Flip LED chip preparation method

A technology of LED chips and LED epitaxial wafers, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of uncontrollable over-thick metal, leakage, and dirty corrosion, achieve good current expansion effect, improve brightness, and avoid Unicom Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] 1) Preparation of P-type ohmic contact layer: Ni / Ag thin film evaporation is carried out using a vacuum coating machine, and the evaporation rate of Ni is The evaporation thickness is The Ag evaporation rate is The evaporation thickness is Forming a P-type ohmic contact layer;

[0035] 2) Perform coating, exposure, development and film hardening on the wafer to form the pattern required for the flip-chip mirror. The distance between the area covered by the photoresist and the N-type gallium nitride area exposed after etching is 7-10 μm , followed by H 2 O:NH 4 F:H 2 o 2 =5:1:1 solution corrosion for 3min, HCl:HNO 3 =3:1 solution etch for 3min, then remove the photoresist;

[0036] 3) P-type ohmic contact layer annealing: annealing in a rapid annealing furnace, annealing at 500 ° C for 1 min;

[0037] 4) Preparation of high ultraviolet reflectance reflector: Evaporate DBR reflective layer, made of SiO 2 with TiO 2 , first deposit a layer of SiO 2 Thickness ...

Embodiment 1

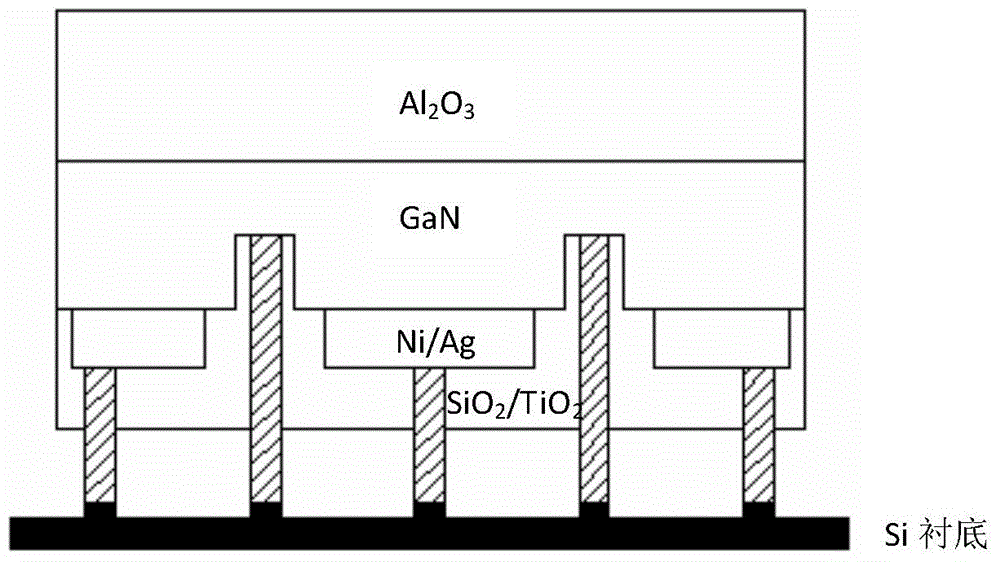

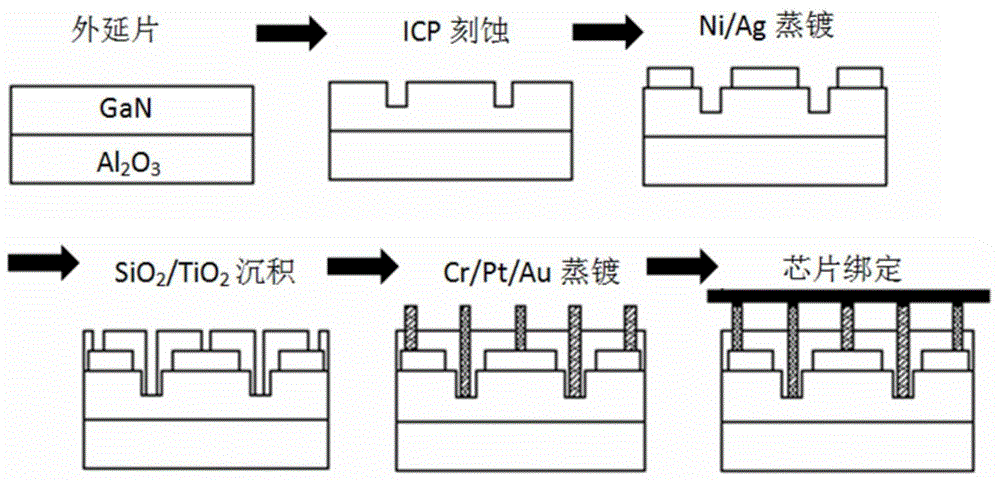

[0043] The flip-chip LED chip structure of the present invention is as figure 1 . Its preparation process is as follows figure 2 As shown, using ICP etching, Ni / Ag evaporation, SiO 2 / TiO 2 deposition, Cr / Pt / Au evaporation and die bonding processes. The present invention is mainly aimed at flip-chip ultraviolet LED chips, and the specific manufacturing process is as follows:

[0044] 1. Use aqua regia (HNO 3 : HCl=1:3) for surface treatment for 10 minutes, rinse with deionized water and dry;

[0045] 2. Put it into the ICP equipment for low-damage ultraviolet gallium nitride etching technology, and etch the P-type gallium nitride layer and the underlying multi-quantum well light-emitting layer in some areas of the epitaxial wafer, exposing the N-type gallium nitride layer, and etching etch using Cl 2 The flow rate is 50sccm, the Antenna RF power is 150W, the Bias RF power is 40W, and the etching depth is 1.3μm;

[0046] 3. The thin film evaporation machine performs Ni...

Embodiment 2

[0055] Embodiment 2 (this embodiment is suitable for preparing Blu-ray chip)

[0056] The thin film evaporation machine performs Ni / Ag thin film evaporation, and the Ni evaporation rate is Evaporation thickness The Ag evaporation rate is Evaporation thickness When evaporating, the vacuum degree is higher than 2.0×10-6Torr; nitrogen protection annealing, annealing temperature 400 ℃, annealing time 8min; deposit a layer of SiO2 thickness of Then TiO2 and SiO2 films are deposited alternately to form a multi-period structure, the number of periods is 8, and the deposition thickness of TiO2 films in 8 periods is the same as The thickness of SiO2 in 8 cycles is the same as The rest of the processes are the same as those in the first embodiment, and a flip-chip blue LED chip can be prepared. (The main difference between the blue light chip and the purple light chip is: the thickness of Ag in the Ni / Ag film is thicker than that of the purple light chip, and the reflectivit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com