A large-size light-emitting diode with invisible extended electrodes and its manufacturing method

A technology of light-emitting diodes and extended electrodes, which is applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of not being suitable for large-sized light-emitting diodes, jagged edges of extended electrodes or shedding of extended electrodes, and reduced luminous efficiency, so as to achieve superior current The effect of the extended effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained according to these drawings without paying creative labor. Please refer to Figure 1 to Figure 15 .

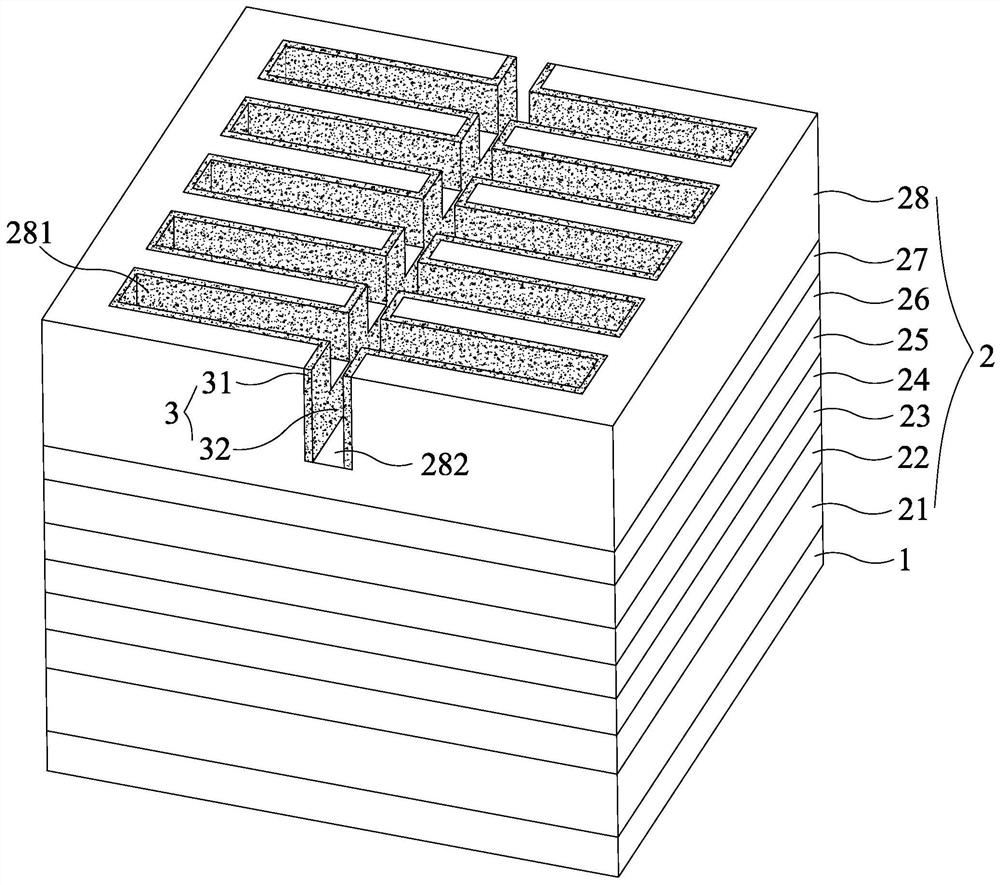

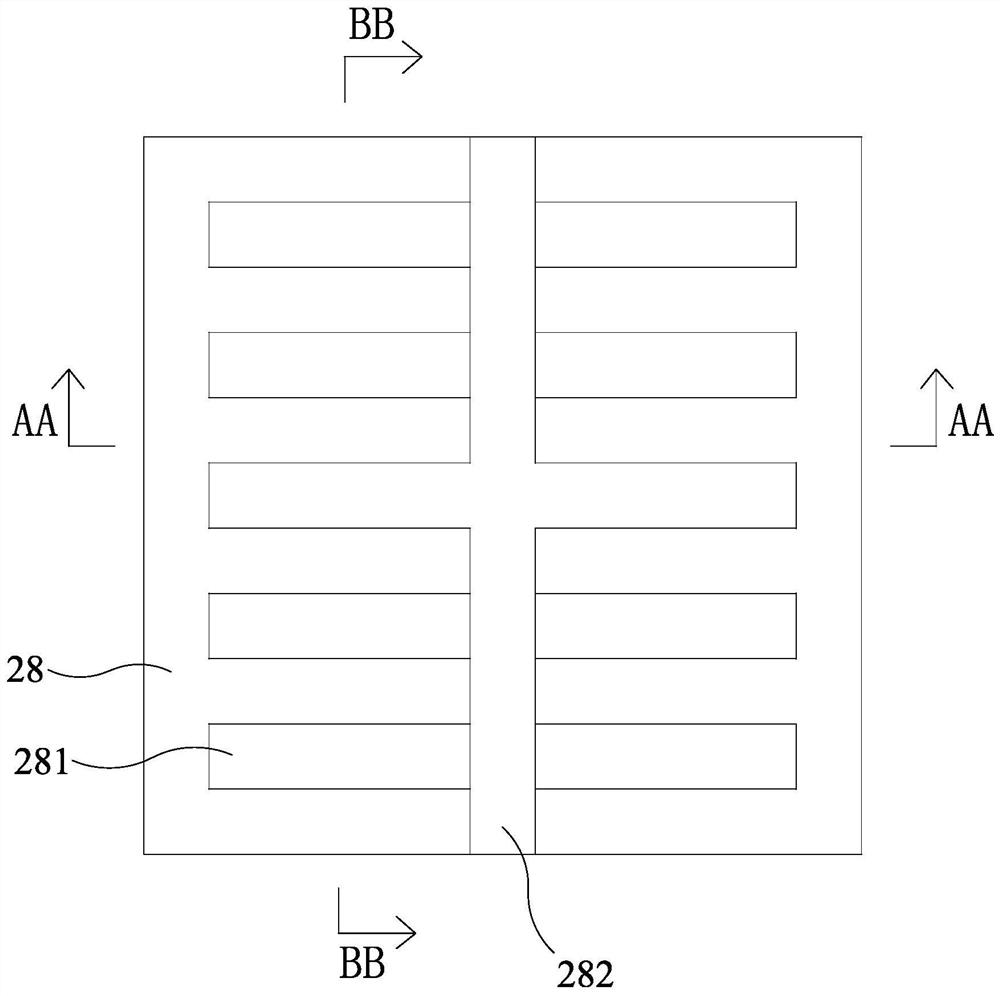

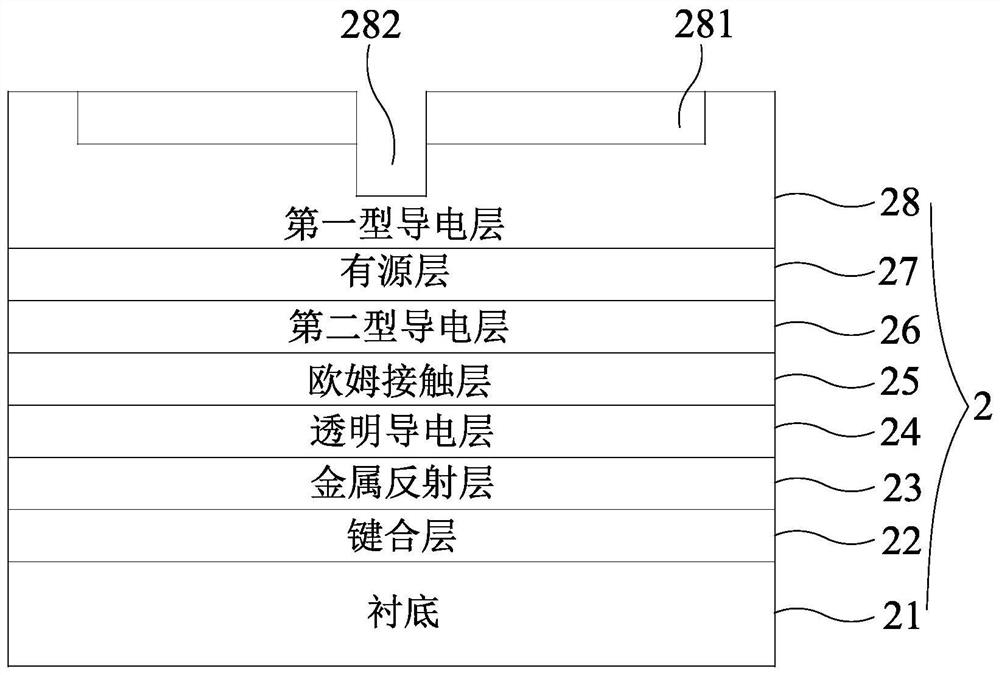

[0048] The following is an example of a light-emitting diode with a vertical structure, such as Figure 7 As shown, the present invention discloses a large-sized light-emitting diode with invisible extended electrodes, including a first electrode composed of a second electrode 1 , an epitaxial structure 2 , and a soldering station electrode 4 connected to a metal extended electrode 3 .

[0049] Such as image 3 and Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com