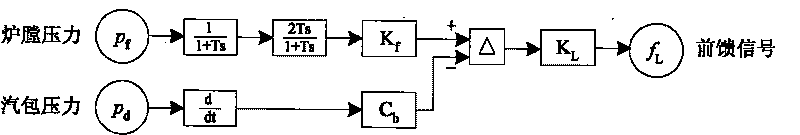

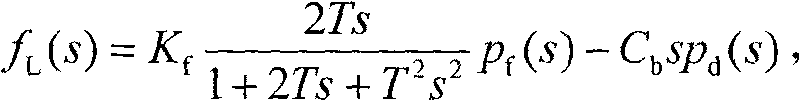

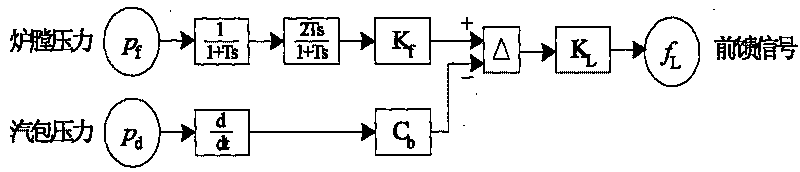

Feedforward signal of drum water level control system of drum boiler

A drum water level and feedforward signal technology, applied in the field of control, can solve problems such as complex algorithms, difficult practical implementation, and difficult debugging, and achieve the effects of improving control quality, easy debugging, and overcoming negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention takes the actual application in a utility boiler as an example to illustrate the specific implementation steps. The whole scheme is divided into 5 steps to implement, and finally put into operation after configuration and debugging in the unit DCS (distributed control system).

[0026] 1. Original signal confirmation

[0027] It is necessary to confirm the furnace pressure p f (Pa), drum pressure p d (MPa), boiler fuel volume r b (kg / s), unit load N E (MW) accuracy. Among them, p f and p d For constructing feed-forward signals, large boilers are equipped with multiple p f and p d Measuring point, design two-choice average or three-choice logic for multiple measured values, in order to improve reliability, p f and p d It is necessary to take the signal of the two-choice average or three-choice logic output. r b and N E It is used to obtain the gain coefficient and filter coefficient when constructing the feedforward signal, N E With hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com