LED chip and manufacturing method thereof

A technology of LED chips and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of limiting the improvement of the external quantum efficiency of LED chips, limiting the brightness of chips, etc., to achieve the improvement of current expansion ability, reduce the probability of occurrence, reduce The effect of reflection and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

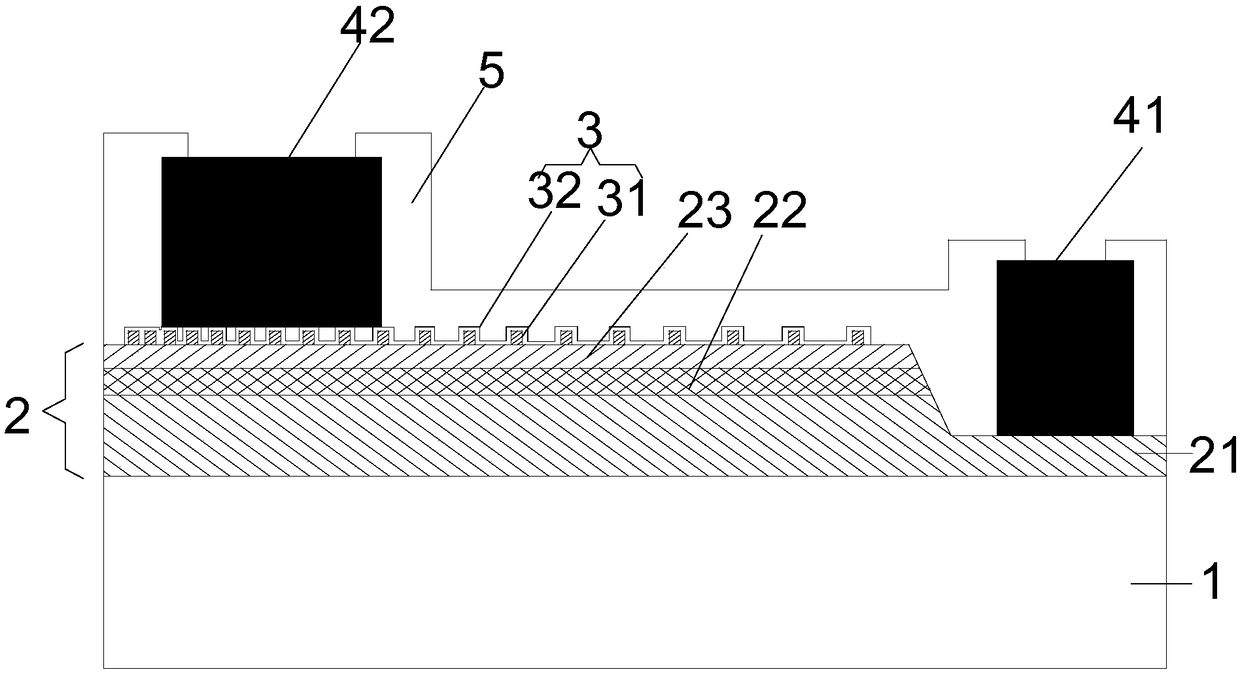

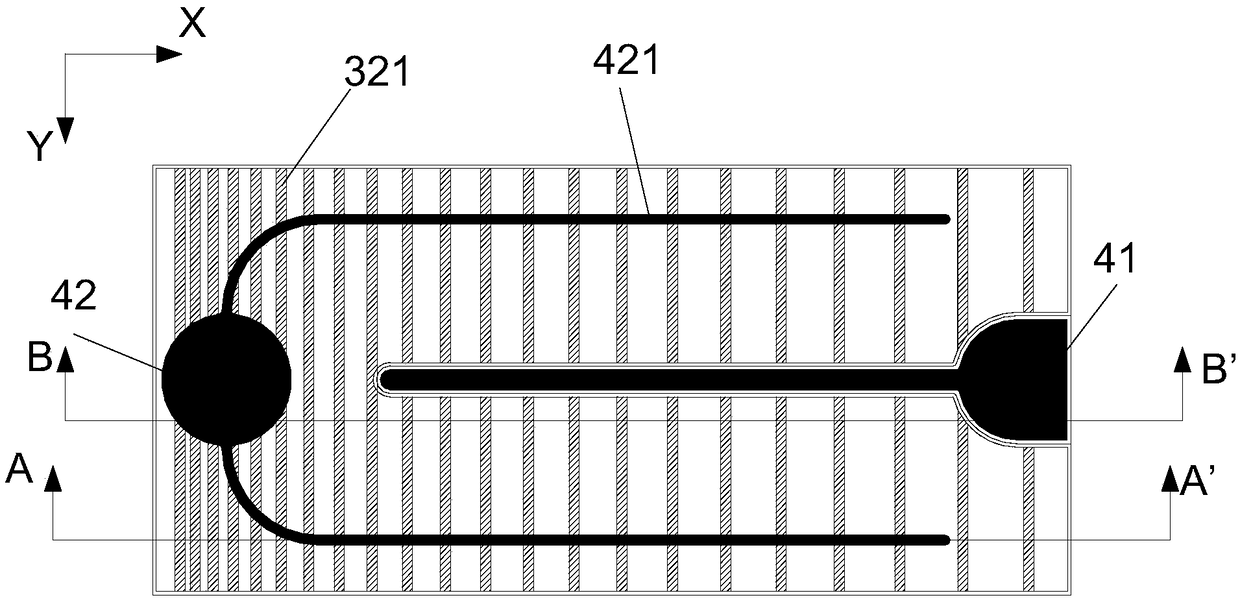

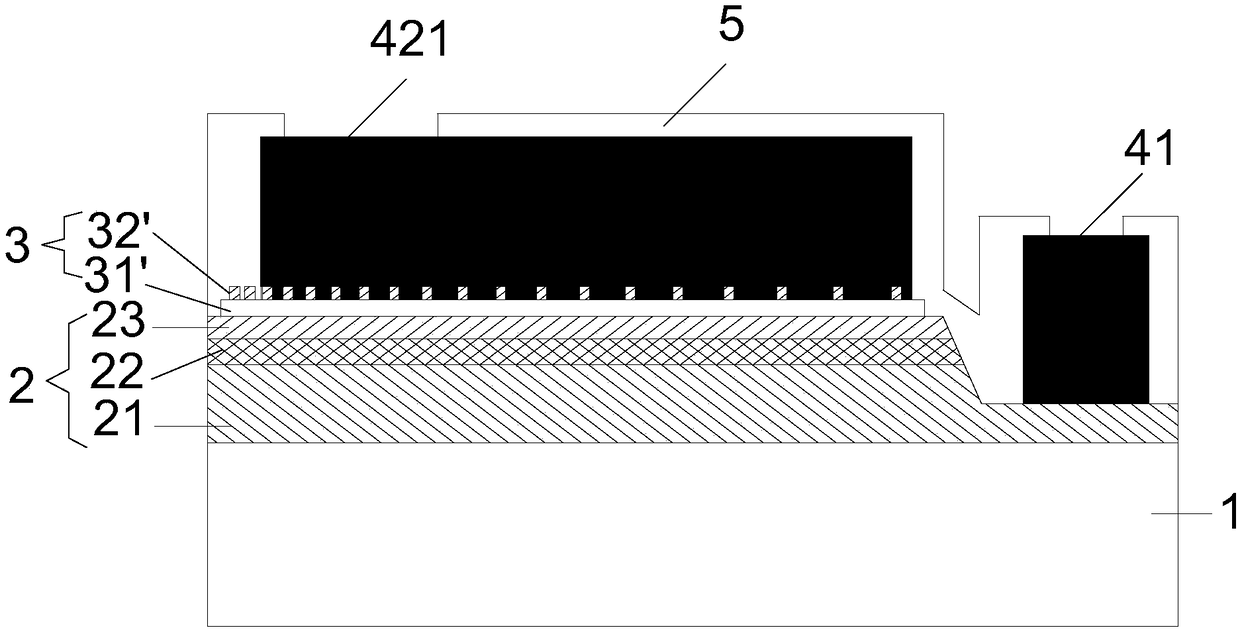

[0053] As mentioned in the background technology section, although the current spreading layer is added in the prior art, the current distribution of the LED chip can be made more uniform, thereby improving the luminous efficiency, but with the increase of the chip size, the semiconductor transparent conductive oxide current Scalability is limited. Although the further addition of metal interdigitated electrodes can further increase the uniformity of current spreading, it also introduces the problem of blocked light, which limits the further improvement of the brightness of the LED chip. At the same time, there is still a large amount of total reflection when the light exits from the entire transparent conductive oxide layer, which affects the off-chip quantum efficiency.

[0054] Based on this, the present invention provides a transparent interdigitated electrode design, which can not only further improve the current uniformity on the surface of the chip, but also form a step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com