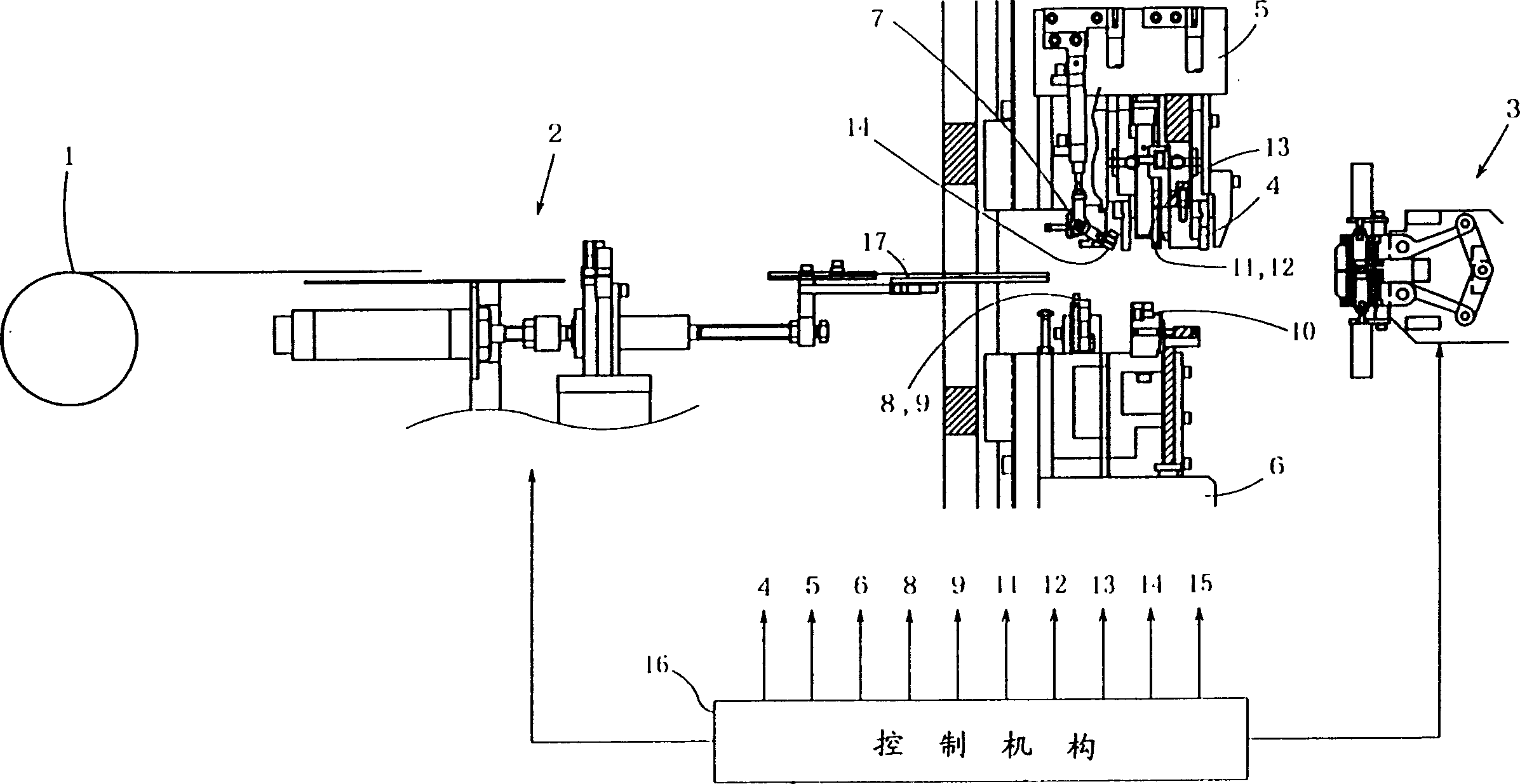

Combined press welding table and automatic press welder provided with same

A combined, pressure-welding machine technology, applied to contact members with insulating cutting edges, coupling devices, parts of connecting devices, etc., can solve the problem of the locking part being difficult to leave the pressure-welding station, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

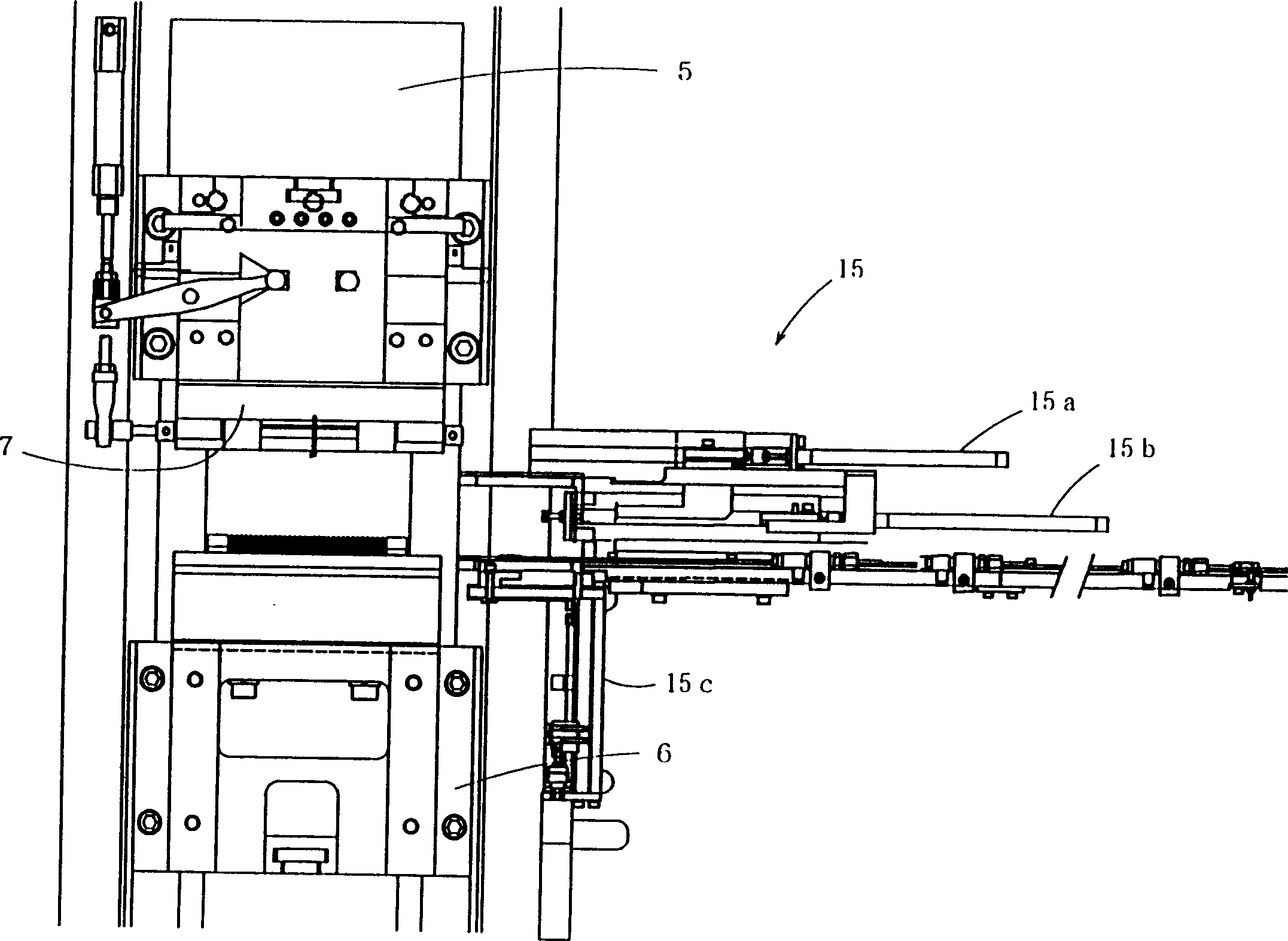

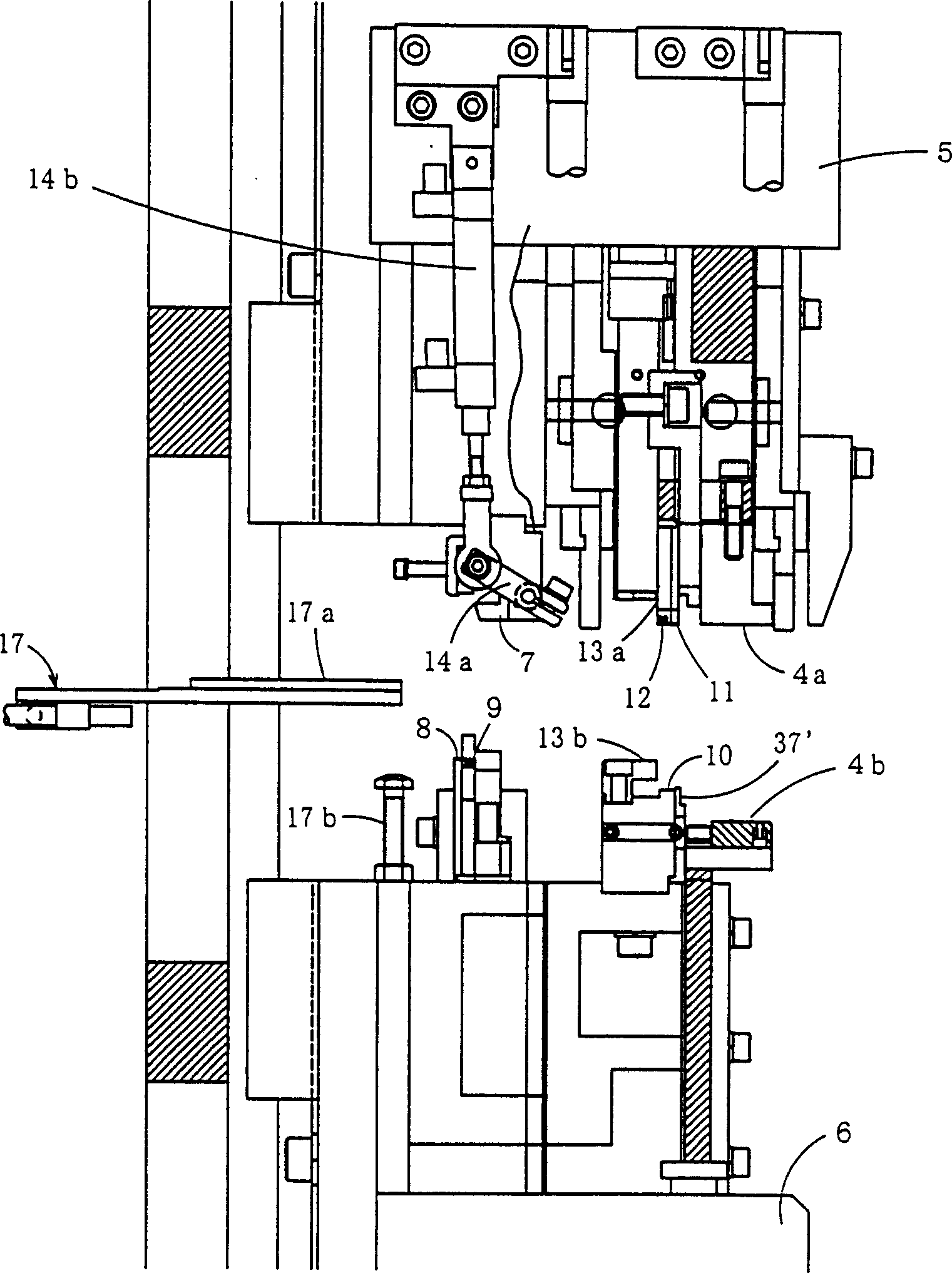

[0046] Hereinafter, embodiments of the combination bonding stand and the automatic bonding machine equipped with the bonding stand according to the present invention will be described.

[0047] First, a pressure-welded connector with a locking portion of an electric wire that is pressure-welded by such an automatic pressure welding machine will be described. Figure 19 ~ Figure 21 A pressure-welded connector 40 with a locking portion of the present embodiment is shown. Although a six-way bonded connector 40 is shown in this embodiment, the number of cores may be arbitrary. Electric wires 60 whose number corresponds to the number of cores are connected in the pressure-welded connector 40 . Also, the pressure-bonded connector 40 is connected to a mating connector 50 .

[0048] The pressure-welded connector 40 includes a connector housing 41 , and male or female contacts 43 . The connector housing 41 is substantially box-shaped and has a hole 42 penetratingly provided in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com