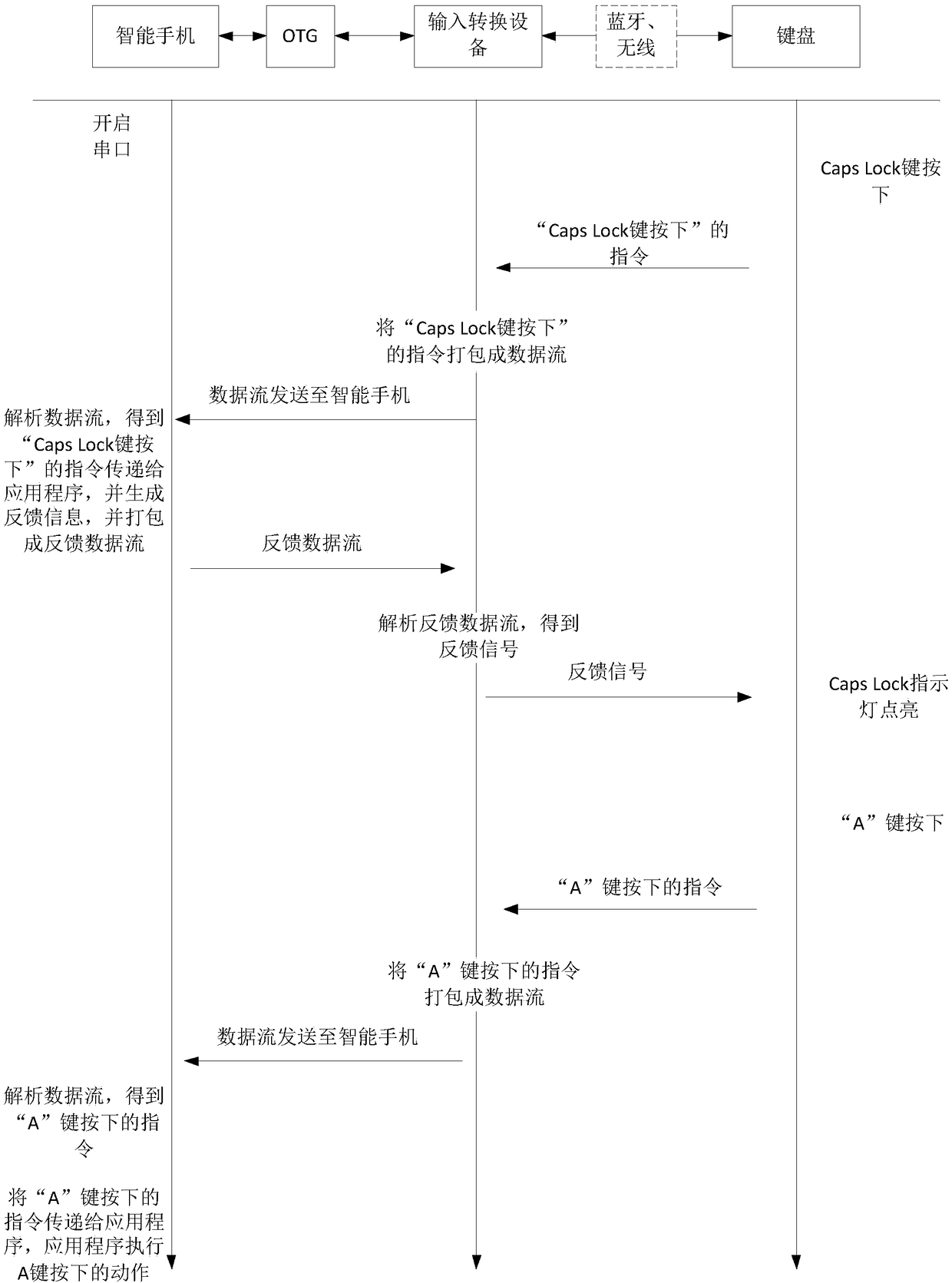

Input method, input device, readable medium and intelligent device

InactiveCN109144585AWithout compromising securityNo reduction in reliabilityBootstrappingInput controlComputer engineering

The invention discloses an input method, an input device, a readable medium and an intelligent device. The method comprises steps: analyzing the input action information by an analysis program presetin the device to obtain an action instruction; the action instruction being transmitted to a preset target application program to complete input control on the target application program. The utilitymodel has the advantages of no ROOT to the intelligent terminal, no damage to the original system of the intelligent terminal, good security, low cost, convenient use and the like.

Owner:长沙市极云网络科技有限公司

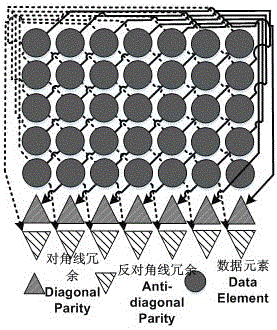

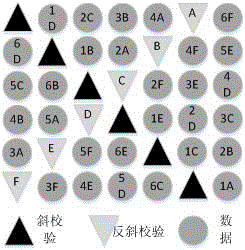

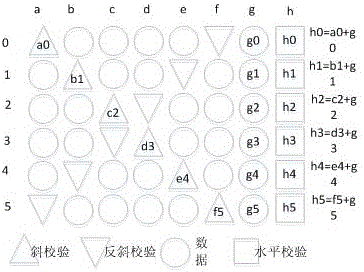

X-coding extension method capable of quickly recovering and realizing load balance

InactiveCN105824725AReduce the total number of shardsBreak the load bottleneckRedundant hardware error correctionRecovery procedureFast recovery

The invention relates to an X-coding extension method capable of quickly recovering and realizing load balance. The method comprises the following steps: performing coding extension based on X-coding used in various storage array systems, additionally arranging redundancy equipment, further reducing the total quantity of blocks required for single disk recovery on the premise of ensuring that double-disk error is allowed and reducing the IO bottleneck of the single disk recovery, thereby improving the system single disk recovery efficiency, shortening the reconstruction time, realizing the system load balance and finally realizing the improvement of system service quality. With respective to any single data disk error in an original system, the total quantity of fragment required for system single disk recovery can be reduced; with respective to any single disc error in the original system, the possible load bottleneck of the original system in the single disk recovery process can be eliminated, so that the load balance of the equipment is realized; by using binary AND-XOR, the update overhead of an additionally-arranged redundant disk is reduced, so that the service life of the redundant disk is prolonged.

Owner:NAT UNIV OF DEFENSE TECH

A testability design method for wireless communication equipment

ActiveCN105553754BAchieve technical effectImprove ObservabilityData switching networksEngineeringRadio frequency

The invention discloses a wireless communication device testability design method. The method includes performing functional unit division on a wireless communication device, including a voice and panel unit, a processor unit, a baseband signal processing unit, a radio frequency unit, a power amplifier unit, a filter unit and a backboard unit, wherein the voice and panel unit, the baseband signal processing unit, the radio frequency unit, the power amplifier unit and the filter unit are connected with the processor unit through respective control interfaces and data communication interfaces via the backboard unit, and the voice and panel unit provides a device internal unit program upgrade interface and maintenance interface to the outside. Main faults of each unit are automatically diagnosed when the device is powered on, a test command is input through the maintenance interface when a fault occurs, a test signal passes through each unit inside and realizes loopback gradually, and the faults of each unit are diagnosed automatically. The wireless communication device testability design method has the beneficial effects of utilizing hardware resources of the device itself, increasing test software to realize testability design of the device itself, accurately positioning the faults inside the device, and greatly reducing debugging and testing and maintenance guarantee cost of the device.

Owner:CHONGQING JINMEI COMM

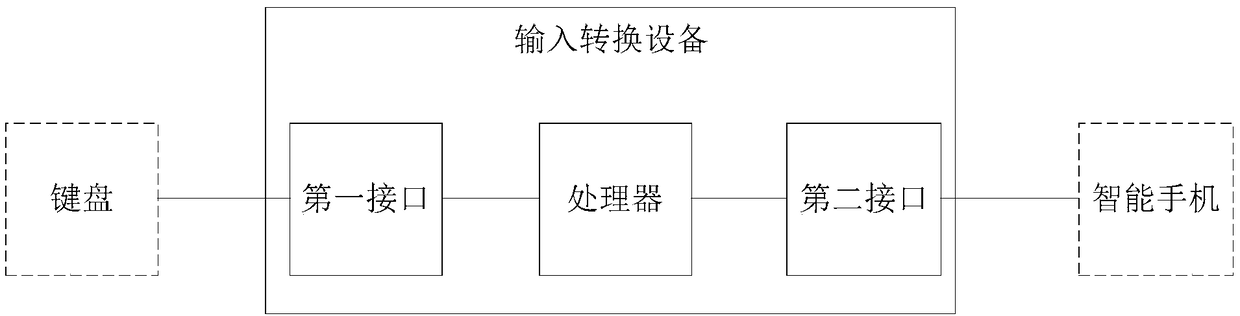

Exclusive input method, input conversion device, input device and intelligent terminal

PendingCN109086227AWithout compromising securityNo reduction in reliabilityInput/output processes for data processingData streamInput reduction

The invention discloses an exclusive input method, an input conversion device, an input device and an intelligent terminal, wherein the input method comprises: receiving an input instruction of the input device, packaging the input instruction into an input data stream, and sending the input data stream to a first device. The input method further comprises the following steps: the first device receives the input data stream, parses the input data stream to obtain a second input instruction, transfers the second input instruction to an application program, and completes the input of the application program. The utility model has the advantages of no ROOT to the intelligent terminal, no damage to the original system of the intelligent terminal, good security, low cost, convenient use and thelike.

Owner:长沙市极云网络科技有限公司

Altitude measurement control system and control method for unmanned aerial vehicles based on fault-tolerant processing

ActiveCN106681336BNo reduction in reliabilityAchieve reliabilityNavigation by speed/acceleration measurementsHeight/levelling measurementFault toleranceControl system

The invention discloses an unmanned-aerial-vehicle height measurement control system based on fault-tolerance processing and a control method. The unmanned-aerial-vehicle height measurement control system comprises a height meter module, a satellite navigation module, an inertial measurement module and a computing and processing module. The height meter module is used for measuring the distance of an unmanned aerial vehicle to the ground in real time; the satellite navigation module is used for receiving and processing satellite signals in real time and measuring the flight position and the direction of the unmanned aerial vehicle; the inertial measurement module is used for measuring the attitude angular velocity and the accelerated velocity of the unmanned aerial vehicle in real time; the computing and processing module is used for receiving data of the height meter module, the satellite navigation module and the inertial measurement module in a parallel mode and computing and obtaining height measurement data. By means of the unmanned-aerial-vehicle height measurement control system based on fault-tolerance processing and the control method thereof, the conditions of the fault of a height meter or the fault of satellite navigation or the faults of a height meter and satellite navigation can be synthetically processed, and the high stability of the unmanned aerial vehicle is guaranteed through the control system to a maximum limit.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

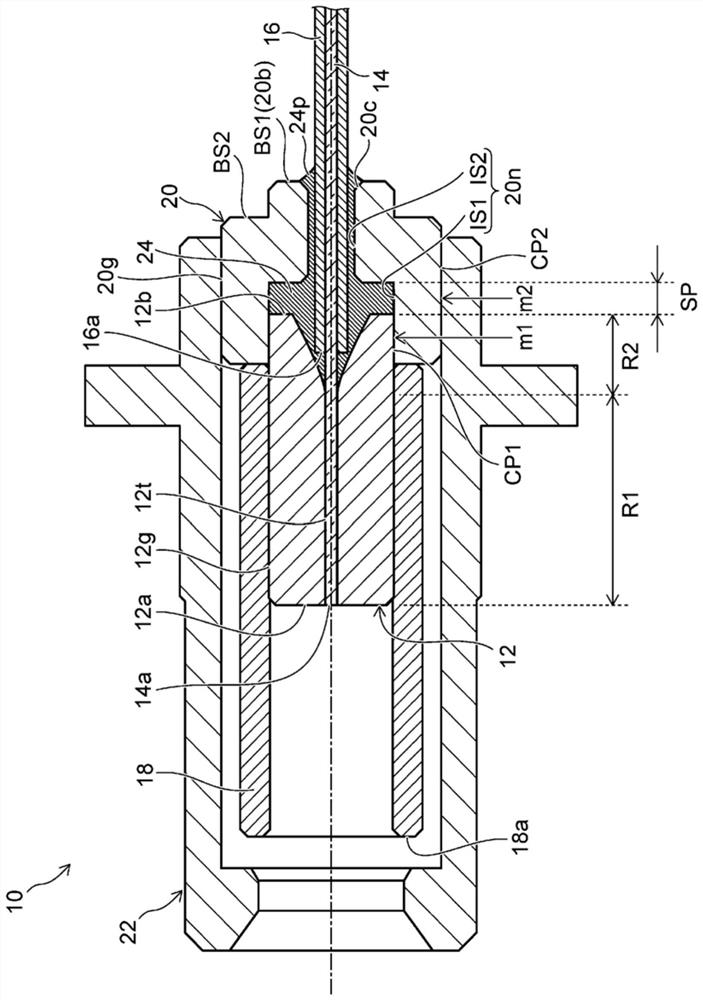

Pigtail-type optical receptacle

A pigtail-type optical receptacle is provided and includes a tubular ferrule having a through-hole extending in an axial direction, an optical fiber inserted into the through-hole such that part of the optical fiber extends outside the ferrule, a protective member covering the part of the optical fiber extending outside the ferrule, a tubular sleeve mounted on a front end side, outer surface of the ferrule, a holder tubular having holding the rear end side of the ferrule, and a tubular housing covering the ferrule and at least a portion of the sleeve. The ferrule through-hole includes first and second regions, the second region being disposed rearward of the first region, and the housing engaging the outer surface of the holder rearward of the first region. As a result, the pigtail-type optical receptacle that can be reduced in size without deteriorating reliability is provided.

Owner:奥比睿株式会社

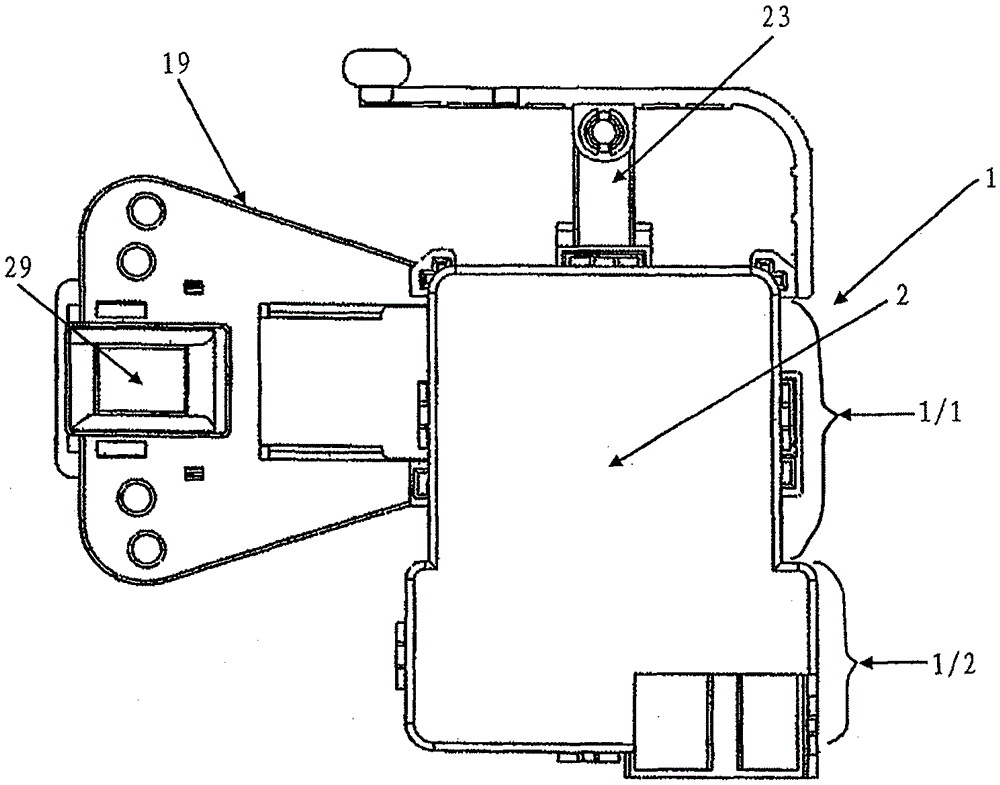

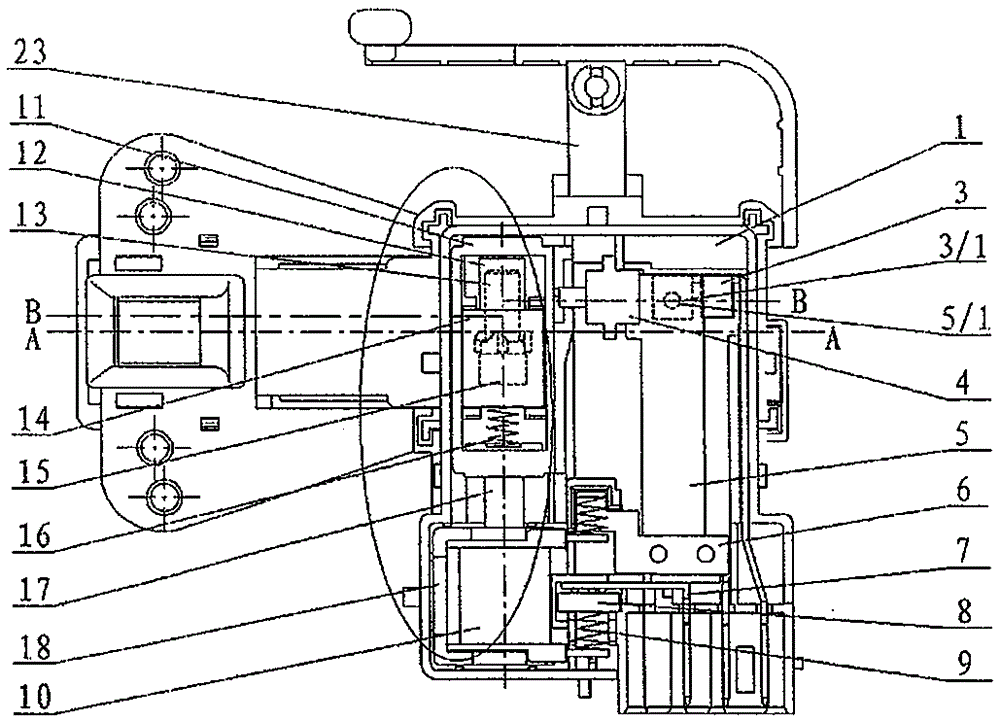

Electromagnetic door locks for electrical equipment

InactiveCN102677983BReduce in quantityCost will not decreaseNon-mechanical controlsElectromagnetic lockEngineering

Owner:ILLINOIS TOOL WORKS INC

Semiconductor luminescent device

InactiveCN1306626CNo reduction in reliabilityHeat transferSolid-state devicesSemiconductor devicesLead frameLight emitting device

A semiconductor light emitting device includes an LED chip (4), a first lead frame (1) on which the LED chip (4) is mounted, a second lead frame (2) electrically connected to the LED chip (4) via a bonding wire (5), and a resin portion (3) surrounding the circumference of the LED chip (4), and fastening the first and second lead frames (1, 2). A metal body (8) is located under the region of the first lead frame (1) where the LED chip (4) is mounted.

Owner:SHARP KK

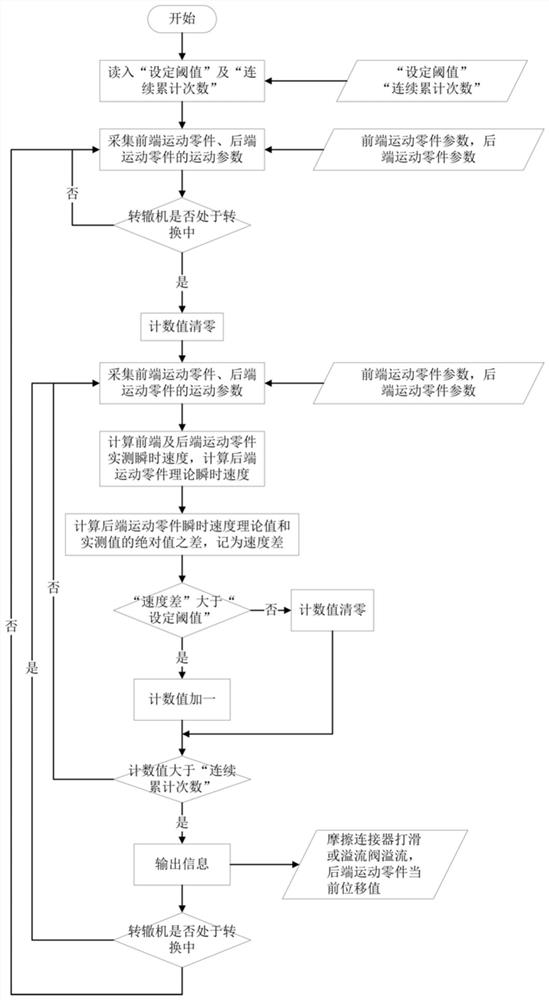

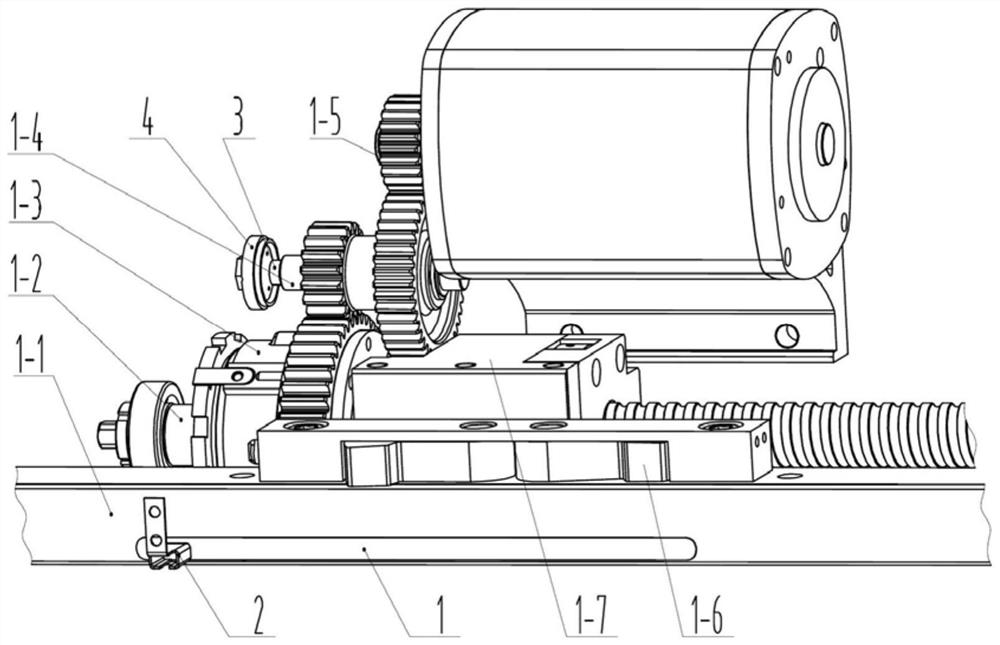

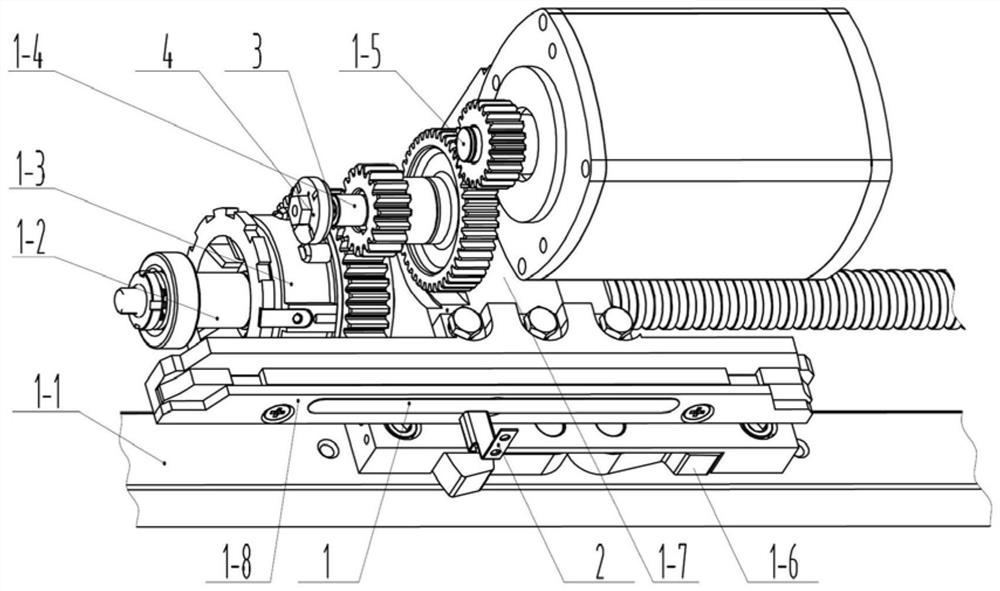

A detection method for the slipping of the friction coupling of the switch machine or the overflow of the relief valve

ActiveCN113447291BConversion has no effectNo reduction in reliabilityMachine valve testingCurrent loadCoupling

The invention belongs to the monitoring and measuring method of turnout switching equipment in the field of rail transit, and is a monitoring device and method for whether the maximum output force of a turnout switch machine (hereinafter referred to as a switch machine) matches the current load. The detection method of friction coupling slipping or overflow valve overflow of the rat machine, which monitors the linear moving parts and rotating moving parts through a non-contact method, and according to the influence of the friction coupling slipping or overflow valve overflow on the back-end moving parts, to Judging whether the maximum output force of the switch machine is too small compared with the current load, guide the maintenance personnel to adjust and maintain the switch machine in time, and prevent the occurrence of jamming faults in the switch conversion. The non-contact monitoring method has no effect on the conversion of the switch machine and will not The reliability of the switch machine is reduced due to the failure of the switch machine due to the installation of the sensor.

Owner:XIAN RAILWAY SIGNAL

Method for manufacturing light-emitting diode emitting light through electrode

ActiveCN104377288AReduce shading areaReduce light blocking areaSemiconductor devicesQuantum efficiencyEtching

The invention discloses a method for manufacturing a light-emitting diode emitting light through an electrode. According to the method, an epitaxy light-emitting structure is formed on an epitaxy of an epitaxy substrate, and a light-pervious channel manufacturing layer is formed on the epitaxy light-emitting structure; a plurality of regular light-pervious channels are formed in an electrode area of the light-pervious channel manufacturing layer by means of a mask and an ICP etching process, and the depth of the portion, undergoing ICP etching, of an electrode area allows the surface of the epitaxy light-emitting structure to be exposed; light-pervious materials are evaporated on the surface of the exposed surface of the epitaxy light-emitting structure until the light-pervious channels are filled with the materials and a light-pervious column is formed; the light-pervious channel manufacturing layer is corroded and removed, the light-pervious column is retained and the epitaxy light-emitting structure is exposed; a soldering station electrode is formed on the surface of the epitaxy light-emitting structure, and the thickness of the solder station electrode is larger than the height of the light-pervious column; the surface of a first electrode or a second electrode which serves as the soldering station electrode is under ICP etching until the upper surface of the light-pervious column is exposed; a back electrode is formed on the epitaxy light-emitting structure, and a light-emitting diode chip is formed on a split sheet. The light blocking area of the soldering station electrode can be reduced, and external quantum efficiency of the light-emitting diode can be improved.

Owner:XIAMEN CHANGELIGHT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com