Patents

Literature

35 results about "Solder station" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

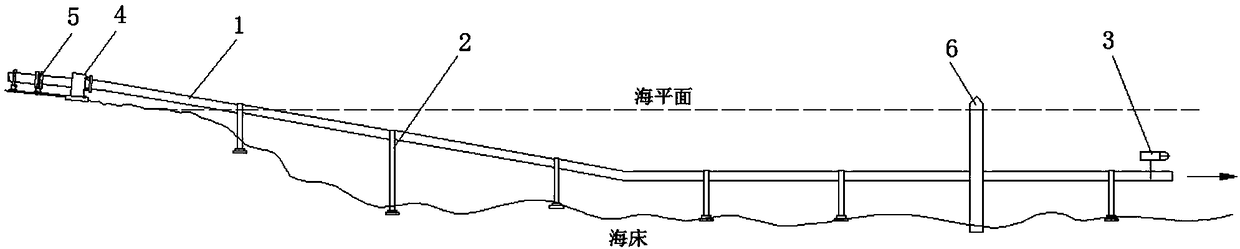

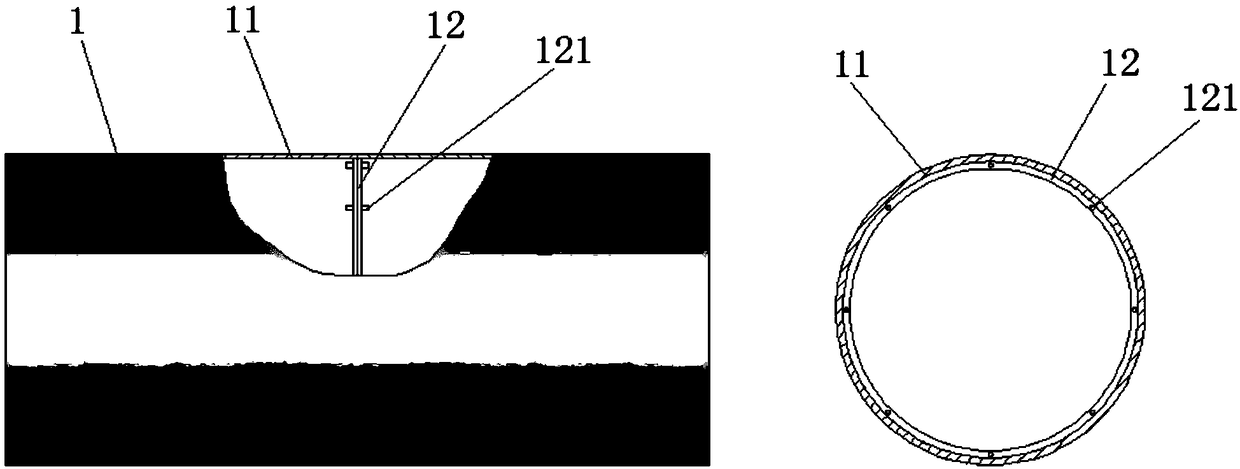

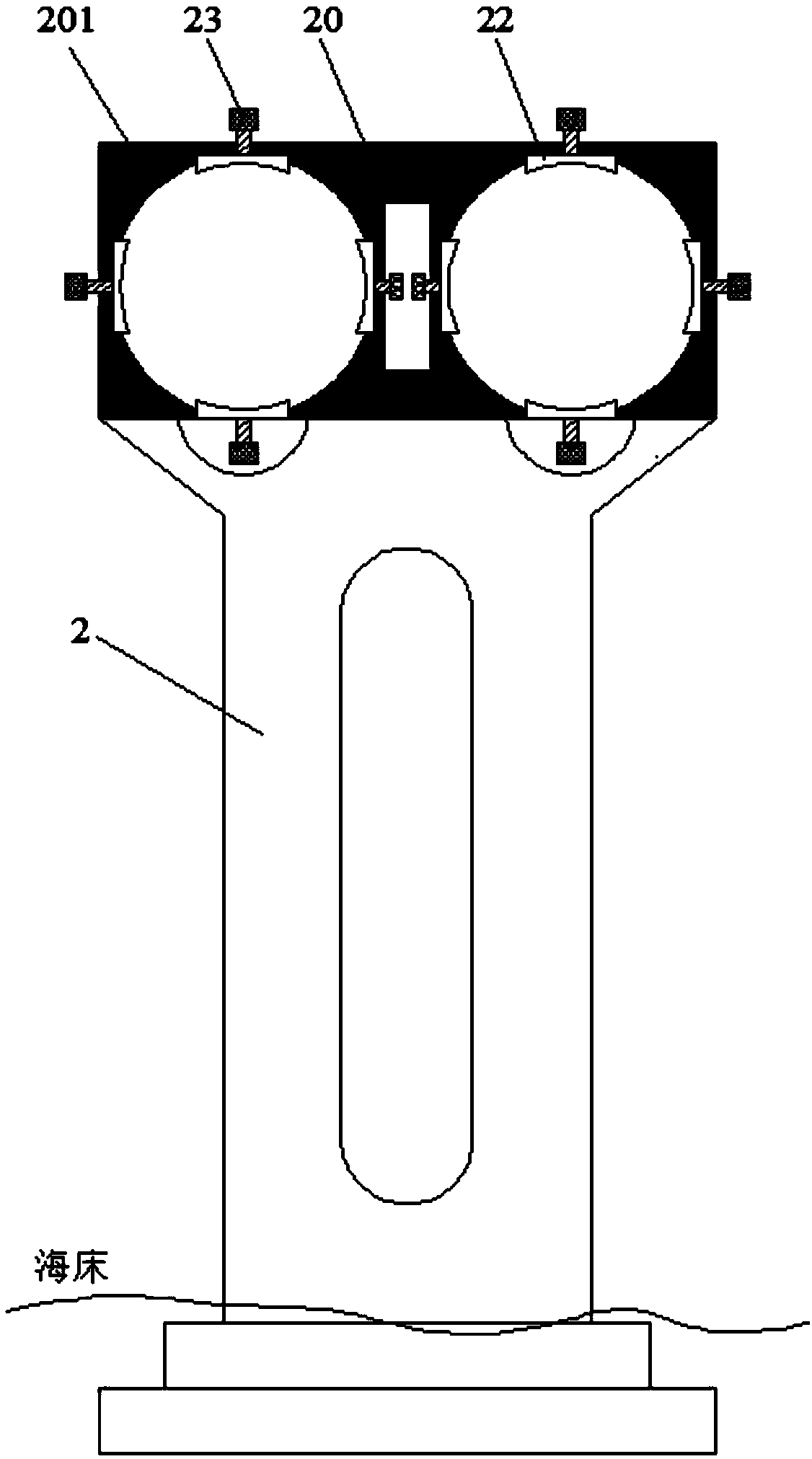

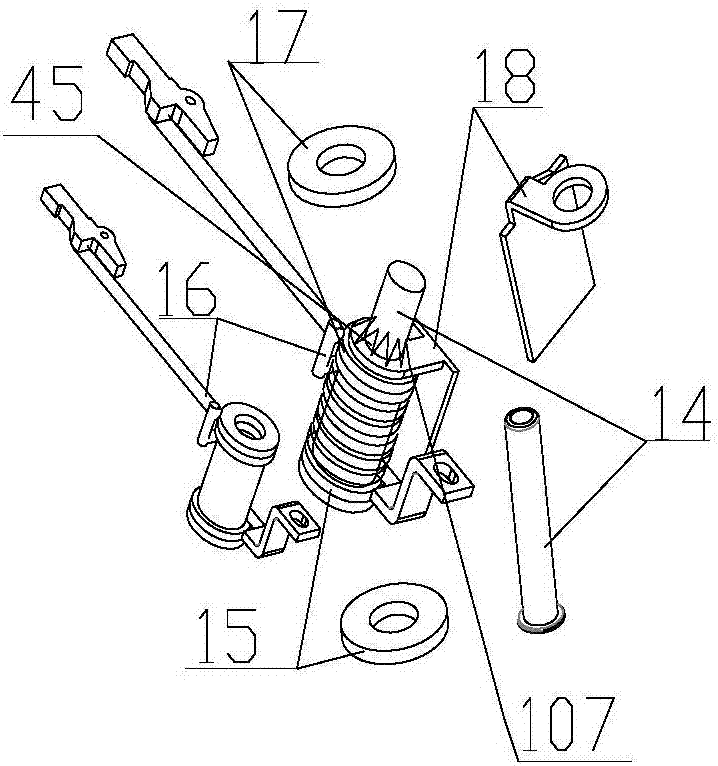

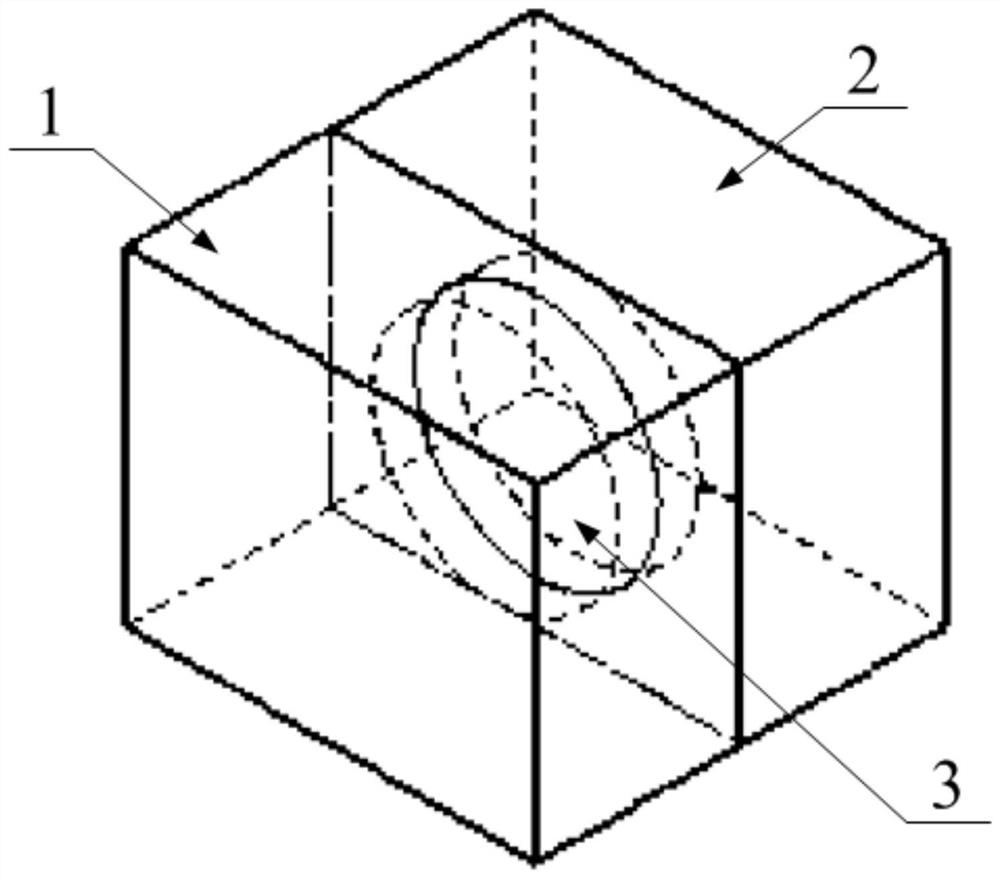

Seafloor vacuum pipeline traffic system and pushing type laying method thereof

ActiveCN109334683AReduce construction costsEasy to layArtificial islandsRailway tunnelsOcean bottomEngineering

The invention discloses a seafloor vacuum pipeline traffic system and a pushing type laying method thereof. The system comprises piers built on a seafloor, a pipeline is erected on the piers, the rearend of the pipeline is cooperatively connected with a pushing device and a welding platform, and welded pipelines are pushed to be extended forwards and laid section by section through the pushing device when construction is conducted; the middle of the seafloor vacuum pipeline is provided with a relay pushing station, the pipeline penetrates through the relay pushing station, the relay pushing station is arranged in an artificial island tower, and the front end of the first section pipeline is provided with a positioning guiding diving instrument; the method comprises the steps that a sealing plug is used for sealing a first section pipeline head to be placed into a pushing platform, the pipeline is tightly clamped by a pushing pipe clamp, and another section pipeline is welded to the welding platform; a pushing rod is started, and the pushing pipe clamp and the pipeline enter the sea and are moved forwards constantly until the shore at the other end of the sea is reached. The systemhas the advantages that it is ensured that there exists no bending in the laying process of the pipeline, the system is rapid, efficient and safe, and the engineering cost is low.

Owner:XIJING UNIV

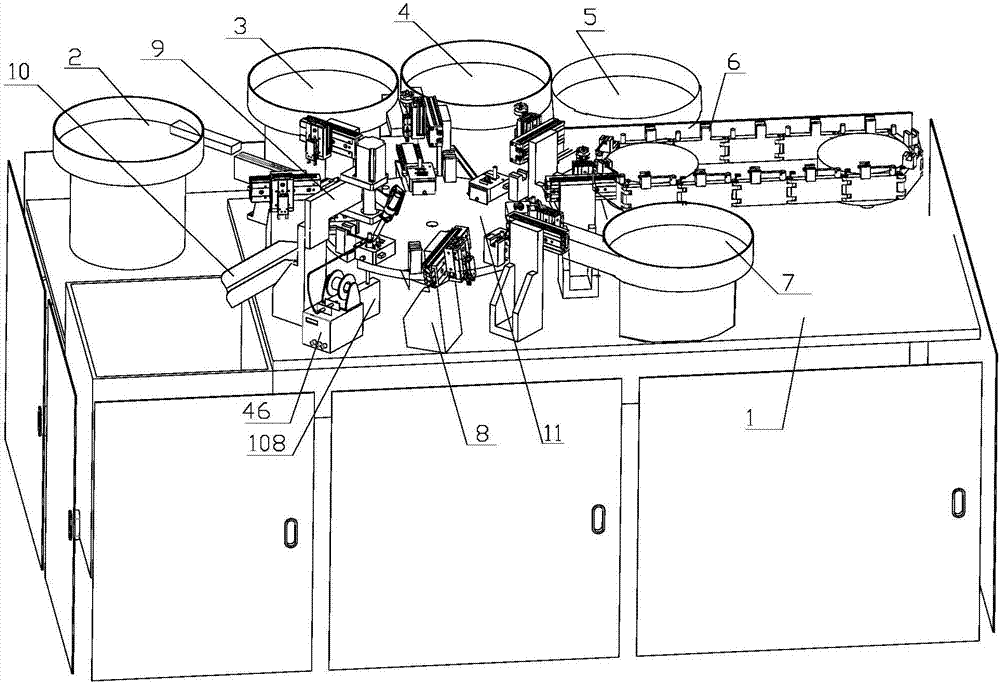

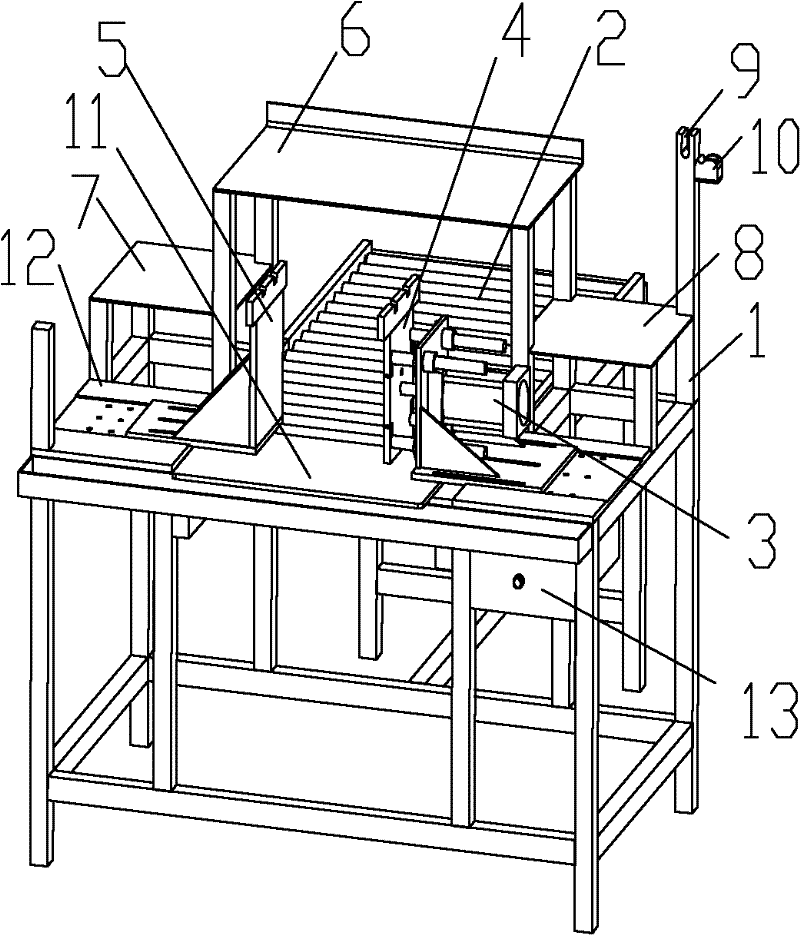

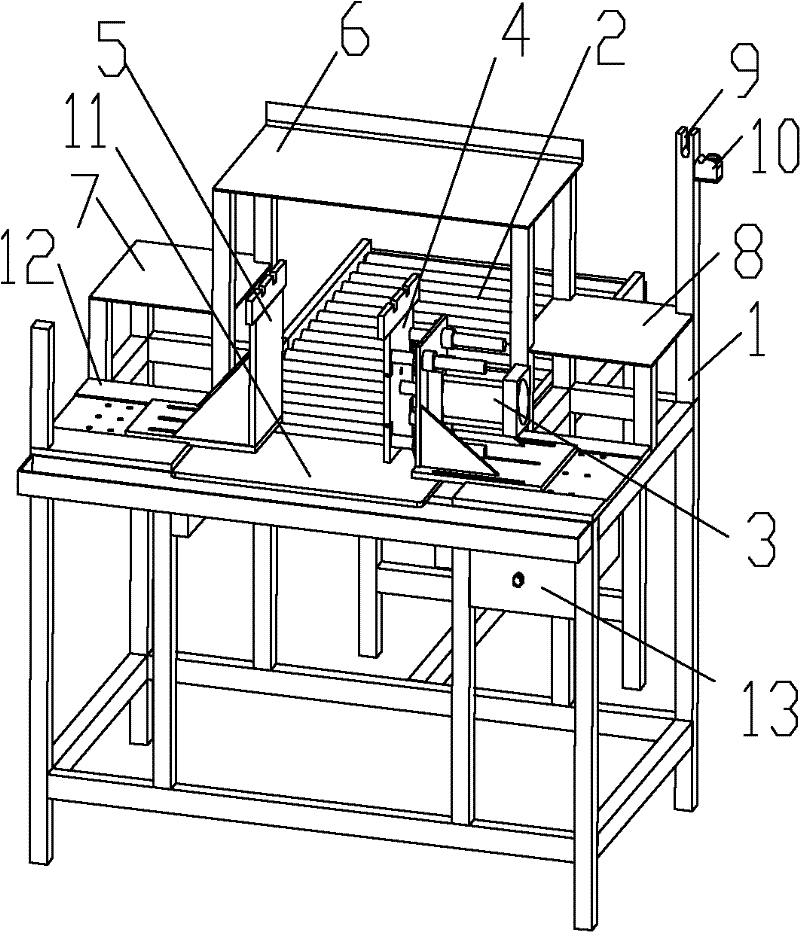

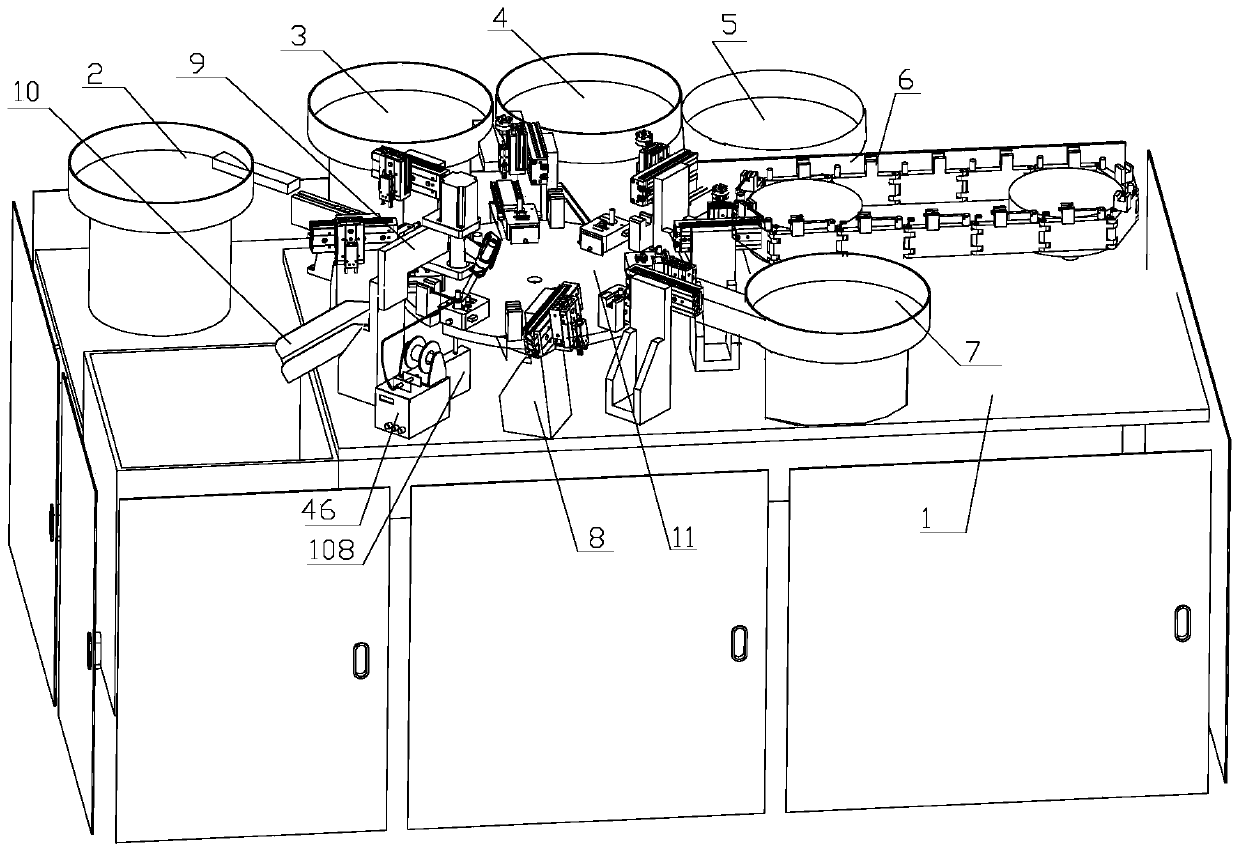

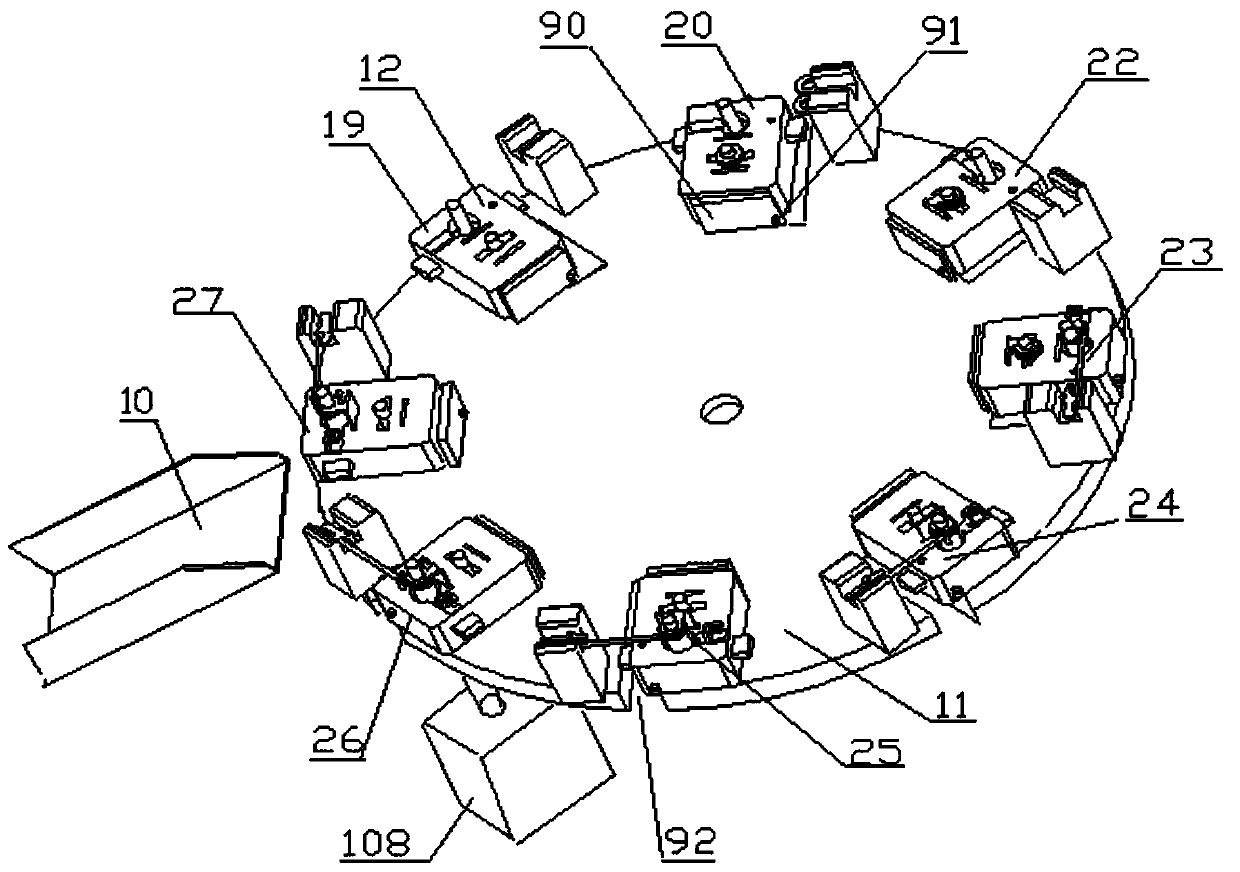

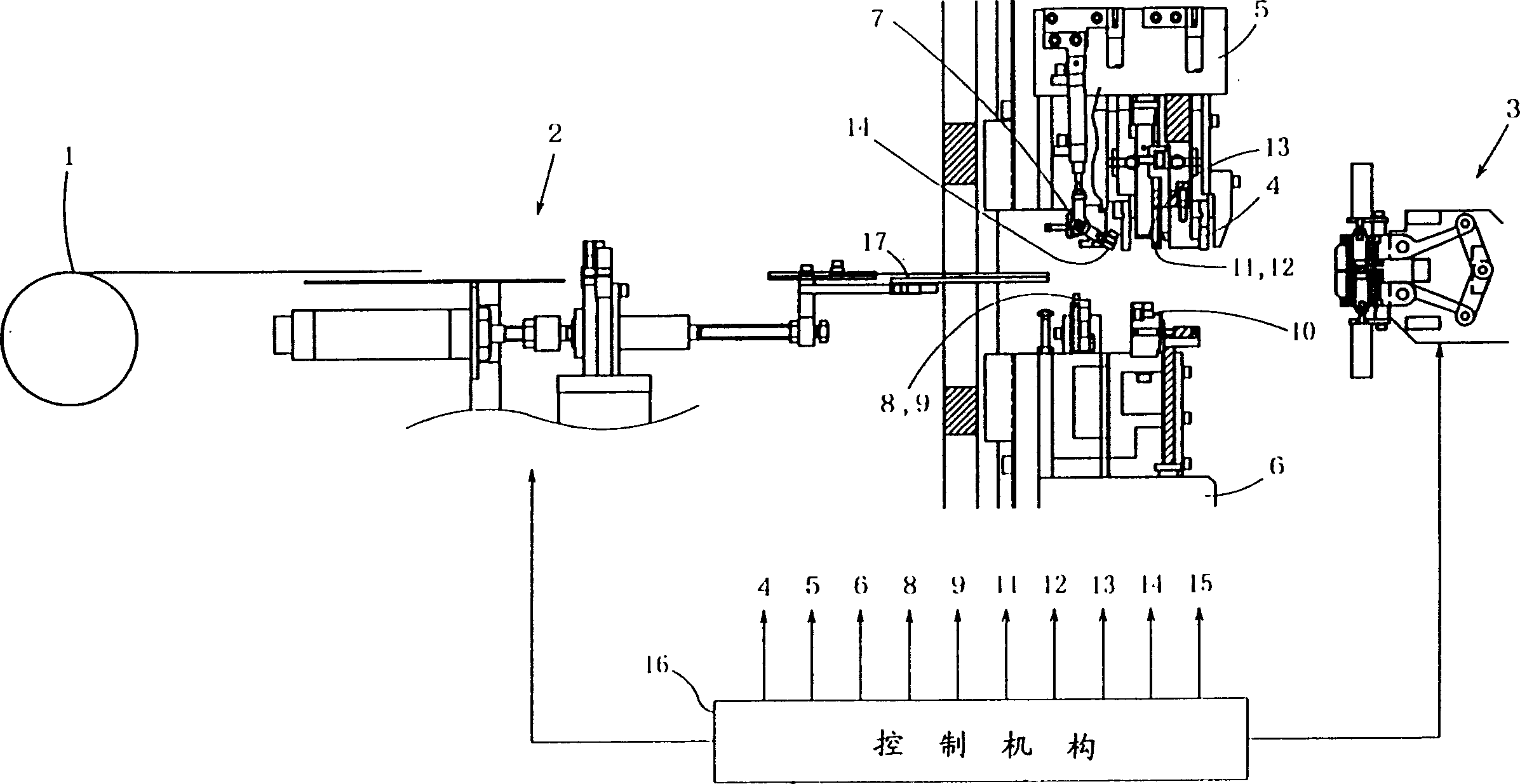

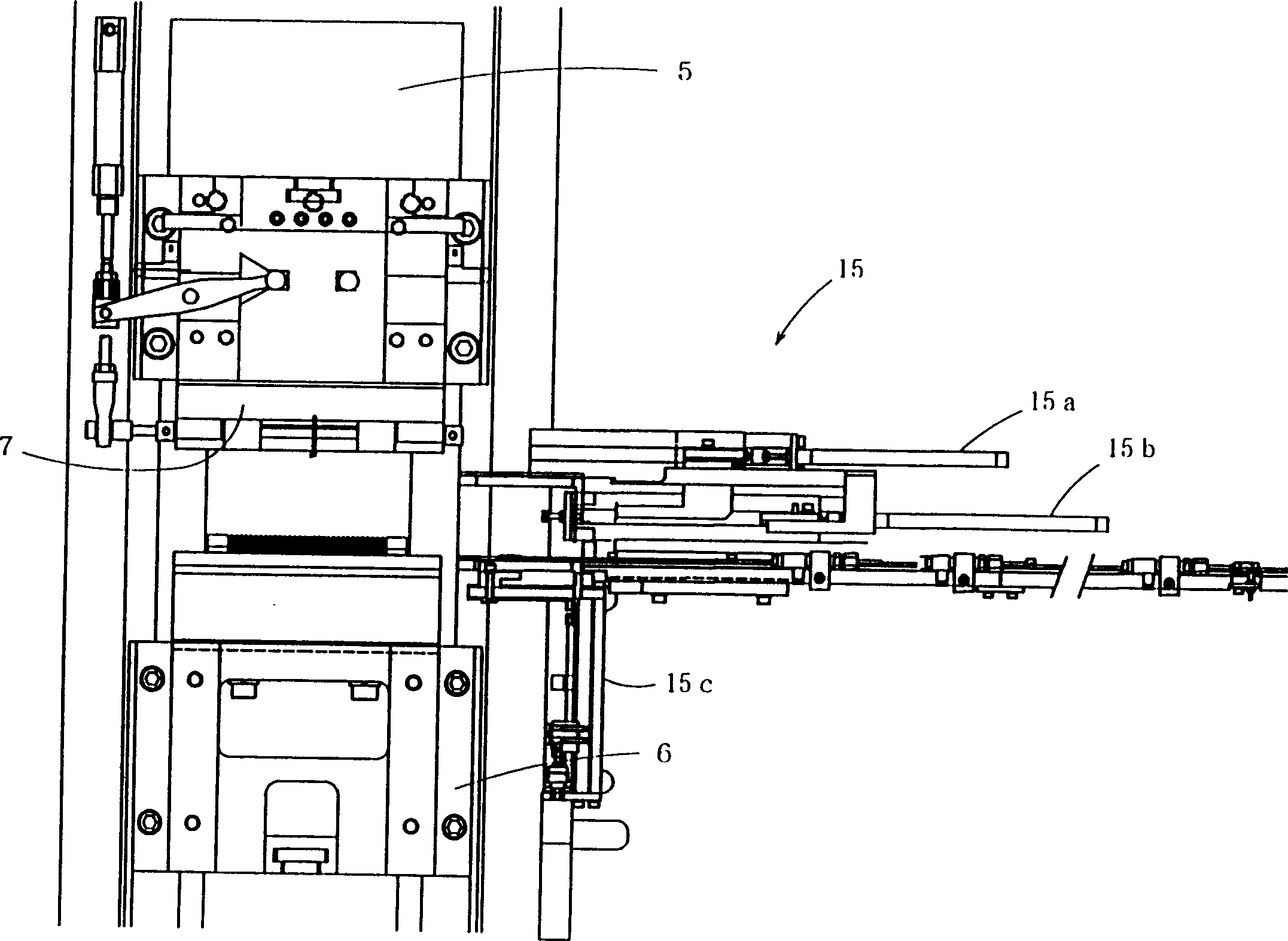

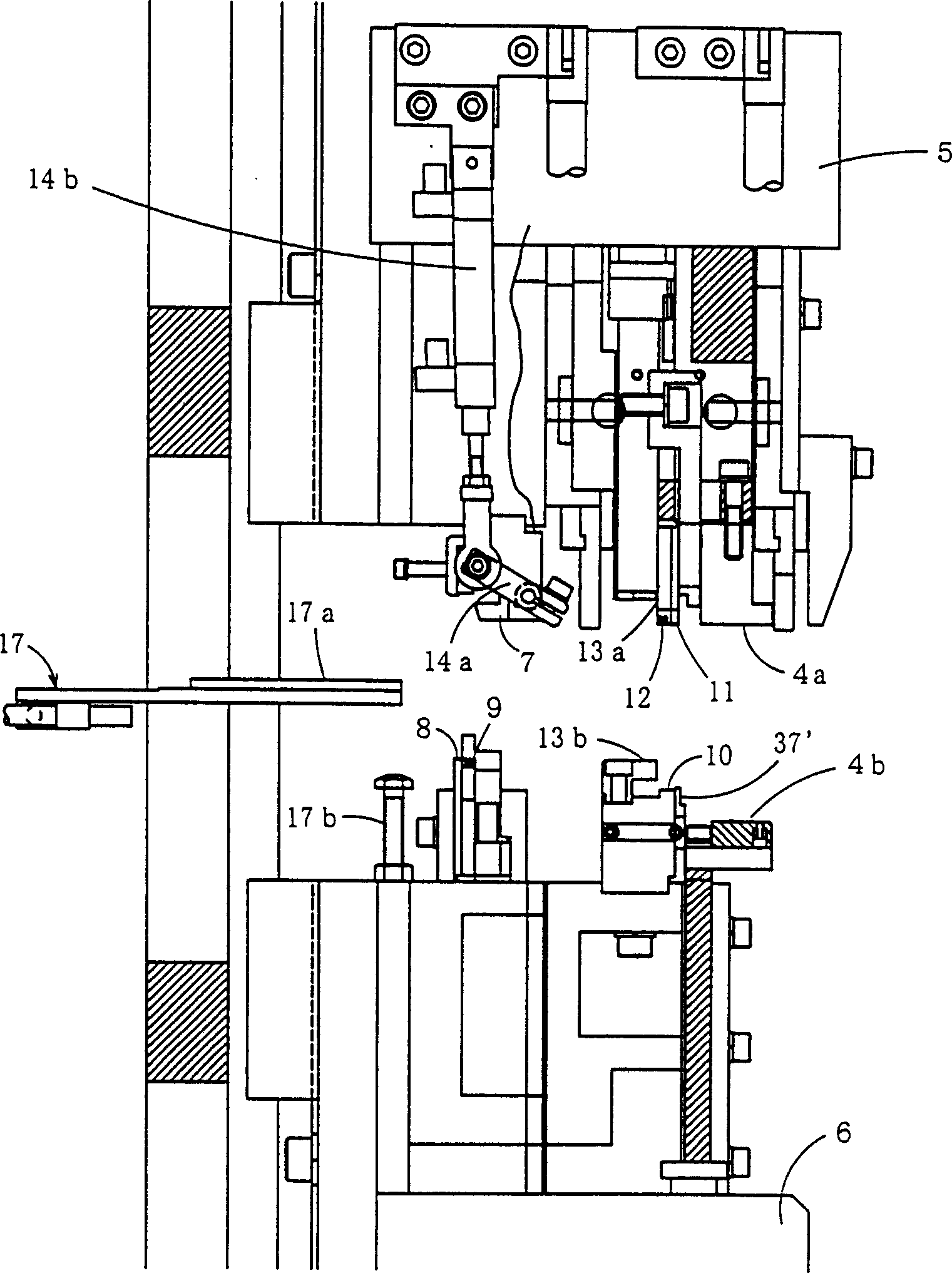

Full-automatic welding system and welding method of electromagnetic assembly of low-voltage circuit breaker

ActiveCN107414236AEliminate weldsIncrease productivitySolder feeding devicesSoldering auxillary devicesLow voltage circuitsEngineering

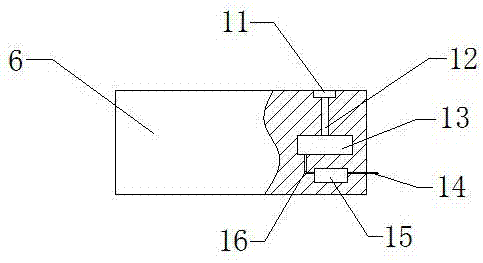

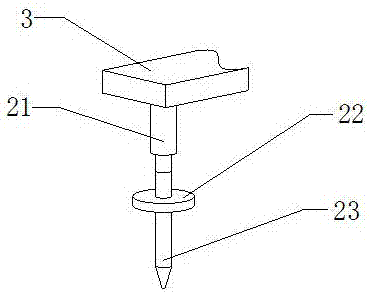

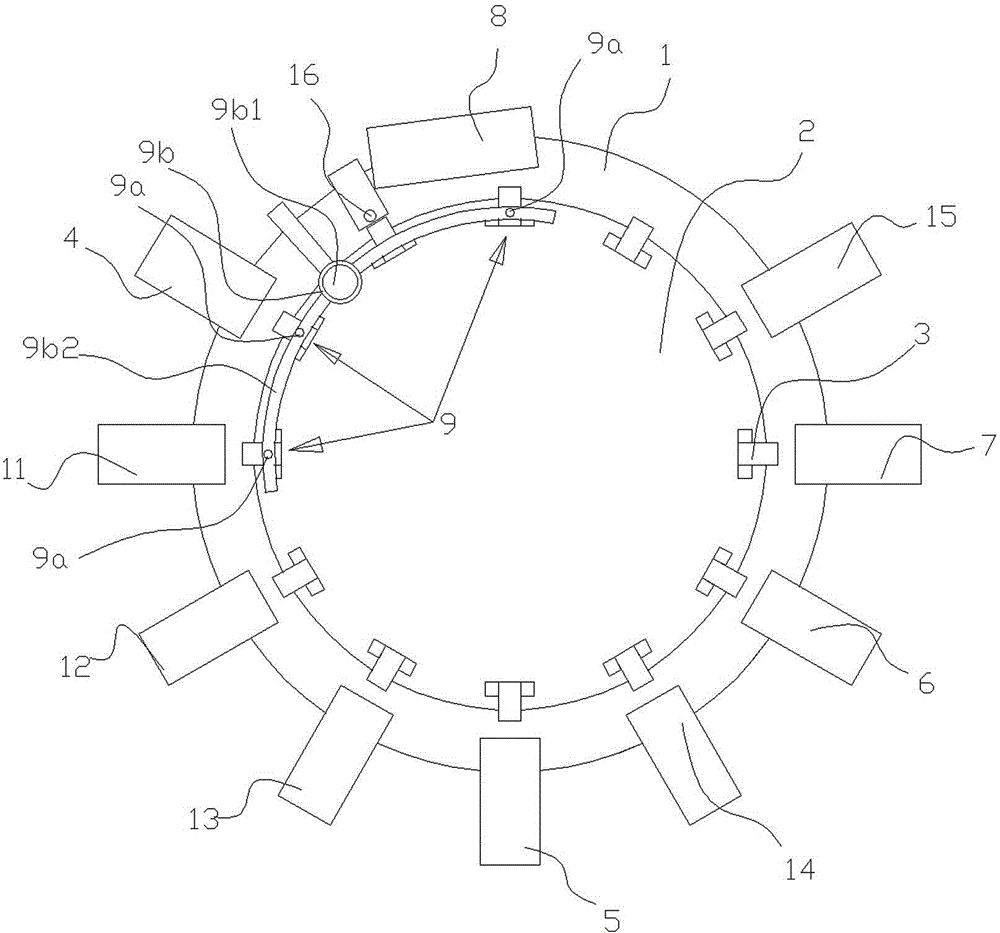

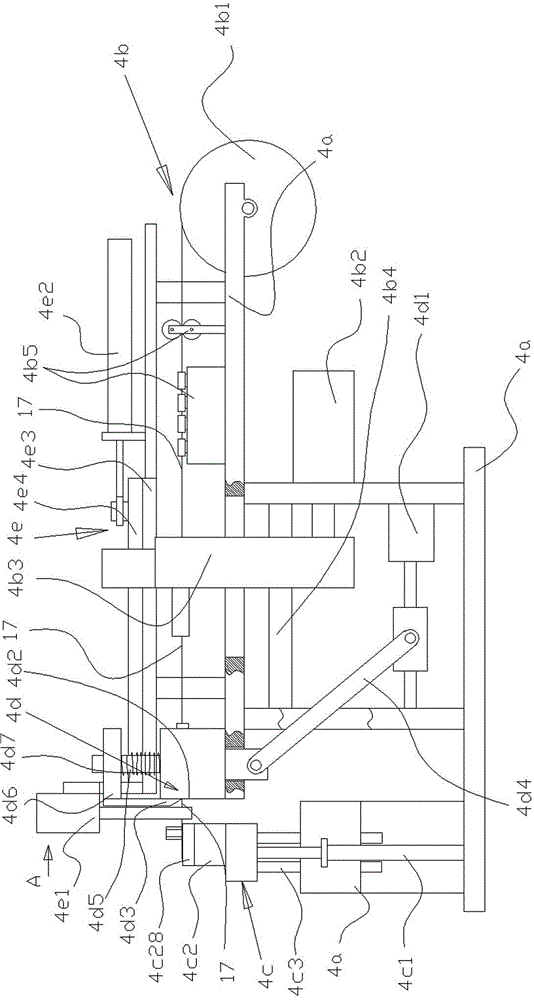

The invention discloses a full-automatic welding system of an electromagnetic assembly of a low-voltage circuit breaker. The system comprises a rotary disc arranged on a horizontal table top. Eight clamp assemblies are uniformly arranged along the circumference close to the outer edge of the rotary disc, and an indexing mechanism is arranged on the lower surface of the rotary disc; eight mechanisms are successively arranged around the periphery of rotary disc on the horizontal table top; the eight clamp assemblies are uniformly distributed as eight rotating stations which are successively an oil cup loading station, a lower gasket loading station, a magnet yoke loading and storing station, a coil loading station, an upper gasket loading station, a magnet yoke loading station, a tin solder station and a discharging station. A product taking mechanism is arranged on the outer side of the discharging station. The invention also discloses a welding method of the electromagnetic assembly of the low-voltage circuit breaker. The device and method disclosed by the invention are compact in structure, reliable to work and high in welding quality.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

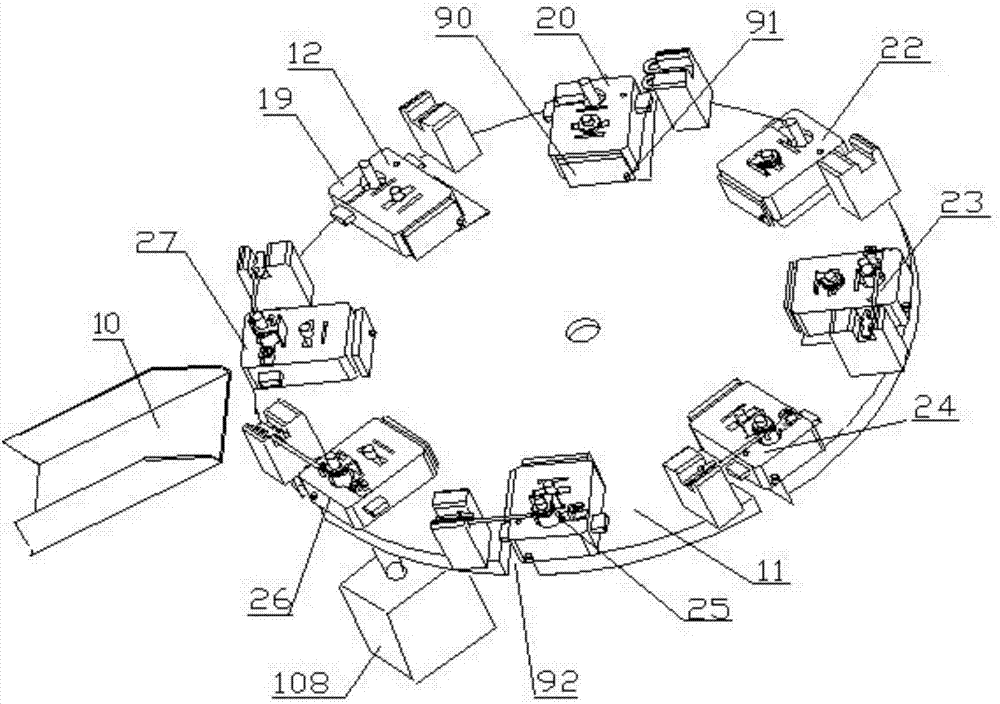

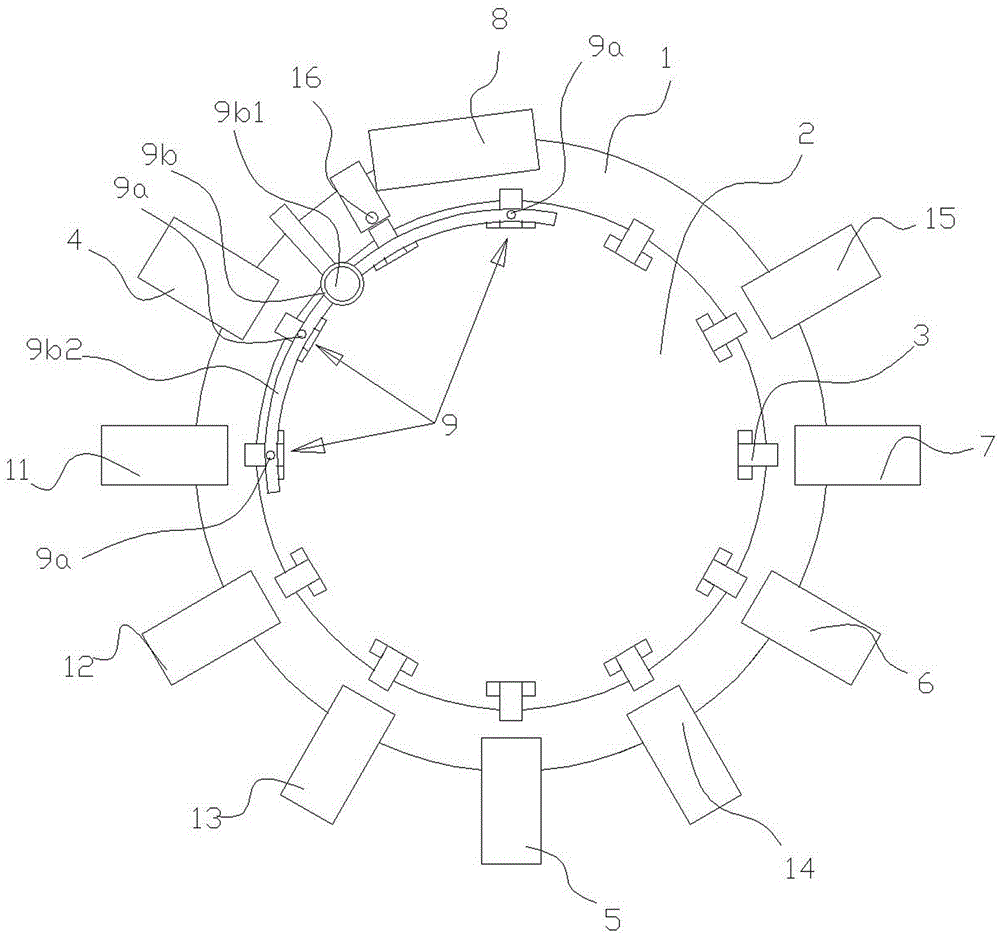

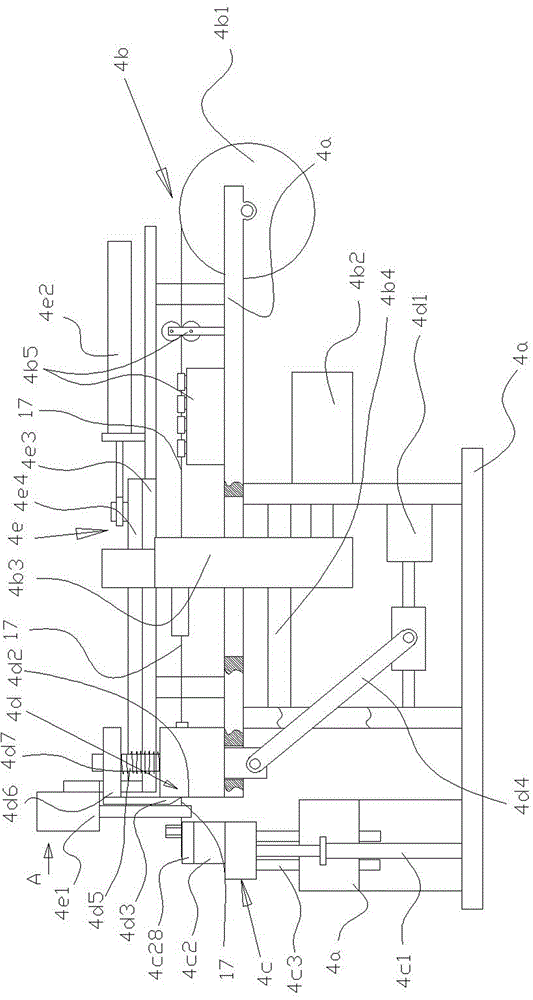

A lamp filament lamp base component continuous production apparatus

InactiveCN103337439AIncrease productivityReduce manpower consumptionSequential operation station machinesElectrode assembly manufactureSolder stationEngineering

A lamp filament lamp base component continuous production apparatus is characterized by comprising a machine frame, a rotating disk arranged on the machine frame and driven by power, clamps arranged at the periphery of the rotating disk and used for clamping the lamp bases, a lamp base molding station, a molybdenum chip bonding station, an upper solder station, a lamp filament soldering station, and a blanking station. The lamp base molding station, the molybdenum chip bonding station, the upper solder station, the lamp filament soldering station, and the blanking station are arranged on the machine frame and arranged from the rotating disk to the periphery sequentially. Compared with prior arts, the lamp filament lamp base continuous production apparatus is advantaged by being high in production efficiency and low in manpower consumption. The lamp filament lamp base continuous production apparatus is also advantaged by being fully automatic.

Owner:李家凌

Accumulator plate pack welding table

InactiveCN102198551AReduce labor intensityIncrease productivityIncandescent ignitionCell component detailsEngineeringSolder station

The invention discloses an accumulator plate pack welding table which comprises a stand, a welding gun rack and an ignition device, wherein both the welding gun rack and the ignition device are arranged on the stand; and the stand is also provided with a rolling way for conveying an accumulator plate pack. By adopting the welding table, a mechanical clamping mode is used for substituting manual operation of workers, meanwhile, welding and subsequent trimming and encapsulating processes of the accumulator plate pack are finished on the rolling way, so that labor intensity of the workers is reduced, and production efficiency is increased.

Owner:ZHAOQING LEOCH BATTERY TECH

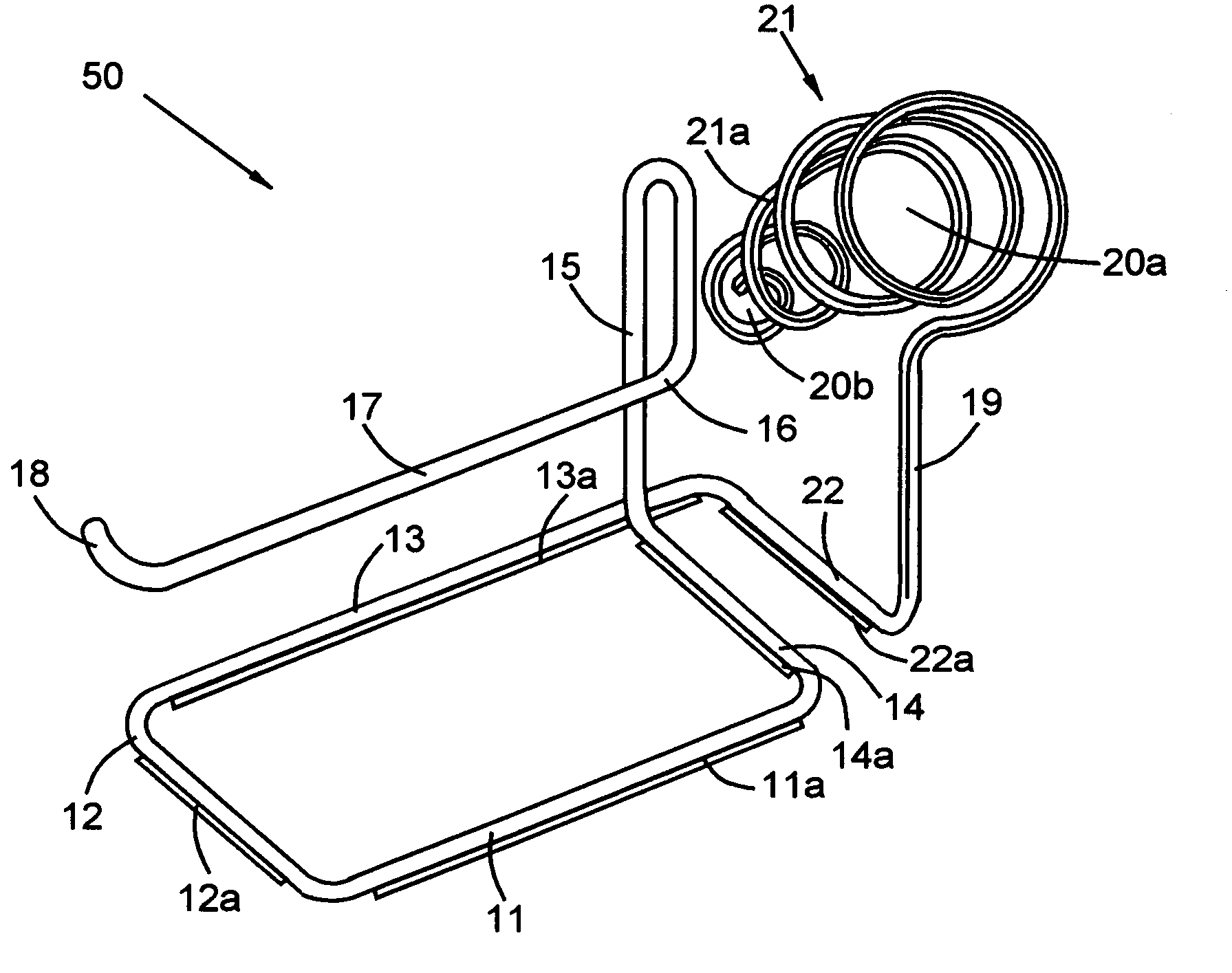

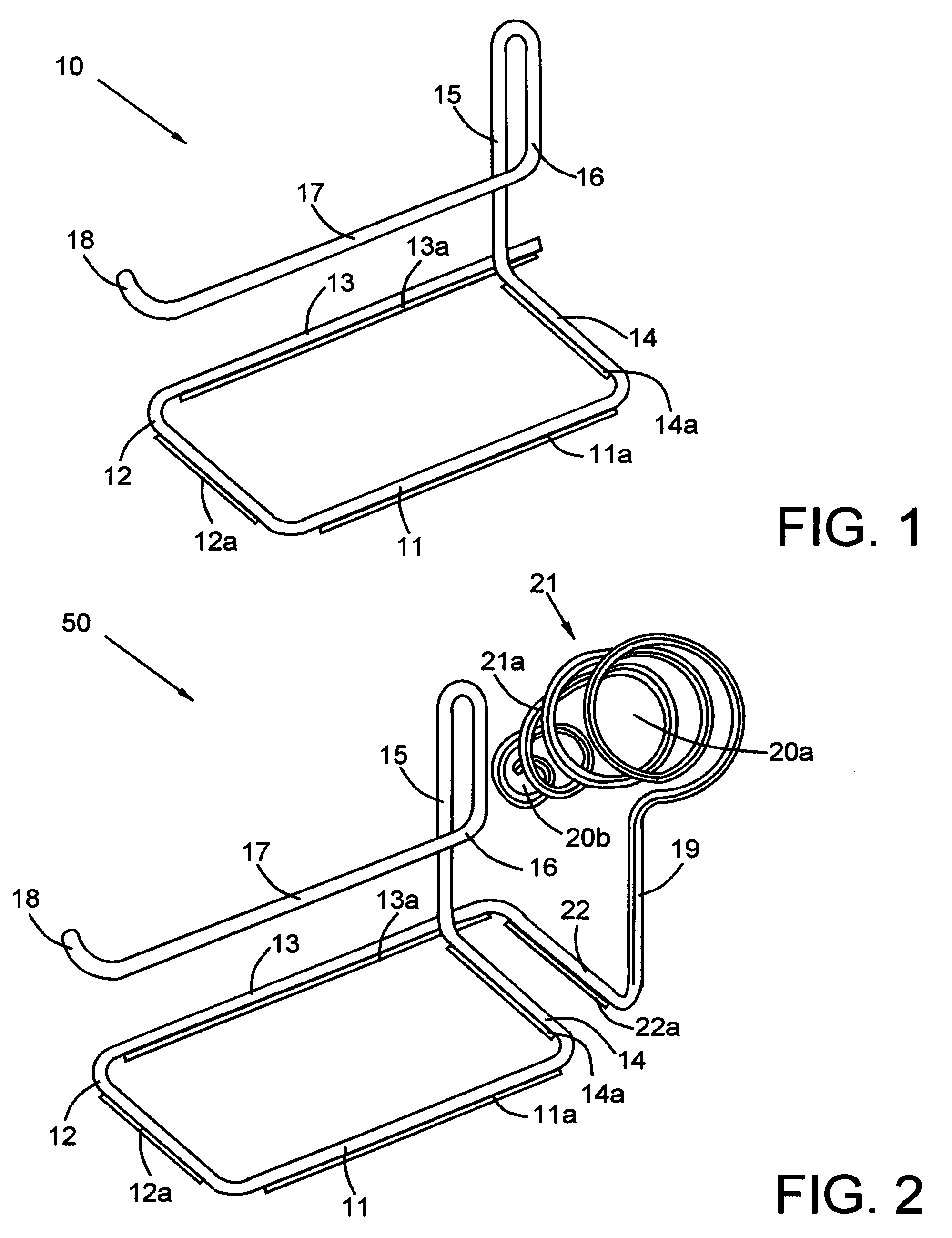

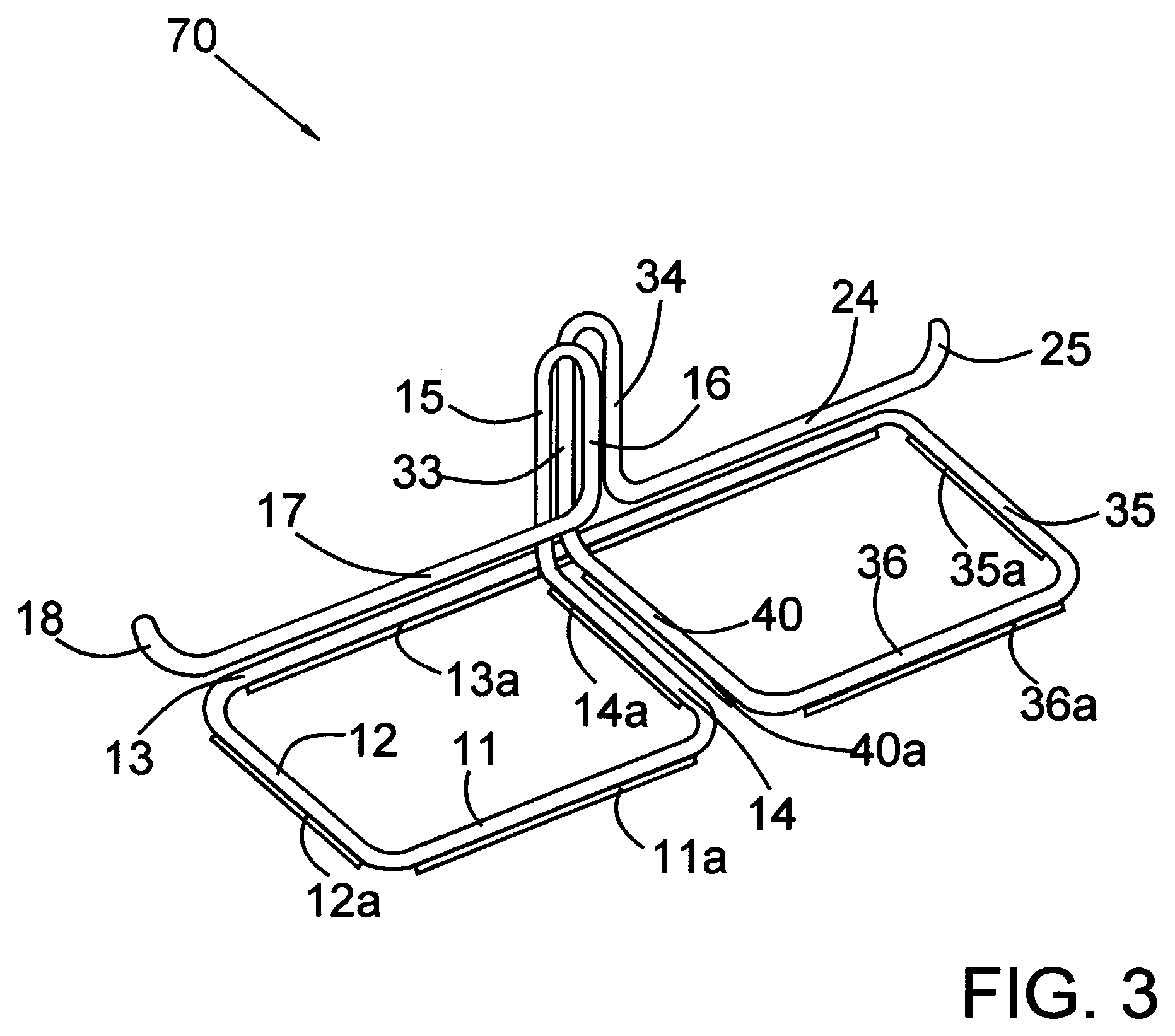

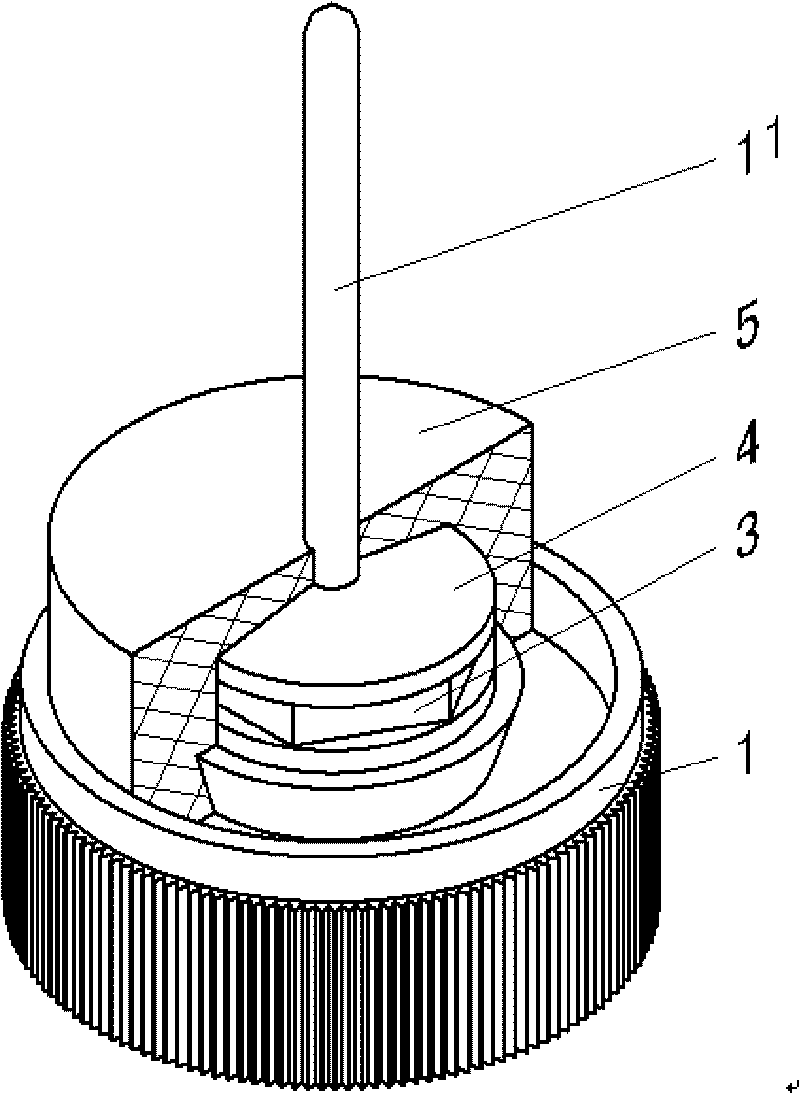

Soldering station

InactiveUS7137584B2Line/current collector detailsElectrically conductive connectionsSolder stationEngineering

A soldering station of unitary construction includes a base member, a sidewall extending upwardly from a base member segment, and a horizontal support member extending from the sidewall. Alternative embodiments include a soldering iron holder and a second sidewall extending upwardly from a second base member segment and a second horizontal support member extending from the second sidewall.

Owner:WONG CHUNG M

Method for welding lead of diode and diode

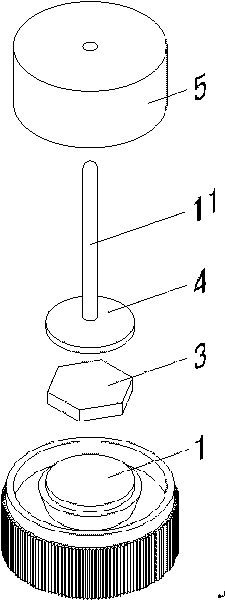

ActiveCN101740409AReduce leakage currentImprove pressure resistanceSemiconductor/solid-state device detailsSolid-state devicesEpoxyLow leakage

The invention discloses a method for welding a lead of diode and a diode. The method comprises the following steps: placing a chip on a welding station of a tube seat, then pressing a lead seat on the chip, and welding the lead seat, the chip and the welding station of the tube seat together by adopting primary welding; and molding and ultrasonically cleaning the station surface after welding, and then encapsulating the whole with epoxy resin. The structure of the diode comprises the tube seat (1) which is connected with the chip (3) and the lead seat (4) in turn; and an epoxy resin sealing layer (5) is arranged outside the chip (3) and the lead seat (4). The method can simplify the welding process, improve the production efficiency and reduce the production cost; and the produced diode has the advantages of low leakage current, low thermal resistance and high voltage resistance, and is not easy to break down.

Owner:GUIZHOU YAGUANG ELECTRONICS TECH

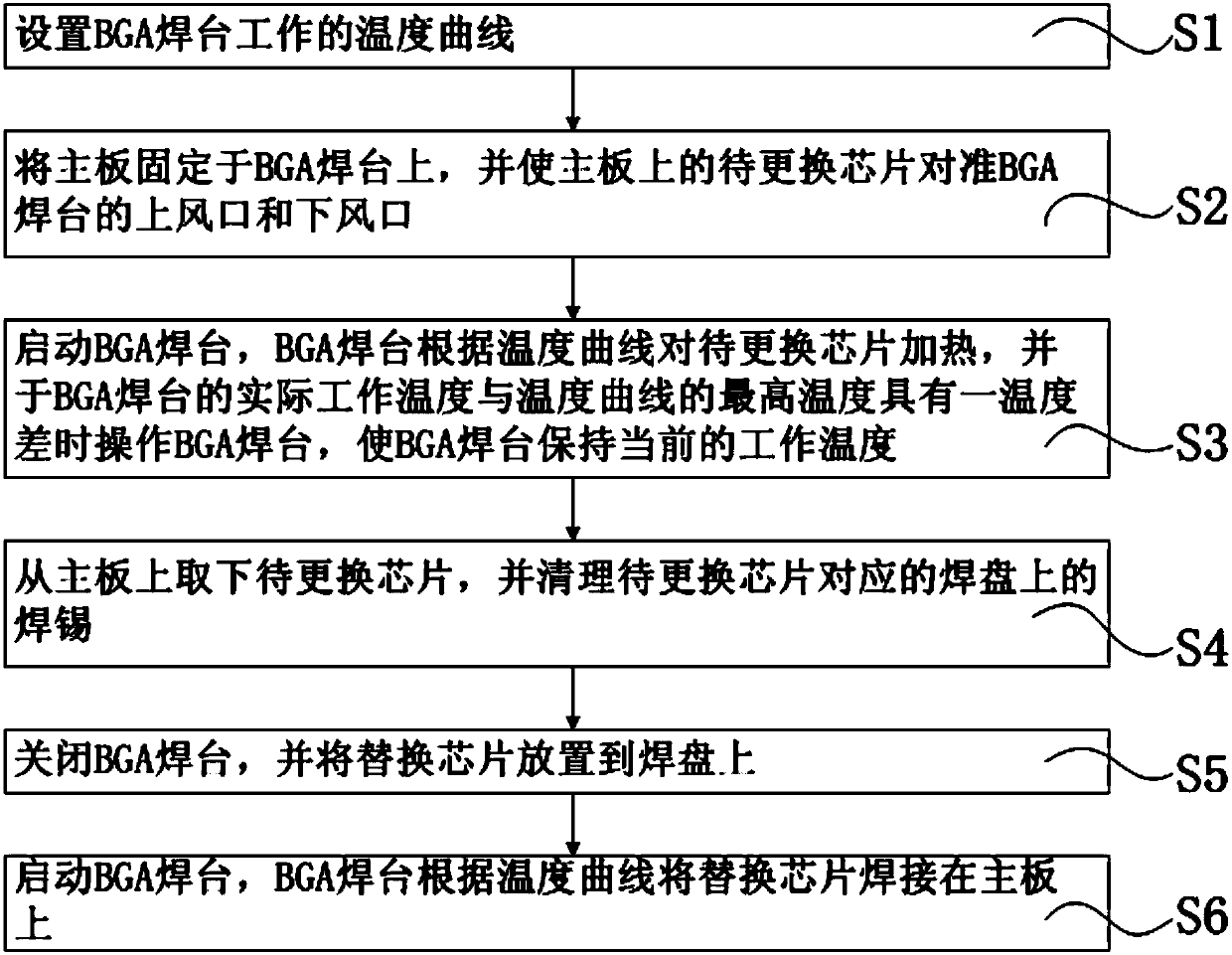

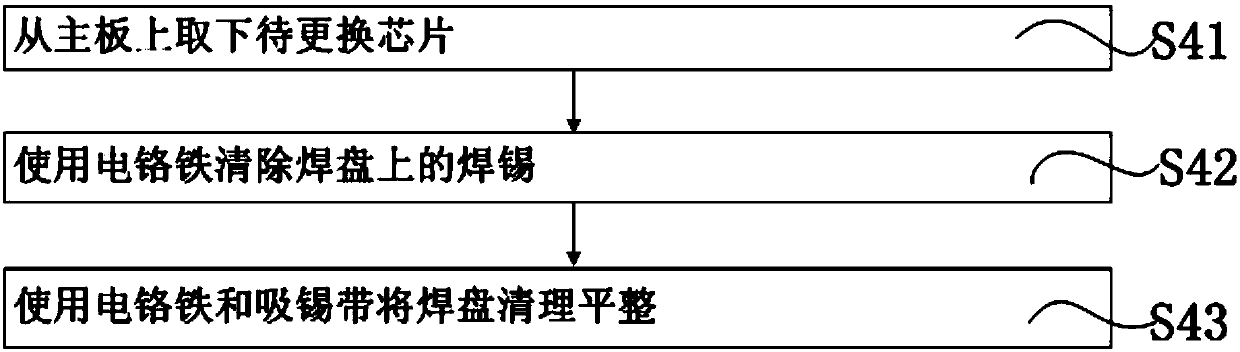

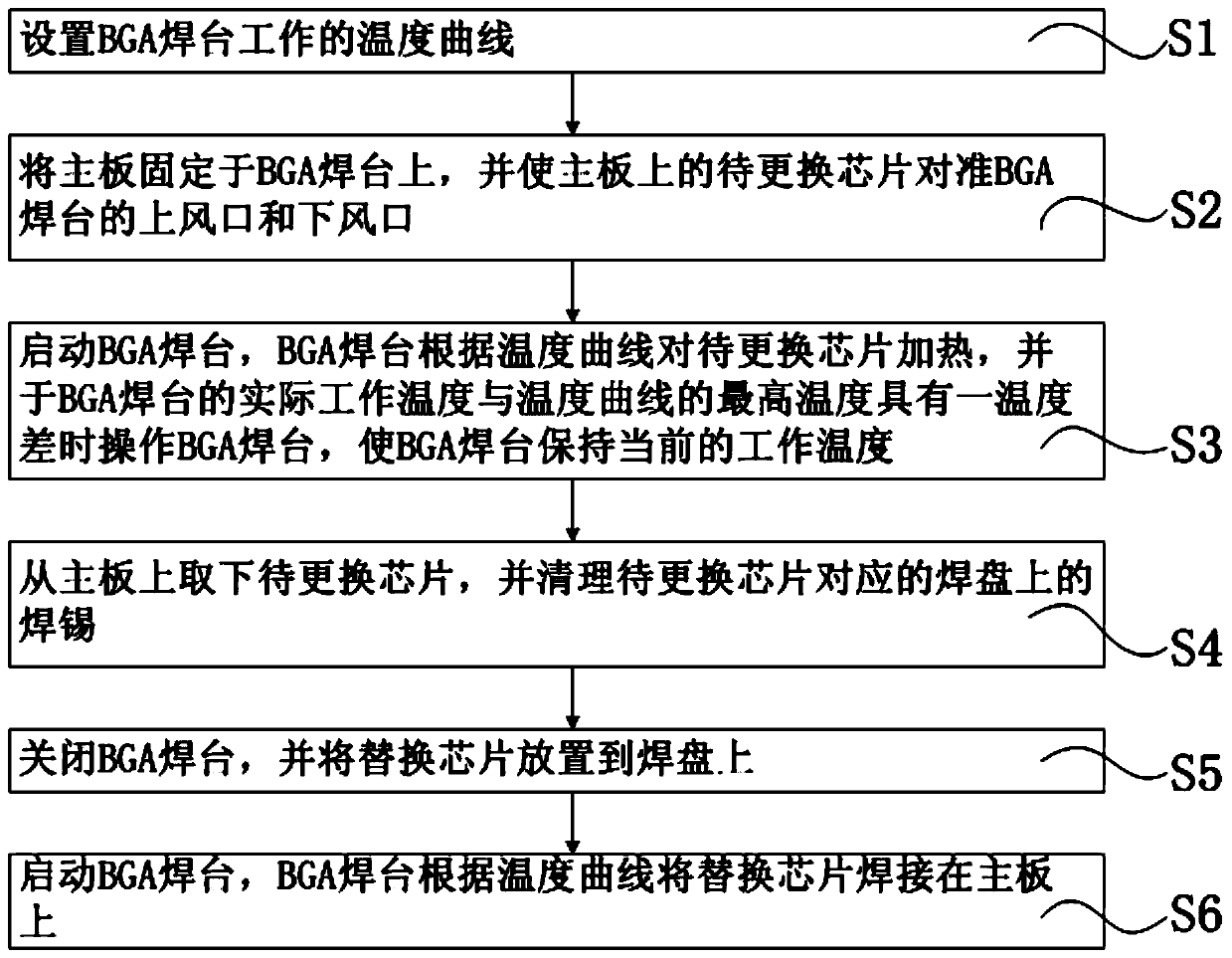

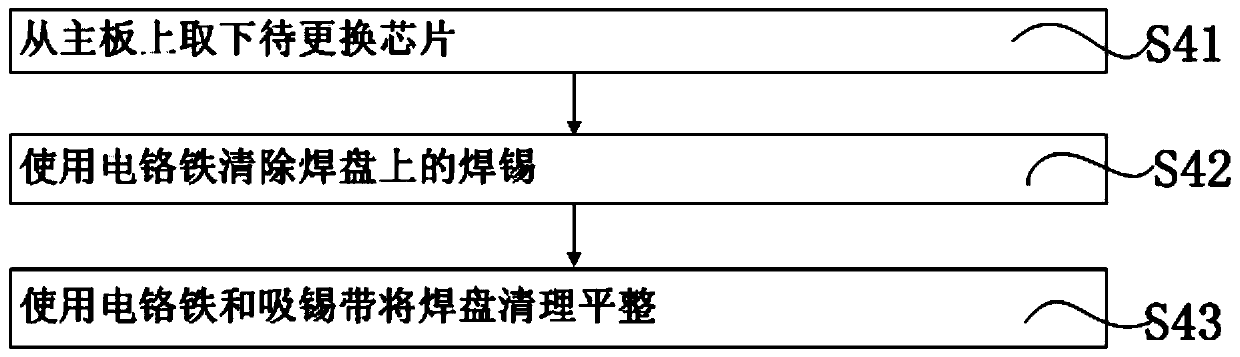

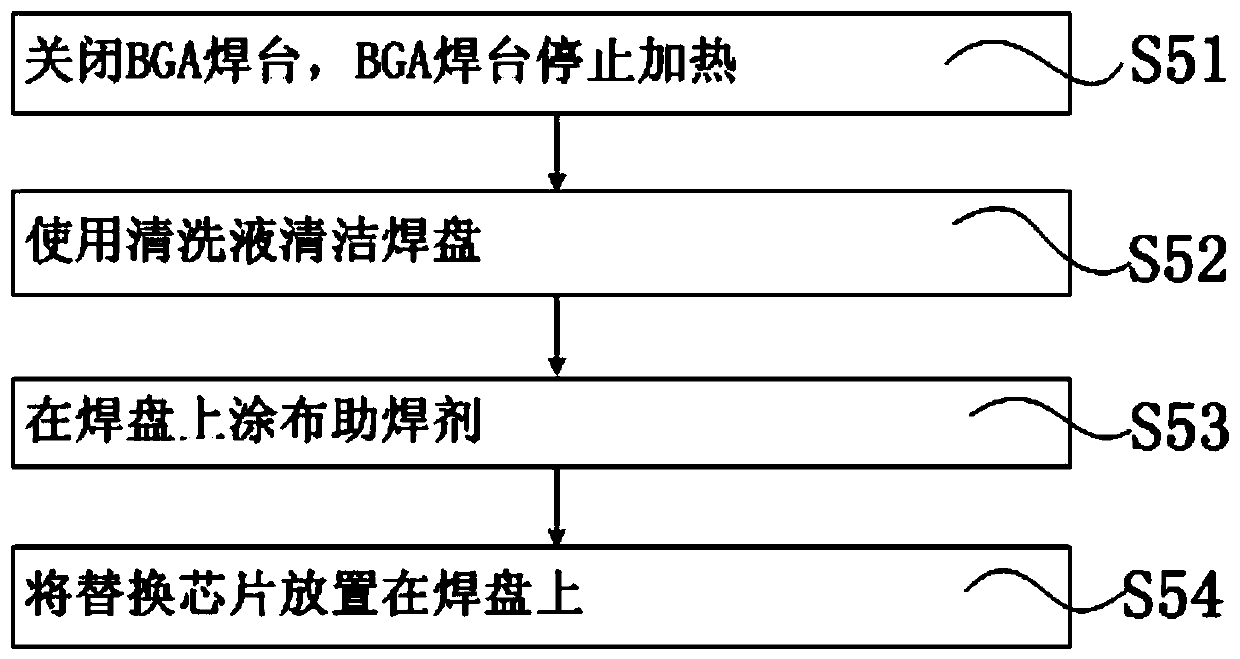

Chip replacement method

ActiveCN107911955AShort replacement timeImprove welding yieldPrinted circuit assemblingTemperature curveSolder ball

A chip replacement method disclosed by the present invention is suitable for replacing a ball grid array (BGA) packaging chip, belongs to the mainboard maintenance technology field, and comprises thefollowing steps of providing a ball grid array soldering station; setting a temperature curve that the BGA soldering station works; fixing a mainboard on the BGA soldering station, and aligning a to-be-replaced chip on the mainboard at a wind inlet and a wind outlet of the BGA soldering station; starting the BGA soldering station, enabling the BGA soldering station to heat the to-be-replaced chipaccording to the temperature curve, and operating the BGA soldering station when the actual working temperature of the BGA soldering station and the highest temperature of the temperature curve have the preset temperature difference to enable the BGA soldering station to keep a current working temperature; taking out the to-be-replaced chip from the mainboard, and cleaning the soldering tin on a pad corresponding to the to-be-replaced chip; turning off the BGA soldering station, and placing a substituting chip on the pad; starting the BGA soldering station, and enabling the BGA soldering station to solder the substituting chip on the mainboard according to the temperature curve. The beneficial effects of the above technical scheme are that the BGA chip replacement time is short, the soldering yield is high, and the BGA chip replacement efficiency is improved.

Owner:AMOLOGIC (SHANGHAI) CO LTD

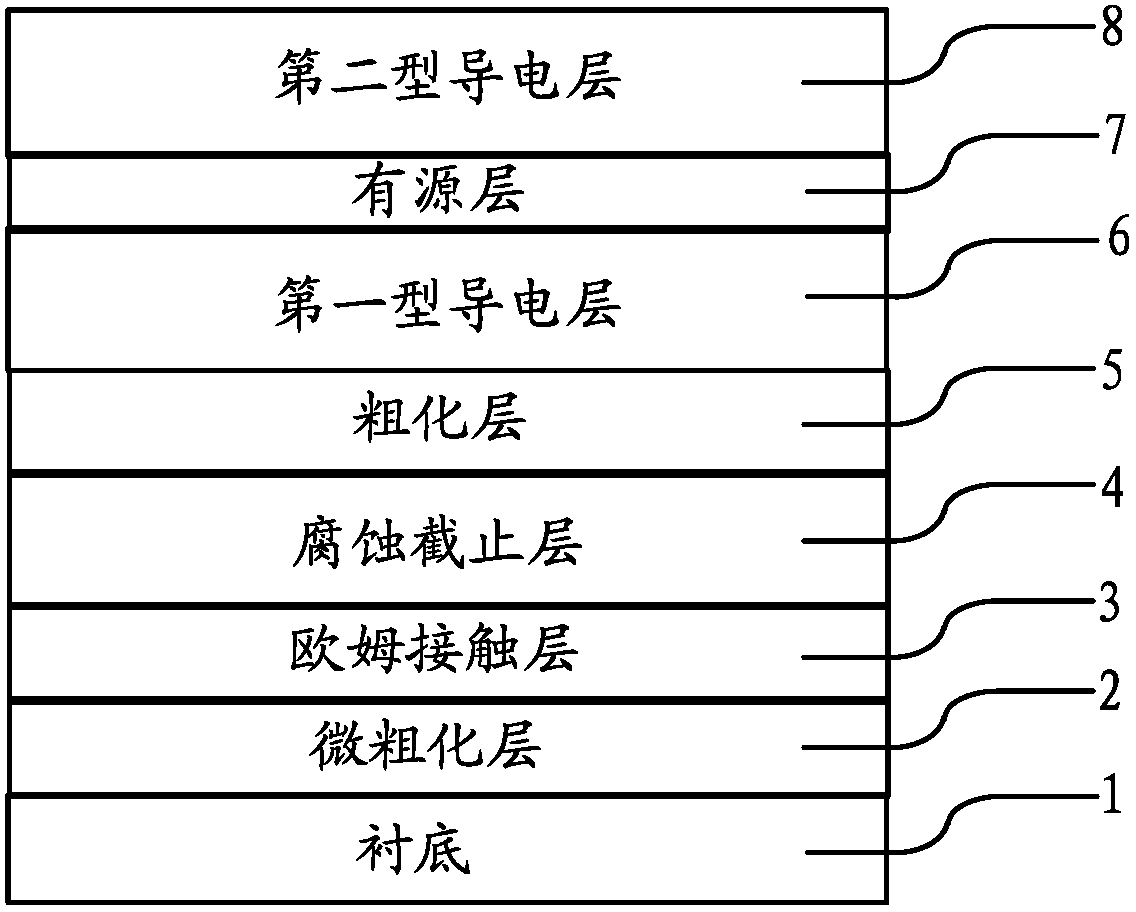

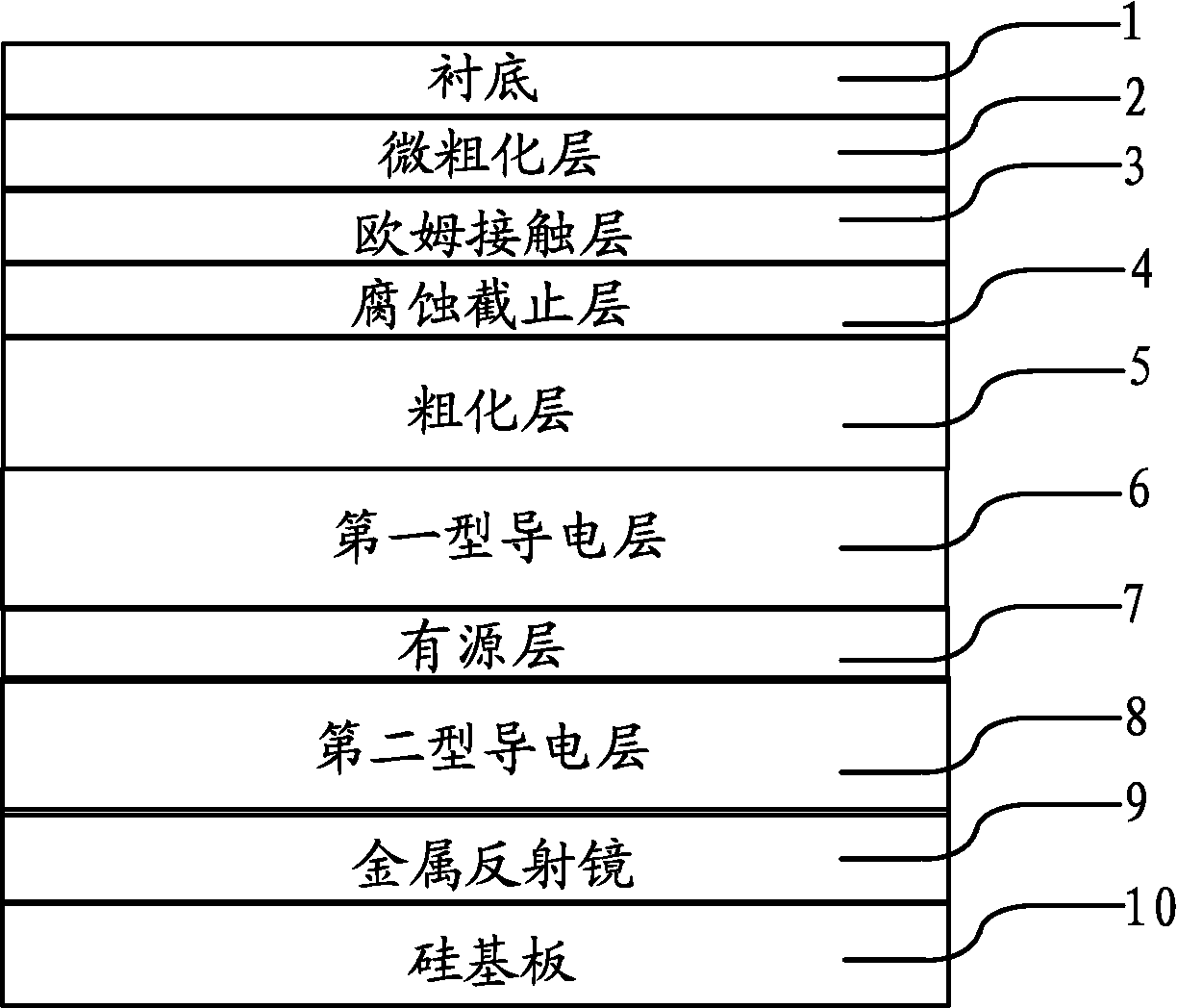

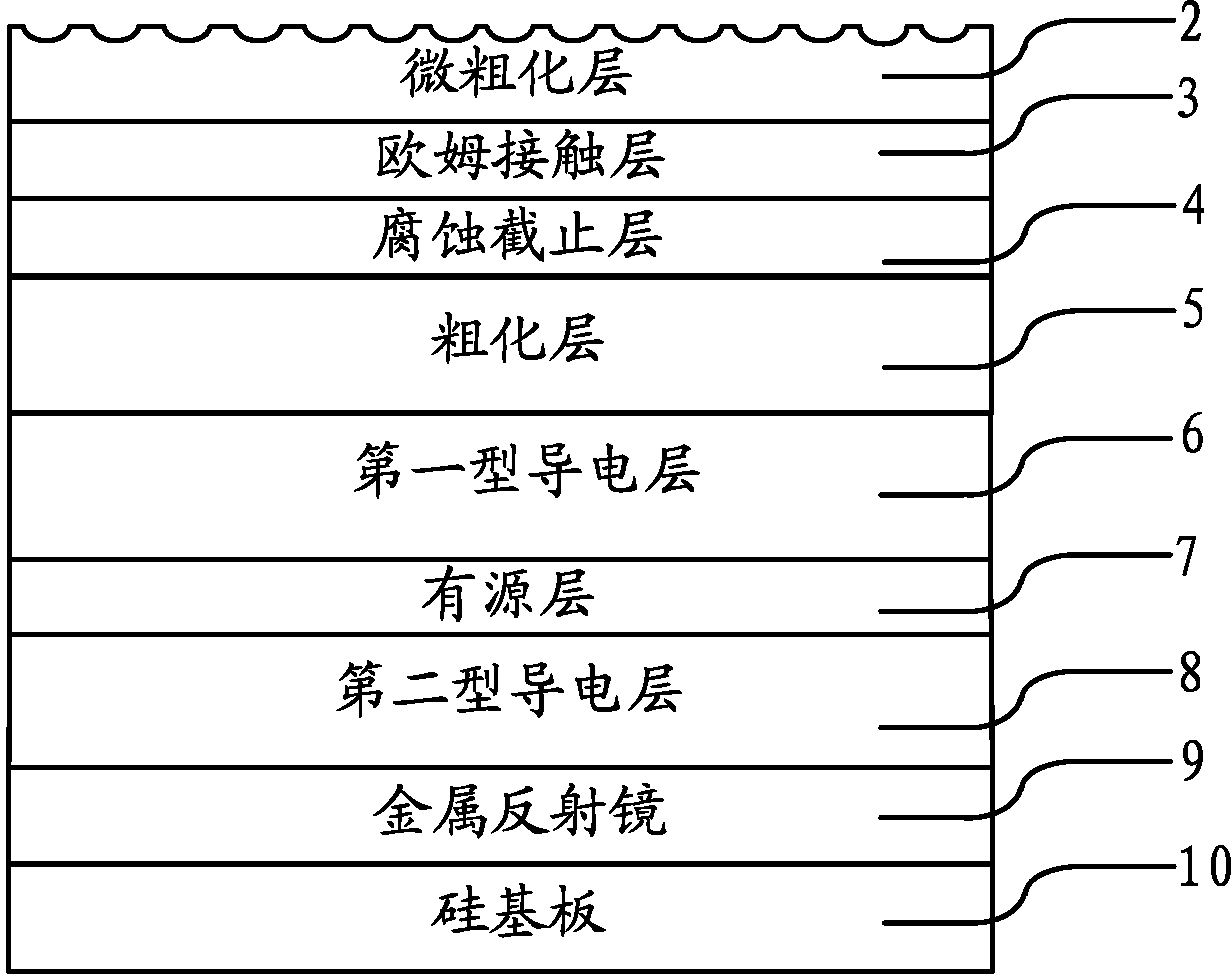

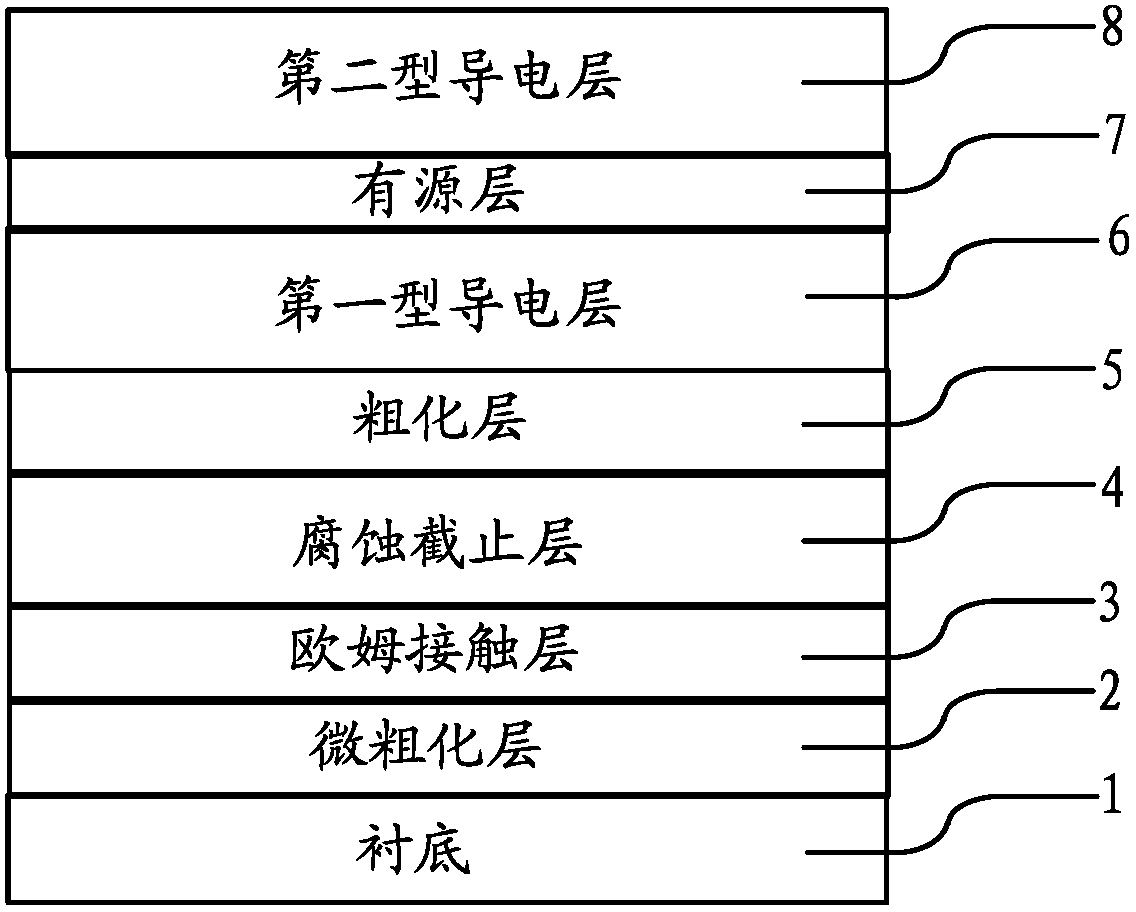

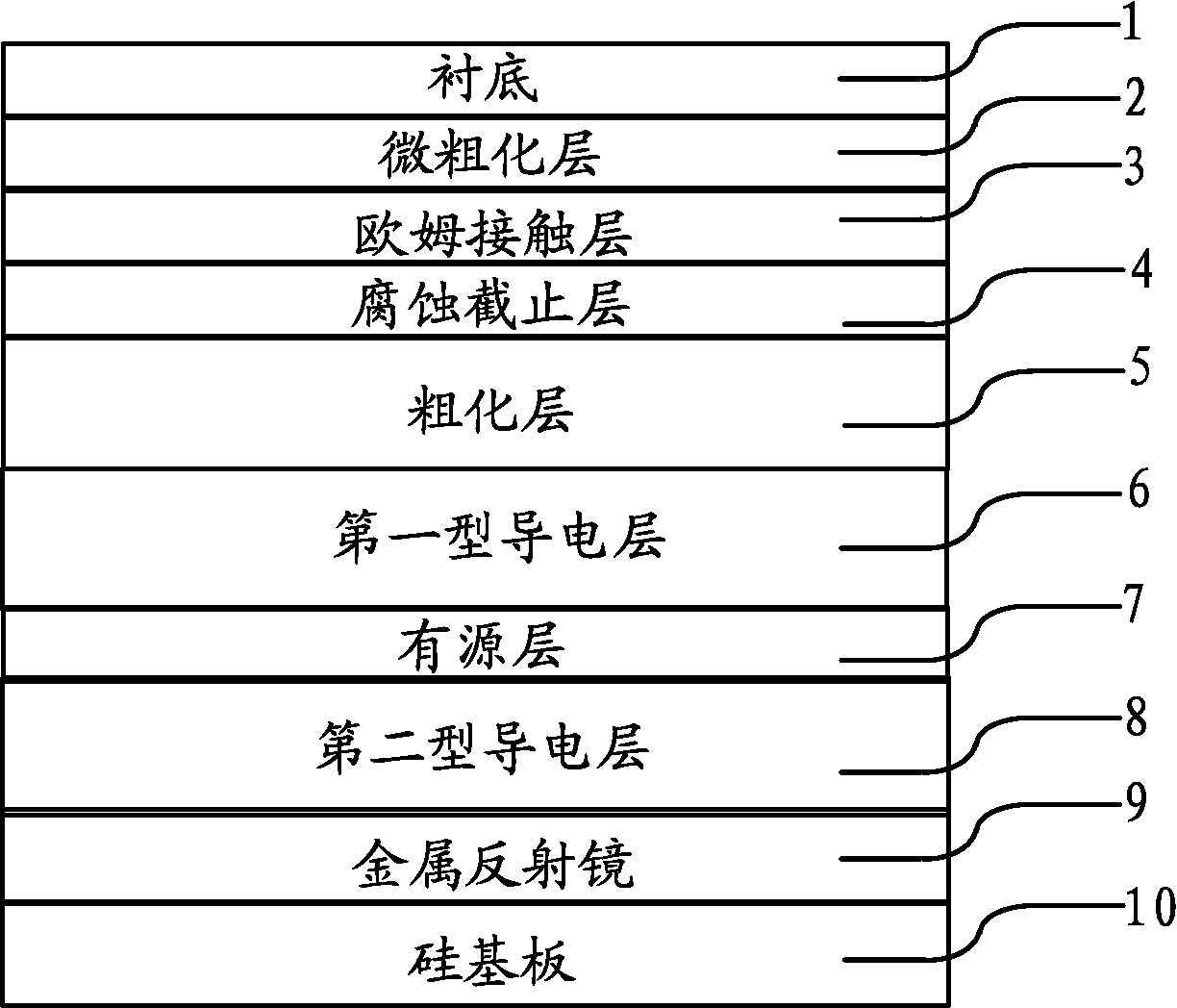

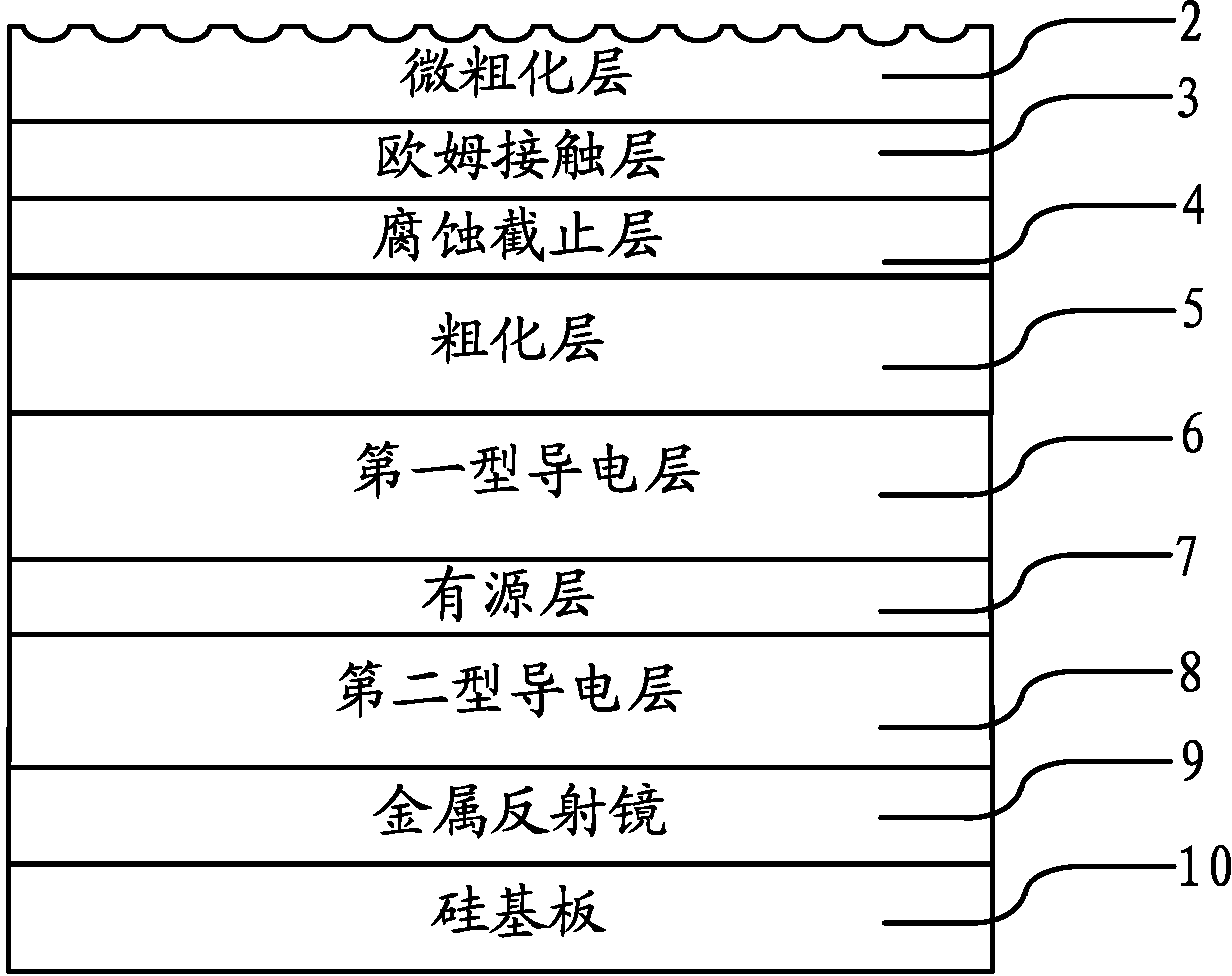

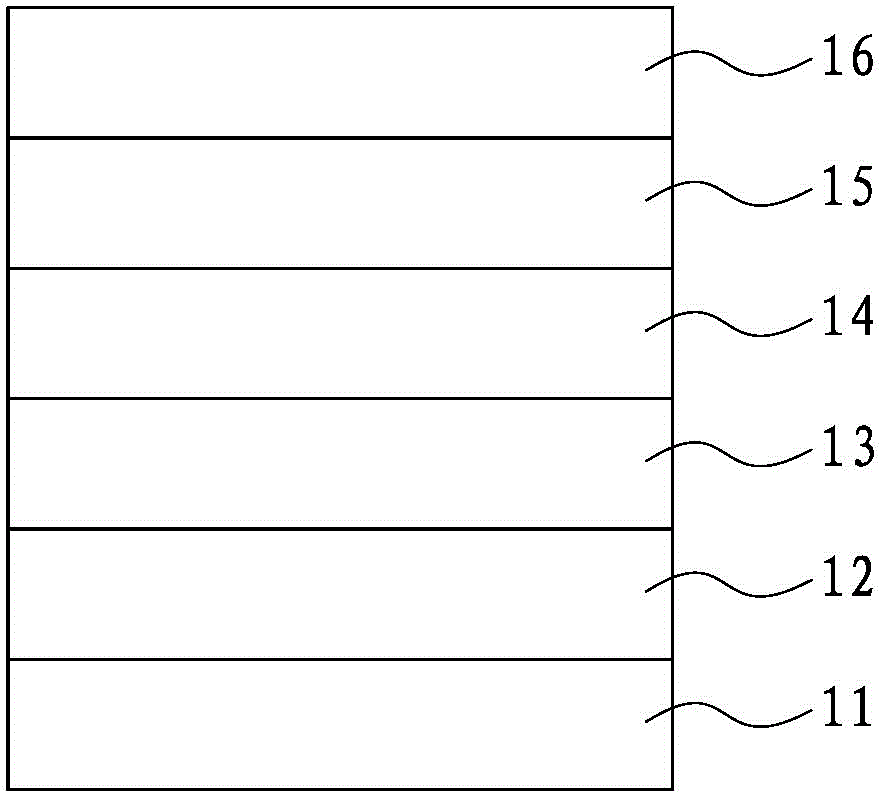

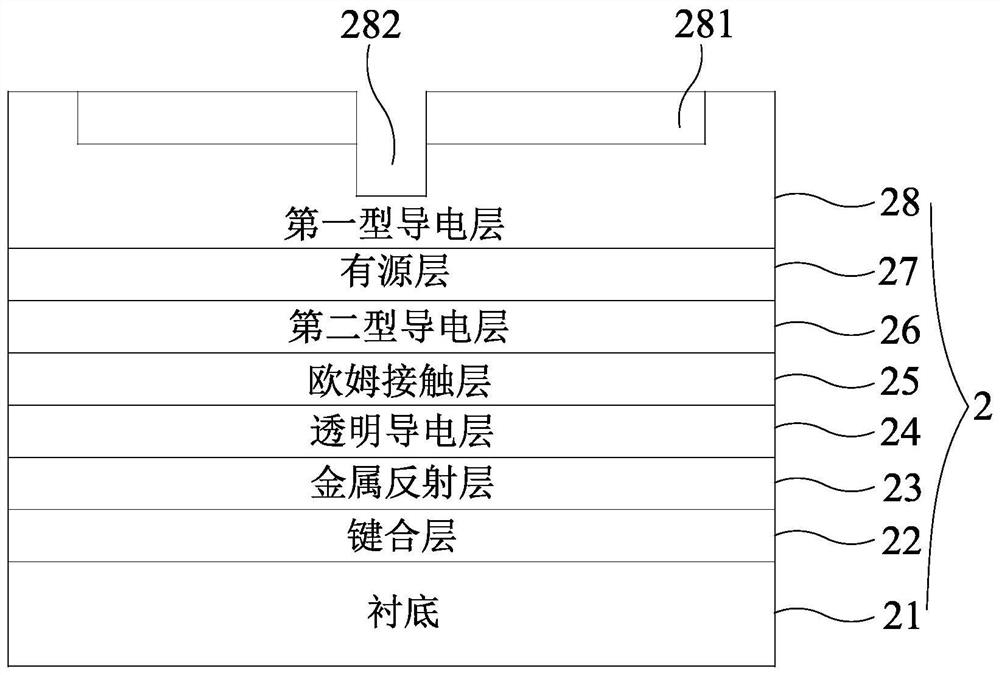

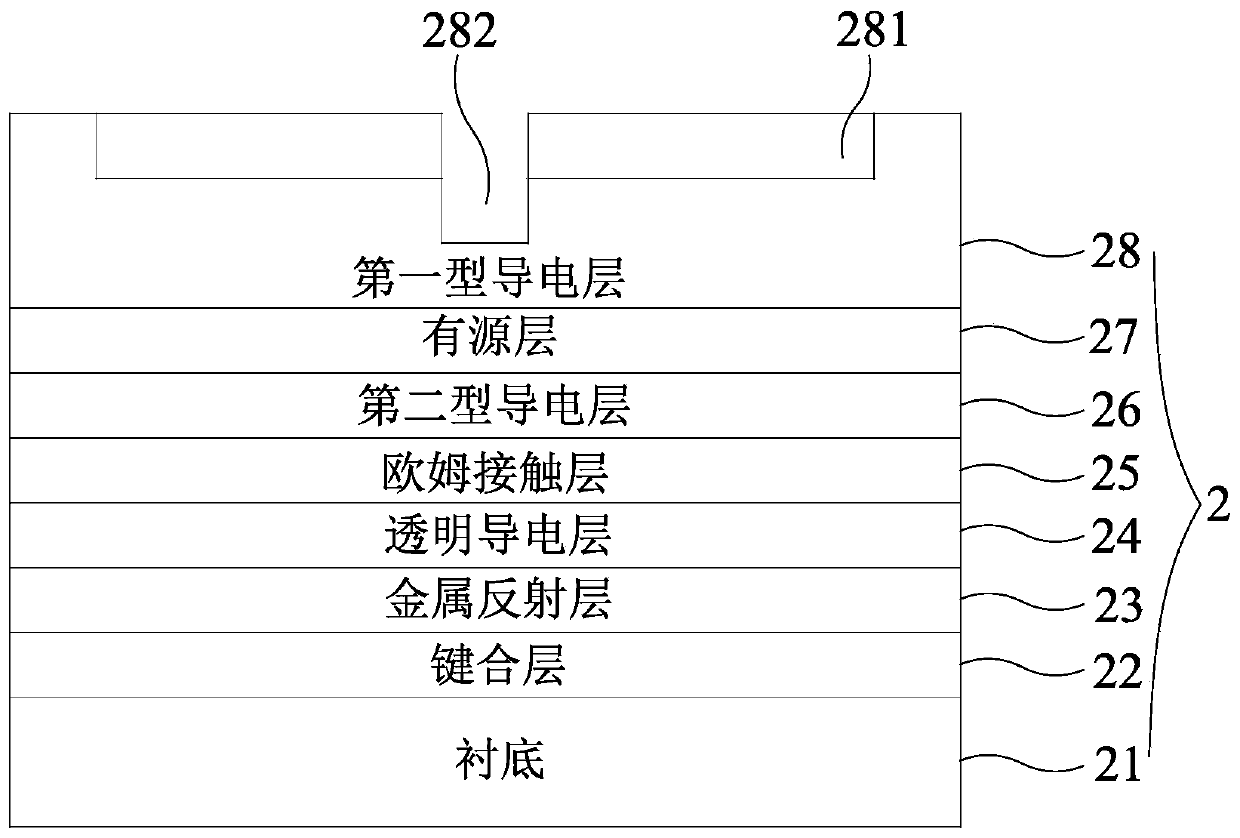

Production method of infrared light-emitting diode with high-reliability electrodes

InactiveCN104201264AIncrease contact surfaceImprove adhesionSemiconductor devicesOhmic contactSolder station

The invention discloses a production method of an infrared light-emitting diode with high-reliability electrodes. The production method includes: providing an epitaxial layer, evaporating a metal reflector on a second-type conducting layer of the epitaxial layer, and bonding the metal reflector on the substrate; removing the epitaxial substrate, and exposing a micro roughening layer; forming roughening morphology on the surface of the micro roughening layer; removing part of the micro roughening layer, producing a bonding pad electrode in the rest area of the micro roughening layer, and exposing an ohmic contact layer in the removed area of the micro roughening layer; forming extension electrode patterns on the surface of the exposed ohmic contact layer; forming the bonding pad electrode and extension electrodes; removing the exposed ohmic contact layer and an corrosion stop layer in a layer-by-layer manner till a roughening layer is exposed; forming surface roughening morphology in the exposed area of the roughening area; evaporating a back electrode on the back of the substrate, and performing fragmentation. By the method, reliability of soldering station electrodes is improved effectively, the problem that soldering station electrodes are prone to falling off due to poor adhesion is solved, and the packaging problem that the epitaxial layer under the soldering station electrodes is easy to break up during wire bonding is solved as well.

Owner:XIAMEN CHANGELIGHT CO LTD

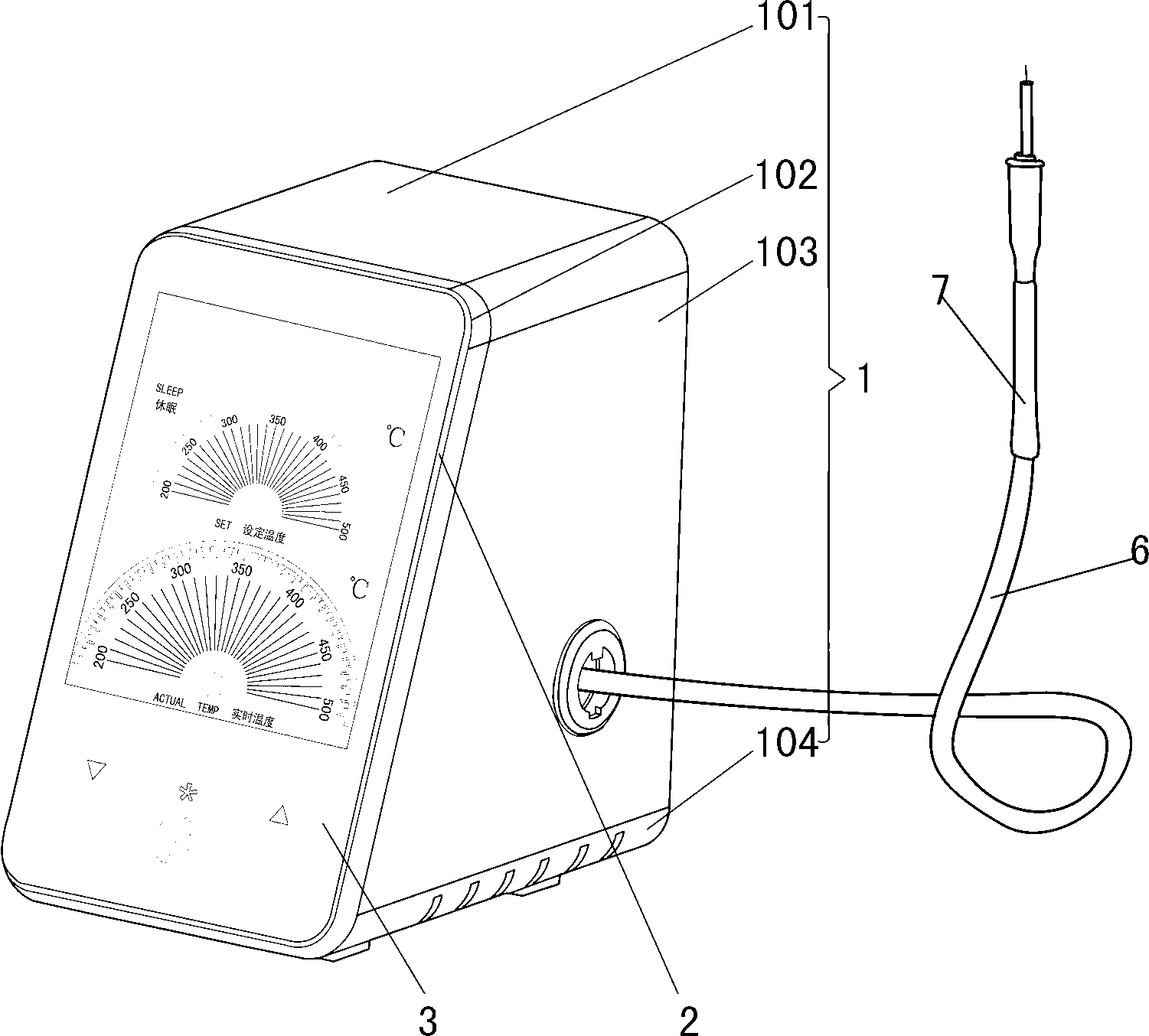

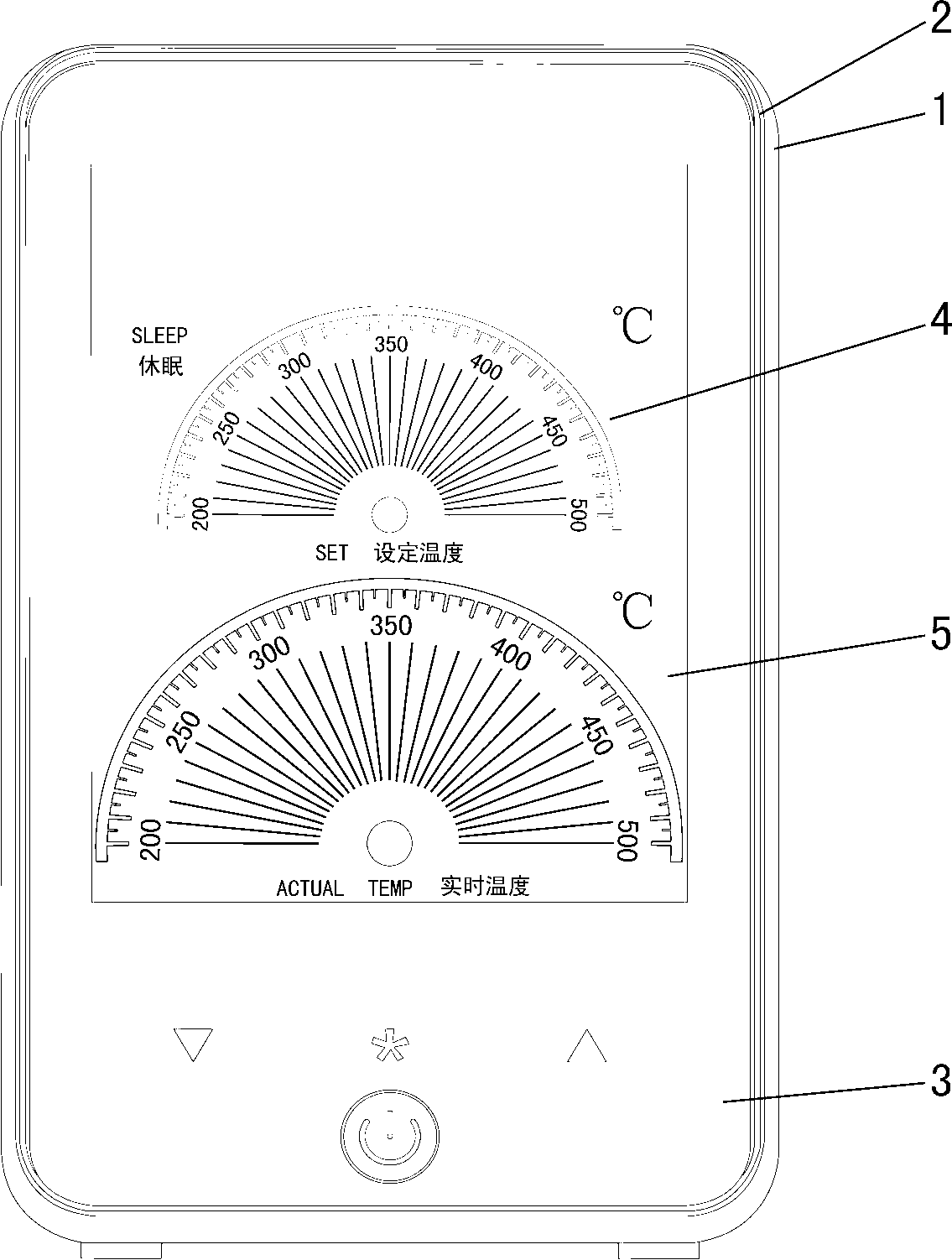

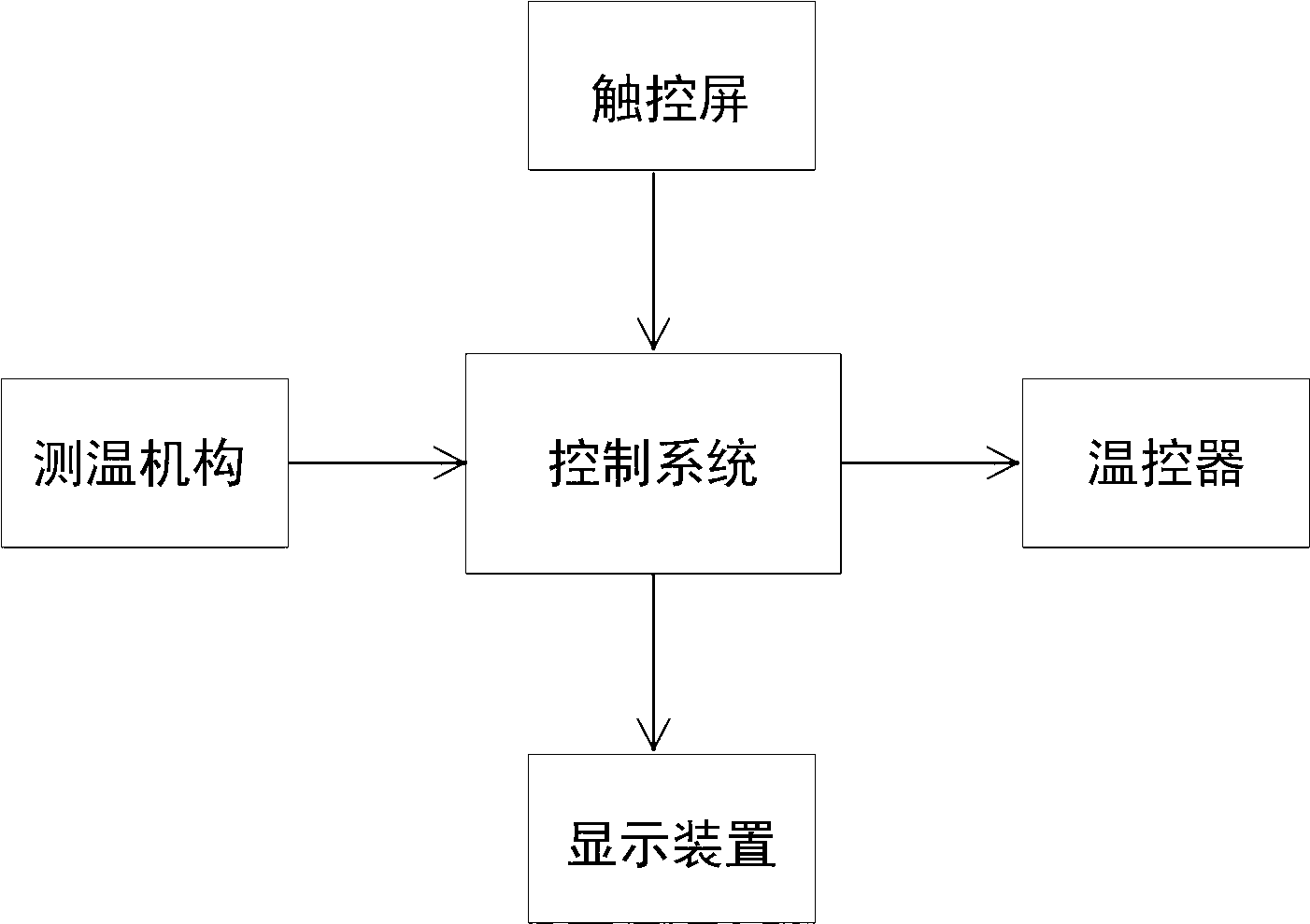

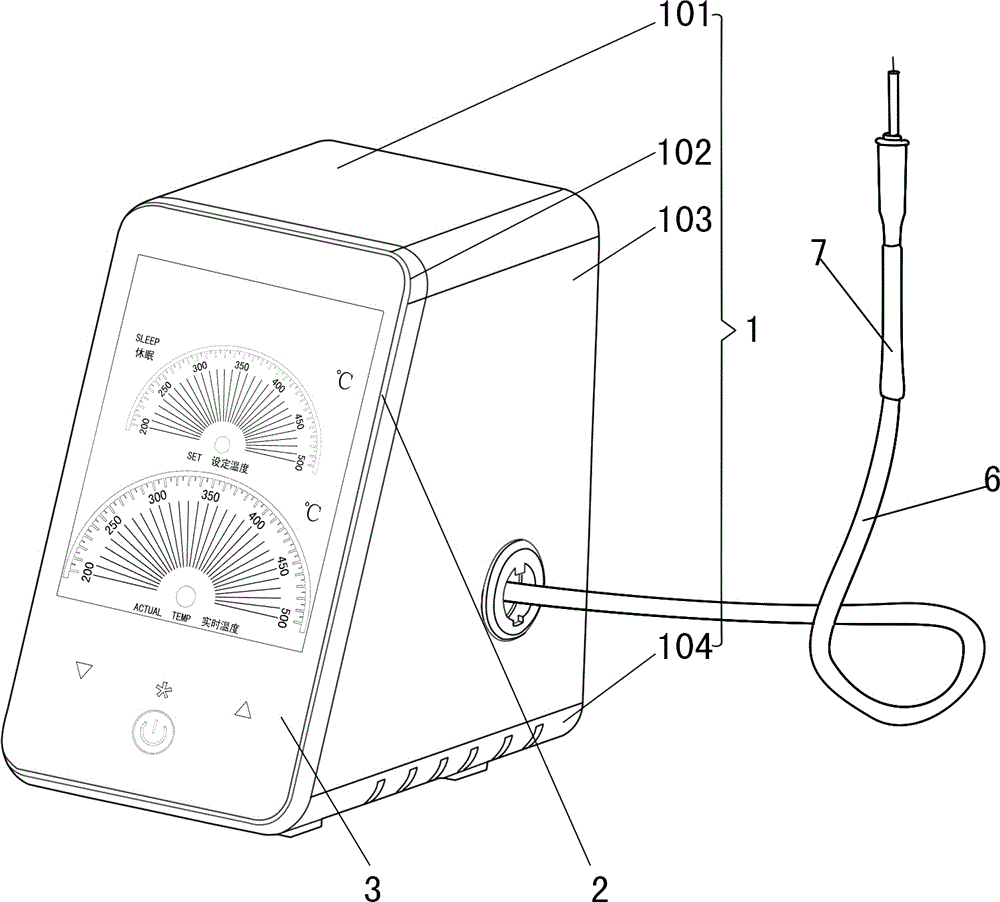

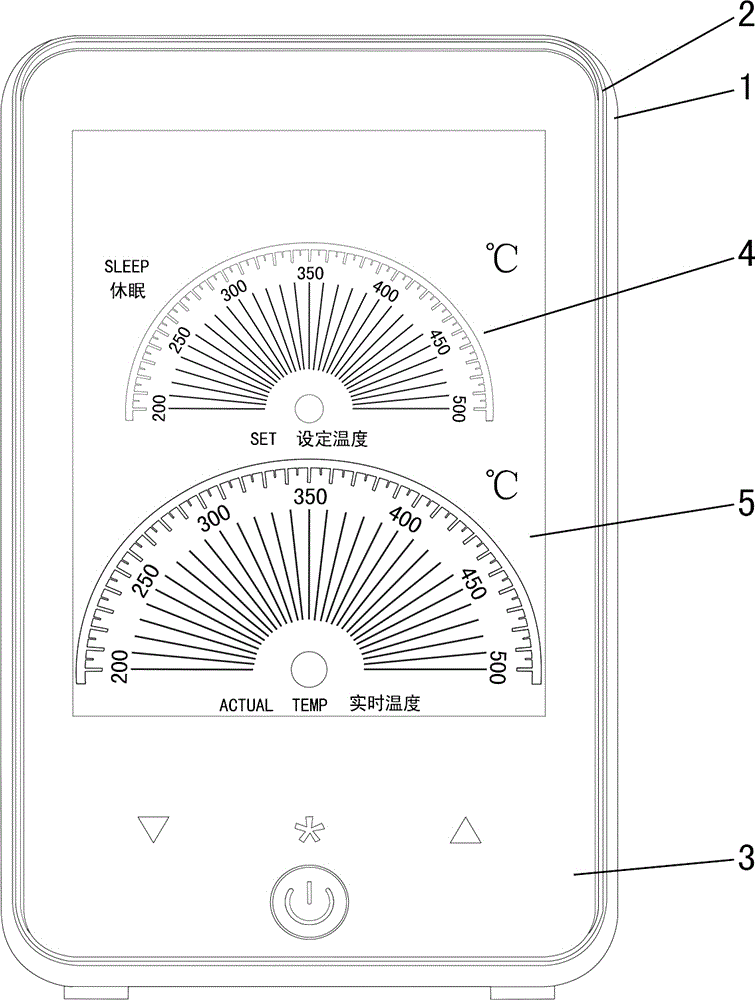

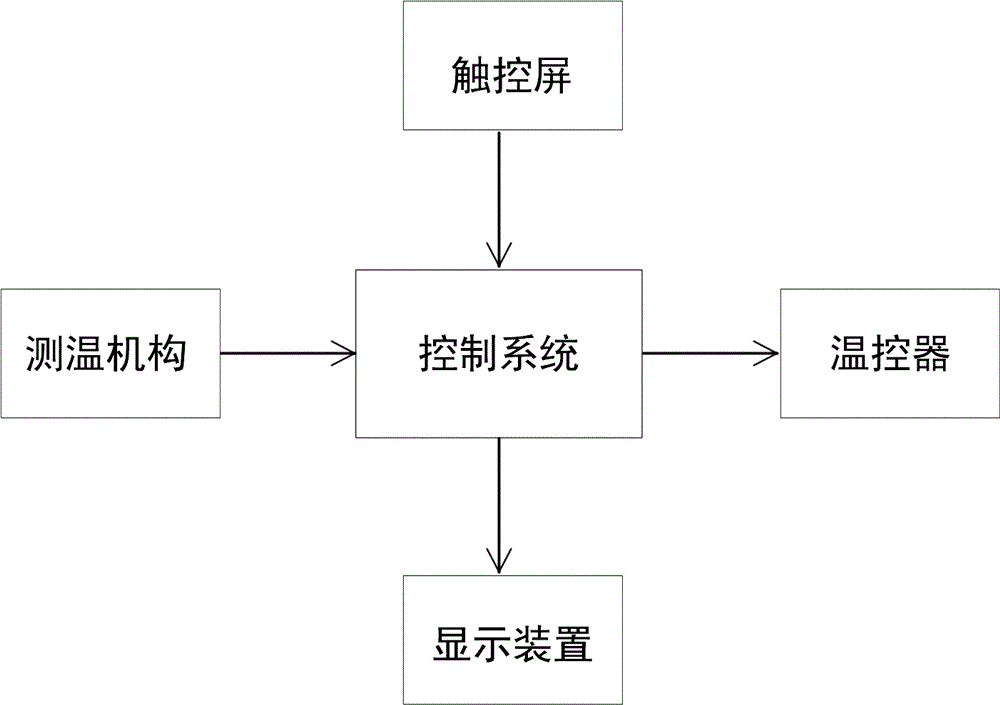

Touch soldering station

InactiveCN103317204AGood lookingBeautiful appearanceSoldering auxillary devicesControl systemDisplay device

The invention provides a touch soldering station and relates to a welding device. The touch soldering station comprises a handle, a casing, a control system arranged in the casing and a temperature controller. The casing comprises a top panel and a front side panel, and a temperature measurement mechanism is arranged in the handle. The touch soldering station is characterized in that a display device is arranged on the outer surface of the front side panel of the casing, and a touch screen is installed on the front surface of the display device. Compared with the prior art, the touch soldering station has the advantages that due to the fact that the touch screen is adopted to replace a mechanical button panel and is a smooth plane and the surface of the touch screen is not provided with other components, the touch soldering station is convenient to operate and simply and attractive in appearance, and due to the fact that a dial plate and a pointer are in a picture displayed by the display device, the problem that a temperature value seen by operators is deviated due to changes of view angles of the operators is solved.

Owner:汕头市华仑电子设备科技有限公司

Environment-friendly energy-saving hot air soldering station with automatic switch

InactiveCN101699605AExtend the life cycleMagnetic/electric field switchesMetal working apparatusElectricityTime delays

The invention discloses an environment-friendly energy-saving hot air soldering station with an automatic switch, which relates to a hot air soldering station, and is mainly developed to solve the problem that the conventional hot air soldering station has no automatic switch. The automatic switch adopts a form of the interaction of a dry reed pipe and a permanent magnet plus a relay. When the dry reed pipe approaches the permanent magnet of a handle bracket in a handle, a reed of the dry reed pipe is magnetized to make a contact closed, so that a coil of the relay is electrified to actuate, a normally closed contact is disconnected to cut off a thyristor trigger signal, a heating element is switched off to stop heating, a normally open contact of the relay is closed to control an air pump motor for time-delay work at the same time, and the shutdown is performed after the maximum airflow is given to the heating element for heat dissipation; and when the handle leaves the handle bracket, the handle begins to work so as to have the function of the automatic switch. The hot air soldering station has the advantages that: the hot air soldering station can prolong more than one time using period of the heating element, save more than 30 percent of electricity, and also prolong more than one time operation period of hot air soldering stations at the same time.

Owner:佟旭民

Touch Soldering Station

InactiveCN103317204BGood lookingBeautiful appearanceSoldering auxillary devicesControl systemDisplay device

The invention provides a touch soldering station and relates to a welding device. The touch soldering station comprises a handle, a casing, a control system arranged in the casing and a temperature controller. The casing comprises a top panel and a front side panel, and a temperature measurement mechanism is arranged in the handle. The touch soldering station is characterized in that a display device is arranged on the outer surface of the front side panel of the casing, and a touch screen is installed on the front surface of the display device. Compared with the prior art, the touch soldering station has the advantages that due to the fact that the touch screen is adopted to replace a mechanical button panel and is a smooth plane and the surface of the touch screen is not provided with other components, the touch soldering station is convenient to operate and simply and attractive in appearance, and due to the fact that a dial plate and a pointer are in a picture displayed by the display device, the problem that a temperature value seen by operators is deviated due to changes of view angles of the operators is solved.

Owner:汕头市华仑电子设备科技有限公司

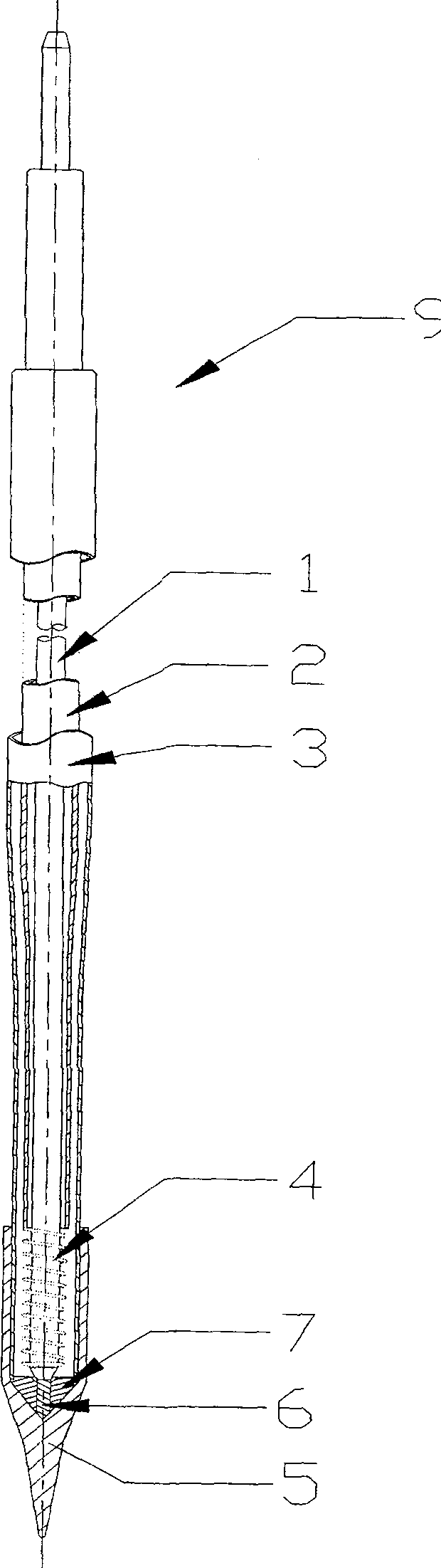

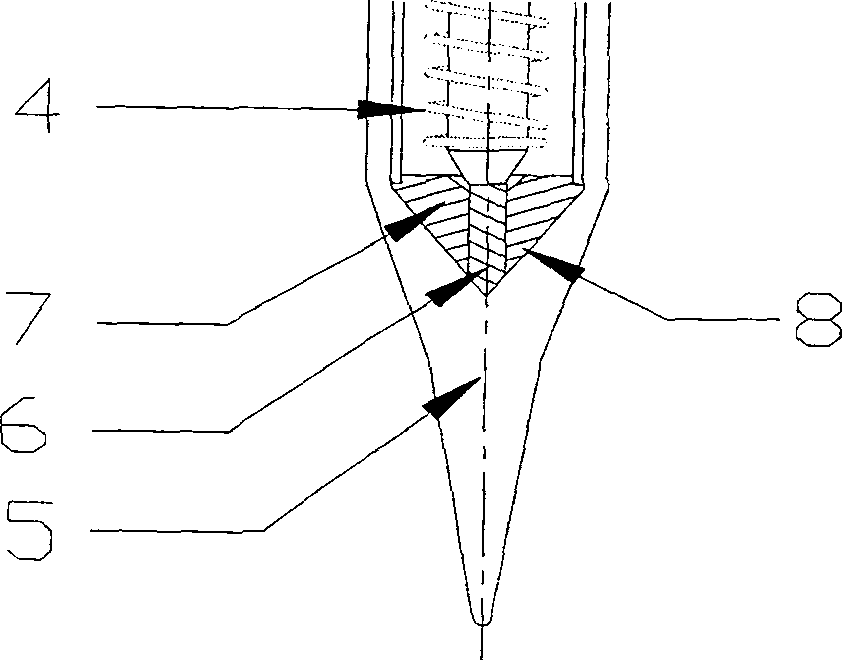

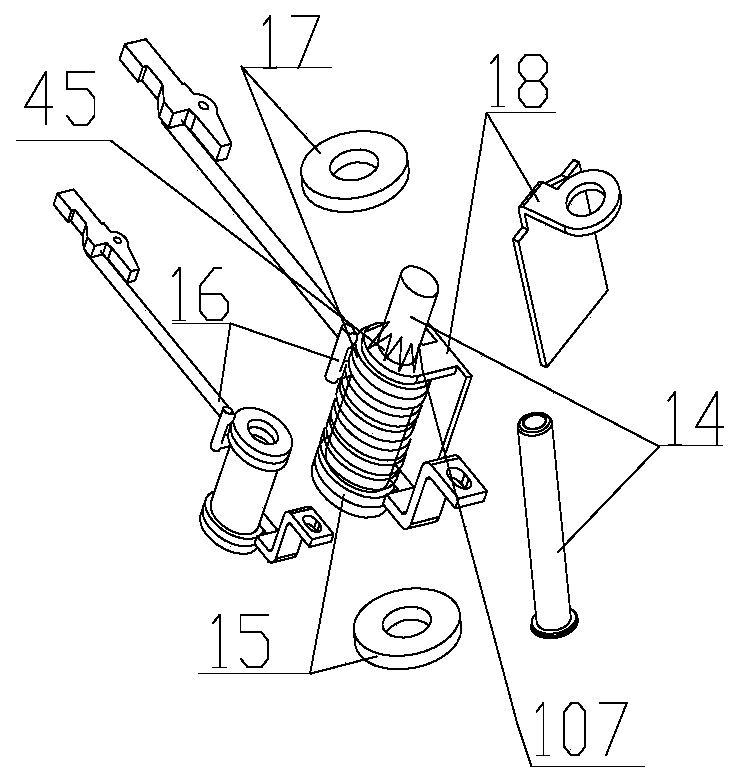

Leadless welding table

InactiveCN100509235CMonitor temperatureDetect temperature changesHeating appliancesSoldering ironElectrical conductorSolder station

The invention relates to a lead-free soldering station, comprising a first conductor (1), a second conductor (2), a third conductor (3), an electric heating element (4), a temperature sensing element (8), a working welding tip ( 5) an integrated soldering iron tip (9); a handle connected to the soldering iron tip; and a control circuit. Wherein, the electric heating element (4) is connected in series between the first conductor (1) and the second conductor (2) to form a heating circuit and connected to the control circuit; the temperature sensing element (8) is connected in series at the first A temperature measurement circuit is formed between a conductor (1) and a third conductor (3) and is connected to the control circuit; there is a cavity at the tail of the working welding tip (5), and the electric heating element (4) and the temperature sensor Elements (8) are located in said cavity. The external shape of the temperature sensing element (8) is a cone, and its conical surface is close to the bottom surface of the cavity of the working welding tip (5). It has the advantages of fast heating and replenishment, accurate temperature measurement, and convenient replacement and disassembly.

Owner:SHENZHEN WENTENG HOT CONTROL ELECTRON

Fully automatic welding system and welding method for electromagnetic components of low-voltage circuit breaker

ActiveCN107414236BEliminate weldsIncrease productivityAssembly machinesSolder feeding devicesLow voltage circuitsSolder station

The invention discloses a full-automatic welding system of an electromagnetic assembly of a low-voltage circuit breaker. The system comprises a rotary disc arranged on a horizontal table top. Eight clamp assemblies are uniformly arranged along the circumference close to the outer edge of the rotary disc, and an indexing mechanism is arranged on the lower surface of the rotary disc; eight mechanisms are successively arranged around the periphery of rotary disc on the horizontal table top; the eight clamp assemblies are uniformly distributed as eight rotating stations which are successively an oil cup loading station, a lower gasket loading station, a magnet yoke loading and storing station, a coil loading station, an upper gasket loading station, a magnet yoke loading station, a tin solder station and a discharging station. A product taking mechanism is arranged on the outer side of the discharging station. The invention also discloses a welding method of the electromagnetic assembly of the low-voltage circuit breaker. The device and method disclosed by the invention are compact in structure, reliable to work and high in welding quality.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

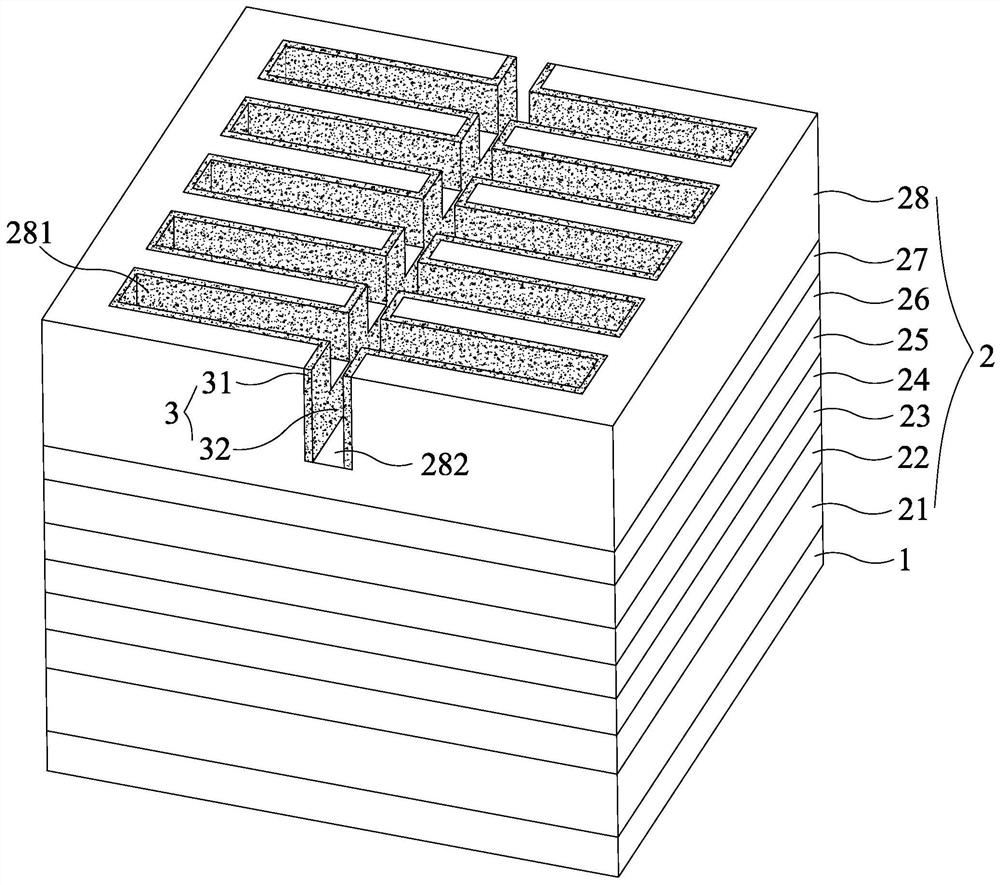

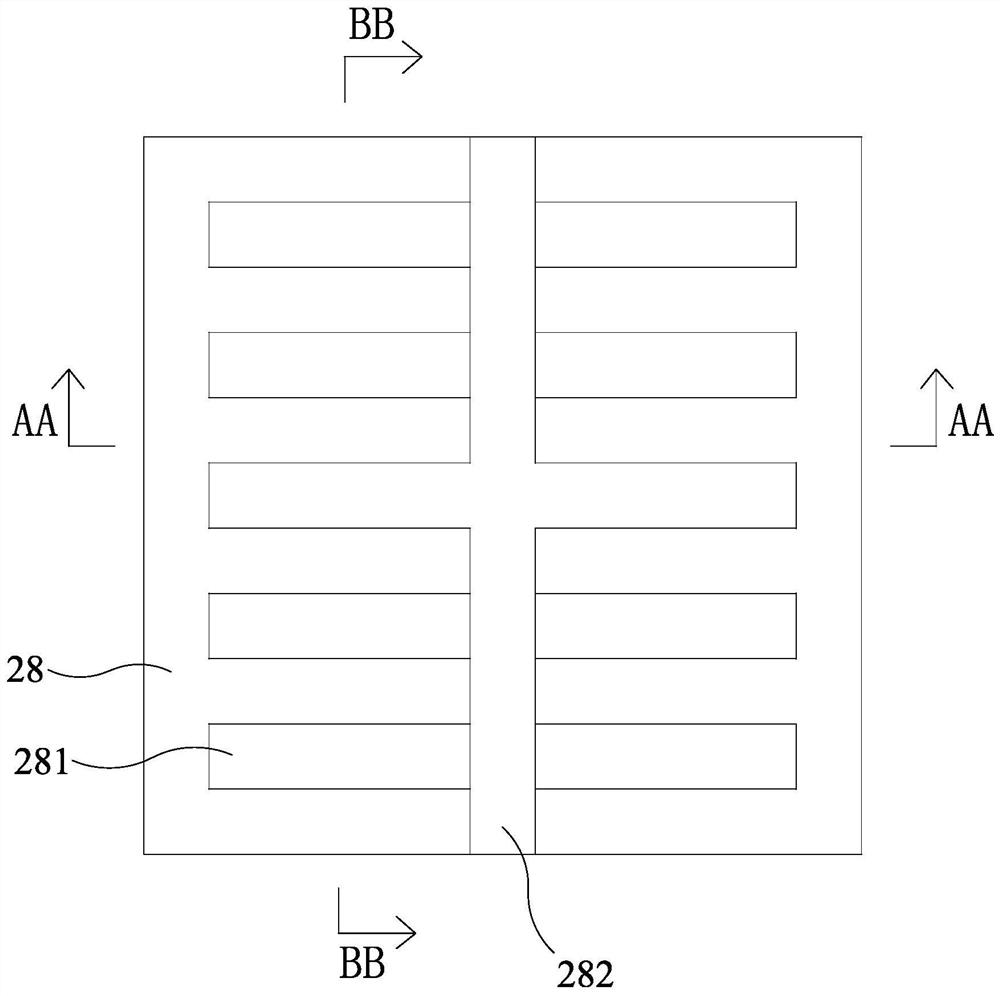

Infrared light-emitting diode with high-reliability electrodes

InactiveCN104201265AIncrease contact surfaceImprove adhesionSemiconductor devicesOhmic contactSolder station

The invention discloses an infrared light-emitting diode with high-reliability electrodes. A roughening layer is arranged on one side of an epitaxial light-emitting structure, a corrosion stop layer is arranged on the roughening layer, an ohmic contact layer is arranged on the corrosion stop layer, extension electrodes are formed on the surface of the ohmic contact layer, a micro roughening layer is arranged on the ohmic contact layer, and a bonding pad electrode is arranged on the micro roughening layer and connected with the extension electrodes; a metal reflector is arranged on the other side of the epitaxial light-emitting structure, a substrate is arranged on the metal reflector, and a back electrode is arranged on the substrate. Reliability of soldering station electrodes is improved effectively, the problem that soldering station electrodes are prone to falling off due to poor adhesion is solved, and the packaging problem that the epitaxial layer under the soldering station electrodes is easy to break up during wire bonding is solved as well.

Owner:XIAMEN CHANGELIGHT CO LTD

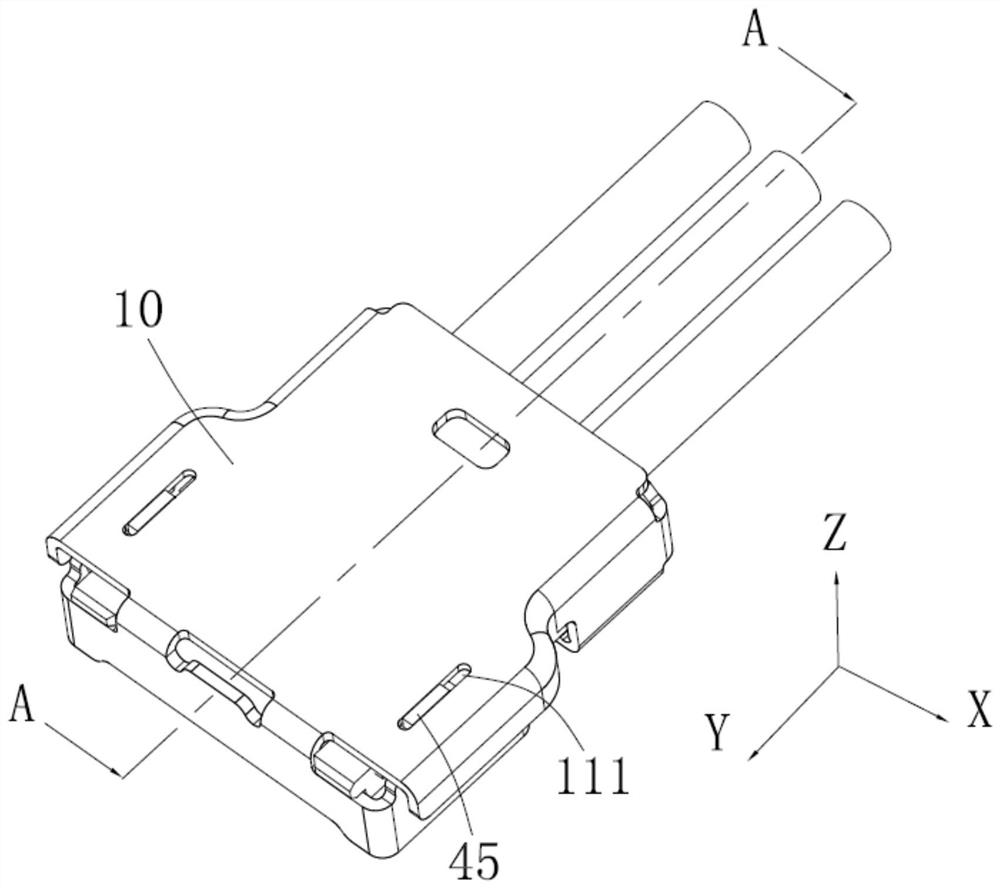

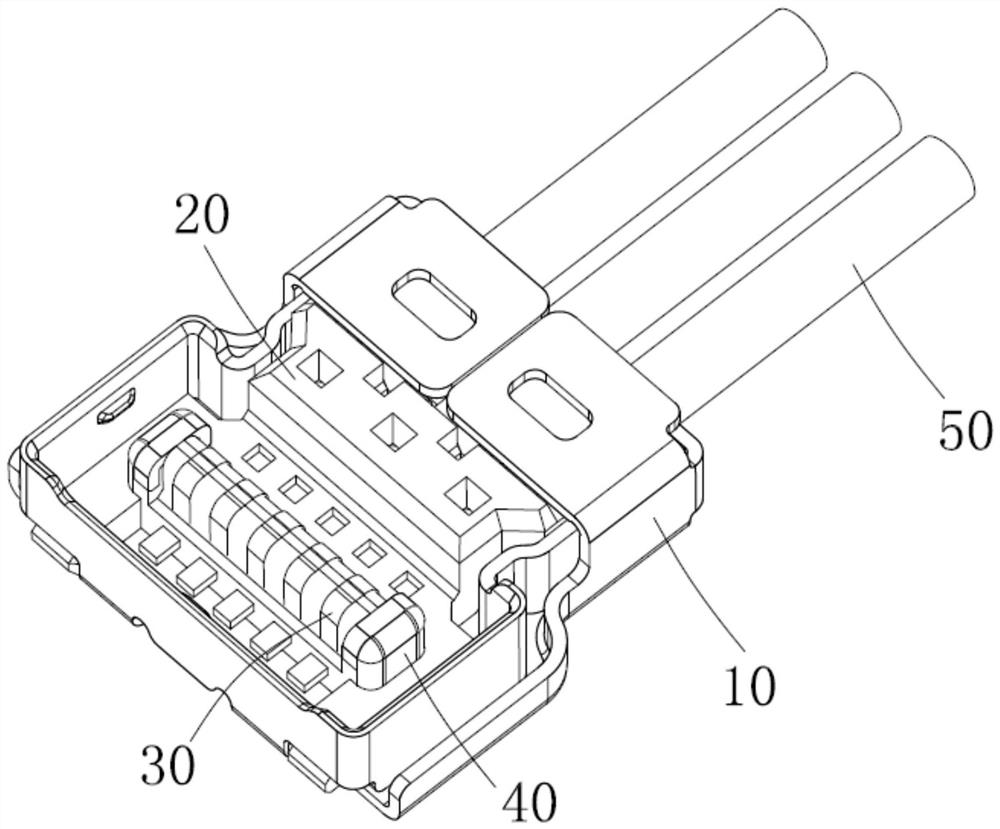

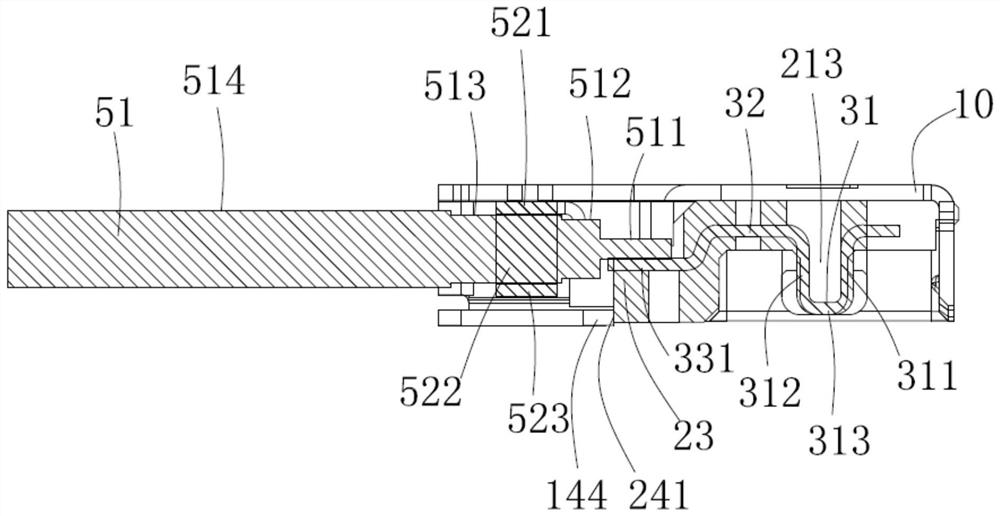

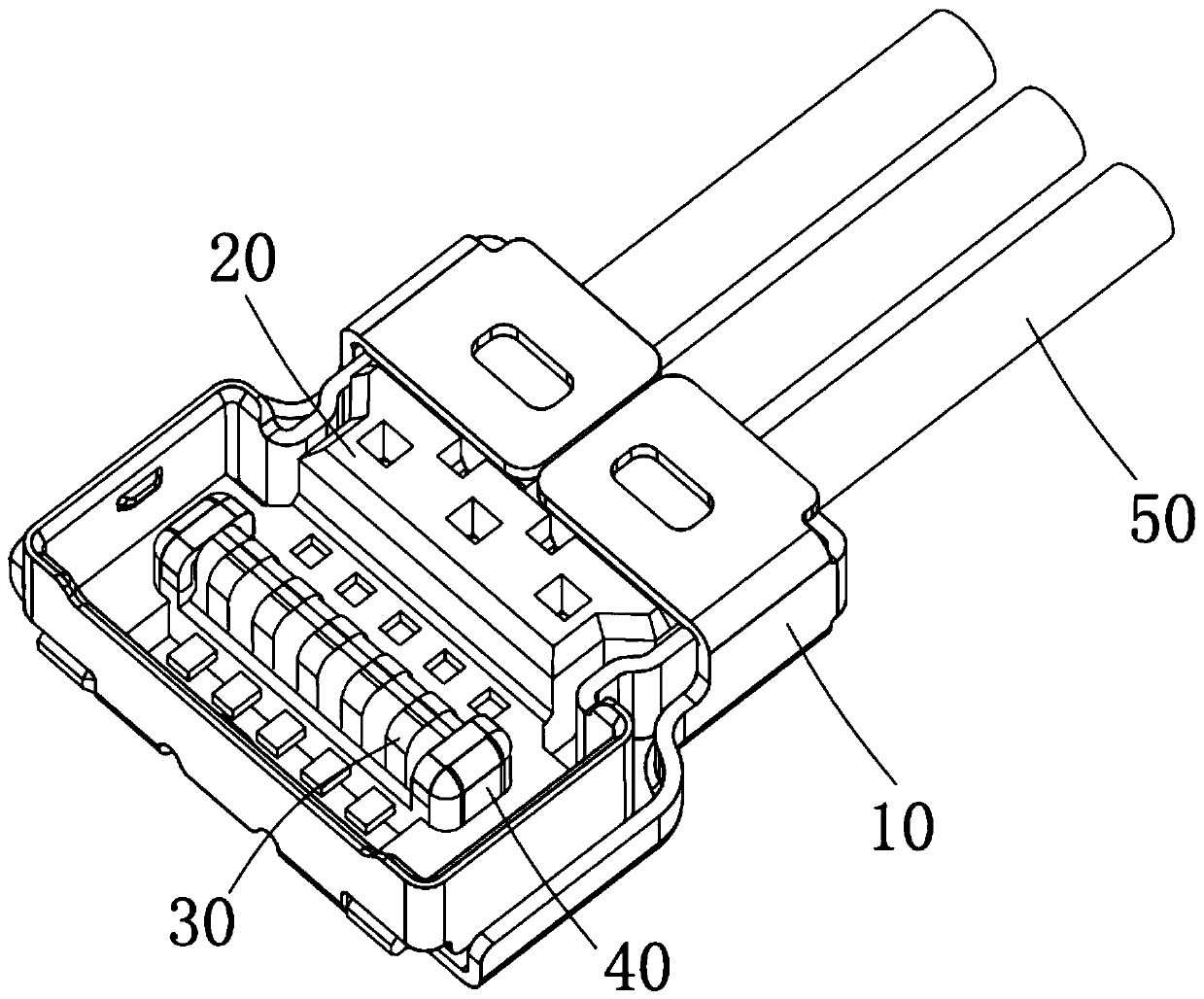

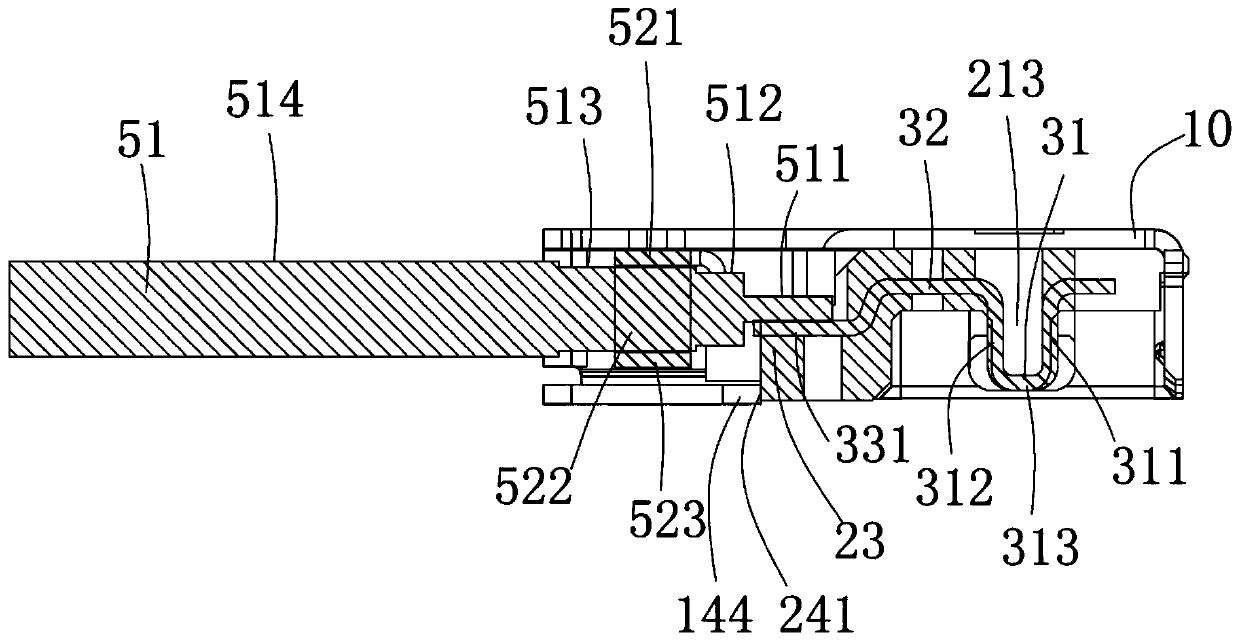

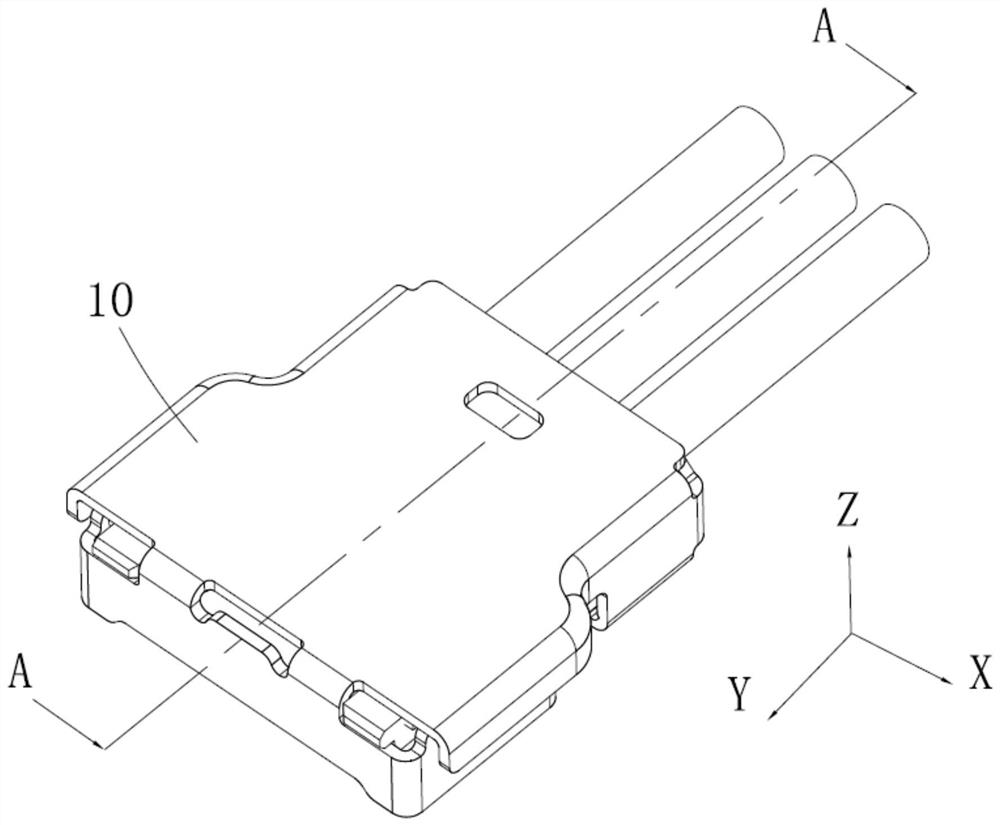

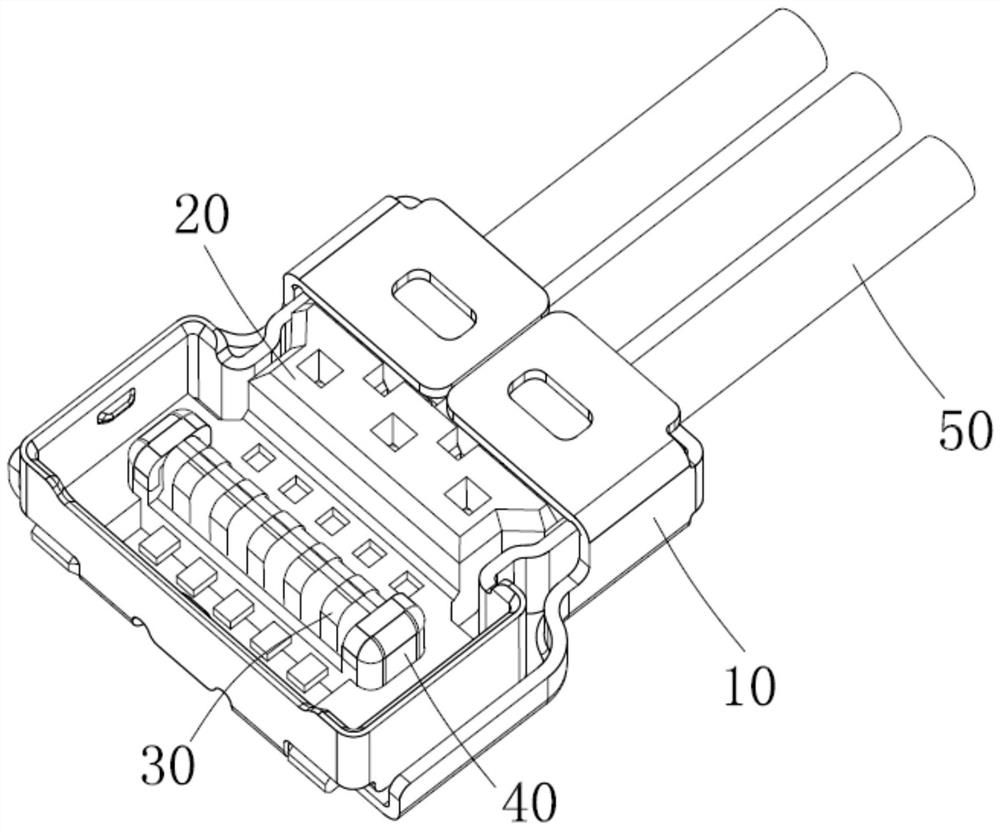

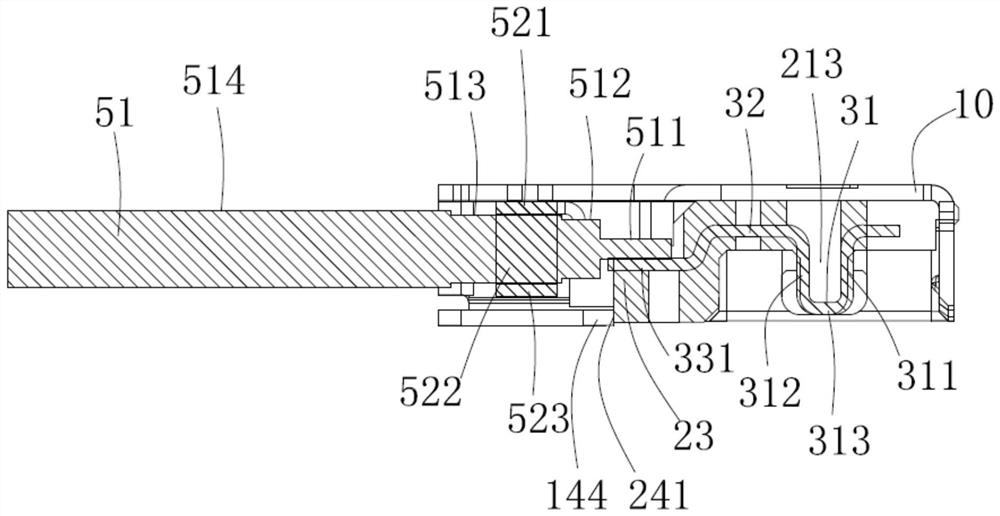

Board to Board Plug

ActiveCN111326904BPrecise push forwardAccurate insertionCoupling contact membersCoupling protective earth/shielding arrangementsStructural engineeringSolder station

A board-to-board plug, comprising several plug terminals, a plug body holding the several plug terminals as a whole, a cable assembly located behind the plug body and connected to the plug terminals, and a A shielding shell, the plug body includes a base and an extension formed from the base, the extension includes a protruding portion protruding downwards and a soldering station at the top, the shielding shell includes a base that covers the plug The covering top plate on the top surface of the main body, the covering front wall formed by bending downwards from the front end of the covering top plate, the covering side walls formed by bending backwards from the lateral ends of the covering front wall, and the plug body is formed with a convex strip, and the covering top plate is provided with a slot that is limited to the convex strip. The application can effectively limit the plug body.

Owner:KUNSHAN KTA COMM TECH CO LTD

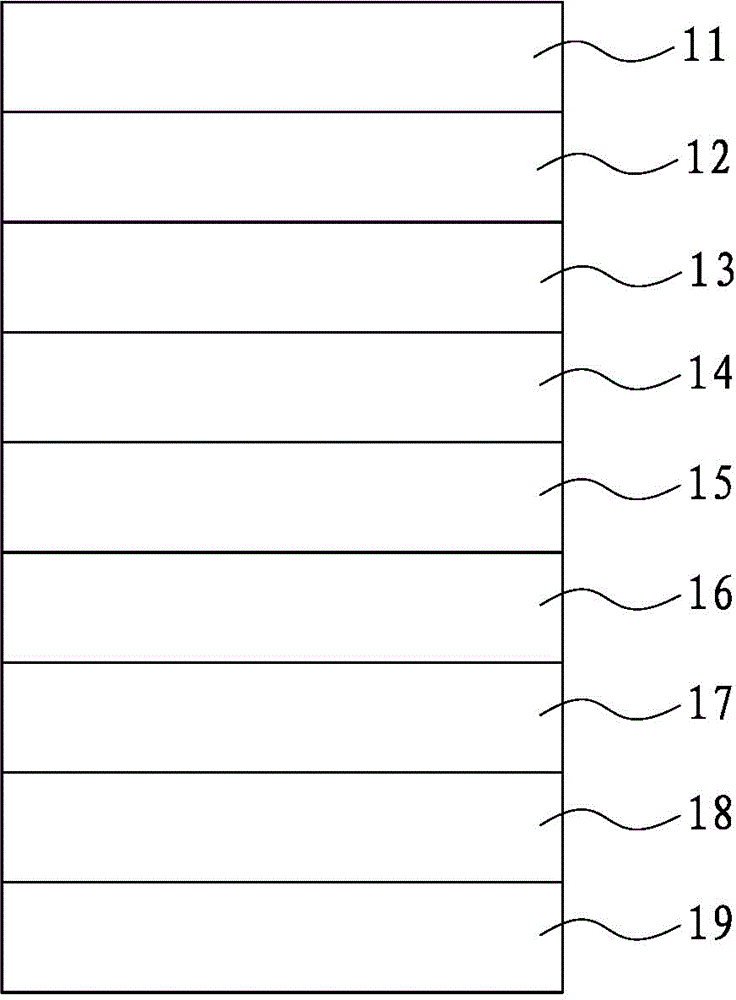

Method for manufacturing light-emitting diode emitting light through electrode

ActiveCN104377288AReduce shading areaReduce light blocking areaSemiconductor devicesQuantum efficiencyEtching

The invention discloses a method for manufacturing a light-emitting diode emitting light through an electrode. According to the method, an epitaxy light-emitting structure is formed on an epitaxy of an epitaxy substrate, and a light-pervious channel manufacturing layer is formed on the epitaxy light-emitting structure; a plurality of regular light-pervious channels are formed in an electrode area of the light-pervious channel manufacturing layer by means of a mask and an ICP etching process, and the depth of the portion, undergoing ICP etching, of an electrode area allows the surface of the epitaxy light-emitting structure to be exposed; light-pervious materials are evaporated on the surface of the exposed surface of the epitaxy light-emitting structure until the light-pervious channels are filled with the materials and a light-pervious column is formed; the light-pervious channel manufacturing layer is corroded and removed, the light-pervious column is retained and the epitaxy light-emitting structure is exposed; a soldering station electrode is formed on the surface of the epitaxy light-emitting structure, and the thickness of the solder station electrode is larger than the height of the light-pervious column; the surface of a first electrode or a second electrode which serves as the soldering station electrode is under ICP etching until the upper surface of the light-pervious column is exposed; a back electrode is formed on the epitaxy light-emitting structure, and a light-emitting diode chip is formed on a split sheet. The light blocking area of the soldering station electrode can be reduced, and external quantum efficiency of the light-emitting diode can be improved.

Owner:XIAMEN CHANGELIGHT CO LTD

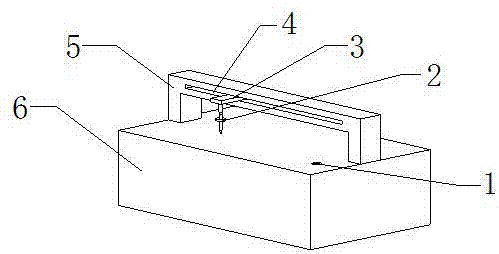

Automatic rectangular coordinate soldering machine for linear module

InactiveCN107529465AAvoid corrosionGuarantee welding qualityMetal working apparatusSoldering auxillary devicesRectangular coordinatesSolder station

The invention provides a linear module Cartesian coordinate automatic soldering machine, which includes a sealing groove, a placement hole, a hollow cavity, an exhaust pipe, a small air pump, an air intake pipe, an electric telescopic rod, a sealing plate and a welding head, and the placement hole It is set in the middle of the lower end surface inside the sealing groove, and the lower end of the placement hole is connected to the hollow cavity. The small air pump is arranged inside the soldering station, the upper end of the air intake pipe is connected to the hollow cavity, and the lower end of the air intake pipe is connected to a small air exhaust machine. The left end of the exhaust pipe is connected to a small air extractor, and the right end of the exhaust pipe extends to the right side of the soldering station. This design realizes the purpose of the vacuum protection welding head of the present invention. The upper end of the electric telescopic rod is installed on the lower end surface of the slide plate. The lower end of the electric telescopic rod is equipped with a welding head, and the sealing disc is assembled on the upper side of the ring side of the welding head. This design realizes the rapid sealing of the present invention. The present invention has high working effect, long service life, good stability and high reliability. .

Owner:陈美赞

A continuous production device for filament lamp foot components

InactiveCN103337439BIncrease productivityReduce manpower consumptionSequential operation station machinesElectrode assembly manufactureSolder stationEngineering

A lamp filament lamp base component continuous production apparatus is characterized by comprising a machine frame, a rotating disk arranged on the machine frame and driven by power, clamps arranged at the periphery of the rotating disk and used for clamping the lamp bases, a lamp base molding station, a molybdenum chip bonding station, an upper solder station, a lamp filament soldering station, and a blanking station. The lamp base molding station, the molybdenum chip bonding station, the upper solder station, the lamp filament soldering station, and the blanking station are arranged on the machine frame and arranged from the rotating disk to the periphery sequentially. Compared with prior arts, the lamp filament lamp base continuous production apparatus is advantaged by being high in production efficiency and low in manpower consumption. The lamp filament lamp base continuous production apparatus is also advantaged by being fully automatic.

Owner:李家凌

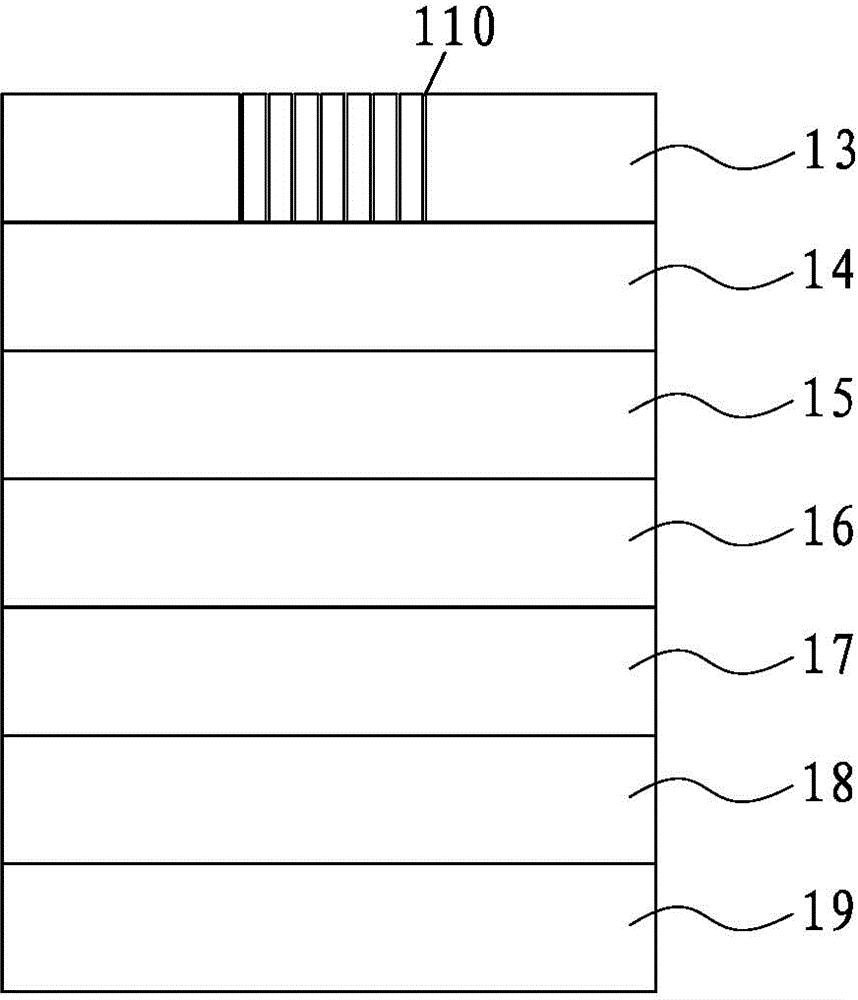

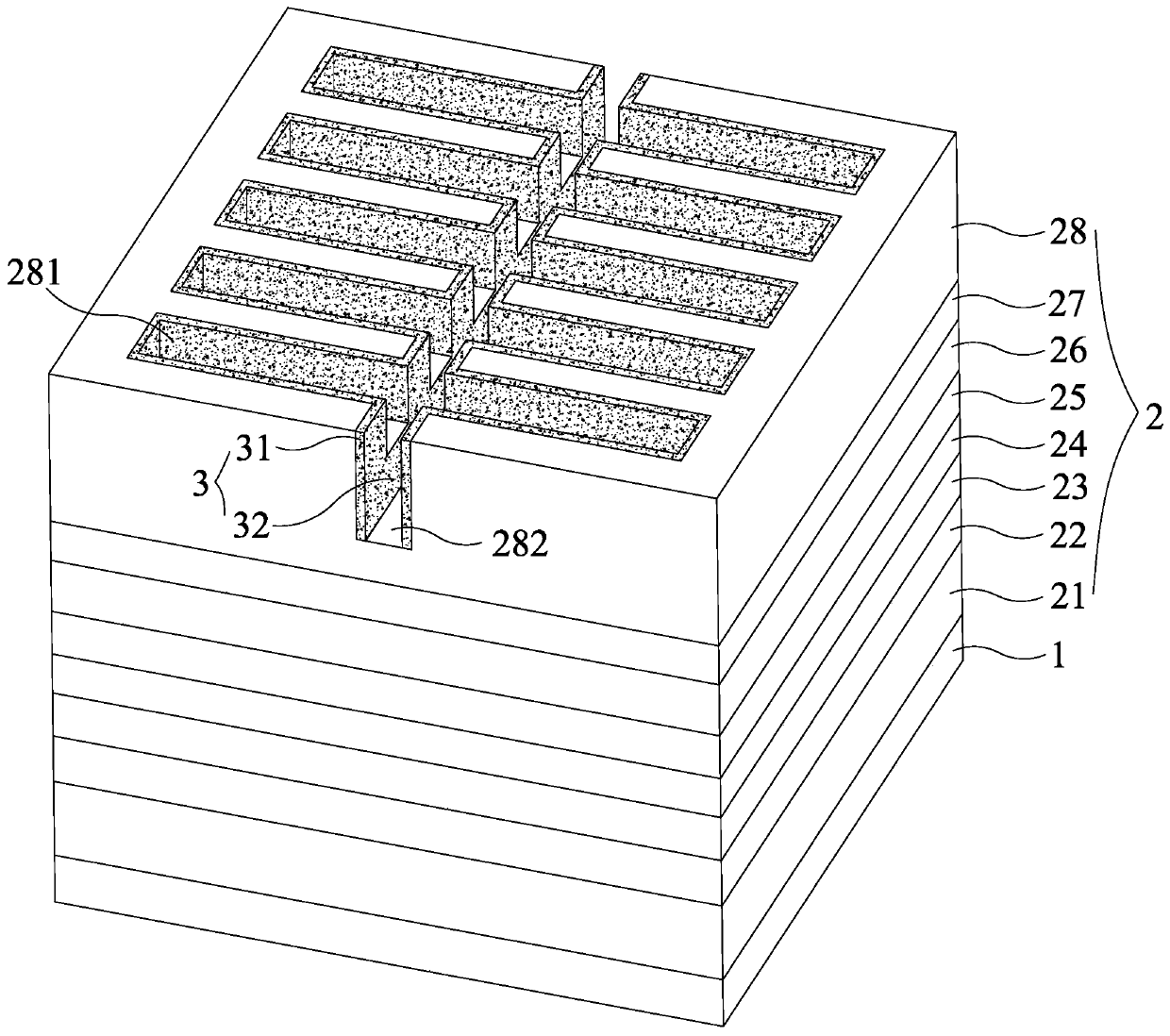

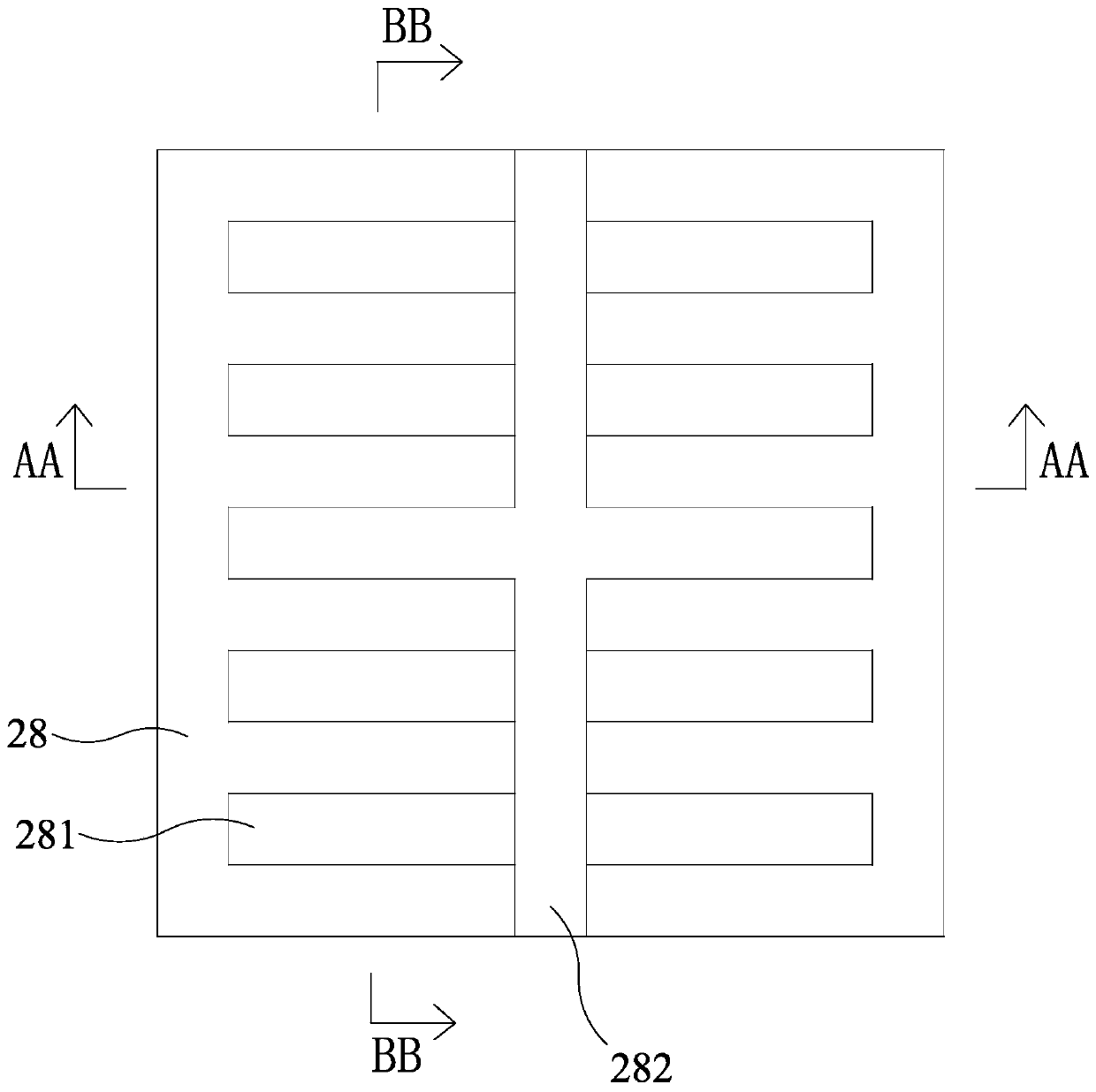

A large-size light-emitting diode with invisible extended electrodes and its manufacturing method

ActiveCN110783436BSolve the problem of blocking lightLarge range of light emitting areaSemiconductor devicesElectrical connectionSolder station

The invention discloses a large-sized LED with a concealed extension electrode. The large-sized LED includes an epitaxial structure, a second electrode, and a first electrode composed of a solder padelectrode connected to a metal extension electrode. The epitaxial structure includes a substrate, a second type of conductive layer, an active layer and a first type of conductive layer. The second type of conductive layer is electrically connected to the second electrode. A groove is formed in the first type of conductive layer. The side walls of the groove form metal extension electrode layers.The metal extension electrode layers of the adjacent side walls are continuous with each other. The solder pad electrode is arranged in the groove. The solder pad electrode and the metal extension electrode layers are electrically connected to each other. The invention also discloses a manufacturing method of the LED. A special groove structure is provided to achieve an effect of uniformly expanding the current. The extension electrode has an extremely low thickness, and is arranged on the vertical surface on the side of the groove, which is equivalent to being invisible. The large-sized LED solves the problem that the bottom surface of a metal extension electrode in the prior art shields light, and realizes a wide range of light emitting area, thereby maintaining a superior current spreading effect.

Owner:XIAMEN CHANGELIGHT CO LTD

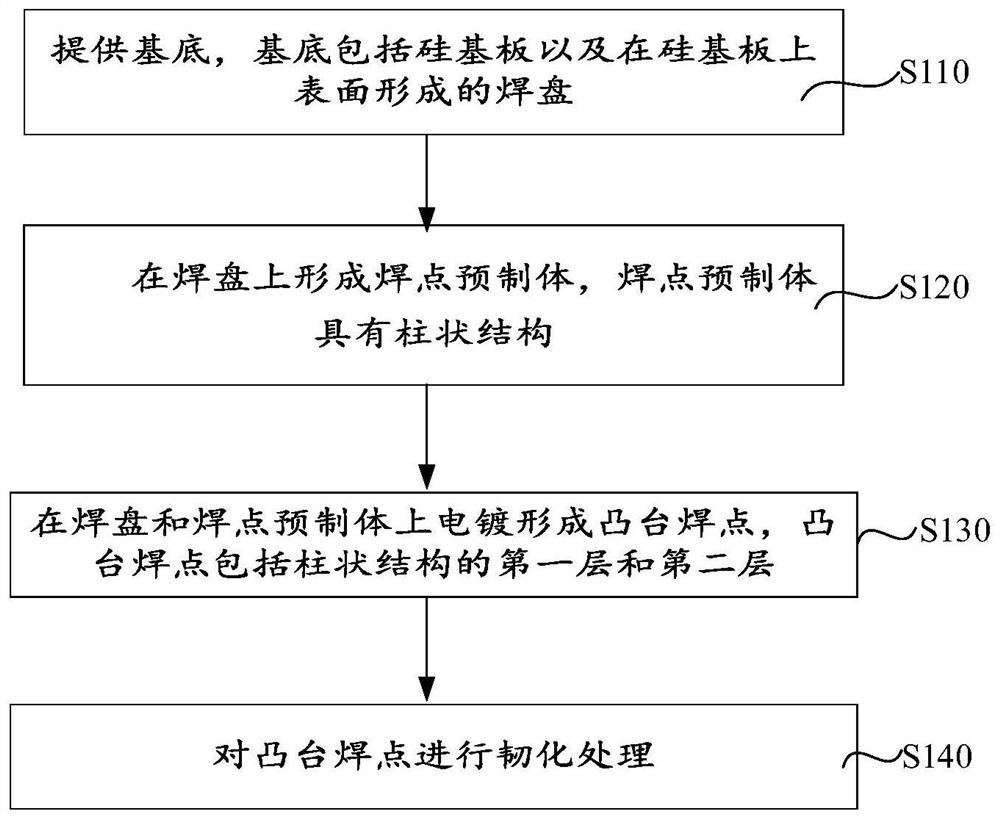

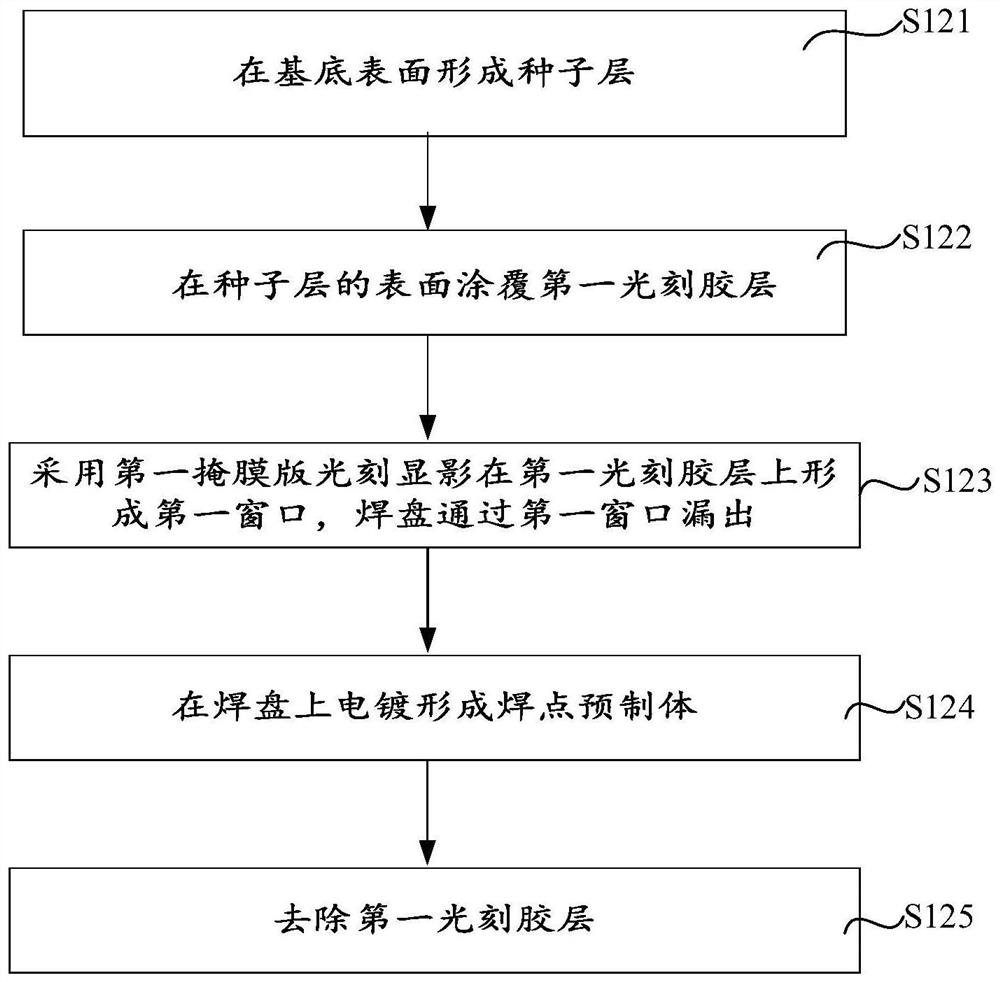

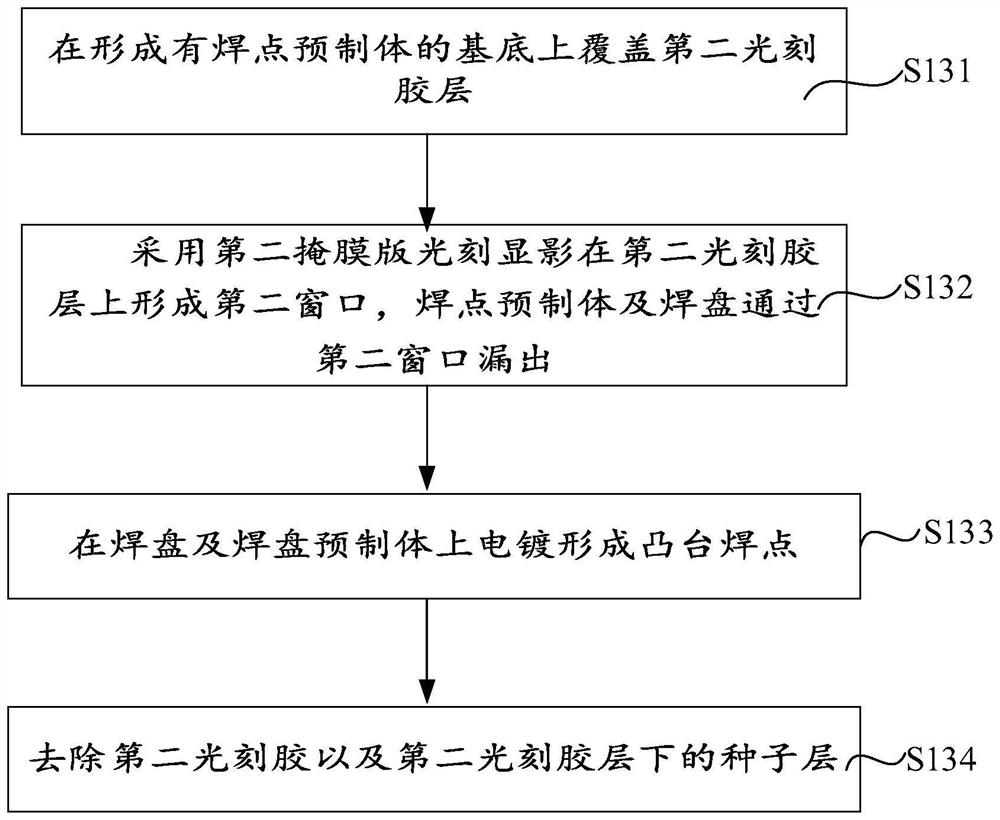

Chip welding spot structure, preparation method thereof and packaging structure

PendingCN114373690AImprove packaging yieldAvoid shortingSemiconductor/solid-state device detailsSolid-state devicesEngineeringStructural engineering

The invention discloses a chip welding spot structure, a preparation method thereof and a packaging structure, and relates to the technical field of electronic components, and the preparation method of the chip welding spot structure comprises the steps that a substrate is provided, and the substrate comprises a silicon substrate and a bonding pad formed on the upper surface of the silicon substrate; forming a welding spot prefabricated body on the bonding pad, wherein the welding spot prefabricated body has a columnar structure; a boss welding spot is formed on the welding pad and the welding spot prefabricated body through electroplating, the boss welding spot comprises a first welding table and a second welding table which are of a columnar structure, the first welding table and the second welding table are arranged in a stacked mode in the extending direction of the columnar structure, and the sectional area of the first welding table is smaller than that of the second welding table. According to the chip welding spot structure, the preparation method thereof and the packaging structure provided by the invention, short circuit between the two welding spots during packaging can be prevented, so that the packaging yield of the chip is improved.

Owner:CHIPMORE TECH CORP LTD +1

A chip replacement method

ActiveCN107911955BShort replacement timeImprove welding yieldPrinted circuit assemblingTemperature curveSolder ball

A chip replacement method disclosed by the present invention is suitable for replacing a ball grid array (BGA) packaging chip, belongs to the mainboard maintenance technology field, and comprises thefollowing steps of providing a ball grid array soldering station; setting a temperature curve that the BGA soldering station works; fixing a mainboard on the BGA soldering station, and aligning a to-be-replaced chip on the mainboard at a wind inlet and a wind outlet of the BGA soldering station; starting the BGA soldering station, enabling the BGA soldering station to heat the to-be-replaced chipaccording to the temperature curve, and operating the BGA soldering station when the actual working temperature of the BGA soldering station and the highest temperature of the temperature curve have the preset temperature difference to enable the BGA soldering station to keep a current working temperature; taking out the to-be-replaced chip from the mainboard, and cleaning the soldering tin on a pad corresponding to the to-be-replaced chip; turning off the BGA soldering station, and placing a substituting chip on the pad; starting the BGA soldering station, and enabling the BGA soldering station to solder the substituting chip on the mainboard according to the temperature curve. The beneficial effects of the above technical scheme are that the BGA chip replacement time is short, the soldering yield is high, and the BGA chip replacement efficiency is improved.

Owner:AMOLOGIC (SHANGHAI) CO LTD

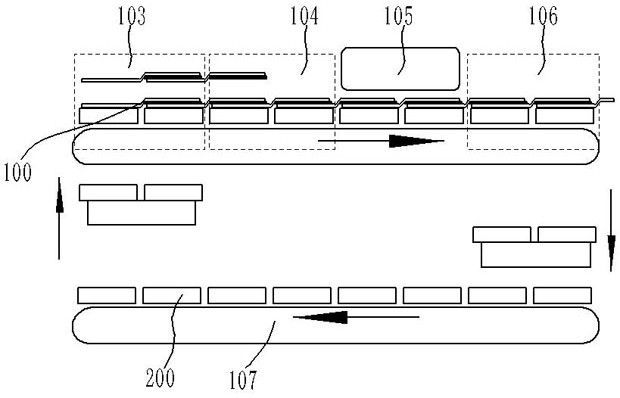

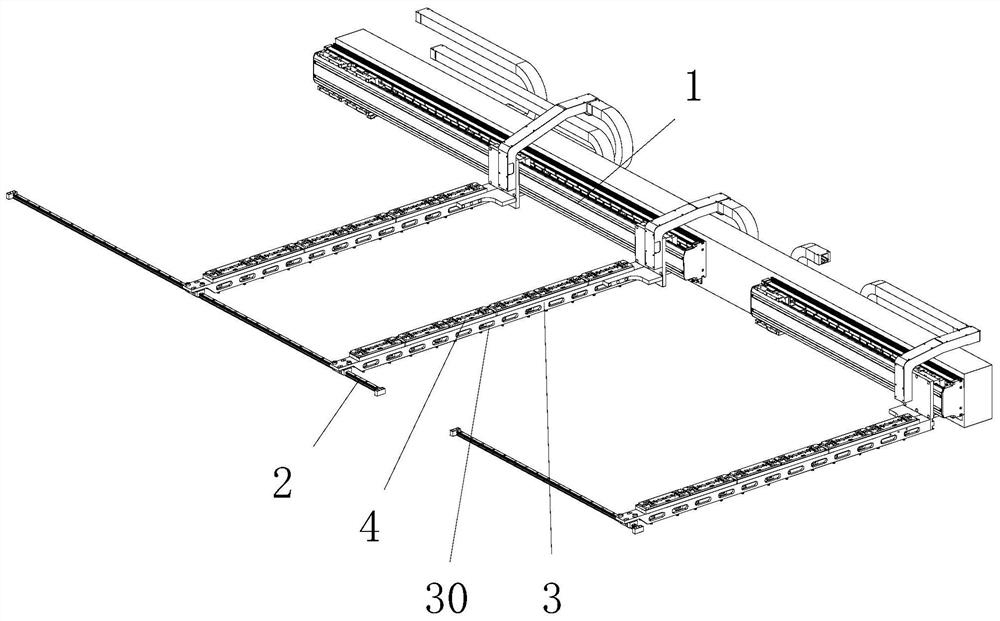

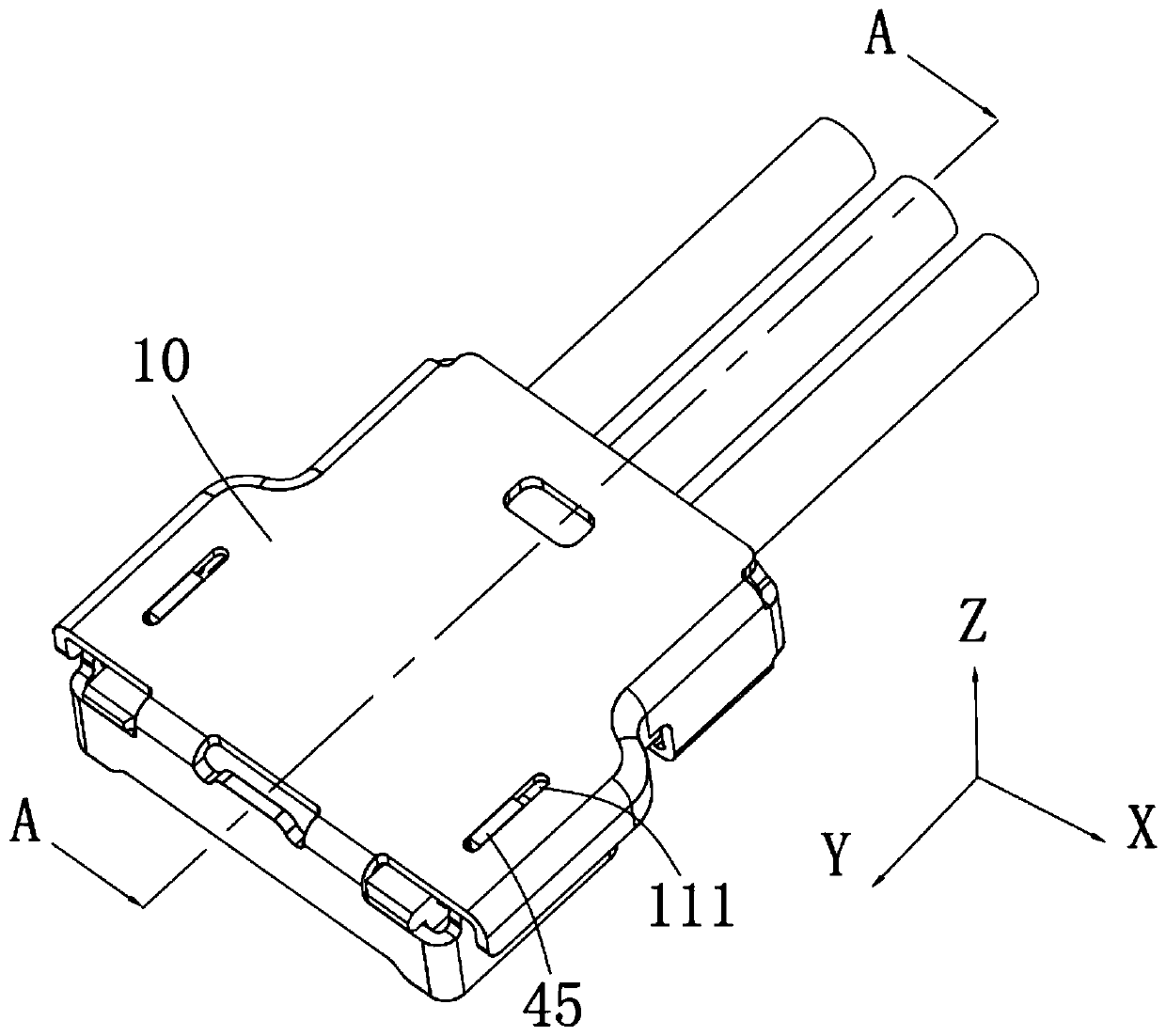

Welding station module circulating device, welding station module and method for welding battery string

ActiveCN114833418AShorten welding timeIncrease productivityFinal product manufactureWelding/soldering/cutting articlesElectrical batteryProcess engineering

The invention discloses a welding station module circulating device, a welding station module and a method for welding a battery string, the welding station module is used for supporting and controlling a welding strip below the unwelded battery string, and an upper-layer transmission mechanism is used for synchronously transmitting the welding station module and the battery string backwards and completing heating and cooling of the battery string, so that the welding strip is fixedly connected with a battery piece; the lower-layer conveying mechanism is used for conveying the welding table module to the front end of the upper-layer conveying mechanism and caching the welding table module; the second transfer mechanism is used for transferring the welding table modules fixedly connected to the upper-layer conveying mechanism to the lower-layer conveying mechanism, and the first transfer mechanism is used for transferring the welding table modules on the lower-layer conveying mechanism to the front end of the upper-layer conveying mechanism to bear the battery strings. Heating and curing of the battery string are separated, heating, curing and battery string laying in the battery string preparation process can be carried out at the same time, the welding time of the battery string is shortened, and the production efficiency of battery string welding is improved.

Owner:江苏小牛自动化设备有限公司

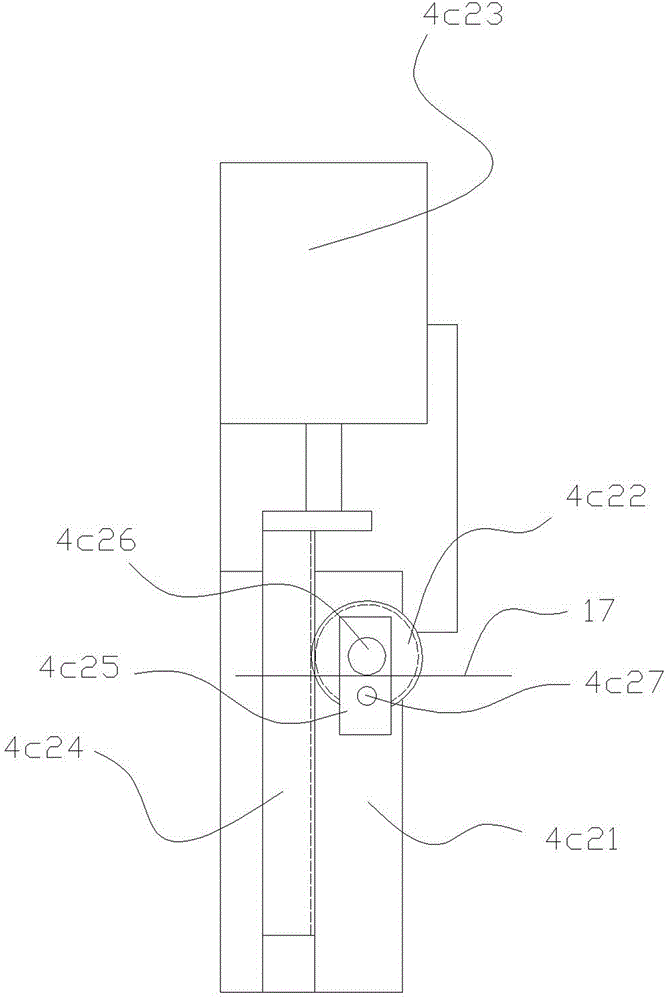

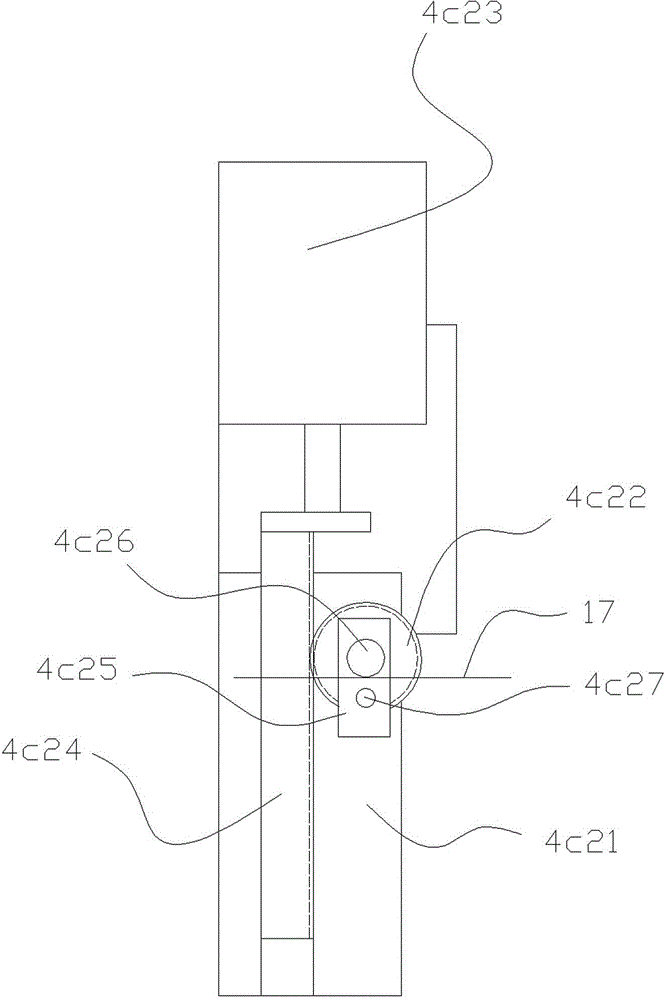

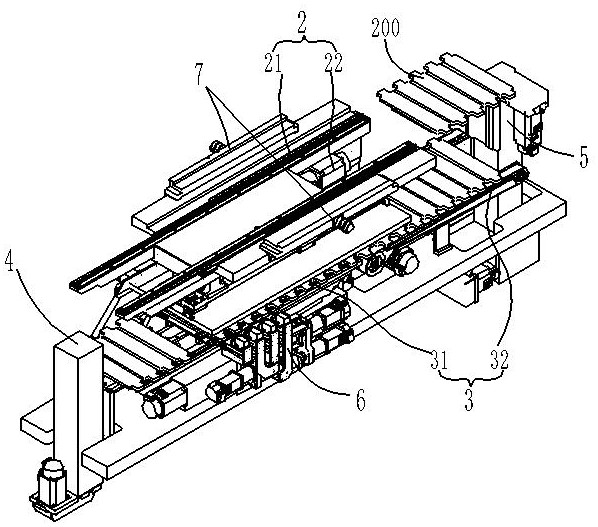

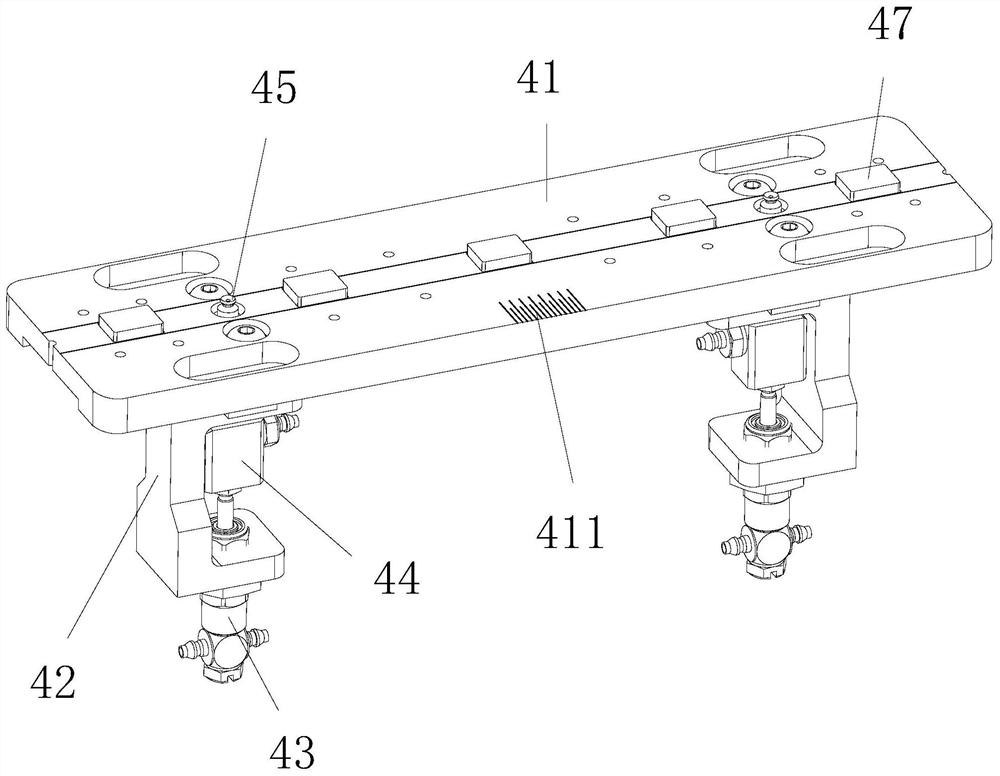

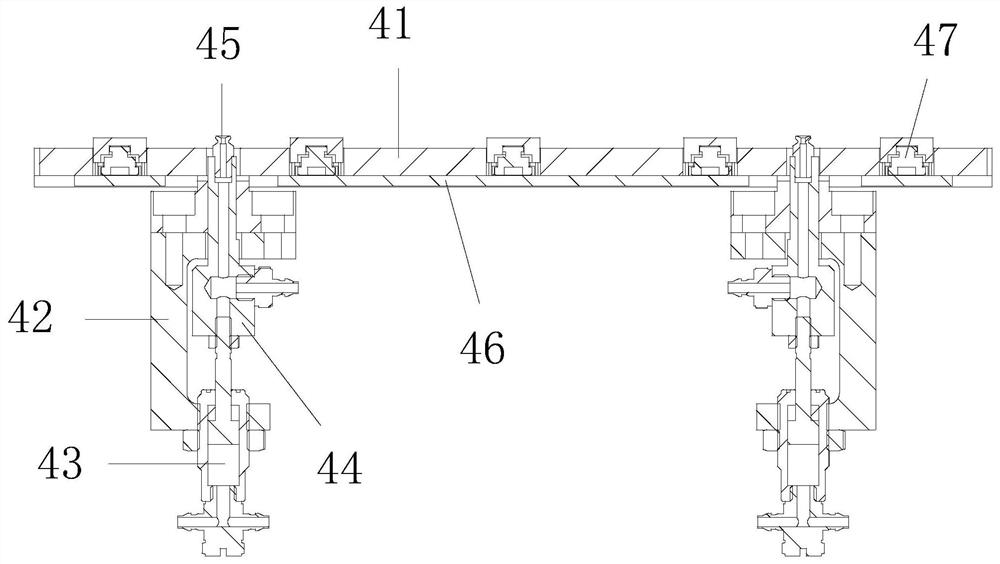

Soldering station mechanism for battery assembly

PendingCN111940973AAdjustable positionWide applicabilityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSolder station

The invention discloses a soldering station mechanism for a battery assembly. The soldering station mechanism for the battery assembly comprises a linear module, a follow-up linear sliding rail, a moving frame and soldering station assemblies, wherein the linear module and the follow-up linear sliding rail are arranged in parallel; the moving frame is installed on a sliding block of the linear module; the other end of the moving frame is arranged on a sliding block of the follow-up linear sliding rail; the position-adjustable soldering station assemblies are installed on the moving frame in anarray mode; horizontally-arranged adjusting holes are formed in the moving frame at equal intervals; and screws penetrate through the adjusting holes and then are locked onto the soldering station assemblies. By means of the mode, the soldering station is compact in structure, stable in operation, and capable of guaranteeing the stability of a welding rod; a rubber sucking disc downwards moves and retreats so as to be prevented from being damaged by high-temperature welding; the positions of each two adjacent soldering station assemblies is adjustable so as to be capable of being matched withproducts of different sizes, so that the applicability is wide; and a welding point floating structure is arranged in a floating mode, so that a welding head is ensured to make close contact with a welding point without damaging a product.

Owner:SUZHOU SHENGCHENG SOLAR EQUIP

Board-to-board plug

ActiveCN111326904APrecise push forwardAccurate insertionCoupling contact membersCoupling protective earth/shielding arrangementsStructural engineeringSolder station

Provided is a board-to-board plug. The a board-to-board plug comprises a plurality of plug terminals, a plug body, a cable assembly and a shielding shell, wherein the plug body is used for fixing theplurality of plug terminals into a whole, the cable assembly is positioned behind the plug body and is connected with the plug terminals, and the shielding shell is coated outside the plug body; the plug body comprises a base part and an extension part formed by extending backwards from the base part, and the extending part comprises a protruding part formed by protruding downwards and a welding table located at the top; the shielding shell comprises a covering top plate covering the top surface of the plug body, a covering front wall formed by bending downwards from the front end of the covering top plate, and a covering side wall formed by bending backwards from the two transverse ends of the covering front wall; and a raised line is formed on the plug body, and the covering top plate isprovided with an open slot limited with the raised line. According to the invention, the plug body can be effectively limited.

Owner:KUNSHAN KTA COMM TECH CO LTD

Large-sized LED with concealed extension electrode and manufacturing method

ActiveCN110783436ASolve the problem of blocking lightLarge range of light emitting areaSemiconductor devicesElectrical connectionSolder station

The invention discloses a large-sized LED with a concealed extension electrode. The large-sized LED includes an epitaxial structure, a second electrode, and a first electrode composed of a solder padelectrode connected to a metal extension electrode. The epitaxial structure includes a substrate, a second type of conductive layer, an active layer and a first type of conductive layer. The second type of conductive layer is electrically connected to the second electrode. A groove is formed in the first type of conductive layer. The side walls of the groove form metal extension electrode layers.The metal extension electrode layers of the adjacent side walls are continuous with each other. The solder pad electrode is arranged in the groove. The solder pad electrode and the metal extension electrode layers are electrically connected to each other. The invention also discloses a manufacturing method of the LED. A special groove structure is provided to achieve an effect of uniformly expanding the current. The extension electrode has an extremely low thickness, and is arranged on the vertical surface on the side of the groove, which is equivalent to being invisible. The large-sized LED solves the problem that the bottom surface of a metal extension electrode in the prior art shields light, and realizes a wide range of light emitting area, thereby maintaining a superior current spreading effect.

Owner:XIAMEN CHANGELIGHT CO LTD

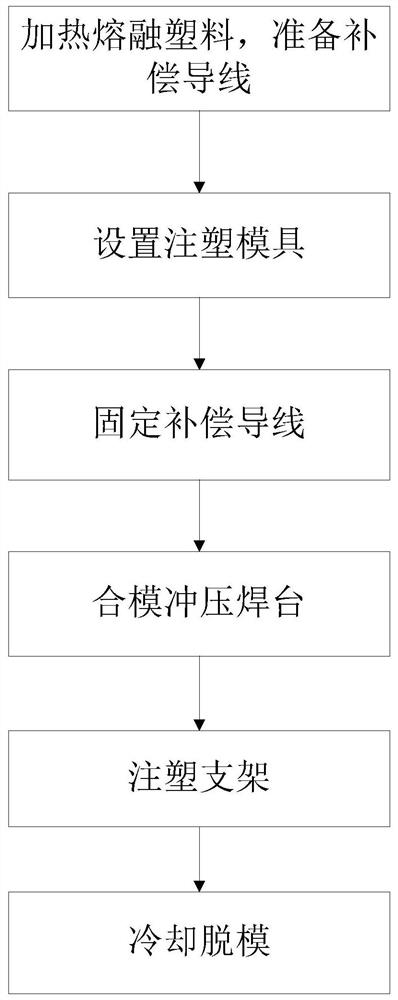

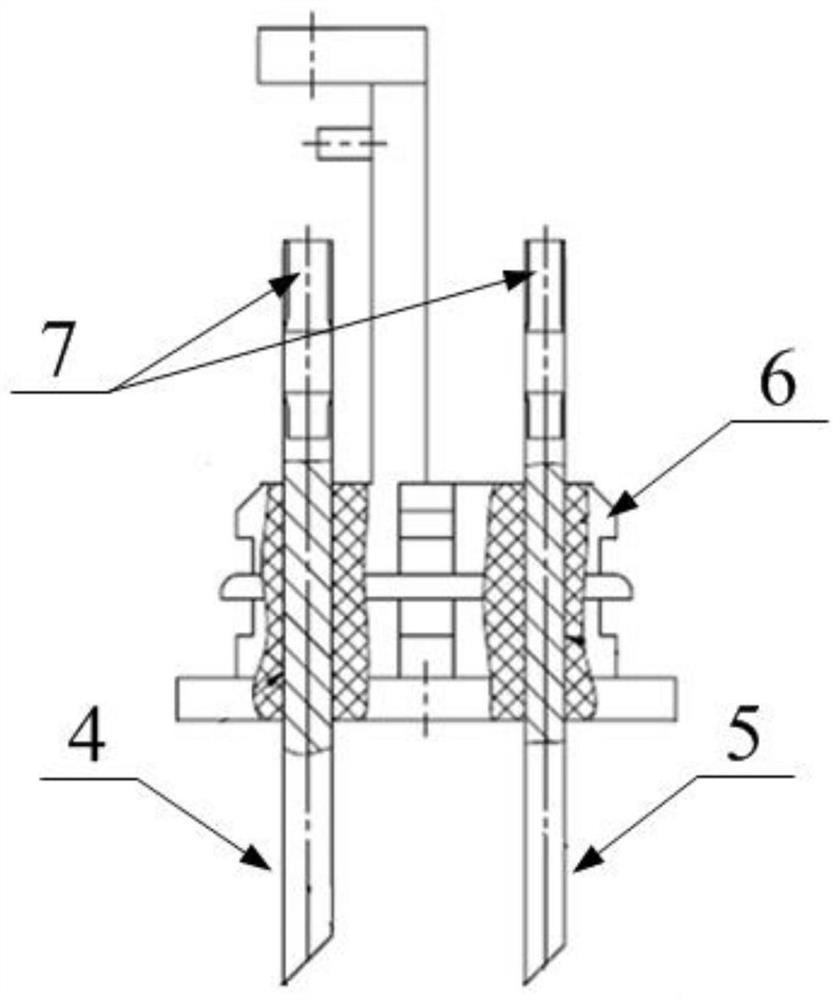

A sub-gun probe temperature measuring bracket and its processing method

ActiveCN109203357BGuaranteed stabilityGuaranteed accuracyThermometer detailsCoatingsStampingEngineering

The invention discloses a processing method for a temperature-measuring bracket of a sub-gun probe, which comprises the steps of: setting an injection mold; fixing a compensation wire; clamping a mold, punching and welding a stand; injection molding a bracket; and cooling and demoulding. This processing method can fix the positive electrode compensation wire and the negative electrode compensation wire while injecting the plastic bracket, and at the same time use the stamping force when the injection mold is closed to form a soldering platform. The height of the welding platform is at the same horizontal position, and the compensation wire fixing structure of the injection mold can ensure that the two compensation wires remain fixed during the stamping and injection molding process. The processing method of this scheme eliminates the assembly process of the plastic bracket and the compensation wire in the past, ensures that the height of the soldering platform of the compensation wire is consistent, ensures the stability and accuracy of the temperature measurement of the sub-gun probe temperature measurement bracket, and simplifies the processing technology and improves the efficiency. Processing efficiency. The invention also discloses a sub-gun probe temperature measuring bracket processed by the above-mentioned processing method.

Owner:HUNAN RAMON SCI & TECH

Combined press welding table and automatic press welder provided with same

InactiveCN1205706CSmooth weldingSmooth dischargeElectrically conductive connectionsCoupling device detailsEngineeringSolder station

The invention provides a combined pressure welding station and an automatic pressure welding machine equipped with the pressure welding station. The combined pressure welding station includes: a fixed platform formed with a height difference between the first surface supporting the pressure-bearing surface of the connector housing and the second surface of the staggered locking part; a connector housing formed with an opening for supporting the joint connection part The third surface of the joint connection part of the connection surface and the fourth surface of the connection part of the connector shell surface supporting the opening of the wire insertion port; the movable platform that is arranged on the fixed platform and presses the wire lead-out surface of the connector shell and puts the The connector housing is pressed into the brake mechanism in the third surface, and the movable platform can leave the fixed platform in the height direction.

Owner:JST MFG CO LTD

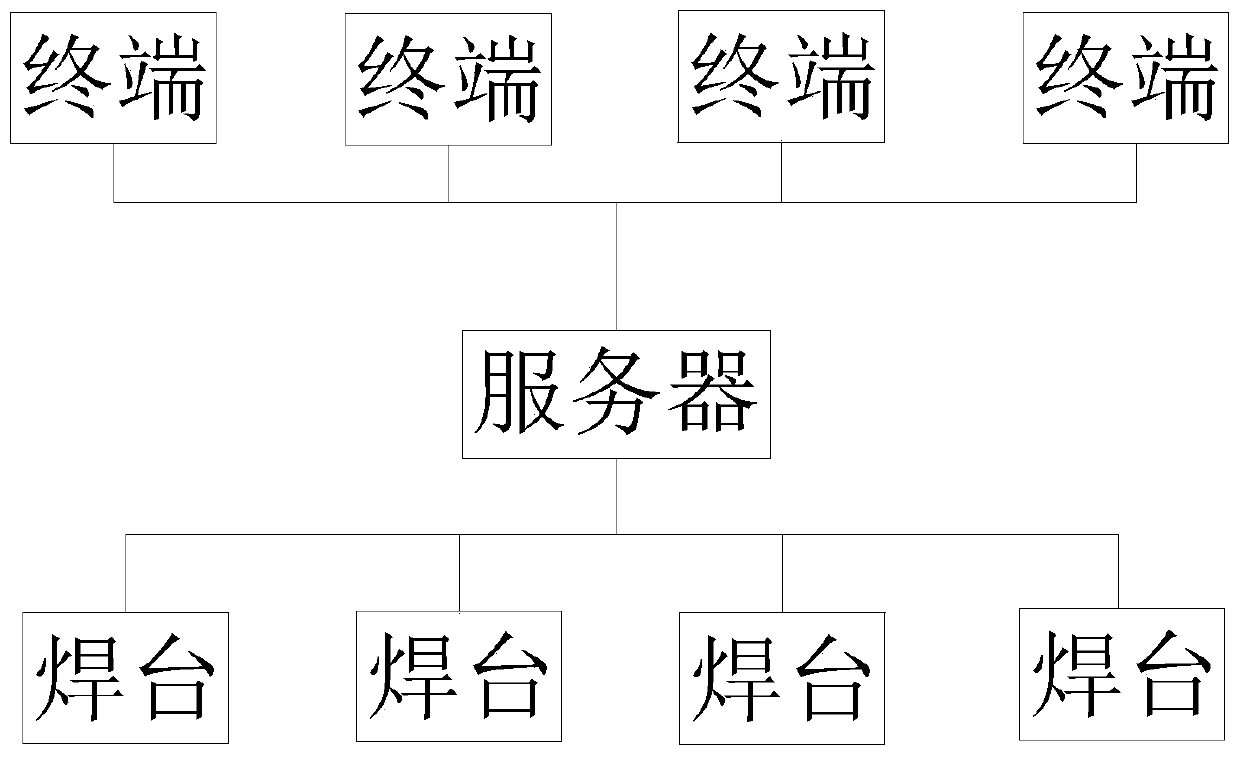

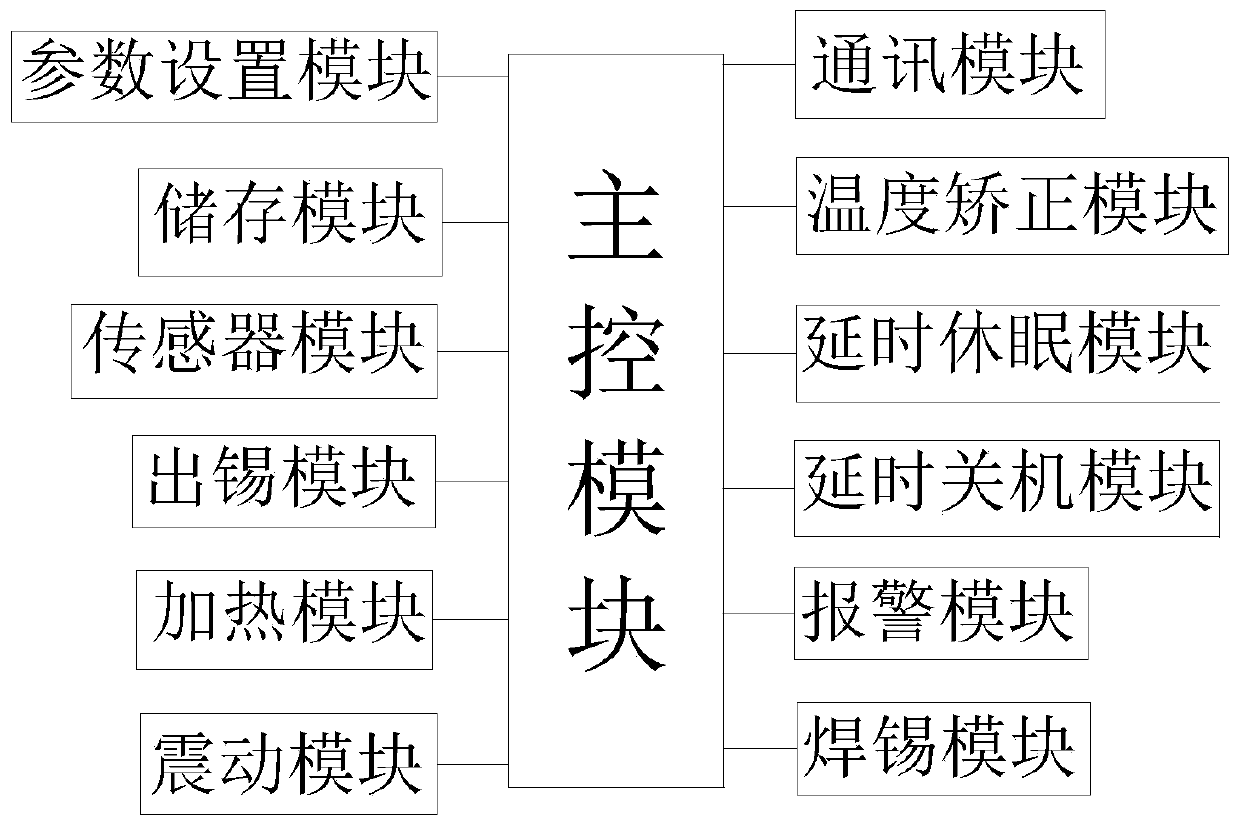

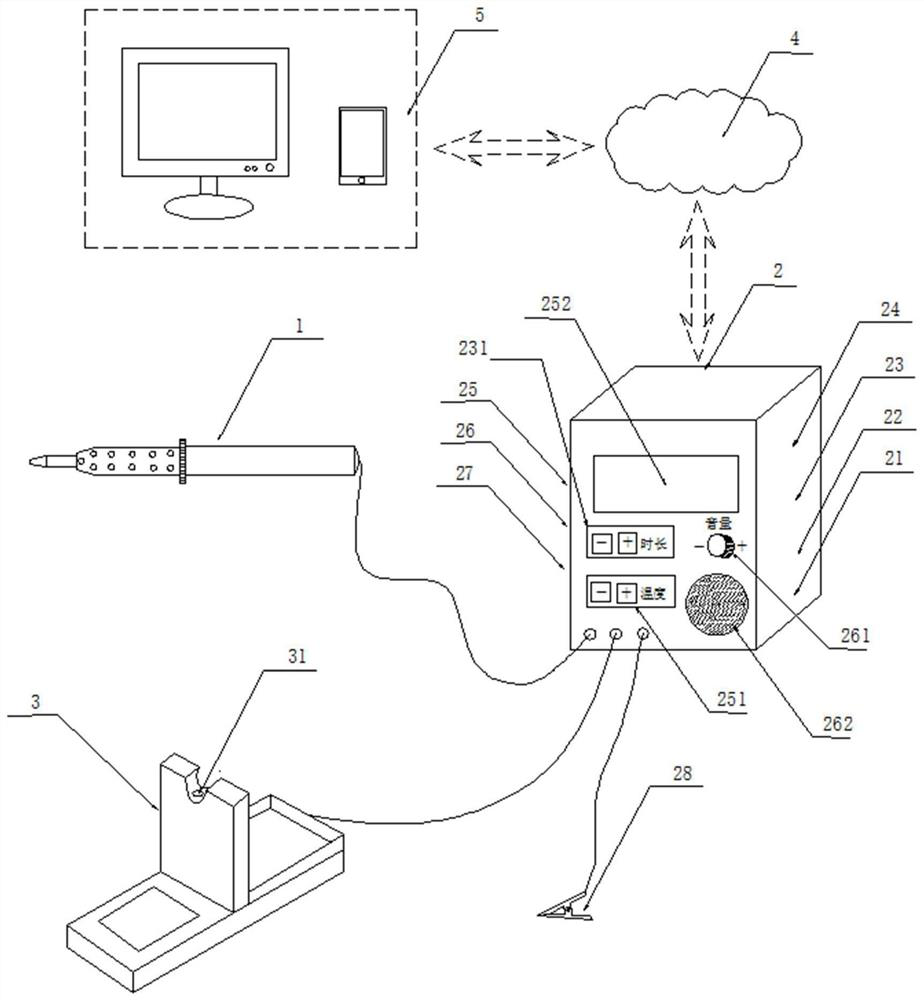

Temperature control system of soldering station

InactiveCN111250810AEasy to set upRealize transmissionHeating appliancesSolder feeding devicesTemperature controlTerminal server

The invention discloses a temperature control system of a soldering station. The system comprises a terminal, a server and more than two soldering stations, wherein each soldering station comprises asoldering tin module, a master control module, a parameter setting module, a storage module and a communication module, the master control modules are in communication connection with the server and are positioned in the soldering stations so as to process soldering station data and issue an instruction; the soldering tin modules, the parameter setting modules, the storage modules and the communication modules are all in communication connection with the master control modules; the terminal comprises a mobile phone, a computer and the like and realizes communication with the server through APP; due to the arrangement of the parameter setting module and the storage module on each soldering station, the regulation and the storage of parameters when the soldering station works are realized, the arrangement of the communication modules between the soldering stations realizes information transmission between the soldering stations, and a function of transmitting the information of one soldering station to other soldering stations is realized so as to be convenient for setting parameters for two soldering stations or above.

Owner:深圳市吉美电子设备有限公司

Board to Board Plug

ActiveCN111293499BRealize limitAvoid shaking from side to sideCoupling contact membersCoupling protective earth/shielding arrangementsStructural engineeringSolder station

A board-to-board plug, comprising several plug terminals, a plug body holding the several plug terminals as a whole, a cable assembly located behind the plug body and connected to the plug terminals, and a A shielding shell, the plug body includes a base and an extension formed from the base, the extension includes a protruding portion protruding downwards and a soldering station at the top, the shielding shell includes a base that covers the plug The covering top plate on the top surface of the body, the covering front wall formed by bending downwards from the front end of the covering top plate, the covering side walls formed by bending backwards from both lateral ends of the covering front wall, and Bending down the protective part located outside the covering side wall, the protective part includes a clamping part that is relatively bent and covers the soldering platform, and the lower surface of the protruding part is formed to be supported by the clamping part limit steps. The application can effectively limit the plug body.

Owner:KUNSHAN KTA COMM TECH CO LTD

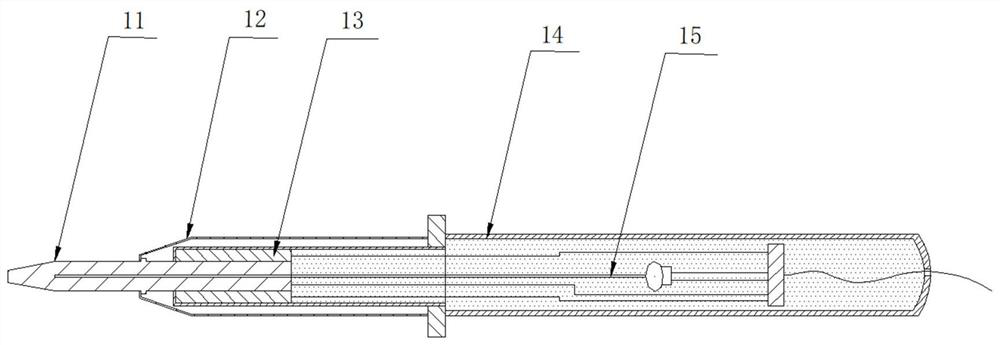

An intelligent electric soldering system and an electric soldering production management method

ActiveCN112427765BAvoid damageAvoid WeldingSoldering ironMetal working apparatusTemperature controlEngineering

The invention relates to the field of welding technology, and discloses an intelligent electric soldering system and an electric soldering production management method, wherein the system includes a soldering pen and a soldering station, the soldering pen includes a soldering iron tip, the soldering iron tip is connected with a temperature detection element, and the temperature detection element It is connected to the soldering station. The soldering station is equipped with a temperature control module and a timing module. The soldering station is also connected with a conductive piece. The conductive piece is used to connect with the circuit where the soldering point is located. The timing module is used to detect the connection between the conductive piece and the soldering iron. When the tip is turned on or when the real-time temperature drop rate of the soldering iron tip is detected to reach the preset rate, the first timing program is triggered, and the first timing program is ended when it is detected that the conductive part is disconnected from the soldering iron tip and the total time of preheating welding is output. . The intelligent electric soldering system and electric soldering production management method provided by the present invention can realize automatic and precise control of the welding temperature of the solder joints; can effectively realize the timing function for the welding process, accurately reflect the welding time, and help ensure the welding quality. Efficient and convenient.

Owner:WUHAN HONGXIN TECH DEV CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com