Leadless welding table

A technology of lead-free soldering stations and soldering nozzles, which is applied to welding equipment, soldering irons, electric heating devices, etc., can solve problems such as difficult temperature control, and achieve the effect of rapid transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

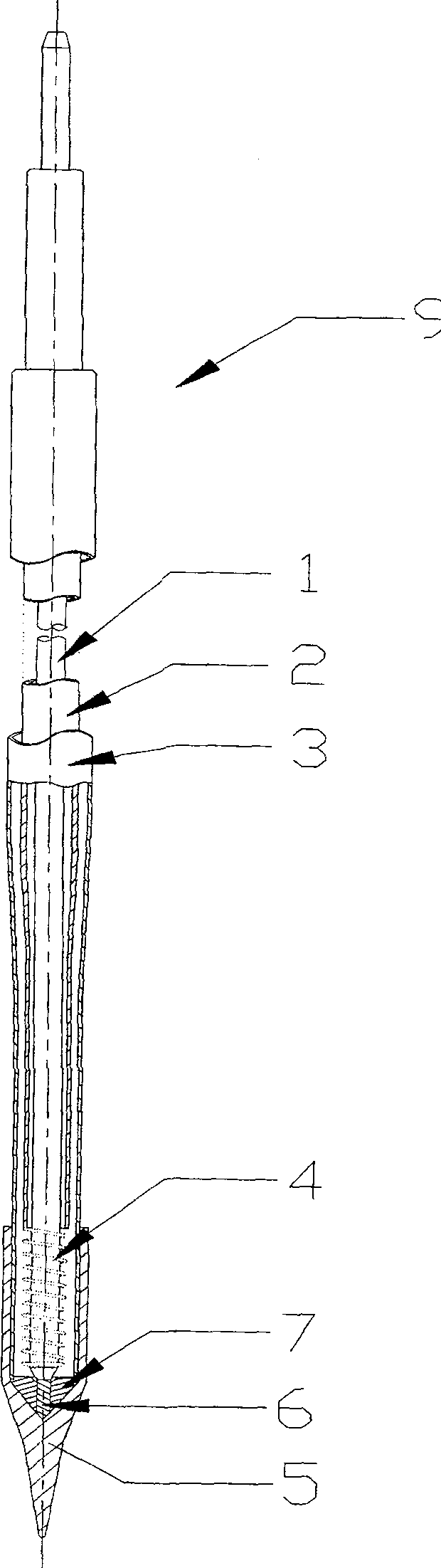

[0032] figure 1 It is a schematic diagram of the integrated soldering iron tip 9 in the embodiment of the present invention. As shown in the figure, the center of the soldering iron tip 9 is a rod-shaped first conductor 1 . The surface oxidized and insulated alloy wire 4 is wound on the first conductor 1 , one end is connected to the first conductor 1 , and the other end is connected to the second conductor 2 sheathed outside the first conductor 1 . In this way, the first conductor 1, the alloy wire 4 and the second conductor 2 form a heating circuit and are connected to a control circuit (not shown).

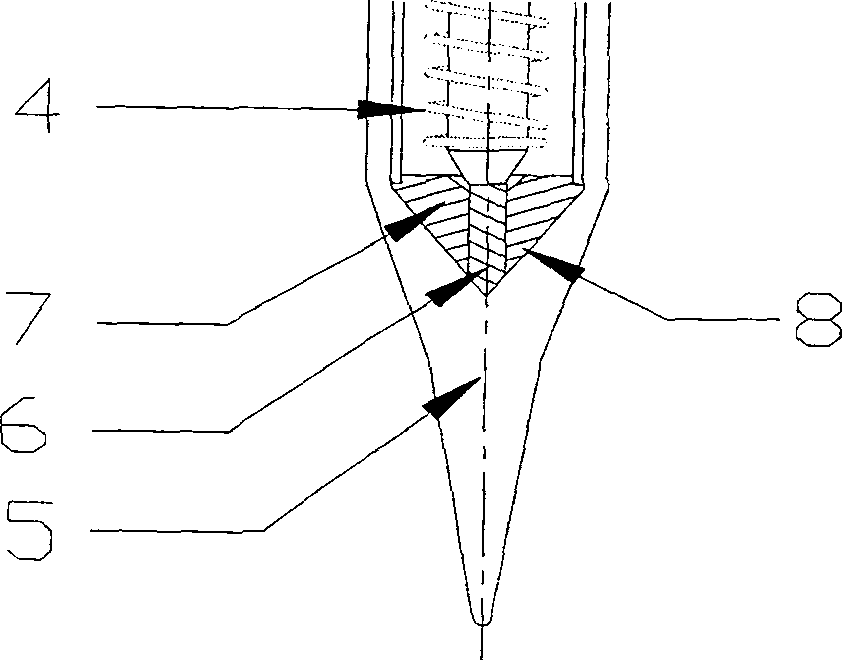

[0033] The third conductor 3 is a hollow cylinder, sheathed on the outside of the second conductor 2 and also surrounds the alloy wire 4 . figure 2 is an enlarged view of a working tip. Such as figure 2 As shown, the temperature sensing element 8 is connected in series between the first conductor 1 and the third conductor 3, forming a temperature measurement circuit and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com