Patents

Literature

222results about "Unstripped conductor connection apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

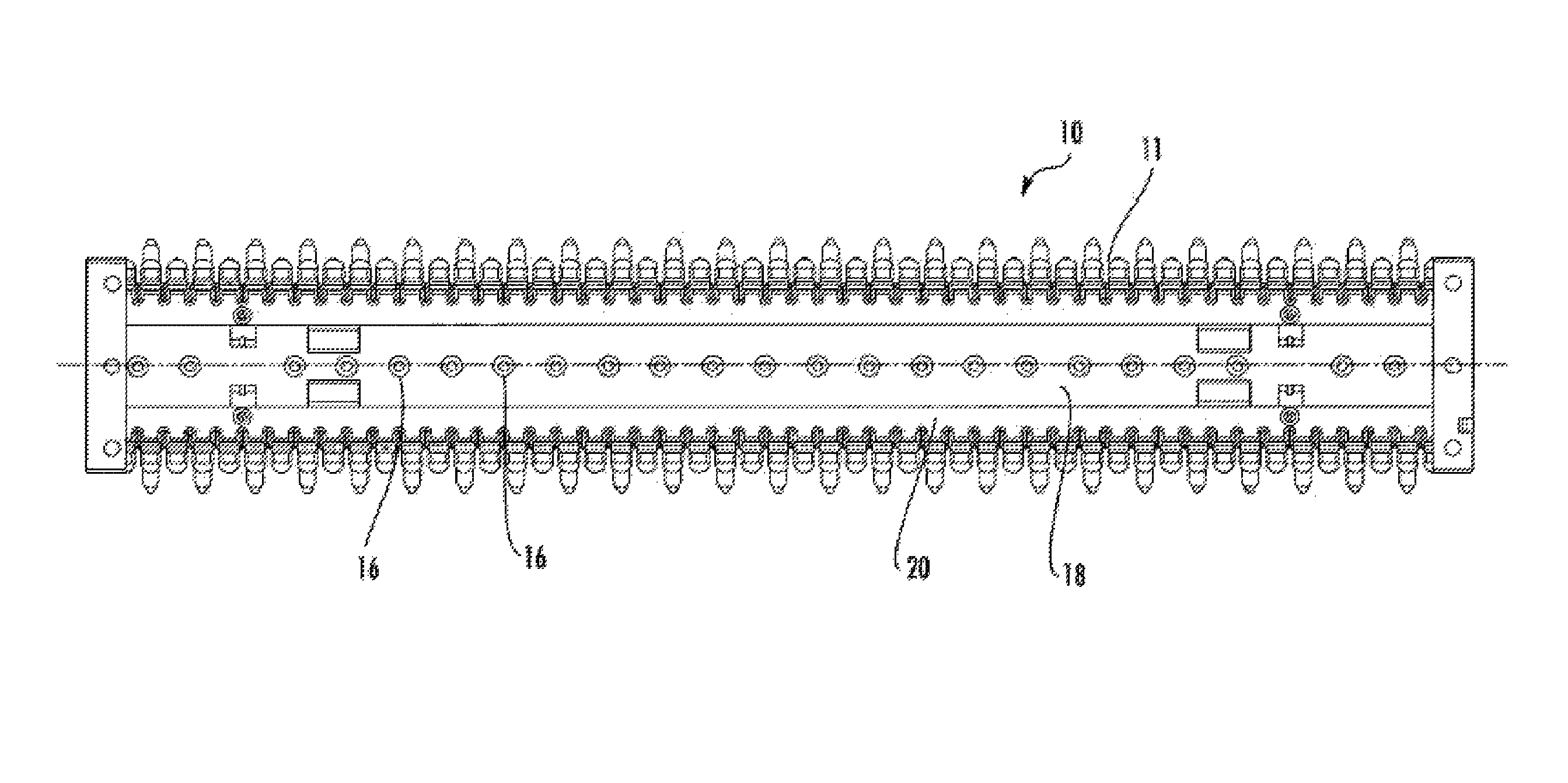

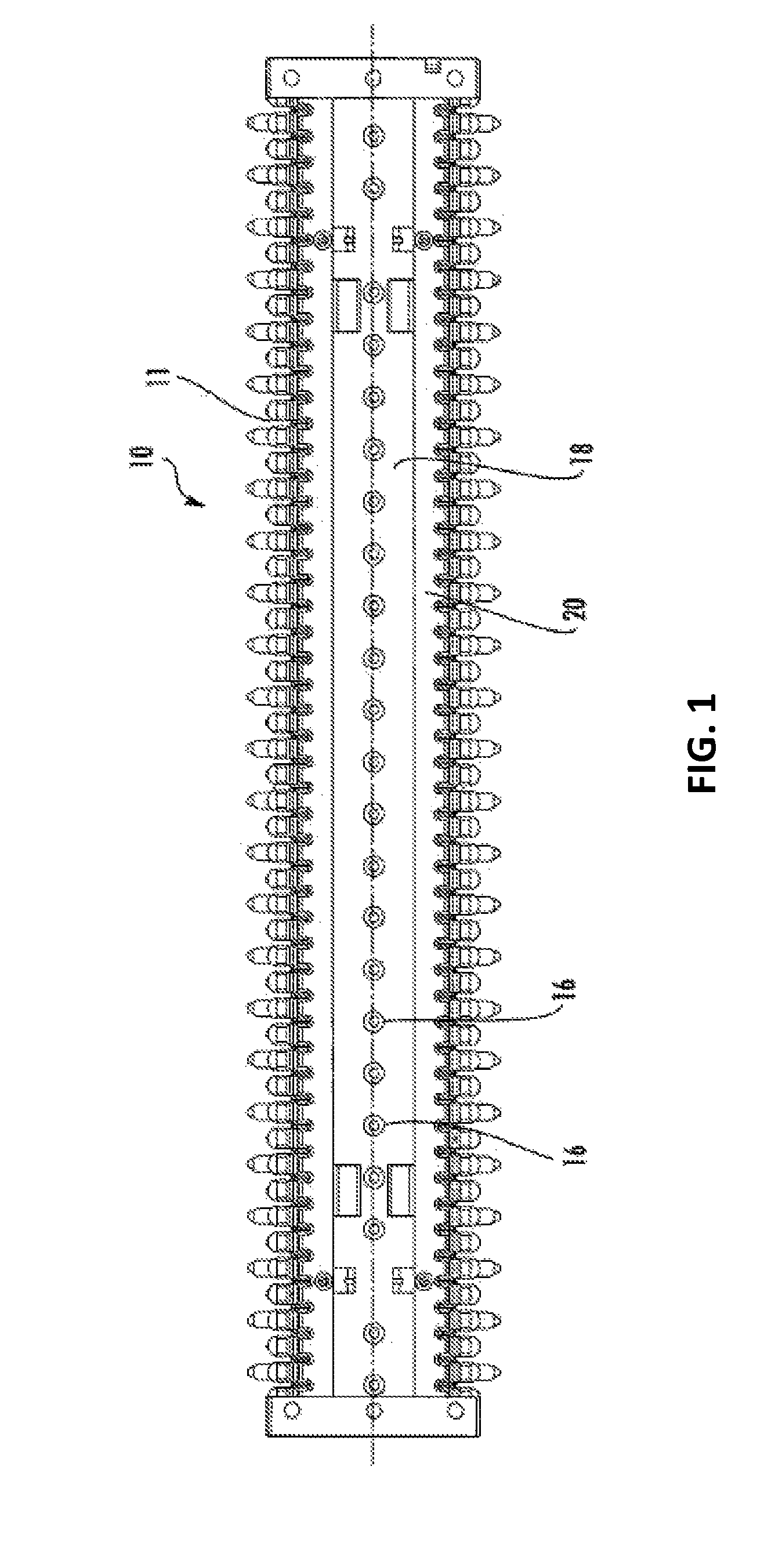

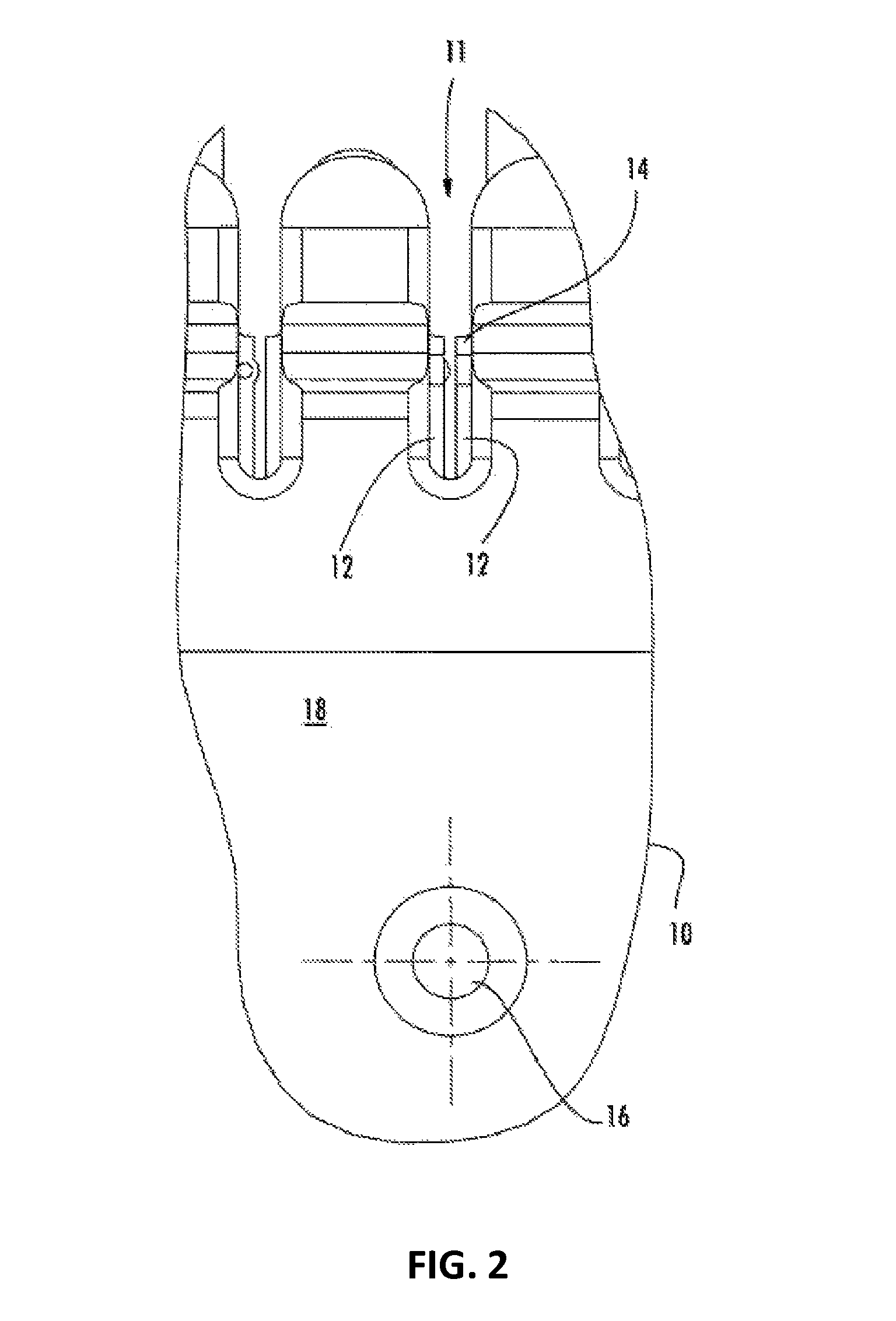

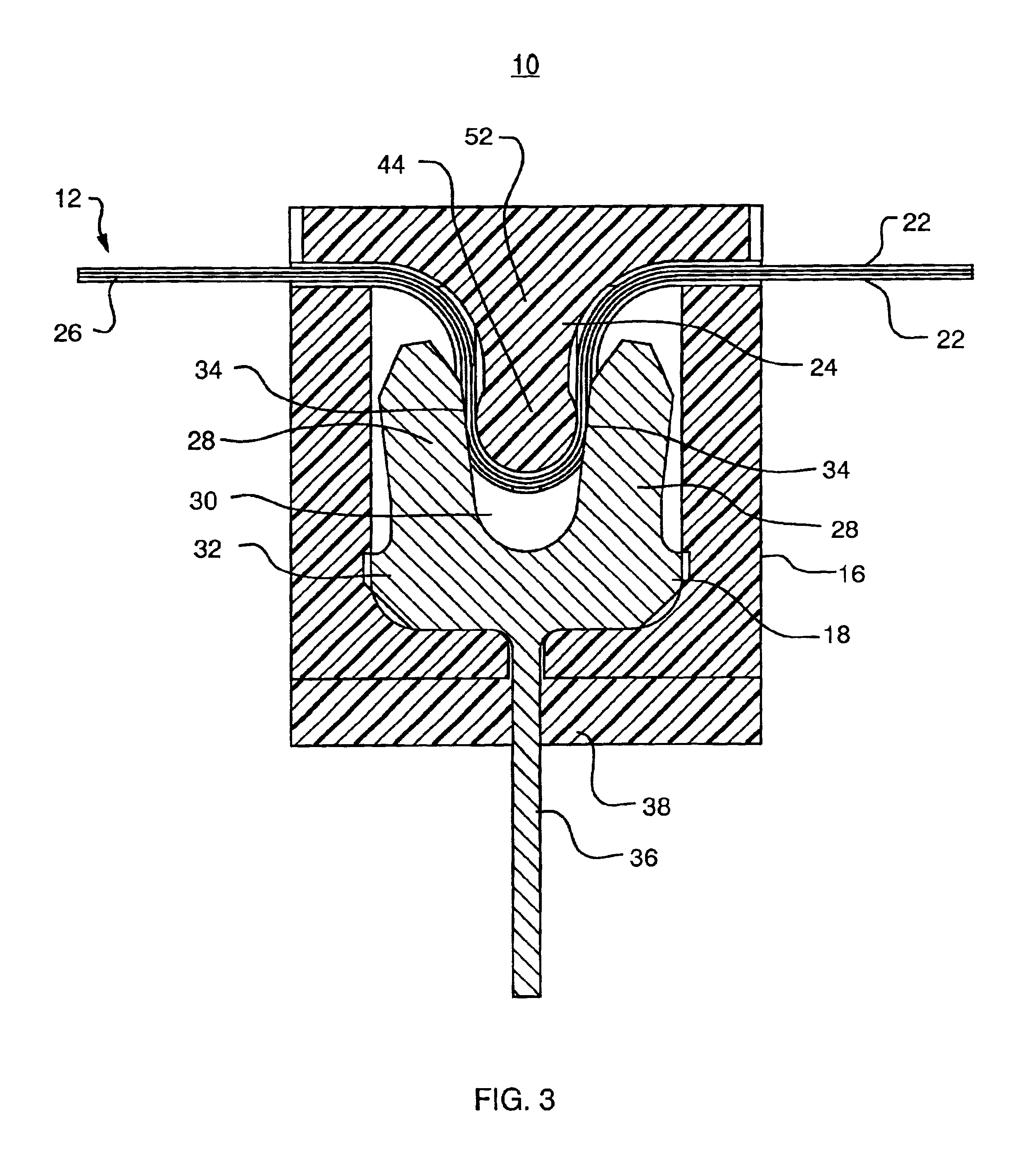

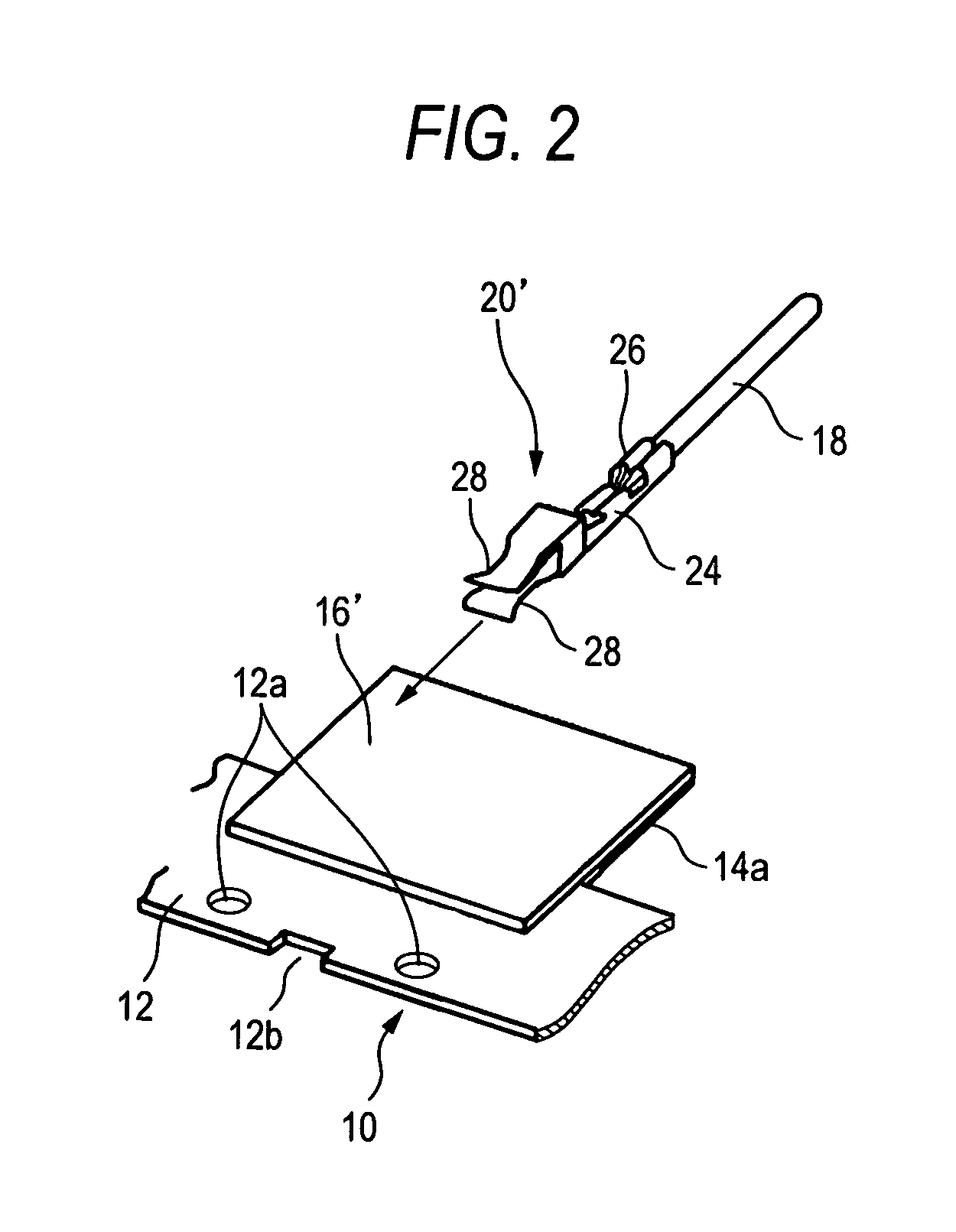

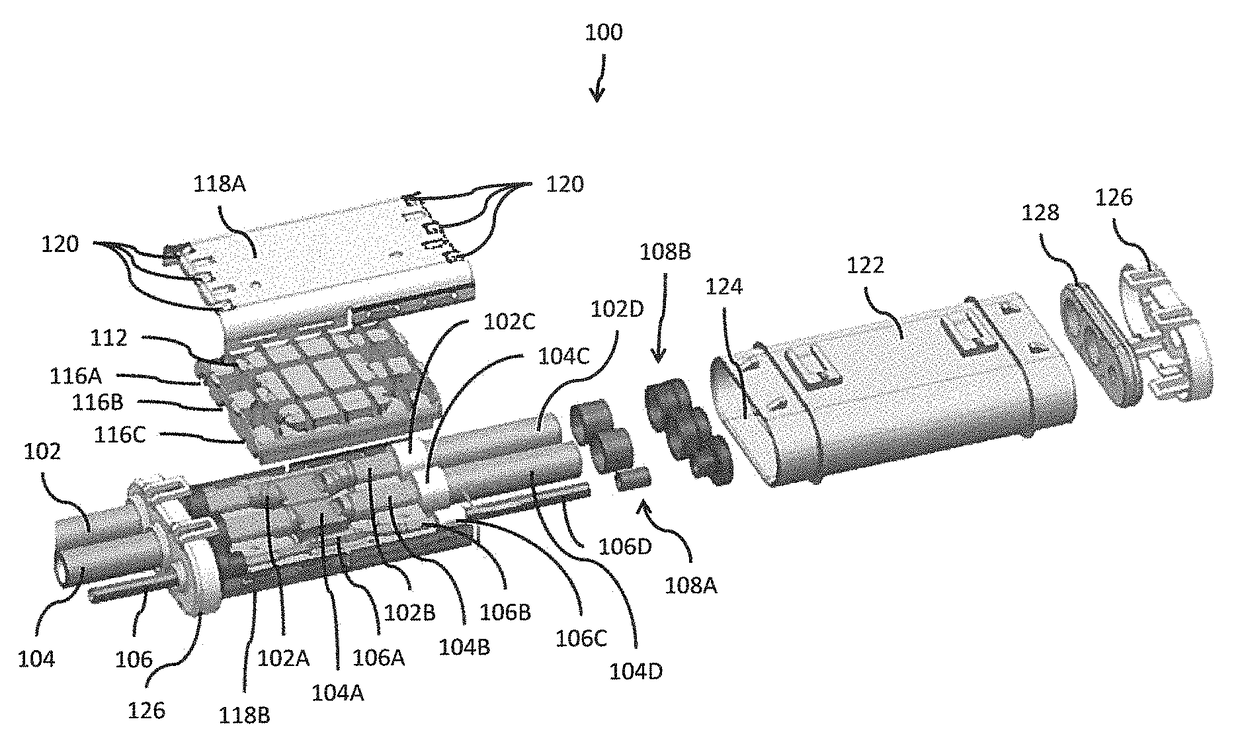

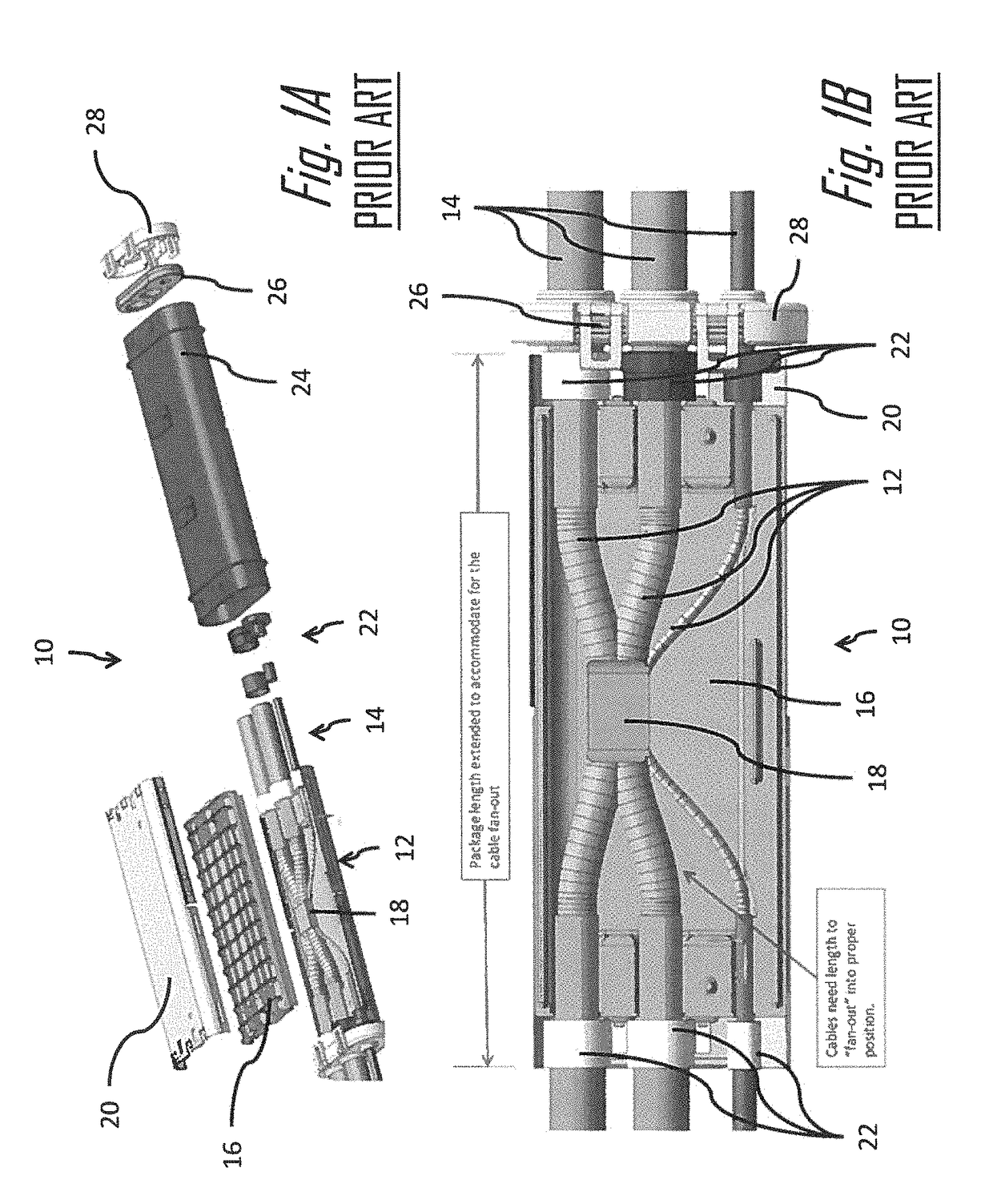

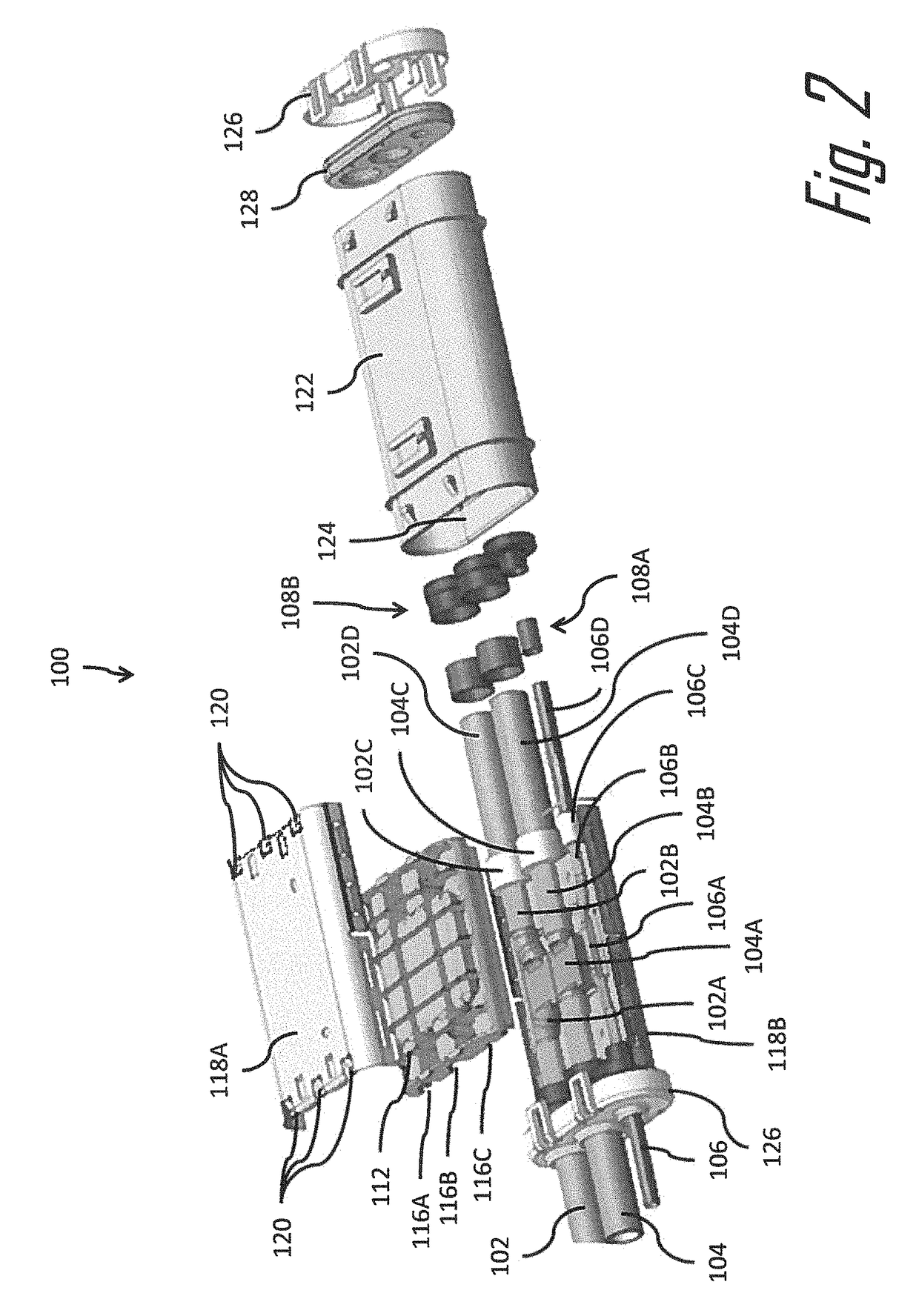

Connector assemblies and methods of manufacture

ActiveUS9548557B2Contact member cases/bases manufactureDustproof/splashproof/drip-proof/waterproof/flameproof connectionEngineeringMechanical engineering

Owner:CORNING OPTICAL COMM LLC

Twisted-pair data cable with electrical connector attached

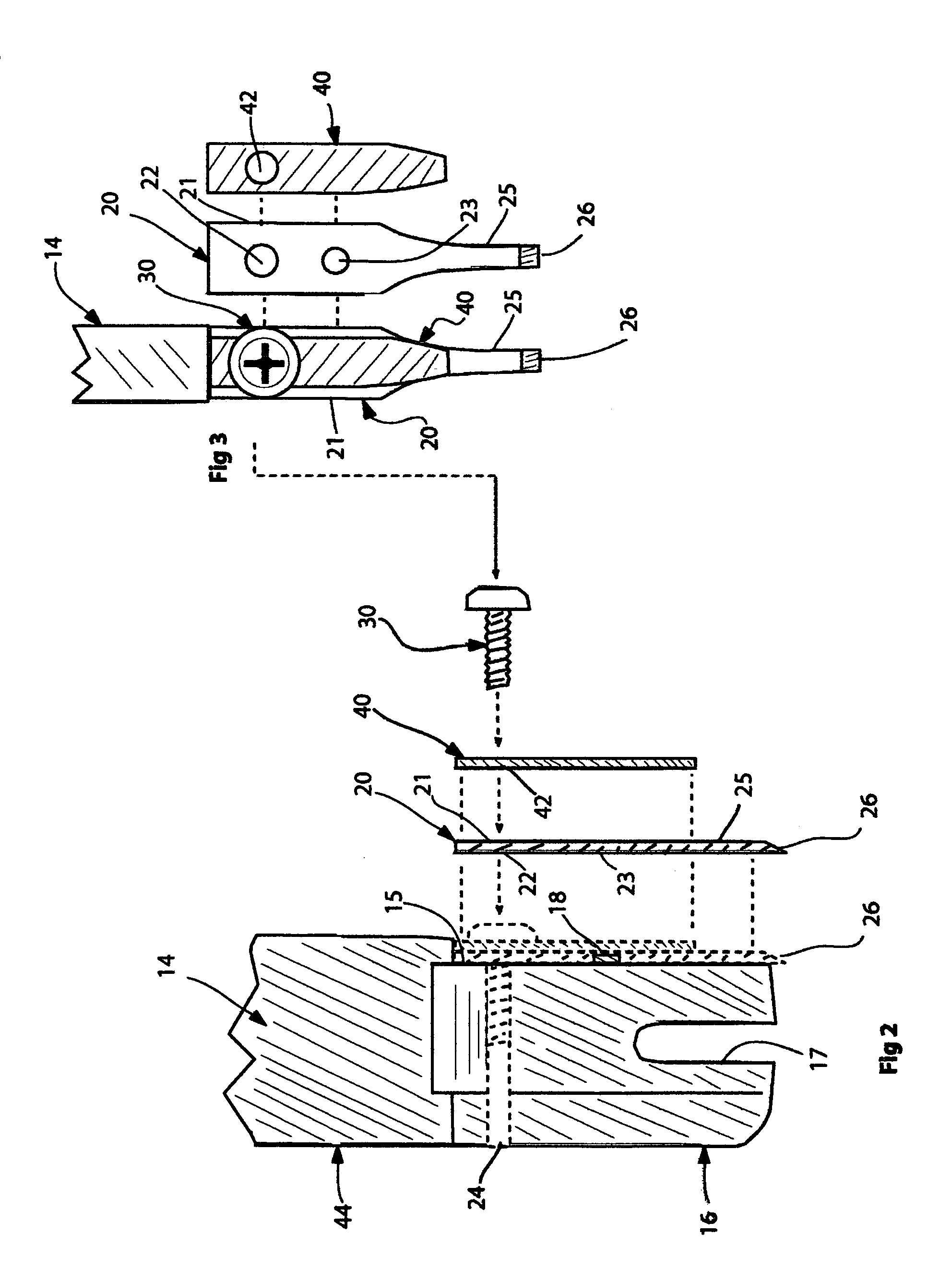

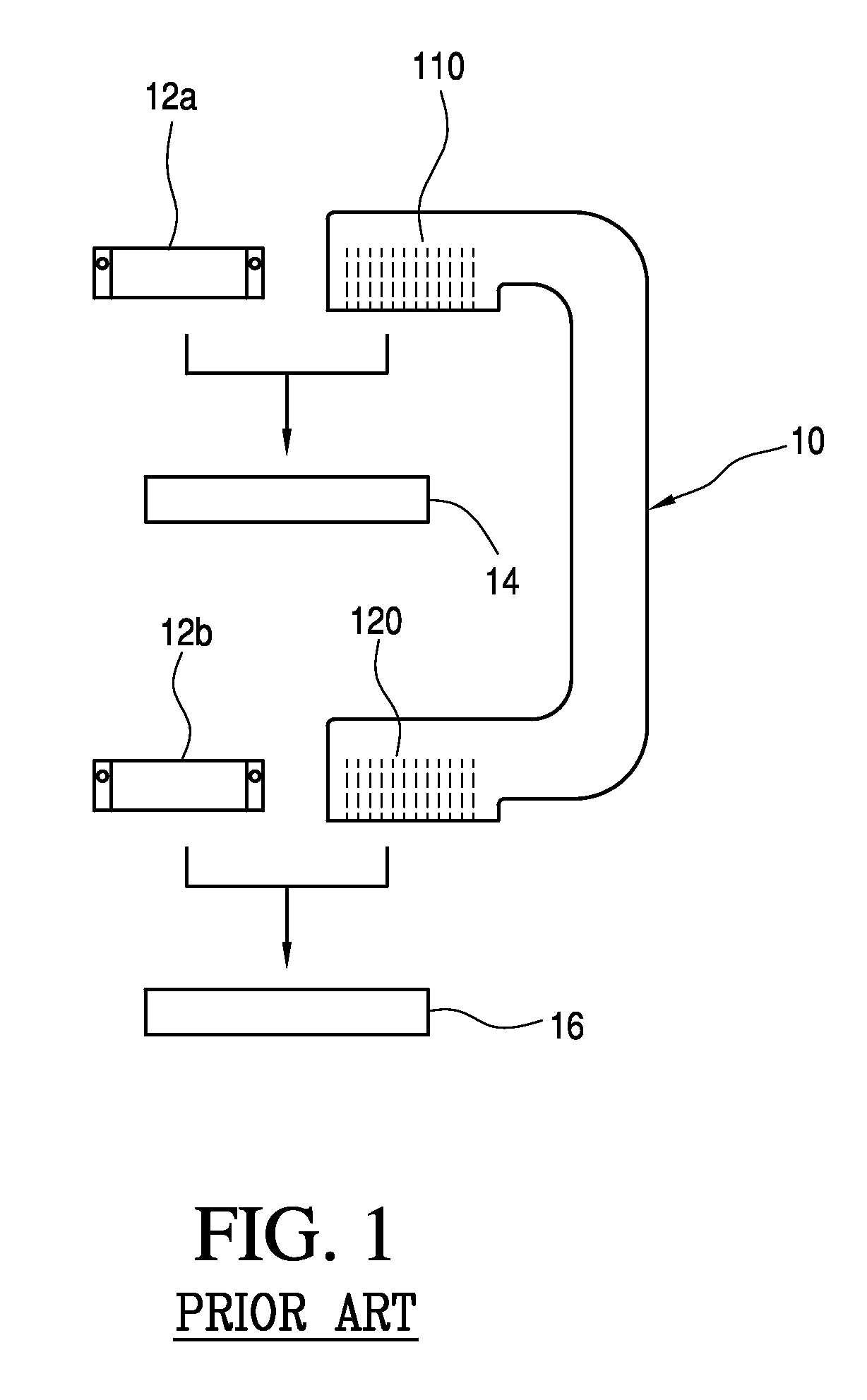

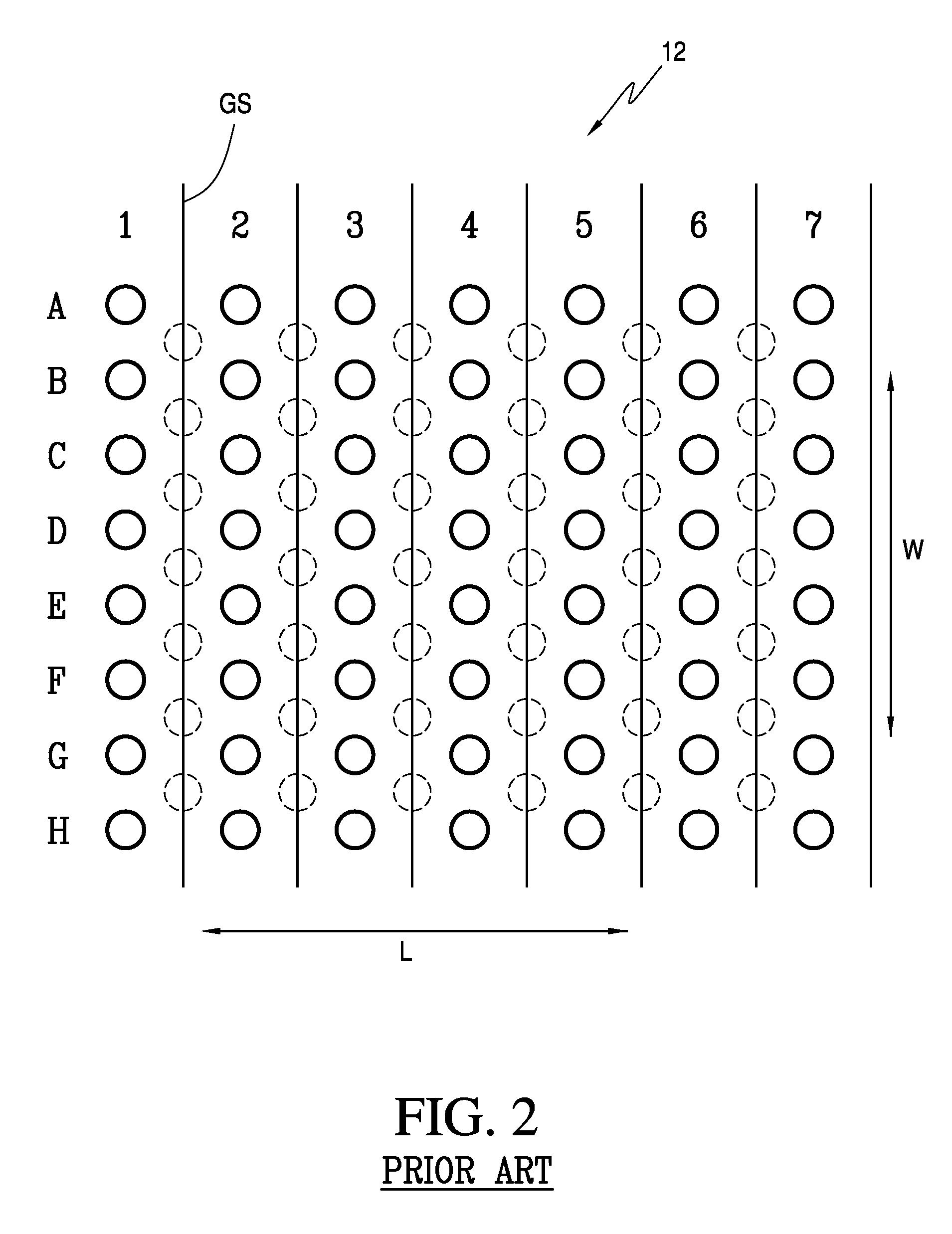

Electrical apparatus for connecting insulated wires of a multi-pair electrical cable to an outlet, including a connector having an opening which receives a plurality of insulated wires in an essentially flat parallel configuration and extends through the connector to allow the ends of the insulated wires to protrude from its remote end, the connector also having a plurality of metal contacts supported in a movable relation perpendicular to the insulated wires; a crimping tool having jaws closable both for crimping the connector to support the insulated wires against longitudinal stress and also for causing the metal contacts to pierce insulation coverings of and conductively engage respective wires in the connector; and a cutting blade supported on the crimping tool and operable during the closing action of the jaws for cutting off the protruding ends of the wires.

Owner:SULLIVAN ROBERT W

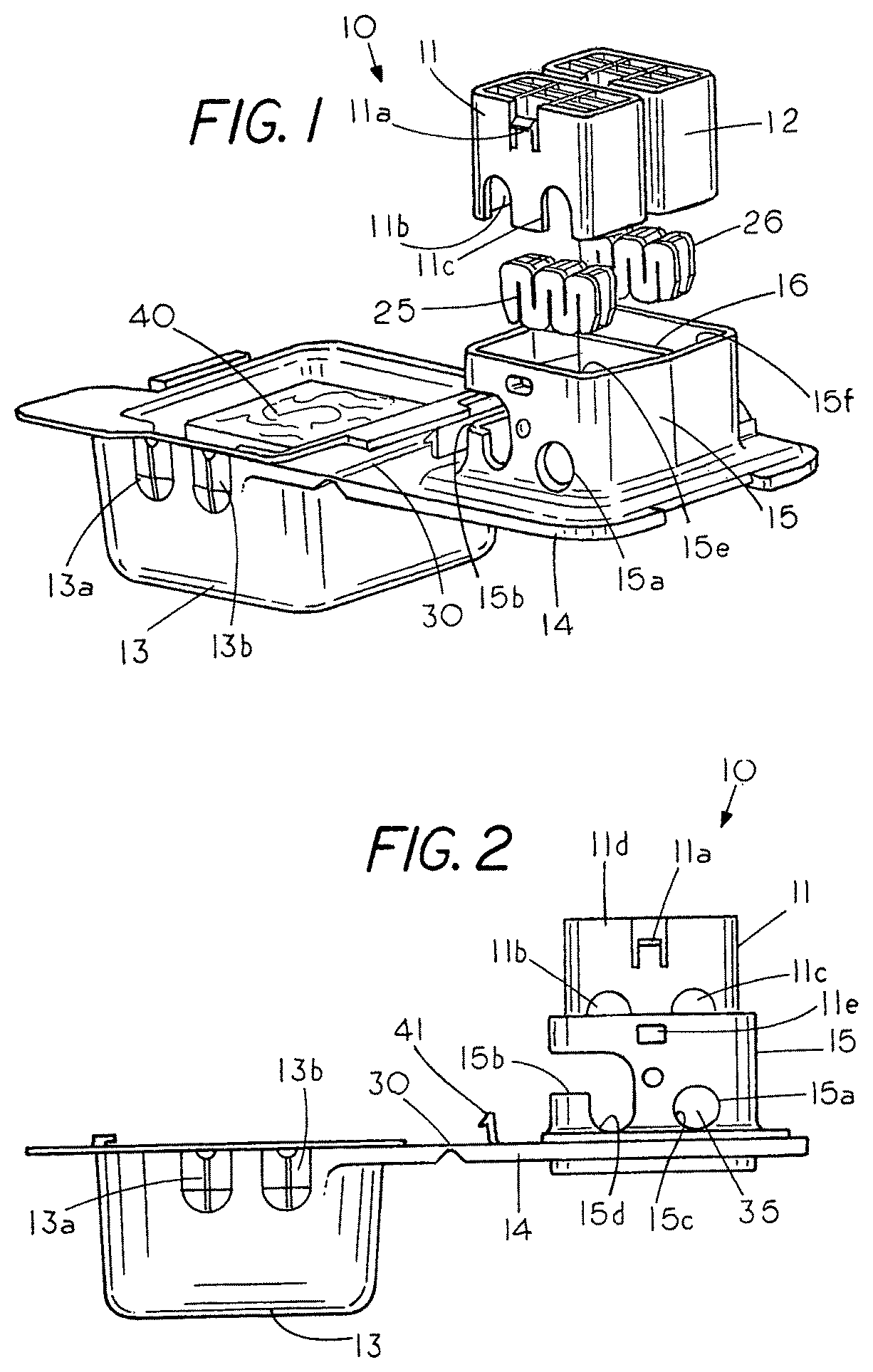

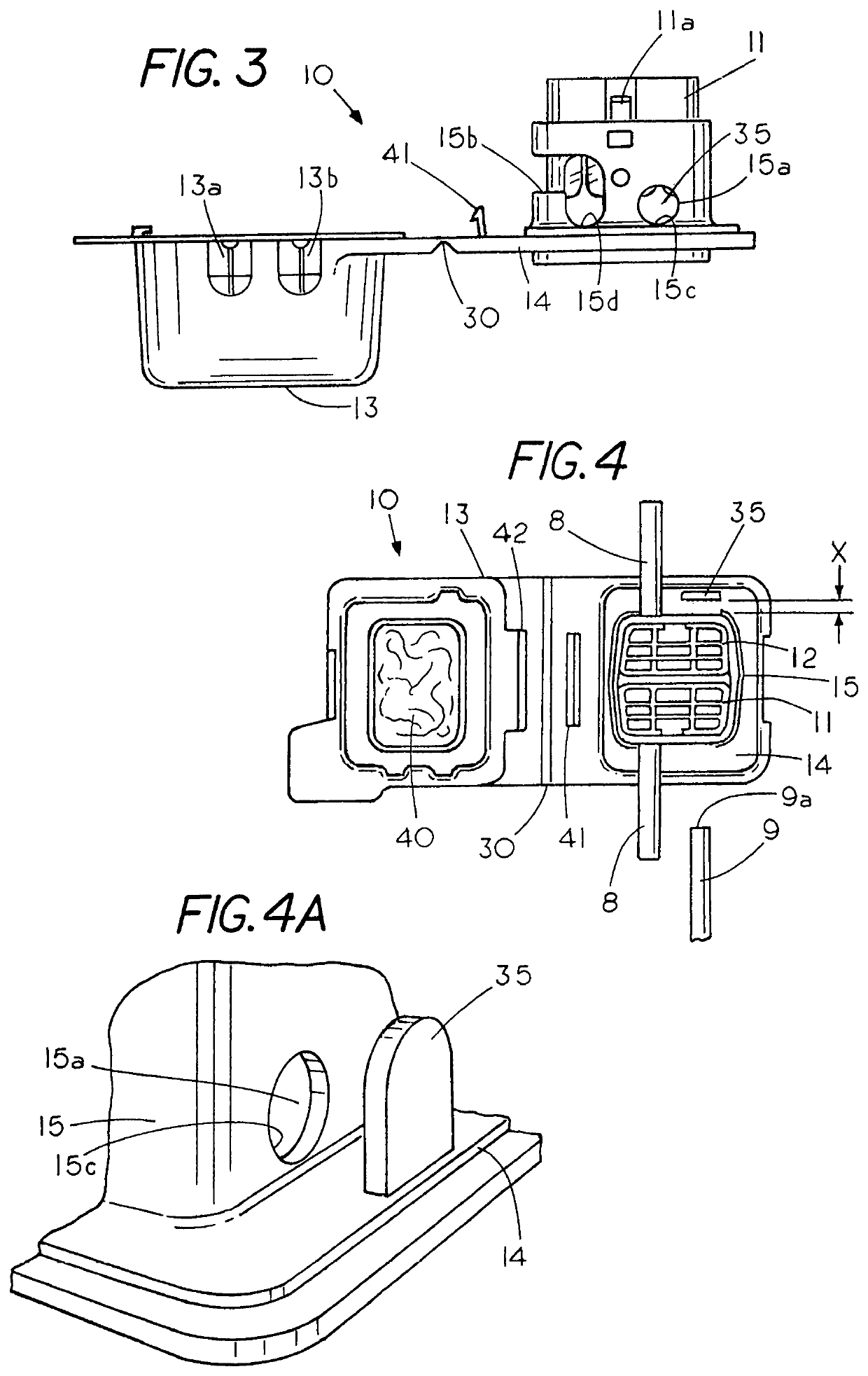

Apparatus for securing twisted-pair electrical cable to a connector

An apparatus for connecting a multi-wire-pair electrical cable to a connector housing with movable wire piercing contacts therein having input and output openings for the wires is disclosed. The outlet opening of the housing has a flat end face plate generally perpendicular to the longitudinal axis of the connector housing and to an anvil supported from the end of the housing. The apparatus comprises a crimping and shearing tool also having protrusions to drive the contacts into the wires of the cable. A shearing blade of the tool is positioned to wipe the flat end face plate of the housing to cut the wires flush with the end face plate.

Owner:SULLIVAN ROBERT W

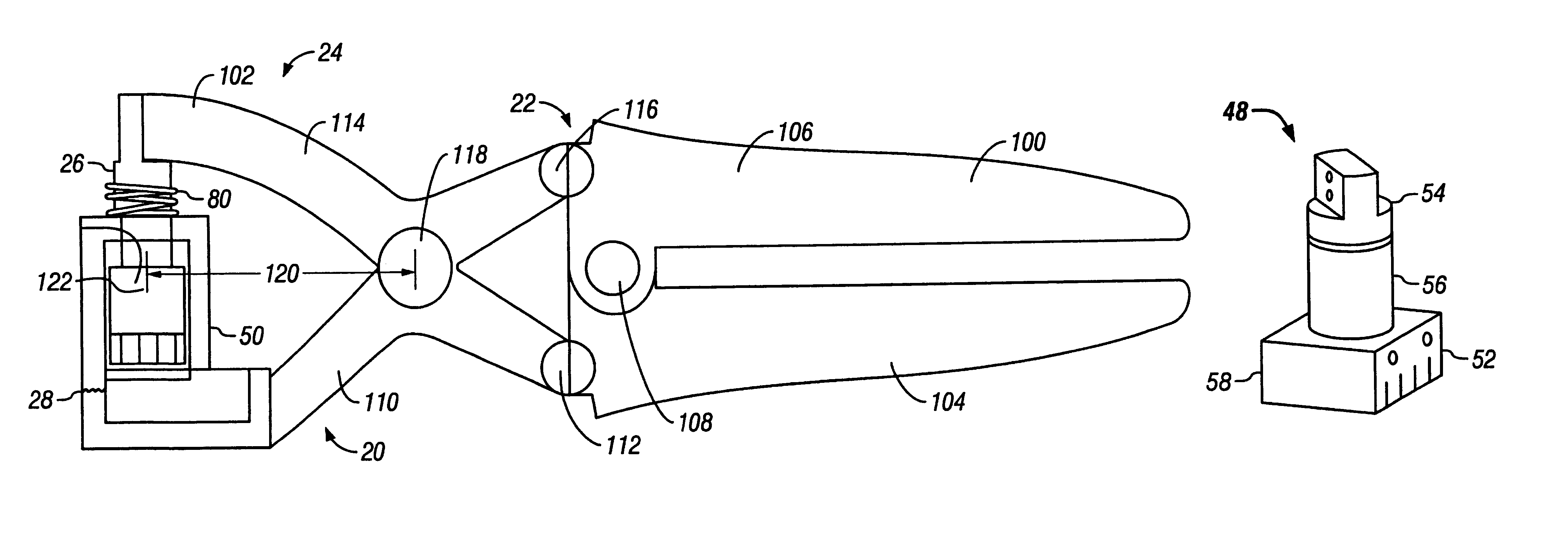

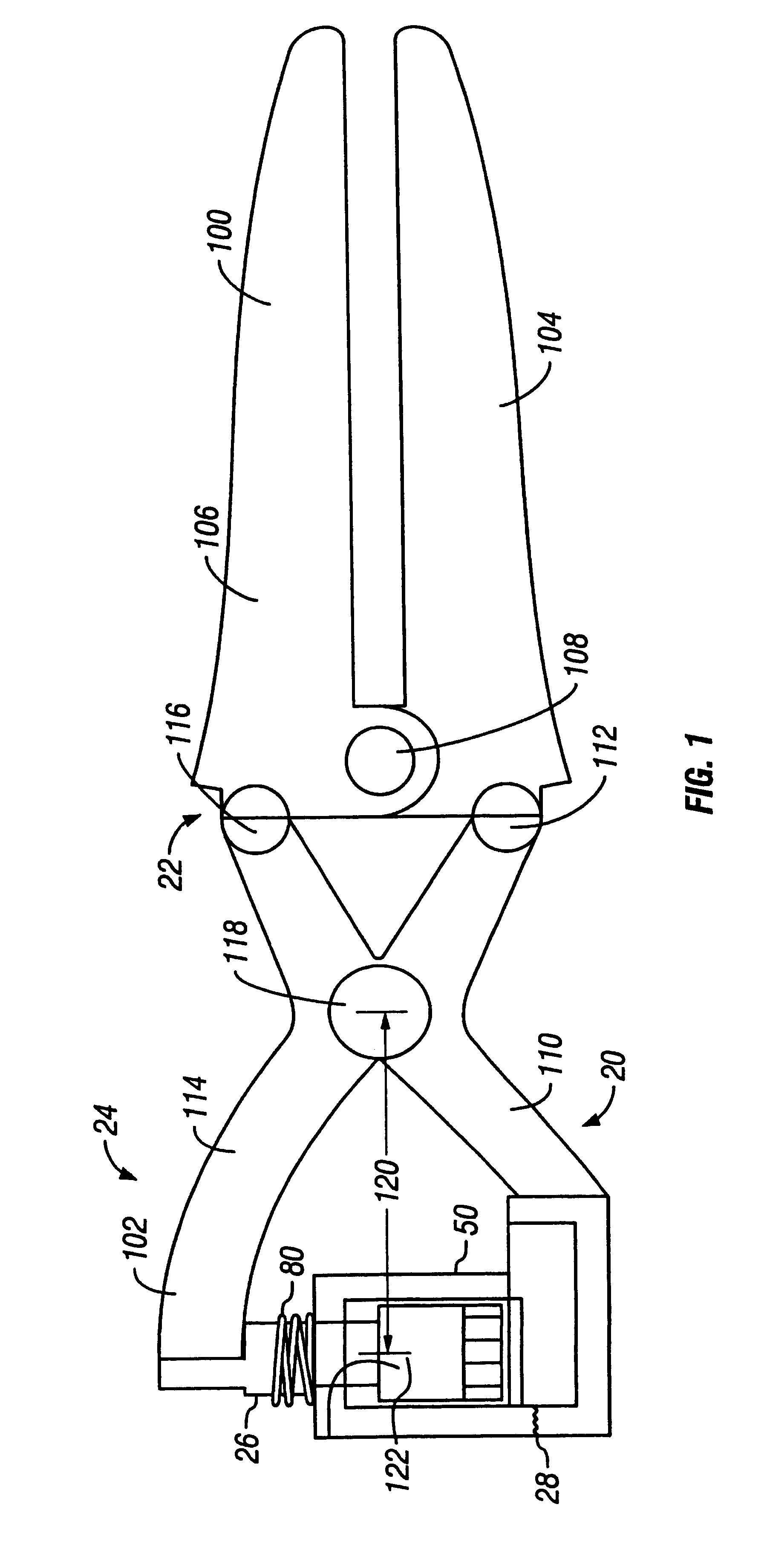

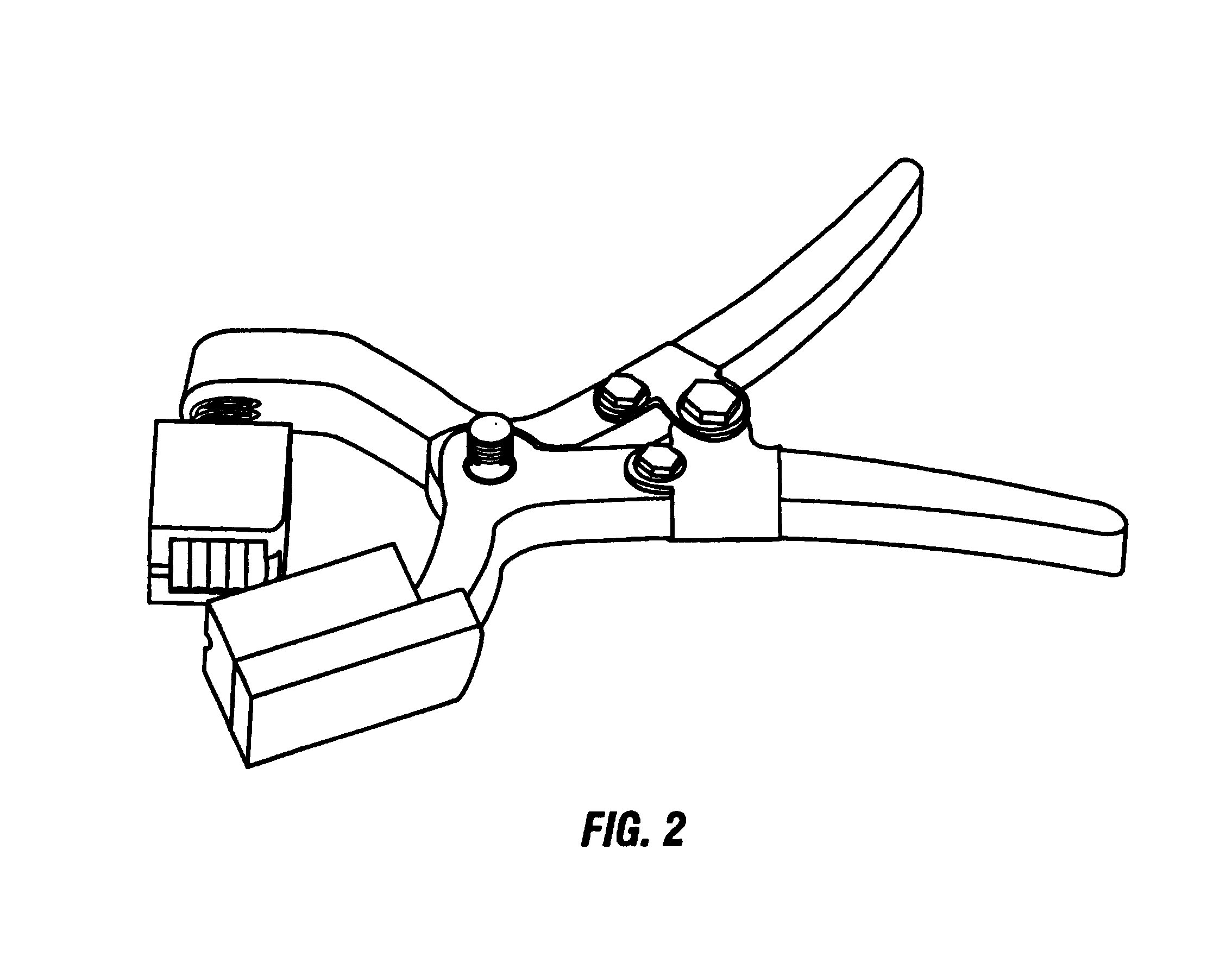

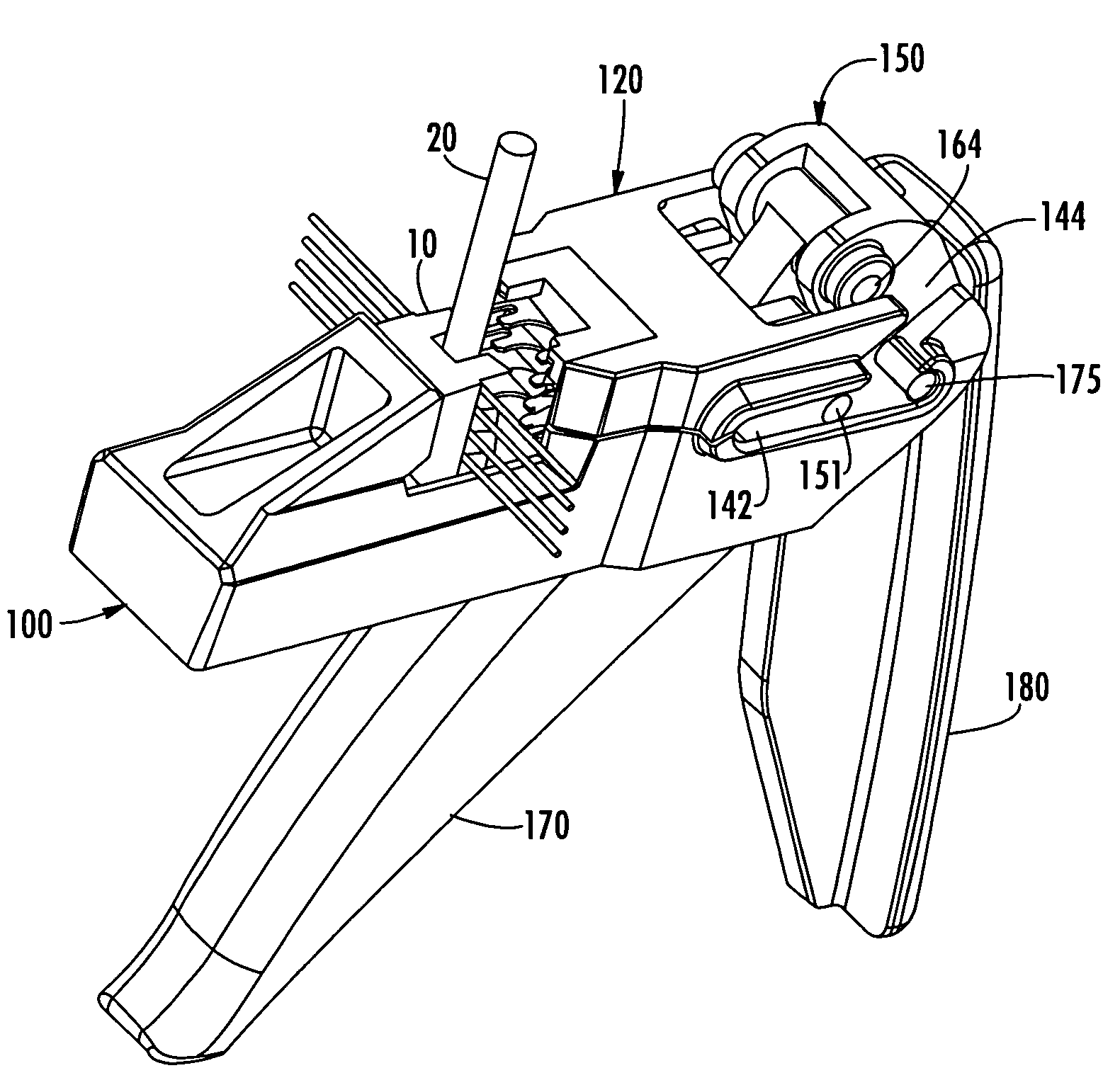

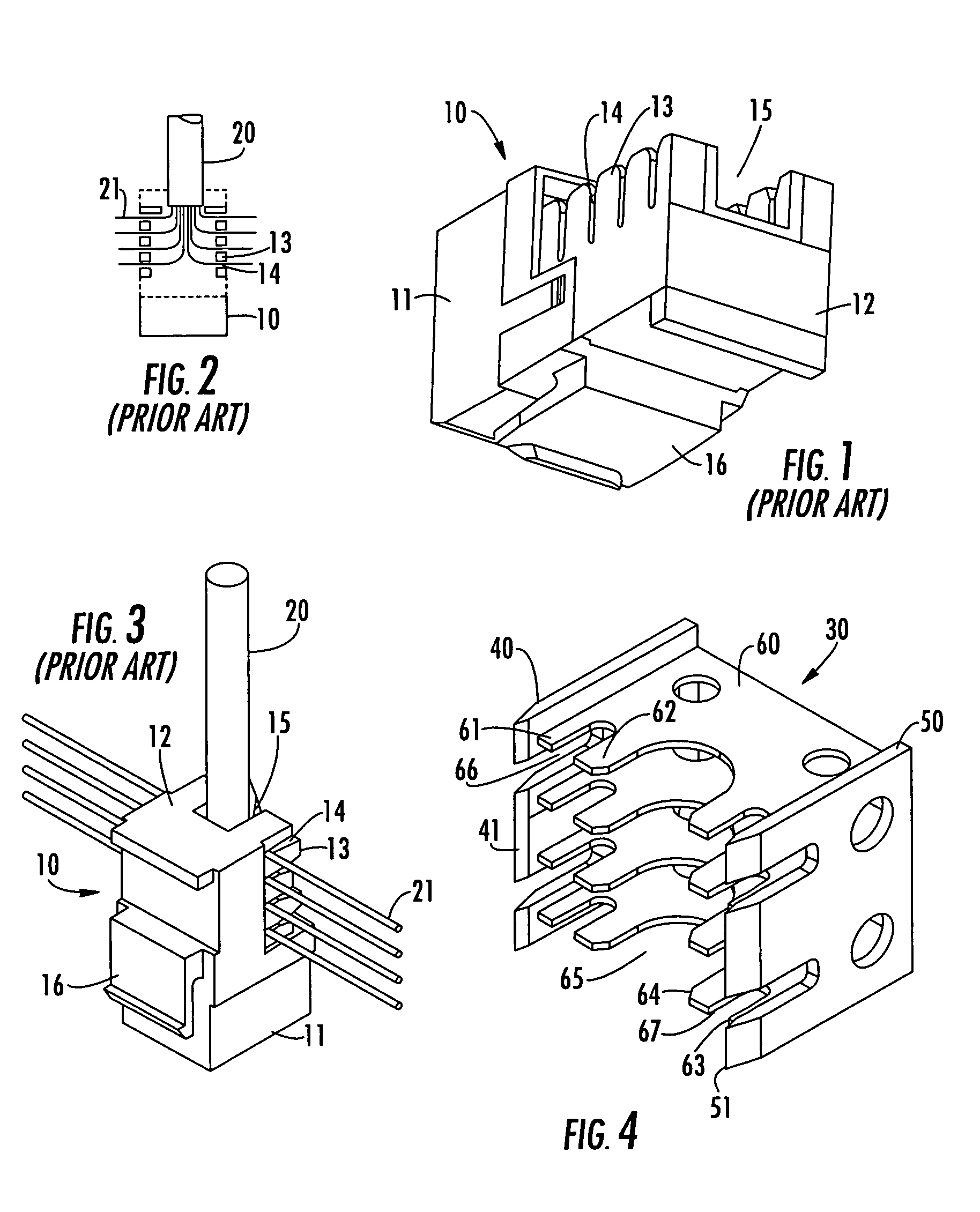

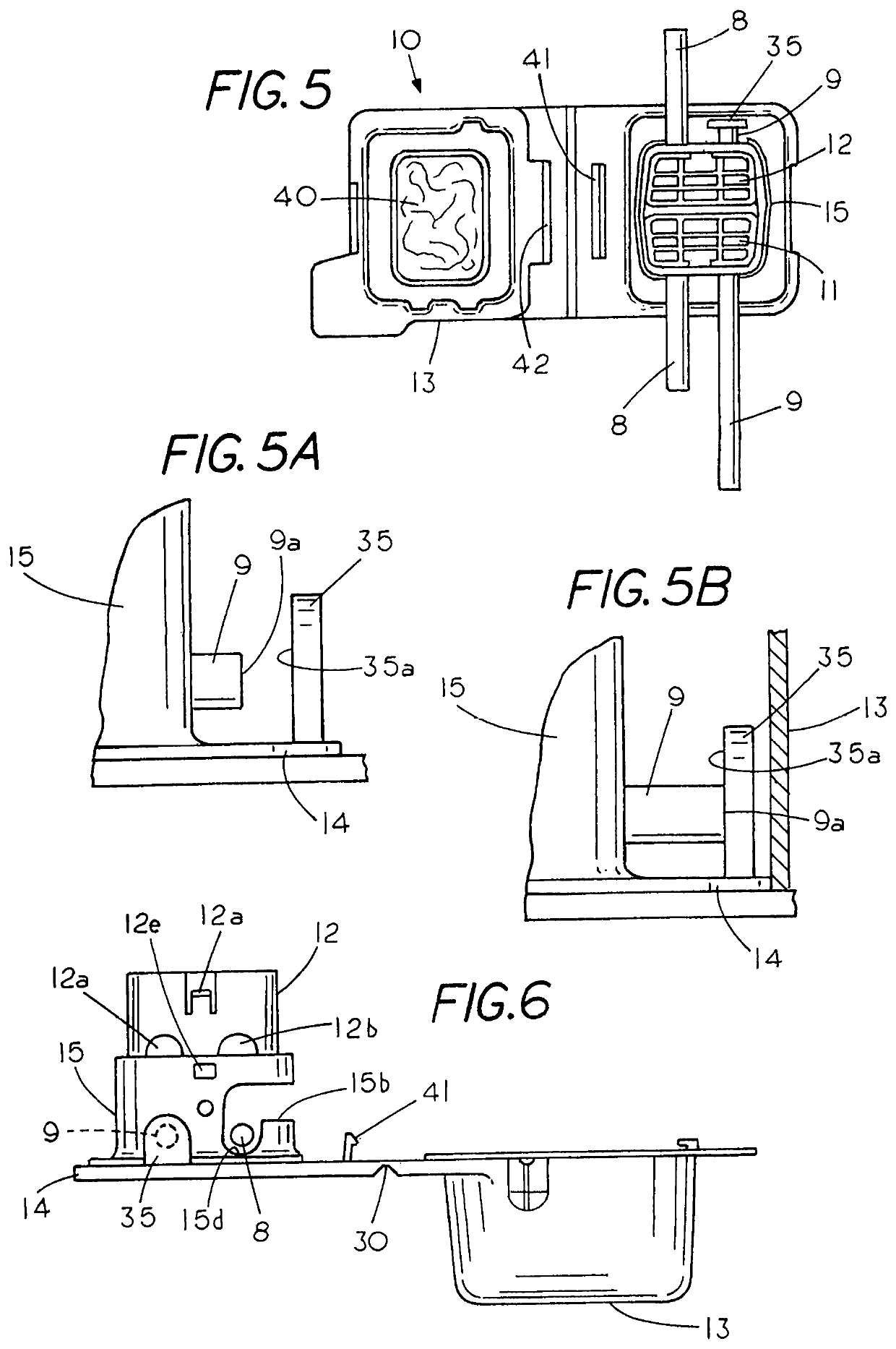

Crimp for a jack

InactiveUS6807728B2Two-part coupling devicesUnstripped conductor connection apparatusLateral regionTwisted pair

A crimping tool has a handle lever portion and a crimp portion with a press and a base housing. The base housing has a placement location with a recessed surface for engaging a jack and a recessed region for a cable. The base housing also has lateral regions that have frictionally engaging surface portions for clamping to wire ends. The press has a plunger and a housing with terminating blades for shearing excess wire from the cable when the tool engages a twisted pair cable to a jack. The blades cut the wires and the excess wire is discarded. The press and the base housing then disengage and the jack is removed from the tool with the cable in communication with the electrical contacts of the jack.

Owner:FOCUS STRATEGIES CAPITAL ADVISORS LLC +1

Cable terminating apparatus

ActiveUS7103968B2Contact member assembly/disassemblyUnstripped conductor connection apparatusComputer terminalElectric cables

Owner:COMMSCOPE TECH LLC

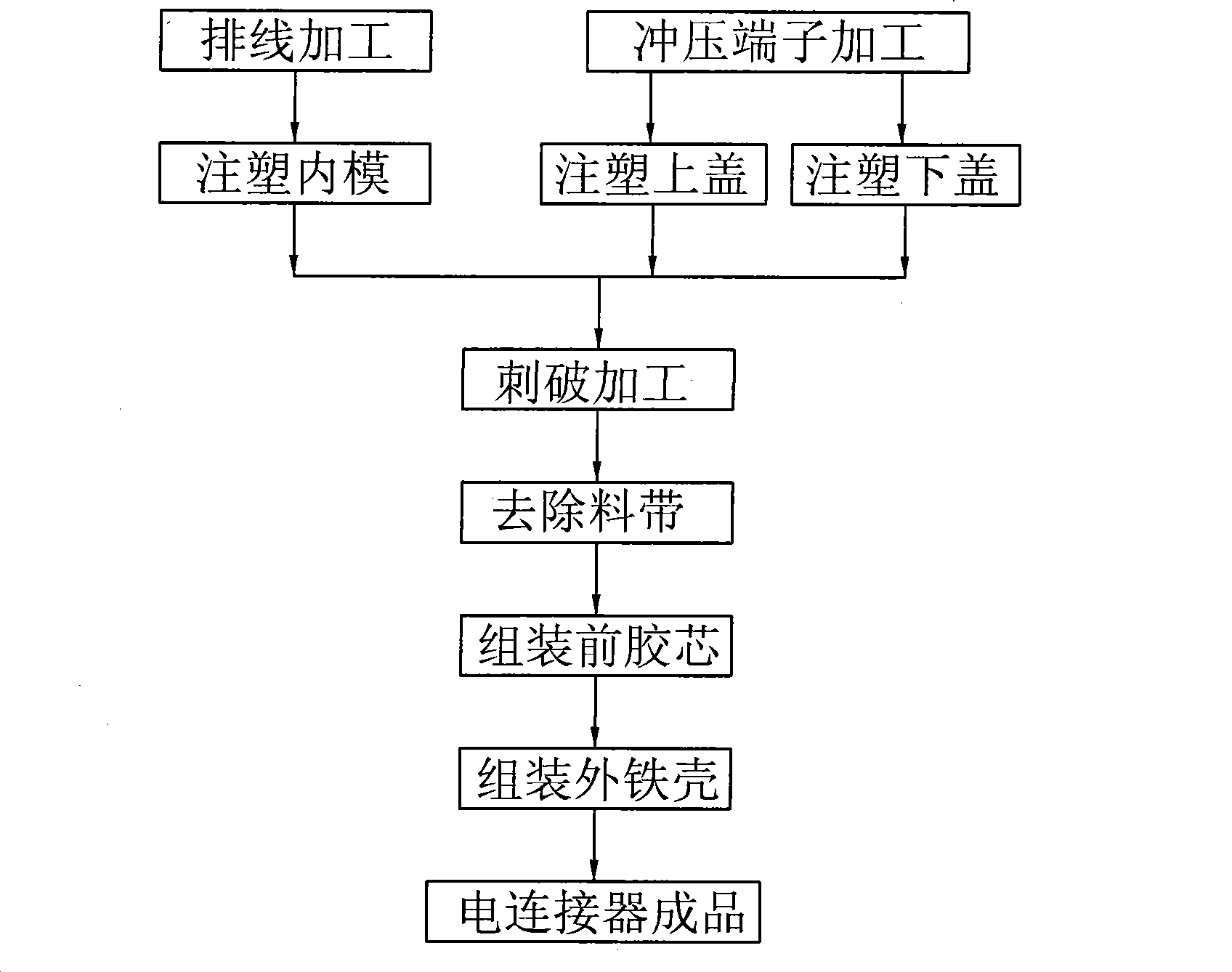

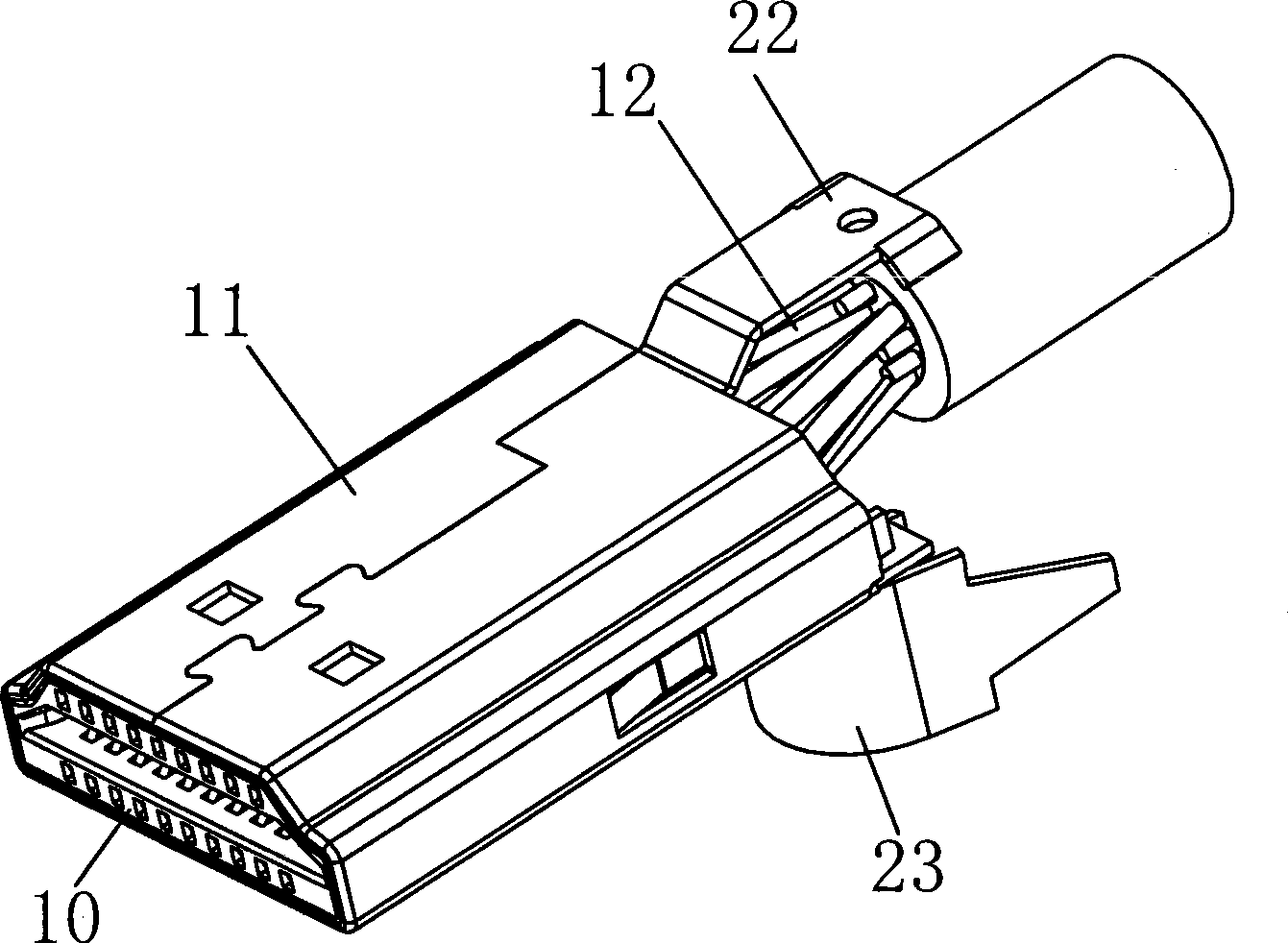

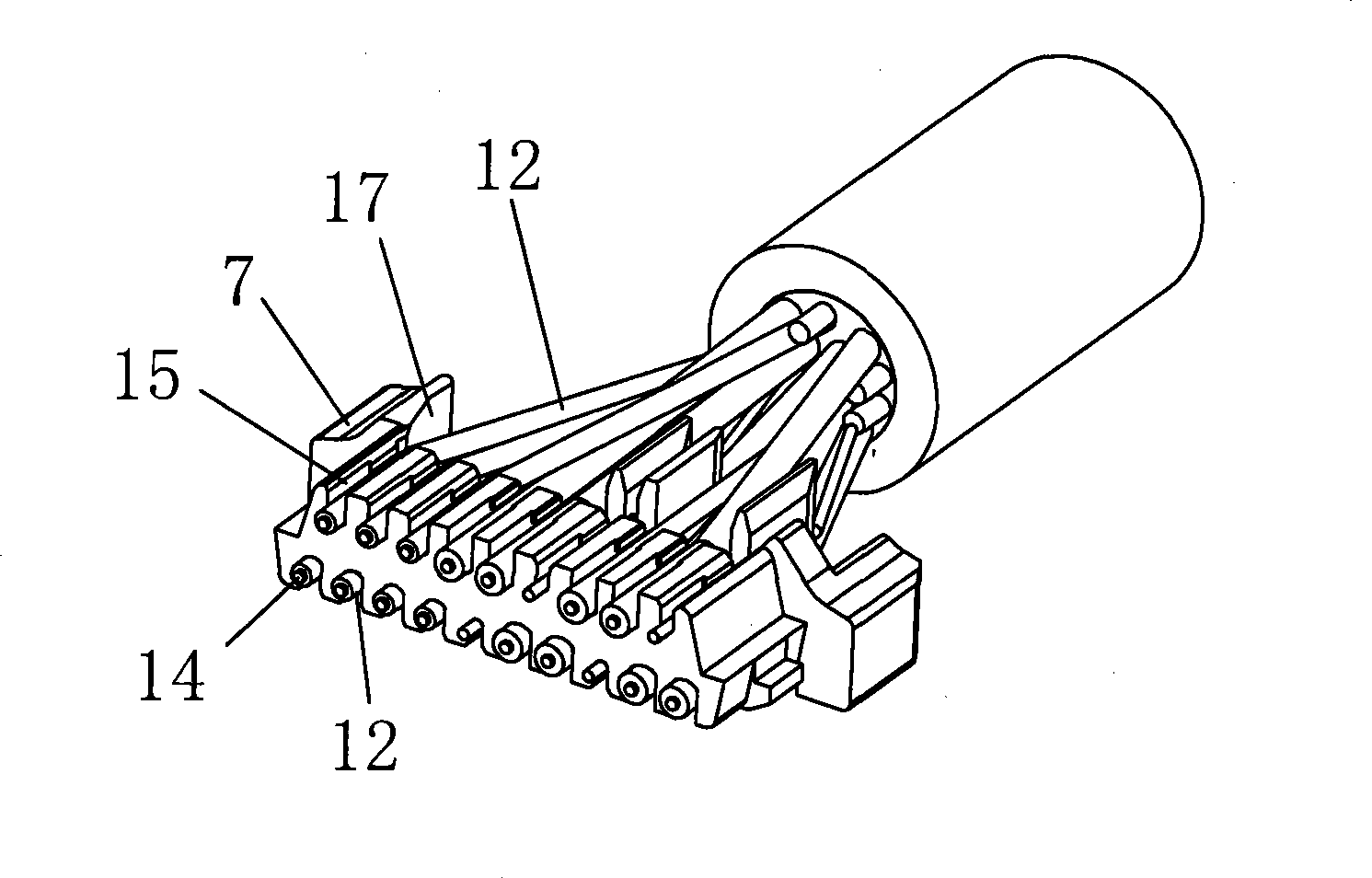

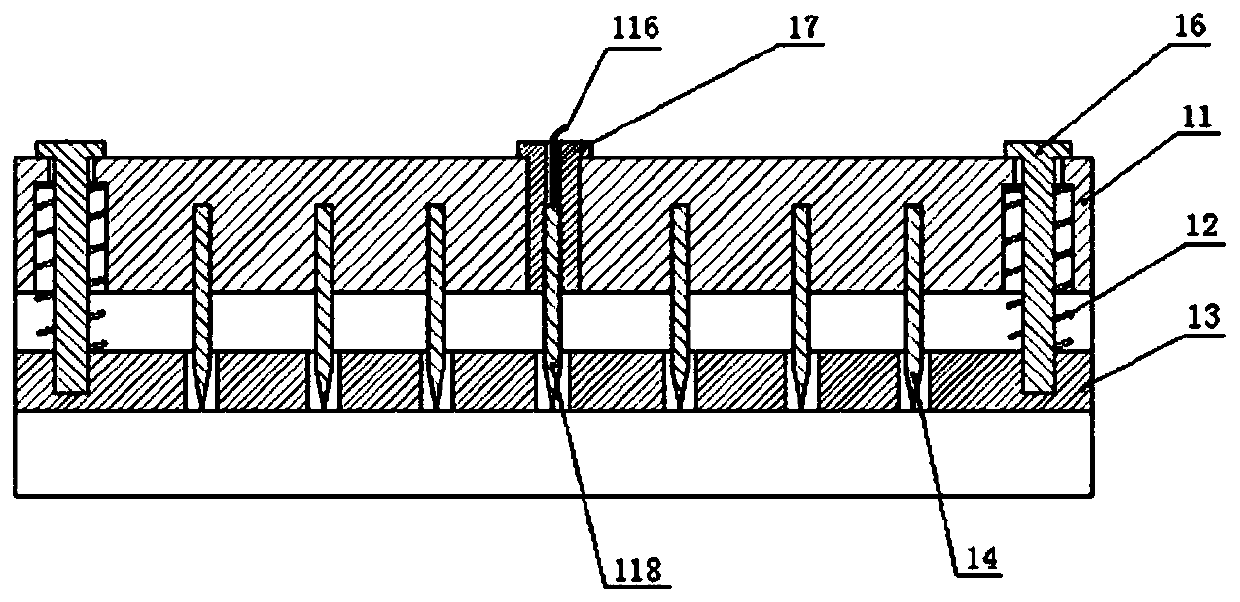

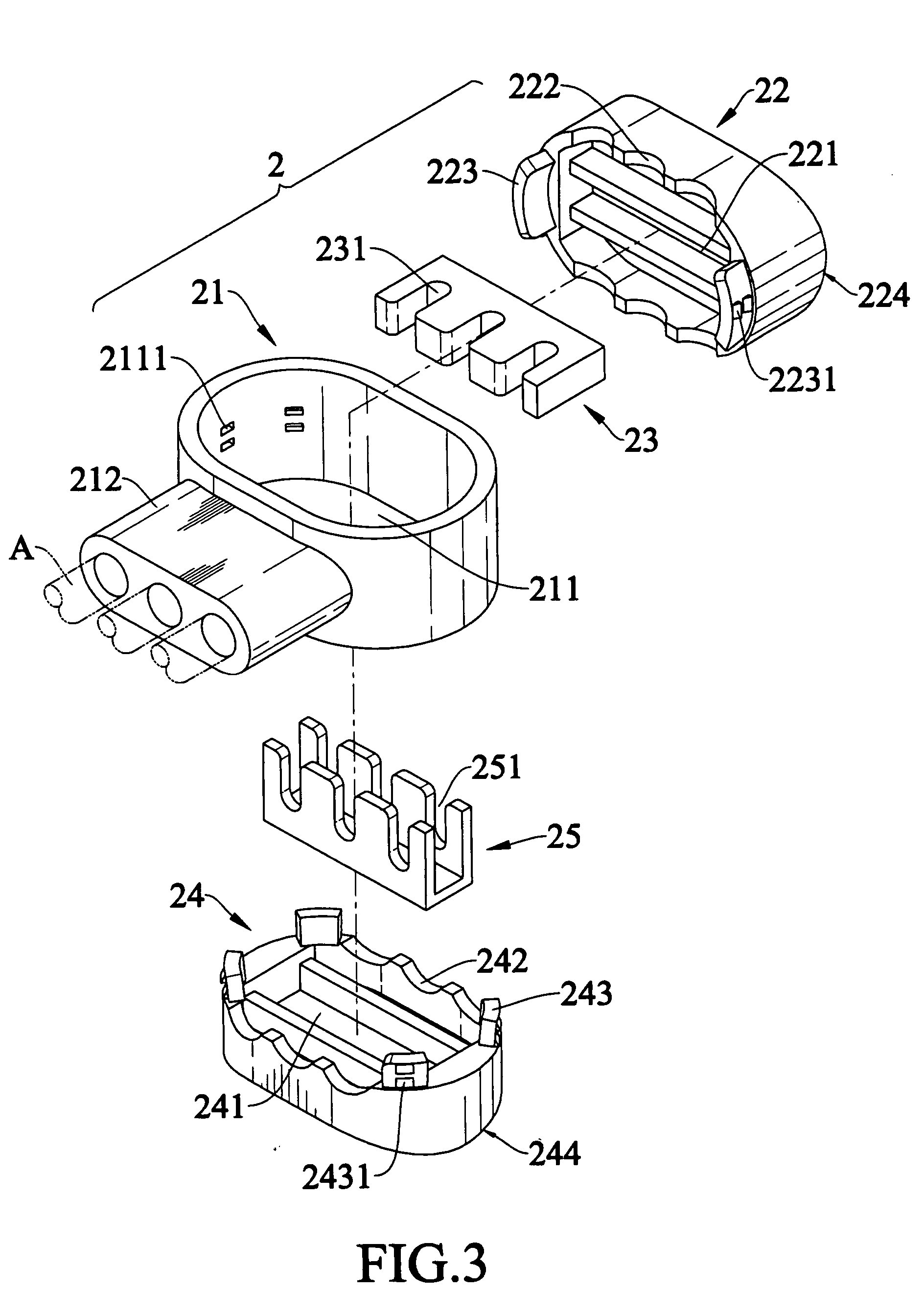

Puncture type terminal, electric connector and technique for producing the same

InactiveCN101465508AMiniaturizationAchieve thinningContact member manufacturingContact member cases/bases manufactureElectricityPunching

The invention relates to an electric connector and the technical field of processing technique, in particular to a puncture type terminal, an electric connector and a manufacturing technique thereof; the processing technique comprises the processing of punching terminals, the processing of wire arrangement, the injection molding of an upper cover and a lower cover, puncture processing, removing strip material, assembling a front rubber core and an outer iron shell; wherein, the upper cover and the lower cover are respectively molding-injected at the middle and rear parts of the corresponding arrayed terminals; the processing technique solves the problem that the existing electric connector can not solve: the contact is unstable and poor, the electrical impedance is high and the electric connector can not be miniaturized; at least two tip teeth, the tip ends of which are distributed in a staggering way, are formed on the electrical connecting part of the puncture type terminal, and the tip tooth is a pyramid shape, and a cambered surface is formed on the inner side surface of the tip tooth; the tip tooth reduces the electrical impedance of the electric connector; the upper cover and the lower cover of the puncture type HDMI electric connector are respectively formed on the arrayed terminals, and the puncture type tip tooth is formed at the rear end of the terminal; the electric connector is more miniaturized and thinned, thus greatly improving the performance of the electric connector.

Owner:YONG TAI ELECTRONICSDONGGUAN LTD

IDC adapter

InactiveUS6319047B1Coupling device detailsTwo-part coupling devicesEngineeringInsulation-displacement connector

An insulation displacement connector type adapter has a housing, a circuit board, two IDCs received in the housing and a cover to enclose the IDCs inside the housing. The two IDCs are vertical with respect to the circuit when the two IDCs are securely engaged with the circuit board, such that the center of gravity of the adapter falls within an area covered by the housing.

Owner:LIANG YU HO

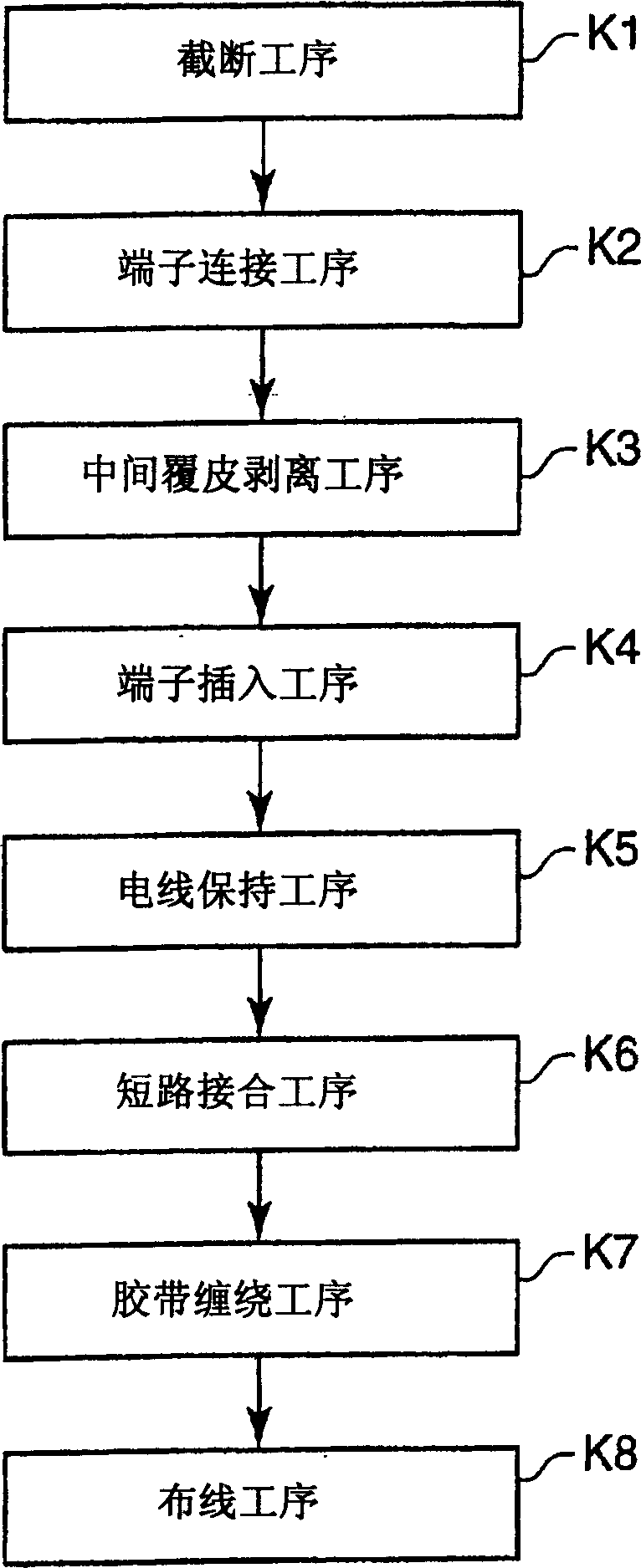

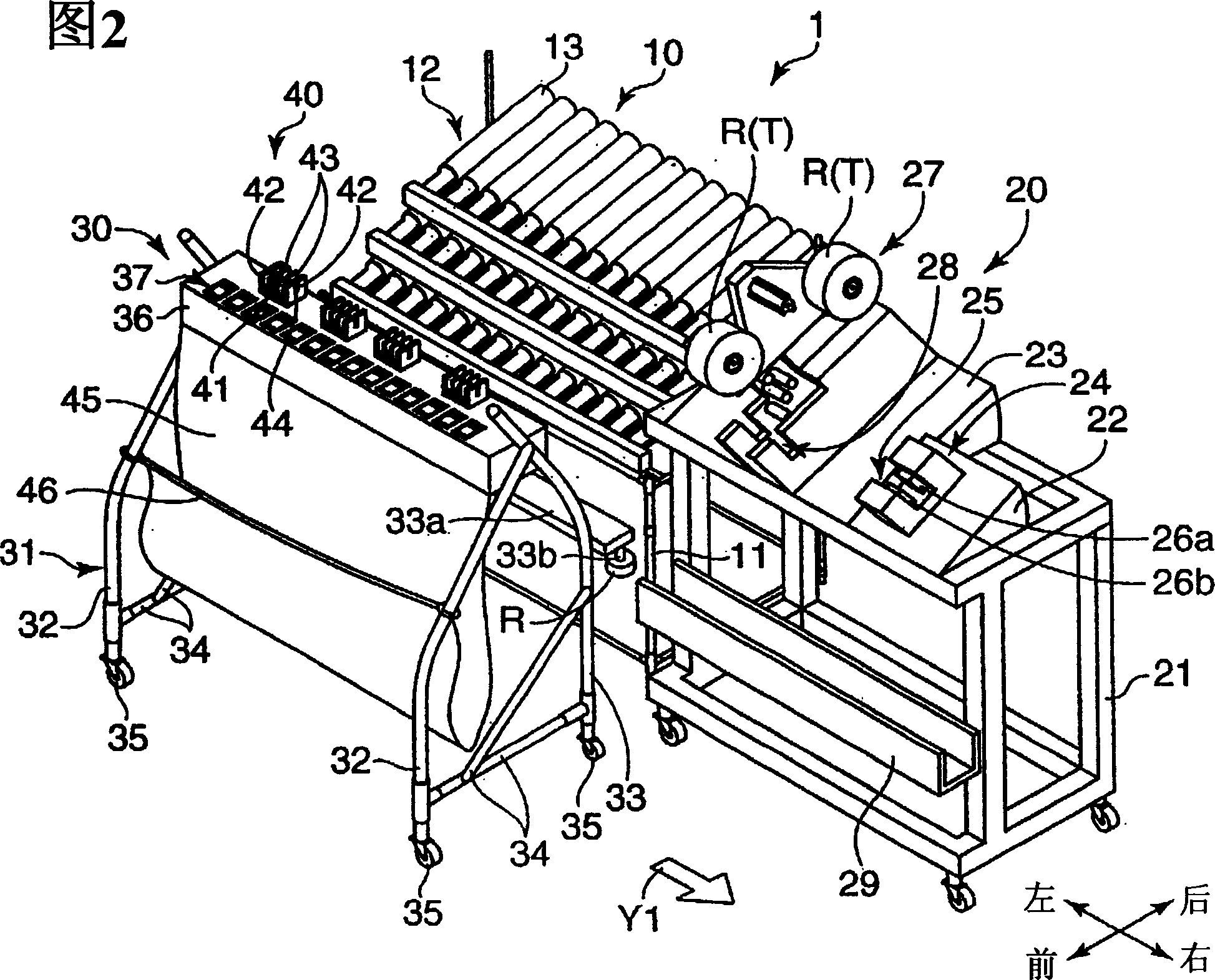

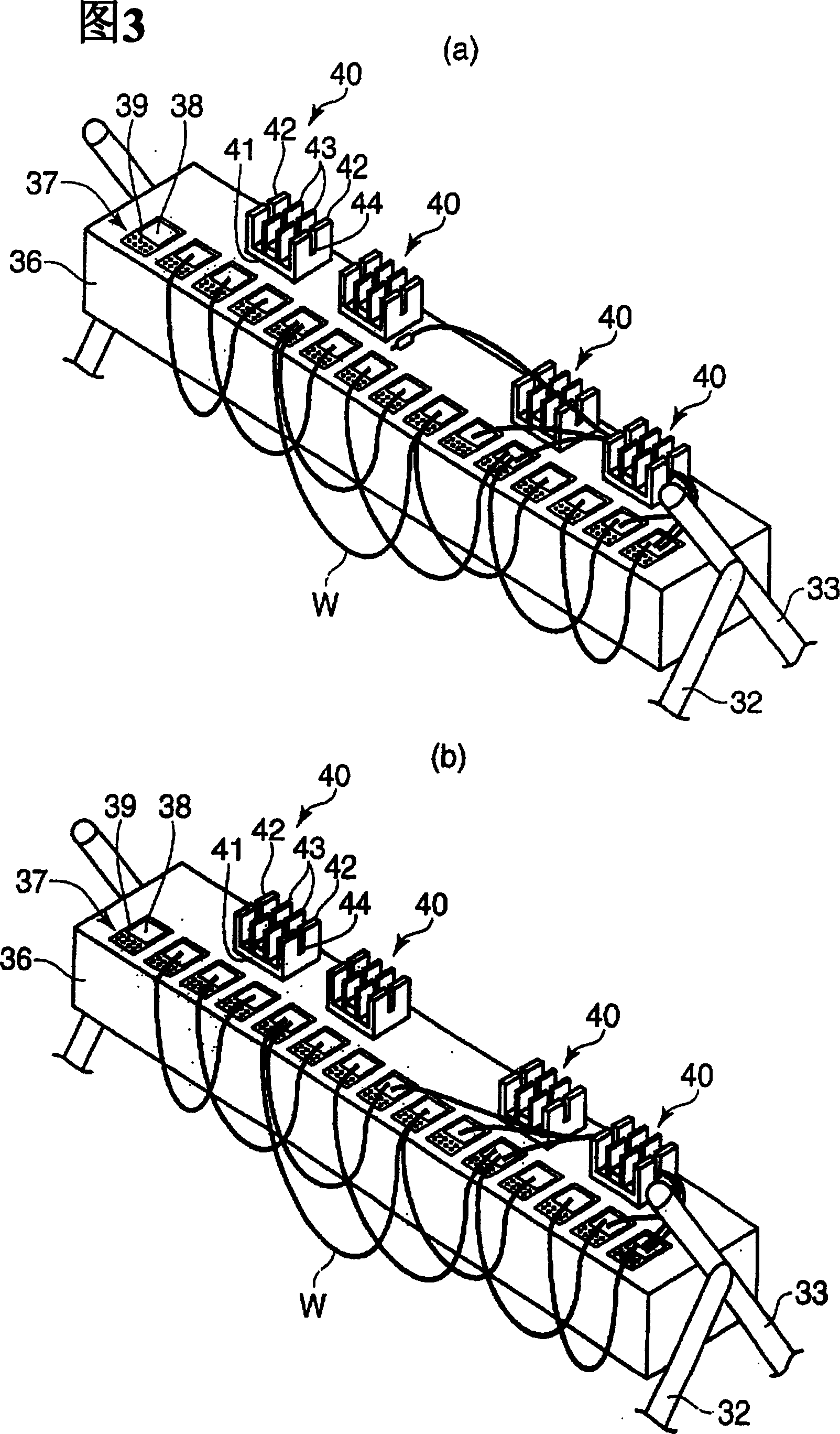

Line pencil manufacturing method and manufacturing device

InactiveCN1551427AReduce the number of rootsLow costContact member assembly/disassemblyUnstripped conductor connection apparatusEngineeringElectric wire

Provided is a manufacturing method and a manufacturing device for wire harness capable of improving the workability and reducing the cost. The manufacturing method of wire harness is provided with a cutting process K1 adjusting the length of covered wire and cutting it, a terminal connection process K2 connecting a terminal to at least one end part of the covered wire after cutting, a terminal insertion process K4 holding a housing of a connector on a working table, and inserting the corresponding terminal of the covered wire into the housing, a wire holding process K5 holding the middle part of a covered wire out of connected covered wires being connected, to which a short-circuit bonding is to be applied while superposing it on a wire holding part on the working table, a short-circuit connection process K6 short-circuiting the middle part of the covered wire being held, and a wiring process K8 moving the connection body of the covered wire processed at the process K7 from the working table onto a drawing board and wiring it.

Owner:SUMITOMO WIRING SYST LTD

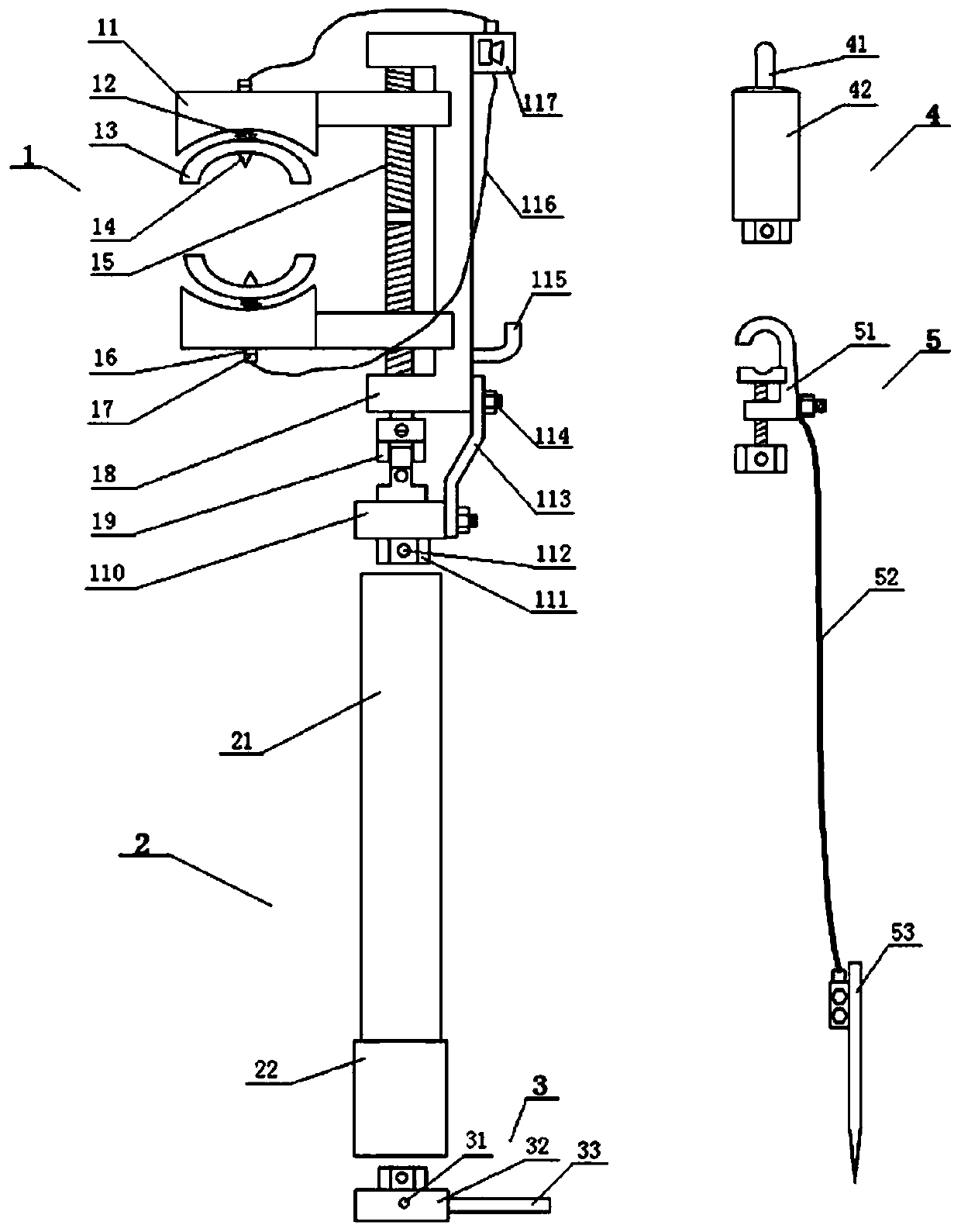

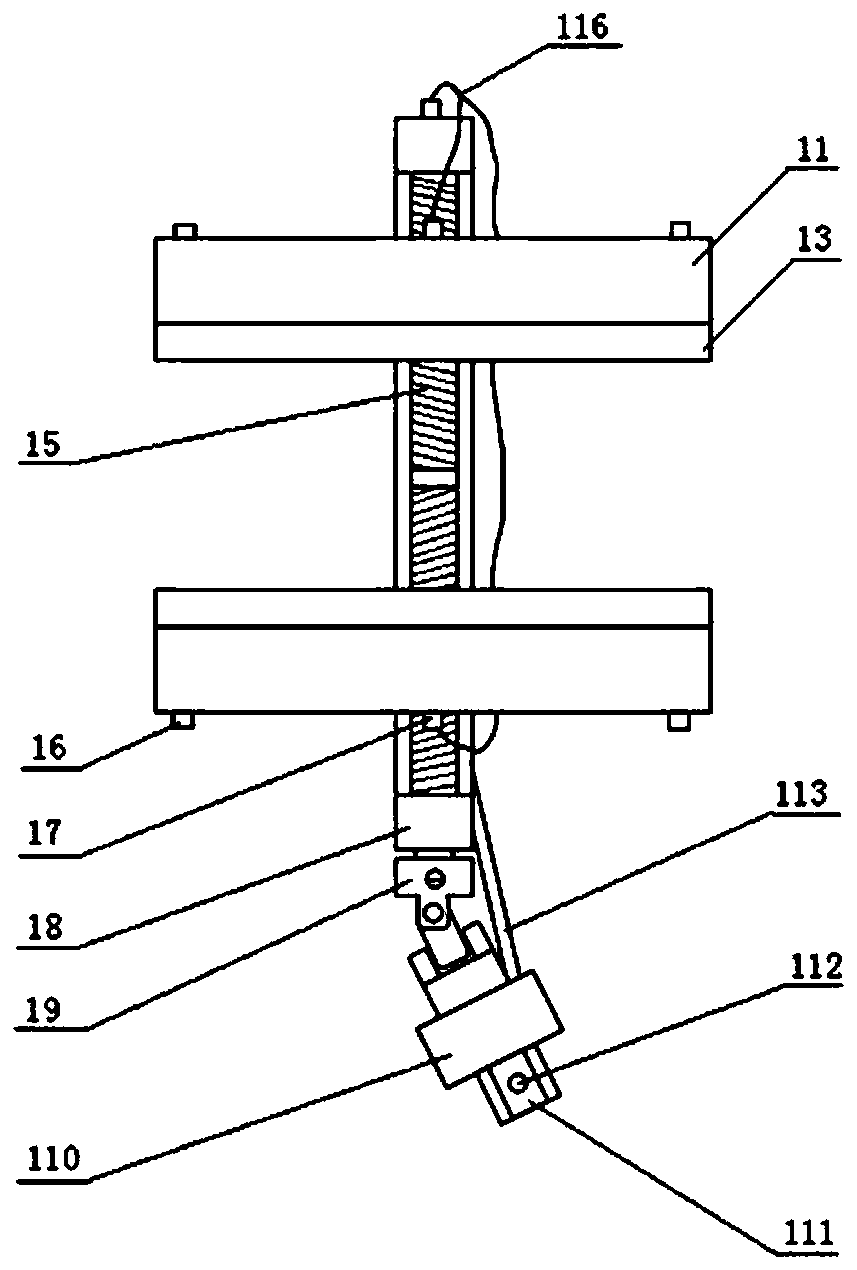

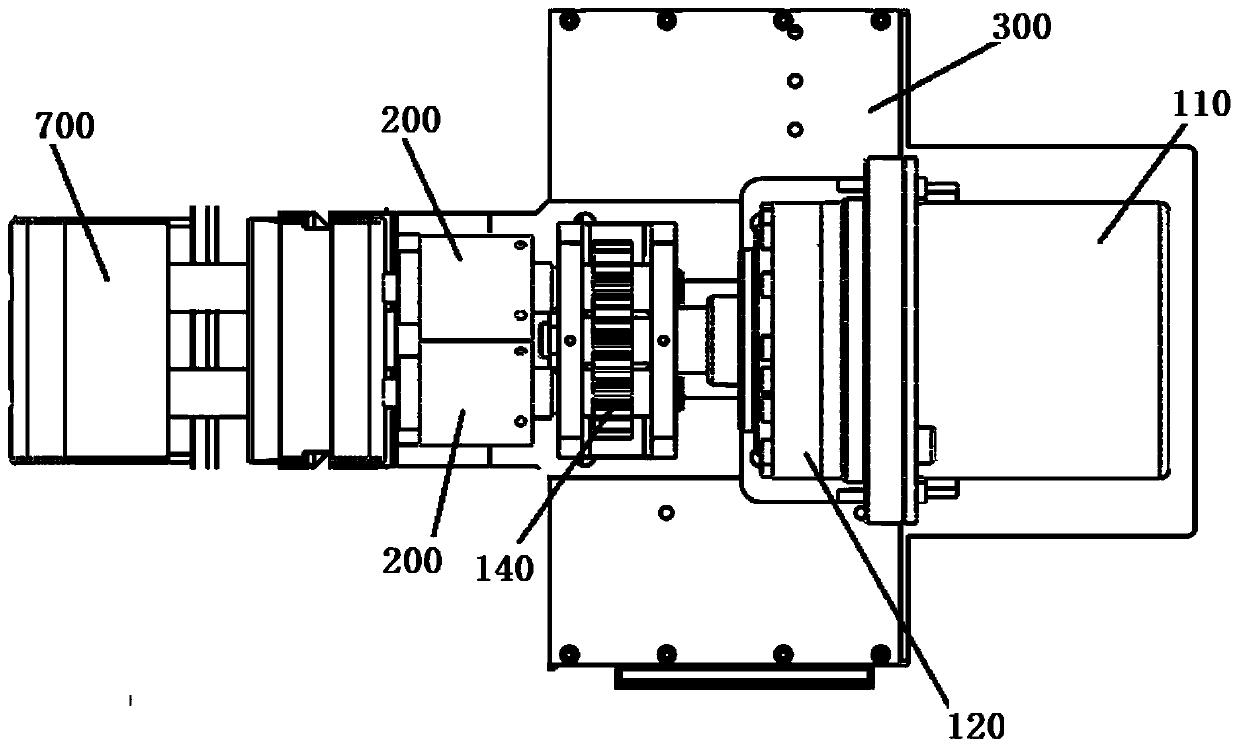

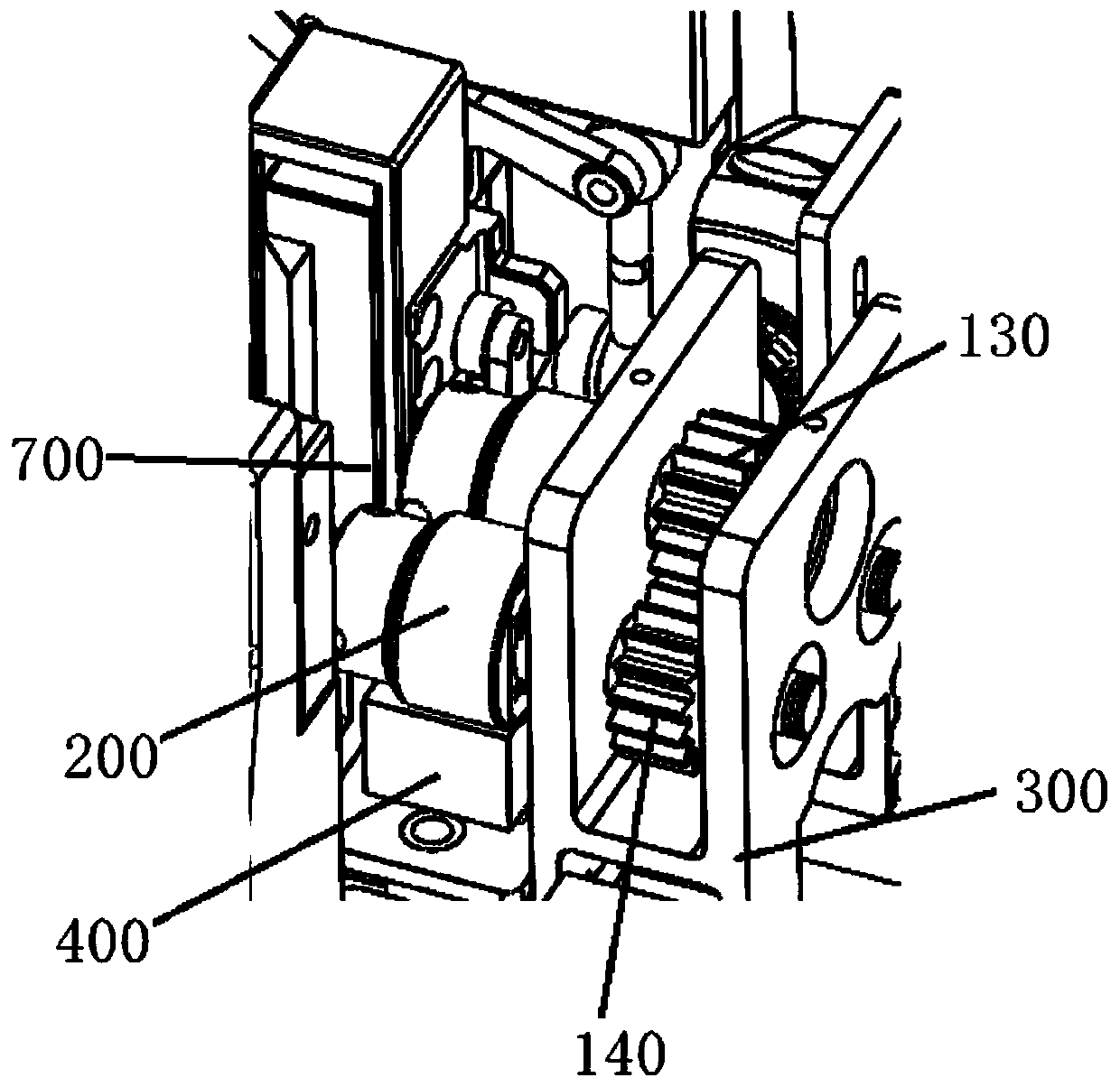

Power distribution network electrified automatic wiring tool set and robot

ActiveCN110071406AImplement automatic connectionReduce labor intensityUnstripped conductor connection apparatusClip conductor connectionLine BreakDistribution grid

The invention relates to the technical field of wiring devices, in particular to a power distribution network electrified automatic wiring tool set and a robot. The automatic wiring tool set comprisesa frame body, a clamping mechanism, a wire clamp tightening mechanism, main line fixing mechanisms, a branch line fixing mechanism, a line breaking mechanism, a controller and induction mechanisms, wherein the clamping mechanism is fixedly arranged on the frame body and is used for clamping a wiring mechanism and has a clamping end for clamping the wiring mechanism; the wire clamp tightening mechanism is arranged on a supporting frame corresponding to the clamping mechanism, and is used for driving the wiring mechanism to act to enable main lines and a branch line to be connected; the main line fixing mechanisms and a branch line fixing mechanism are arranged on the frame body corresponding to the wiring mechanism separately and are used for fixing the main lines and the branch line; theline breaking mechanism is arranged on the frame body corresponding to the wiring mechanism, and is used for cutting off redundant branch lines; the controller is connected with driving mechanisms onthe clamping mechanism, the wire clamp tightening mechanism, the main line fixing mechanisms, the branch line fixing mechanism and the line breaking mechanism separately; by controlling the driving mechanisms, the actions of the clamping mechanism, the wire clamp tightening mechanism, the main line fixing mechanisms and the branch line fixing mechanism can be controlled; and the induction mechanisms are in signal connection with the controller.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

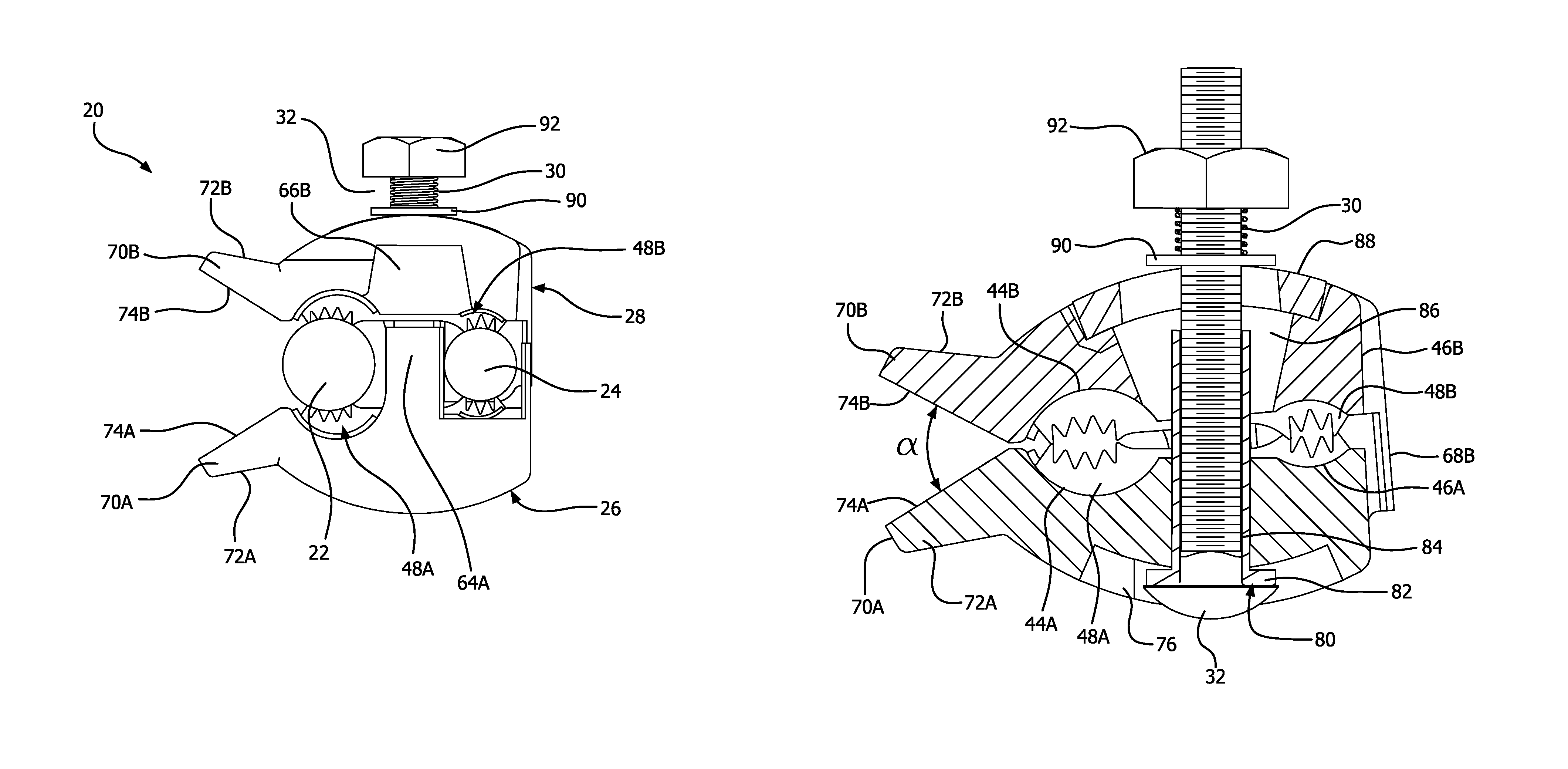

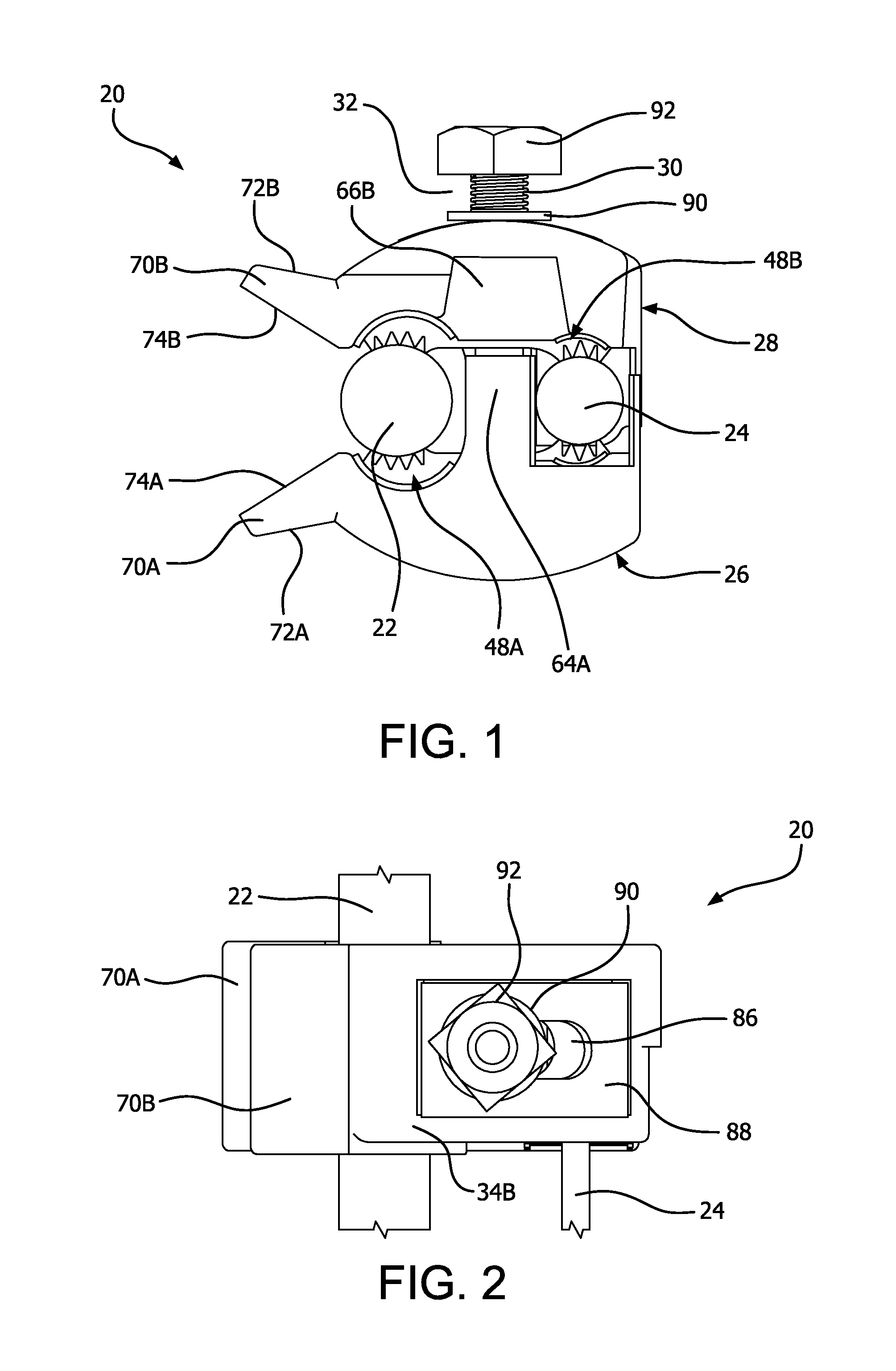

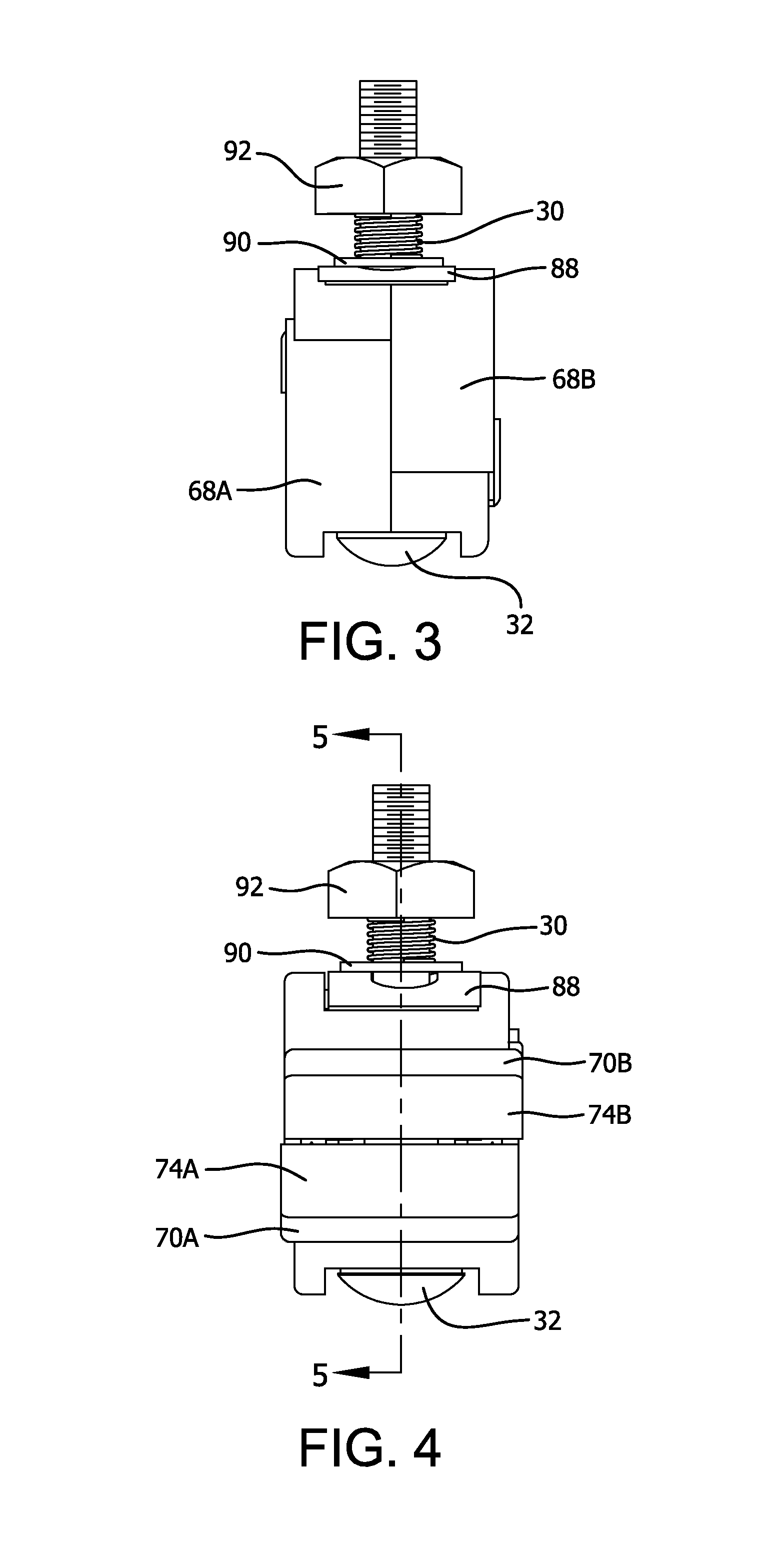

Spring loaded insulation piercing electrical connector

ActiveUS9577351B2Contact member manufacturingUnstripped conductor connection apparatusElectrical connectorFastener

An electrical connector includes first and second pads. The first pad includes first and second grooves and the second pad includes third fourth grooves. A first insulation displacing contact extends from the first groove to the second groove. A second insulation displacing contact extends from the third groove to the fourth groove. The first and second pads are connected by a mechanical fastener. When the first and second pads are connected the first groove aligns with the third groove and the second groove aligns with the fourth groove.

Owner:HUBBELL INC

Wire end insert tool with replaceable cutting blade

ActiveUS7096564B2Improve actionIncrease stiffnessUnstripped conductor connection apparatusOther manufacturing equipments/toolsEngineeringMechanical engineering

A tool assembly includes an elongated metal tool body for forcibly inserting the end of an insulated wire into a telephone connector of the insulation displacing type, and having a separate and replaceable cutting blade removably attached to the tool body for cutting off the then protruding end of the insulated wire after electrically conductive engagememnt of the wire with the blades of the connector has been achieved.

Owner:SULLSTAR TECH

Cable terminating apparatus and method

Owner:TE CONNECTIVITY CORP

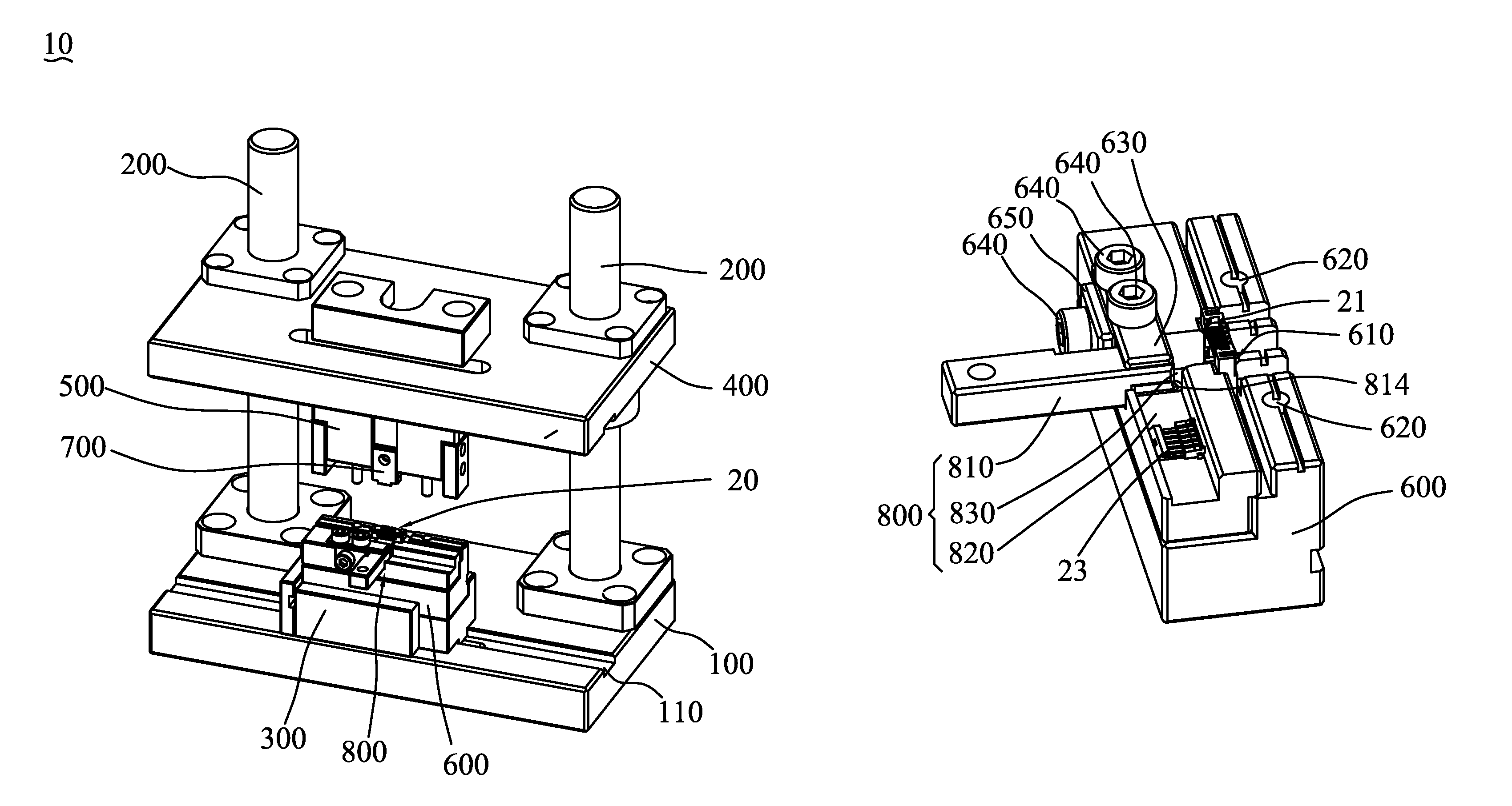

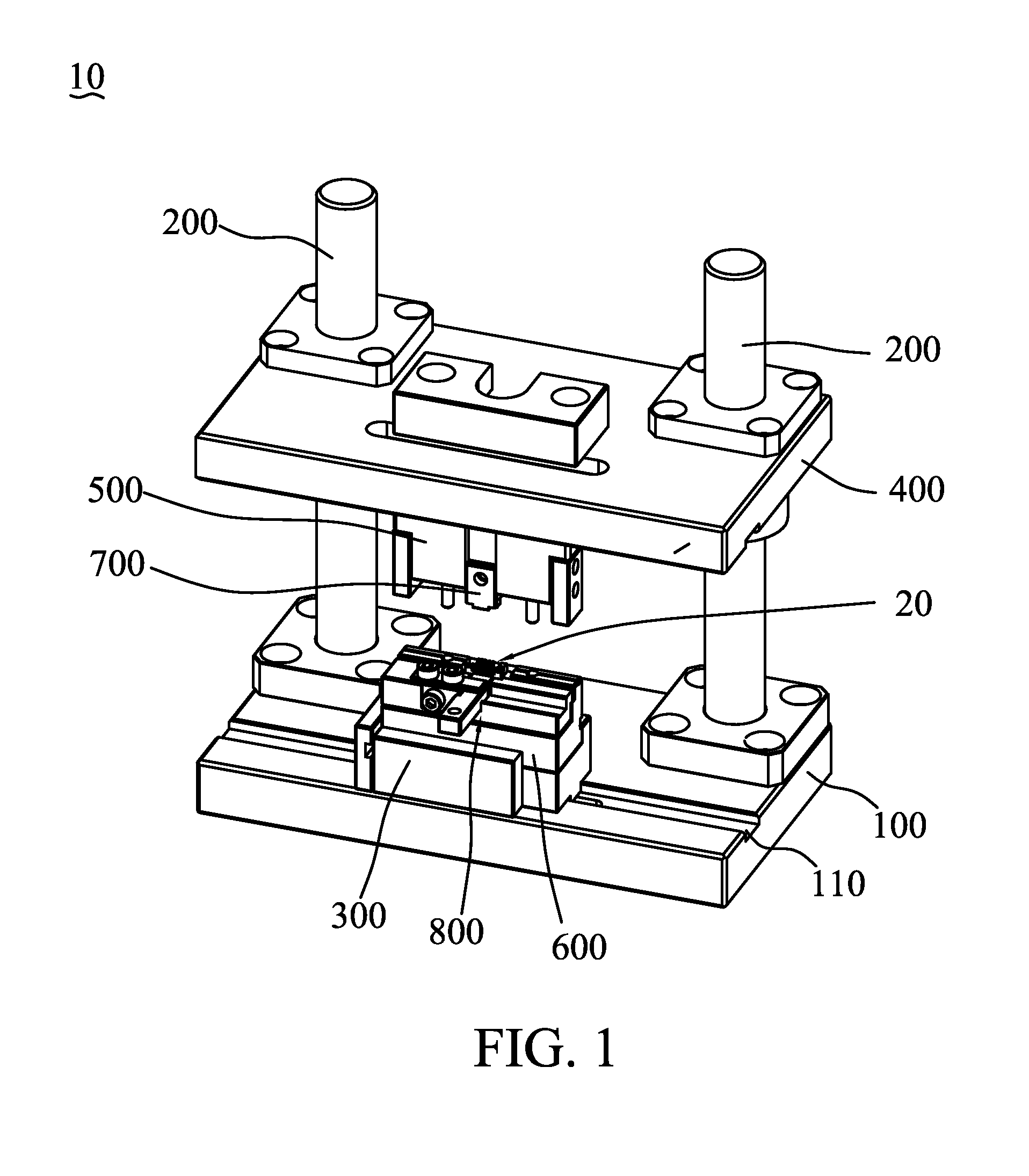

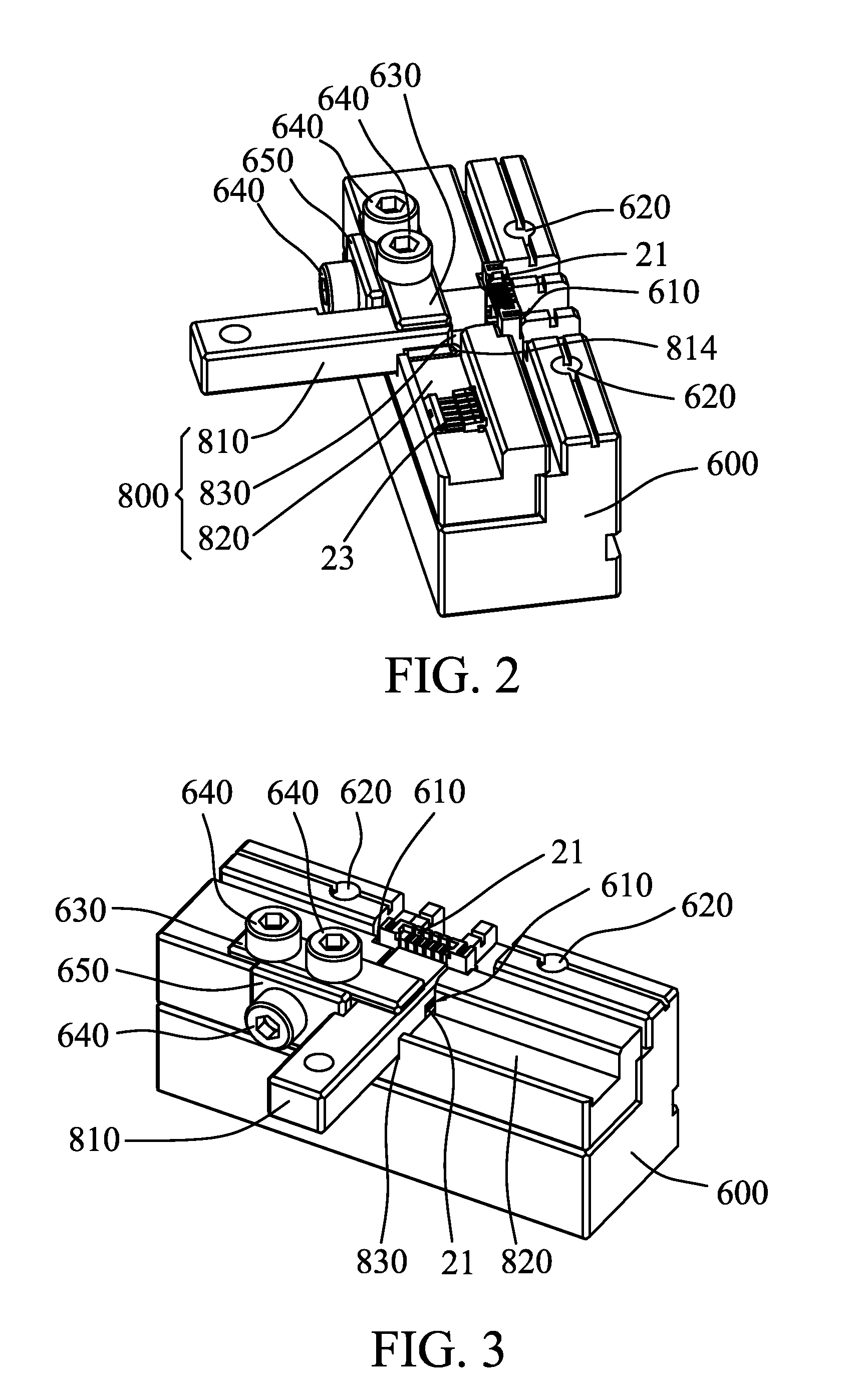

Flexible printed circuit connector assembling fixture

InactiveUS8141237B1Easy to assembleReduce laborWorkpiece holdersContact member assembly/disassemblyEngineeringMechanical engineering

A flexible printed circuit (FPC) connector assembling fixture is provided for assembling an FPC connector. The assembling fixture includes a base that is set horizontally. A lower slidable carriage is slidably coupled to the base. Upper and lower molds are respectively and rotatably coupled to an upper slidable carriage and the lower slidable carriage. A terminal fitting mechanism and a cover mounting mechanism are respectively mounted to the upper and lower molds. Guide posts are mounted to the base. The upper mold is slidably coupled to the base with the guide posts. The lower mold forms an accommodation chamber. The cover mounting mechanism includes a push rod and first and second slide channels. The second slide channel is in communication with the accommodation chamber and the first slide channel. The push rod is received in and slidably coupled to the second slide channel.

Owner:CHENG UEI PRECISION IND CO LTD

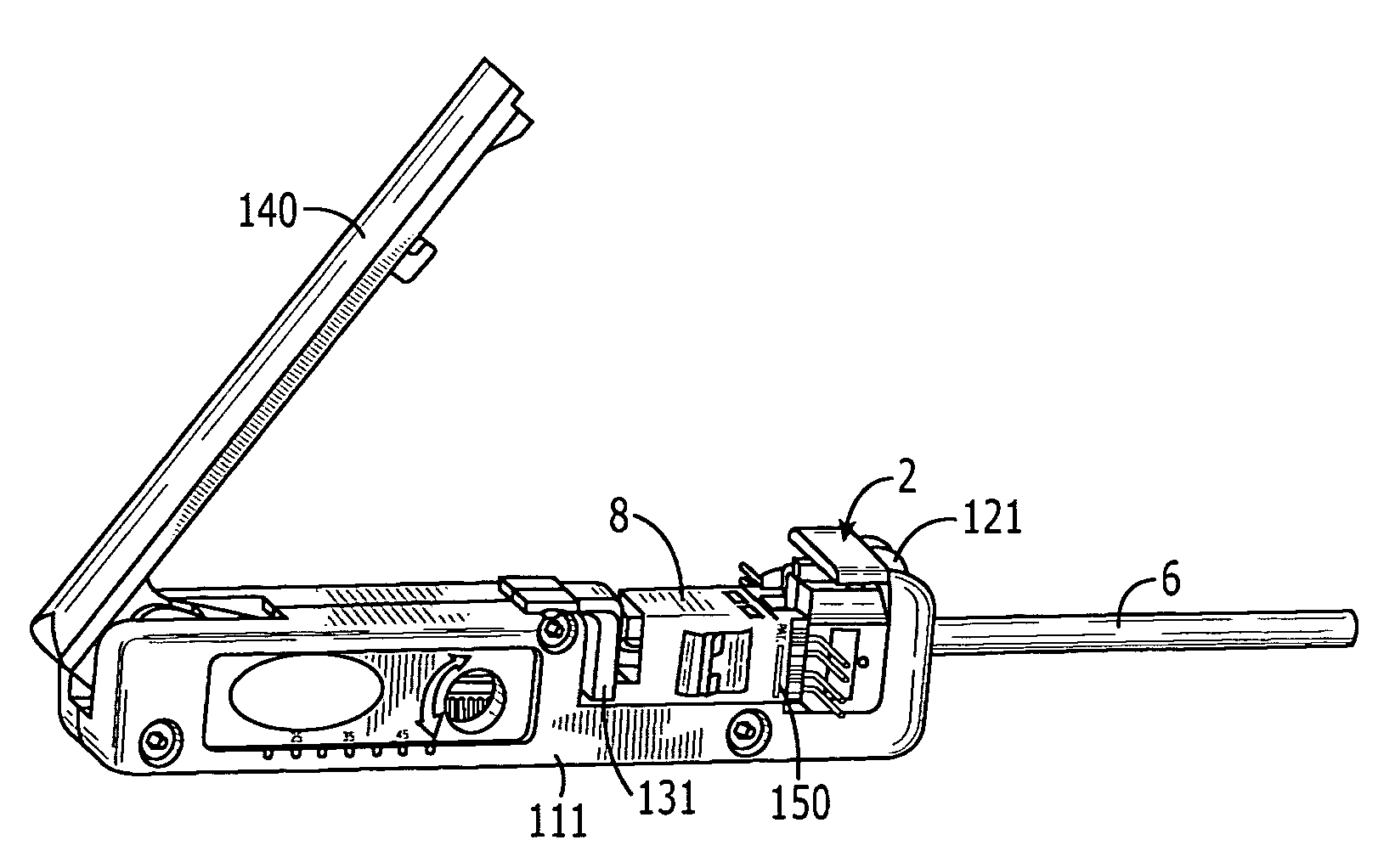

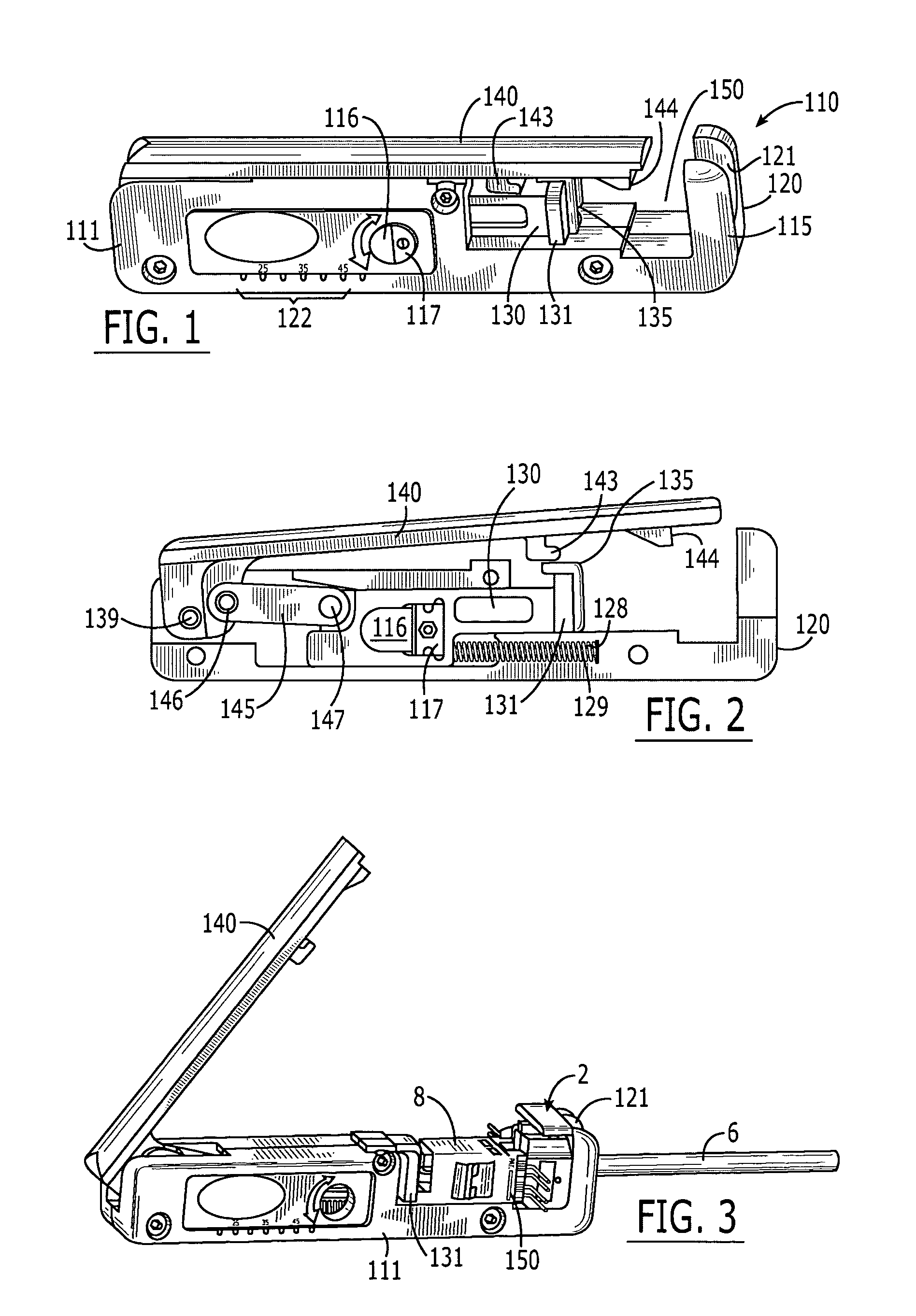

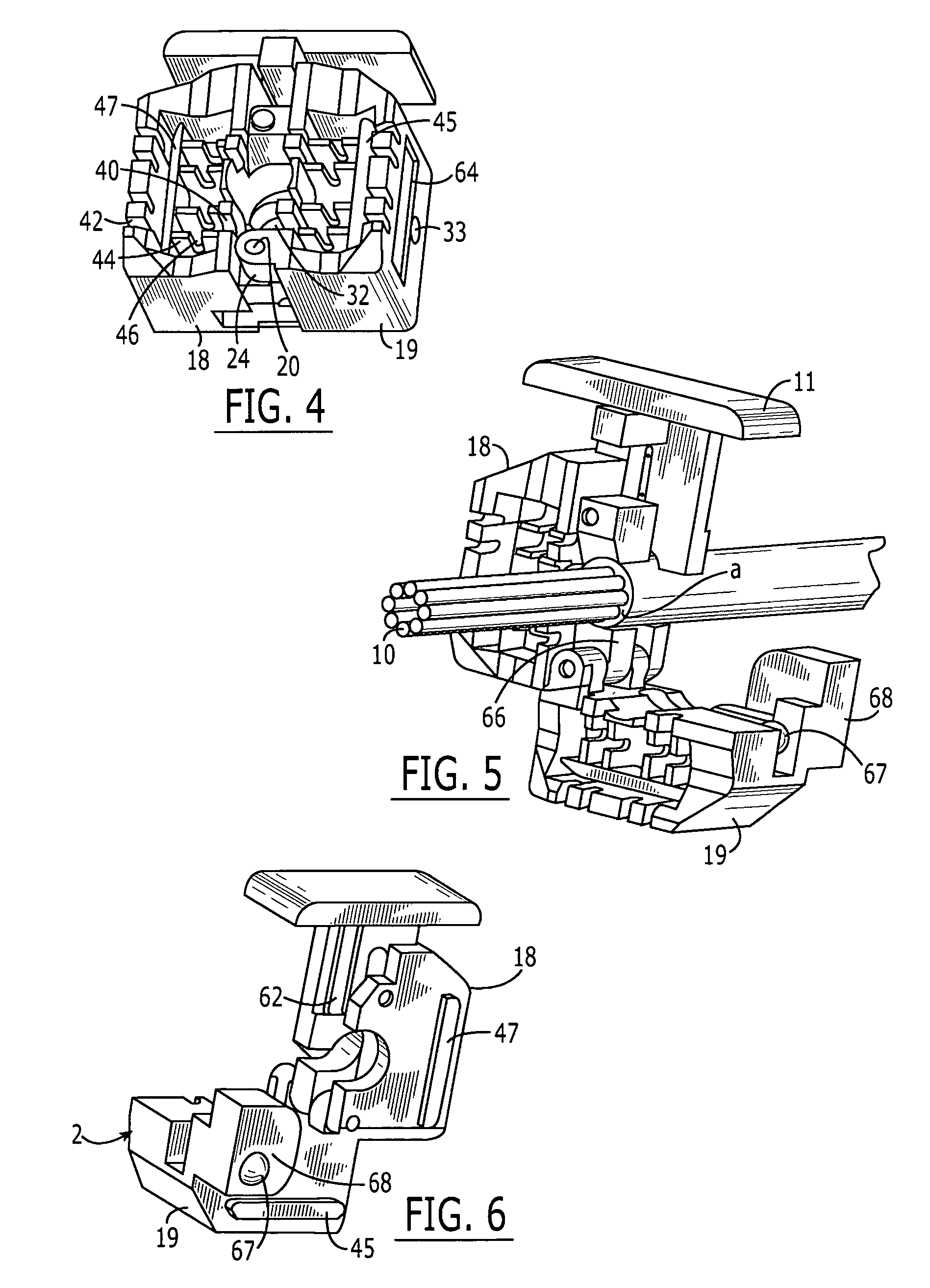

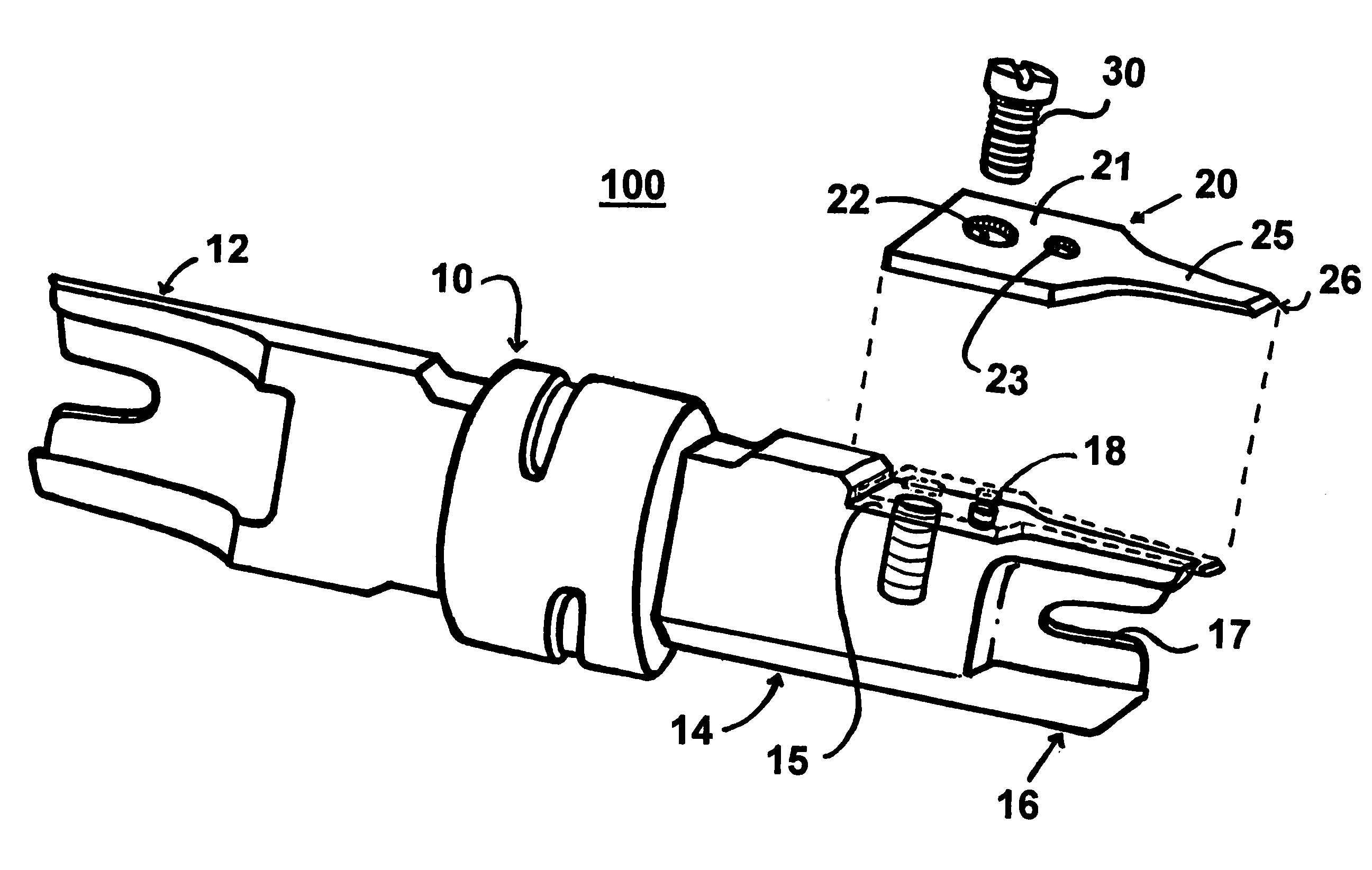

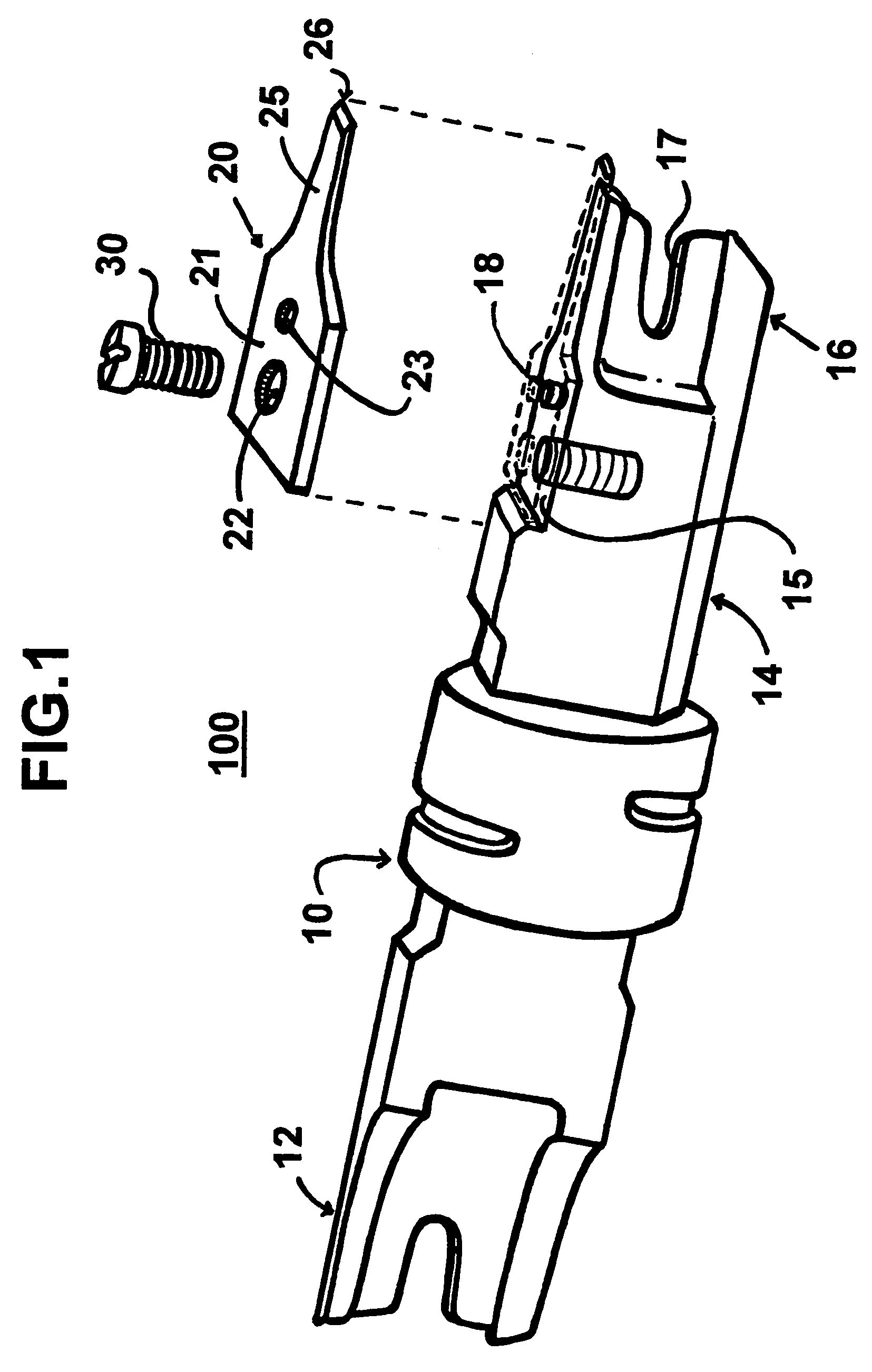

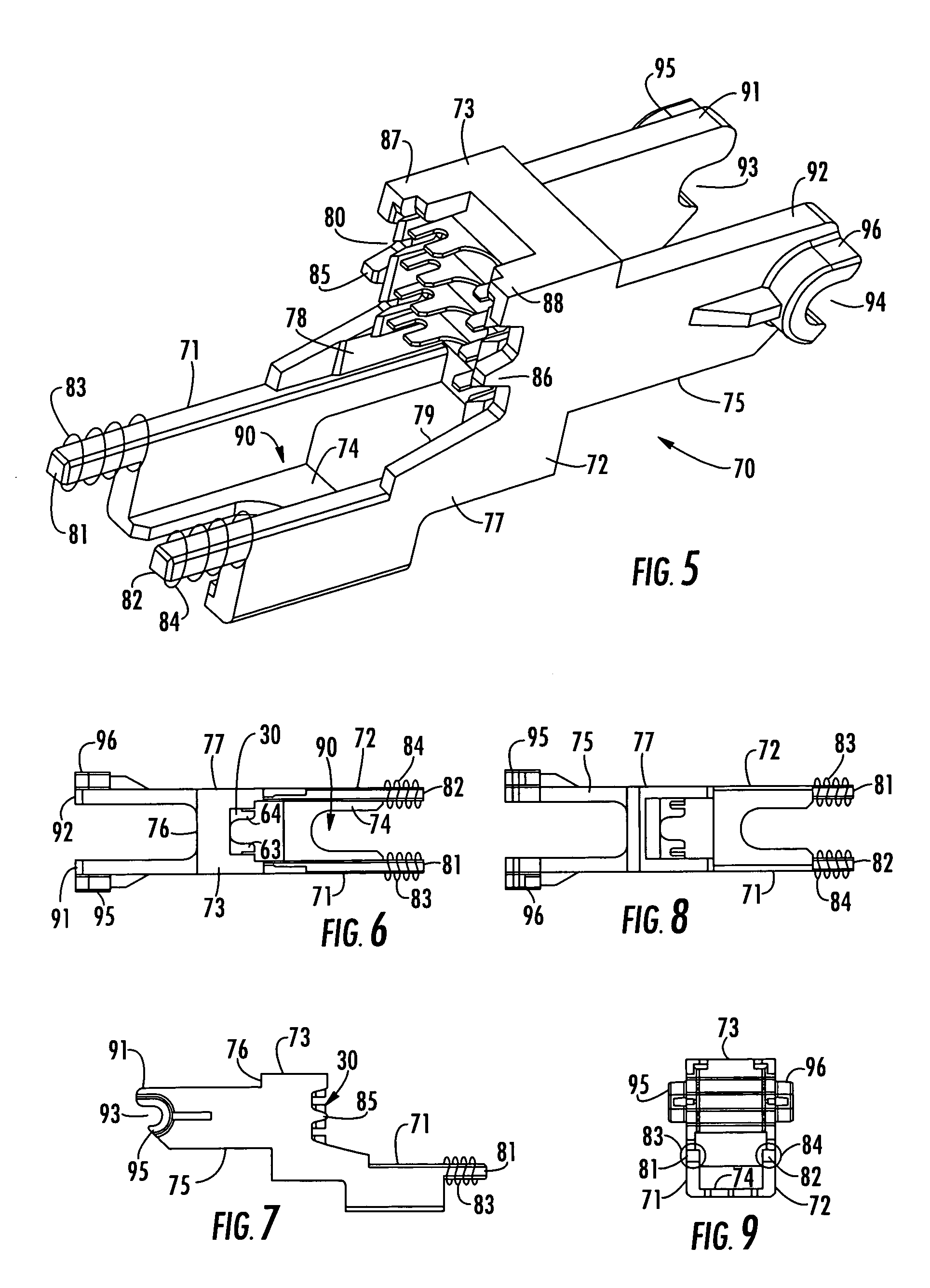

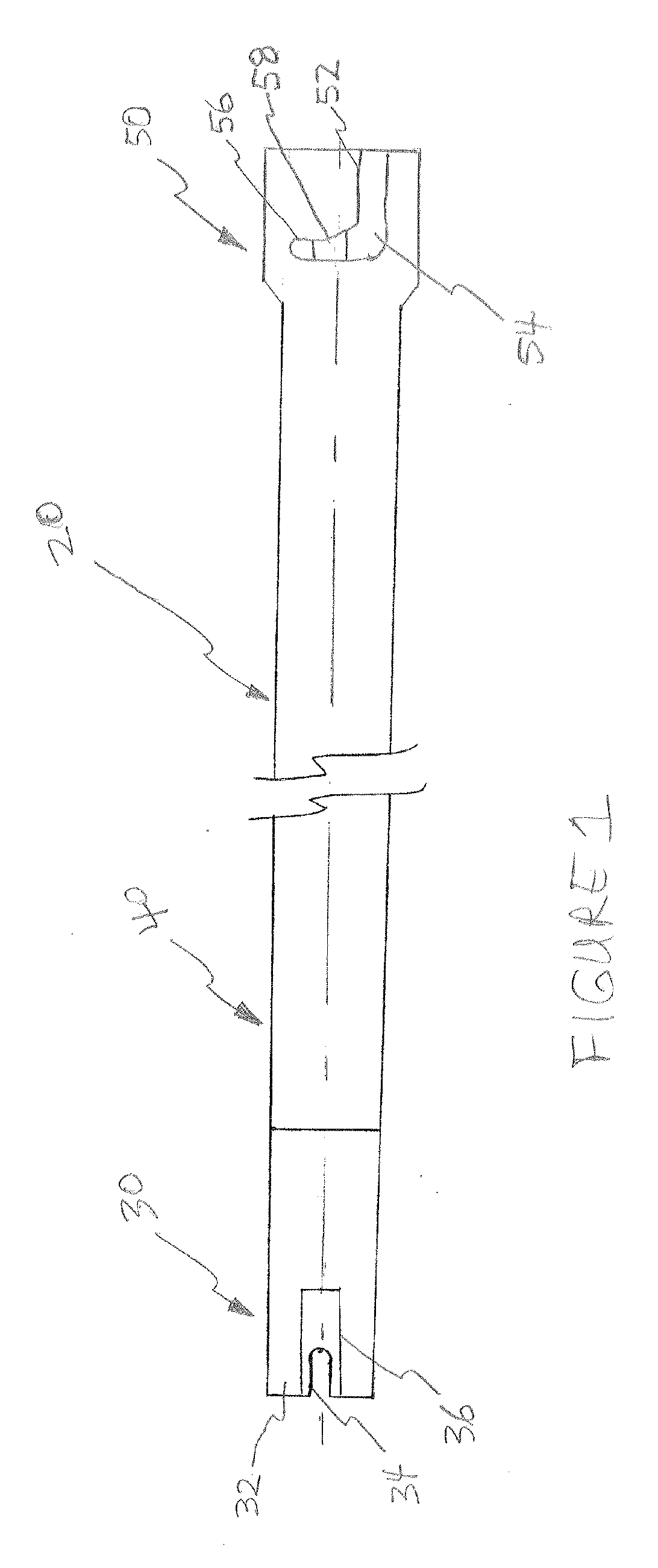

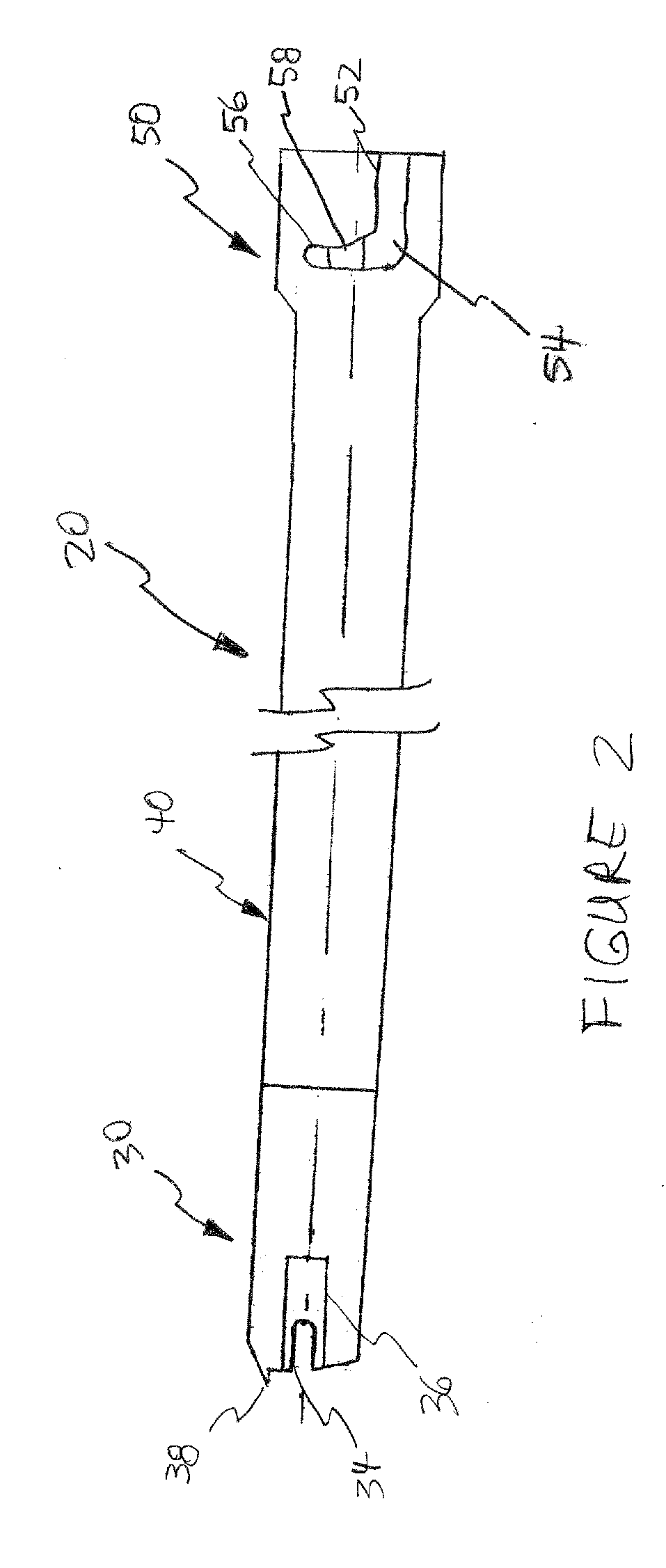

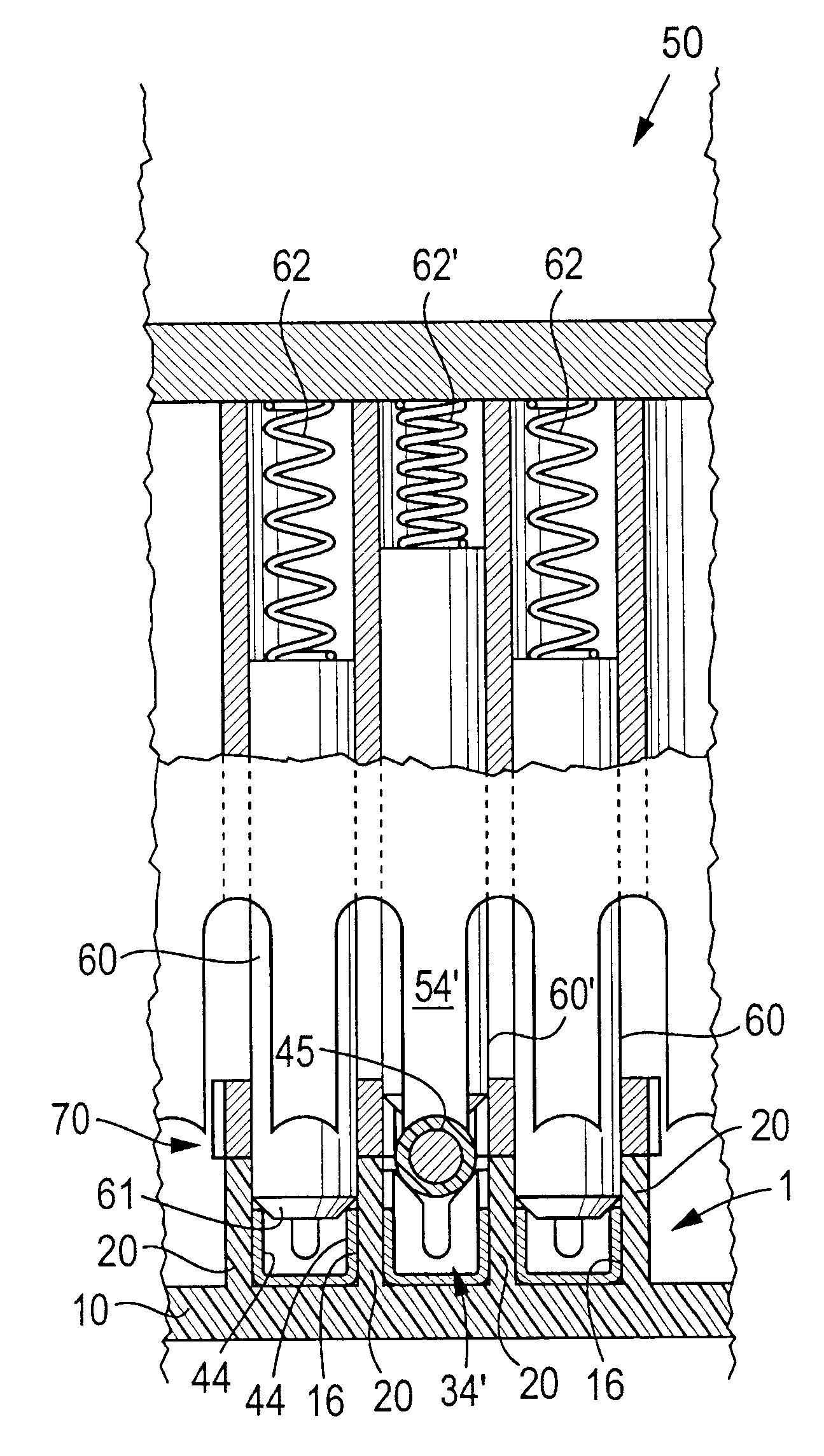

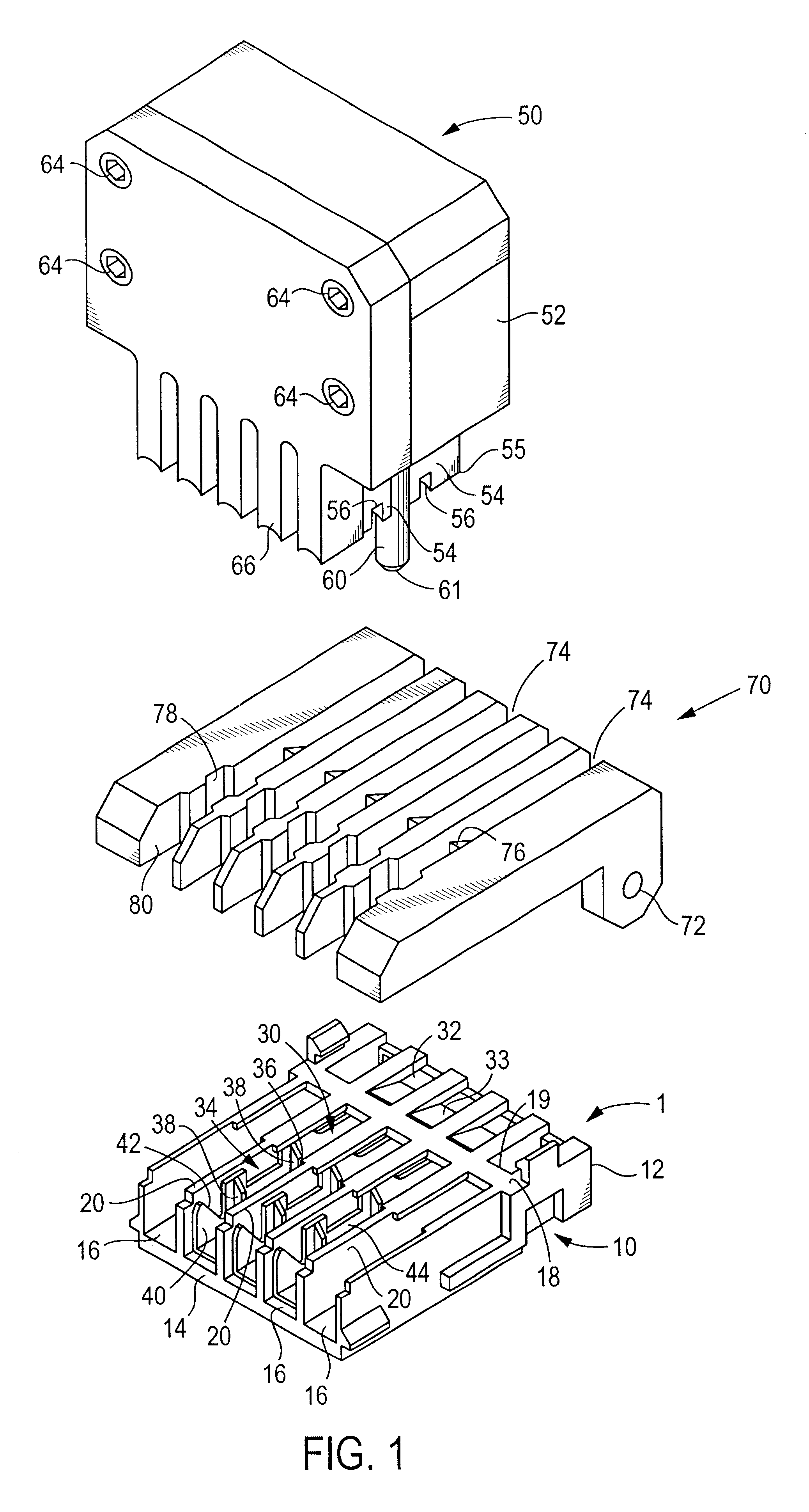

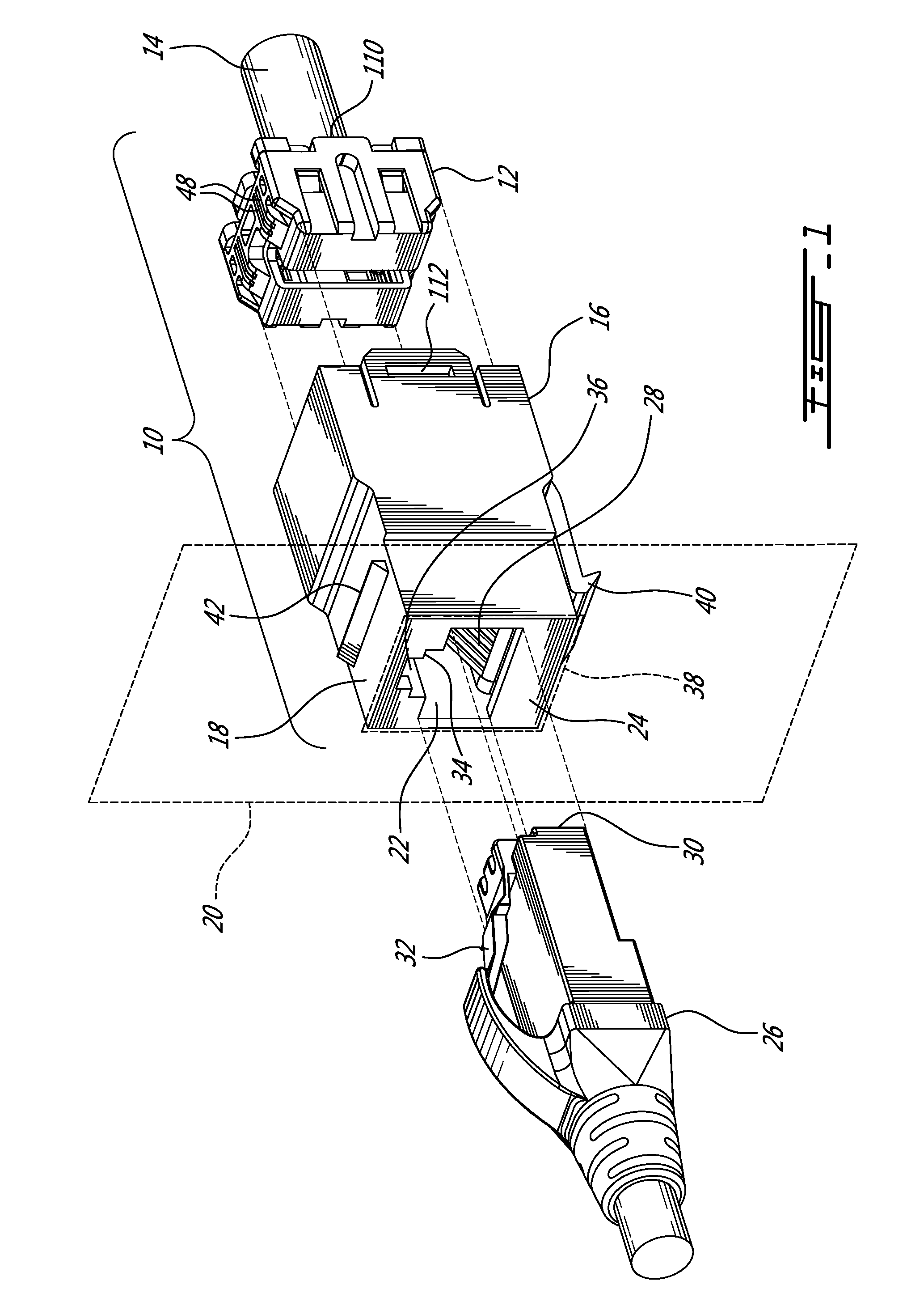

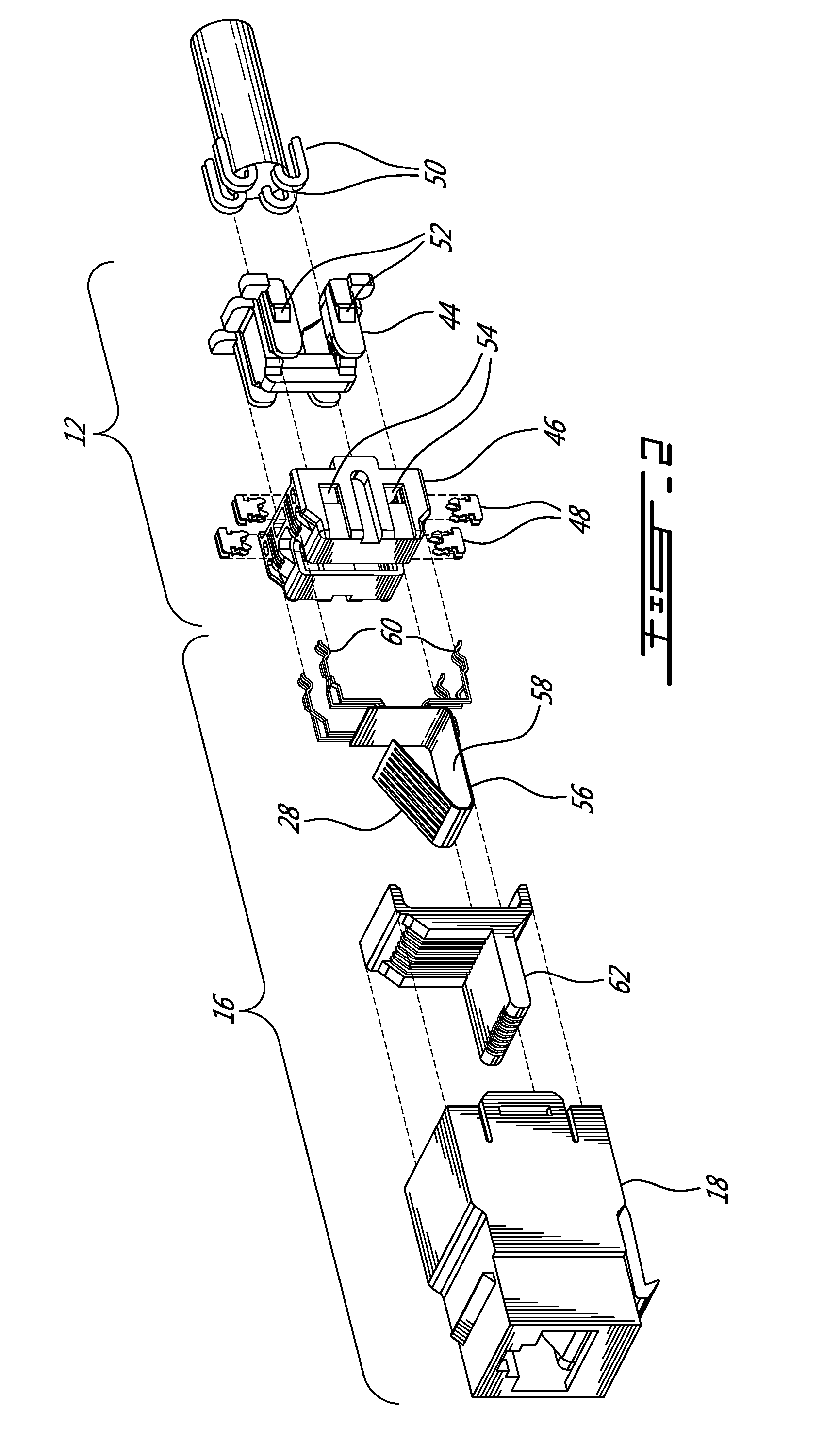

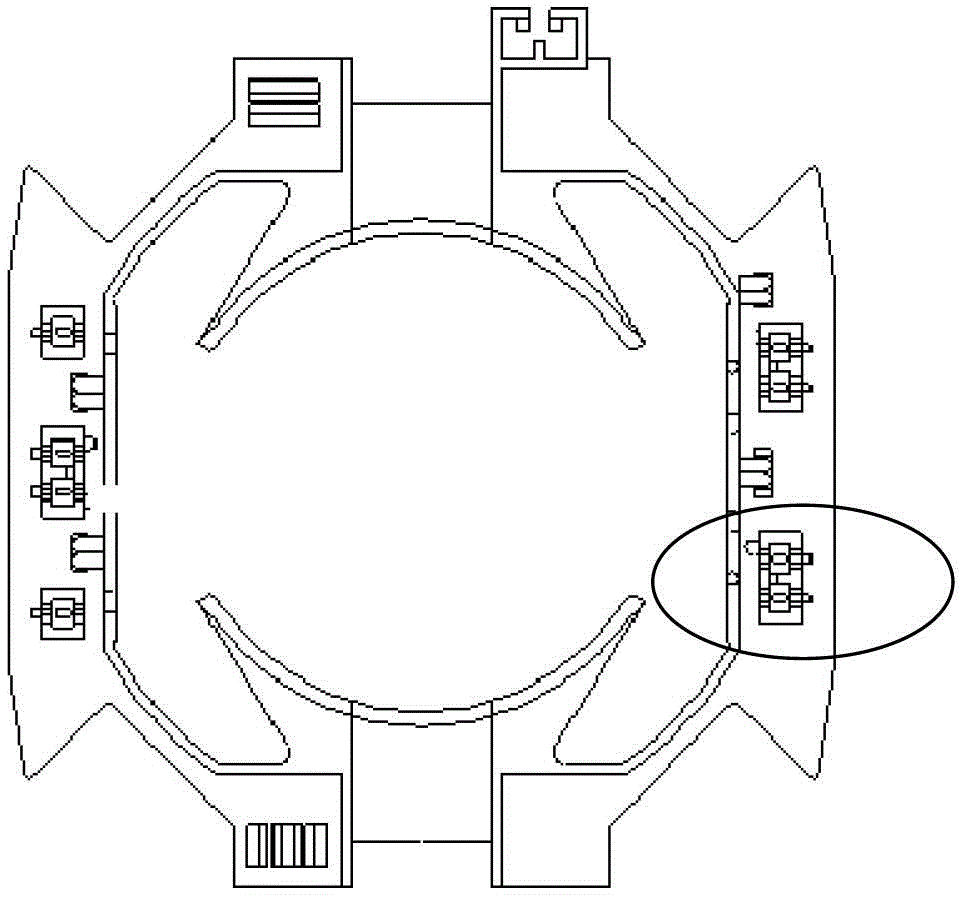

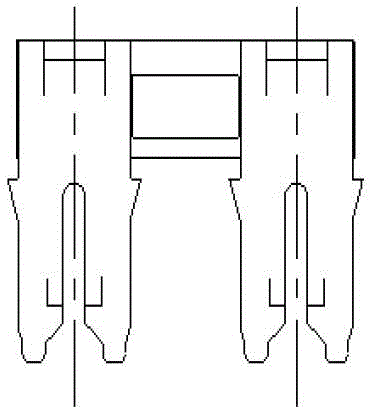

Multiple-wire termination tool with translatable jack and cutting blade precision alignment carrier

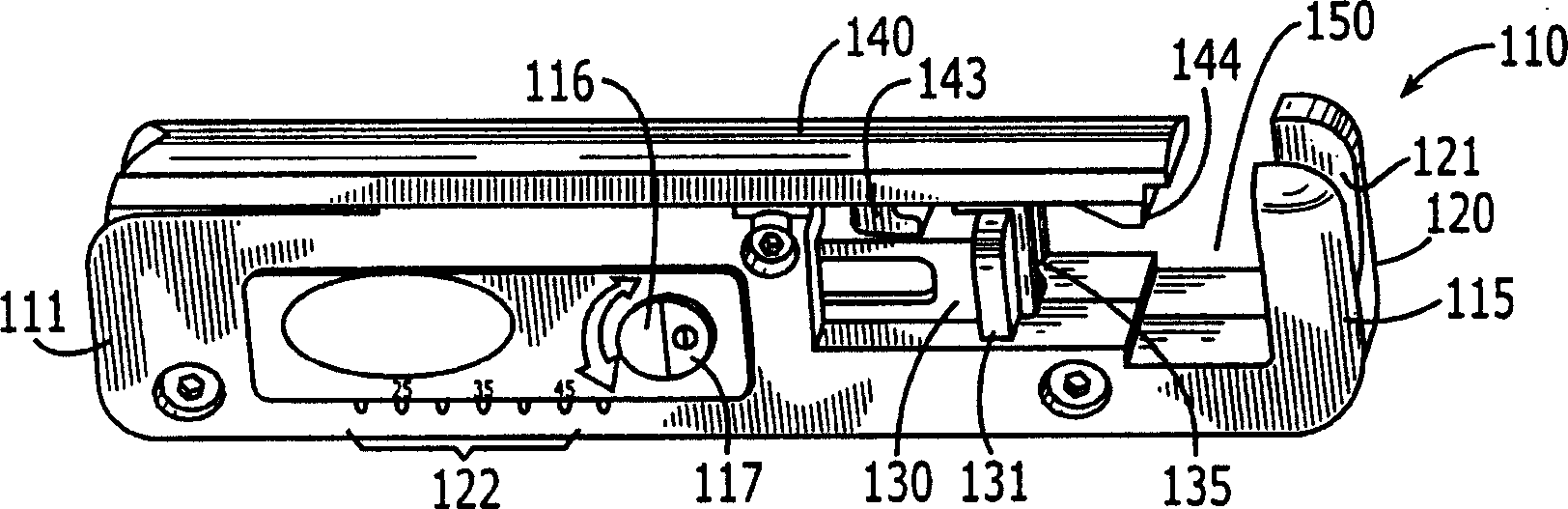

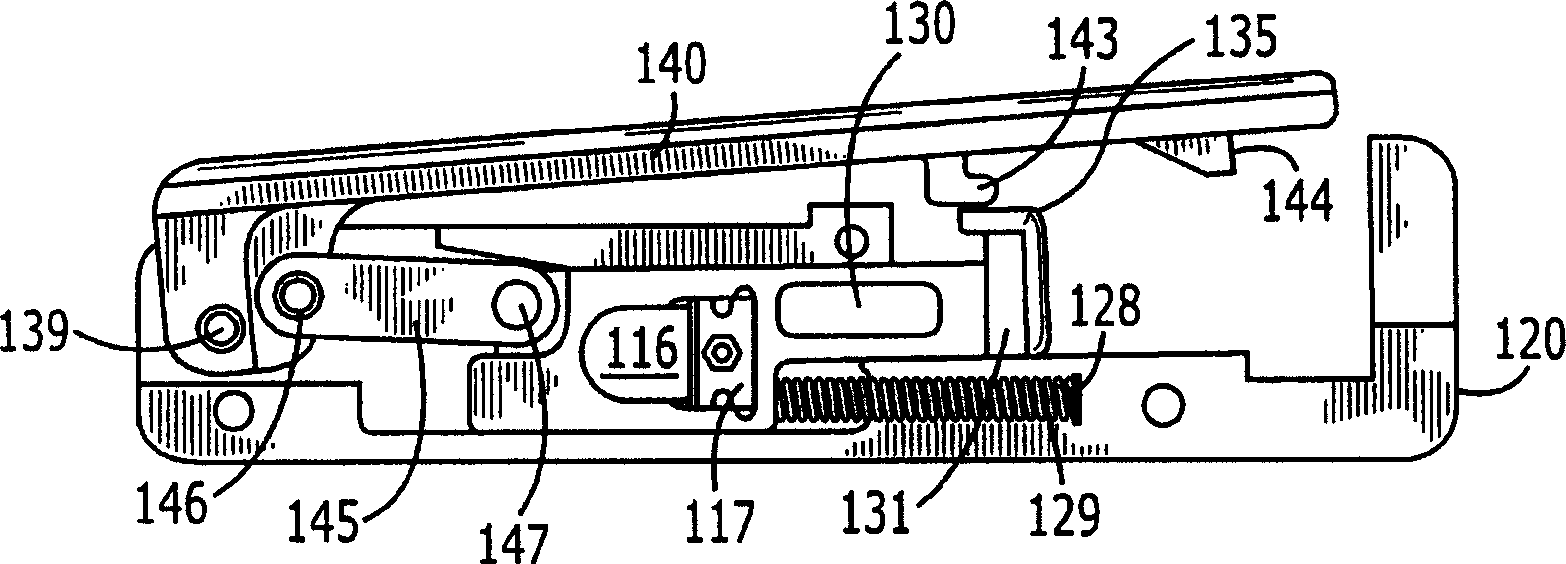

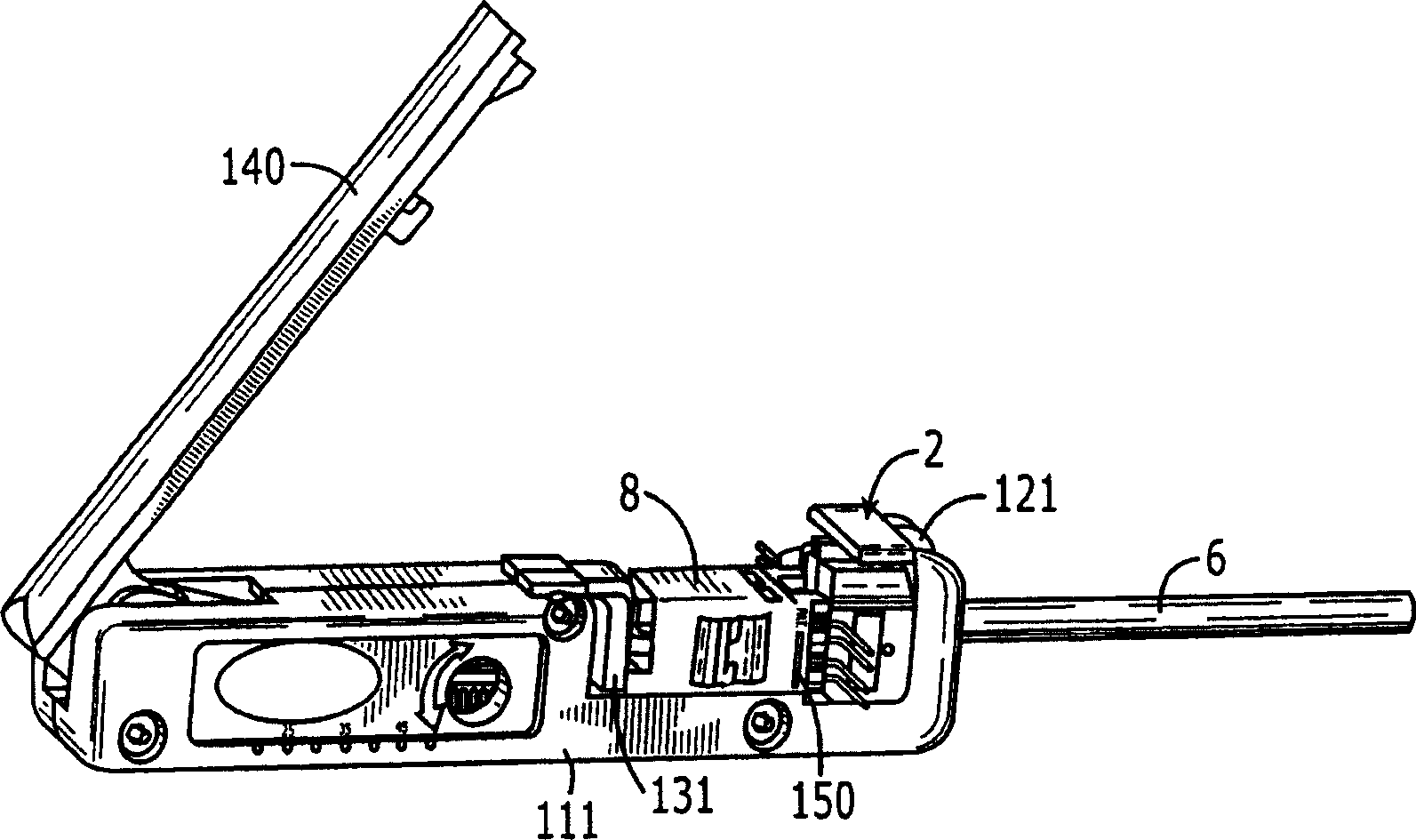

ActiveUS7073245B2Easy to disassembleInhibition of translationTwo-part coupling devicesUnstripped conductor connection apparatusEngineeringMechanical engineering

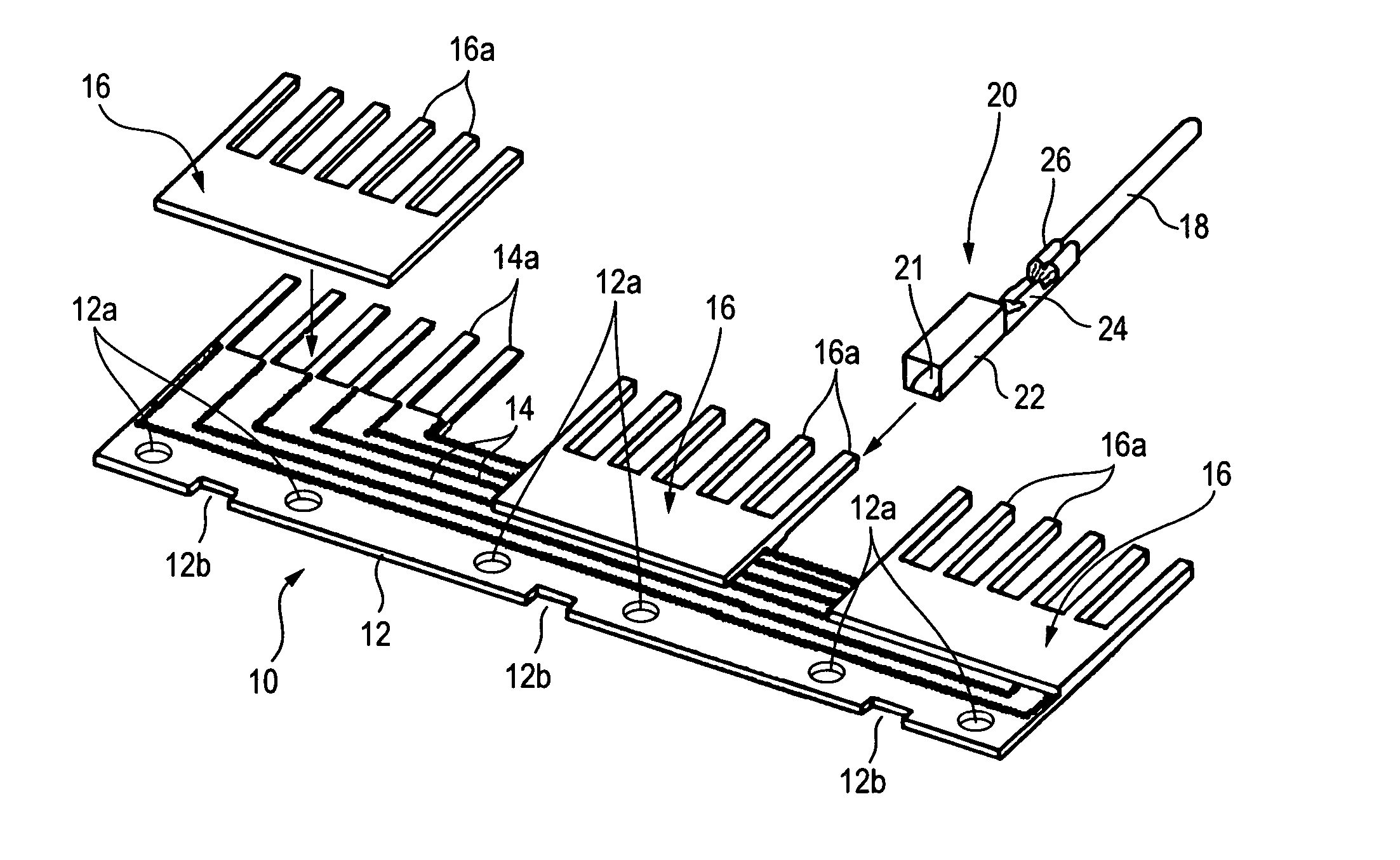

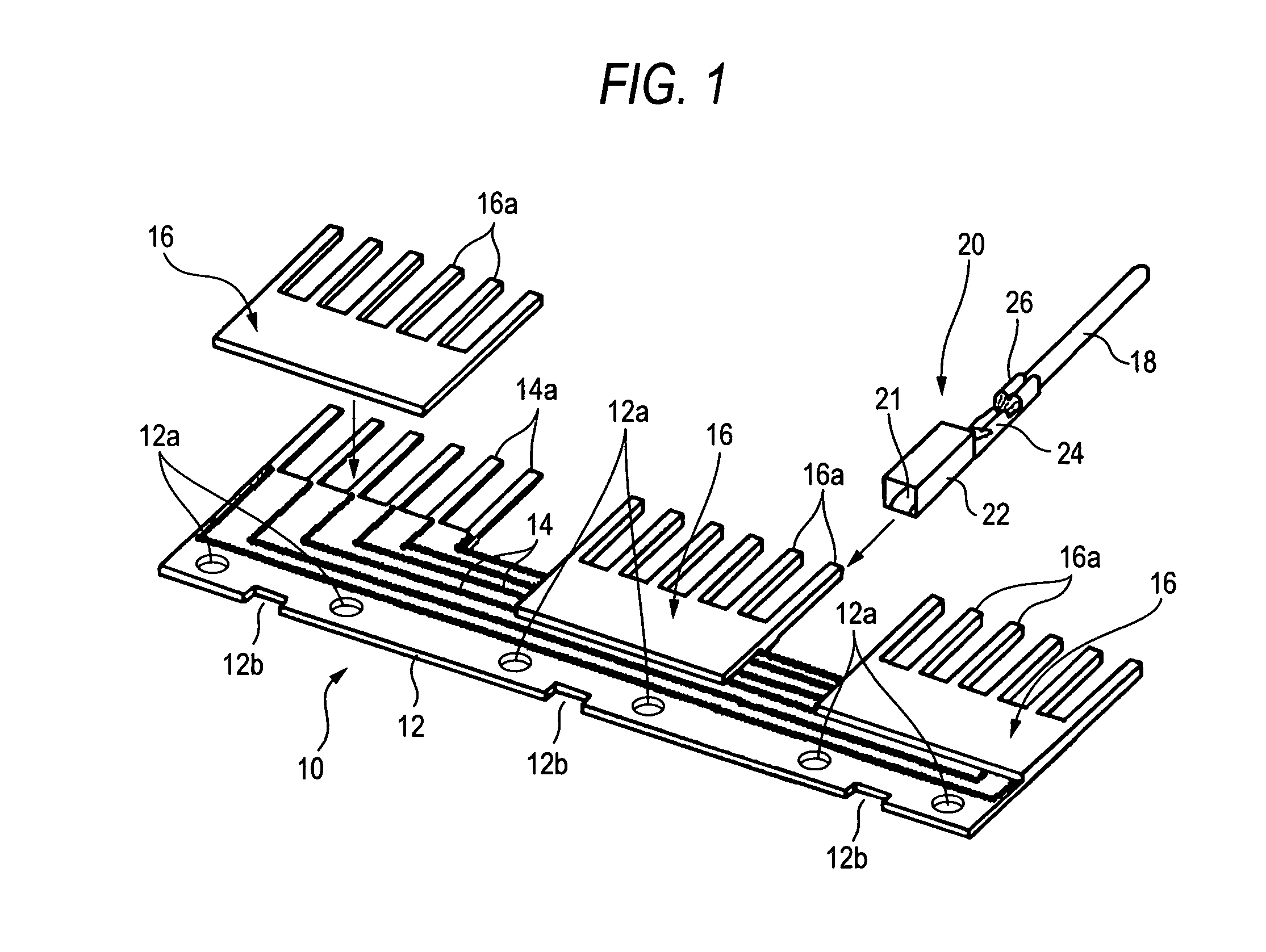

A tool that seats and cuts multiple wires inserted into terminals of a multi-terminal jack includes a support housing for a linearly translatable, and removable carrier. The carrier fixedly retains one of a blade head and a jack, and slidably retains the other of the jack and the blade head, in such a manner that the jack is maintained in precision alignment with the blade head as the carrier is linearly translated within the support housing. A carrier translation control mechanism is coupled to the support housing in a manner that pushes and thereby linearly translates the carrier, so as to bring the blades of the translated blade head into precise stuffing and cutting engagement with the wires in the jack.

Owner:JOHN FLUKE MFG CO INC

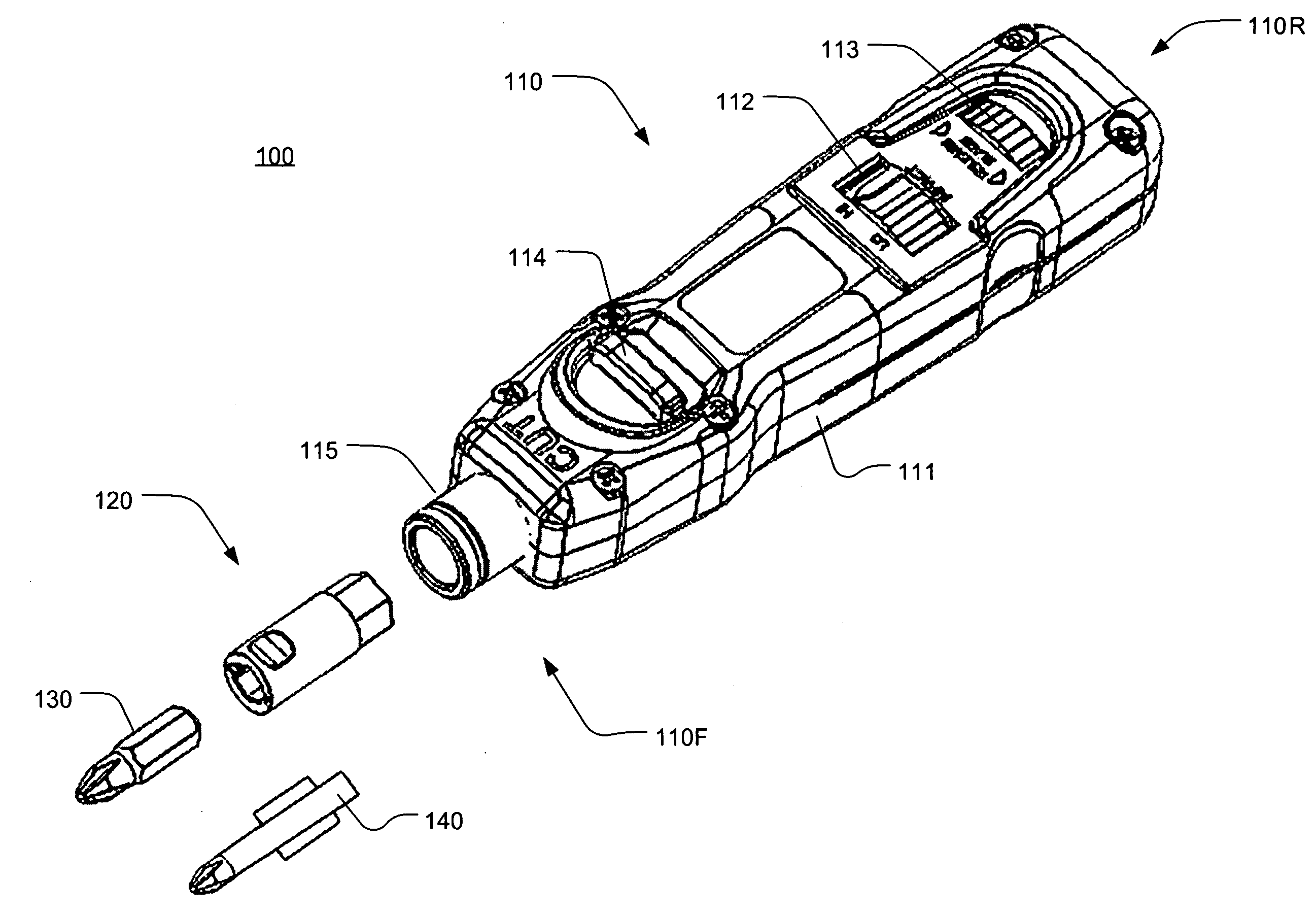

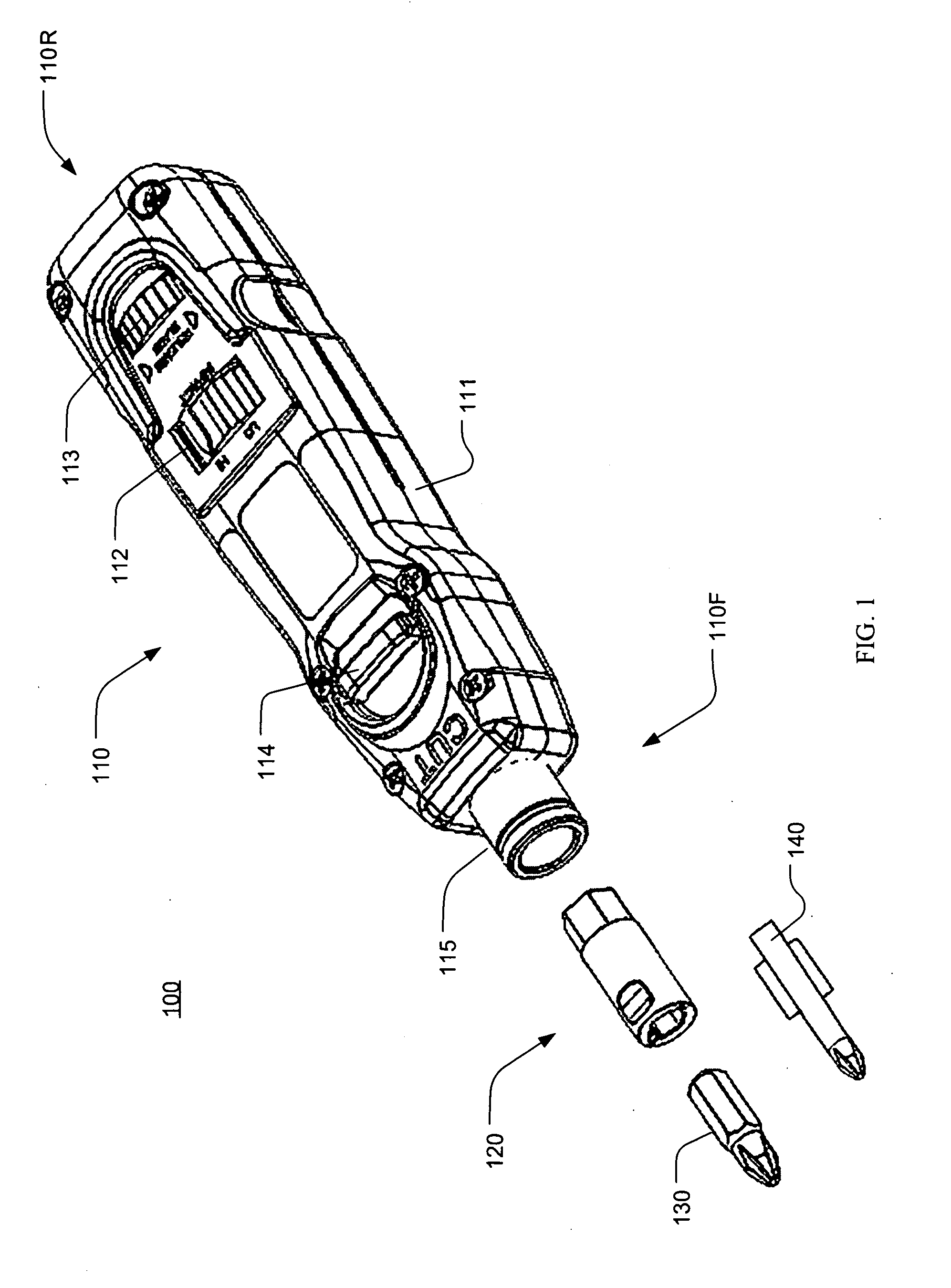

Compound tool with screwdriver attachment

There is disclosed an impact termination tool, a receiver for an impact termination tool, and a work end adapter for an impact termination tool. The work end adapter is adapted to receive standard tool bits and standard finned shaft tips. The impact termination tool is adapted to receive standard impact termination blades and to receive the work end adapter. When installed in the impact termination tool, the work end adapter rotates only with the impact termination tool, and will not rotate independently of the impact termination tool. The impact termination tool has a spring-loaded impact mechanism and a lock-out button to prevent the tool's impact mechanism from operating.

Owner:KLEIN TOOLS INC

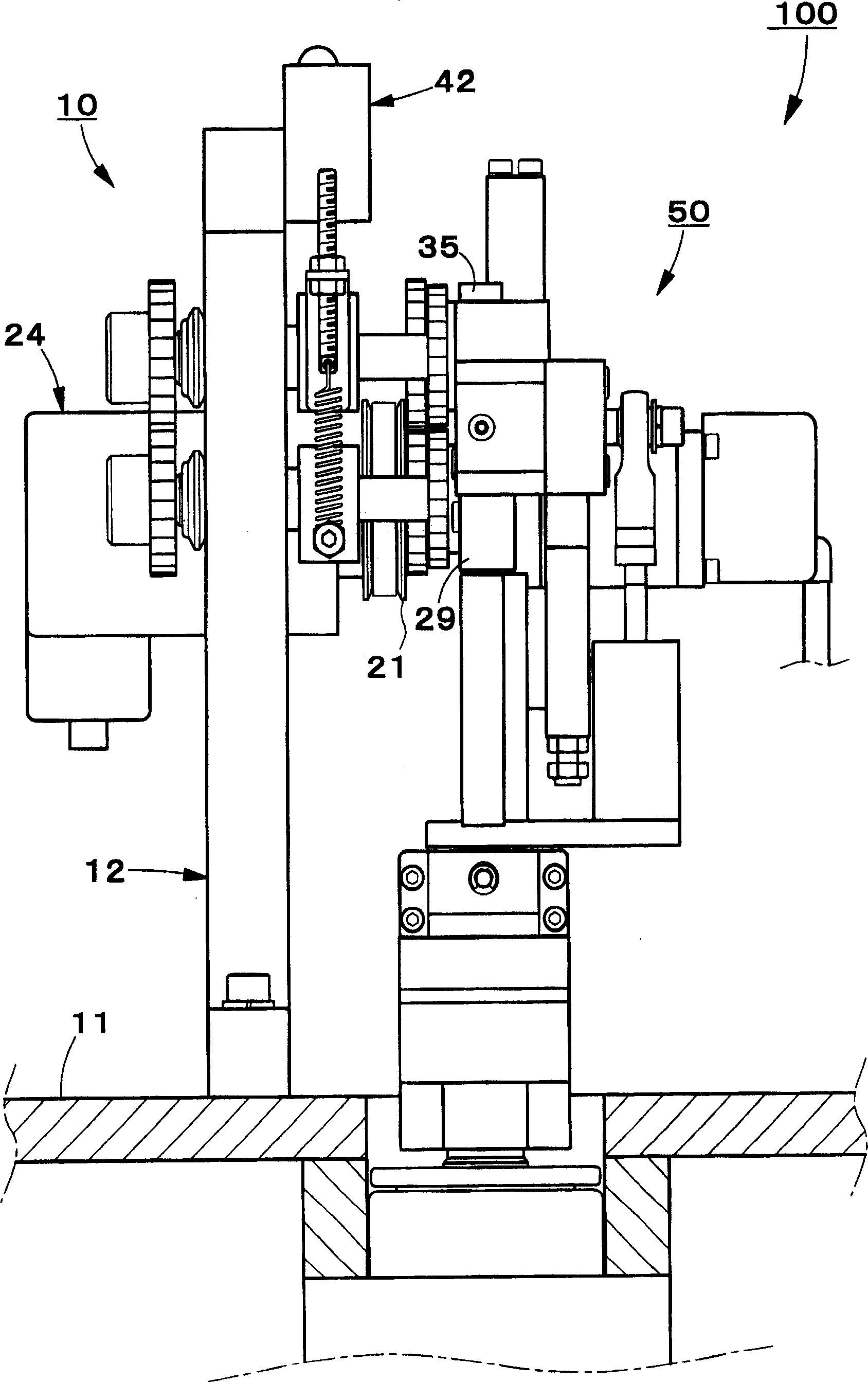

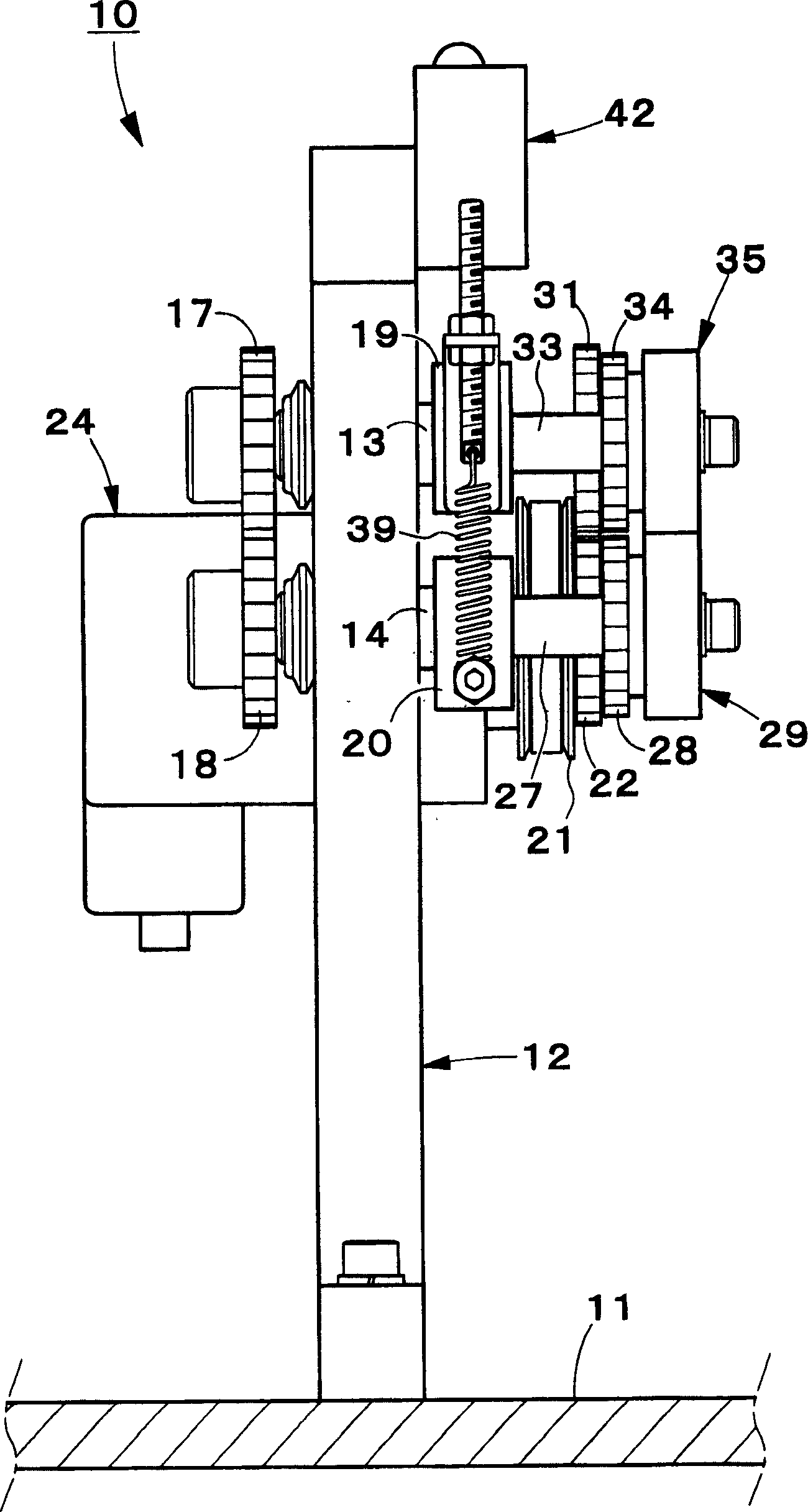

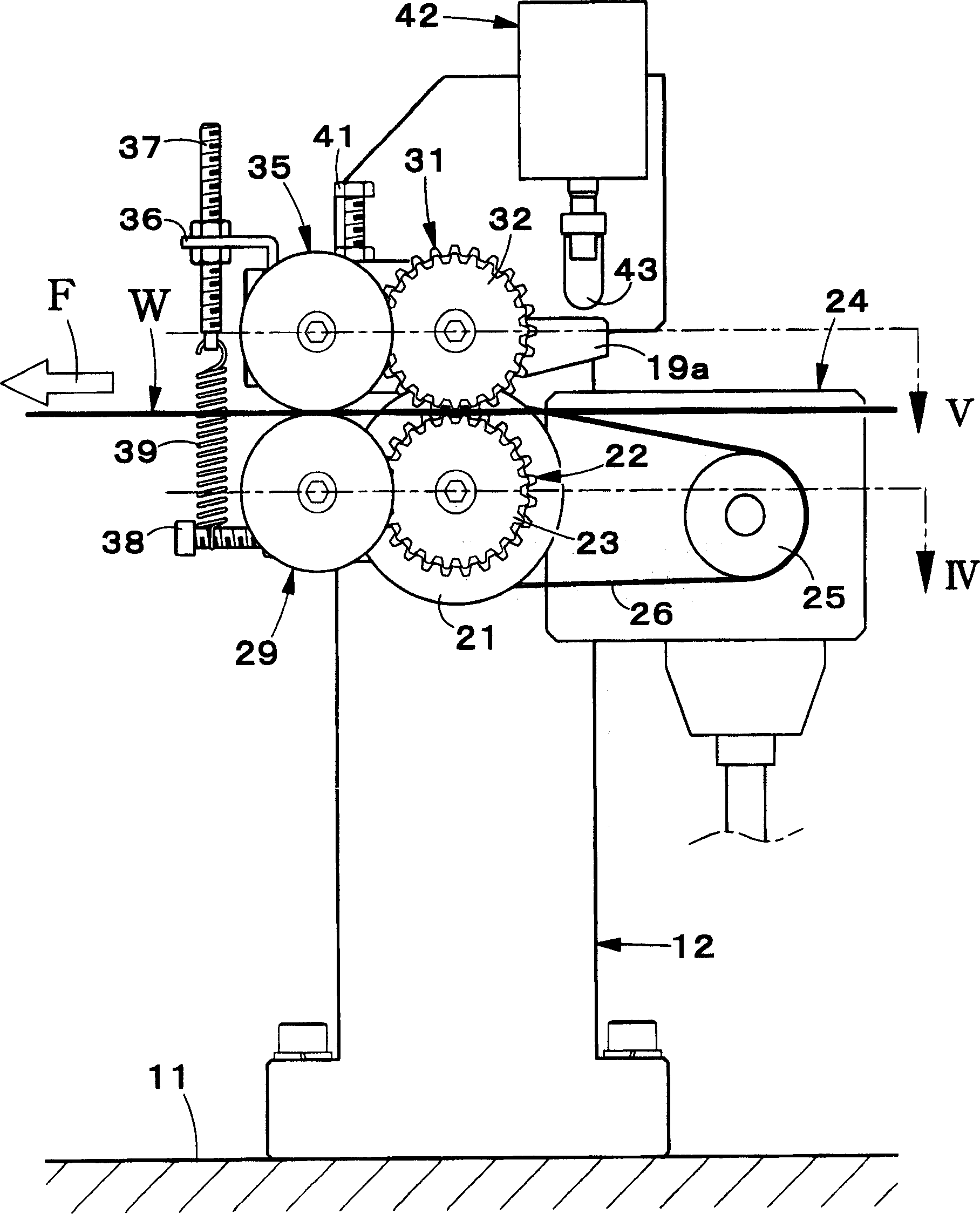

Wire length measuring and feeding device

InactiveCN1657386ADecreased overall length dimensional accuracySwing high speedFilament handlingUnstripped conductor connection apparatusElectric wireMoving parts

Provided is an electric wire measuring / feeding device capable of rocking a rocking part in a higher speed without reducing overall length accuracy of an electric wire for feeding.In the electric wire measuring / feeding device 100, an electric wire feeding mechanism 10 fixed to the base is separated from an electric wire measuring / moving mechanism 50 moving on the base, so that a moving part is lightened and the moving speed can be improved. When the electric wire measuring / moving mechanism 50 lies at a first moving position, feed rollers 35 and 29 of the electric wire feeding mechanism 10 unlockably engage with a part lying on the front end side in the wire feeding direction of the electric wire W supported by the electric wire measuring / moving mechanism 50, and feed the electric wire W of a predetermined length.

Owner:JAPAN AUTOMATIC MACHINE

Insulation displacement connector

ActiveUS10541478B1Reliably splicingUnstripped conductor connection apparatusContact members penetrating/cutting insulation/cable strandsElectrical connectionEngineering

A method and apparatus for forming a blind connection between a first wire and a second wire where each of the wires are inserted into a sleeve with the first wire laterally inserted into the sleeve for positioning along the first wire and the second wire axially inserted through the sleeve and into engagement with a stop located outside the sleeve to ensure that the second wire is properly positioned in the sleeve before an unseen electrical connection is formed between the first wire and the second wire.

Owner:THE PATENT STORE

Punch-Down Tool Blade with Extended Reach

InactiveUS20100031492A1Precious timeIncrease competitionUnstripped conductor connection apparatusOther manufacturing equipments/toolsPatch panelVisibility

Disclosed is a punch-down tool blade suited for seating, and seating and cutting data transmission and telephony wires into crowded patch panels. Also disclosed are embodiments of an elongated punch-down tool blade having a slidable locking collar which may be used in reversibly locking a punch-down tool blade with either the seating tip being used as the working tip or the seating and cutting tip used as the working tip without compromising both the ability of the tool tip to gain access to terminating clips or the tradesman's visibility of terminating clips so that patch panels may be efficiently and accurately wired while providing enhanced safety and decreased worker fatigue.

Owner:AMBRIGHT LEE

Method of connecting multi conductor cable connector

InactiveUS6931727B2Coupling device connectionsContact member assembly/disassemblyElectrical conductorElectrical connection

This invention is an electrical connection method for connecting multiple conductor cable, ideally flat flexible cable. The method involves using an actuator for pressing the cable against multiple contacts in a base, each of which contacts has a sharp edge for removing insulation from the cable.

Owner:MIRACO

Portable overhead insulated conductor grounding device

PendingCN110061370AGuaranteed insulation performanceReduce security risksUnstripped conductor connection apparatusClip conductor connectionInsulation layerElectrical conductor

The invention discloses a portable overhead insulated conductor grounding device. The grounding device is characterized by comprising a conductor chuck component, an insulating rod component, a ratchet handle component, an electroscope component and a grounding wire component. The grounding device achieves grounding of an overhead insulated conductor by a puncturing method on the premise of not damaging an insulating property of an insulation layer of the insulated conductor; the grounding device is portable; a grounding wire can be mounted in a position where the grounding wire is required tobe mounted according to a working place; the grounding device is flexible and convenient to carry, mount and dismount; the working efficiency is greatly improved; and the grounding device achieves mounting of the grounding wire in any working place, ensures the insulating property of the overhead insulated conductor, reduces potential safety hazards to persons and a power grid since a conductor is exposed and is not in an insulating state at a mounting position of a fixed grounding wire hanging loop and also lowers mounting cost of the fixed grounding wire hanging loop at the same time.

Owner:谭加新

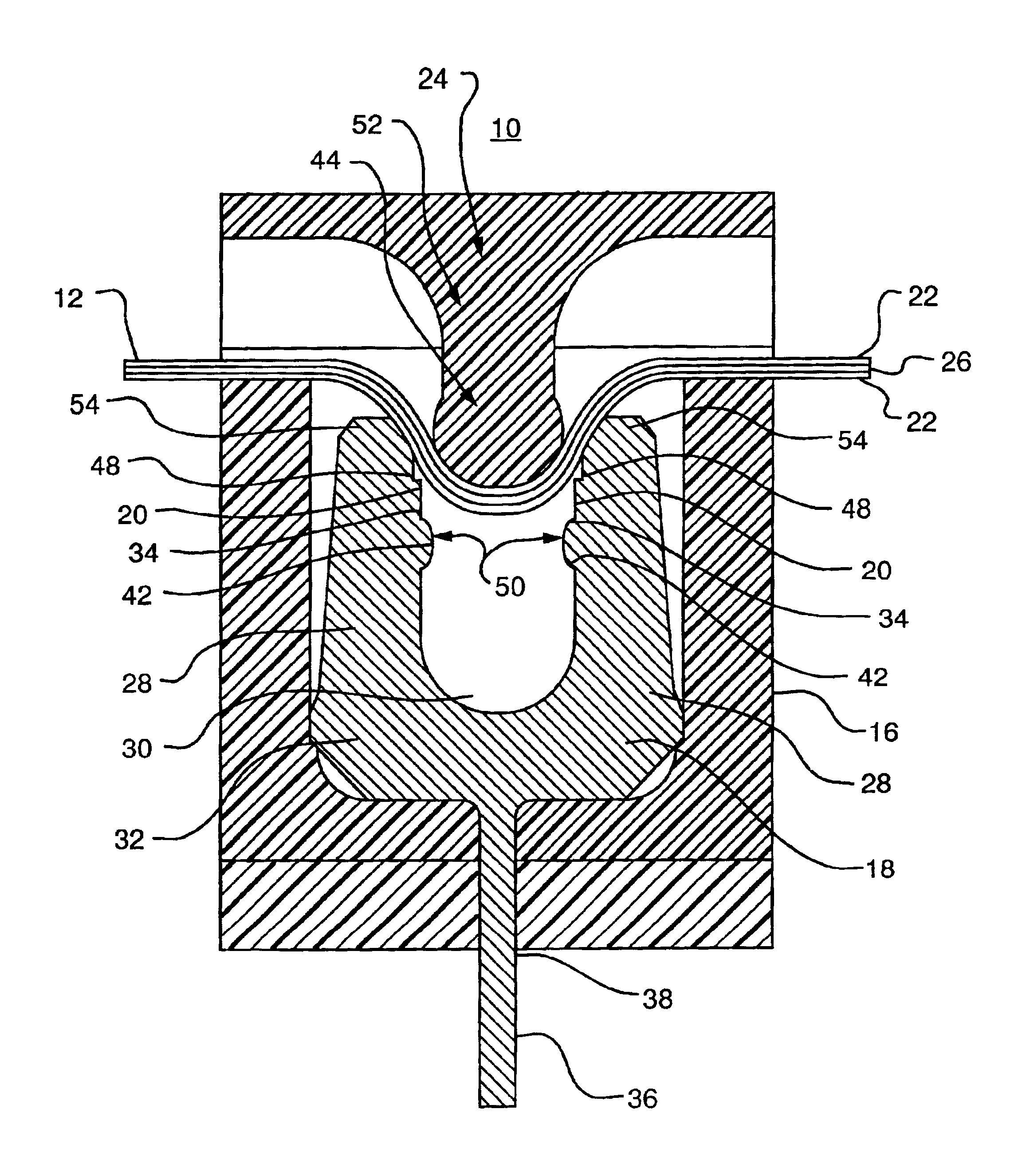

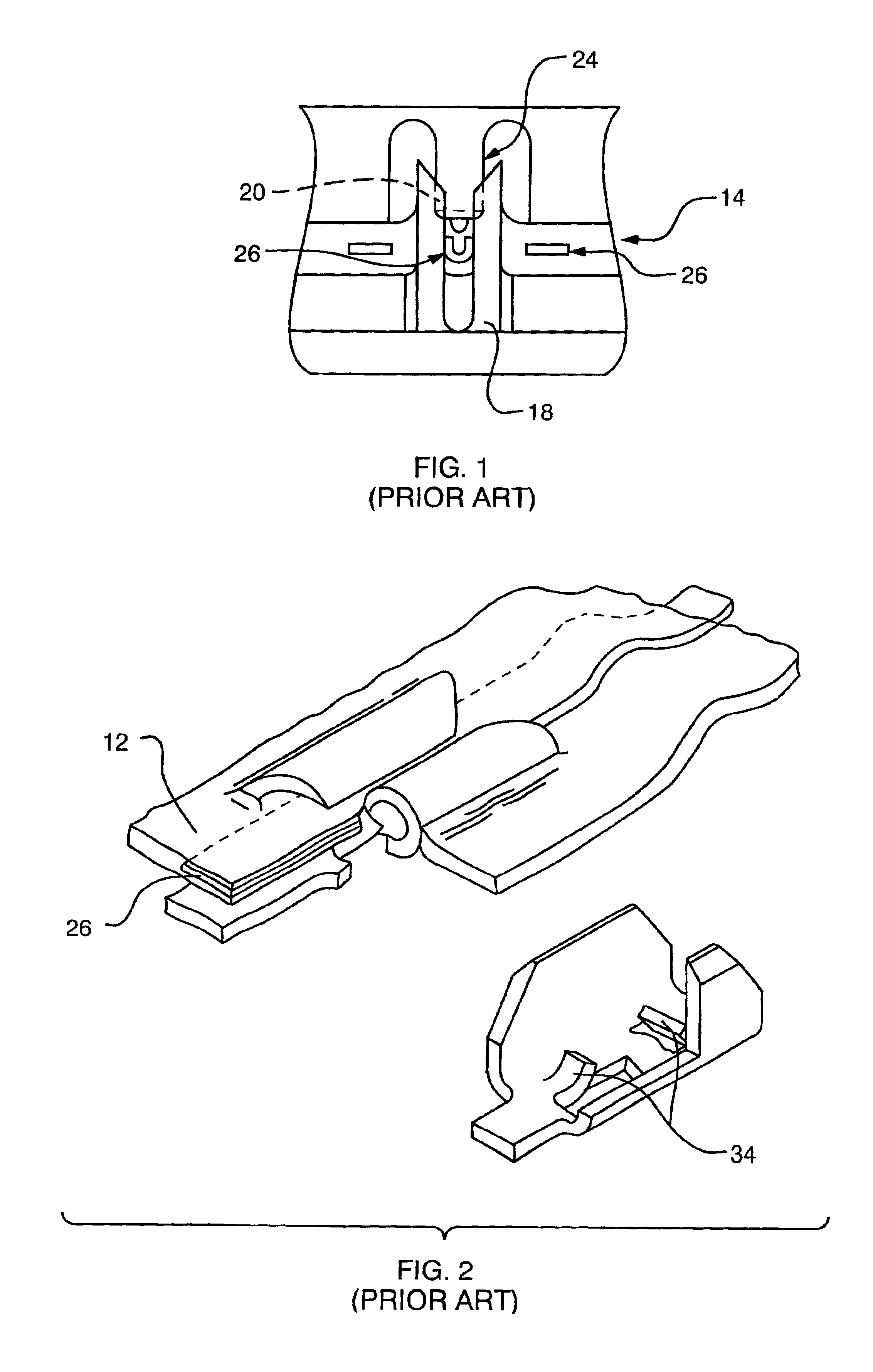

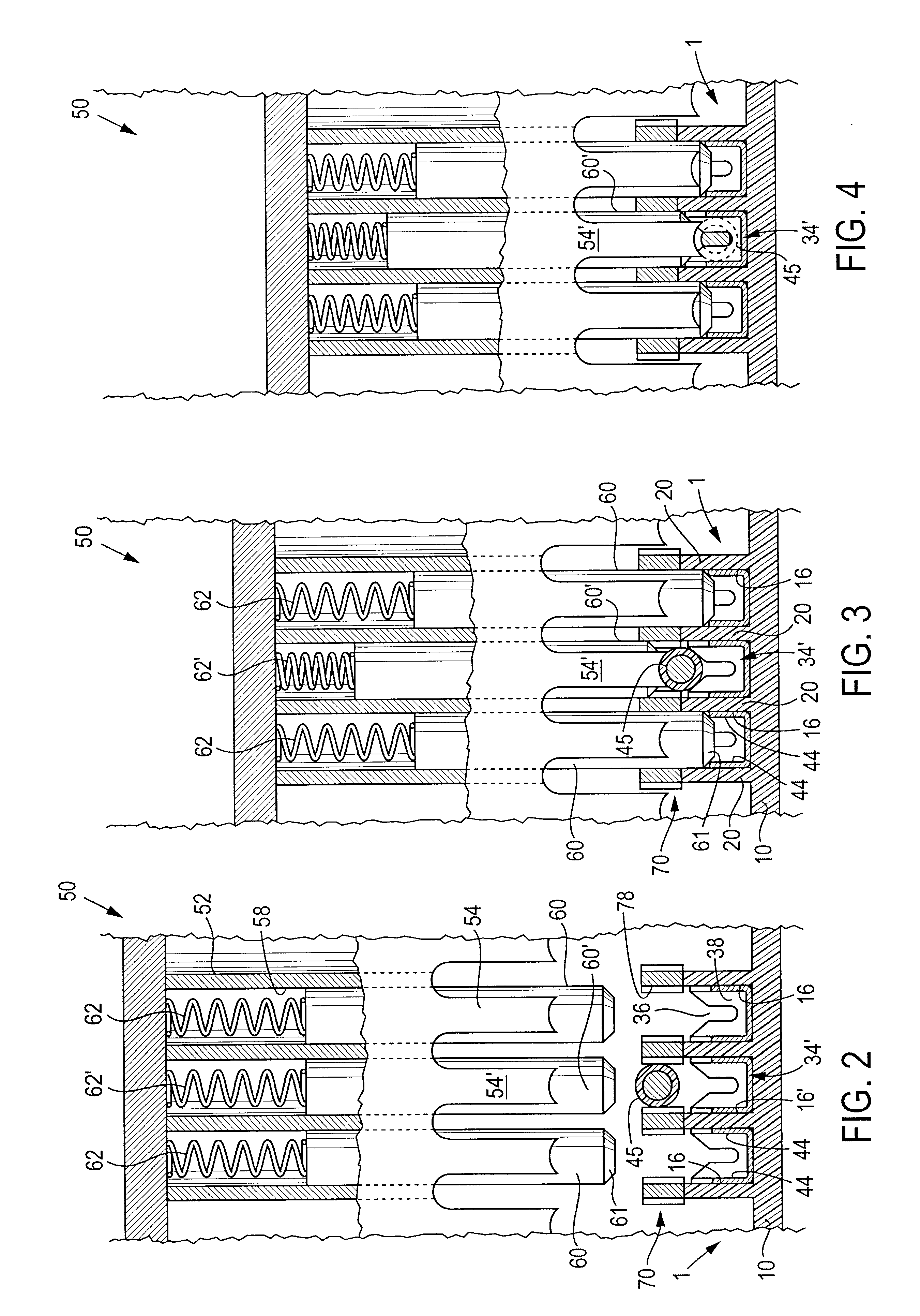

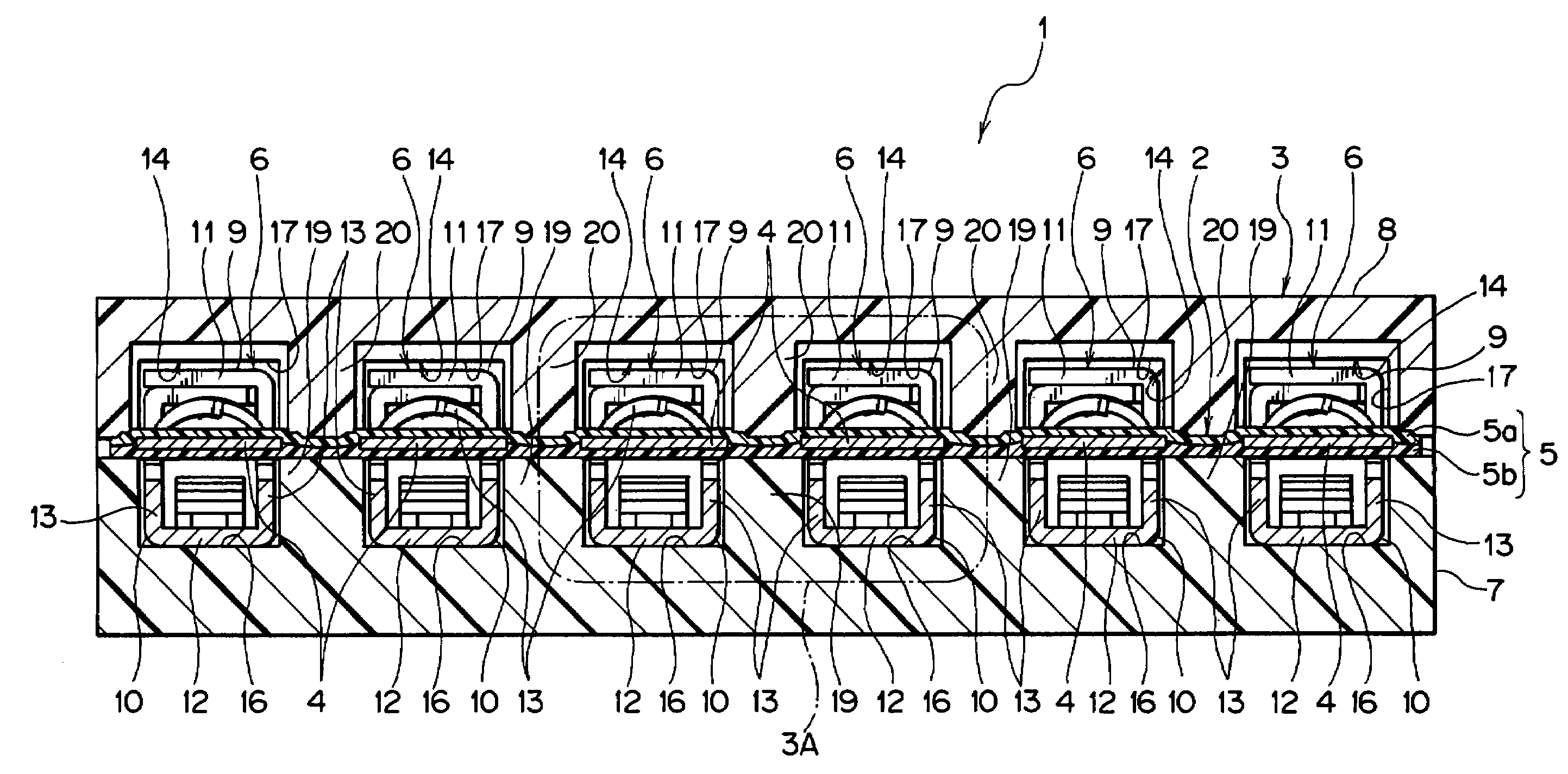

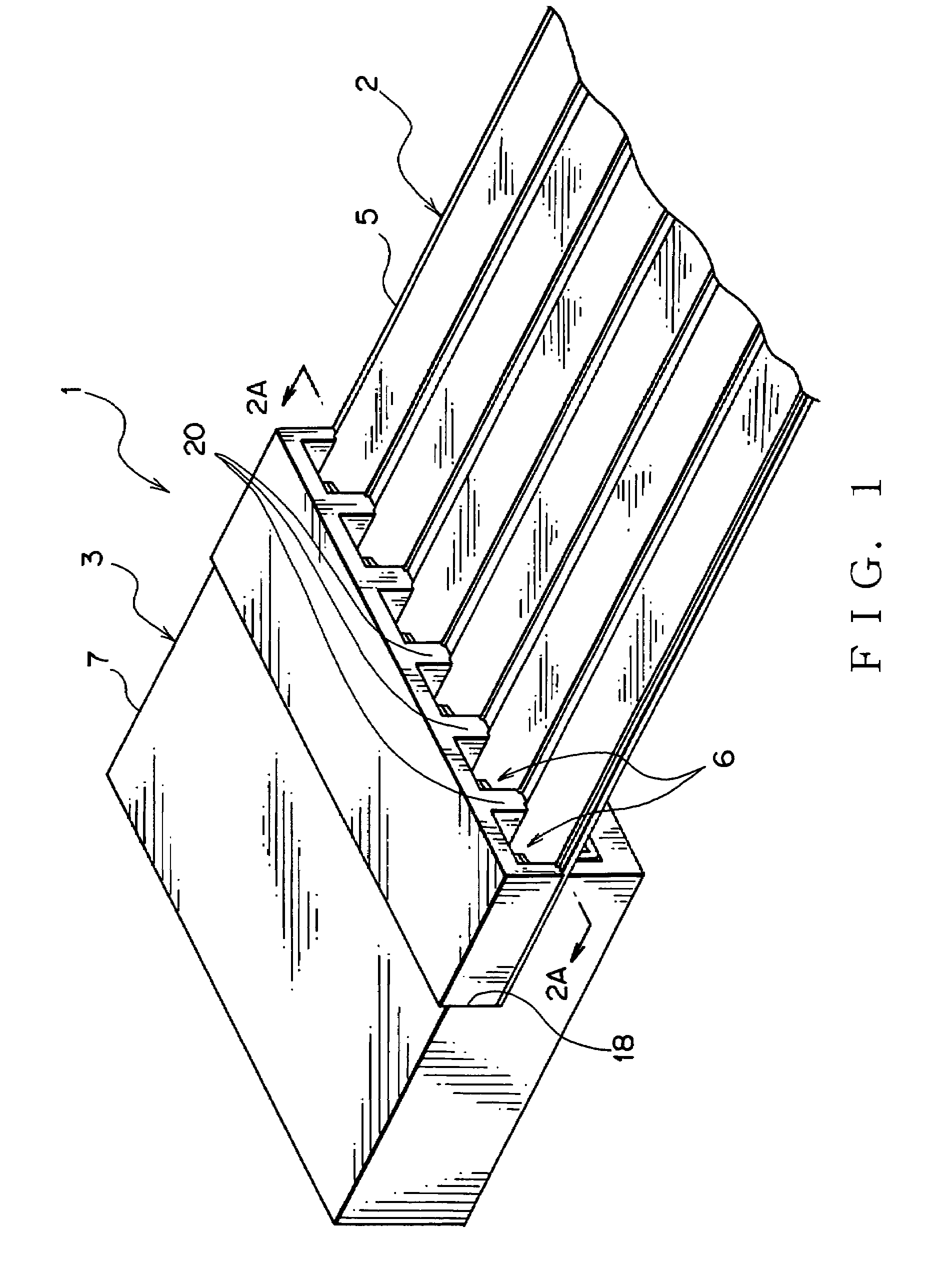

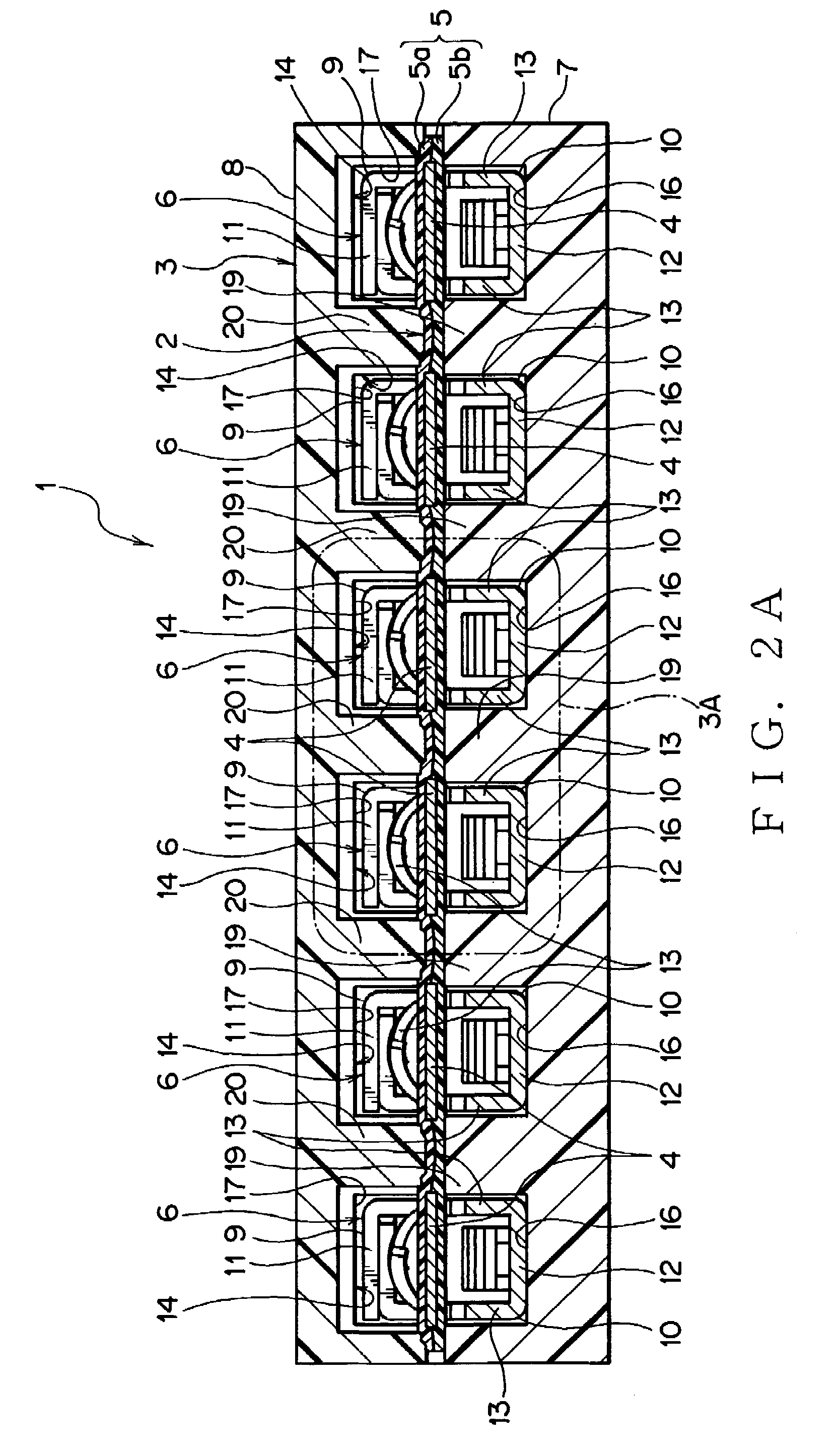

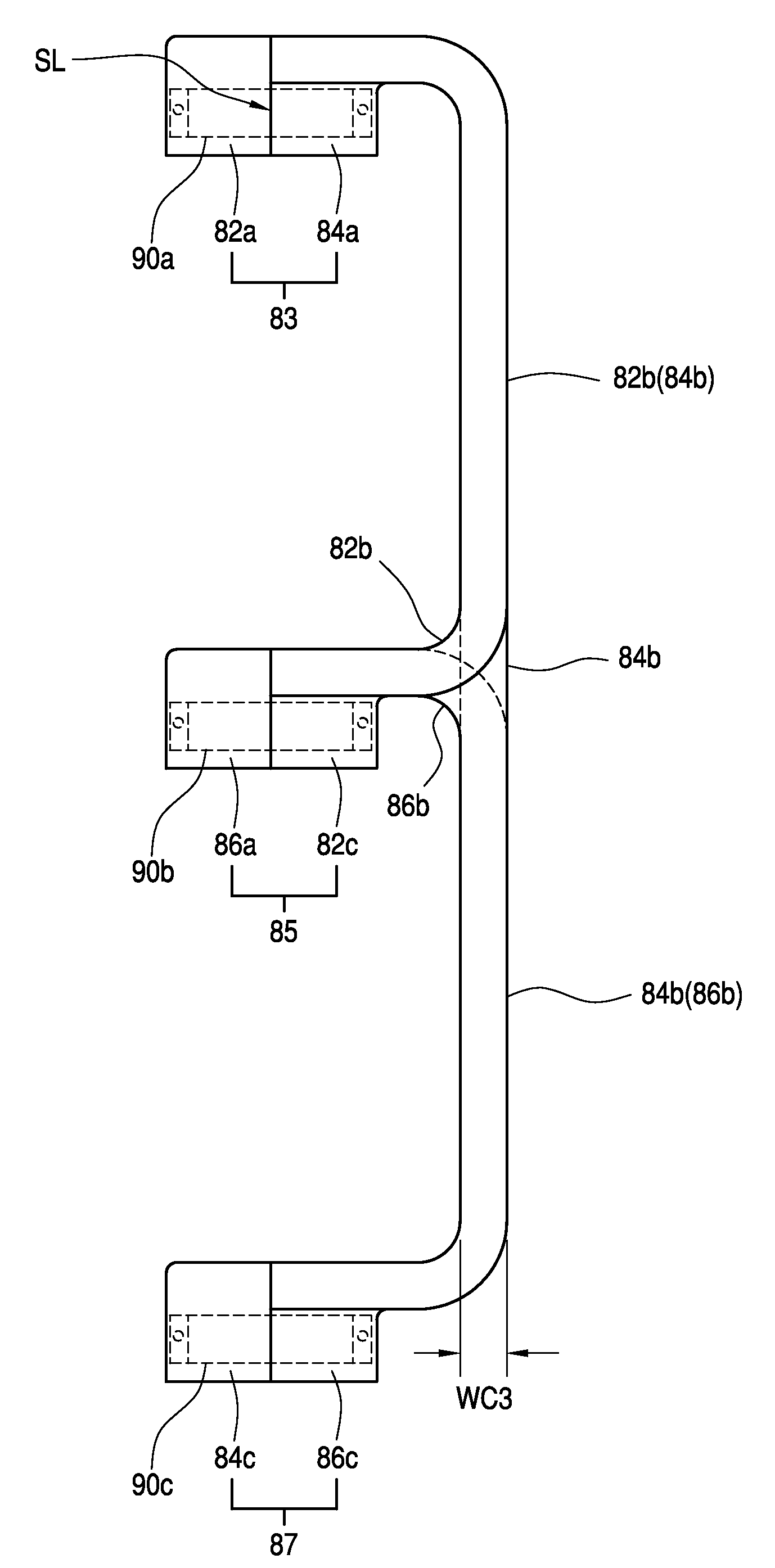

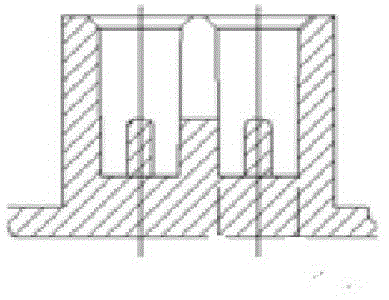

Pressure welding apparatus and pressure welding method

InactiveUS6371353B1Welding/cutting auxillary devicesUnstripped conductor connection apparatusEngineeringWelding process

A pressure welding apparatus includes a pressing die assembly 50 which has a plurality of stuffers 54 that pressure-weld electric wires 45 to the pressure-welding parts 34 of contacts 30, and a comb 70. The pressing die assembly 50 has a plurality of pins 60 which are located adjacent to the respective stuffers 54 and which are constantly driven downward by springs 62 so that the pins 60 protrude beyond the lower ends of the stuffers 54. The widths of the respective pins 60 are set so that these widths are substantially equal to the widths of the cavities 16 of the housing 10 in which the contacts 30 are accommodated. As a result, the pins 60 advance into the housing cavities 16 located adjacent to the contact 30 on which pressure-welding is to be performed, and support the housing partition walls 20 from the sides during the pressure welding process.

Owner:TYCO ELECTRONICS SERVICES GMBH +1

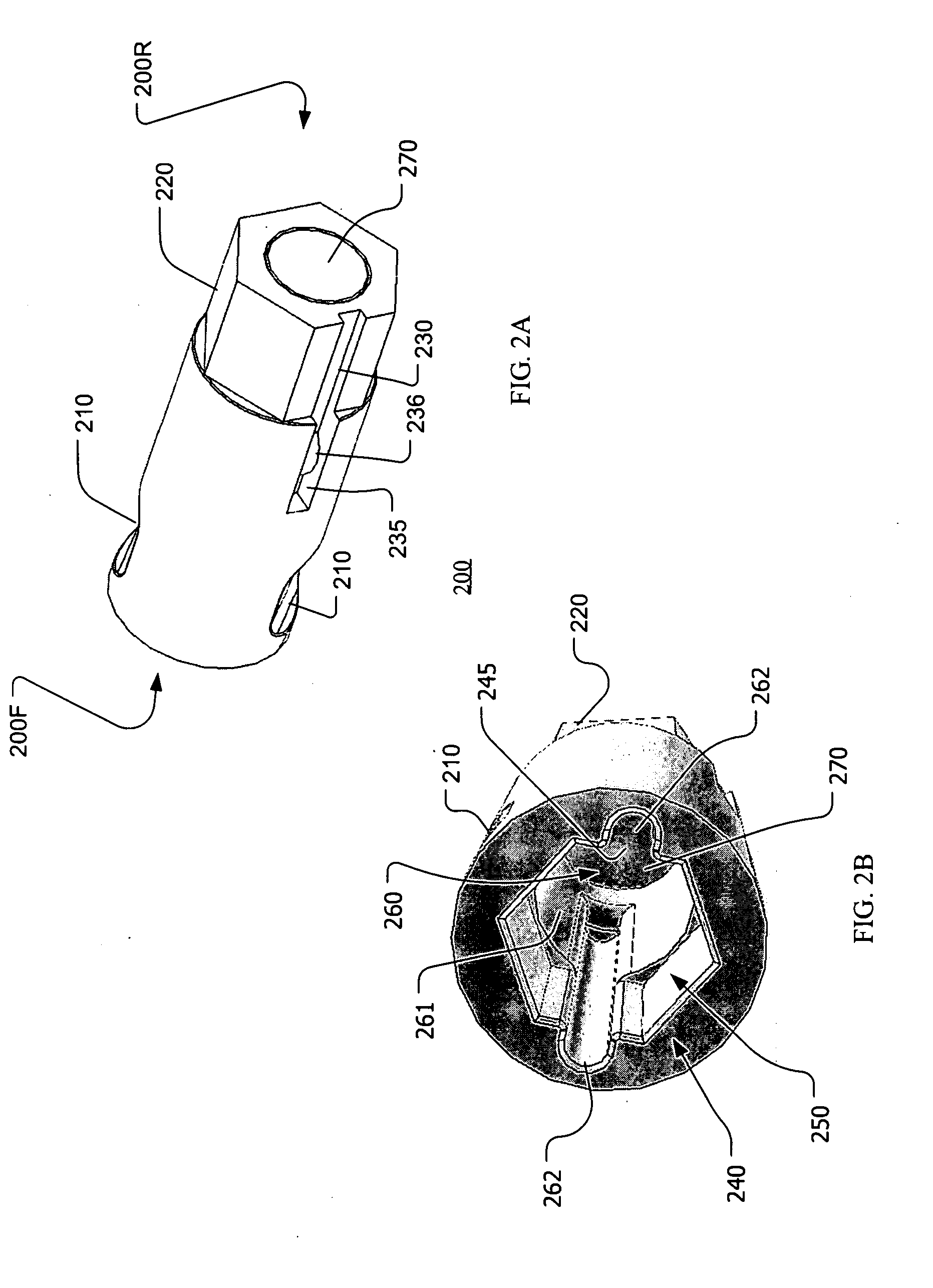

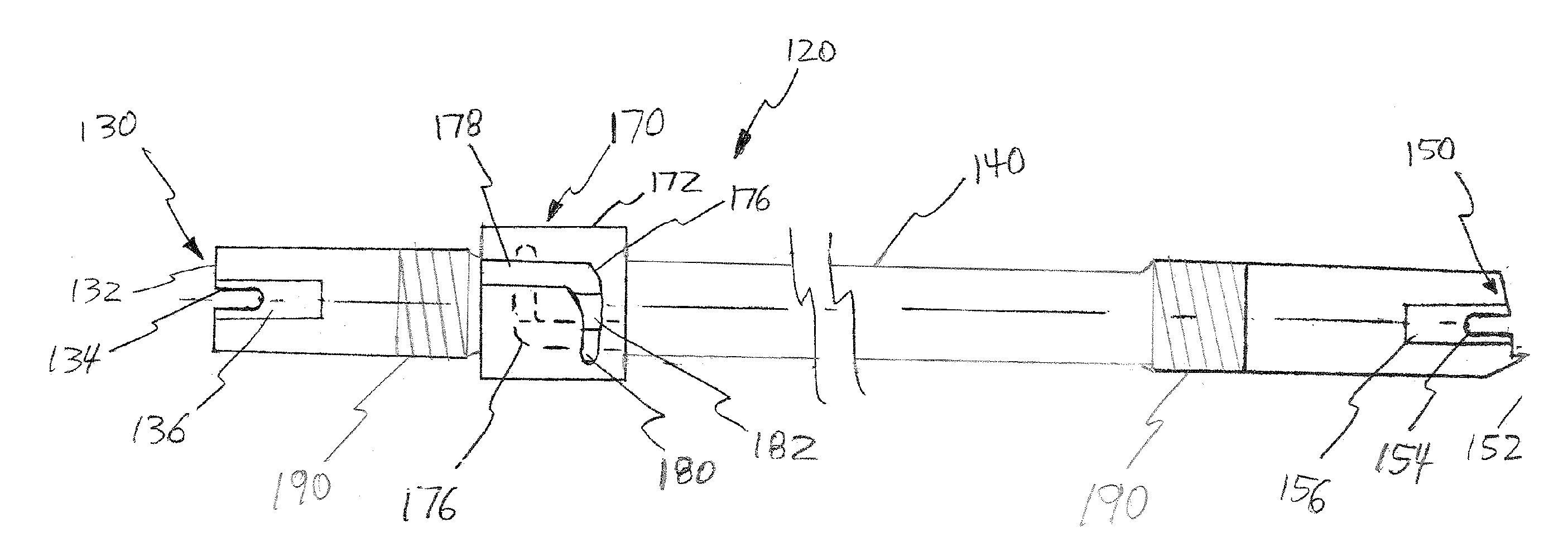

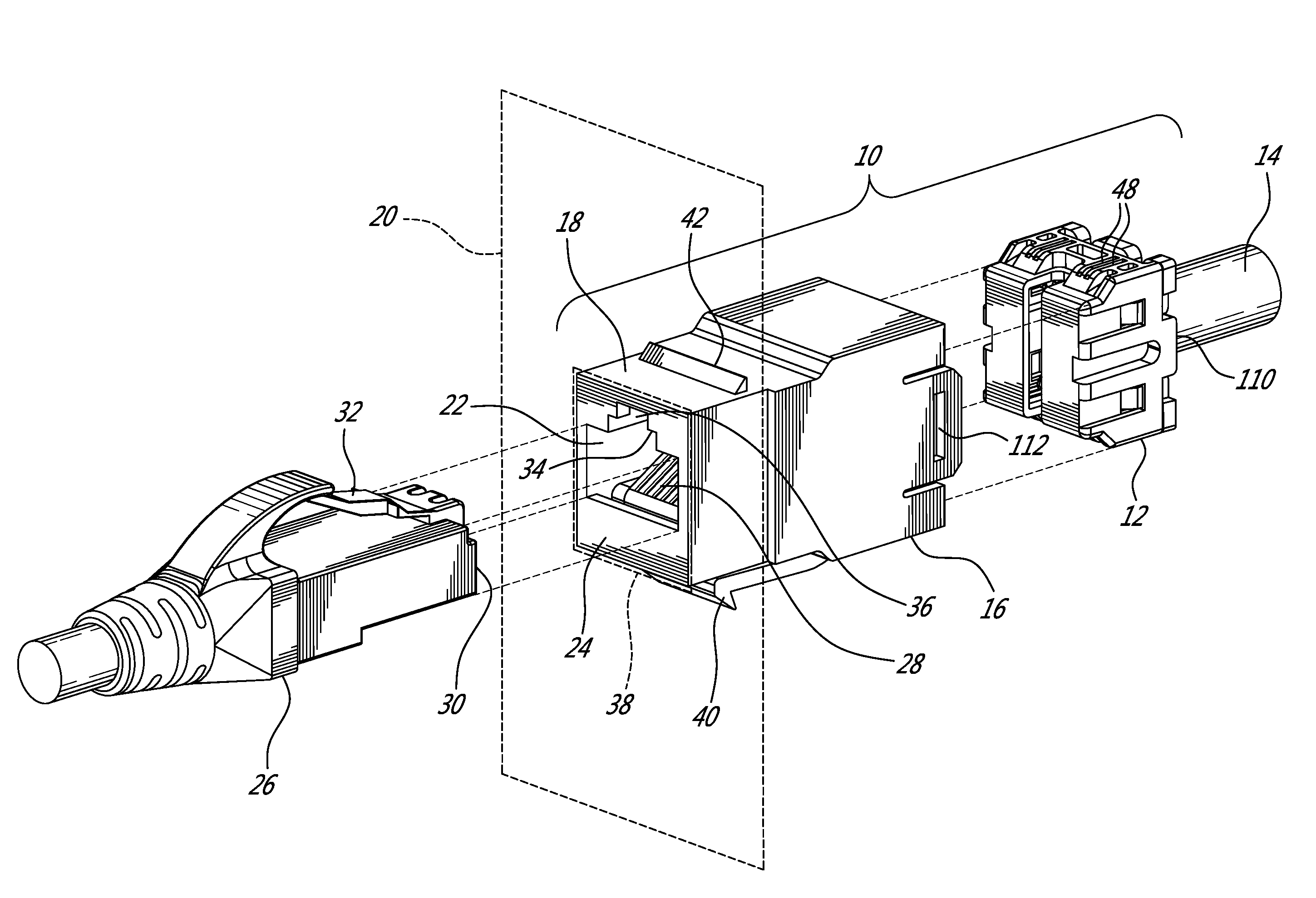

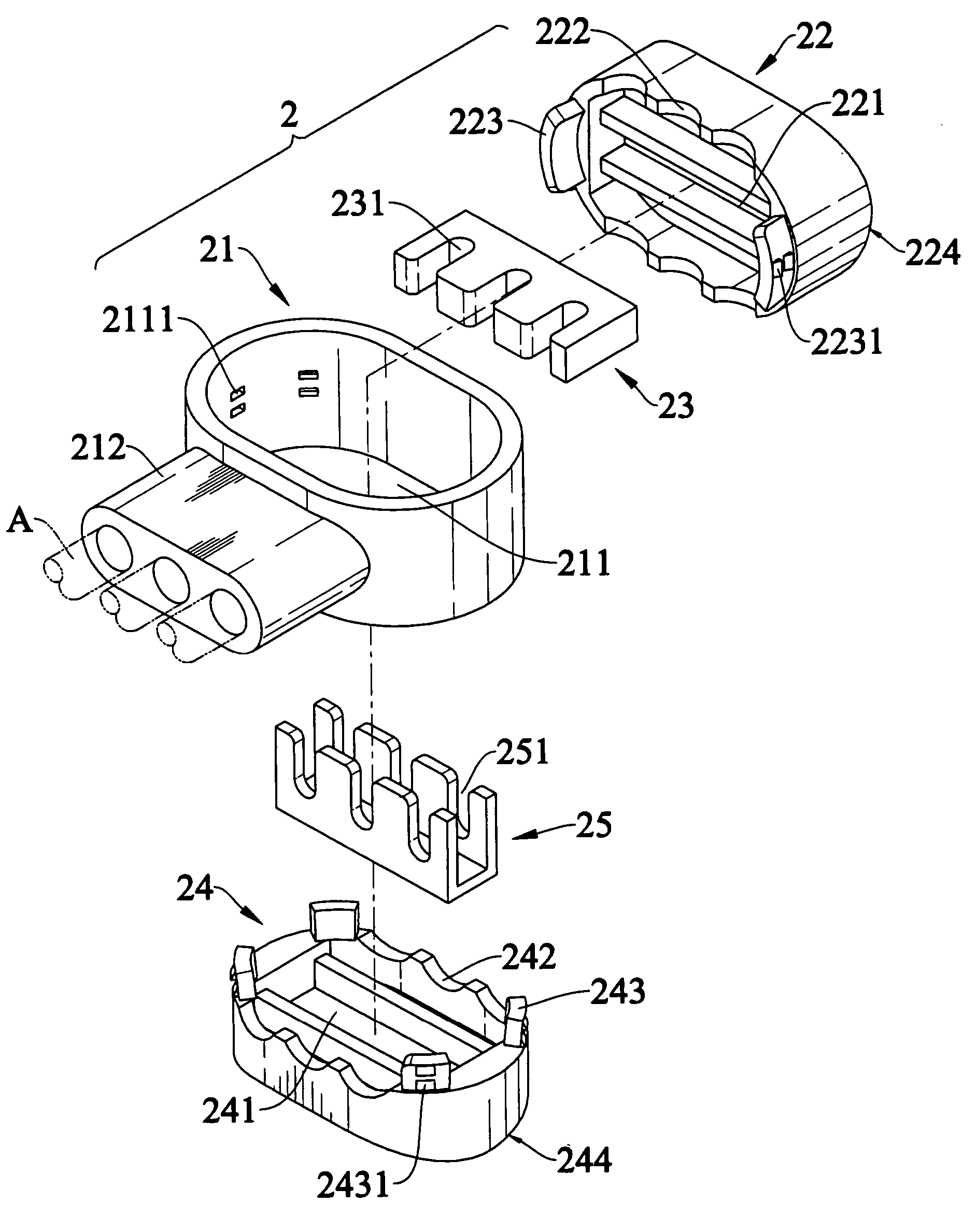

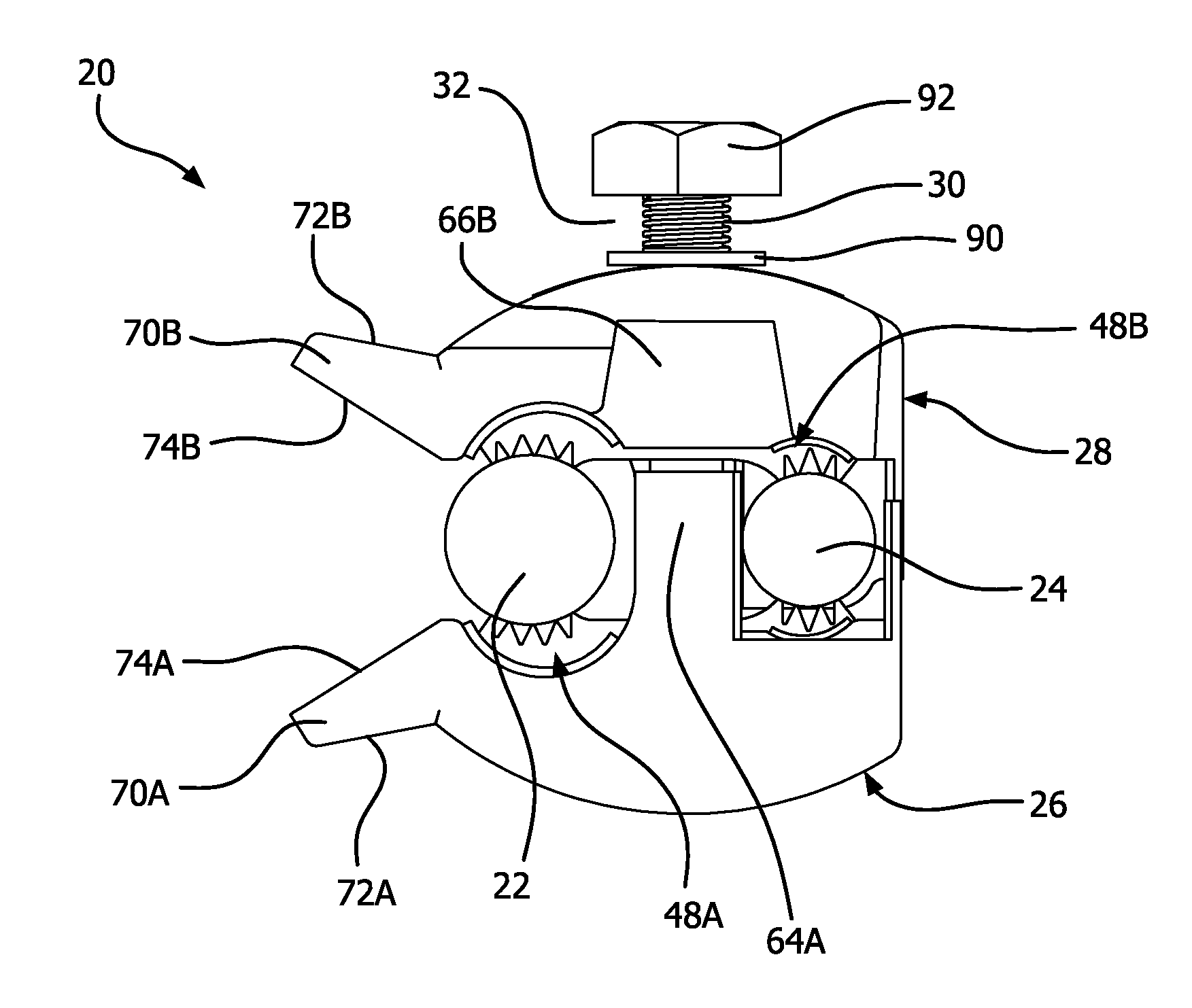

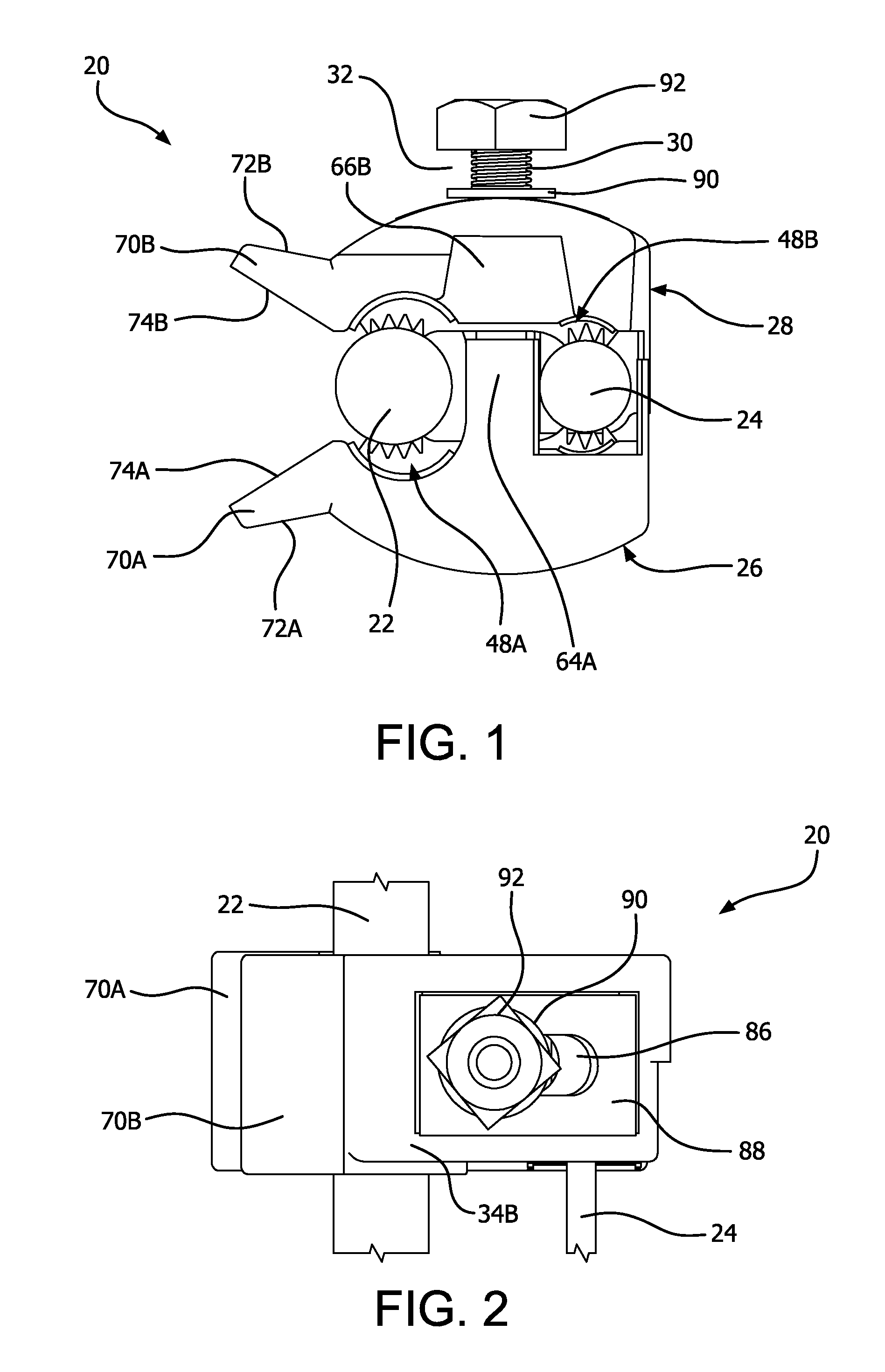

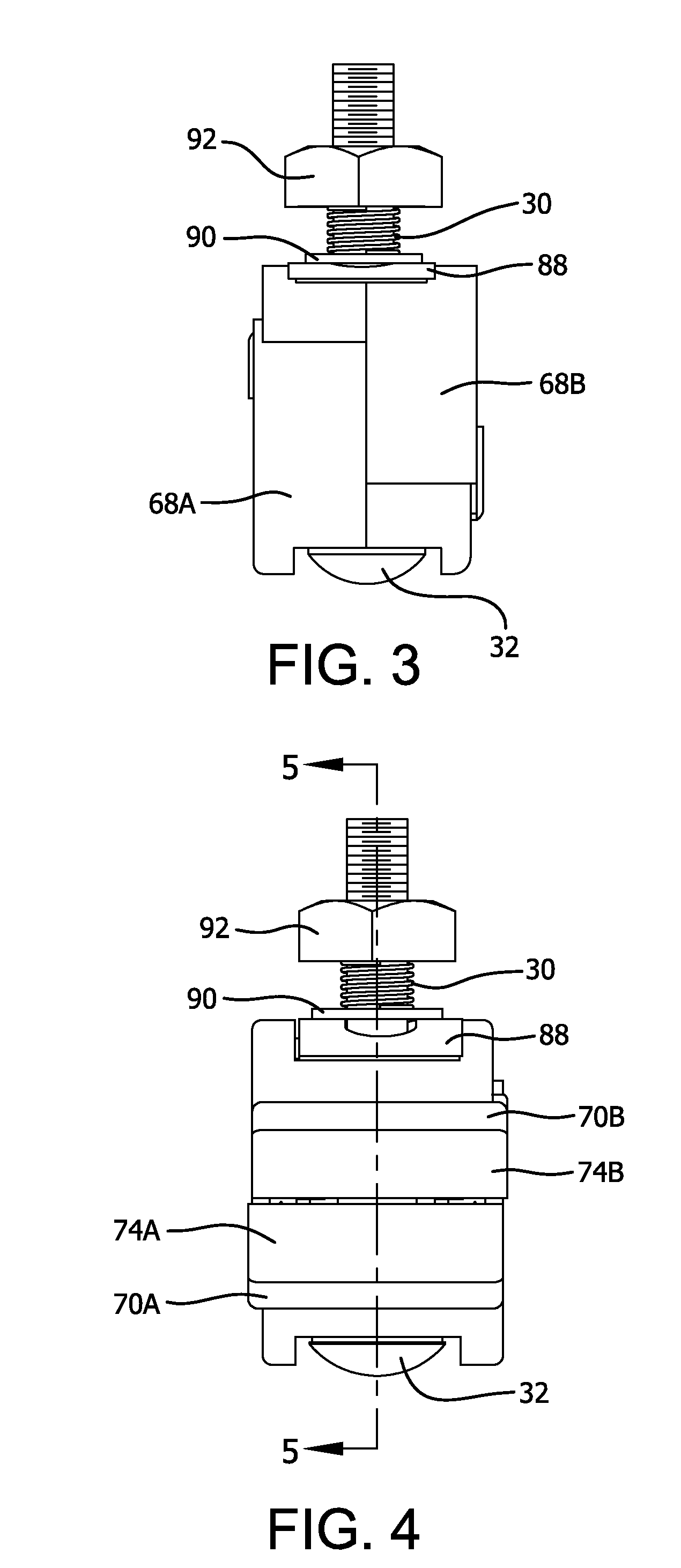

Coupler connector and cable terminator with side contacts

ActiveUS20160072240A1Contact member manufacturingCoupling device detailsElectrical conductorElectric wire

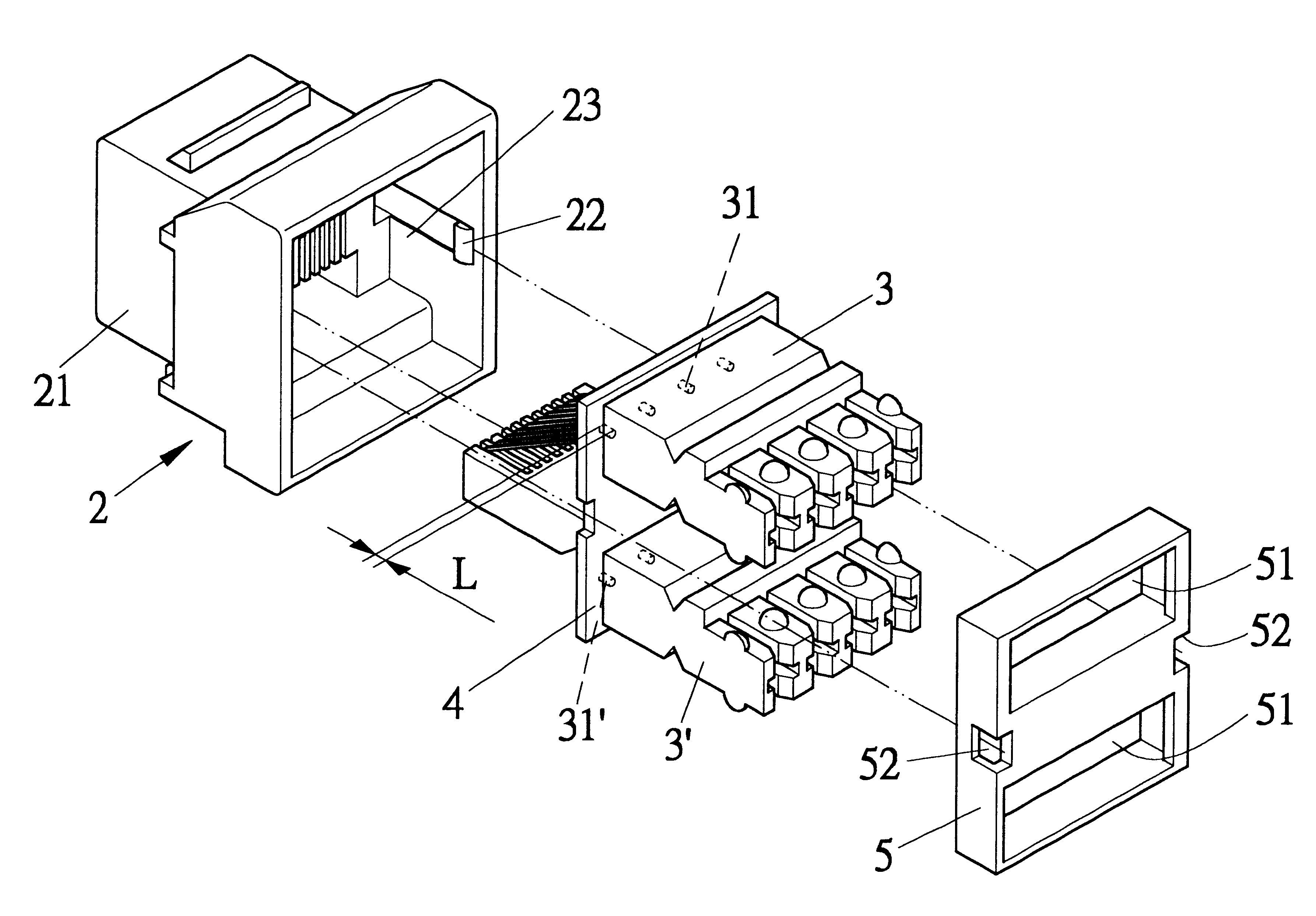

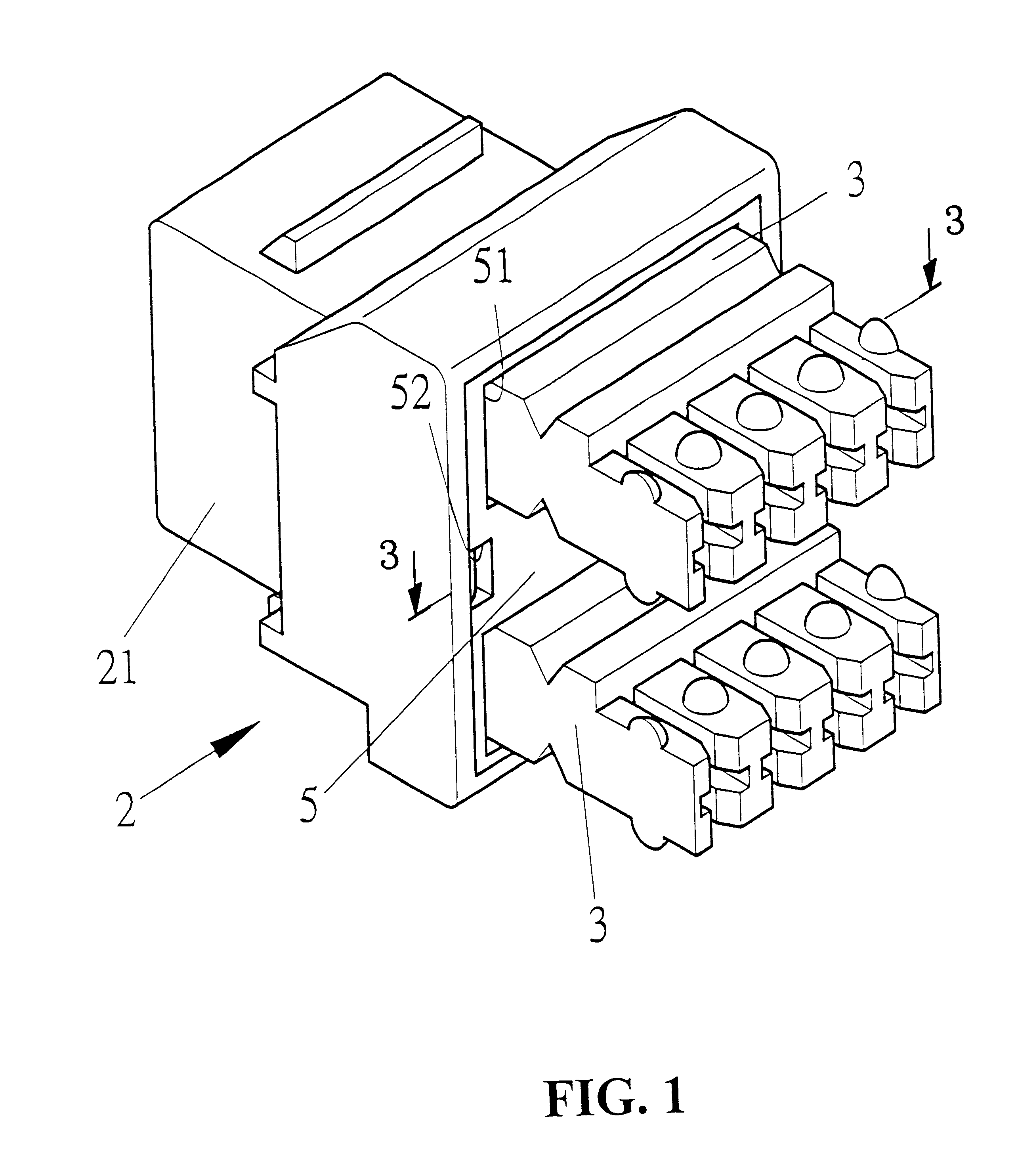

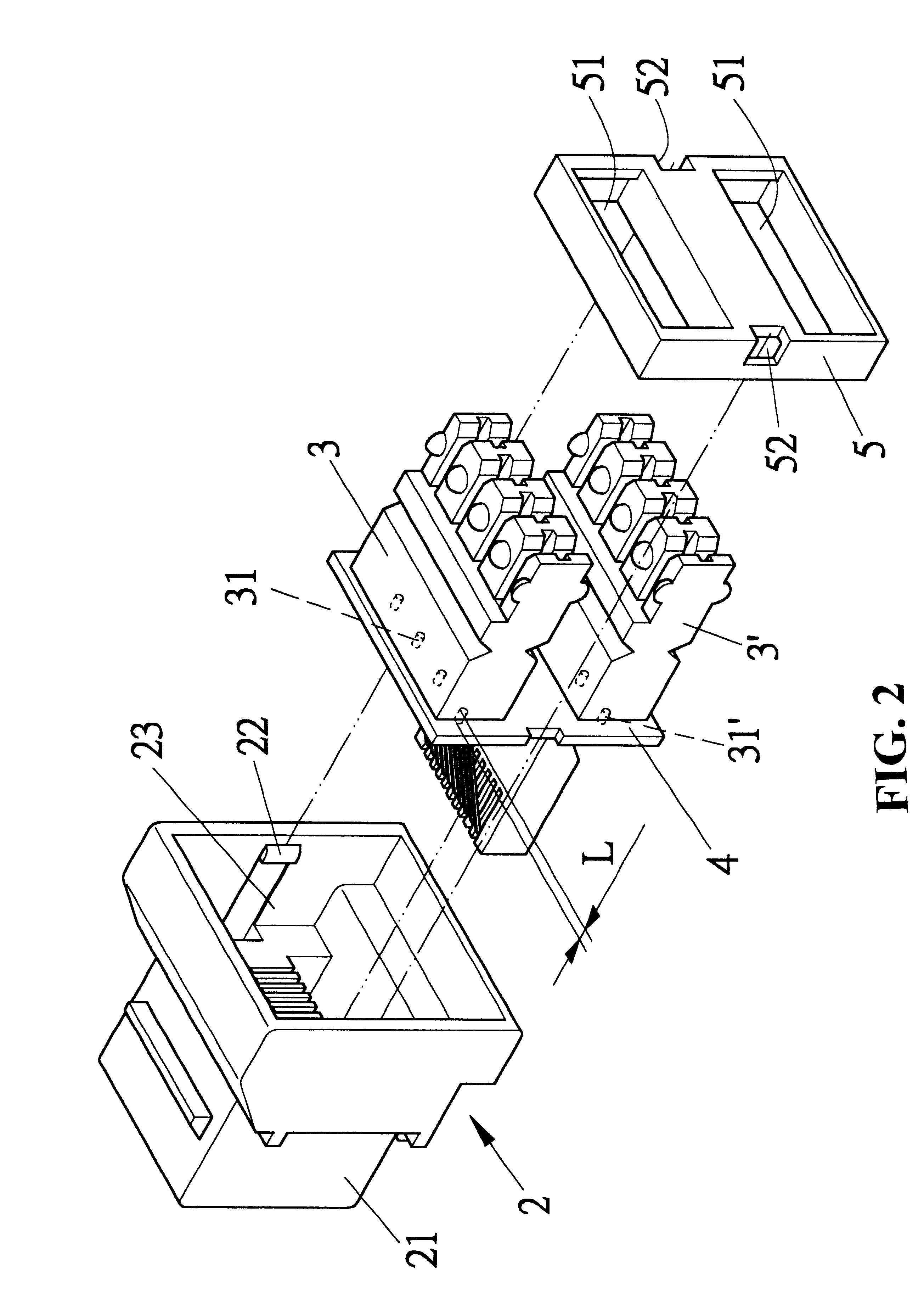

An assembly comprising a cable terminator comprising a wire guide, a cube shaped securing cap comprising an open end for installation over the wire guide, and pairs of piercing contacts for piercing respective conductors of the cable. When assembled, an outer end of each of the piercing contacts is exposed on an outer surface of a respective securing cap sidewall. The assembly also comprises a coupler connector comprising one of a modular (for example RJ-45 compatible) socket or a modular (for example RJ-45 compatible) plug, a rearward surface comprising a cable terminator receiving socket, wherein pairs of contacts are exposed along at least one side wall of the socket, and further wherein each of a plurality of the tines in the modular socket or the terminal contacts of the plug is interconnected with a respective one of the contacts. When the cable terminator is inserted into the cable terminator receiving socket, each of the piercing contacts comes into contact with a respective one of the contacts, thereby interconnecting each of the tines (or each of the terminal contacts) with a respective one of the conductors. A back-to-back connector is also disclosed.

Owner:BELDEN CANADA ULC

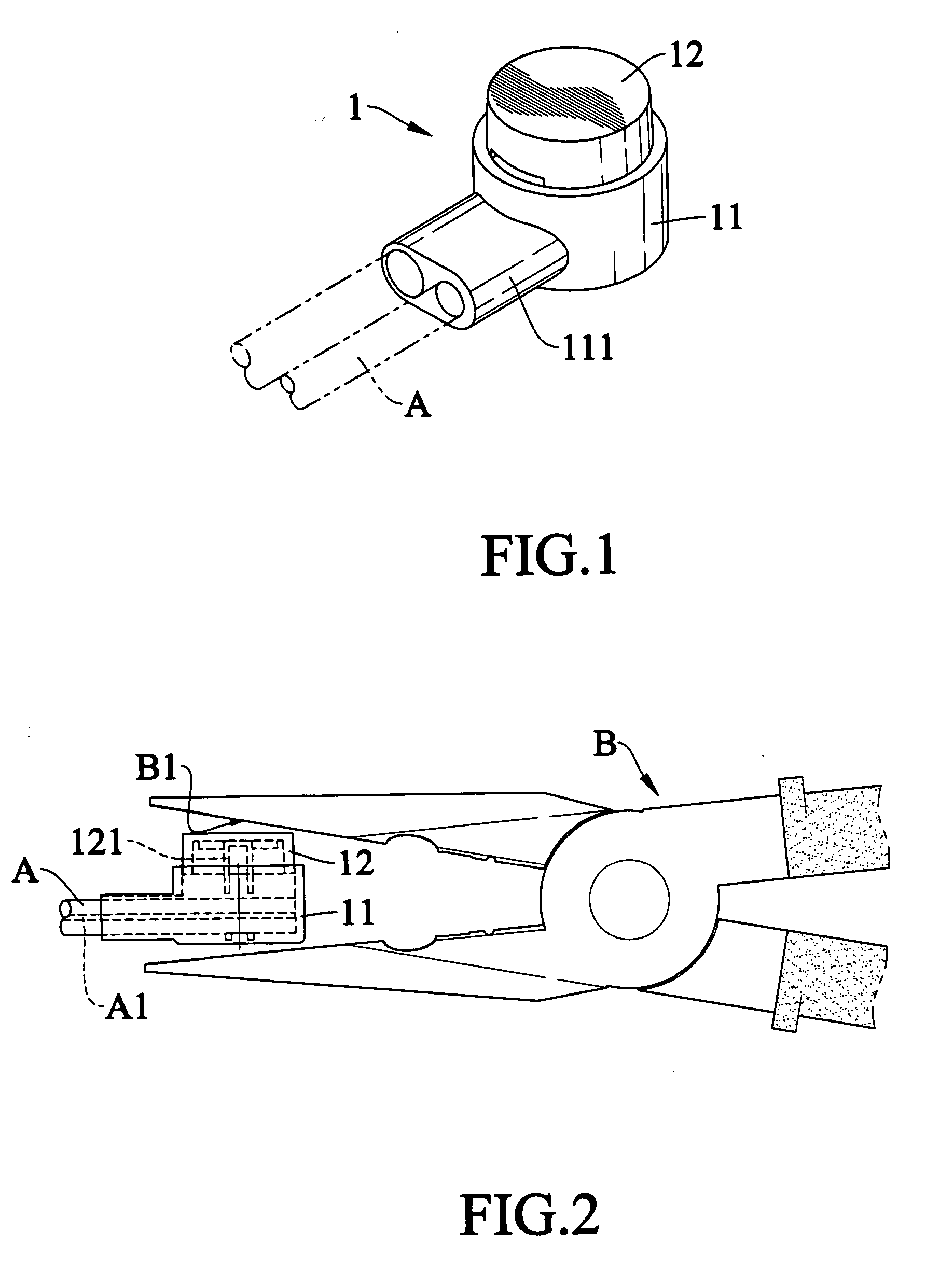

Wire connector

InactiveUS20050070147A1No deformationStablyCoupling device detailsUnstripped conductor connection apparatusElectric wire

Owner:HUNG PAO TIEN

Wiring harness, connector, and method of assembling the wiring harness

ActiveUS7273388B2High mechanical strengthConvenience to workUnstripped conductor connection apparatusContact members penetrating/cutting insulation/cable strandsElectrical conductorEngineering

Owner:YAZAKI CORP

Spring-loaded insulation piercing electrical connector

ActiveUS20160020529A1Describe wellContact member manufacturingContact member assembly/disassemblyEngineeringElectrical connector

An electrical connector includes first and second pads. The first pad includes first and second grooves and the second pad includes third fourth grooves. A first insulation displacing contact extends from the first groove to the second groove. A second insulation displacing contact extends from the third groove to the fourth groove. The first and second pads are connected by a mechanical fastener. When the first and second pads are connected the first groove aligns with the third groove and the second groove aligns with the fourth groove.

Owner:HUBBELL INC

Split flex cable

InactiveUS20100084160A1Reduce thicknessReduced combined widthPrinted circuit assemblingCoupling device connectionsEngineeringFlexible cable

A cable assembly for interconnecting a plurality of circuit boards together by using a connector assembly connected to each of the circuit boards. The cable assembly includes a first cable having a first end part and a second cable having a second end part. A first periphery of the first end part has a plurality of first half vias that collectively form a column along a width direction of the connector assembly. A second periphery of the second end part has a plurality of second half vias that collectively form a column along the width direction of the connector assembly. The first and second end parts are coupled together to form a connecting unit, such that the first half vias and the second half vias are joined together to form full vias.

Owner:GLOBALFOUNDRIES INC

Joint member and joint connector for wire harness

InactiveUS20050106903A1Reduce thicknessReduce protrusionPrinted circuit aspectsLaminating printed circuit boardsJoint componentEngineering

Owner:AUTONETWORKS TECH LTD +2

Aluminium wire-contained motor joint and processing method thereof

InactiveCN104037517AImprove reliabilityPrevent Corrosion Short CircuitUnstripped conductor connection apparatusContact members penetrating/cutting insulation/cable strandsOxidation resistantAluminium

The invention discloses an aluminium wire-contained motor joint comprising an aluminium enameled wire and a wiring terminal. A clamp groove is formed in the motor and includes an aluminium enameled wire leading-out wire accommodation portion and a wiring terminal accommodation portion; an aluminium enameled wire leading-out wire is pressed into the aluminium enameled wire leading-out wire accommodation portion and penetrates the wiring terminal accommodation portion; and the wiring terminal is pressed into the wiring terminal accommodation portion with a pointed portion. When the wiring terminal is pressed into the wiring terminal accommodation portion, the pointed portion punctures the enamelling layer of the aluminium enameled wire, thereby completing condution with the aluminium wire. According to the processing method, the aluminium wire is compressed by using the wiring terminal and the clamp groove instead of using the traditional heat-shrinkable bush, thereby not only ensuring the oxidation-resistant capability and preventing phenomena of short circuit and poor contact at the joint but also improving the aluminium wire joint protection reliability. The motor running reliability is improved and easy production and operation are also realized.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

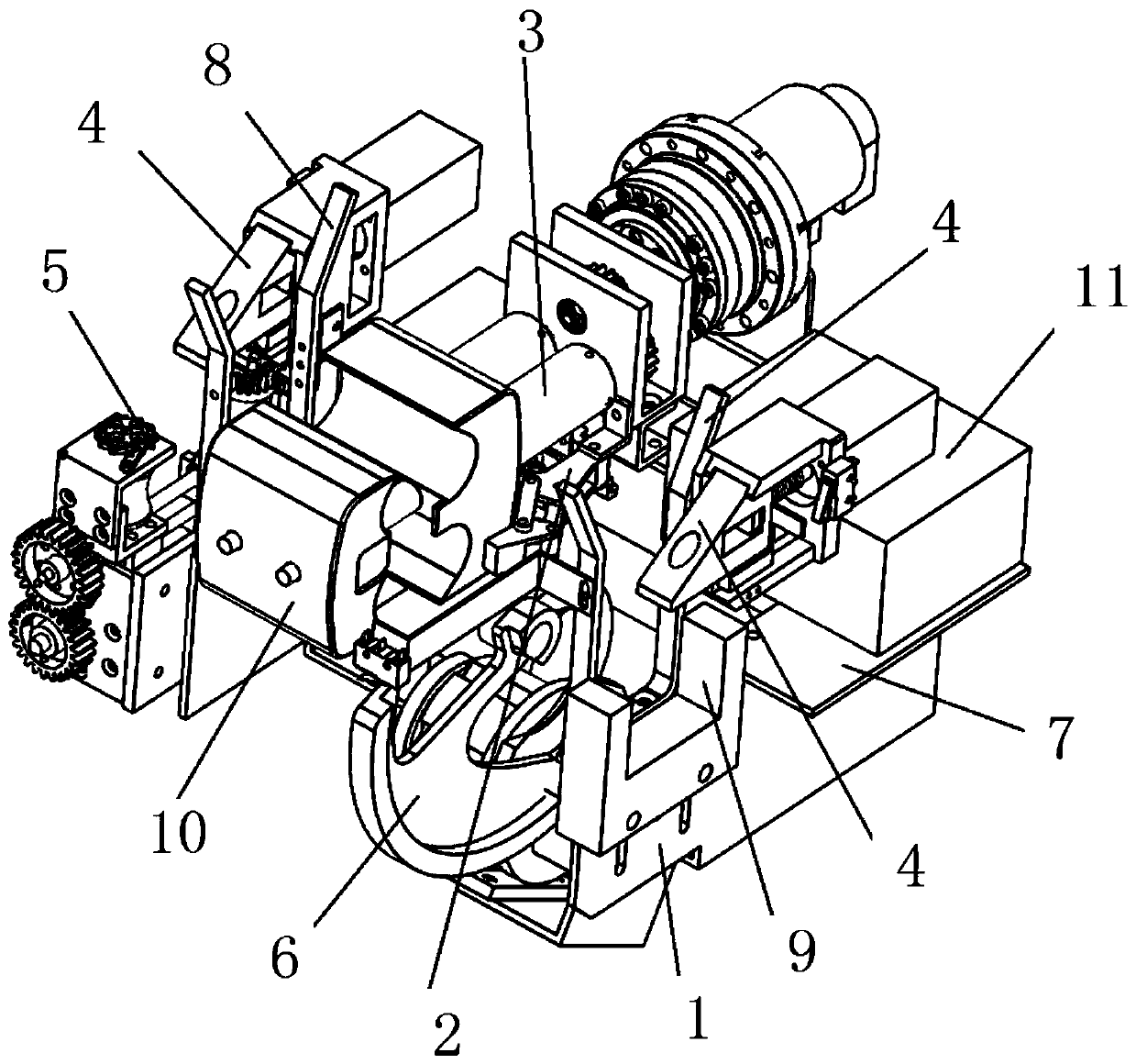

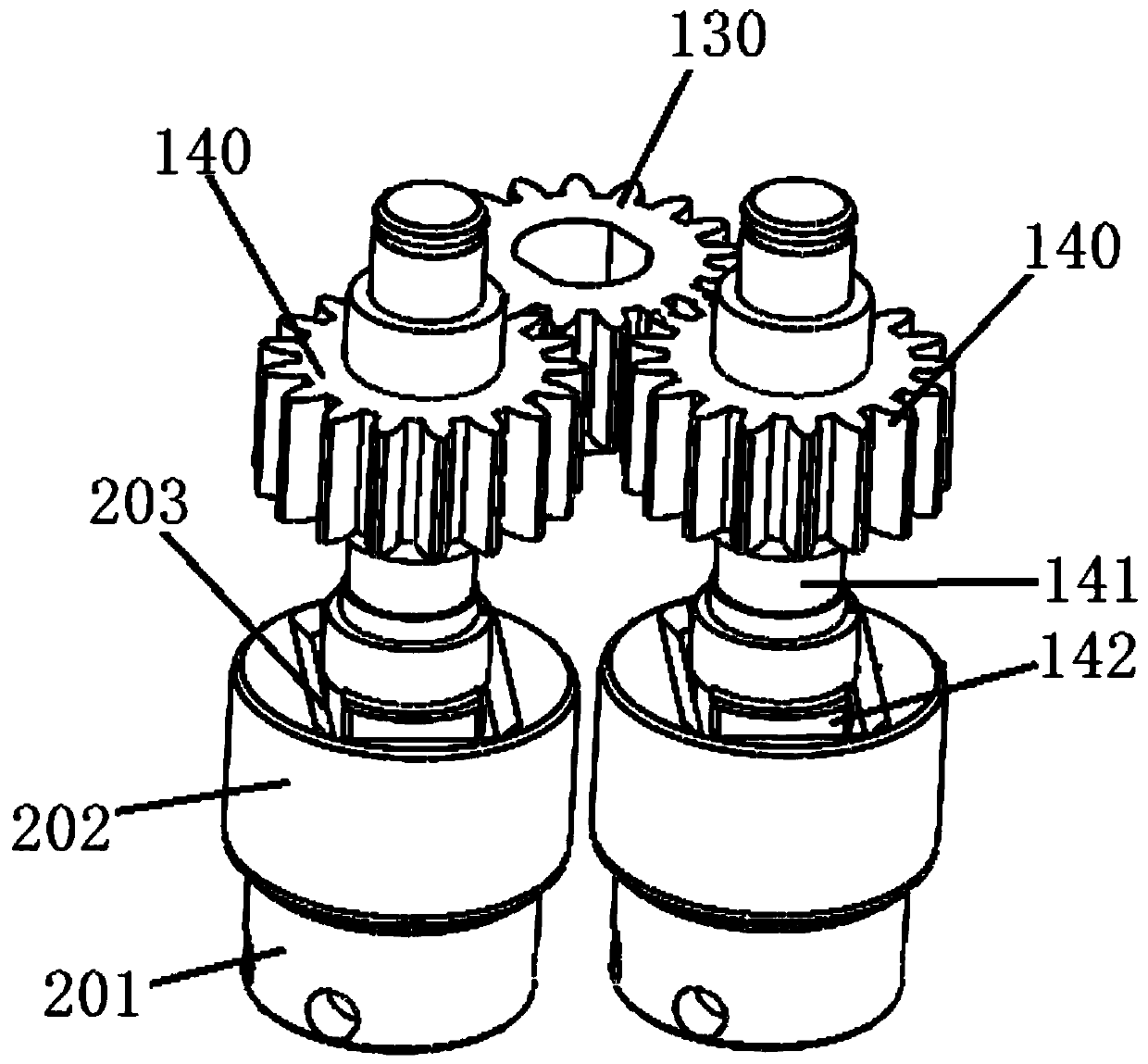

Screwing up device and live wire connecting device of puncturing wire clamp

ActiveCN109950768ASolve the problem of easy sticking in the sleeveSolve technical problems that are difficult to removeUnstripped conductor connection apparatusEngineeringMechanical engineering

The invention discloses a screwing up device and live wire connecting device of a puncturing wire clamp, and relates to the technical field of auxiliary devices of puncturing wire clamp. Concretely, the screwing up device of the puncturing wire clamp comprises a driving mechanism and sleeves, the driving mechanism can drive the sleeves to rotate via an output shaft, the number of the sleeves is the same with that of moment bolt heads of the puncturing wire clamp, the sleeves are arranged in one to one correspondence with the moment bolt heads, the two ends of each sleeve are communicated, thefirst end of each sleeve is adapted to the corresponding moment bolt head, and the second end of the sleeve can be detachably connected with the output shaft of the driving mechanism. Thus, the technical problem that a fractured moment bolt head tends to be stuck in the sleeve and is hard to take out is solved, and operation is convenient and rapid.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +2

Device and method for splicing shielded wire cables

ActiveUS9928939B1Vehicle connectorsSoldered/welded conductive connectionsConductive materialsEngineering

A wire cable assembly, such as those used in electric or hybrid electric vehicles, having a plurality of shielded wire cables that are spliced together is presented. The assembly includes a splicing device having a generally planar bus bar formed of a conductive material, wherein the exposed core conductors of the shielded wire cables are welded to the bus bar, thereby electrically interconnecting the exposed core conductors. A conductive sleeve encloses bus bar and interconnects the shield conductors of the shielded wire cables, providing shielding for the exposed core conductors and continuity for the shield conductors. An outer insulator enclosing the conductive sleeve. A method of splicing shielded wire cables using such a device is also presented herein.

Owner:APTIV TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com