Screwing up device and live wire connecting device of puncturing wire clamp

A technology of puncture wire clamp and equipment, which is applied in the field of puncture wire clamp auxiliary equipment, which can solve problems such as difficulty in taking out, torque bolt head easily stuck in the sleeve, torque bolt head easily stuck in the sleeve, etc., and achieves the effect of convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

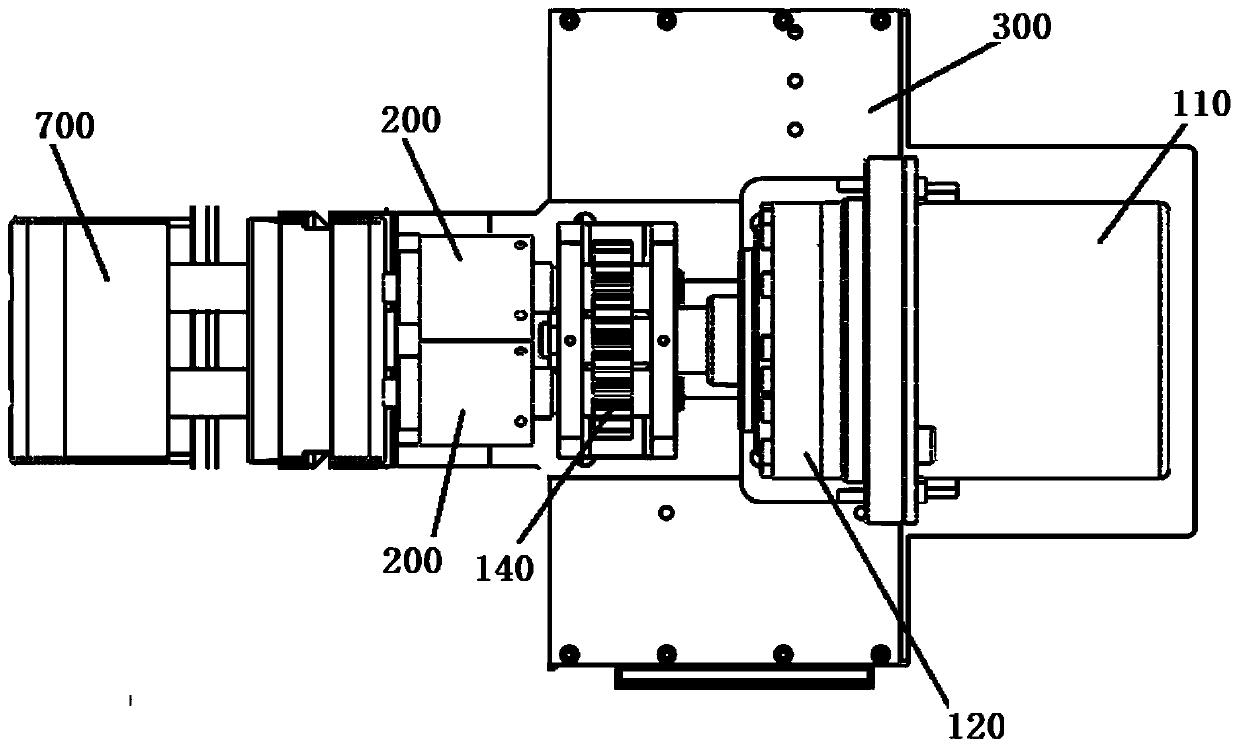

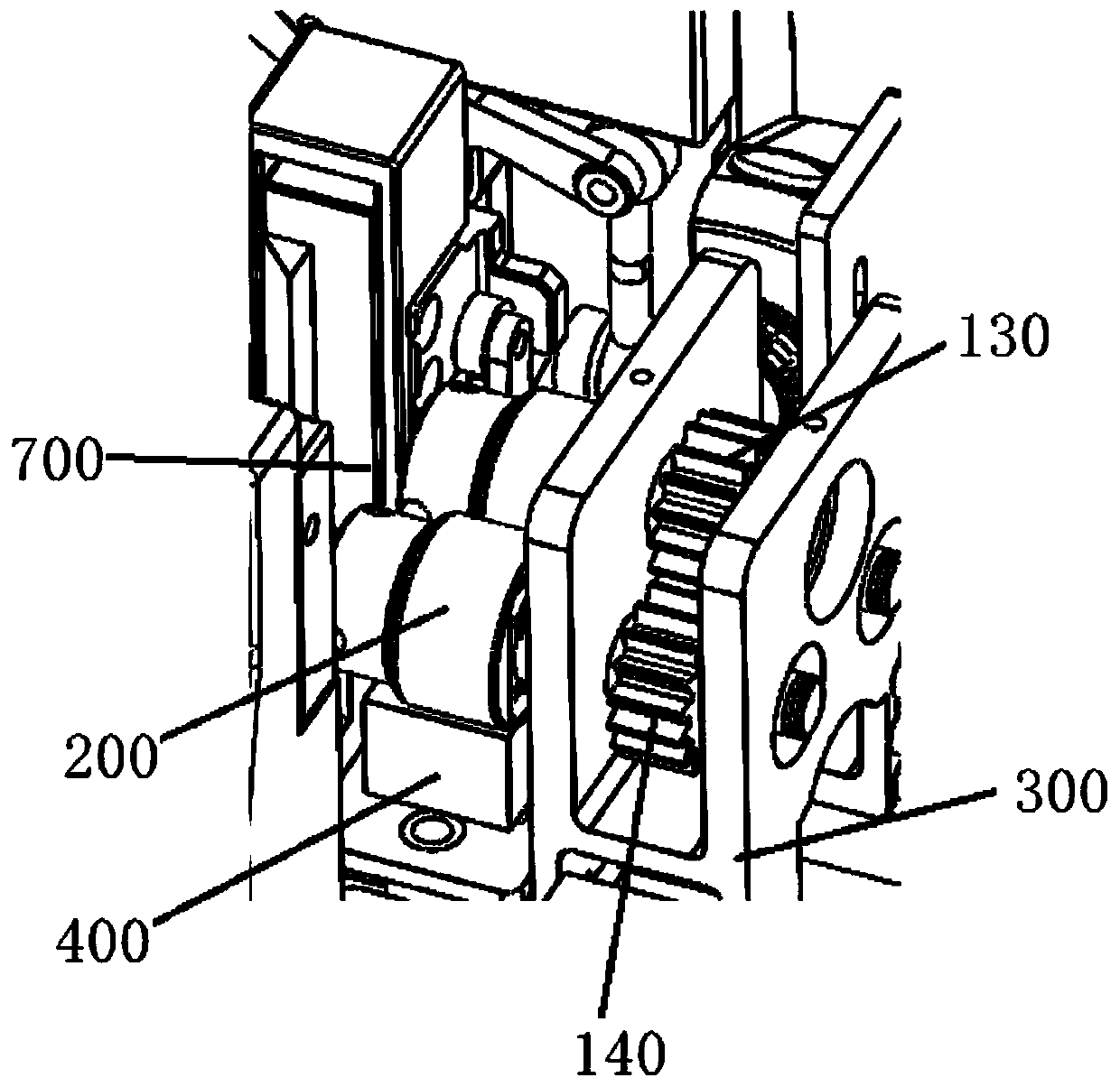

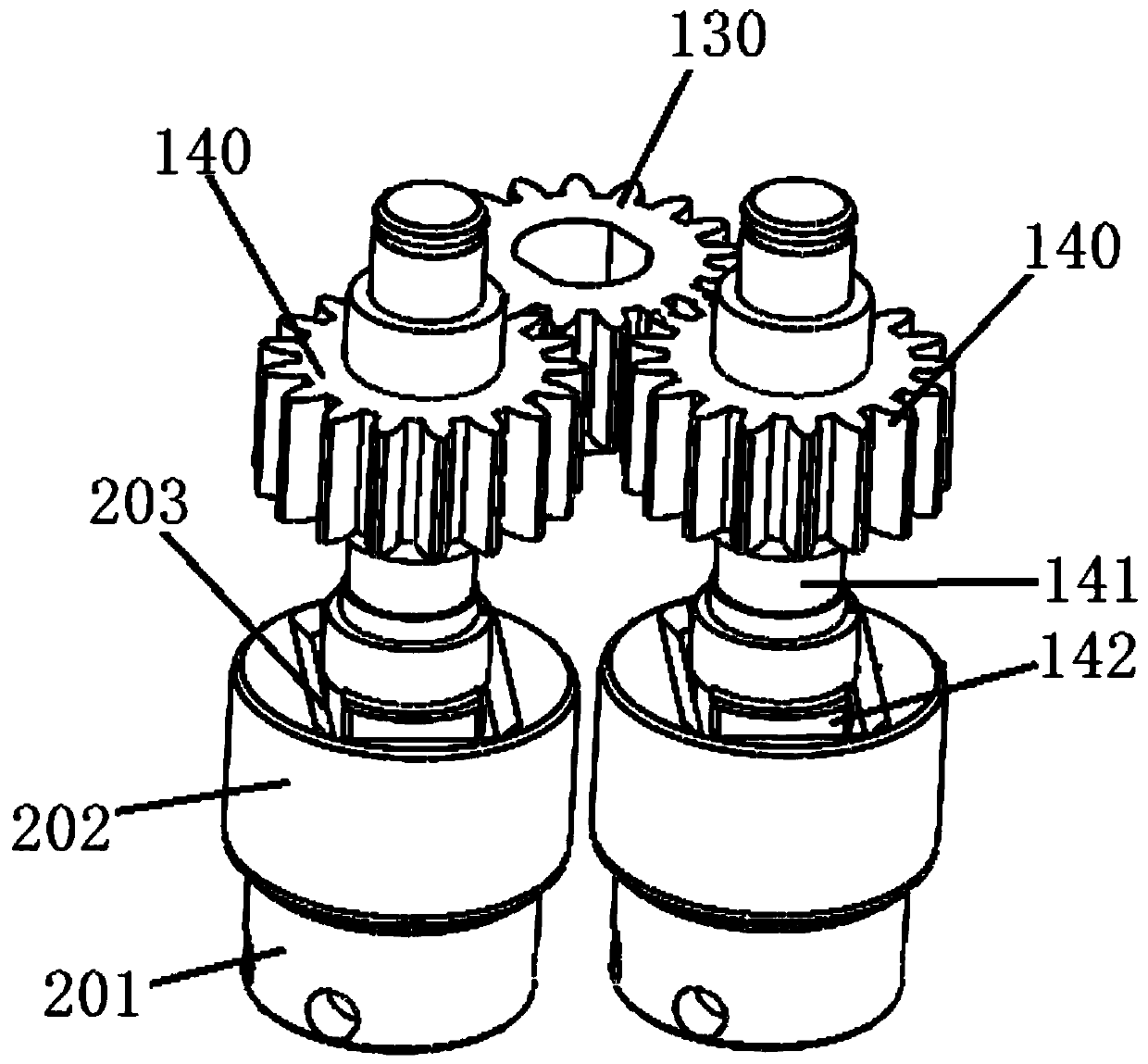

[0038] See Figure 1 to Figure 6 As shown, this embodiment provides a tightening device for a puncture clamp, which includes a driving mechanism 100 and a sleeve 200, and the output shaft of the driving mechanism can be detachably connected to the sleeve 200.

[0039] Wherein, the number of sleeves 200 is the same as the number of torque bolt heads of the piercing clamp 700, and the sleeves 200 are arranged in one-to-one correspondence with the torque bolt heads of the piercing clamp 700, respectively. Generally speaking, the piercing clamp 700 is connected by tightening two torque bolts, so the number of torque bolt heads is generally two, and the number of corresponding sleeves 200 is also two. The two ends of the sleeve 200 are in communication, and the first end 201 of the sleeve is matched with the torque bolt head, and the second end 202 of the sleeve is detachably connected with the output shaft of the driving mechanism 100.

[0040] The function of the driving mechanism 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com