Nitride light-emitting diode (LED) epitaxial wafer and growing method thereof

A technology of LED epitaxial wafers and growth methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced radiation recombination efficiency, reduced radiation recombination probability, poor antistatic properties, etc., to achieve ESD improvement, reasonable process, The effect of reducing the polarizing electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The growth process adopts MOCVD equipment (Crius 31-piece commercial machine of Aixtron Company), and the V group source used is ammonia gas (NH 3 ), the Group III organic source materials are trimethylgallium (TMGa) and trimethylindium (TMIn), and the P-type and N-type doped well elements are respectively Mg and Si. The substrate can be selected from sapphire, silicon, silicon carbide or gallium arsenide.

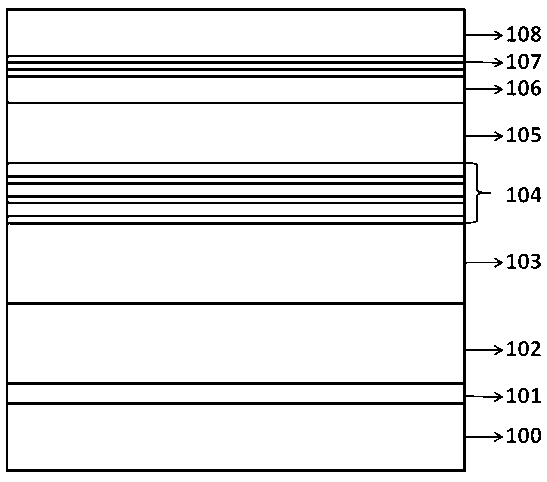

[0020] combine figure 1 , the growth step:

[0021] 1. A GaN low-temperature buffer layer 101 with a thickness of 0.01-1 μm is grown on the substrate 100, with H 2 As a carrier gas, the growth temperature is 500-600° C., and the pressure is 50-1000 mbar. In this case the thickness is 30 nm.

[0022] 2. Raise the temperature, grow an unintentionally doped GaN layer 102 with a thickness of about 2 μm on the GaN low-temperature buffer layer 101 under the conditions of a temperature of 800-1200° C. and a pressure of 50-1000 mbar.

[0023] 3. Reheating, on the unint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com