Patents

Literature

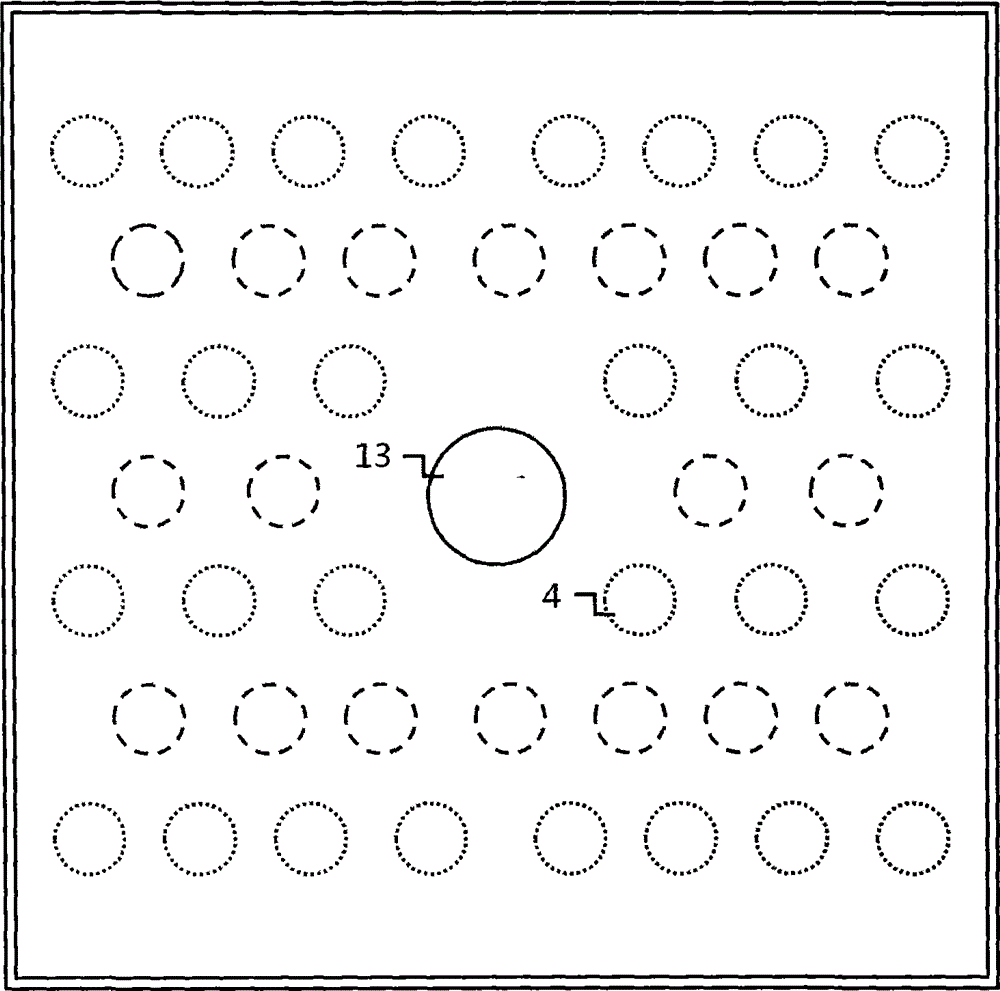

86results about How to "Improve current spreading effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

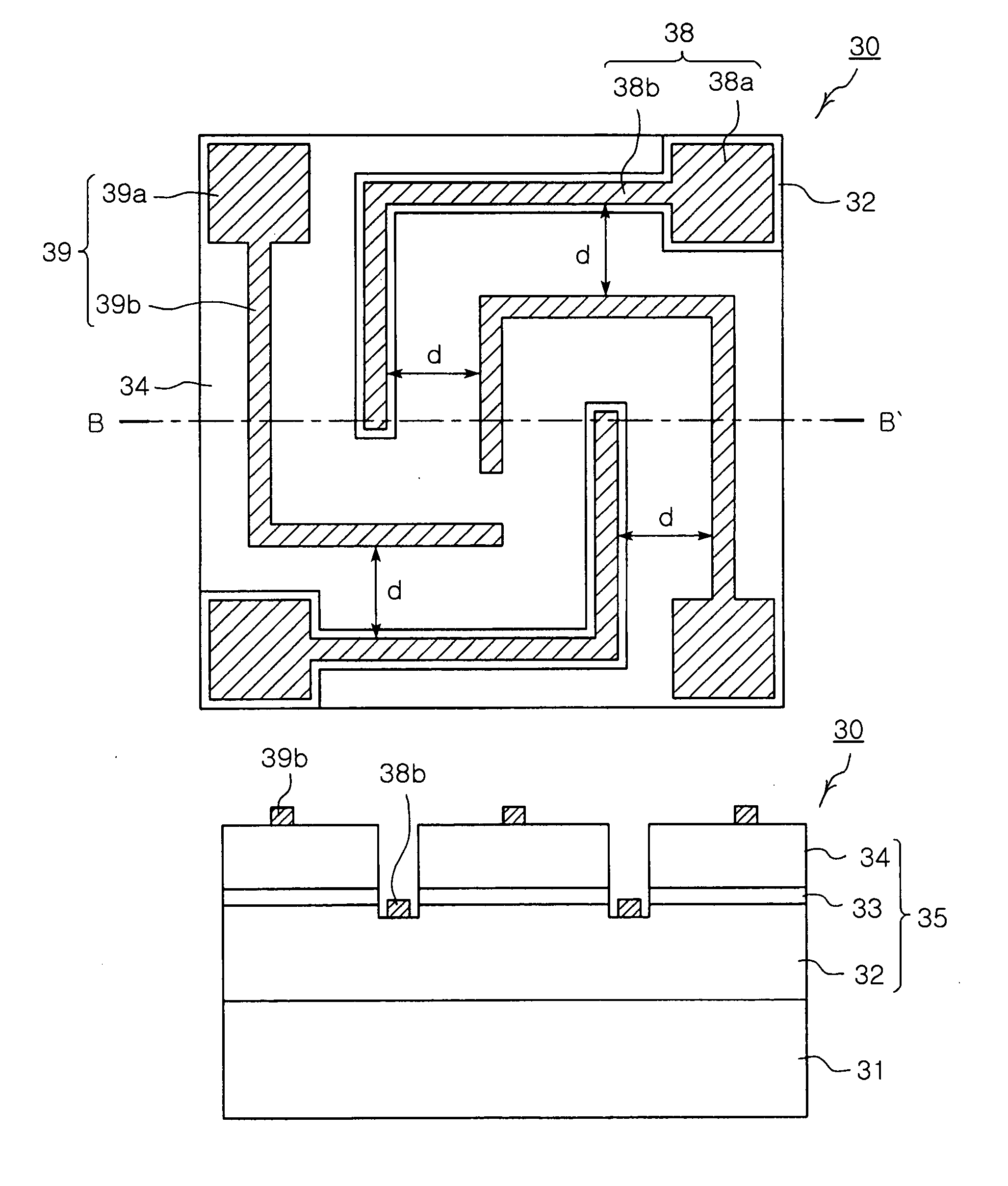

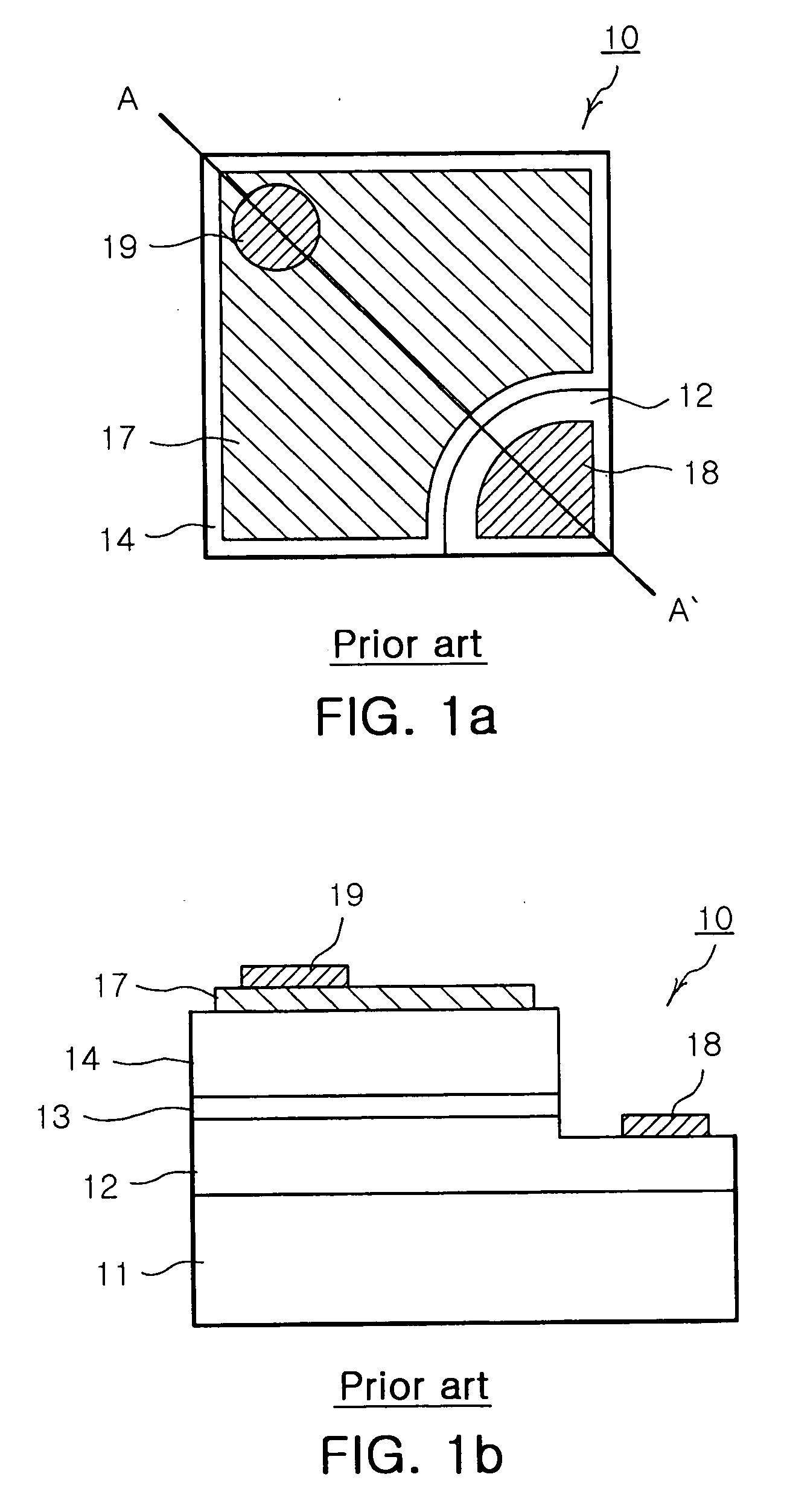

Nitride semiconductor light emitting device

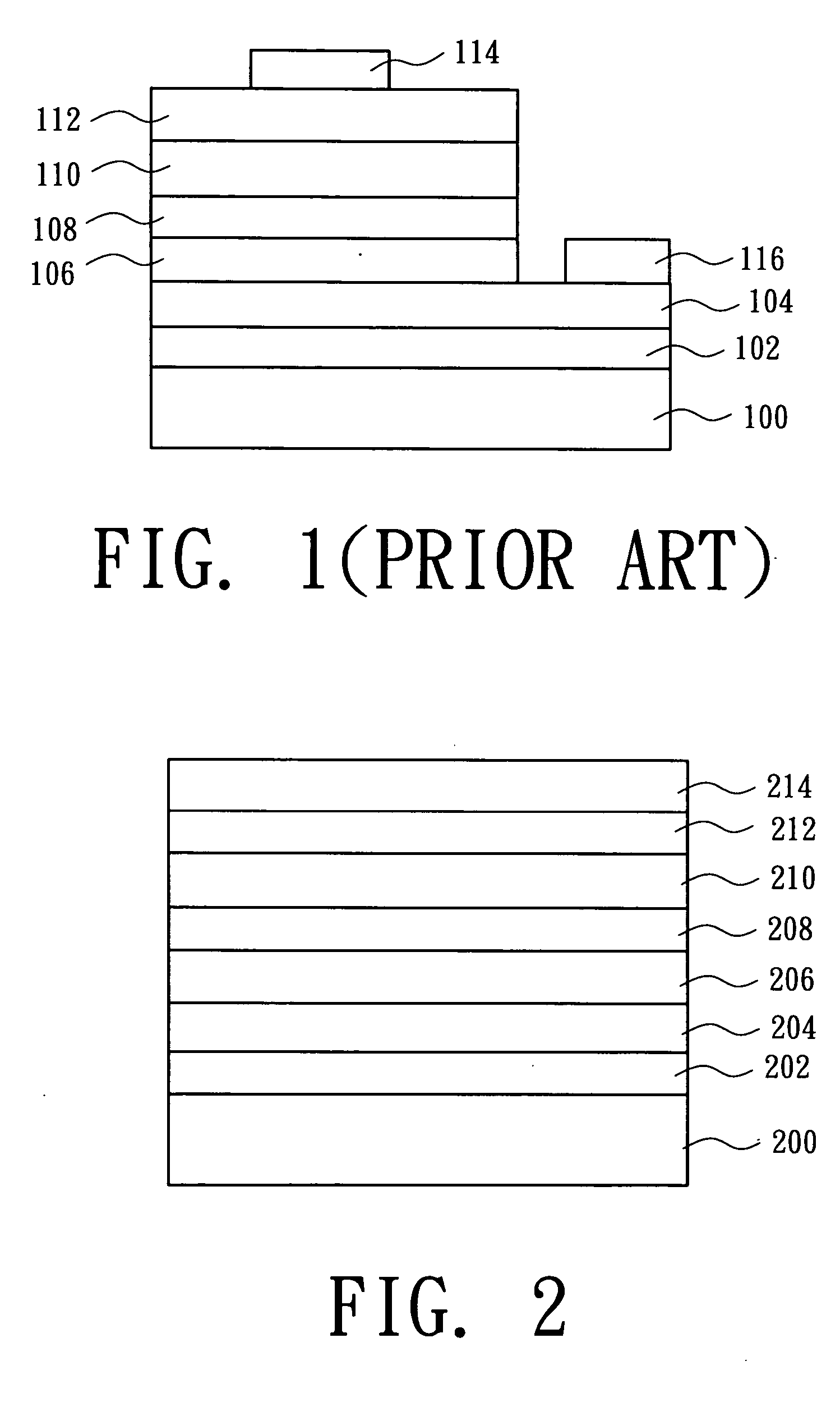

InactiveUS20060192223A1Firm supportImprove adhesionTicket-issuing apparatusSolid-state devicesSymmetric configurationAlong edge

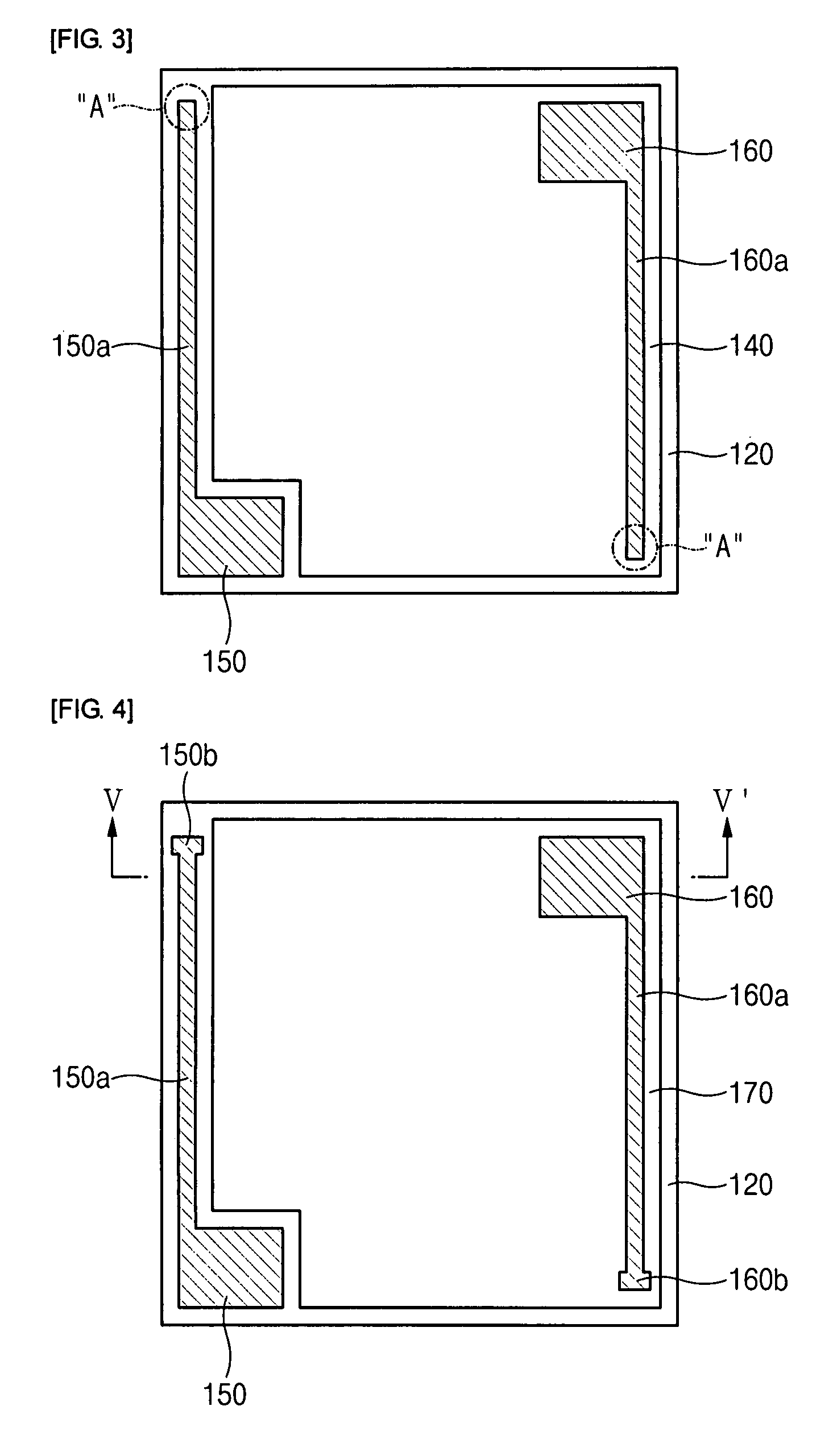

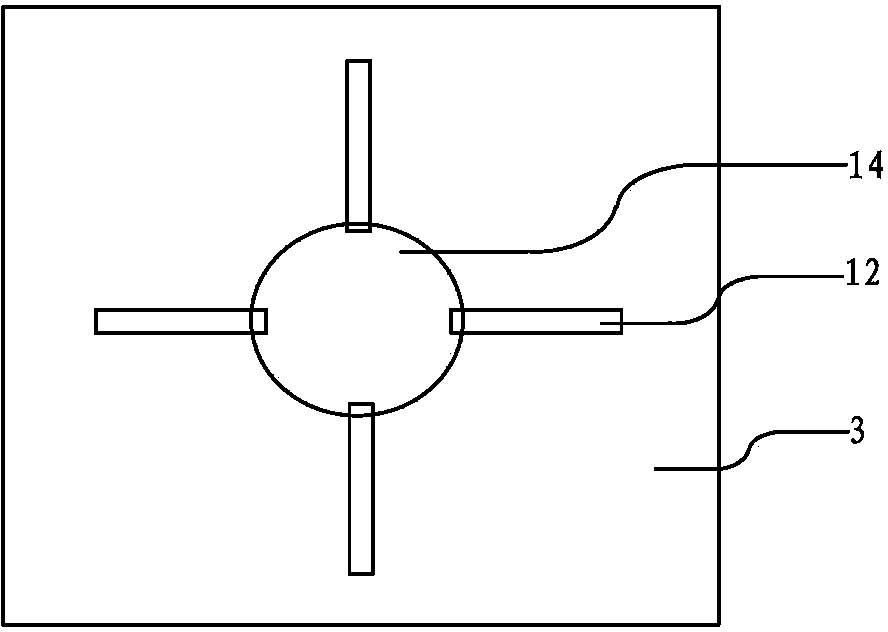

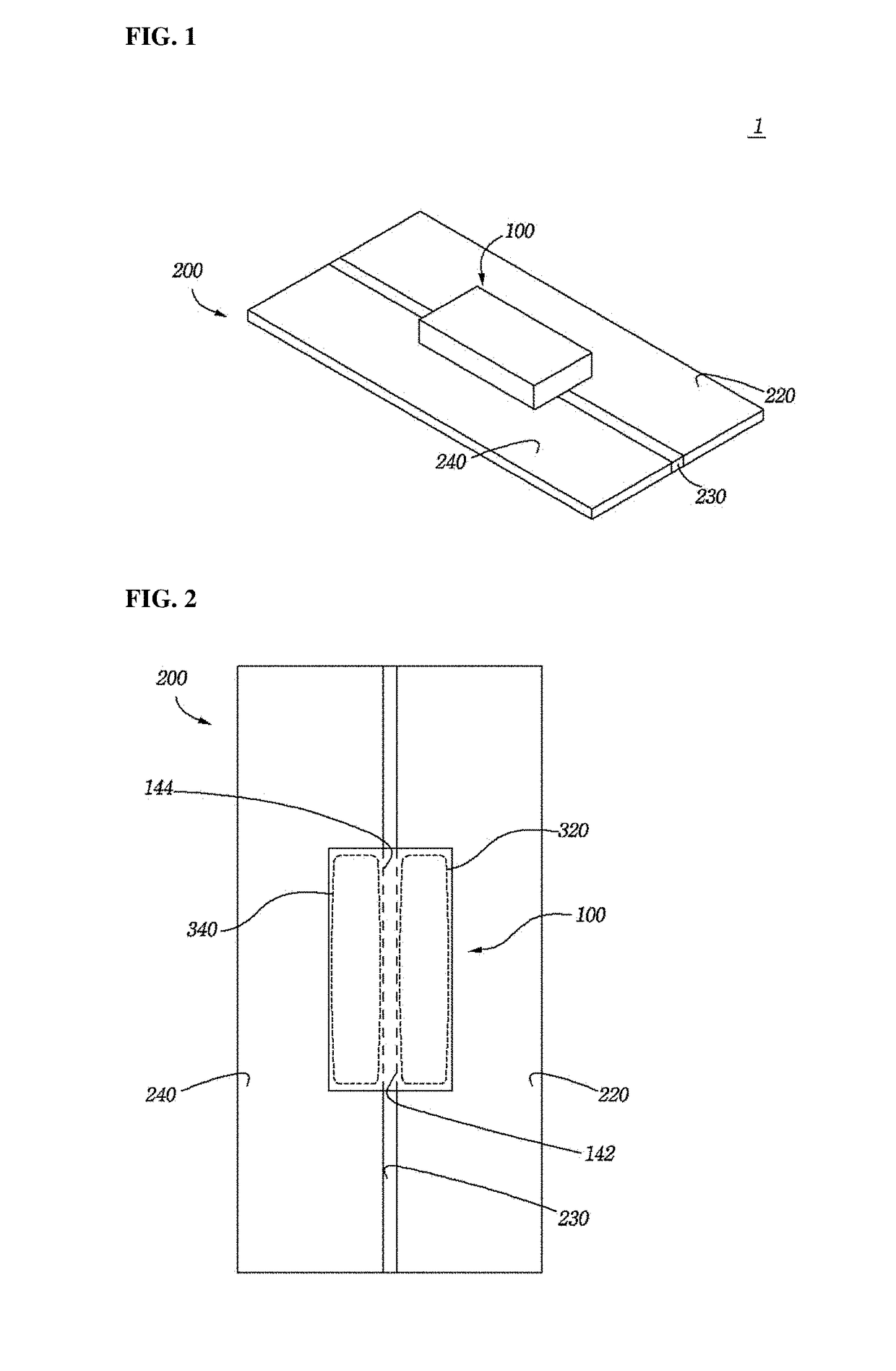

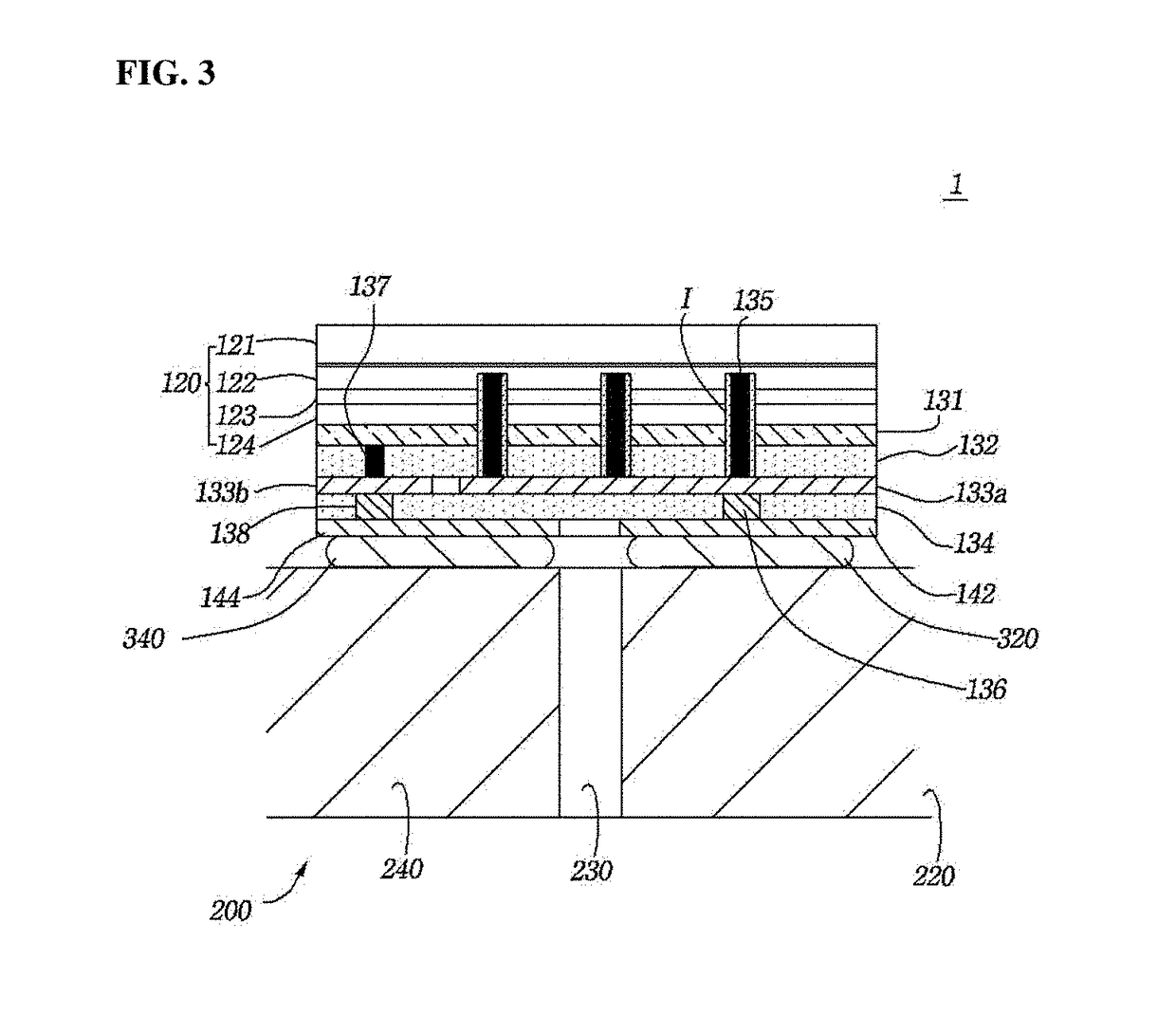

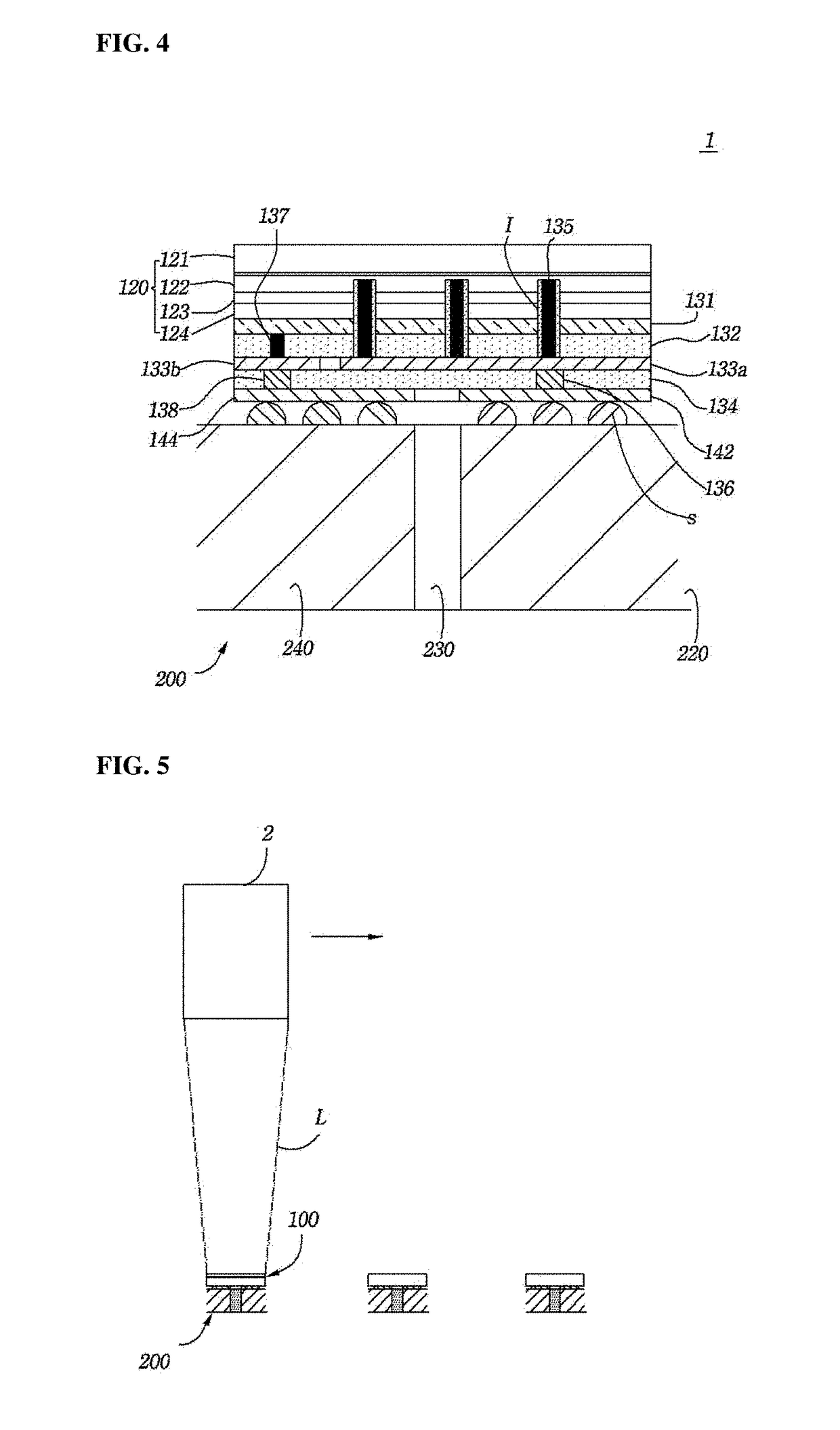

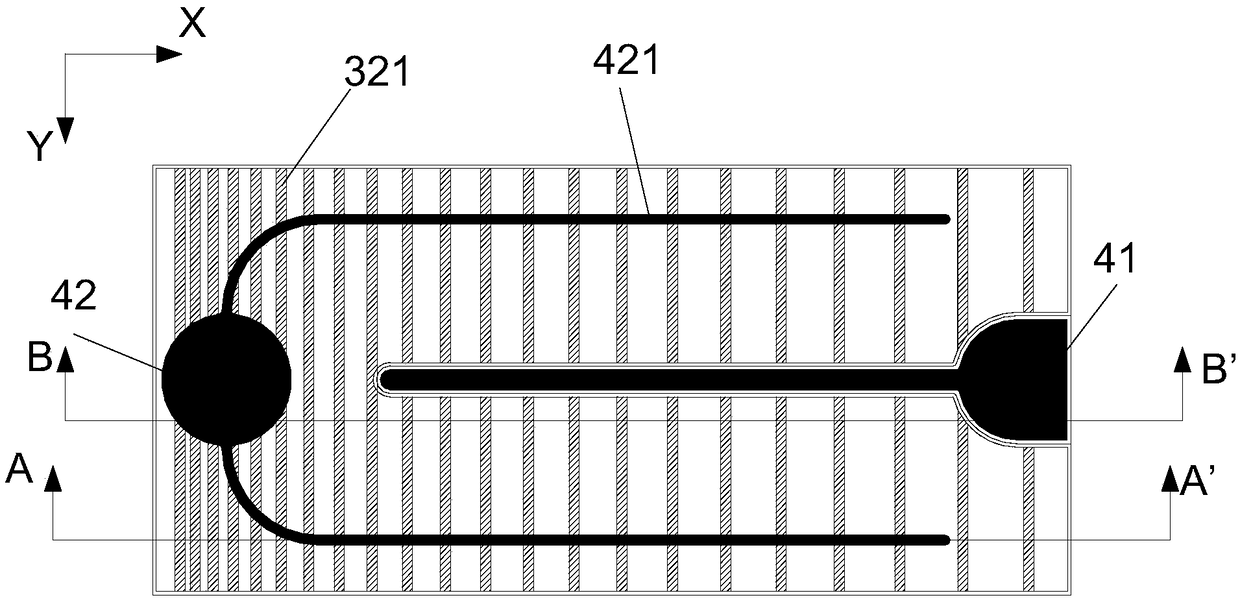

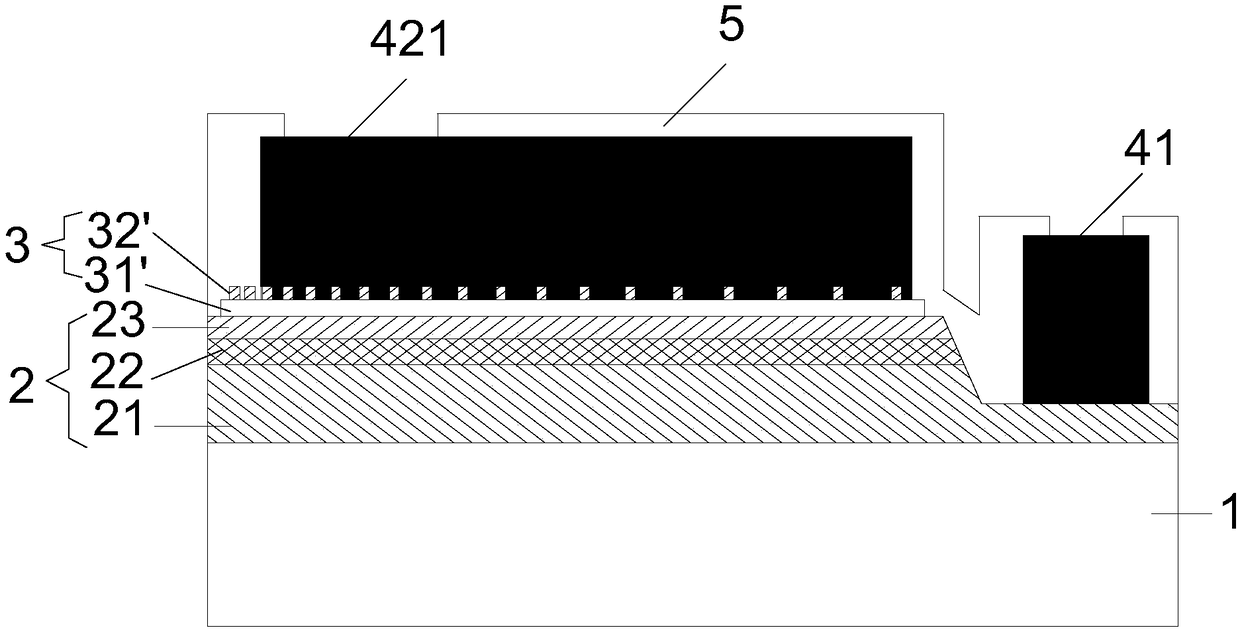

The invention relates to a flip-chip nitride semiconductor LED. In the LED, a light emitting structure has first and second conductivity type nitride semiconductor layers and an active layer interposed therebetween. Each of plurality of first and second electrodes has a bonding pad placed adjacent to a top corner of the light emitting structure and at least one electrode finger extended from the bonding pad. The first and second electrodes are connected to the first and second conductivity type nitride semiconductor layers, respectively. Also, bonding pads are arranged alternately along edges of the light emitting structure with different polarity, in a substantially symmetric configuration with respect to the center of the light emitting structure. In addition, each of electrode fingers is extended from a corresponding pad and bent at least once toward the center of the light emitting structure to adjoin the electrode finger having different polarity.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

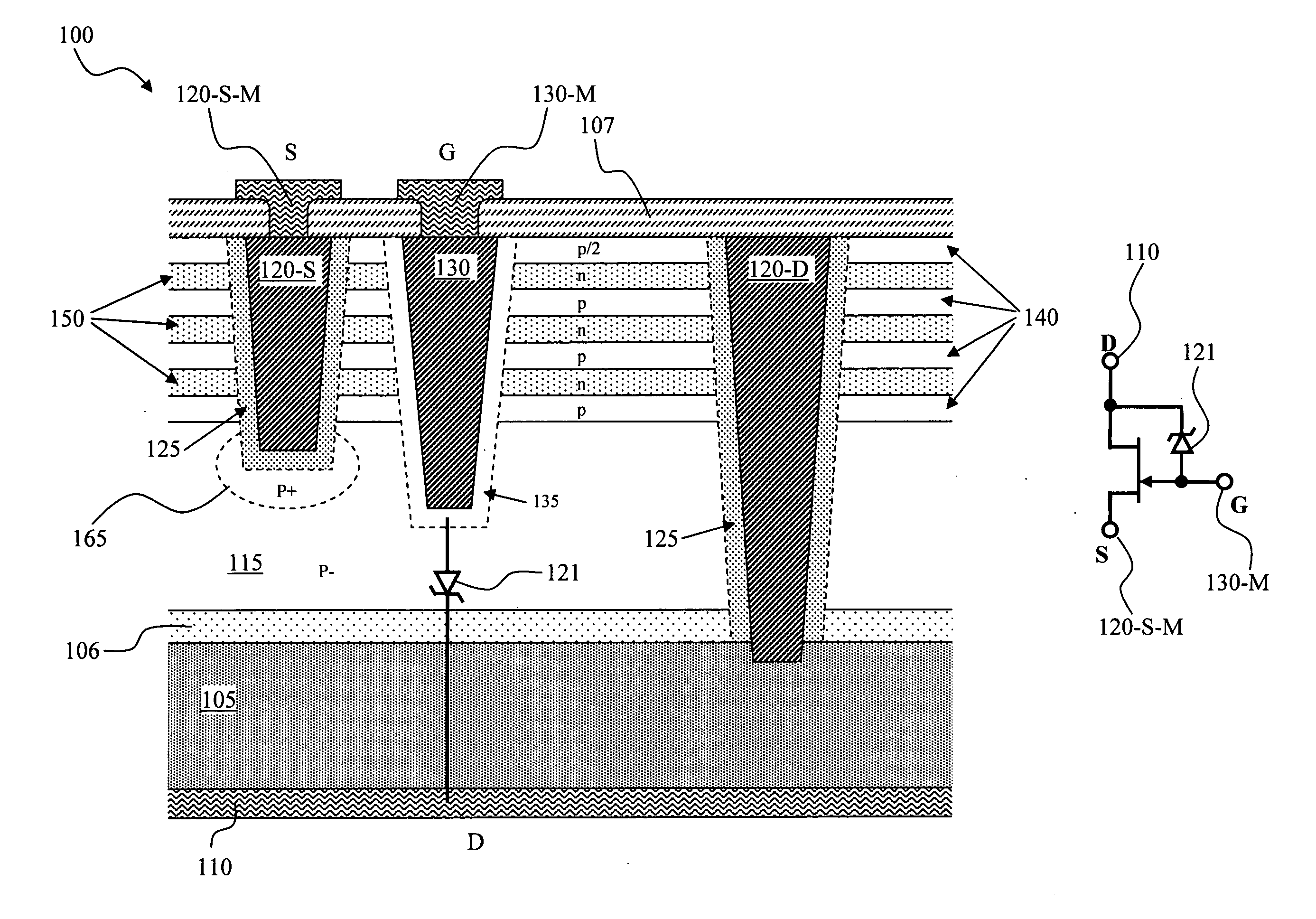

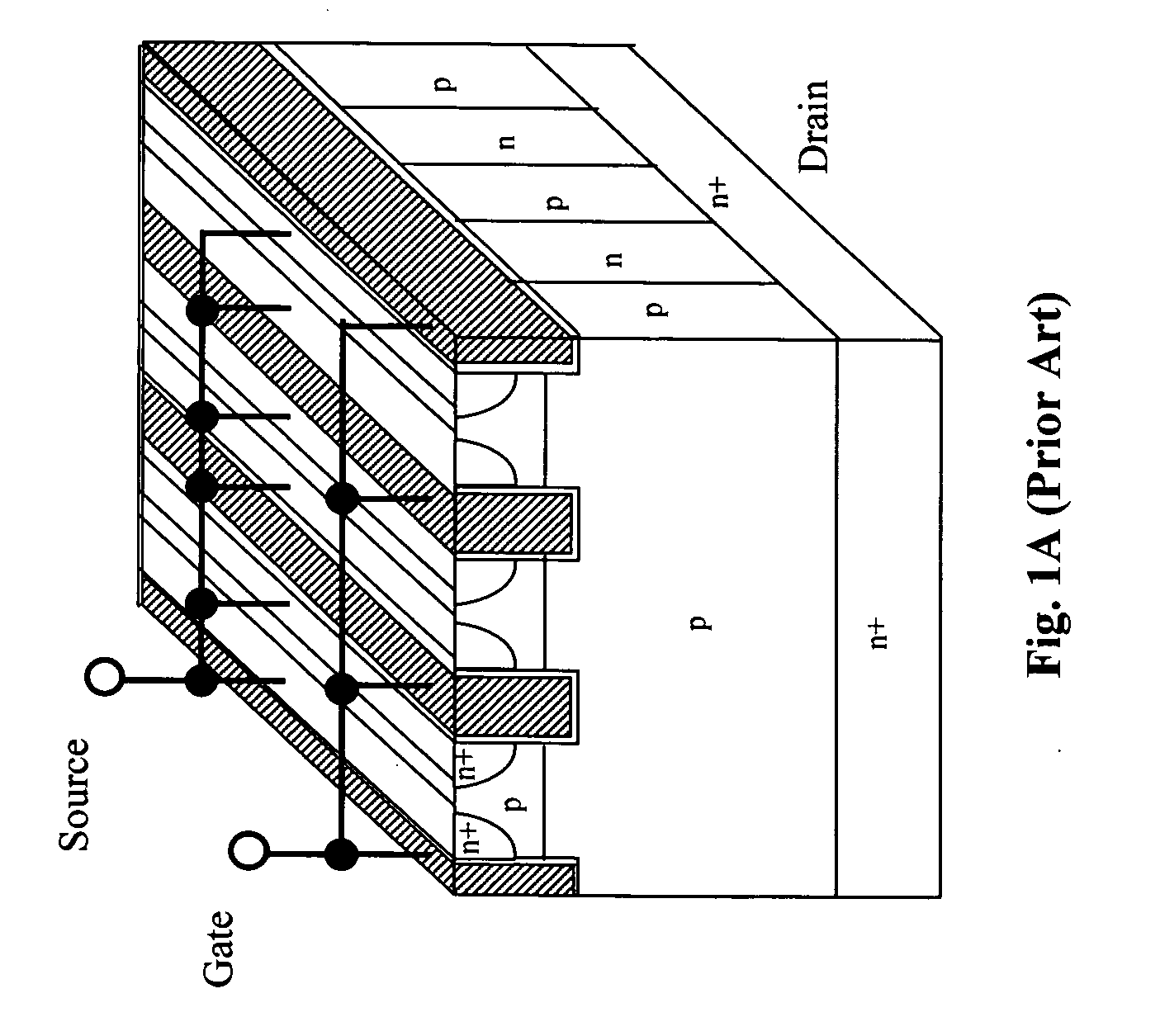

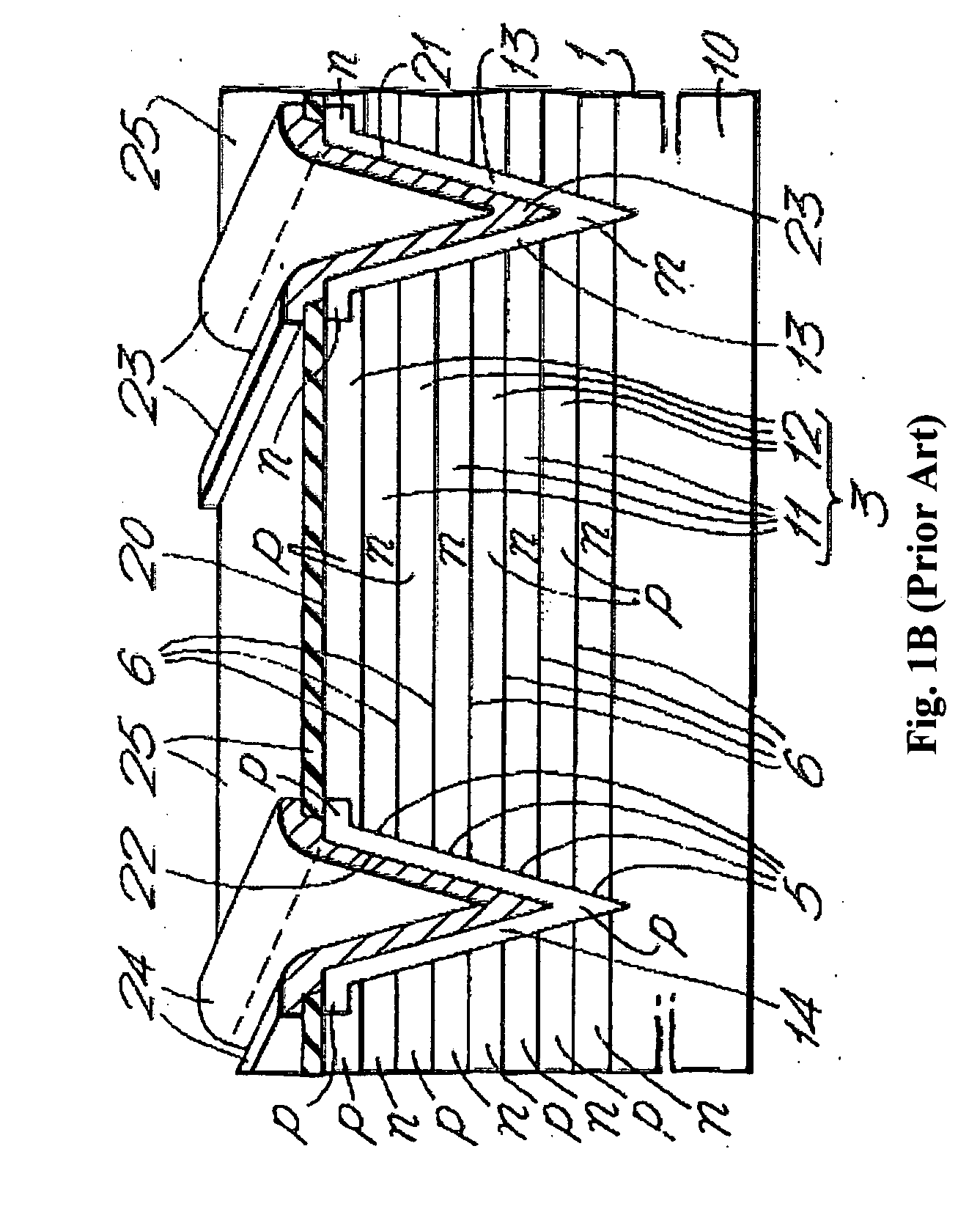

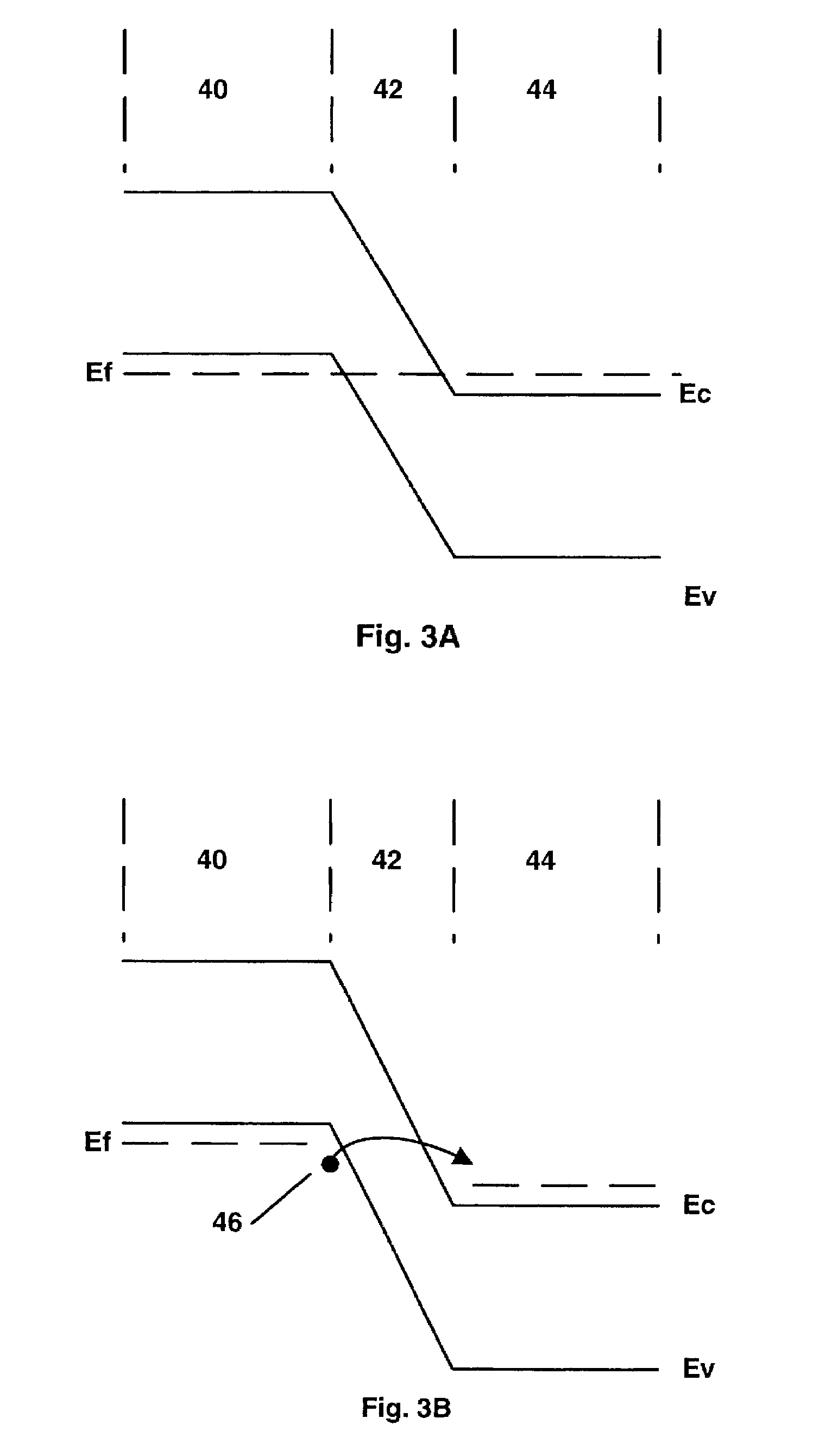

Lateral super junction device with high substrate-gate breakdown and built-in avalanche clamp diode

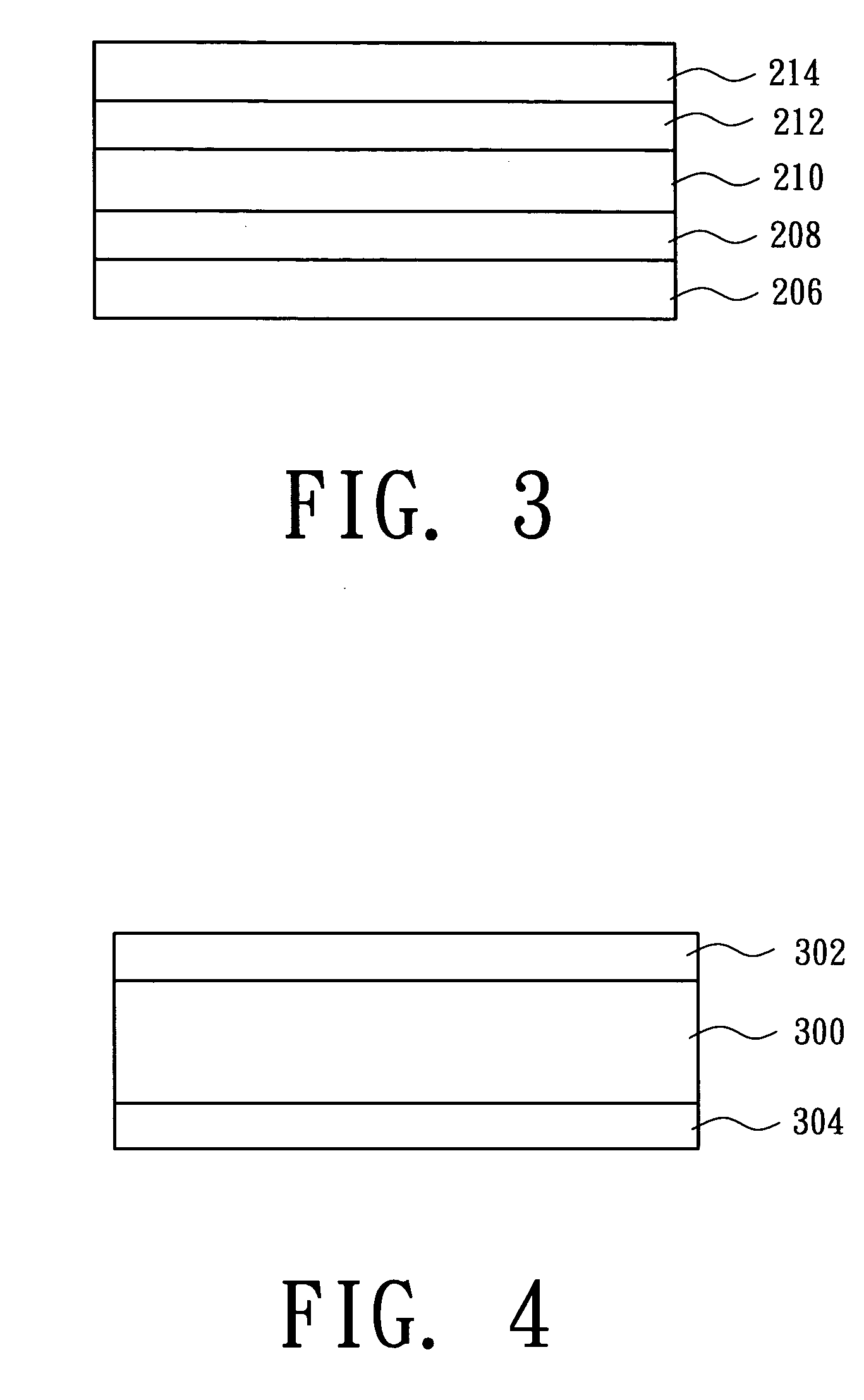

ActiveUS20110127586A1Improve current spreading effectHigh blocking voltageTransistorThyristorEngineeringSemiconductor

A lateral super junction JFET is formed from stacked alternating P type and N type semiconductor layers over a P-epi layer supported on an N+ substrate. An N+ drain column extends down through the super junction structure and the P-epi to connect to the N+ substrate to make the device a bottom drain device. N+ source column and P+ gate column extend through the super junction but stop at the P-epi layer. A gate-drain avalanche clamp diode is formed from the bottom the P+ gate column through the P-epi to the N+ drain substrate.

Owner:ALPHA & OMEGA SEMICON INC

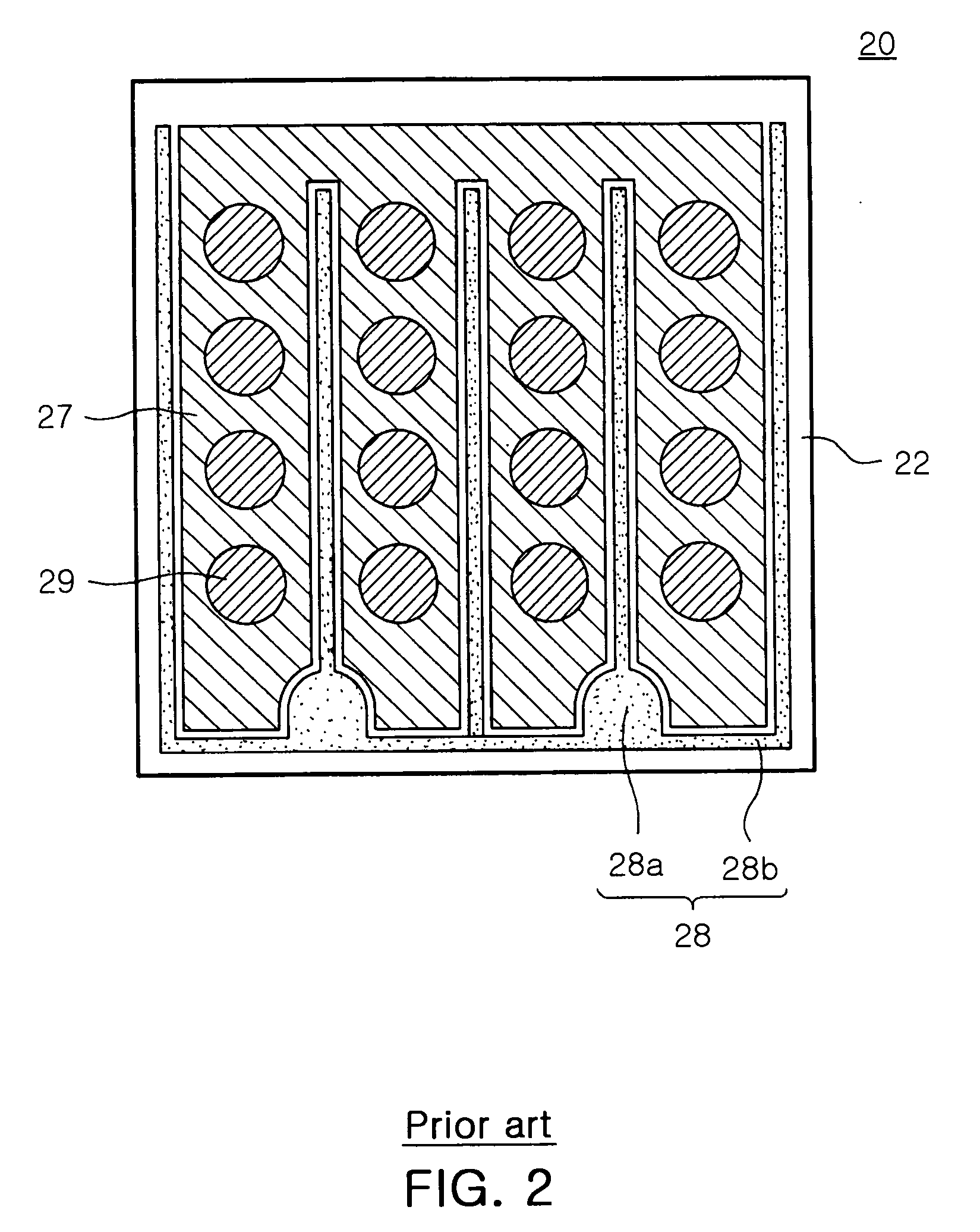

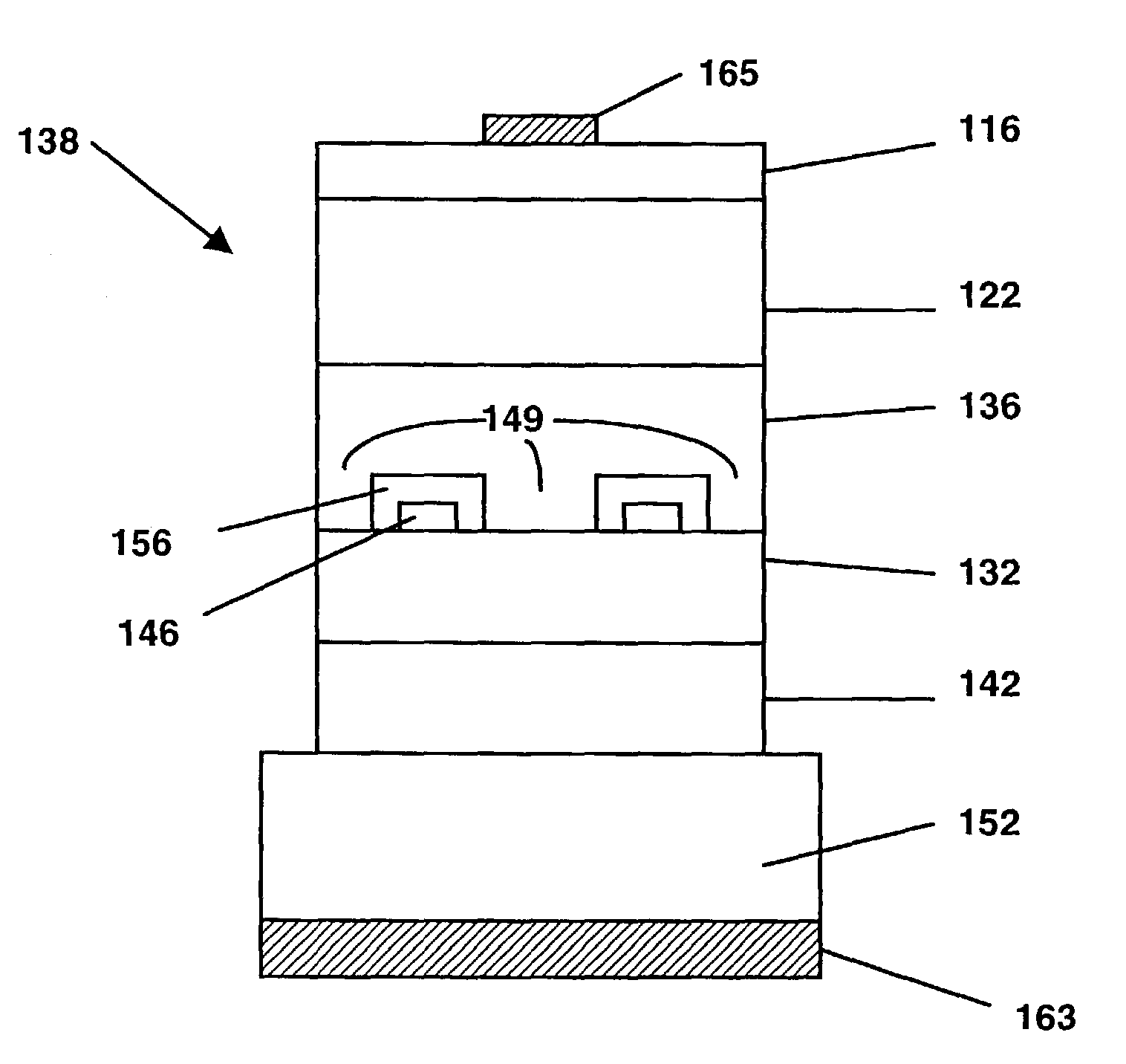

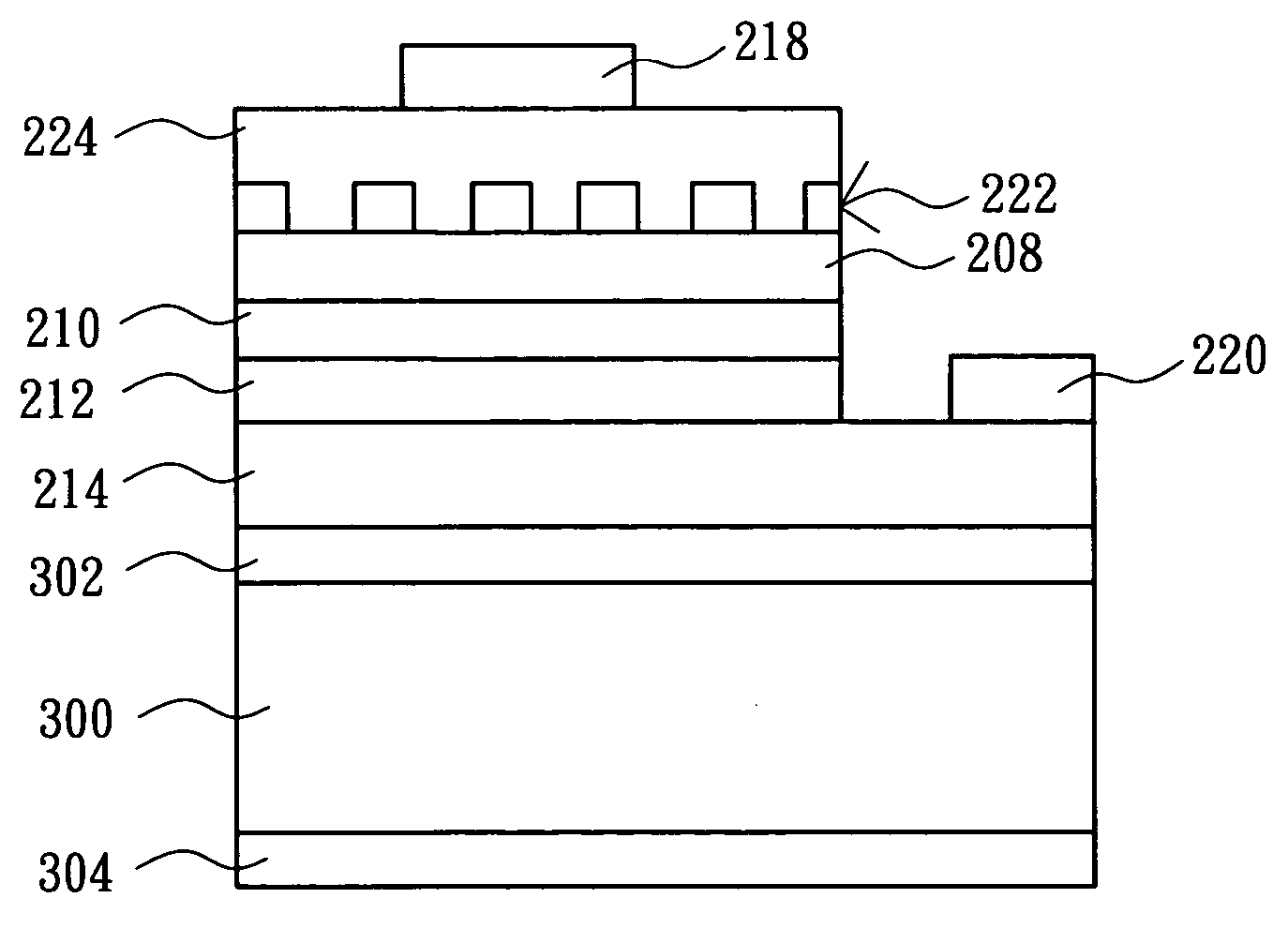

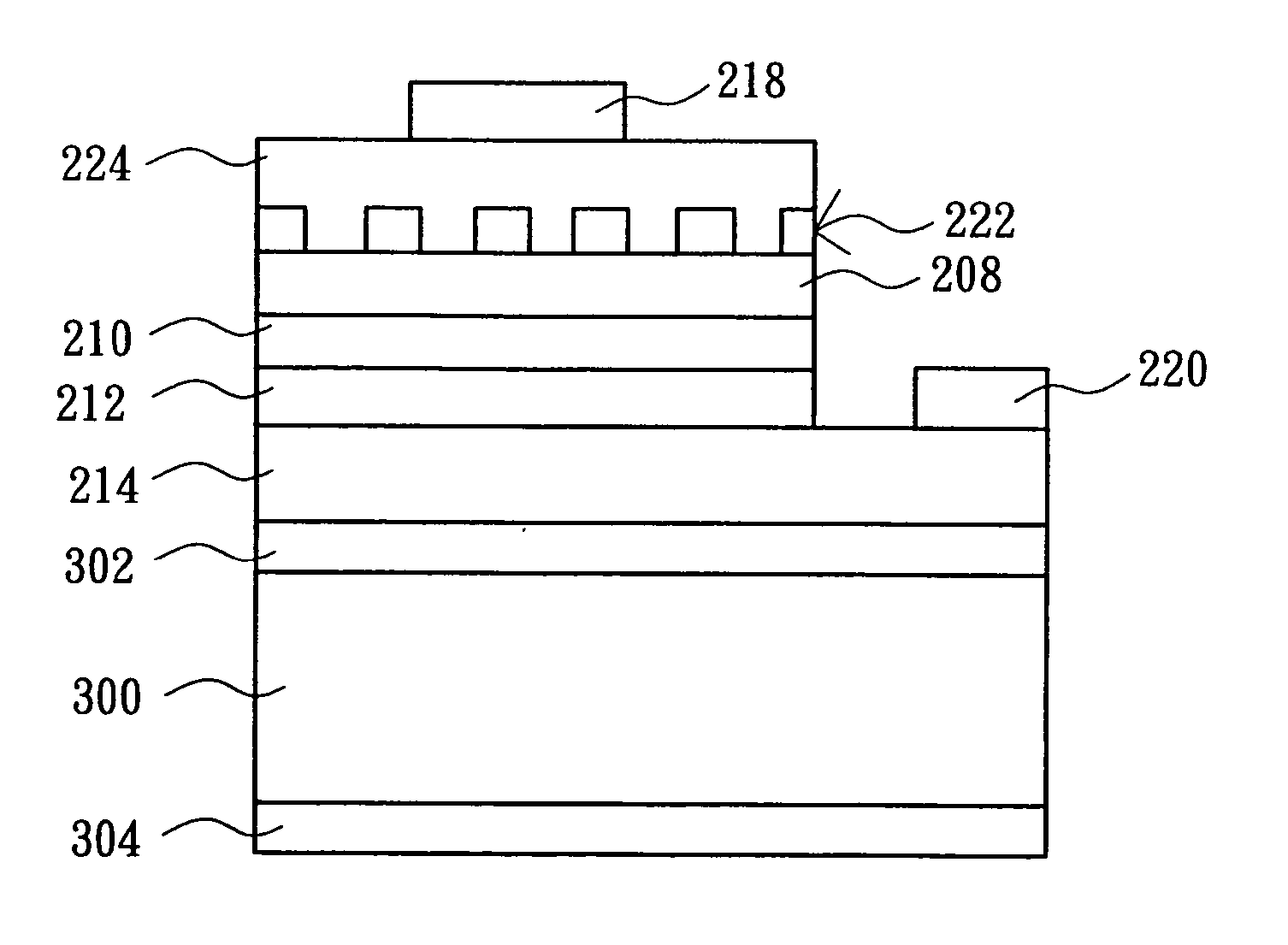

Inverted light emitting diode on conductive substrate

ActiveUS7170097B2Improve conductivityImprove current spreading effectSolid-state devicesSemiconductor/solid-state device manufacturingActive layerLight-emitting diode

An electronic device includes a conductive n-type substrate, a Group III nitride active region, an n-type Group III-nitride layer in vertical relationship to the substrate and the active layer, at least one p-type layer, and means for providing a non-rectifying conductive path between the p-type layer and the n-type layer or the substrate. The non-rectifying conduction means may include a degenerate junction structure or a patterned metal layer.

Owner:CREELED INC

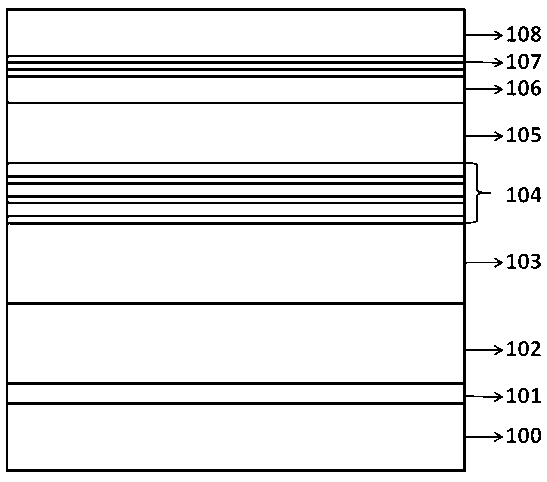

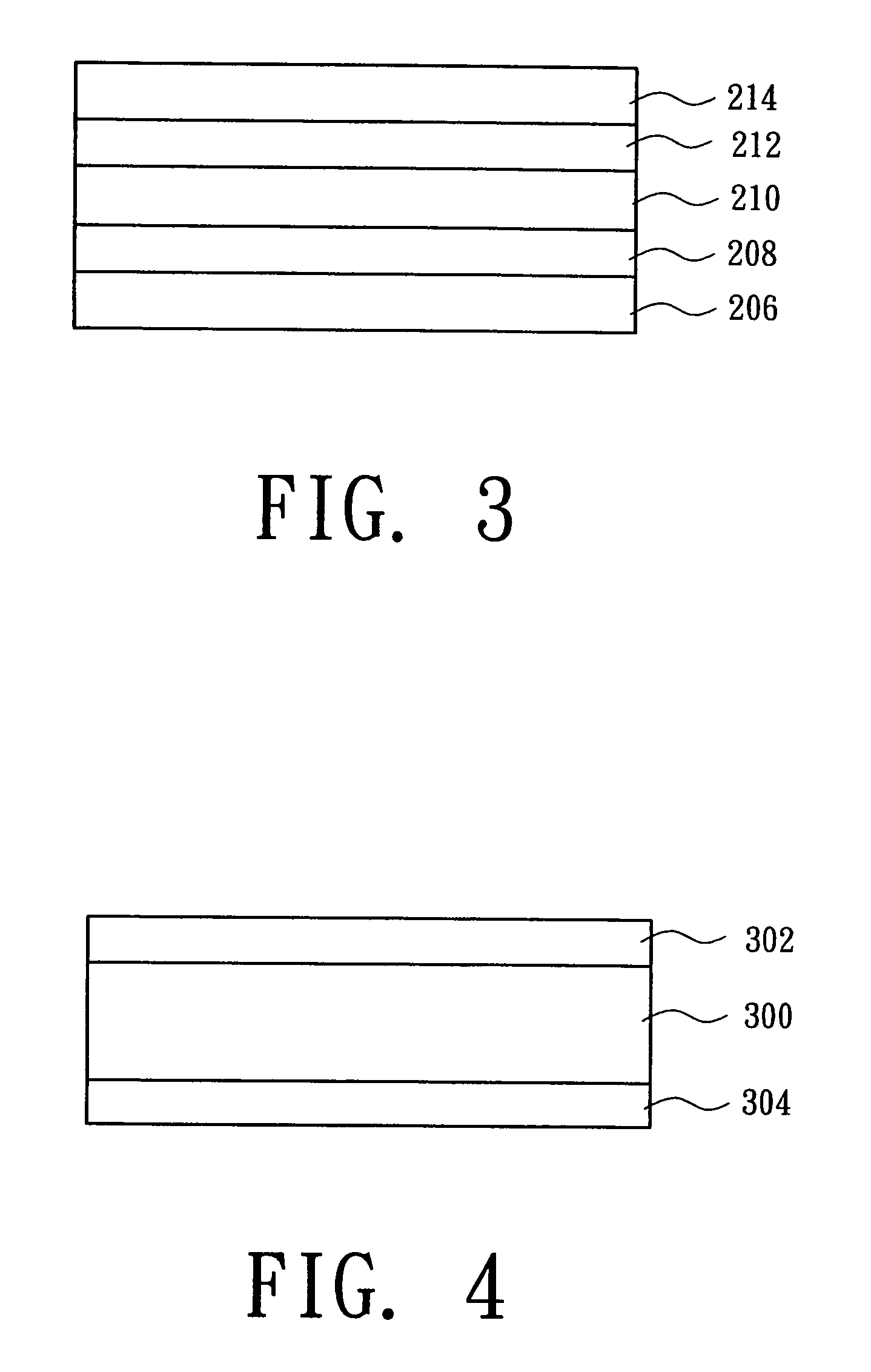

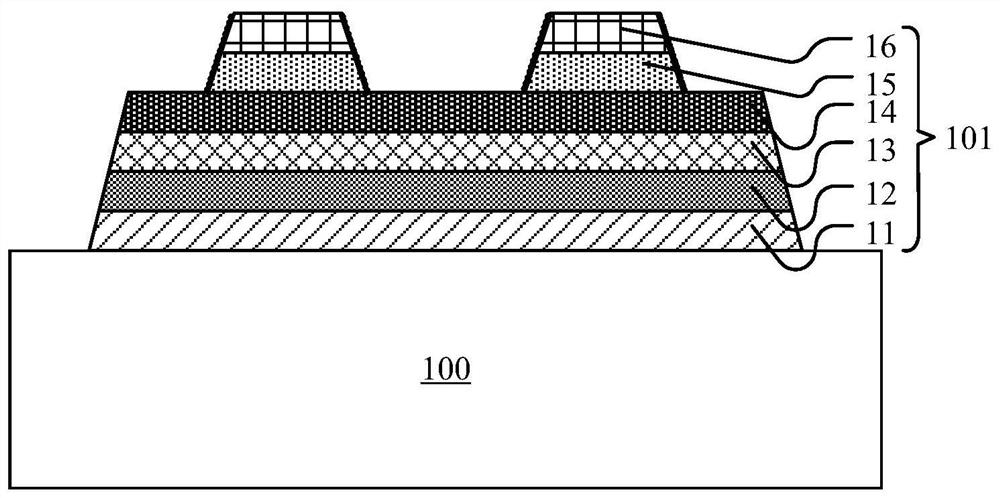

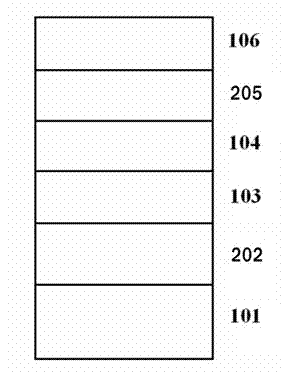

Nitride light-emitting diode (LED) epitaxial wafer and growing method thereof

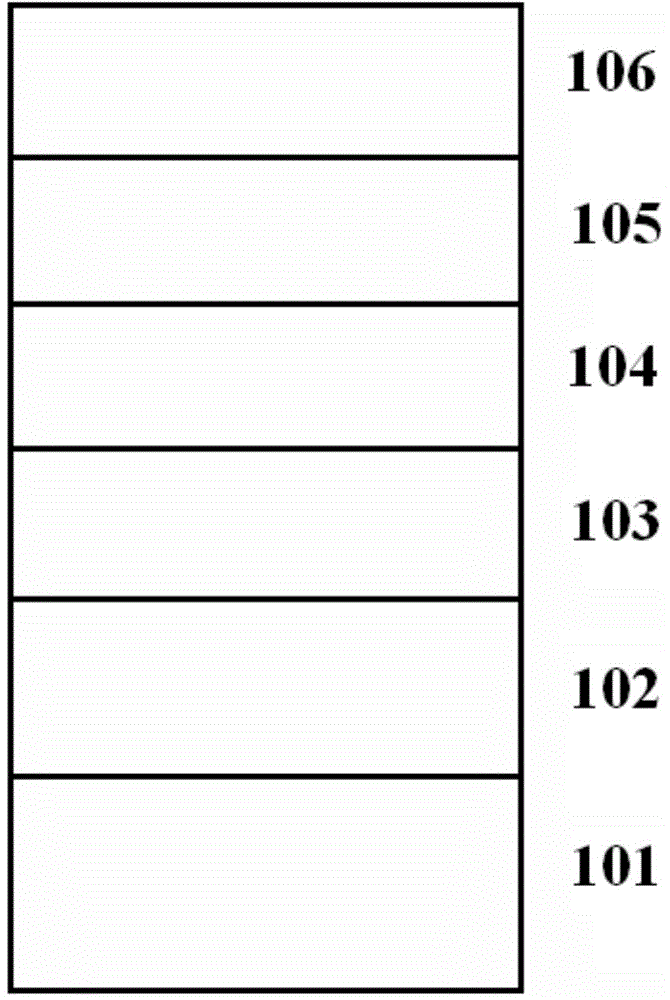

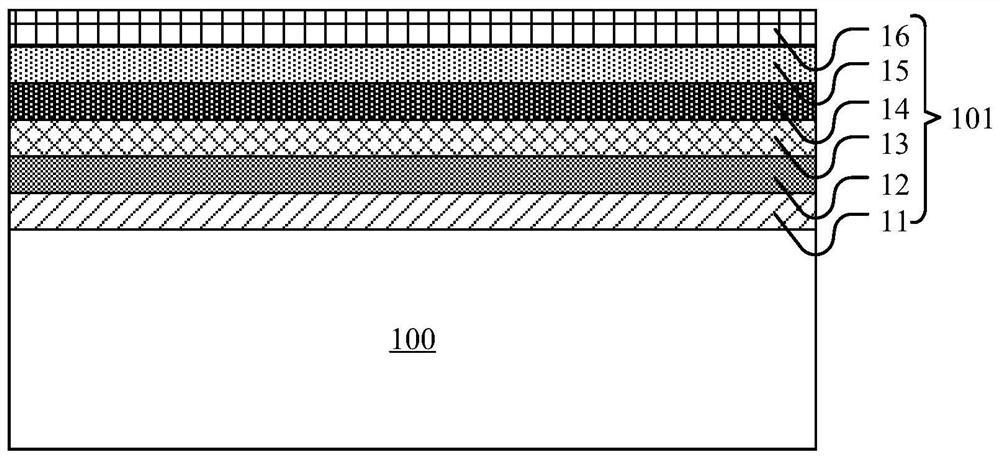

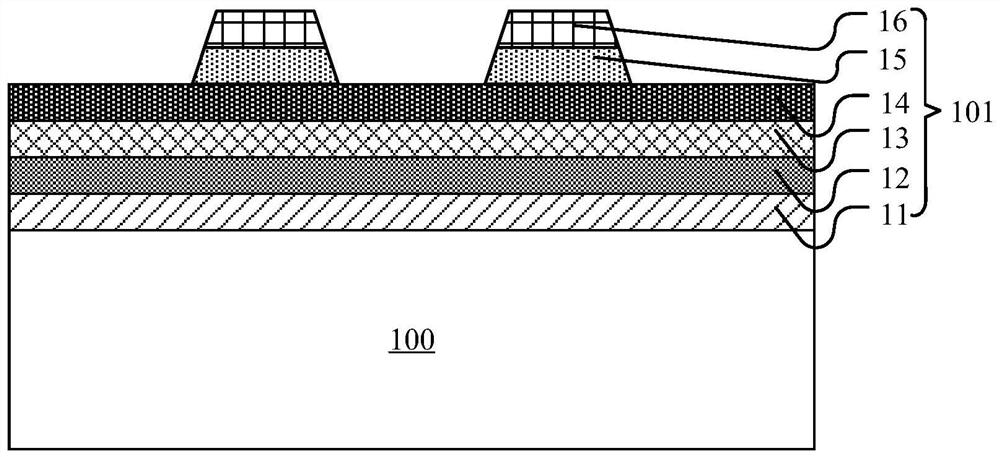

InactiveCN102969416AStress reliefReduced polarizing electric fieldSemiconductor devicesPower flowHole injection layer

The invention provides a nitride light-emitting diode (LED) epitaxial wafer and a growing method thereof and relates to the technical field of semiconductor optoelectronics. The nitride LED epitaxial wafer structurally and sequentially comprises a substrate, a low-temperature buffer layer, an unintentionally doped GaN, an N-shaped electron-injection layer, an InGaN / GaN inserting layer, an active area, an electron blocking layer, a u-GaN / p-GaN superlattice and a p-GaN hole-injection layer from bottom to top. The InGaN / GaN inserting layer is grown between the N-shaped electron-injection layer and the active area so as to effective relieve stress of the active area, lower polarization electric fields, reduce limitation of stark effect through a quantum well, and improve luminance and anti-static properties. The u-GaN / p-GaN superlattice is inserted between the electron blocking layer and the P-shaped hole-injection layer so as to improve current expansion capacity and lower chip operating voltage.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

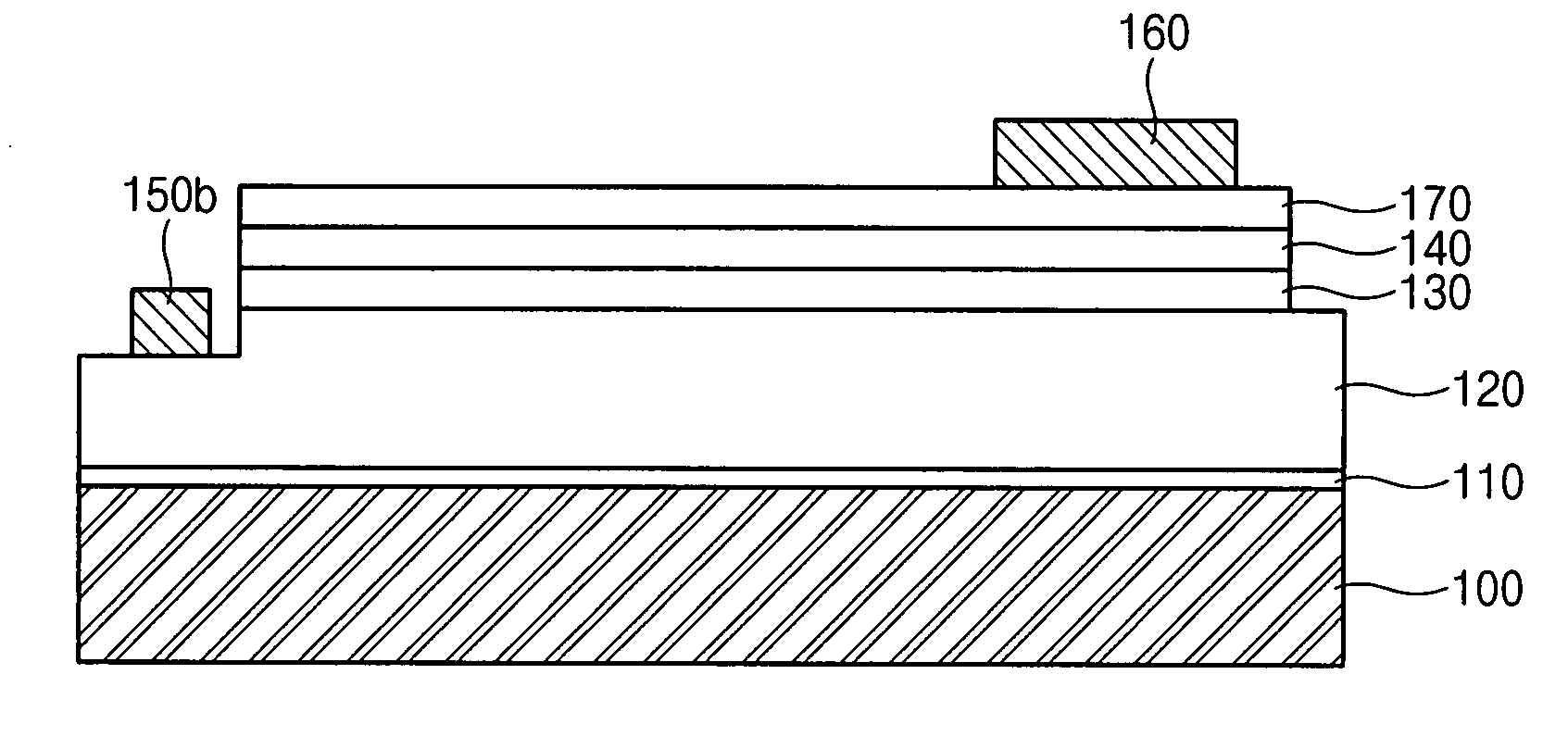

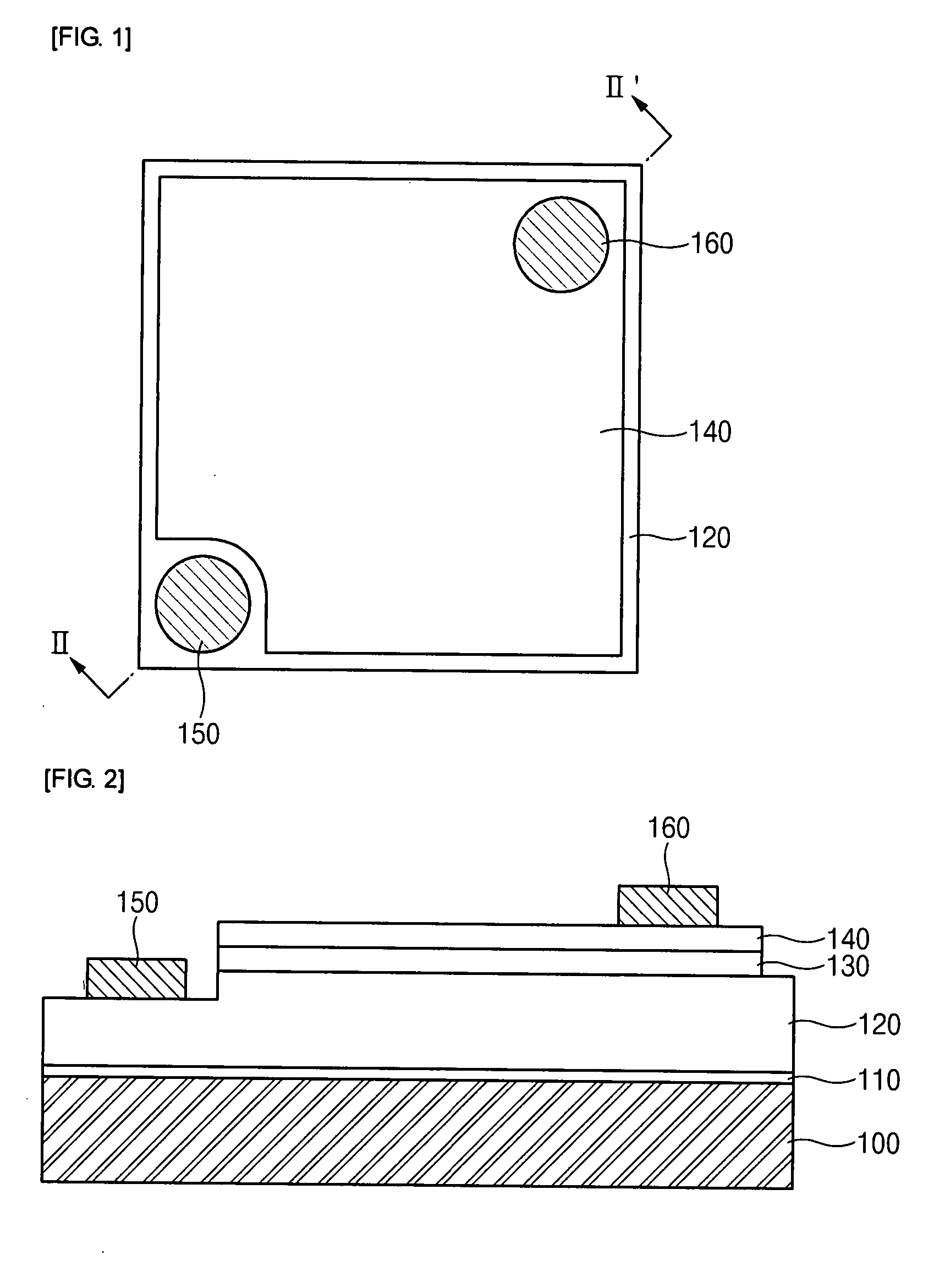

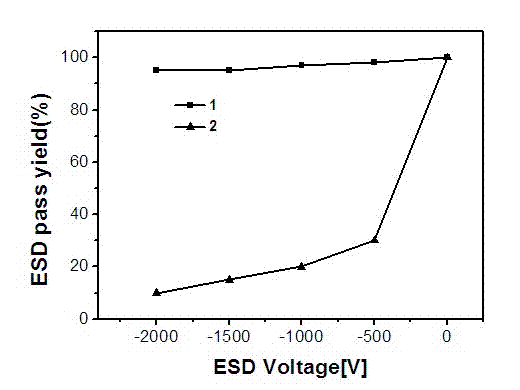

Nitride-based semiconductor light emitting diode

InactiveUS20070284593A1Improve current spreading effectMinimize ESD impactSolid-state devicesSemiconductor devicesActive layerLight-emitting diode

A nitride-based semiconductor LED comprises a substrate; an n-type nitride semiconductor layer formed on the substrate; an active layer formed on a predetermined region of the n-type nitride semiconductor layer; a p-type nitride semiconductor layer formed on the active layer; a p-electrode formed on the p-type nitride semiconductor layer, the p-electrode having a p-type branch electrode; a p-type ESD pad formed at the end of the p-type branch electrode, the p-type ESD pad having a larger width than the end of the p-type branch electrode; an n-electrode formed on the n-type nitride semiconductor layer, on which the active layer is not formed, the n-electrode having an n-type branch electrode; and an n-type ESD pad formed at the end of the n-type branch electrode, the n-type ESD pad having a larger width than the end of the n-type branch electrode.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

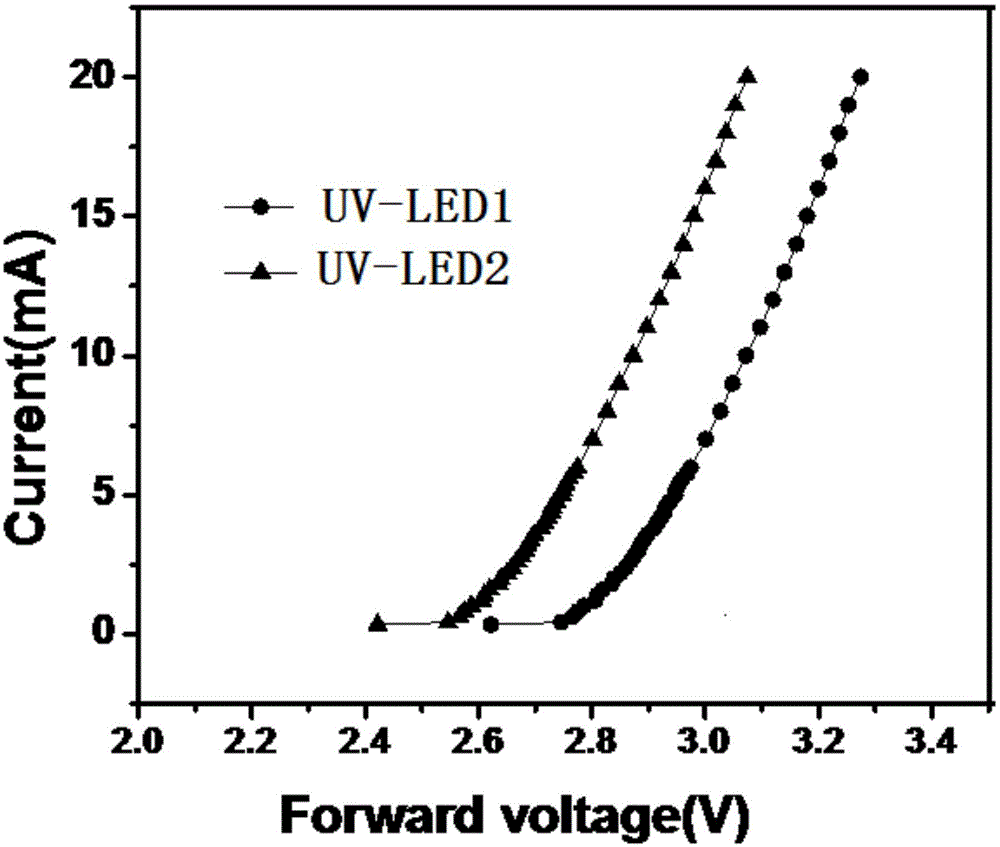

High-brightness near ultraviolet LED and preparation method thereof

ActiveCN104538521AImprove current spreading effectImprove luminous efficiencySemiconductor devicesPower flowQuantum well

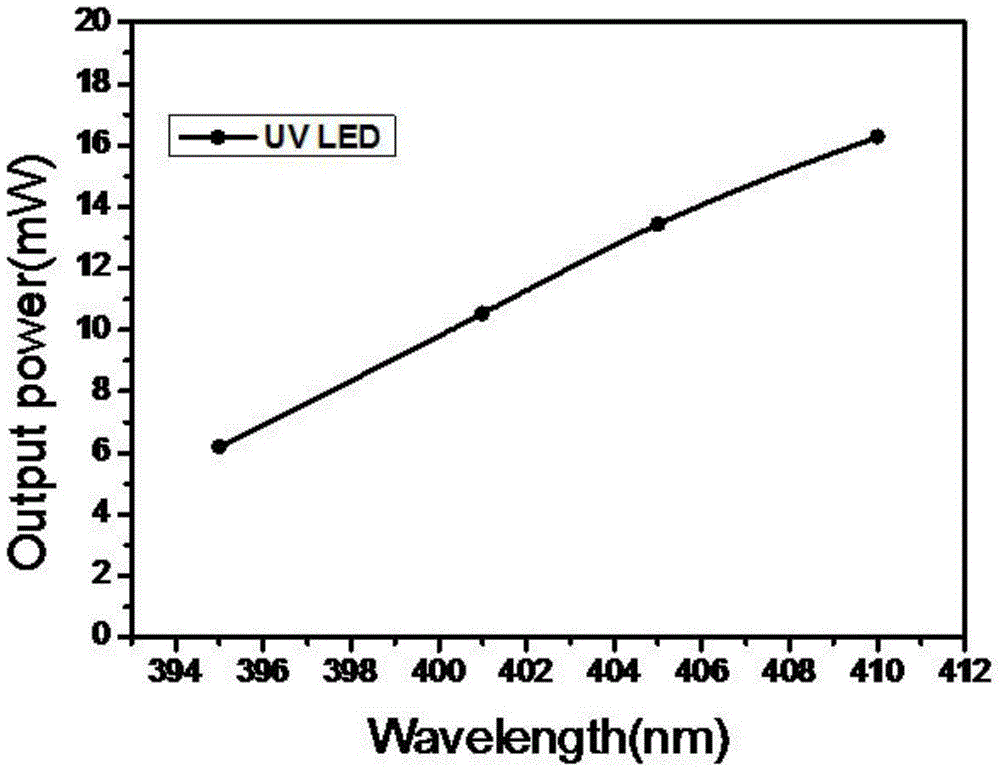

The invention discloses a high-brightness near ultraviolet LED and a preparation method of the high-brightness near ultraviolet LED, and belongs to the technical field of semiconductor photoelectronics. The LED structurally comprises a patterned sapphire substrate, a low-temperature GaN nucleating layer, a high-temperature non-doping GaN buffering layer, an n-type GaN layer, a stress release layer of an n-InxlGa1-x1N / Aly1Ga1-y1N quantum well structure, a low-temperature n-Aly1Ga1-y1N current spreading layer, an n-InxlGa1-xN / Aly1Ga1-yN multi-quantum well light-emitting layer, a p-Aly2Inx2Ga1-x2-y2N electronic barrier layer, a high-temperature p-type GaN layer and a p-type InGaN contact layer from bottom to top in sequence. The LED current spreading effect of the near ultraviolet LED can be improved by optimizing the n-type stress release layer and the n-type current spreading layer, and thus the light-emitting efficiency of the near ultraviolet LED is effectively improved.

Owner:PEKING UNIV

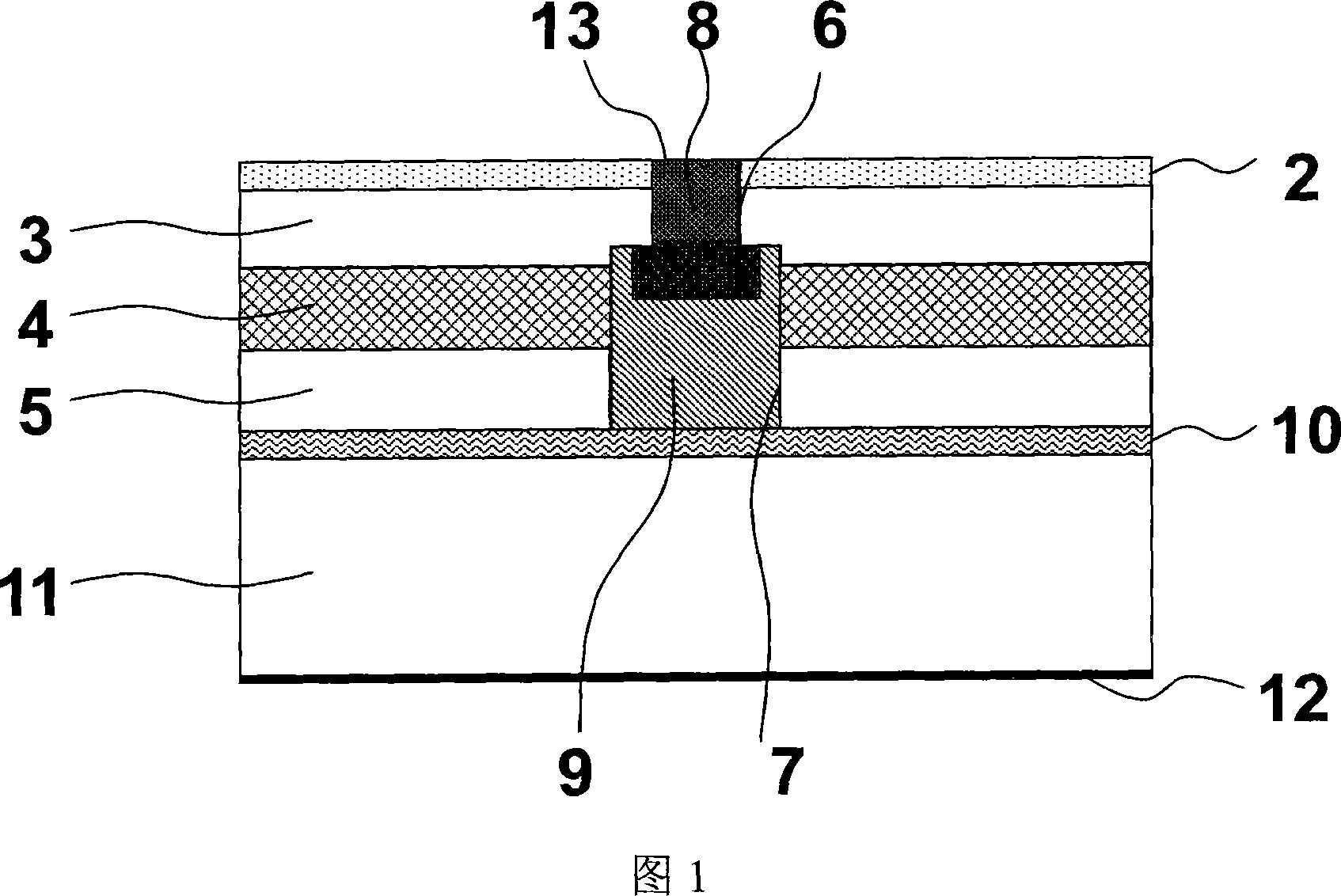

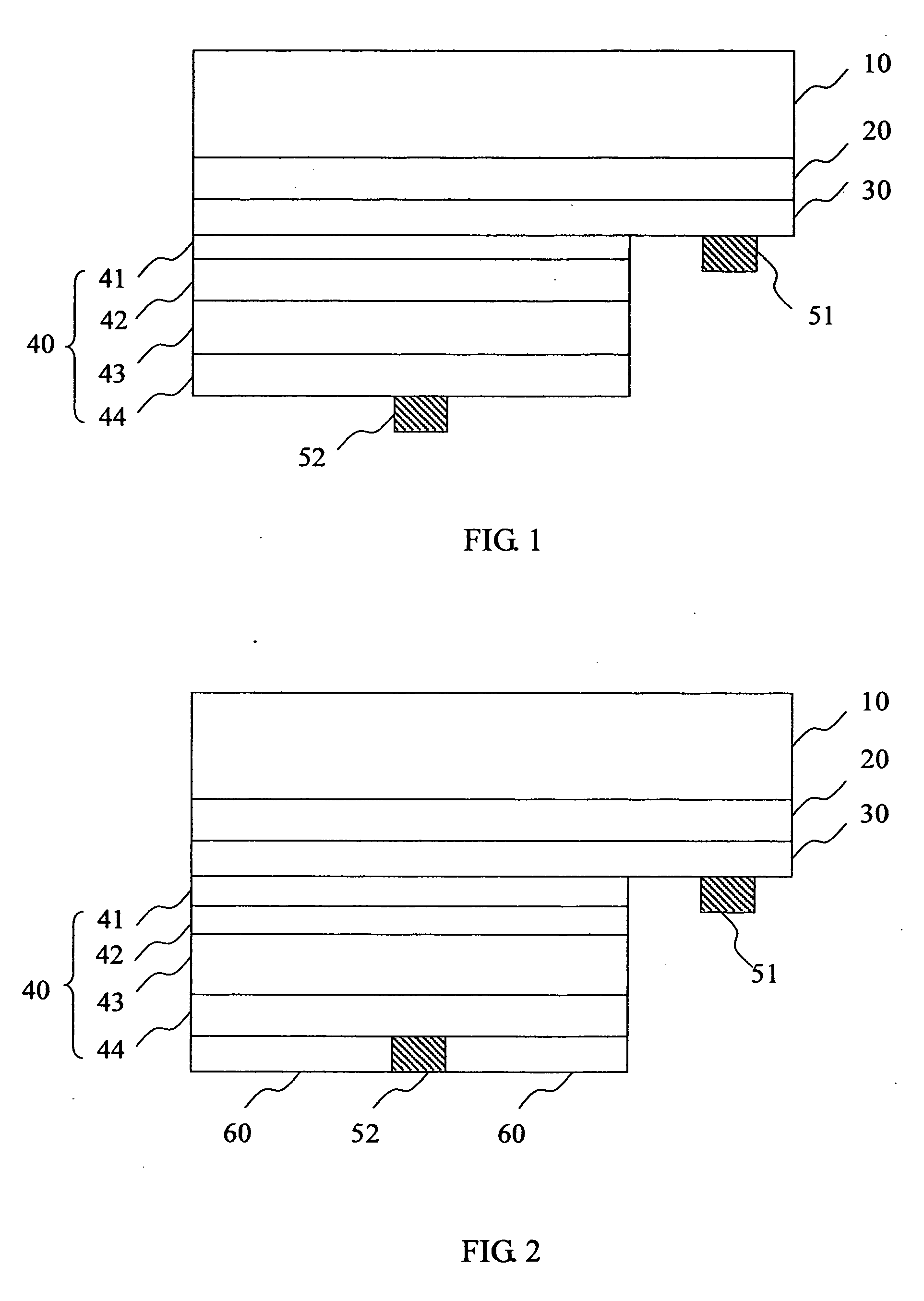

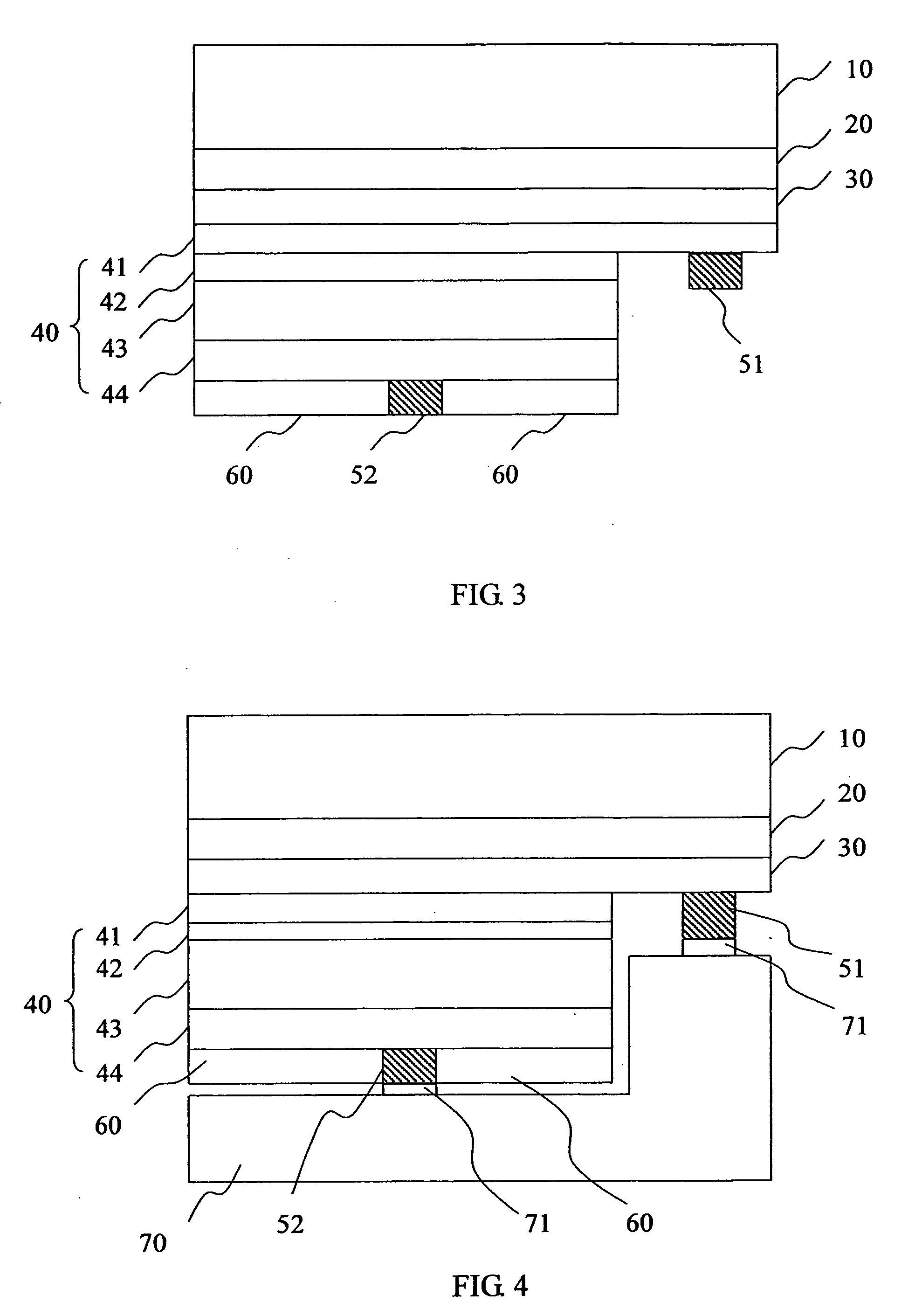

Light emitting diode and method for manufacturing the same

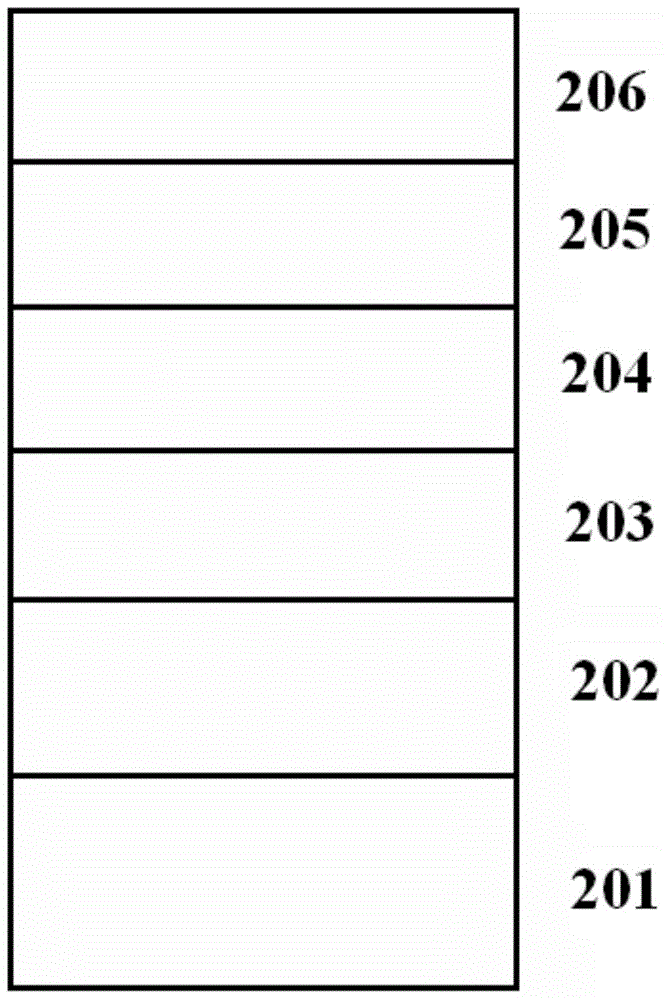

InactiveUS20050001224A1Improve current spreading effectReduce lossesSemiconductor/solid-state device manufacturingSemiconductor devicesContact layerPrism

A light emitting diode and a method for manufacturing the same are disclosed. The light emitting diode comprises: a transparent substrate; a reflective layer located on a surface of the transparent substrate; a solder layer located on the other surface of the transparent substrate; a semiconductor epitaxial structure located on the solder layer, wherein the semiconductor epitaxial structure comprises a n-type contact layer, and the n-type contact layer can be a structure having a continuous flat surface, a structure having a continuous reticulate or bar surface, or a cylinder or prism structure having a discontinuous surface; and a transparent conductive layer located on the n-type contact layer of the semiconductor epitaxial structure.

Owner:EPITECH +1

Method for preparing high-efficiency near-ultraviolet LED with asymmetric current expansion layer by using MOCVD

ActiveCN105449052AImprove current spreading effectImprove antistatic performanceSemiconductor devicesNon symmetricQuantum well

The invention provides a method for preparing a high-efficiency near-ultraviolet LED with an asymmetric current expansion layer by using MOCVD. The method, by designing a novel LED structure, improves current expansion in the horizontal direction so as to increase the luminous efficiency of the near-ultraviolet LED. The method comprises growing an asymmetric n-type current expansion layer between n-GaN and an InGaN / AlGaN multi-quantum well active region; and optimizing the current expansion layer to be (1) an n-type AlInGaN current expansion layer with gradually-changed asymmetric Al component, In component, and n doping, (2) a multi-period n-type AlInGaN / AlGaN superlattice-structured or quantum-well-structured hole expansion layer with gradually-changed asymmetric Al component, In component, and n doping, (3) a multi-period n-type InGaN / AlGaN superlattice-structured or quantum-well-structured hole expansion layer with gradually-changed asymmetric Al component, In component, and n doping, or (4) a multi-period n-type AlInGaN / GaN / AlGaN superlattice-structured or quantum-well-structured hole expansion layer with gradually-changed asymmetric Al component, In component, and n doping. The method effectively increases the luminous efficiency of the near-ultraviolet LED by designing the novel current expansion layer structure.

Owner:SINO NITRIDE SEMICON +1

Al component gradually-changed N-type LED structure and preparation method thereof

ActiveCN105140356AIncrease concentrationImprove antistatic performanceSemiconductor devicesPotential wellPeriodic alternating

An Al component gradually-changed N-type LED structure and a preparation method thereof are disclosed. The Al component gradually-changed N-type LED structure successively comprises, from bottom to top, a substrate, a nucleating layer, a buffer layer, an N-type Al<Y>In<X>Ga<1-X-Y>N layer, a multi-quantum well light-emitting layer, and a P-type GaN layer. In the N-type Al<Y>In<X>Ga<1-X-Y>N layer, X is more than or equal to 0 but less than or equal to 1, and Y is more than 0 but less than 1. An Al component in an N-type GaN layer is gradually changed. The method comprises the following steps of: (1) growing the nucleating layer on a processed substrate; (2) growing a non-doped gallium nitride buffer layer on the nucleating layer; (3) growing the N-type Al<Y>In<X>Ga<1-X-Y>N layer on the buffer layer; (4) growing the multi-quantum well light-emitting layer on the N-type Al<Y>In<X>Ga<1-X-Y>N layer, wherein the multi-quantum well light-emitting layer is formed by periodically and alternately superposed InGaN potential well layers and GaN barrier layers; and (5) growing the P-type GaN layer on the multi-quantum well light-emitting layer. An N-type region is prepared by an Al component gradually-changed mode, thereby improving electron concentration and an antistatic effect, essentially improving GaN film quality, enhancing current expansion capability, and increasing light extraction efficiency.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

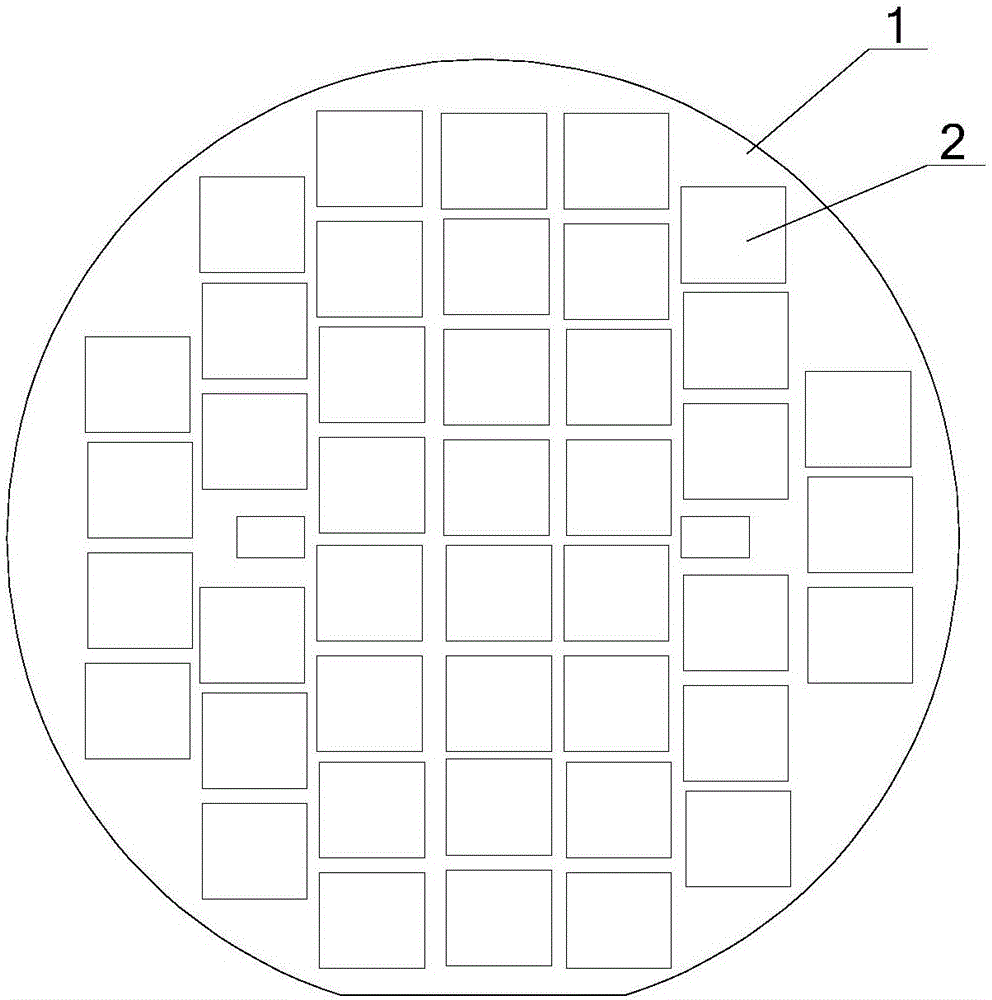

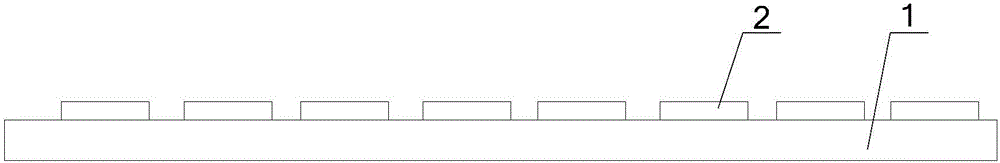

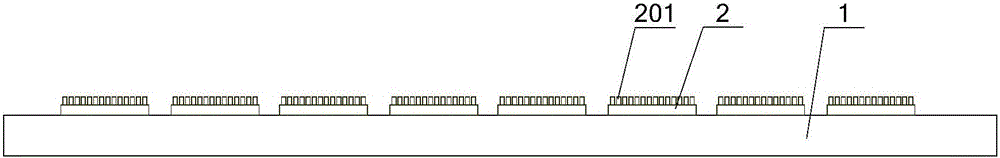

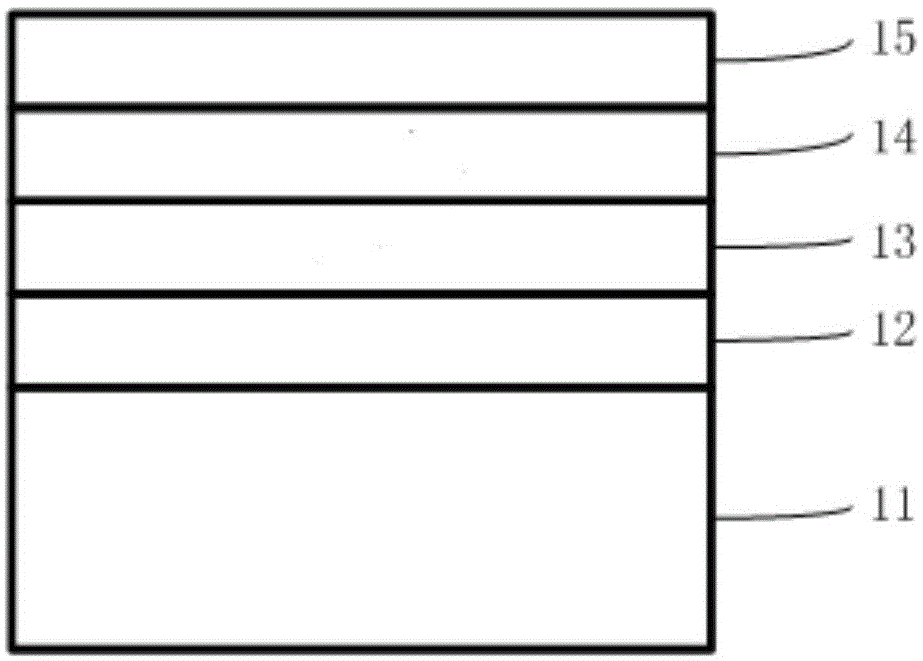

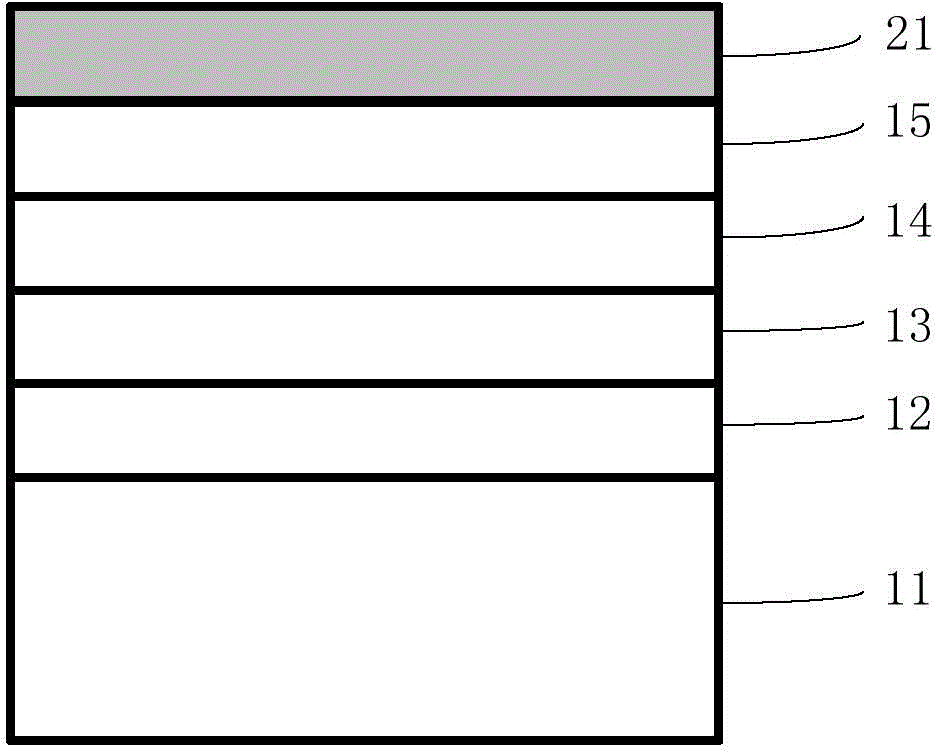

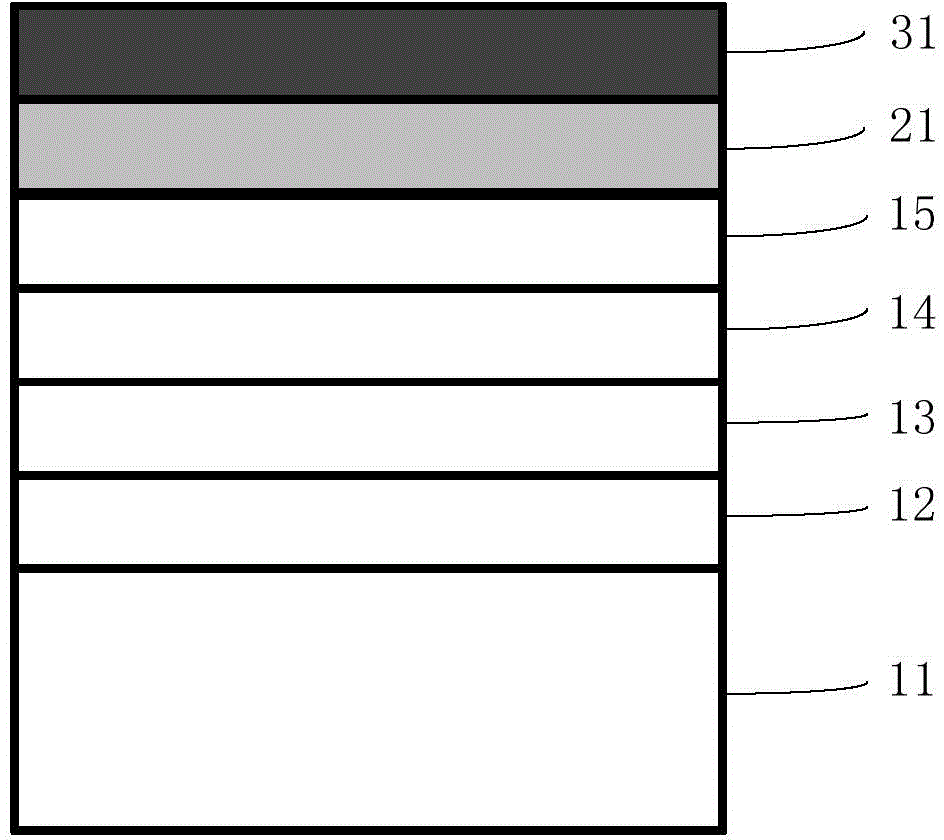

Epitaxial structure for improving GaN (Gallium Nitride)-based current spreading and growth method thereof

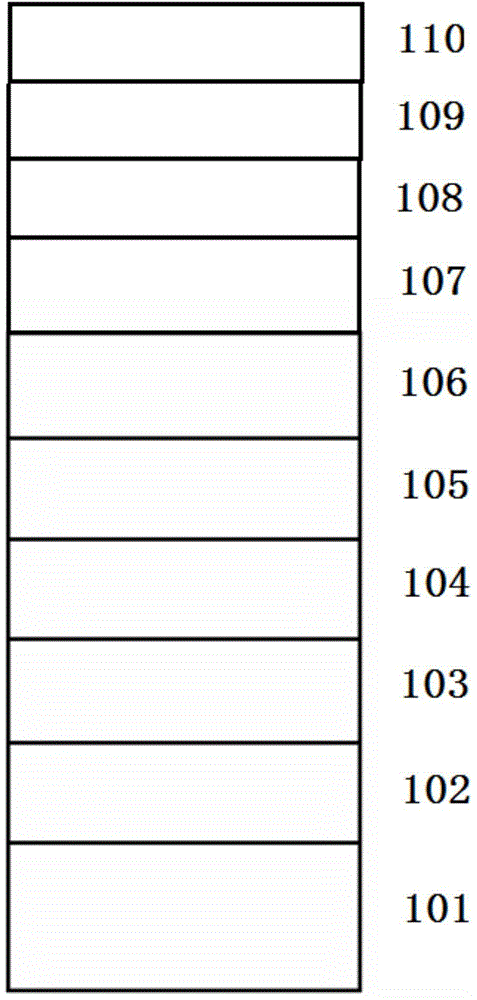

InactiveCN103400914AImprove reliabilityImprove leakageSemiconductor devicesContact layerGallium nitride

The invention relates to an epitaxial structure for improving GaN (Gallium Nitride)-based current spreading and a growth method thereof. From bottom to top, the epitaxial structure sequentially comprises a substrate, a low-temperature GaN buffer layer, a GaN undoped layer, an n-type GaN layer n1 layer, an n-type AlGaN (Aluminum Gallium Nitride) layer, an n-type GaN layer n2 layer, an n-type GaN layer LN layer, an MQW (Multiple Quantum Well) structure, an MQW active layer, a low-temperature p-type GaN layer, a p-type AlGaN layer, a high-temperature p-type GaN layer and a p-type contact layer. The growth method of the n-type GaN layer LN layer comprises the steps of firstly growing the n-type GaN layer nGaN3-1 layer, then growing the n-type AlGaN layer and finally growing the n-type GaN layer nGaN3-2 layer. The epitaxial structure and the growth method thereof provided by the invention have the advantages that the current can be effectively enabled to be uniformly spread, the crystal quality of an epitaxial layer is improved and the performance of a device is improved.

Owner:江苏华功半导体有限公司

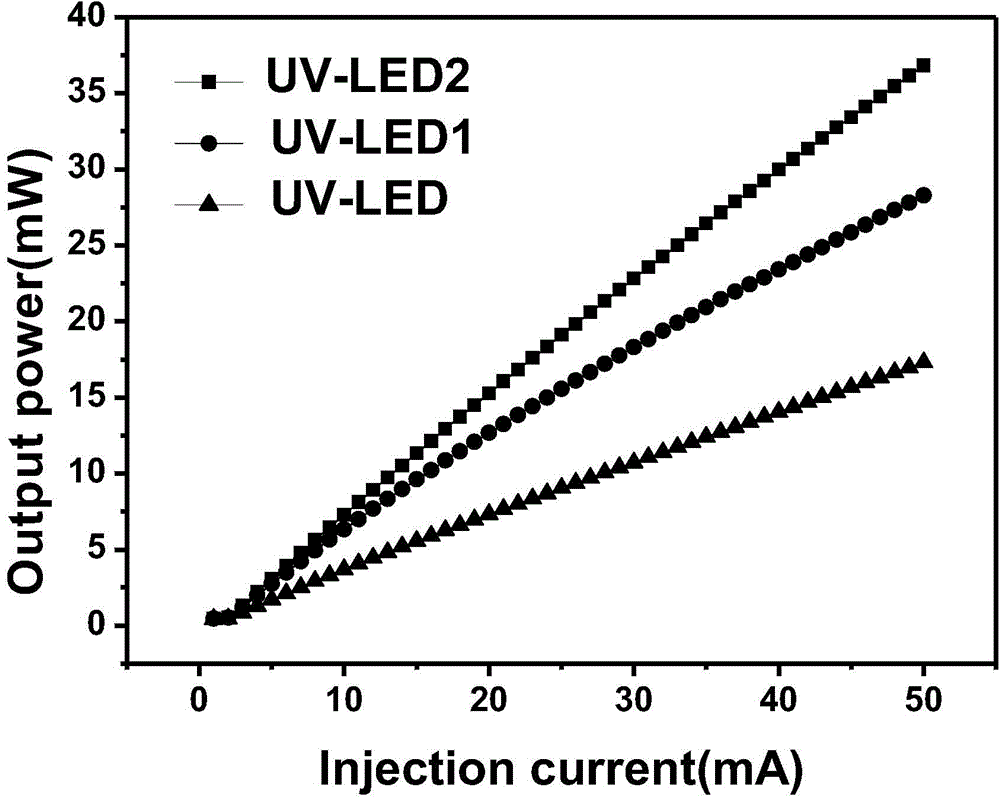

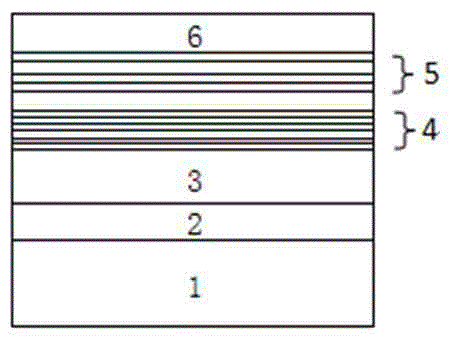

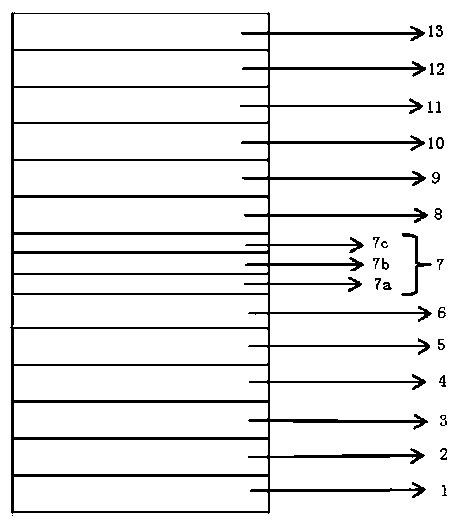

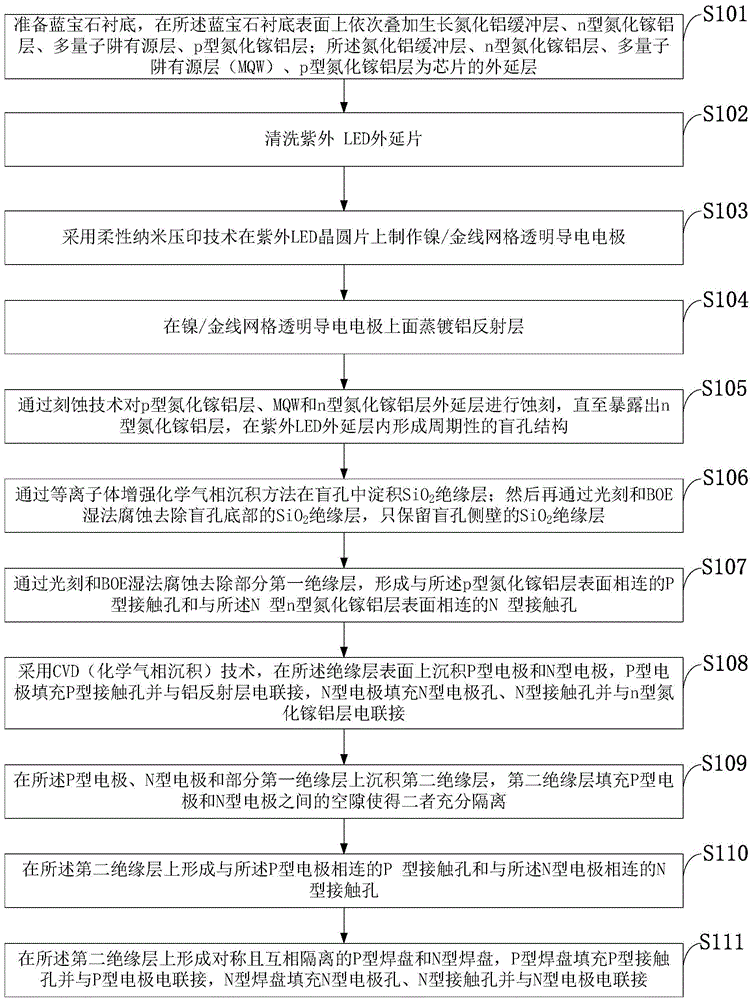

Ultraviolet light-emitting diode chip and preparing method thereof

ActiveCN105655459AImprove light extraction efficiencyImprove external quantum efficiencySemiconductor devicesWire gridLine width

The invention discloses an ultraviolet light-emitting diode chip provided with a metal wire grid transparent conduction electrode and a preparing method thereof. The ultraviolet light-emitting diode chip comprises a substrate, an aluminum nitride buffering layer, an n-type aluminum gallium nitride layer, a multiple-quantum-well active layer (MQW) and a p-type aluminum gallium nitride layer, wherein the aluminum nitride buffering layer, the n-type aluminum gallium nitride layer, the multiple-quantum-well active layer (MQW) and the p-type aluminum gallium nitride layer grow from the surface of the substrate sequentially in an overlaid mode. The aluminum nitride buffering layer, the n-type aluminum gallium nitride layer, the multiple-quantum-well active layer (MQW) and the p-type aluminum gallium nitride layer form an epitaxial layer of the chip. A metal wire grid is deposited on the epitaxial layer. An aluminum reflecting layer is deposited on the metal wire grid. The chip is provided with an n-type electrode hole penetrating through the aluminum reflecting layer, the metal wire grid, the p-type aluminum gallium nitride layer, the multiple-quantum-well active layer (MQW) and the n-type aluminum gallium nitride layer. The line width, the duty ratio and the thickness of the metal wire grid can be adjusted and controlled, the ultraviolet light transmittance rate is larger than 90%, and square resistance is smaller than 25 ohm. Light outlet efficiency of installing the ultraviolet LED chip in an inverted or upright mode is improved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

Method of adopting MOCVD technology to manufacture near ultraviolet LED possessing step-type quantum well structure

ActiveCN106033787AStress reliefImprove luminous efficiencyPolycrystalline material growthFrom chemically reactive gasesControl layerUltraviolet lights

The method provides a method of adopting a MOCVD technology to manufacture a high-brightness near ultraviolet LED possessing a step-type quantum well structure. The invention discloses the high-brightness near ultraviolet LED with a peak value wavelength scope of 395-410nm. An epitaxial structure successively comprises a graphical sapphire substrate, a low-temperature GaN nucleating layer, a high-temperature non-doped GaN buffer layer, an n-type GaN layer, an n-type Inx1Ga1-x1N / Aly1Ga1-y1N superlattice stress releasing layer, an InxGa1-xN / GaN / AlyGa1-yN multi-quantum-well active layer, a p-type Aly2Ga1-y2N / GaN superlattice electronic barrier layer, a high-temperature p-type GaN layer and a p-type InGaN contact layer from bottom to top. The active-layer multi-quantum well adopts an InxGa1-xN / gaN / AlyGa1-yN step type structure. A thickness scope of an InxGa1-xN well layer is 2-4nm. A GaN stress regulation and control layer thickness is 0.5-5nm. An AlGaN barrier layer thickness is 8-20nm. Through design an ultraviolet light LED novel active layer structure, stress borne by the quantum well can be effectively alleviated, quantum well crystal quality is increased and near ultraviolet LED luminescence efficiency is increased too.

Owner:SINO NITRIDE SEMICON

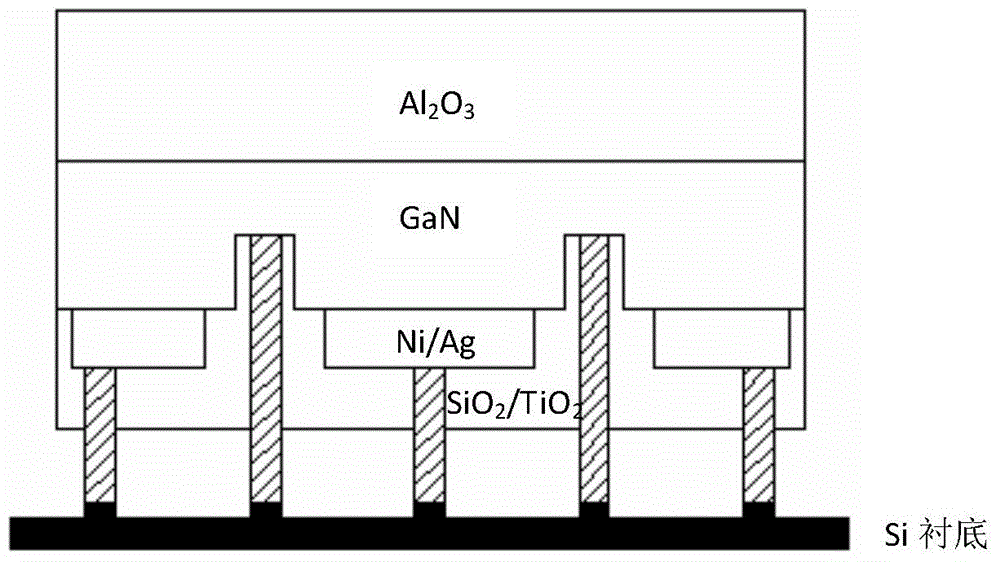

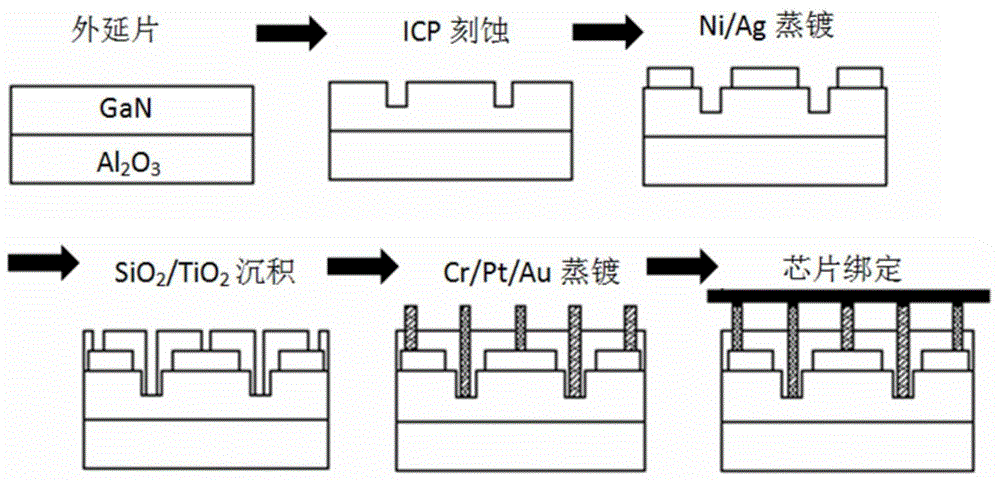

Flip LED chip preparation method

InactiveCN104701434AReduce absorptionIncrease brightnessSemiconductor devicesSilicon oxideOptoelectronics

The invention discloses a novel flip LED chip preparation method. The novel flip LED chip preparation method is used for preparing a high-reflectivity reflector and the related structure. Through combining an ultra-thin Ni / Ag film with a DBR reflector, the light absorption of the metal can be reduced, the chip brightness is effectively improved, and meanwhile, the DBR reflector replaces a traditional silicon oxide passivation layer to protect the chip. The evaporation rate of Ni in the Ni / Ag film is expressed in a FORMULA (as shown in the description), the evaporation thickness is expressed in a FORMULA (as shown in the description), the evaporation rate of Ag is FORMULA (as shown in the description), and the evaporation thickness is expressed in a FORMULA (as shown in the description); a DBR reflecting layer comprises single-layer SiO2 and a multi-period structure formed by alternately depositing TiO2 and SiO2 films based on the single-layer SiO2, and the period number is larger than 4.

Owner:西安利科光电科技有限公司

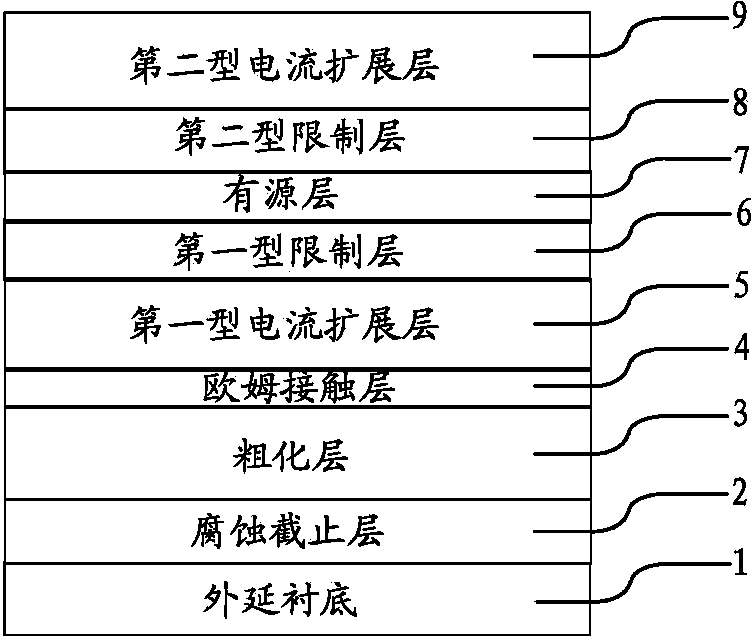

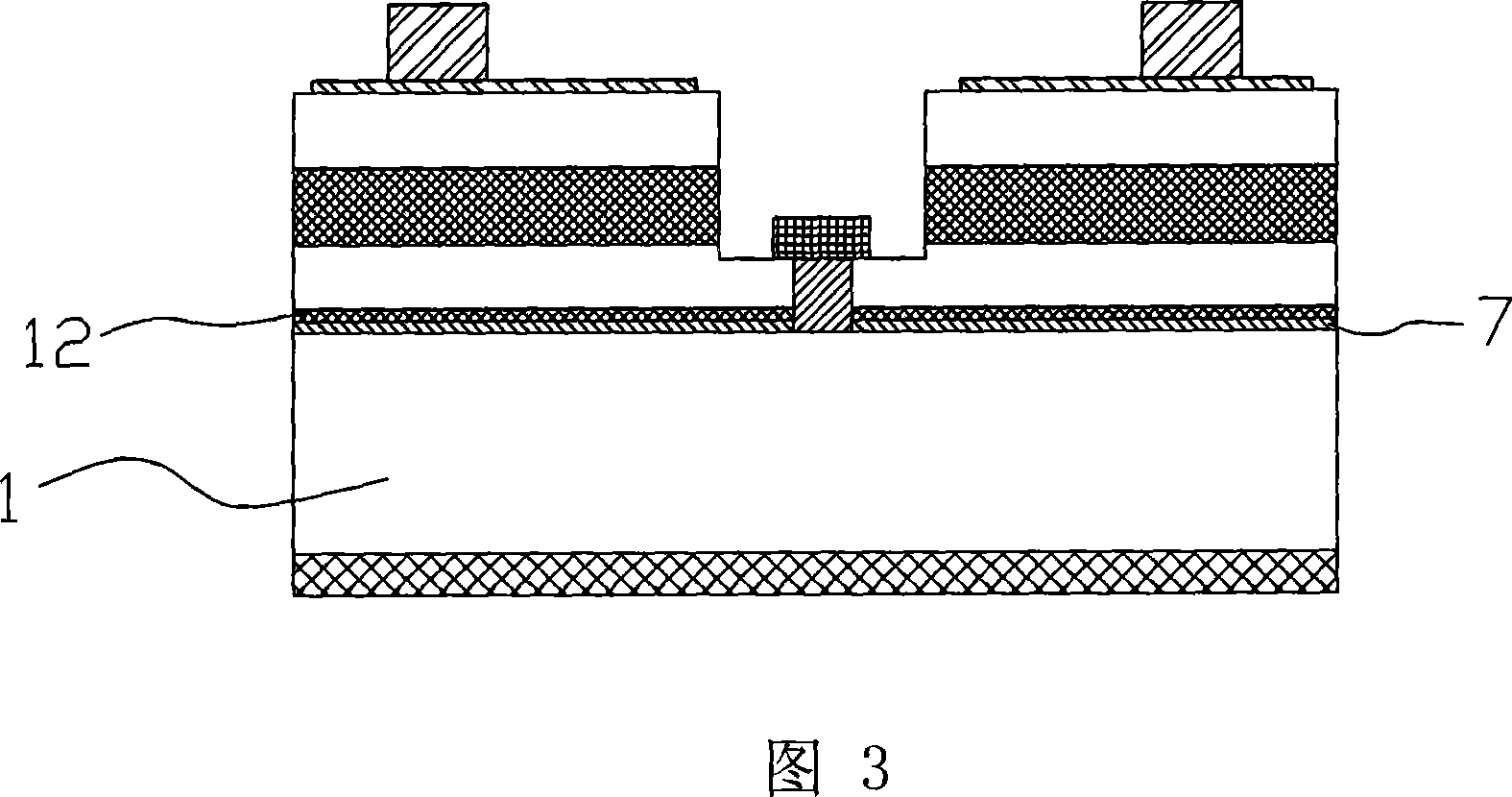

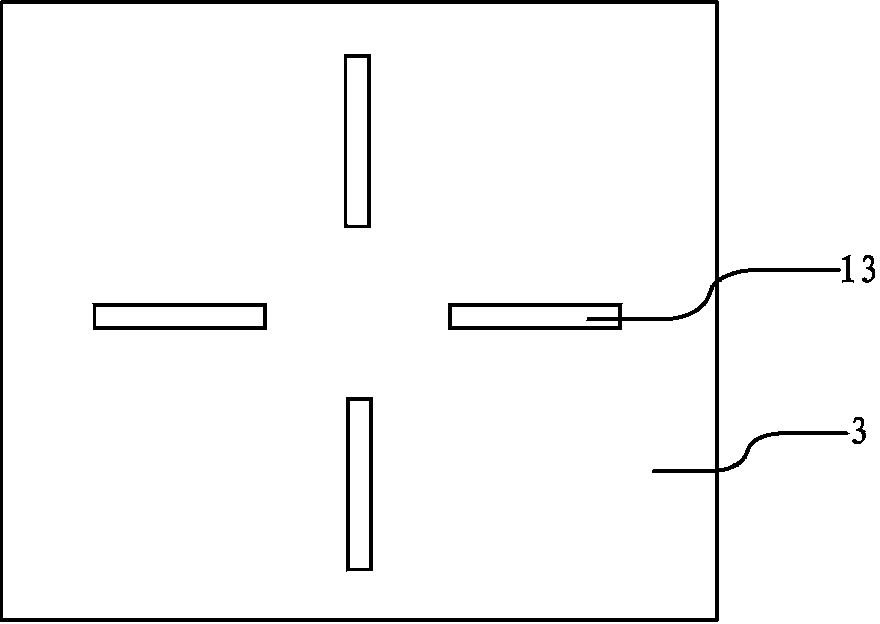

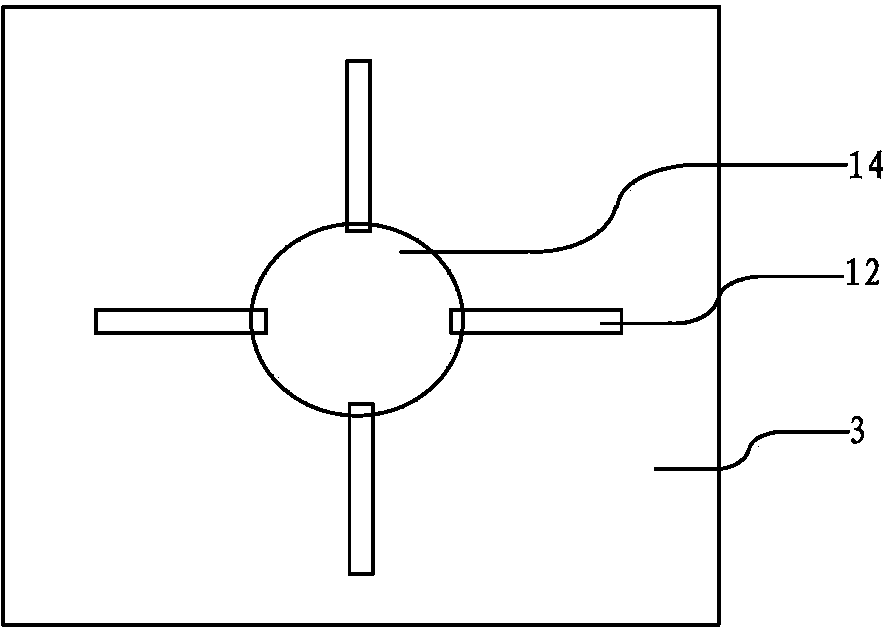

Manufacturing method for infrared light emitting diode with embedded extended electrode

InactiveCN104201268ATroubleshoot falling technical issuesPrevent side erosionSemiconductor devicesPower flowOhmic contact

The invention discloses a manufacturing method for an infrared light emitting diode with an embedded extended electrode. The manufacturing method for the infrared light emitting diode with the embedded extended electrode includes that forming a corrosion resisting layer, an armoring layer, an ohmic contact layer, a first current extension layer, a first limit layer, an active layer, a second limit layer and a second current extension layer on an epitaxial substrate in sequence; forming a metal reflector layer on the second current extension layer through evaporation; bonding a metal reflecting layer to a base plate; removing the epitaxial substrate and corrosion resisting layer to expose the armoring layer; forming an extended electrode pattern channel in the surface of the armoring layer, wherein the channel is deep enough to expose the ohmic contact layer; evaporating metal material in the channel to form the extended electrode; manufacturing a bonding pad electrode at the surface of the armoring layer, and communicating the bonding pad electrode with the extended electrode; evaporating a back electrode at the back of the base plate, removing protecting layers of the bonding pad electrode and extended electrode, and shredding to obtain the infrared light emitting diode with the embedded extended electrode. The manufacturing method for the infrared light emitting diode with the embedded extended electrode is capable of improving the reliability of the extended electrode, obtaining better current extension effect and improving the light emitting efficiency of the infrared light emitting diode.

Owner:XIAMEN CHANGELIGHT CO LTD

LED micro-display screen and preparing method thereof

ActiveCN106652820AWill not be damaged by high temperatureImprove transmittanceStatic indicating devicesSolid-state devicesOhmic contactBonding process

The invention discloses a preparing method of an LED micro-display screen. The preparing method includes the steps that low-temperature bonding is carried out on a prepared graphene thin layer serving as a negative pole electrode and an n-GaN surface of an LED pixel structure on a display screen backing plate to form ohmic contact, and low-temperature bonding is carried out on the graphene thin layer and a metal connecting structure of a control circuit of the display screen backing plate. As the graphene thin layer can ensure high transmissivity, compared with an ITO layer, graphene has more excellent current conduction capacity and thermal diffusion capacity, connection between the graphene thin layer and n-GaN as well as the metal connecting structure is completed through the low-temperature bonding process, the graphene thin layer and n-GaN as well as the graphene thin layer and the metal connecting structure are connected through van der waals force, and the high-temperature process in the ITO layer manufacturing process is not needed, so that components of the LED micro-display screen are prevented from being damaged by high temperature. The invention further discloses an LED micro-display screen prepared through the preparing method.

Owner:GOERTEK INC

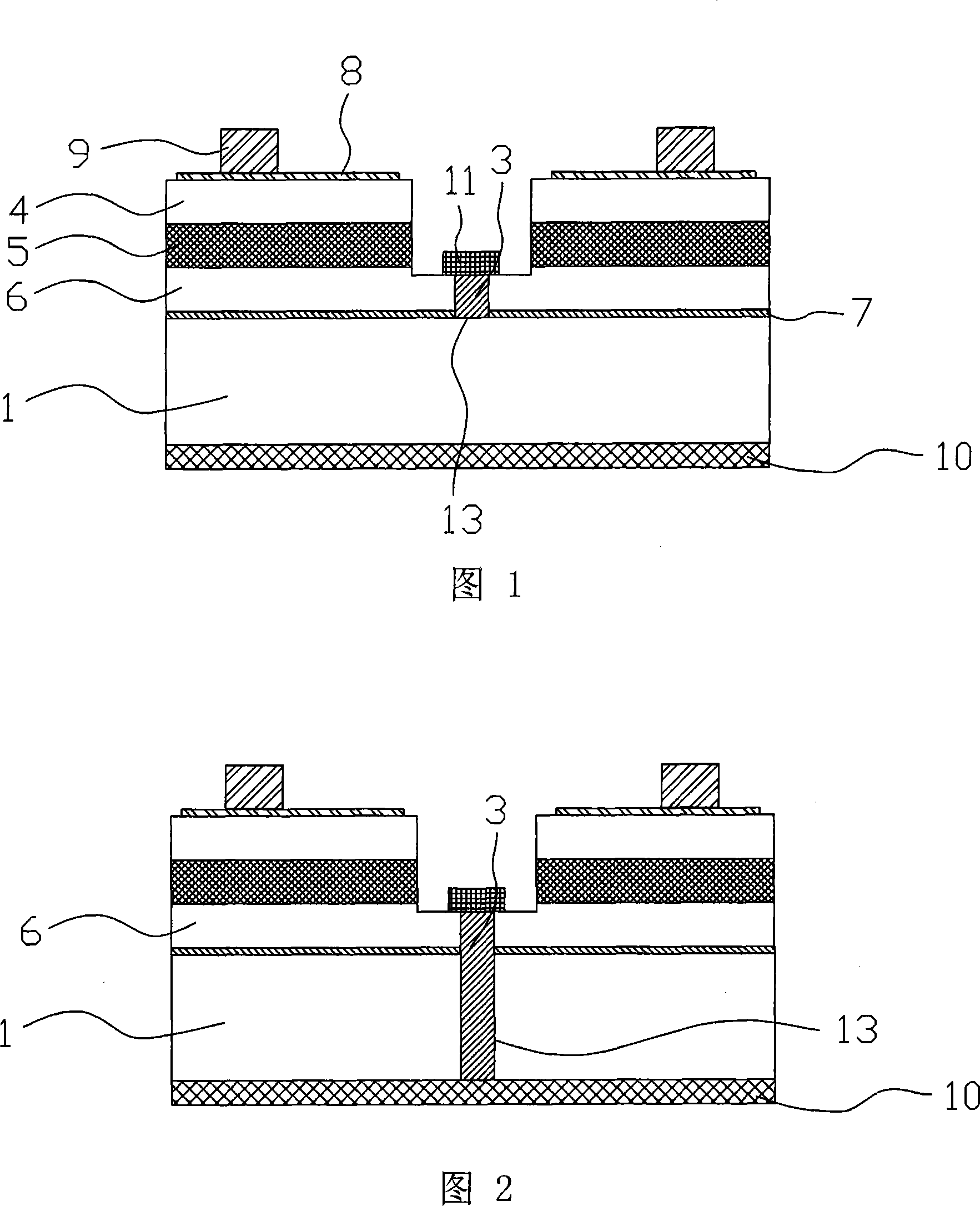

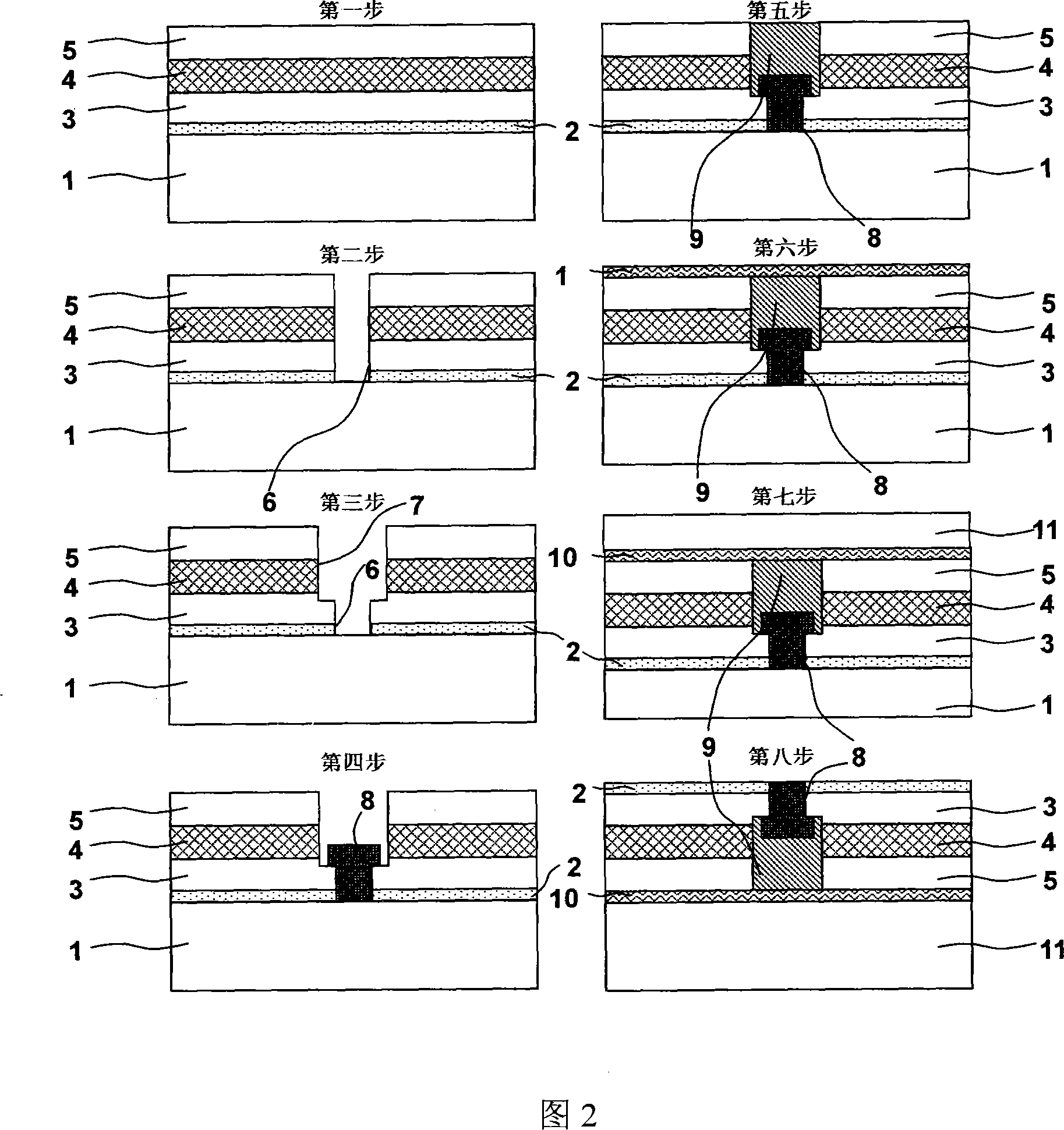

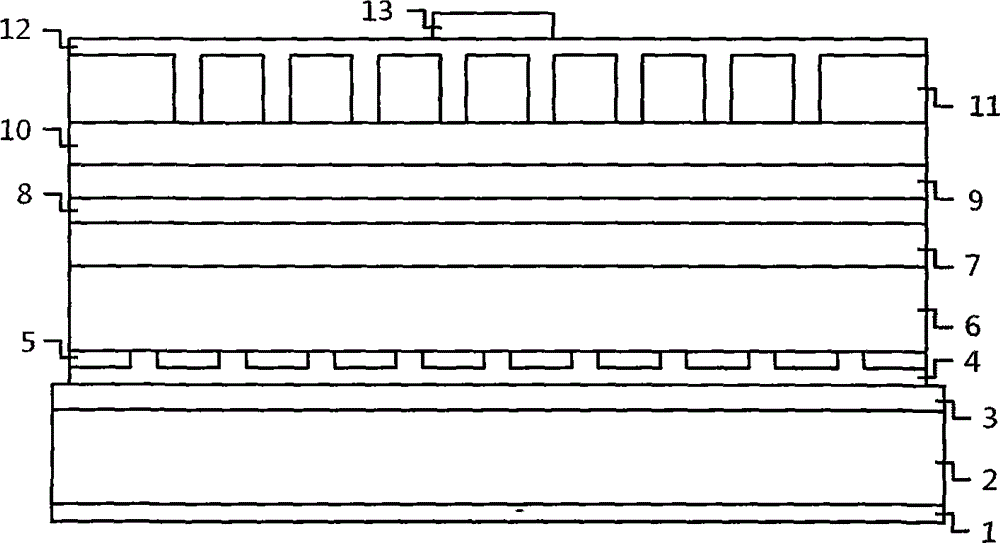

Semiconductor luminescent device and mfg method thereof

InactiveCN101159301AEliminate current blocking effectLow working voltageSemiconductor devicesSemiconductorOperating voltage

The invention discloses a semiconductor illuminating device, which comprises a substrate and a semiconductor extended laminated layer that is laminated on the substrate. The semiconductor extended laminated layer sequentially comprises, from bottom to top, an N-type layer, an illuminating layer, and a P-type layer. An electrode is equipped on the lower surface of the substrate. A P-type electrode is equipped on the upper surface of the P-type layer, wherein part of the P-type layer is etched into the N-type layer and equipped with an N-type electrode, meanwhile, a conductor is equipped in this part of the N-type layer, one end of the conductor is connected with the N-type electrode, and the other end of the conductor is contacted with the substrate. The conductor is composed of a cylindrical through-hole and conducting material in the through-hole. The conductor can also be extended to the bottom of the substrate and connected with the electrode on the lower surface of the substrate. The invention can effectively reduce the operating voltage and improves the output power of the semiconductor illuminating device. Furthermore, the invention also discloses a method of manufacturing the semiconductor illuminating device.

Owner:SUN YAT SEN UNIV

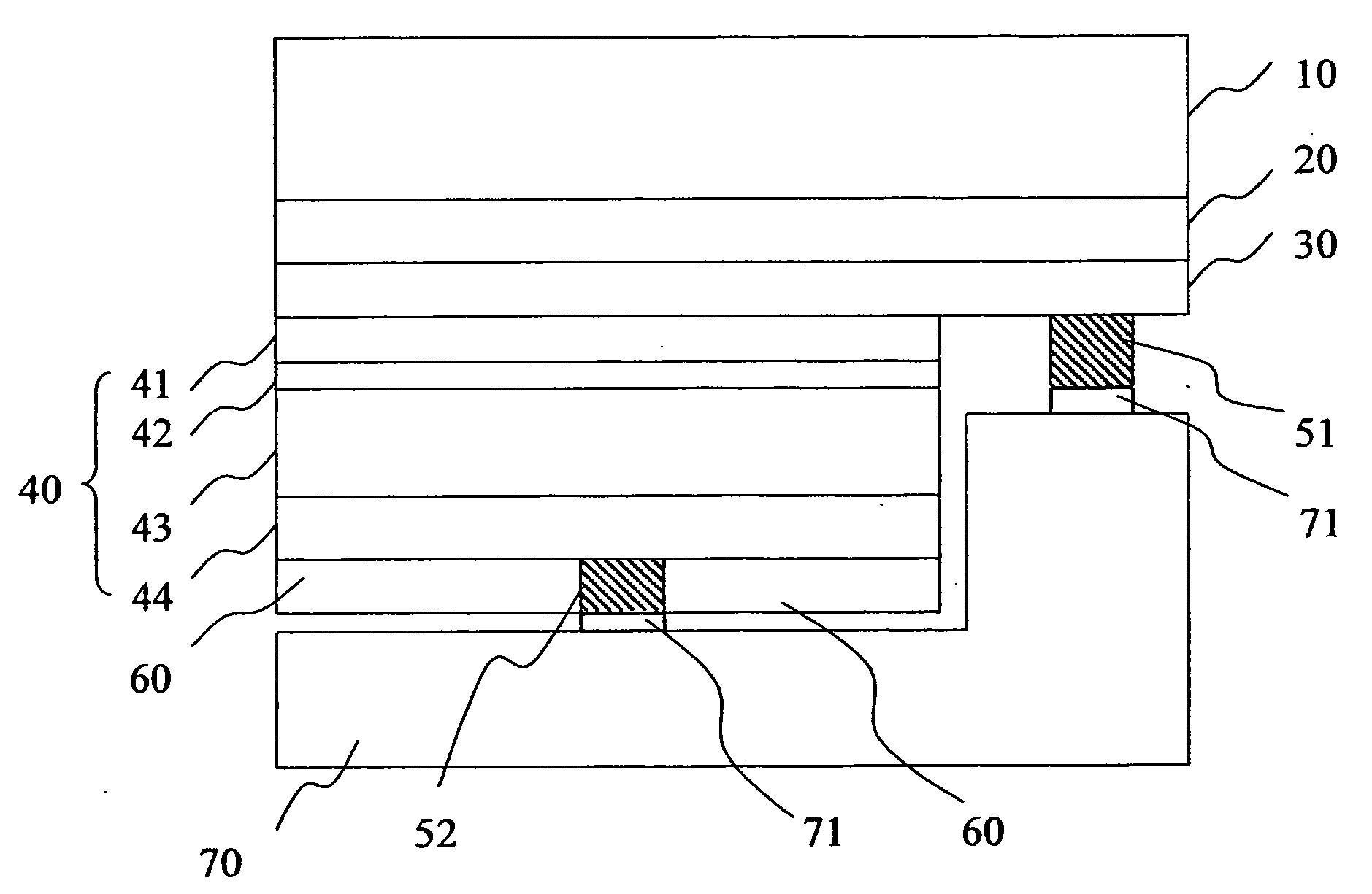

Light emitting diode and method for manufacturing the same

InactiveUS20050001226A1Improve current spreading effectReduce lossesSemiconductor/solid-state device manufacturingSemiconductor devicesPrismReflective layer

A light emitting diode and a method for manufacturing the same are disclosed. The light emitting diode comprises: a transparent substrate; a reflective layer located on a surface of the transparent substrate; a solder layer located on the other surface of the transparent substrate; a semiconductor epitaxial structure located on the solder layer, wherein the semiconductor epitaxial structure comprises a n-type contact layer, and the n-type contact layer can be a structure having a continuous flat surface, a structure having a continuous reticulate or bar surface, or a cylinder or prism structure having a discontinuous surface; and a transparent conductive layer located on the n-type contact layer of the semiconductor epitaxial structure.

Owner:EPISTAR CORP +1

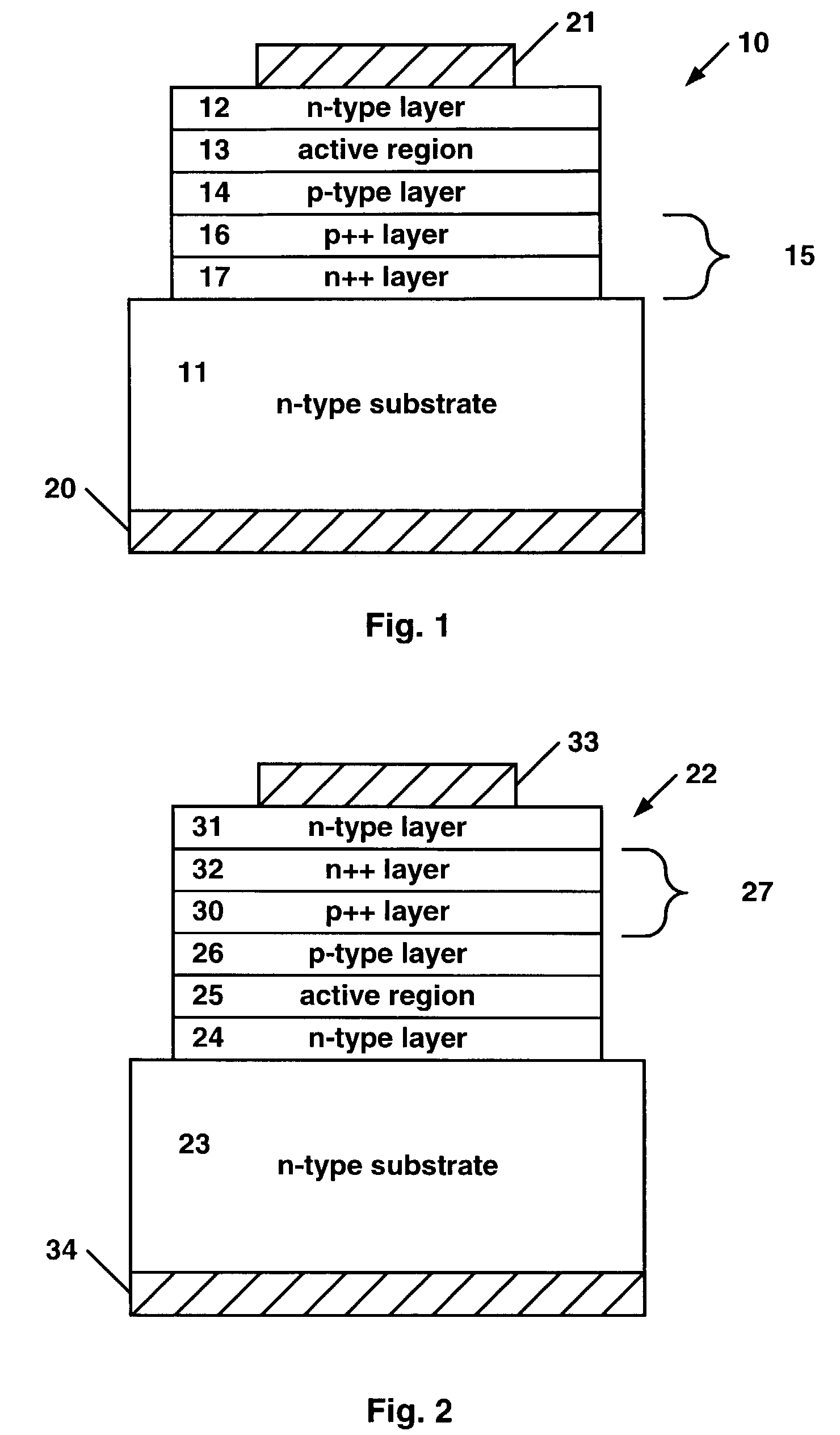

Semiconductor light emitting device and method for manufacturing the same

InactiveCN101226981AImprove heat transfer performanceIncrease contact areaSemiconductor devicesDielectric layerLight emitting device

The invention discloses a semiconductor light-emitting device, which comprises a substitution substrate and a semiconductor extension laminated layer which is orderly connected with the substitution substrate through a metal layer, wherein the semiconductor extension laminated layer at least comprises a buffer layer, an N type layer, a luminous layer and a P type layer from the upper to the lower, a conductor is arranged in the N type layer, one end of the N type layer extents to expose the buffer layer, and an N type electrode is arranged, and a dielectric layer is arranged between the other end of the conductor and the metal layer. The lower end of the substitution substrate is quipped with a P type electrode, and the conductor, the P type layer and the metal layer are separated. The device of the invention sends light from the side of the N type layer, a transparency electrode does not need to use on the side of sending the light, thereby being capable of effectively improving the output power of the semiconductor device, and also being capable of reducing the thermal resistance of a light emitting diode device. Further, the invention also discloses a method for preparing a semiconductor light emitting diode.

Owner:SUN YAT SEN UNIV

Reverse-polarity AlGaInP light-emitting diode structure with window layer being covered with indium tin oxide

InactiveCN104916752AImprove extraction efficiencyReduce occlusionSemiconductor devicesPower flowIndium tin oxide

The invention provides a reverse-polarity AlGaInP light-emitting diode structure with a window layer being covered with an indium tin oxide (ITO). The structure sequentially comprises, from the bottom up, a p electrode, a substrate, a bonding layer, a reflector layer, an insulating layer, a current extension layer, a p-type semiconductor layer, an active region, an n-type semiconductor layer, an n-type semiconductor contact layer, the window layer, an indium tin oxide layer and an n electrode, wherein the indium tin oxide layer is covered on the window layer and runs through the window layer having openings in a cylinder form and is directly contacted with the n-type semiconductor contact layer. The structure can improve light extraction efficiency and current expansion efficiency of an LED chip and is easy to combine with the existing process.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

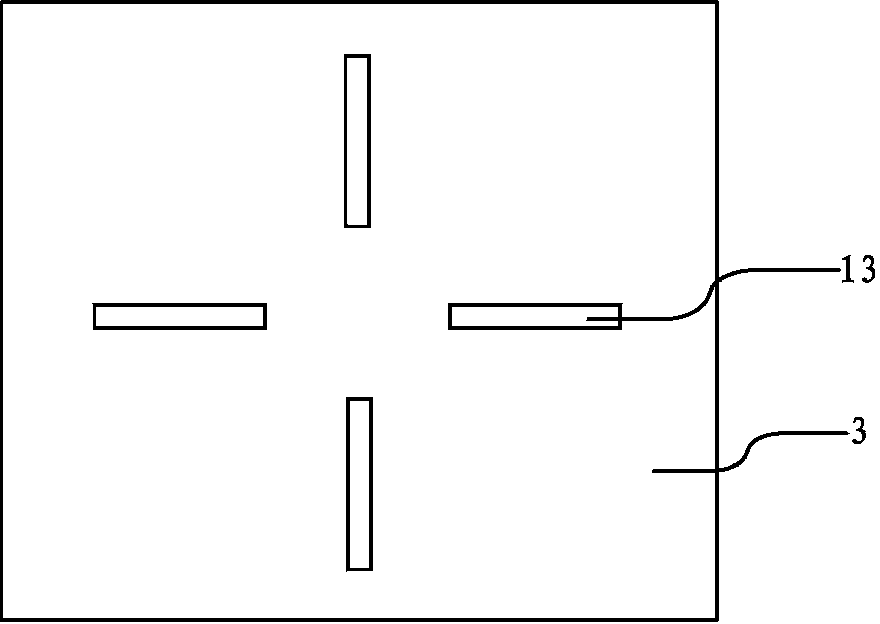

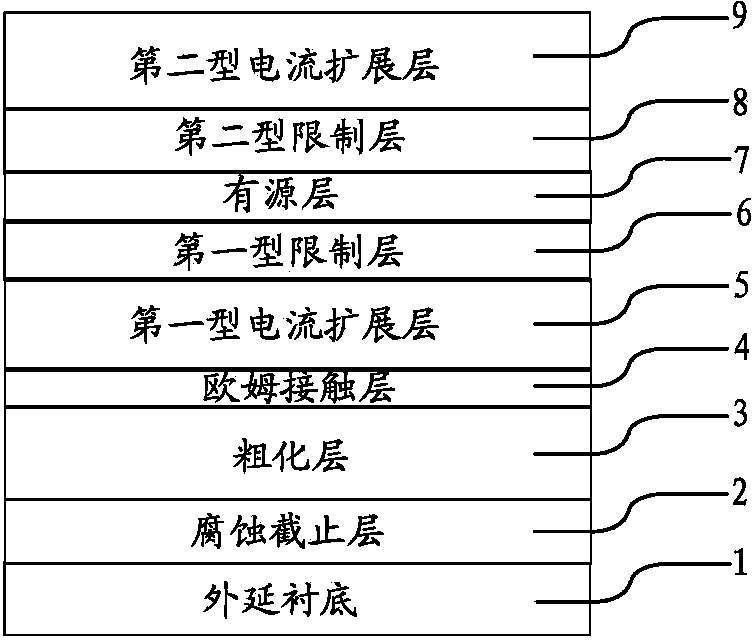

Infrared light-emitting diode with embedded expanded electrode

InactiveCN104183679ATroubleshoot falling technical issuesPrevent side erosionSemiconductor devicesPower flowOhmic contact

The invention discloses an infrared light-emitting diode with an embedded expanded electrode. An ohmic contact layer is arranged on one side of a light-emitting structure, a coarsening layer is arranged on the ohmic contact layer, a groove is formed in the coarsening layer, the expanded electrode is formed in the groove and is in contact with the ohmic contact layer to form ohmic contact, and a bonding pad electrode is manufactured on the surface of the coarsening layer with the masking technology, the photoetching technology and the evaporation technology and connected with the expanded electrode in an on mode. By means of the infrared light-emitting diode, the reliability of the expanded electrode can be improved, the better current expanding effect can be obtained, and the light-emitting efficiency of the infrared light-emitting diode can be improved.

Owner:XIAMEN CHANGELIGHT CO LTD

Light emitting element and method for fabricating the same

ActiveUS20190058099A1Low efficiencyReduce the amount requiredSemiconductor devicesIr laserOptoelectronics

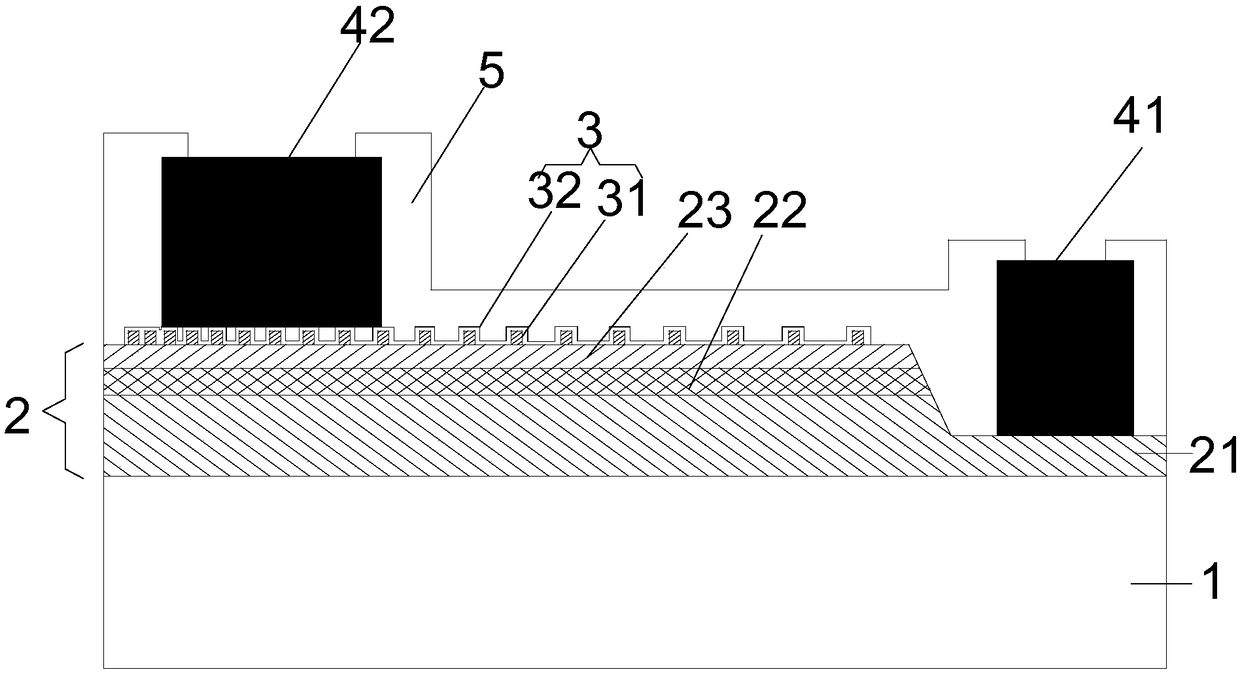

A light emitting element is disclosed. The light emitting element includes: an LED chip including a light emitting semiconductor stack and first and second electrode pads disposed under the light emitting semiconductor stack and spaced apart from each other; a substrate mounted with the LED chip and including a first electrode corresponding to the first electrode pad and a second electrode corresponding to the second electrode pad; a first solder portion connecting the first electrode pad and the first electrode; and a second solder portion connecting the second electrode pad and the second electrode. The first solder portion and the second solder portion are formed without escaping from the mounting area of the LED chip on the substrate by heating a solder material to its melting point or above with an IR laser.

Owner:LUMENS

LED chip and manufacturing method thereof

ActiveCN108878615AImprove current expansion capabilityReduce the chance of occurrenceSemiconductor devicesPower flowSemiconductor

The present application provides an LED chip and manufacturing method thereof, wherein the LED chip comprises a substrate, an LED epitaxial structure, and a transparent conductive layer on a surface of the LED epitaxial structure. The transparent conductive layer comprises two-layer structure, which are a first transparent conductive layer and a second transparent conductive layer locating on thefirst transparent conductive layer and deviating from a second-type semiconductor layer, wherein, one of the first transparent conductive layer and the second transparent conductive layer is a whole layer structure, and the other one is a patterned structure. That is, a current spreading layer on the LED chip of the invention comprises an entire current spreading layer and a patterned current spreading layer. The patterned transparent conductive layer has no shielding effect on the LED chip due to the transparent structure, and a plurality of transparent interdigital electrodes are added to anexisting LED chip through the guiding of the patterned transparent conductive layer, so that the current spreading capability is greatly improved.

Owner:XIAMEN CHANGELIGHT CO LTD

Deep ultraviolet light emitting diode and manufacturing method thereof

ActiveCN112510126AIncreased sidewall area ratioImprove light extraction efficiencySemiconductor devicesOhmic contactUltraviolet lights

The invention discloses a deep ultraviolet light emitting diode and a manufacturing method thereof. The deep ultraviolet light emitting diode comprises an epitaxial layer, a first ohmic contact layerand a second ohmic contact layer; the epitaxial layer comprises a first semiconductor layer, a multi-quantum well layer and a second semiconductor layer, the epitaxial layer comprises a first step, the step surface of the first step is the surface of the second semiconductor layer, the side wall of the first step is the side wall of the multi-quantum well layer and the side wall of the second semiconductor layer, and the other step surface of the first step is the surface of the first semiconductor layer; the first ohmic contact layer is in contact with the first semiconductor layer; and the second ohmic contact layer is in contact with the second semiconductor layer. According to the invention, the first steps in array distribution are formed in the epitaxial layer of the deep ultravioletlight emitting diode, and a roughened surface is formed on the side wall of each first step, so that the area ratio of the side wall of the deep ultraviolet light emitting diode is increased, and thelight extraction efficiency of the deep ultraviolet light emitting diode is improved.

Owner:HANGZHOU SILAN AZURE +1

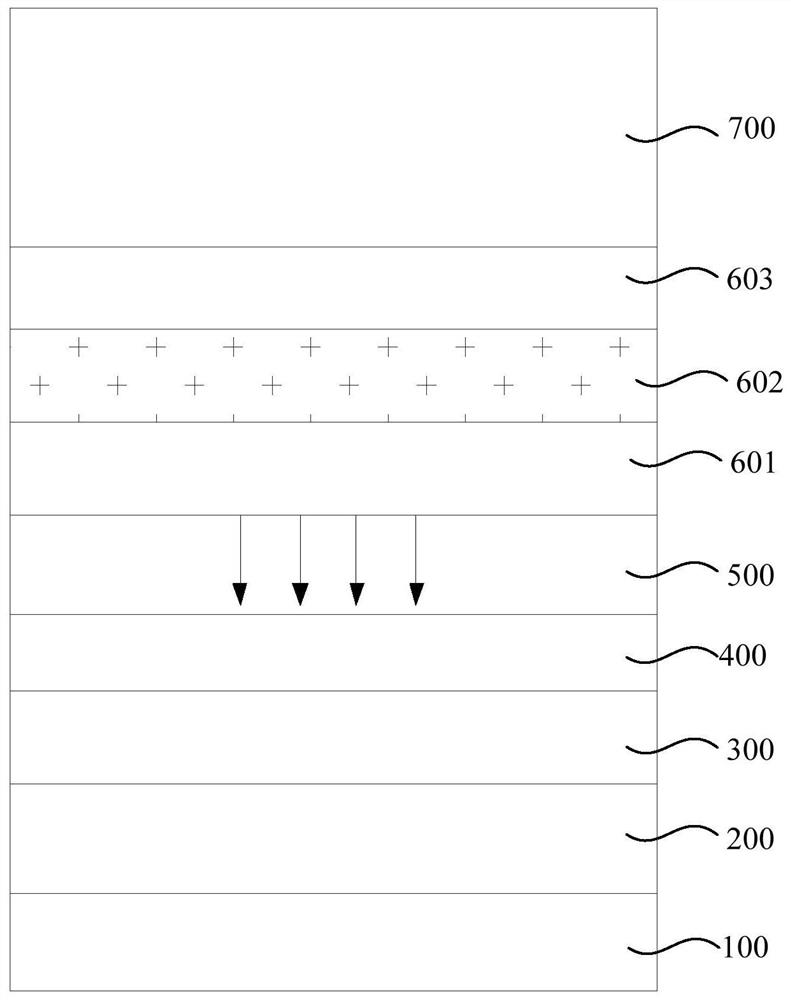

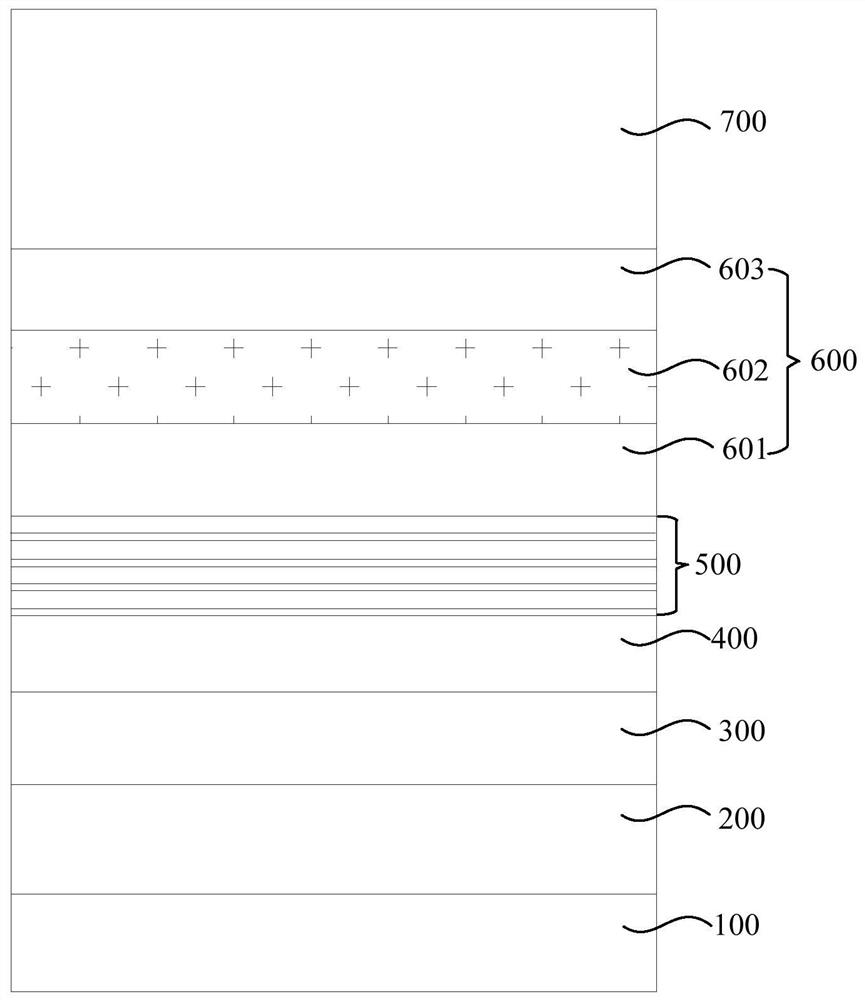

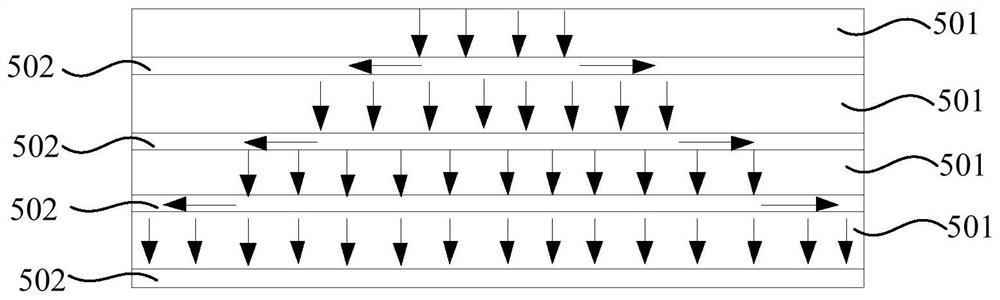

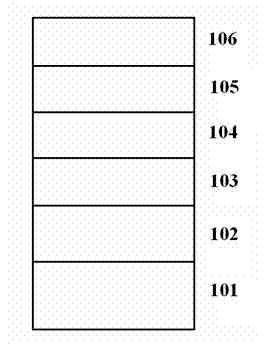

Semiconductor epitaxial structure and preparation method thereof, and LED chip

PendingCN113644173AImprove antistatic performanceImprove scalabilitySemiconductor devicesEngineeringActive layer

The invention discloses a semiconductor epitaxial structure and a preparation method thereof, and an LED chip, and the structure comprises a growth substrate which is provided with a first surface and a second surface, and the first surface and the second surface are opposite to each other; a first current expansion layer arranged above the first surface of the growth substrate; an epitaxial layer which is arranged on the surface of the first current expansion layer and sequentially comprises a first semiconductor layer, an active layer and a second semiconductor layer; and a second current expansion layer arranged above the second semiconductor layer; wherein the first current expansion layer comprises a first doping layer and a second doping layer which are alternately arranged, and the doping concentration of the first doping layer is larger than that of the second doping layer. According to the invention, the high and low concentration doping layers of the first current expansion layer are alternately arranged, so that current expansion is facilitated, and the anti-static performance of the chip is further improved.

Owner:TIANJIN SANAN OPTOELECTRONICS

Method for producing light emitting diode

InactiveUS20050032383A1Improve emission efficiencyReduce resistanceSemiconductor/solid-state device manufacturingCoatingsPolymer adhesiveTransparent conducting film

The present invention discloses a method for producing an LED (light emitting diode), in which a transparent conductive film is formed between a transparent window and the front surface of a LED epitaxial layer. The transparent conductive film can be oxides, nitrides or fluorides of metals. The transparent conductive film can be preliminarily formed on one of the transparent window and the LED epitaxial layer or both of them by a suitable process, for example, thermal pressure. By involving the transparent conductive film, current spreading is improved and resistance is reduced because of larger cross section areas provided, particularly compared with the conventional spin on glass or polymer adhesives. Additionally, light-emitting efficiency can be improved since the conventional opaque substrate, such as a GaAs substrate.

Owner:NAT SCI COUNCIL

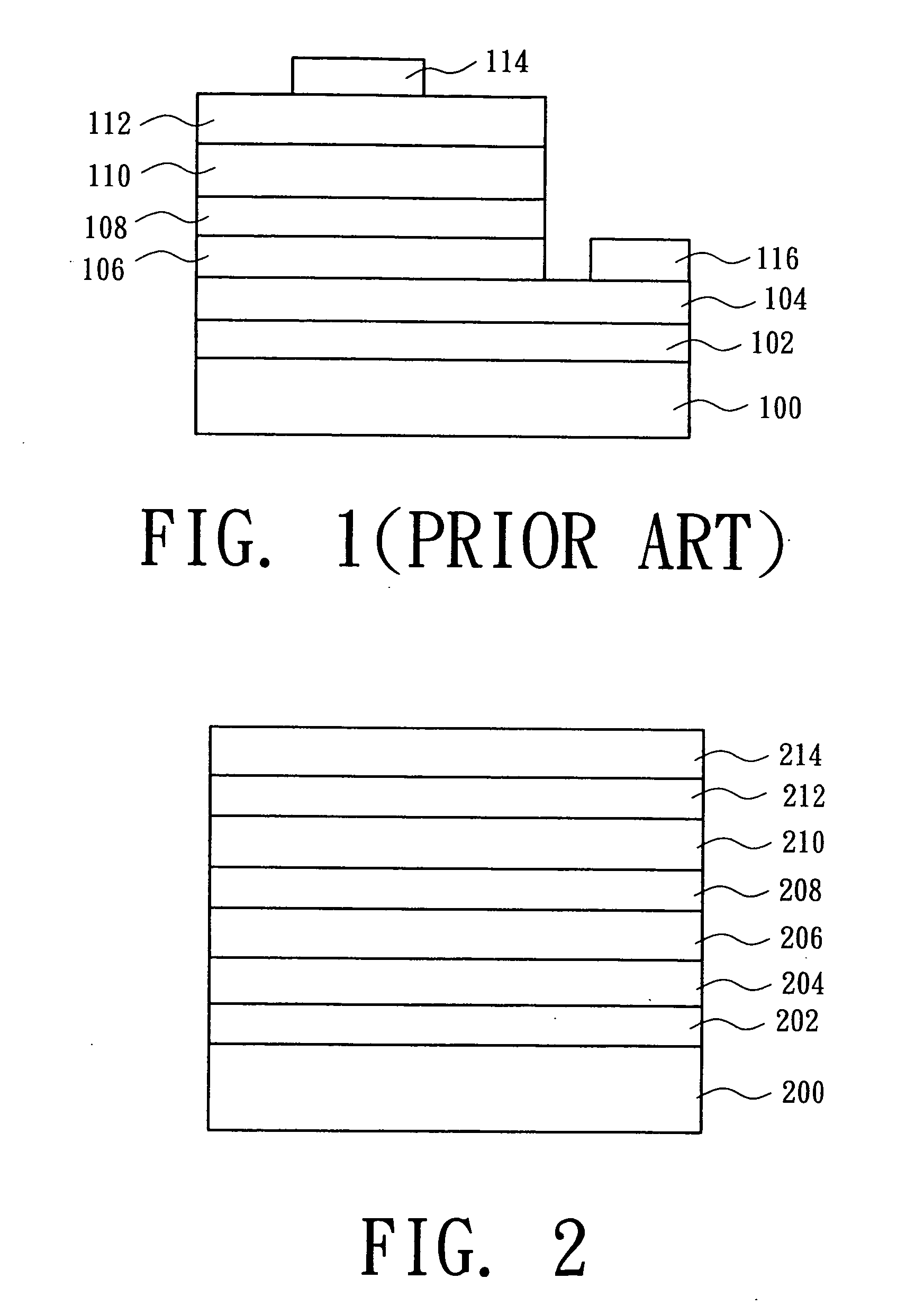

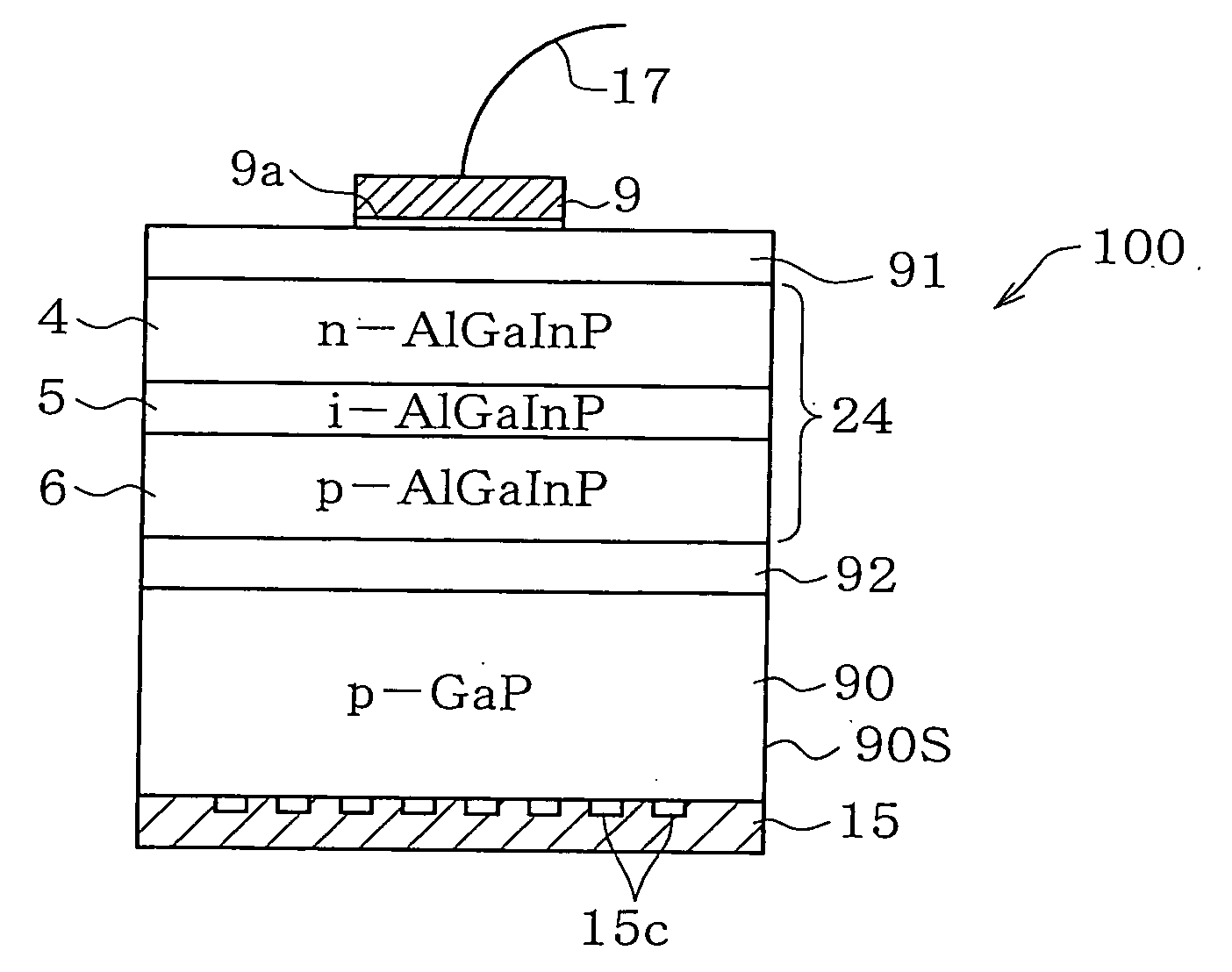

Light emitting device and method of fabricating the same

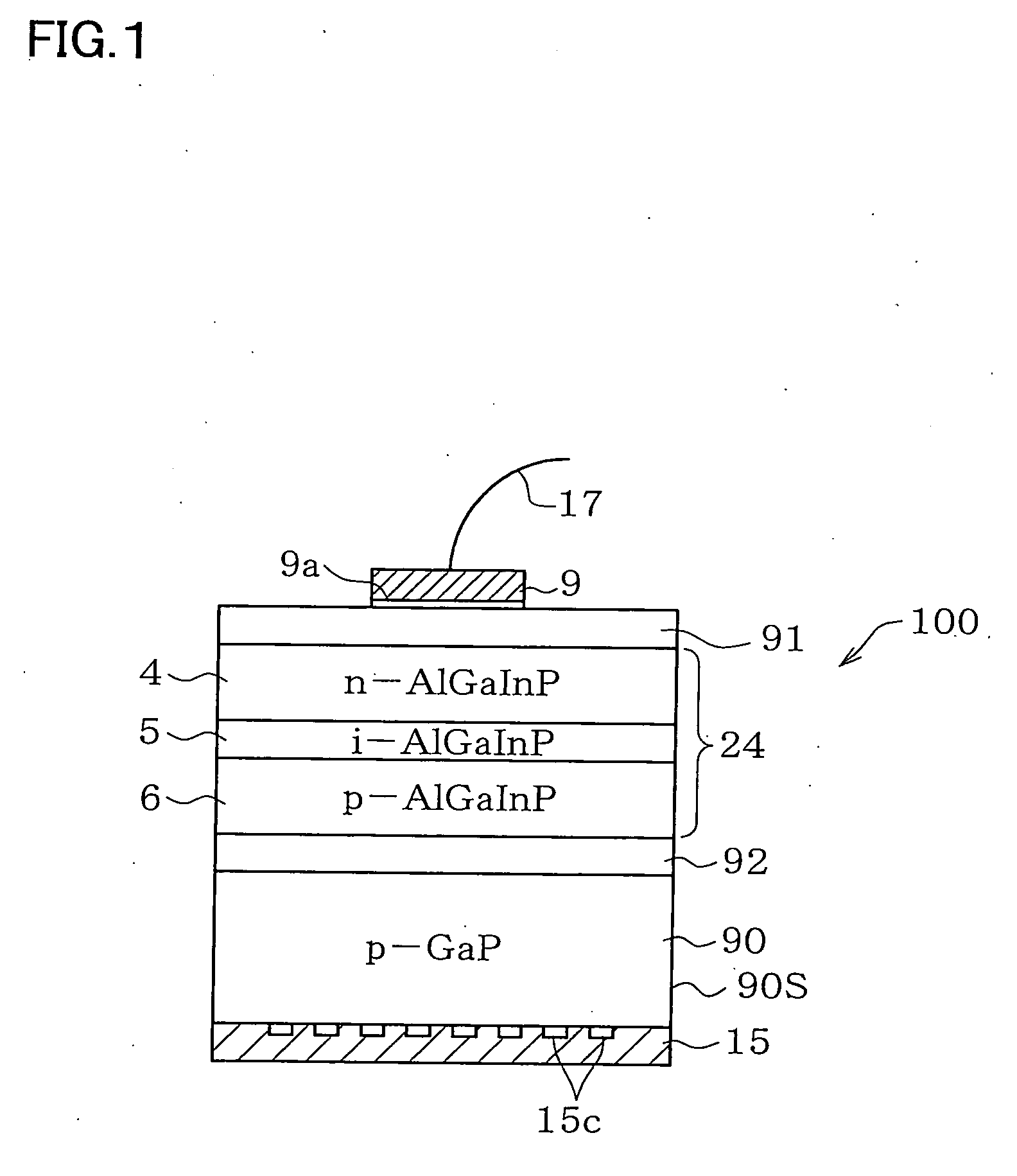

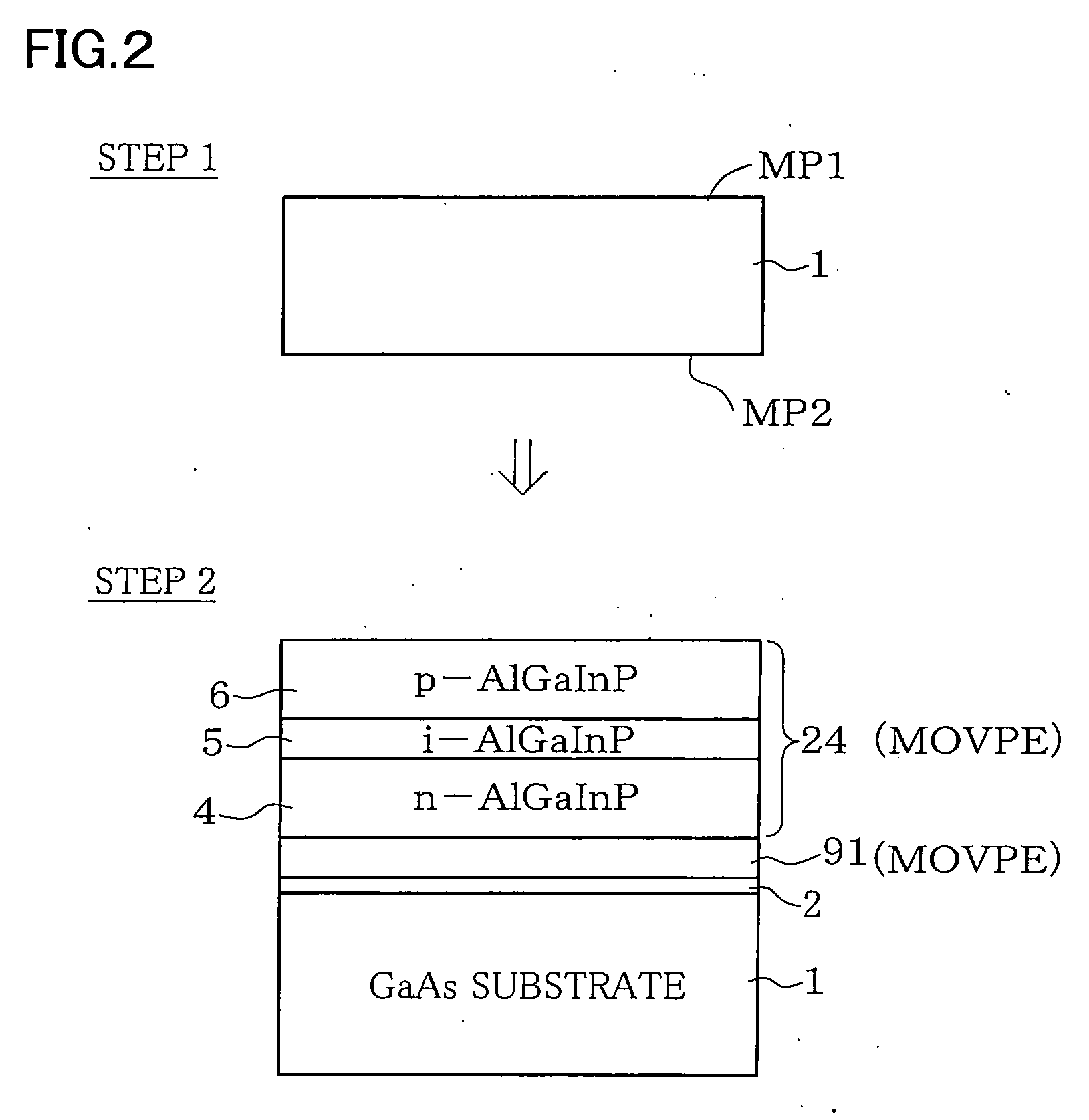

ActiveUS20070145405A1Current spreading effect can be made moreImprove current spreading effectSolid-state devicesSemiconductor/solid-state device manufacturingPeak valueLength wave

Disclosed is a light-emitting device (100) has a light-emitting layer portion (24) which is composed of a group III-V compound semiconductor and a transparent thick-film semiconductor layer (90) with a thickness of not less than 40 μm which is formed on at least one major surface side of the light-emitting layer portion (24) and composed of a group III-V compound semiconductor having a band gap energy larger than the photon energy equivalent of the peak wavelength of emission flux from the light-emitting layer portion (24). The transparent thick-film semiconductor layer (90) has a lateral surface portion (90S) which is a chemically etched surface. The dopant concentration of the transparent thick-film semiconductor layer (90) is not less than 5×1016 / cm3 and not more than 2×1018 / cm3. The light-emitting device can have a transparent thick-film semiconductor layer while being significantly improved in light taking-out efficiency from the lateral surface portion.

Owner:SHIN-ETSU HANDOTAI CO LTD

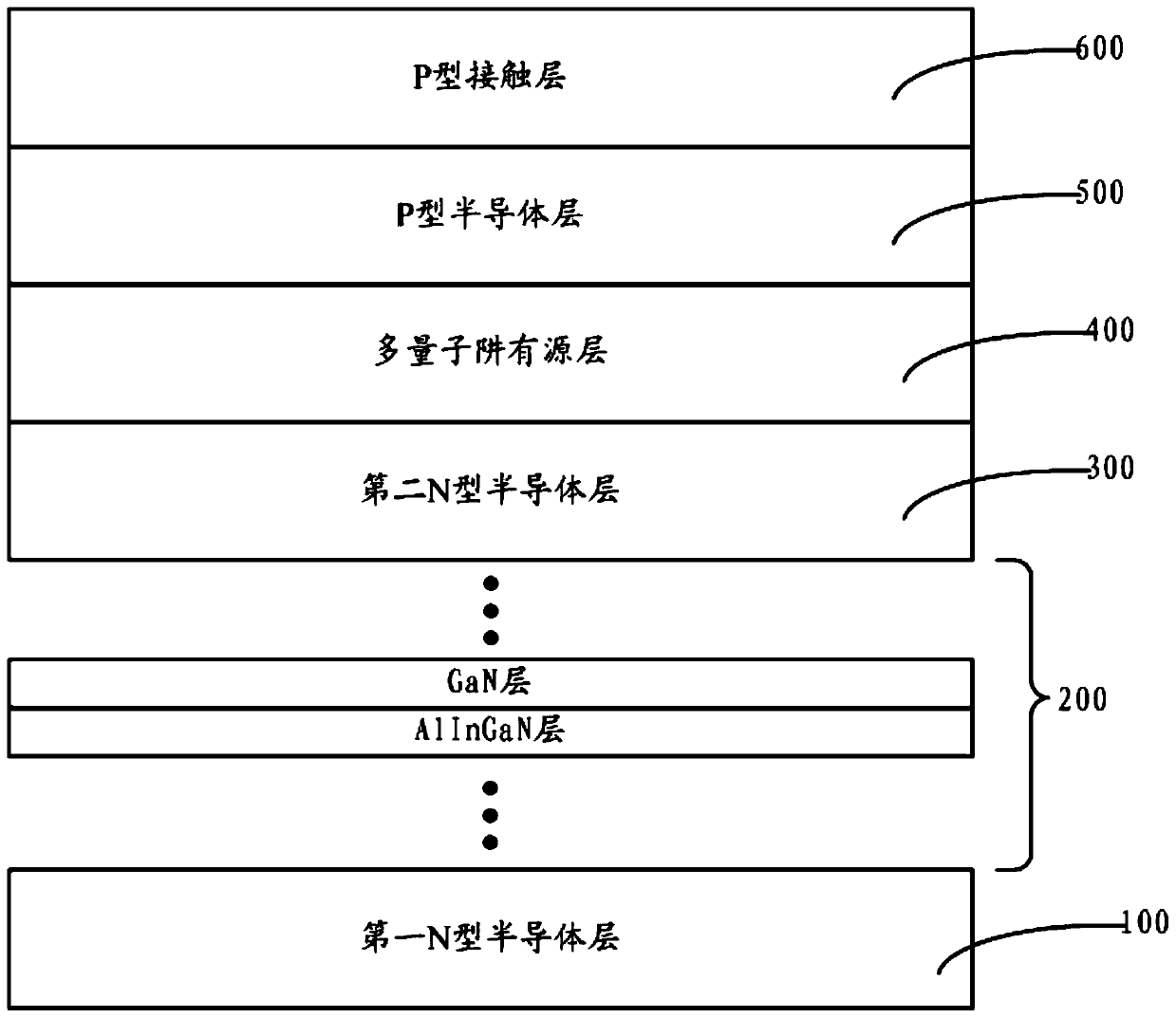

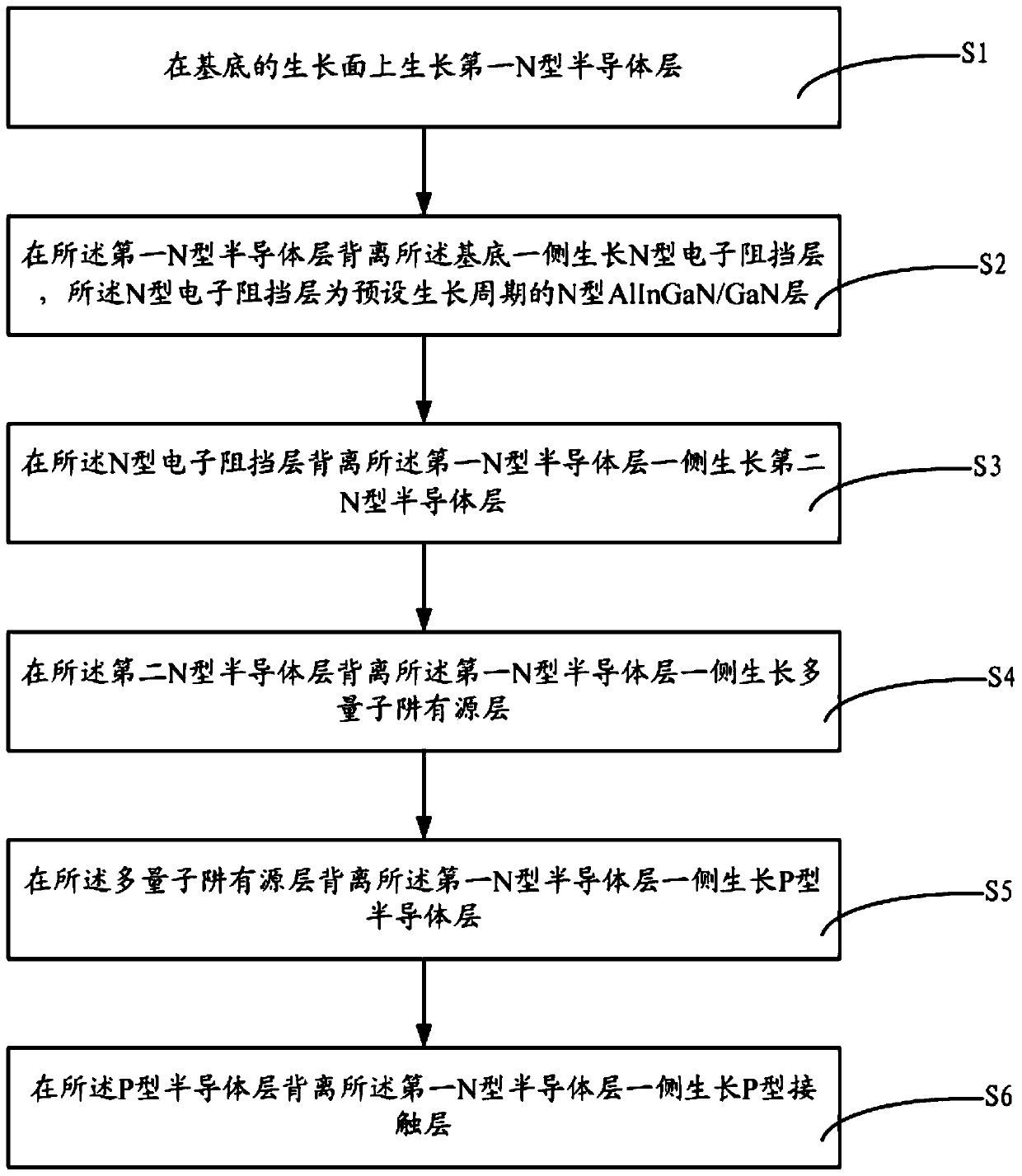

LED epitaxial wafer, manufacturing method thereof and semiconductor device

PendingCN110491975AReduced polarizing electric fieldIncrease lateral current expansion capabilitySemiconductor devicesPower semiconductor devicePower flow

The invention discloses an LED epitaxial wafer, a manufacturing method thereof and a semiconductor device. An N-type electron barrier layer is embedded between a first N-type semiconductor layer and asecond N-type semiconductor layer. The N-type electron barrier layer is an N-type AlInGaN / GaN layer; as the lattice mismatch of AlInGaN and GaN in the N-type AlInGaN / GaN layer is relatively small, through stress modulation, a polarization electric field of a quantum well region is reduced, so that adverse effects caused by sudden efficiency drop can be reduced, and meanwhile, the lateral currentexpansion capability of the LED epitaxial wafer is also improved, so that the semiconductor device has good current expansion capability. Moreover, the P-type electron barrier layer is removed from the LED epitaxial wafer, so that hole injection can be increased, uneven distribution of carriers in the quantum wells is relieved, the multi-quantum-well active layer emits light more uniformly, the light emitting efficiency of the LED epitaxial wafer is improved, and the performance of the semiconductor device is improved.

Owner:XIAMEN CHANGELIGHT CO LTD

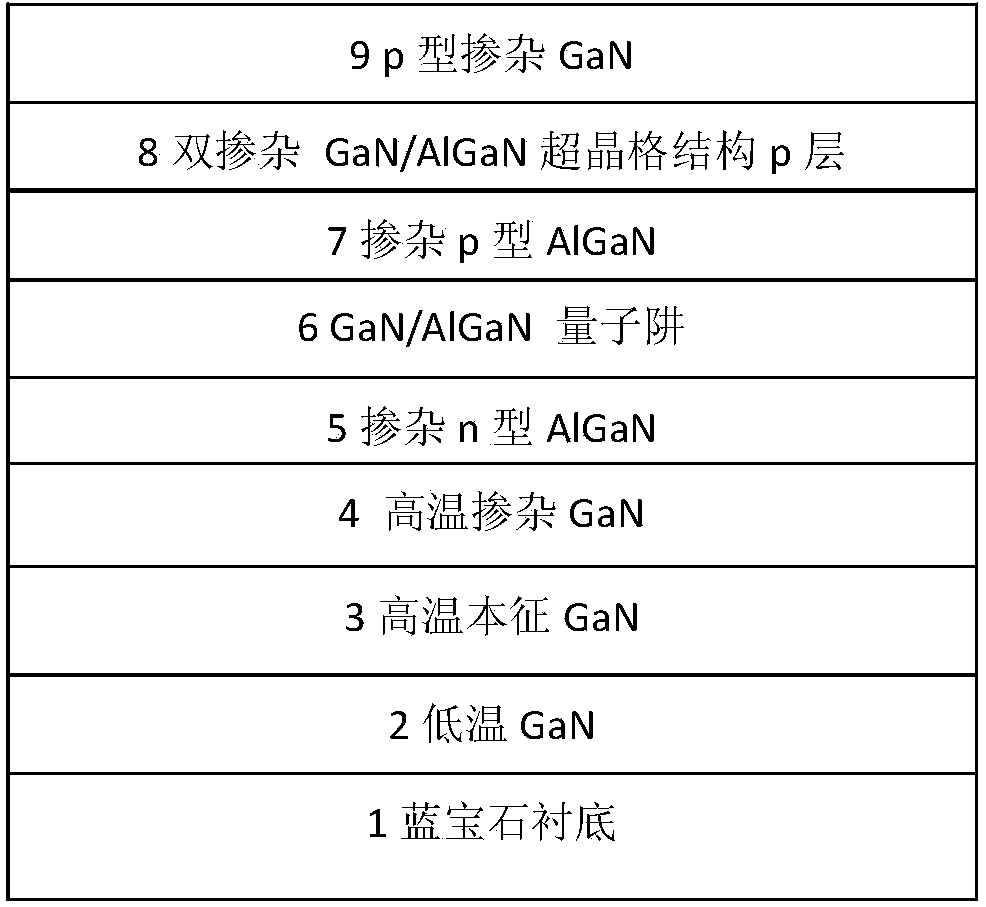

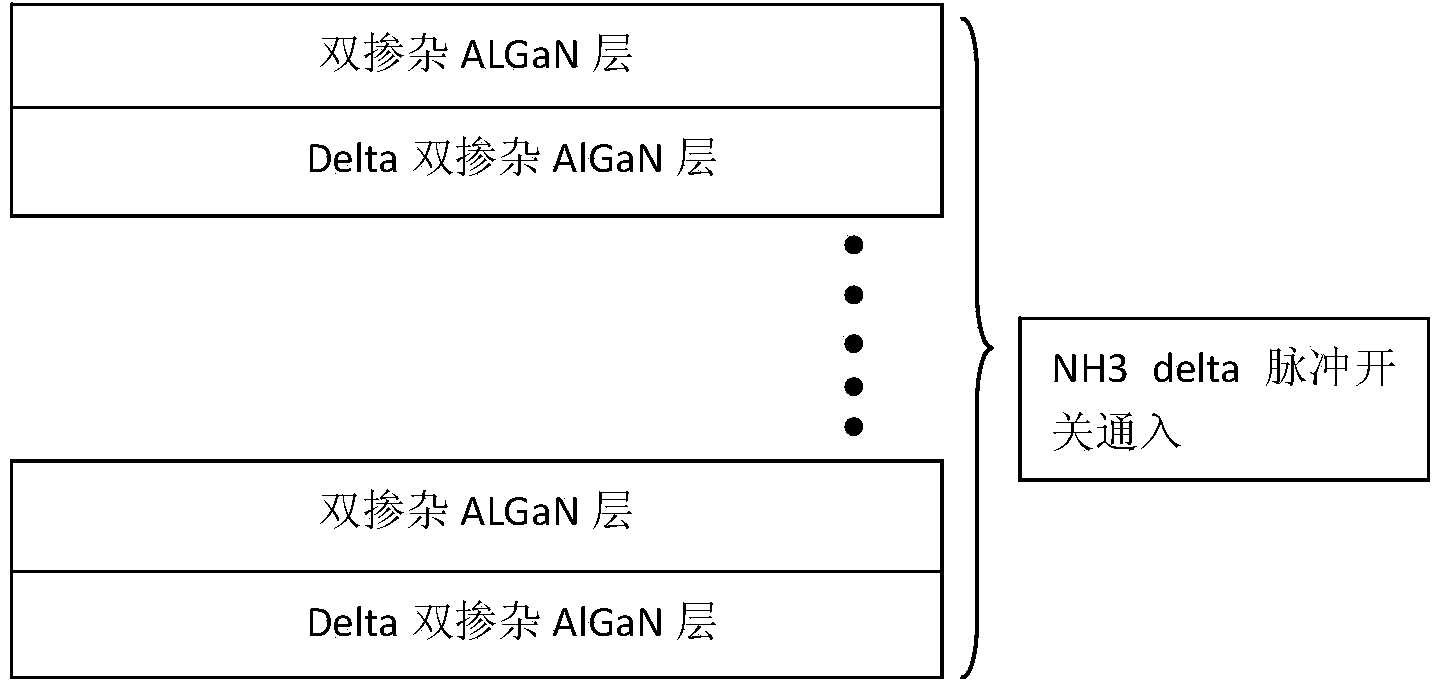

Epitaxial growth method with p-layer special doped structure

InactiveCN103854976AImprove luminous efficiencyImprove mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesSilanesSelf compensation

The invention discloses an epitaxial growth method with a p-layer special doped structure. According to the method, when a p-type layer of an LED (Light Emitting Diode) is grown, double-element doping of a GaN / AlGaN superlattice structure is adopted, that is, a small amount of silane is doped when doping magnesium. The silane is doped as a donor, however, due to the small amount of the doped silane, the lattice imperfection caused by the doped magnesium can be remarkably improved, a self-compensation effect is reduced, the crystal quality is improved, non-composite imperfection centers are reduced, a small number of scattering centers are caused, the carrier mobility and the ionization efficiency of an accepter are improved, and in addition, as the growing temperature of AlGaN is high, such doping is beneficial for improving the doping concentration of magnesium, the doping effect of the p-layer is improved, and the overall lighting efficiency of the LED is greatly improved. Due to improvement of the crystal quality and the improvement of barrier layer conductivity, the current expansion capability is improved, and the reliability of the LED device is also improved.

Owner:西安利科光电科技有限公司

Three-dimensional LED luminescent device

InactiveCN104701437AImprove current spreading effectImprove cooling effectSemiconductor devicesOhmic contactLight-emitting diode

The invention relates to a three-dimensional LED luminescent device and belongs to the field of a light emitting diode. The three-dimensional LED luminescent device comprises an LED chip and a radiating substrate, a p type ohmic contact electrode and an n type ohmic contact electrode are arranged on the LED chip; a plurality of electric conduction and heat conduction through holes are formed in the radiating substrate, an insulating layer, a seed layer and an electric conduction and heat conduction metal hole core are deposited on an inner wall of the electric conduction and heat conduction through hole in sequence; the p type ohmic contact electrode is welded to the electric conduction and heat conduction metal hole core. The three-dimensional LED luminescent device has the advantages that the volume of the LED luminescent device is reduced, the luminous efficiency and the heat dispersion are enhanced for the LED luminescent device, and reliability of the LED luminescent device is improved.

Owner:WUHAN UNIV

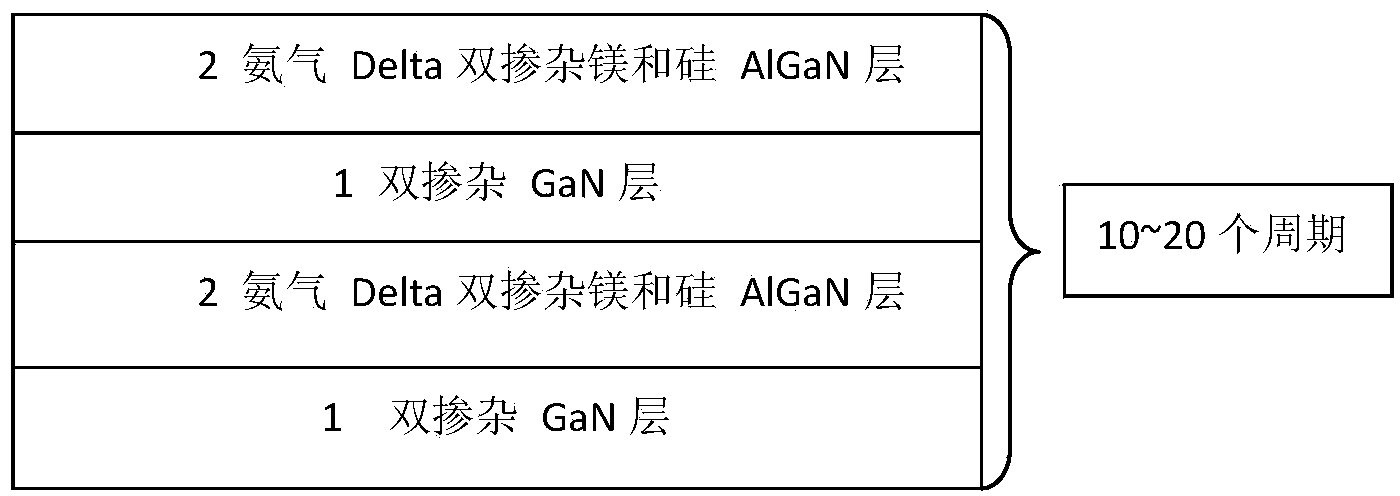

Method for growing high-antistatic LED (light-emitting diode) by adopting metal organic compound vapor phase epitaxy technology

InactiveCN102332510AReduce thicknessAdd built-in capacitorPolycrystalline material growthFrom chemically reactive gasesCapacitanceHydrogen atmosphere

The invention discloses a method for growing a high-antistatic LED (light-emitting diode) by adopting a metal organic compound vapor phase epitaxy technology, which is used to reduce the thickness of a depletion layer of the LED and increase the built-in capacitance of the LED. The method comprises the following steps of: firstly, treating a sapphire Al2O3 (alumina) substrate in a metal organic compound vapor phase epitaxy reaction chamber for 5 minutes; then three-dimensionally growing a GaN (gallium nitride) buffer layer and an n-GaN layer in a hydrogen atmosphere; growing an n-type insert layer with high electron concentration in a nitrogen atmosphere, and then growing a quantum well active area with various periods; growing a p-type insert layer with high hole concentration on the active area in the nitrogen atmosphere; and growing a p-GaN layer in the hydrogen atmosphere. The method has the advantages of relatively simple technological processes, good repeatability and low additional cost. The LED chip grown by the method has good optoelectronic performance and greatly improved reliability and stability.

Owner:SINO NITRIDE SEMICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com