High-brightness near ultraviolet LED and preparation method thereof

A near-ultraviolet, high-brightness technology, used in semiconductor devices, electrical components, circuits, etc., can solve problems such as affecting luminous efficiency, unable to eliminate V-type dislocations, increasing quantum well and barrier layer stress mismatch, etc., to improve luminescence. Efficiency, effect of improving current spreading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

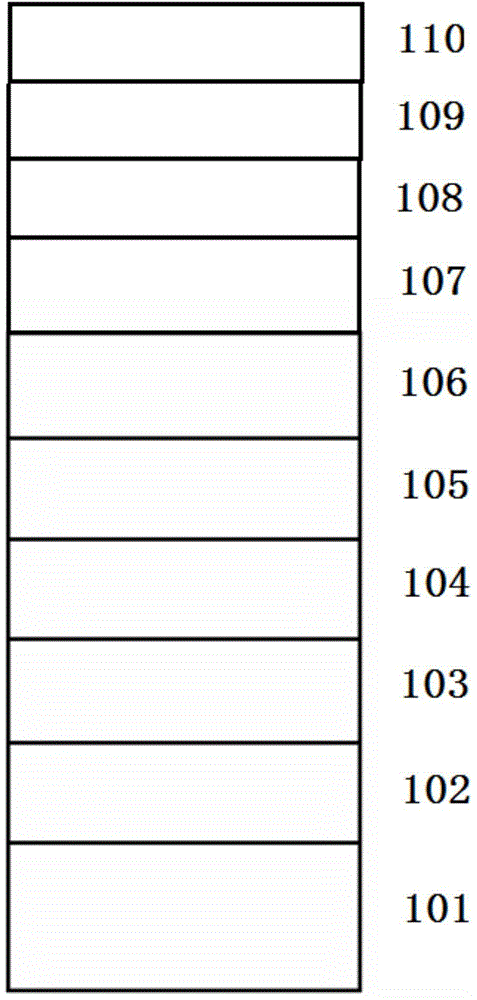

[0020] Use Aixtron company, tightly coupled vertical reaction chamber MOCVD growth system. Trimethylgallium (TMGa), trimethylindium (TMIn), trimethylaluminum (TMAl) were used as Group III sources during the growth process, ammonia (NH 3 ) as a Group V source, silane (SiH 4 ) as an n-type dopant source, dimagnesocene (Cp 2 Mg) as a p-type dopant source, the patterned Al 2 o 3 The substrate 101 is heated to 1080-1100 degrees centigrade, and the pressure in the reaction chamber is 100 torr. 2 Under treatment for 5 minutes, then cool down to 530-550 degrees Celsius in the patterned Al 2 o 3On the substrate, the pressure of the reaction chamber is 500torr, under the hydrogen (H2) atmosphere, the V / III molar ratio is 500-1300, and the GaN nucleation layer after three-dimensional growth of 20-30 nanometers, at 1000-1500°C, the reaction chamber pressure is 200-300torr, in hydrogen (H 2 ) atmosphere, the V / III molar ratio is 1000-1300; grow a 1-3 micron thick high-temperature u-...

Embodiment 2

[0022] Use Aixtron company, tightly coupled vertical reaction chamber MOCVD growth system. Trimethylgallium (TMGa), trimethylindium (TMIn), trimethylaluminum (TMAl) were used as Group III sources during the growth process, ammonia (NH 3 ) as a Group V source, silane (SiH 4 ) as an n-type dopant source, dimagnesocene (Cp 2 Mg) as a p-type dopant source, the patterned Al 2 o 3 The substrate is heated to 1080-1100 degrees Celsius, the pressure in the reaction chamber is 100torr, and the H 2 Under treatment for 5 minutes, then cool down to 530-550 degrees Celsius in the patterned Al 2 o 3 On the substrate, the pressure of the reaction chamber is 500torr, under the hydrogen (H2) atmosphere, the V / III molar ratio is 500-1300, and the GaN nucleation layer after three-dimensional growth of 20-30 nanometers, at 1000-1500°C, the reaction chamber pressure is 200-300torr, in hydrogen (H 2 ) atmosphere, the V / III molar ratio is 1000-1300; grow a 1-3 micron thick high-temperature u-G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com