Semiconductor light emitting device and method for manufacturing the same

A technology for light-emitting devices and semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor chip current expansion, increased process cost, poor heat dissipation performance, etc., to improve the current expansion effect, improve light extraction efficiency, eliminate The effect of the current blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

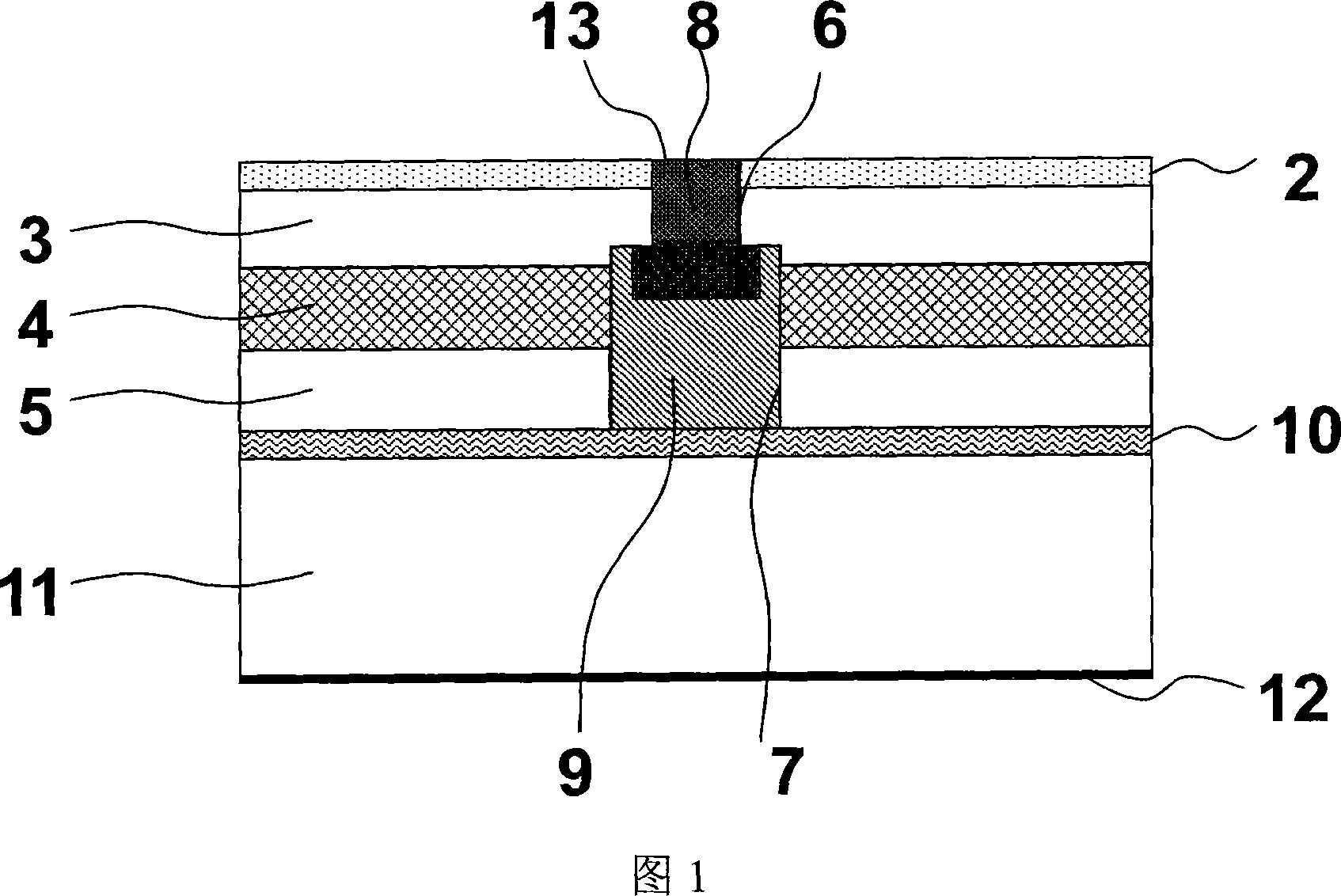

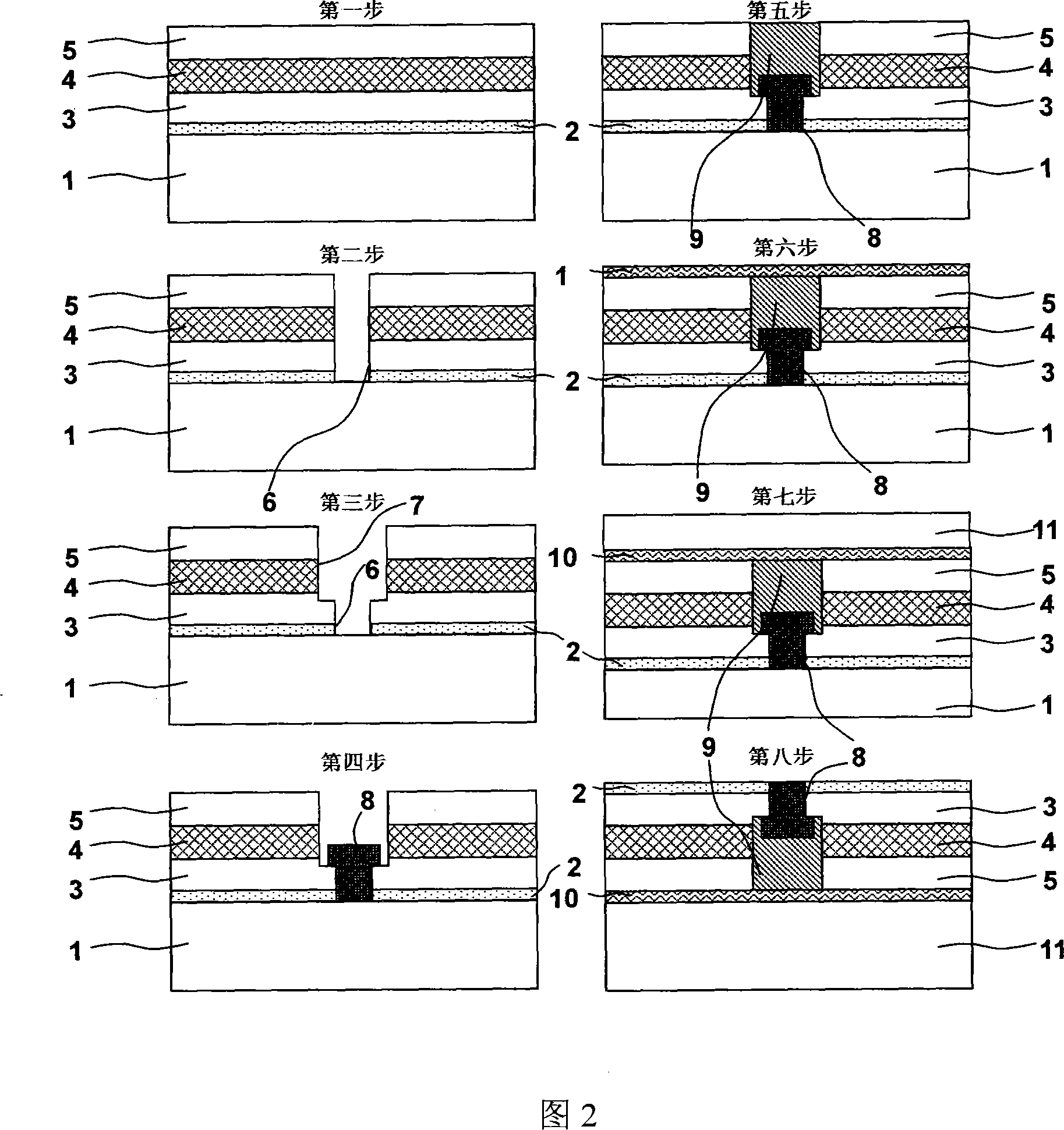

[0028] Referring to FIG. 1 , a semiconductor light-emitting device includes a conductive substitute substrate 11 and a semiconductor epitaxial stack connected to the substrate 11 through a metal layer 10. The semiconductor epitaxial stack includes a buffer layer 2, N-type layer 3 , light emitting layer 4 and P-type layer 5 . Wherein, a conductor is arranged in the N-type layer 3, one end of which extends upward to expose the buffer layer 2, and an N-type electrode 13 is provided, and an insulating medium layer is arranged between the other end and the metal layer 10, replacing the lower end of the substrate as a P electrode 12.

[0029] The conductor is composed of a columnar small through hole 6 and a conductive substance 8 filled in the small through hole 6, the conductor is only in contact with the buffer layer 2, the side wall of the N-type layer 3 and the lower edge of the N-type layer 3, It is not in contact with the light-emitting layer 4 , the P-type layer 5 and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com