Light emitting diode and method for manufacturing the same

a technology of light-emitting diodes and manufacturing methods, which is applied in the direction of basic electric elements, electrical apparatus, semiconductor devices, etc., can solve the problems of lowering yield and low yield, and achieve the effects of enhancing current-spreading effect, reducing the loss of light intensity resulting from the absorbing of substrates, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

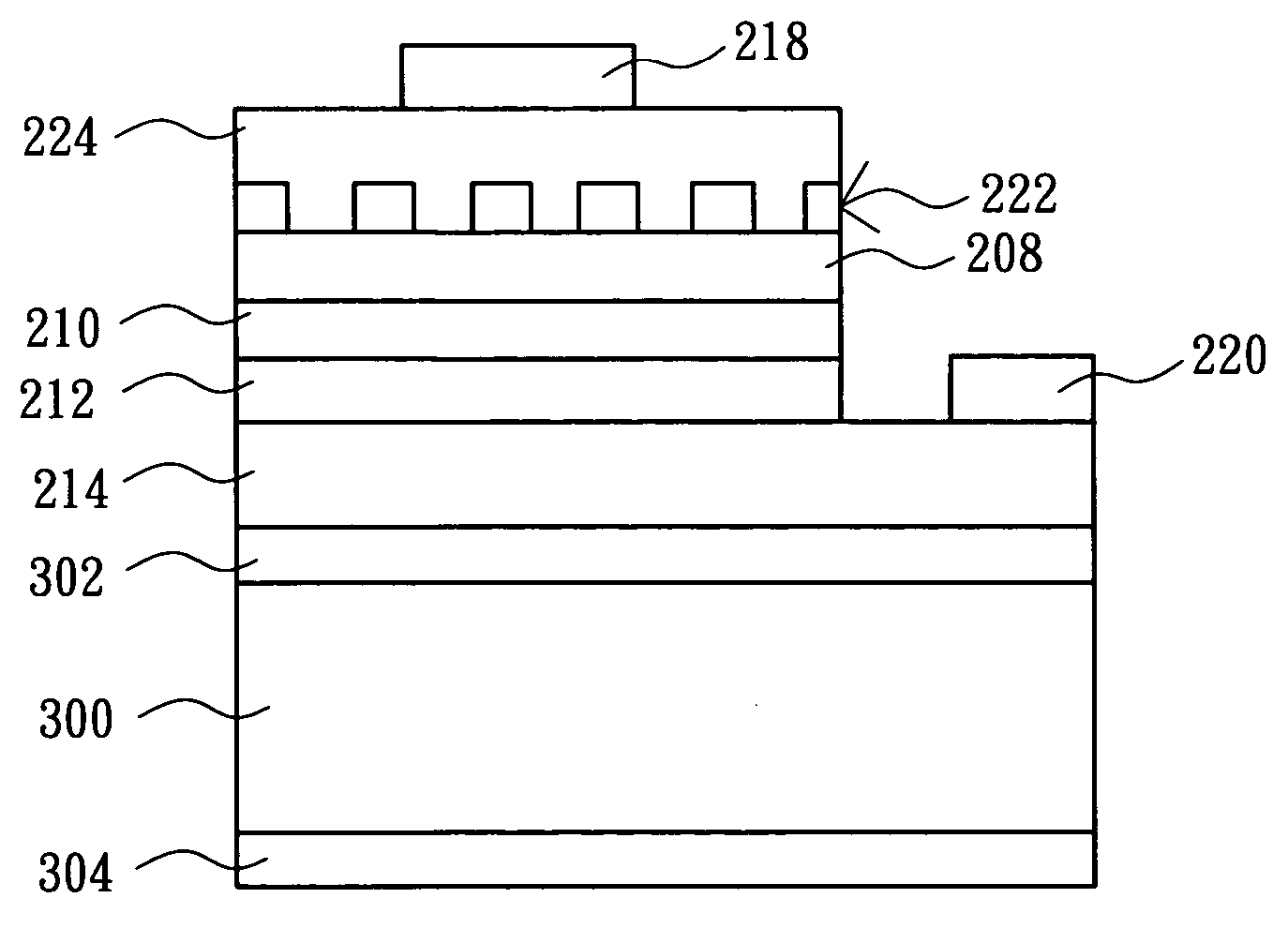

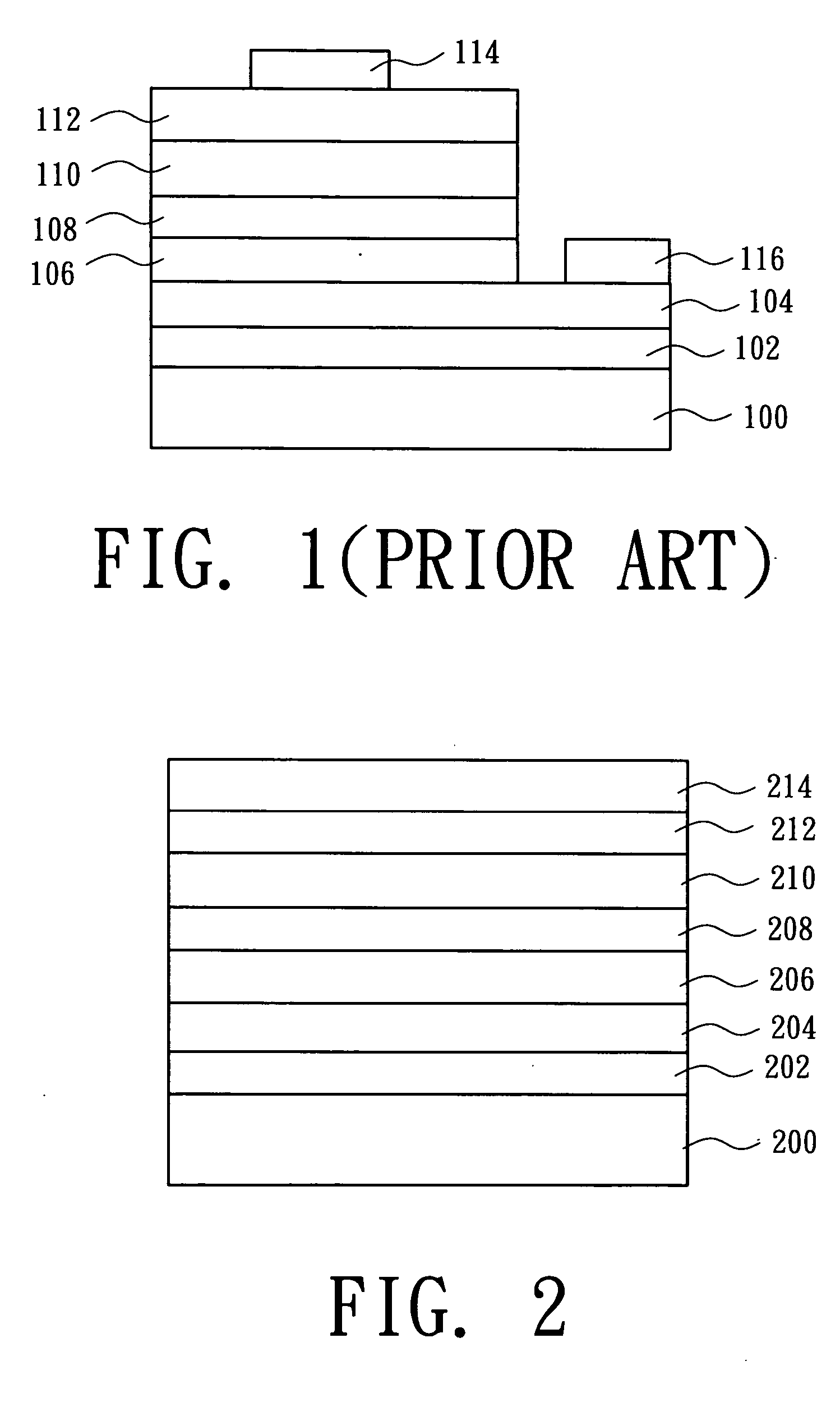

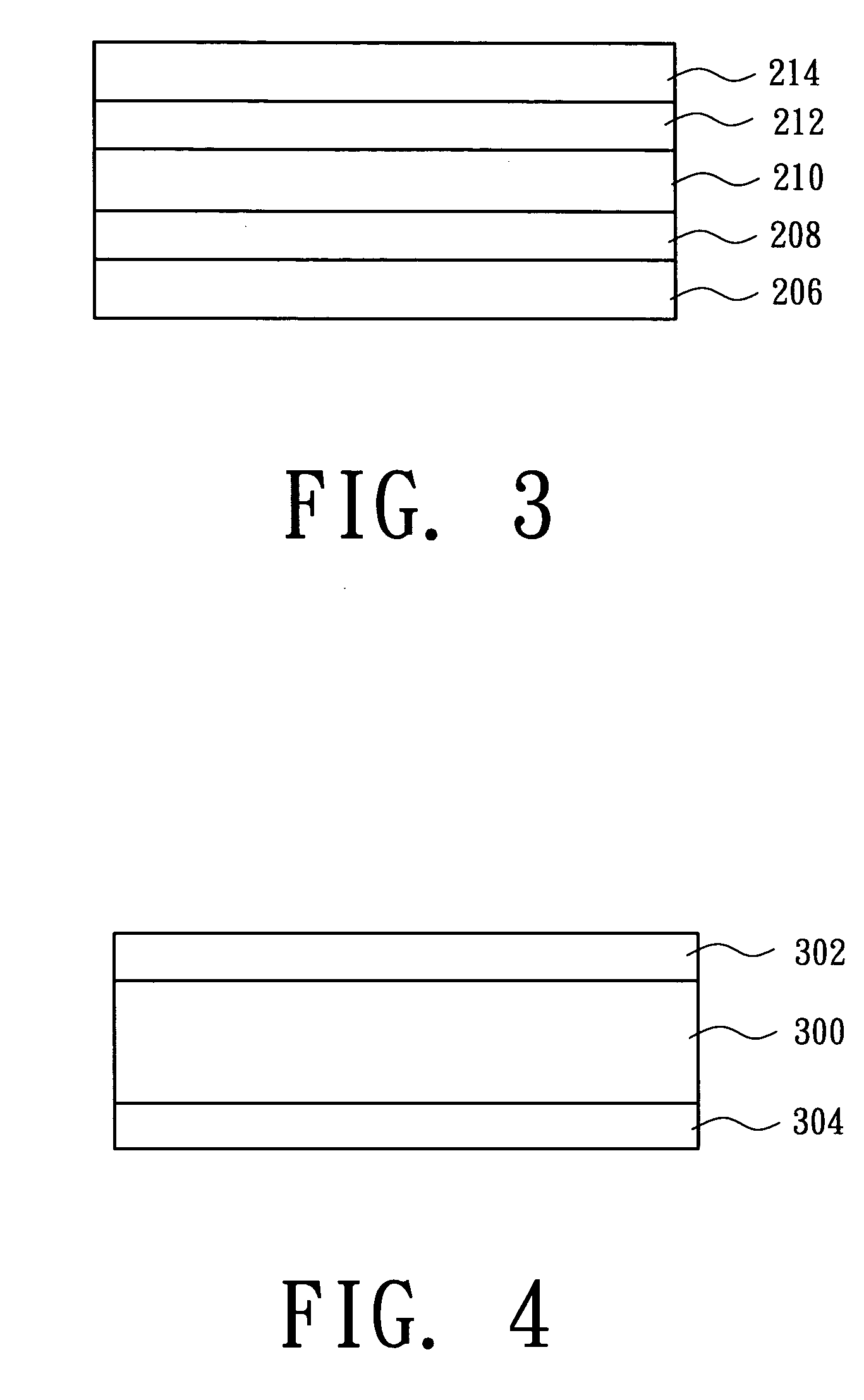

[0019] The present invention discloses a light emitting diode and a method for manufacturing the same. In order to make the illustration of the present invention more explicitly and completely, the following description and the drawings from FIG. 2 to FIG. 6 are stated.

[0020] Among semiconductor light emitting devices, AlGaInP is a very commonly-used material. Because AlGaInP is a kind of direct bandgap materials, appropriately adjusting the ratio of In / (Al+Ga) in the AlGaInP material can make the lattice constant of the AlGaInP material and the GaAs substrate matched. Adjusting the ratio of Al and Ga in the AlGaInP material can make light emitted between 550 nm (green light) and 680 nm (red light) in wavelength. It is very easy to adjust the AlGaInP material on the device epitaxy, so it is easy to obtain emitting light with desired wavelengths by a linear method, and AlGaInP is very suitable for use in manufacturing a light emitting device of visible light zone.

[0021] Besides, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com