Method of adopting MOCVD technology to manufacture near ultraviolet LED possessing step-type quantum well structure

A near-ultraviolet and quantum well technology, applied in chemical instruments and methods, crystal growth, electrical components, etc., can solve the problem that the output power is only the input power, and achieve the effects of improving crystal quality, increasing luminous efficiency, and relieving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

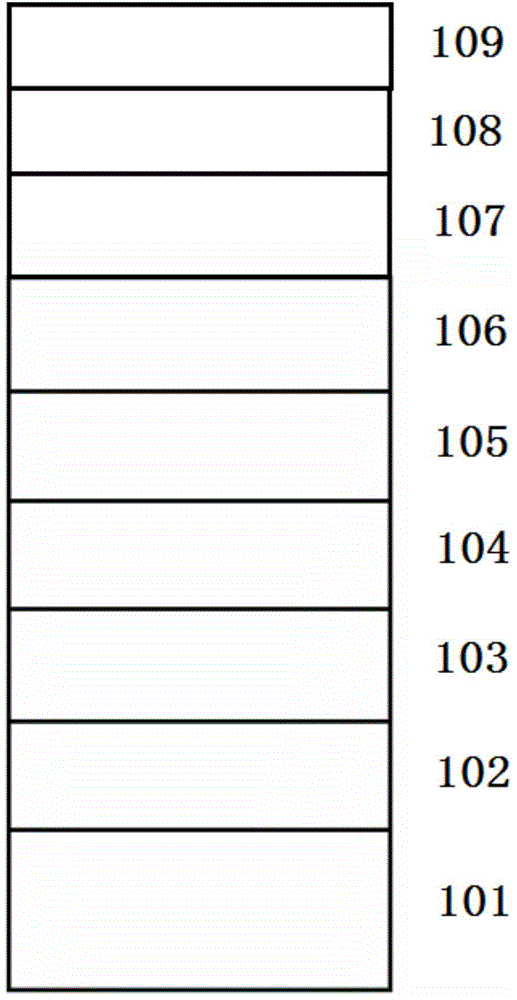

[0019] The invention provides a method for preparing a near ultraviolet LED with a stepped quantum well structure by using MOCVD technology. By designing a new type of LED structure, a stepped quantum well structure is adopted. Effectively alleviate the stress on the quantum well, improve the quality of the quantum well crystal, and improve the luminous efficiency of the near-ultraviolet LED. figure 1 It is an embodiment of the present invention, a vertical cross-sectional view of a near-ultraviolet LED with a stepped quantum well structure prepared by using MOCVD technology.

[0020] Such as figure 1 Shown is an embodiment of the present invention, a vertical cross-sectional view of a high-brightness near-ultraviolet LED with a stepped quantum well structure prepared by using MOCVD technology.

[0021] Use Aixtron company, close-coupled vertical reaction chamber MOCVD growth system. During the growth process, trimethylgallium (TMGa), trimethylindium (TMIn), and trimethylaluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com