Three-dimensional LED luminescent device

A technology of light-emitting devices and LED chips, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of difficulty in uniform expansion of injected current and heat dissipation, and achieve the effect of enhancing luminous efficiency and reliability and improving current expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

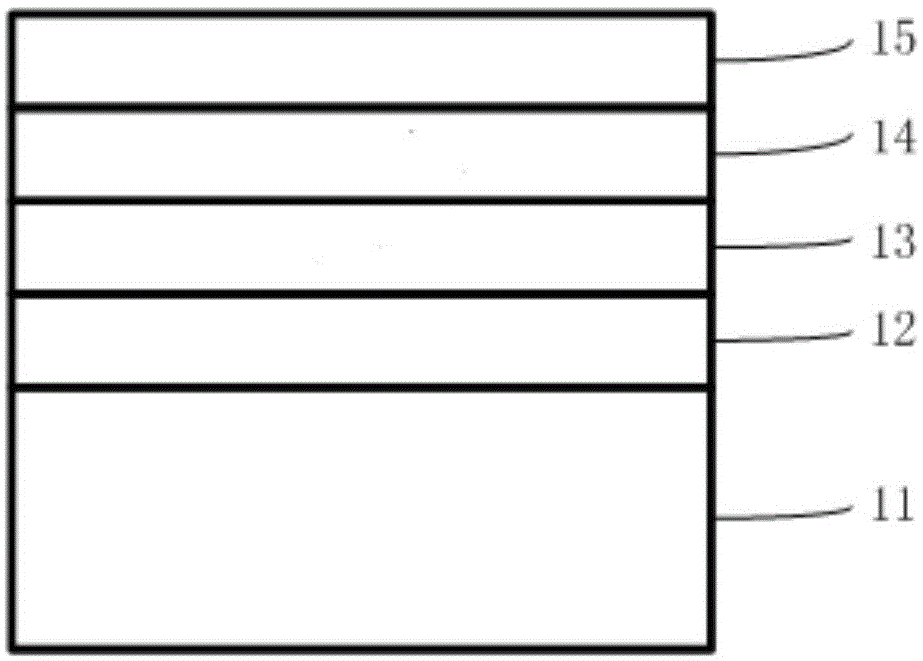

[0053] (1) On the sapphire substrate 11, undoped GaN or AlN buffer layer 12, n-type doped GaN or AlGaN semiconductor material 13, multiple quantum well (MQW) 14, p-type doped GaN or AlGaN are sequentially grown on the sapphire substrate 11 Semiconductor materials15, such as figure 1 shown;

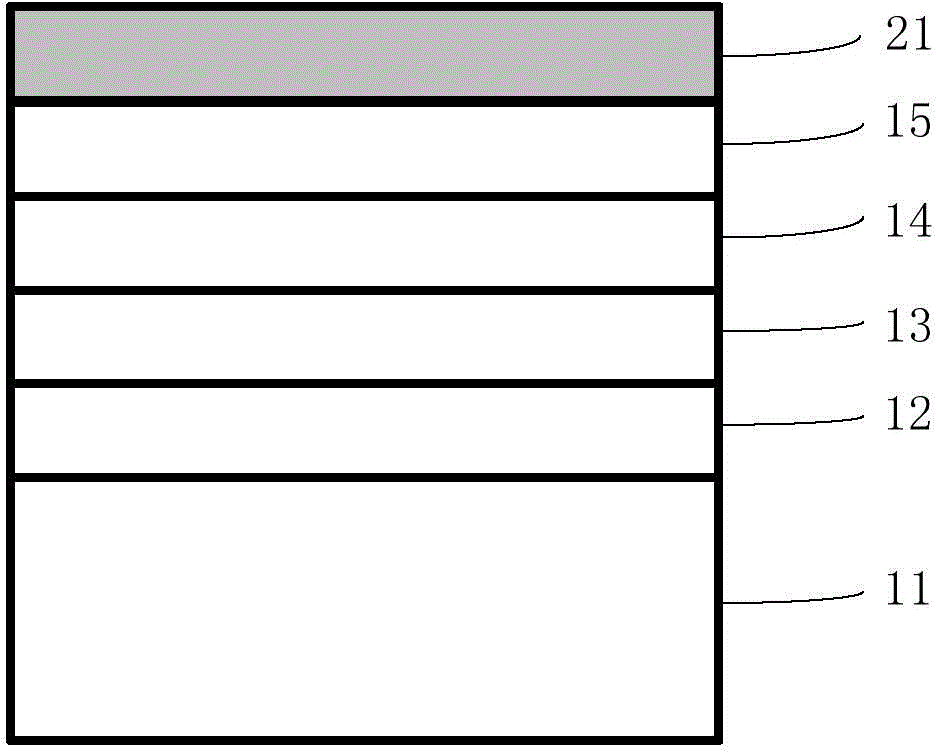

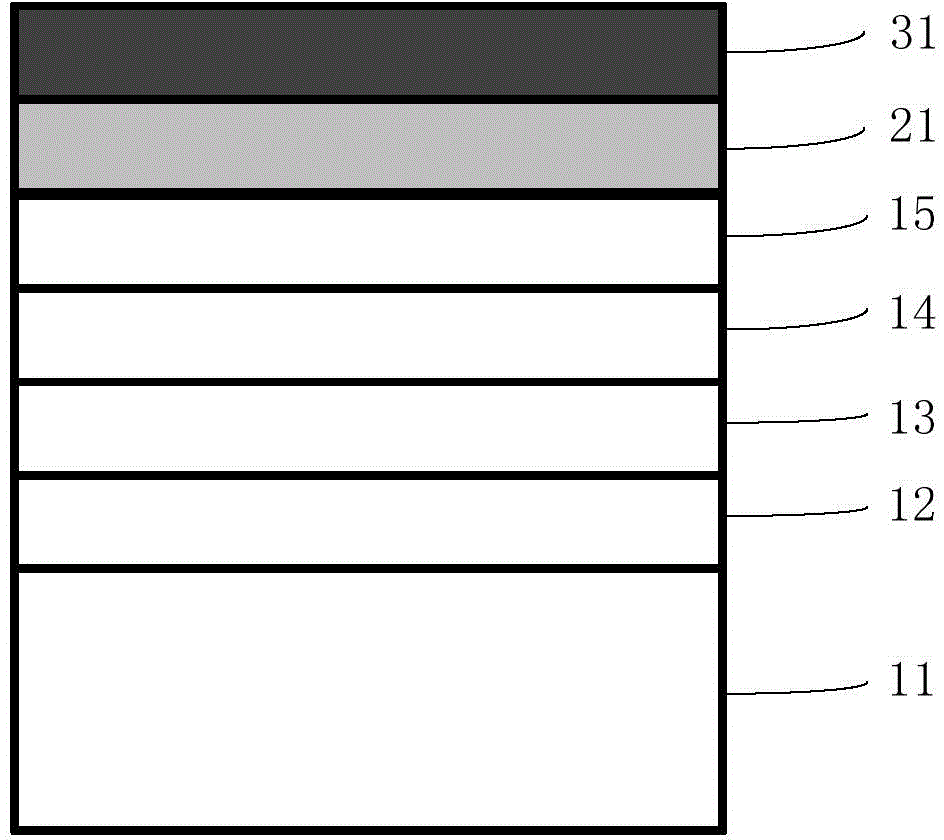

[0054] (2) Forming a transparent conductive layer 21 on the p-type doped GaN or AlGaN semiconductor material 15, such as figure 2 Shown; Adopt sputtering mode to form reflective layer 31 on transparent conductive layer 21, this reflective layer all has higher reflectivity to ultraviolet light and visible light, as image 3 shown.

[0055] (3) Photolithography and dry etching or wet etching are used to process the reflective layer 31, the transparent conductive layer 21, the p-type doped GaN or AlGaN semiconductor material 15, the multiple quantum well (MQW) 14, and the n-type The doped GaN or AlGaN semiconductor material 13 is microfabricated to form periodically or non-periodically d...

Embodiment 2

[0066] A three-dimensional LED light-emitting device includes an LED chip and a heat dissipation substrate. The LED chip is provided with a p-type ohmic contact electrode and an n-type ohmic contact electrode; An insulating layer, a seed layer and a conductive and heat-conducting metal hole core are deposited in sequence; the p-type ohmic contact electrode and the n-type ohmic contact electrode are welded on the conductive and heat-conducting metal hole core through metal wires.

[0067] The LED chip (horizontal structure LED chip) sequentially includes a sapphire substrate, a GaN or AlGaN layer and an n-type doped GaN or AlGaN semiconductor layer from bottom to top; There are n-type ohmic contact electrodes and multi-quantum well light-emitting layers, and p-type doped GaN or AlGaN semiconductor layers, transparent conductive layers and p-type ohmic contact electrodes are sequentially arranged on the multi-quantum well light-emitting layers. The p-type ohmic contact electrode...

Embodiment 3

[0070] A three-dimensional LED light-emitting device includes an LED chip and a heat dissipation substrate. The LED chip is provided with a p-type ohmic contact electrode and an n-type ohmic contact electrode; An insulating layer, a seed layer and a conductive and heat-conducting metal hole core are deposited in sequence; the p-type ohmic contact electrode and the n-type ohmic contact electrode are welded on the conductive and heat-conducting metal hole core through metal wires.

[0071] The LED chip includes an n-type ohmic contact electrode, a GaN or AlGaN layer, an n-type doped GaN or AlGaN semiconductor layer, a multi-quantum well light-emitting layer, a p-type doped GaN or AlGaN semiconductor layer, a transparent Conductive layer, reflective layer and p-type ohmic contact electrode.

[0072] The conductive substrate 81 is used as the p-electrode of the vertical structure LED chip, and the n-electrode 82 is located on the top of the vertical structure LED chip, such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com