Pigtail-type optical receptacle

A fiber optic connector, line type technology, applied in optics, light guides, optical components, etc., can solve problems such as space enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

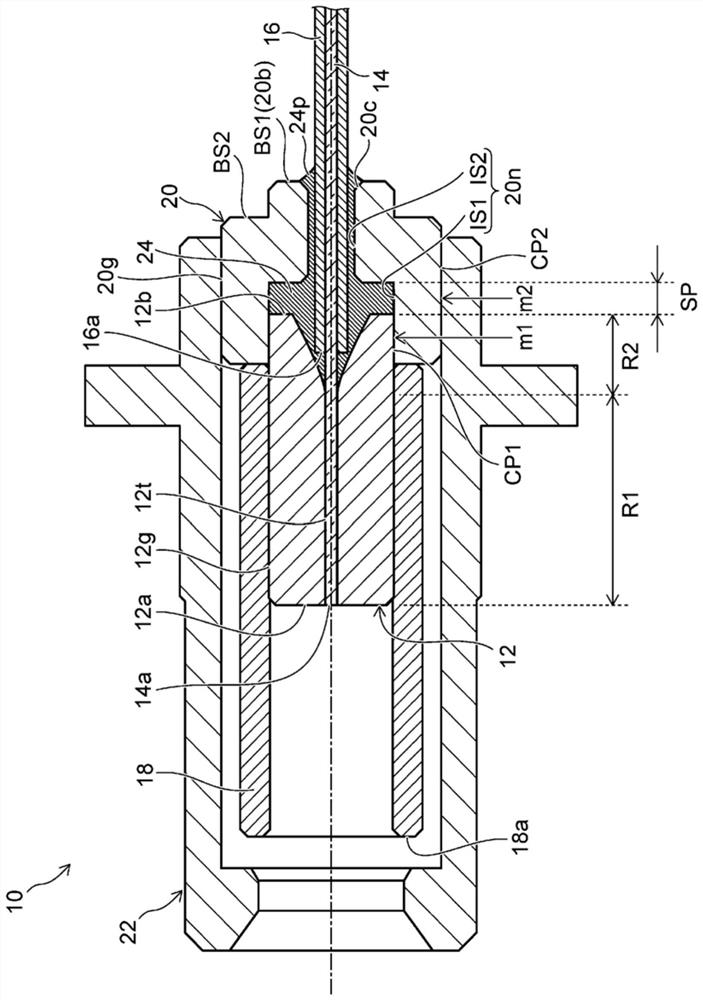

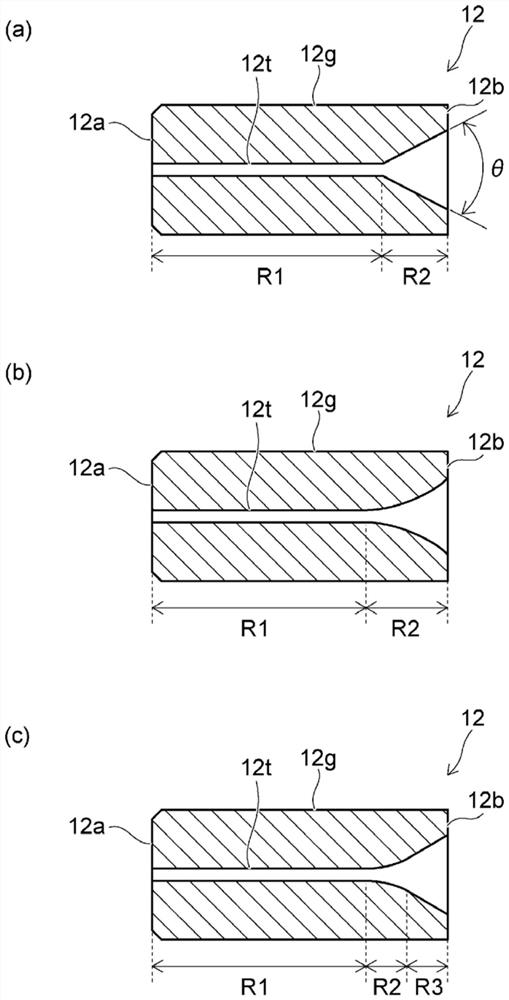

[0096] figure 1 It is a sectional view showing the pigtail type optical fiber connector according to the first embodiment.

[0097] Such as figure 1 As shown, a pigtail type optical fiber connector (hereinafter referred to as an optical fiber connector) 10 includes a ferrule 12 , an optical fiber 14 , a protective member 16 , a sleeve 18 , a holder 20 , and an accommodating portion 22 .

[0098] The sleeve 12 has a cylindrical shape having a through-hole 12t extending in the axial direction. The through hole 12t passes through between the top end 12a and the rear end 12b of the sleeve 12 in a straight line. The optical fiber 14 extends laterally from the rear end 12 b of the ferrule 12 to the outside of the ferrule 12 while being held by the ferrule 12 while being inserted into the through hole 12 t . In other words, ferrule 12 holds one end of optical fiber 14 .

[0099] The optical fiber 14 is inserted into substantially the entirety of the through hole 12t. The tip 14a...

no. 2 Embodiment approach

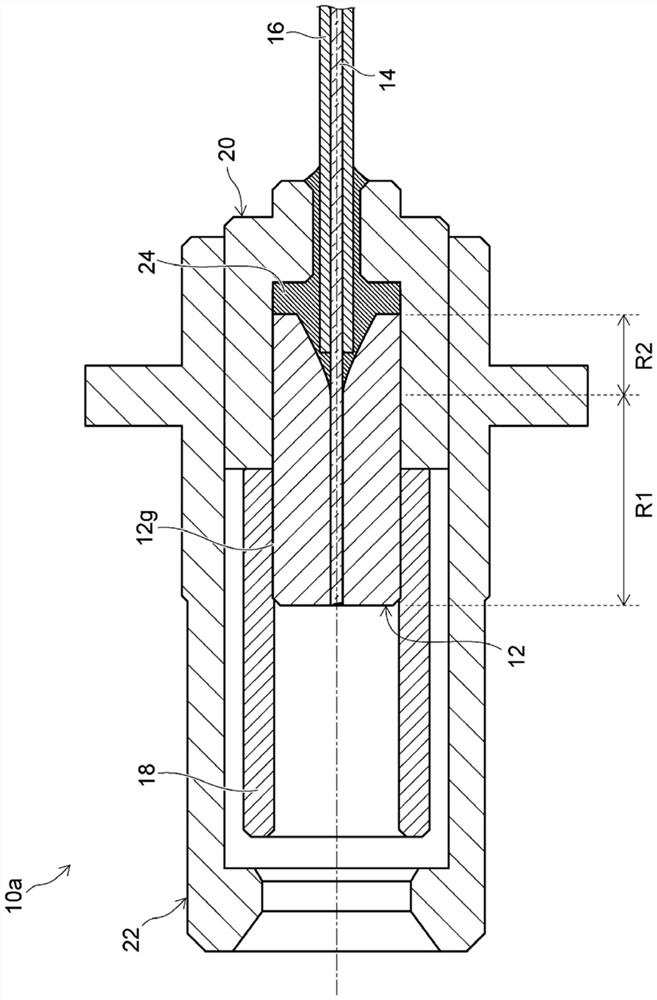

[0162] Figure 5 It is a sectional view showing a pigtail type optical fiber connector according to the second embodiment.

[0163] Such as Figure 5 As shown, in the optical fiber connector 100, the outer surface 120g of the holder 120 has a first outer peripheral portion OS1 and a second outer peripheral portion OS2.

[0164] The first outer peripheral portion OS1 is held by the housing portion 22 . The outer diameter of the first outer peripheral portion OS1 of the holder 120 is substantially the same as the inner diameter of the housing portion 22 . For example, the holder 120 is held by the accommodating portion 22 by press-fitting a portion of the first outer peripheral portion OS1 into the accommodating portion 22 .

[0165] The second outer peripheral portion OS2 is provided at the distal end portion of the holder 120 . The second outer peripheral portion OS2 is provided, for example, in front of the first outer peripheral portion OS1 , continues to the first outer...

no. 3 Embodiment approach

[0184] Figure 9 It is a cross-sectional view showing a pigtail type optical fiber connector according to the third embodiment.

[0185] Such as Figure 9 As shown, in the optical fiber connector 200 , the receiving portion 222 is mounted on the tip side of the holder 220 .

[0186] The holder 220 has a mounting portion 220 a for mounting the receiving portion 222 . The mounting portion 220 a is provided at the top end portion of the holder 220 . The receiving portion 222 has a mounted portion 222 a attached to the mounting portion 220 a of the receiving portion 222 . The mounted portion 222 a is provided at the rear end portion of the housing portion 222 . The mounting part 220a and the mounted part 222a are cylindrical. The mounted portion 222a is fitted on the outside of the mounting portion 220a. Thus, the receiving portion 222 is attached to the distal end side of the holder 220 .

[0187] The holder 220 has a flange portion 220f. The flange portion 220f is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com