Paper-based friction material test clamp and test method thereof

A technology of paper-based friction materials and test fixtures, which is applied in the direction of analyzing materials, testing wear resistance, measuring devices, etc., can solve the problems of difficulty in testing paper-based friction materials, and achieve the effect of convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

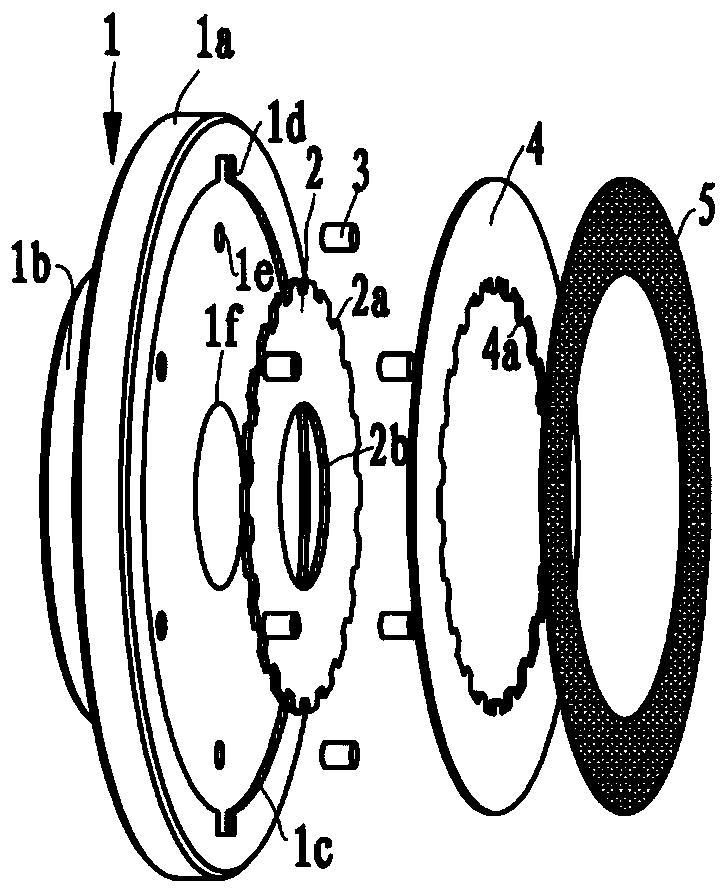

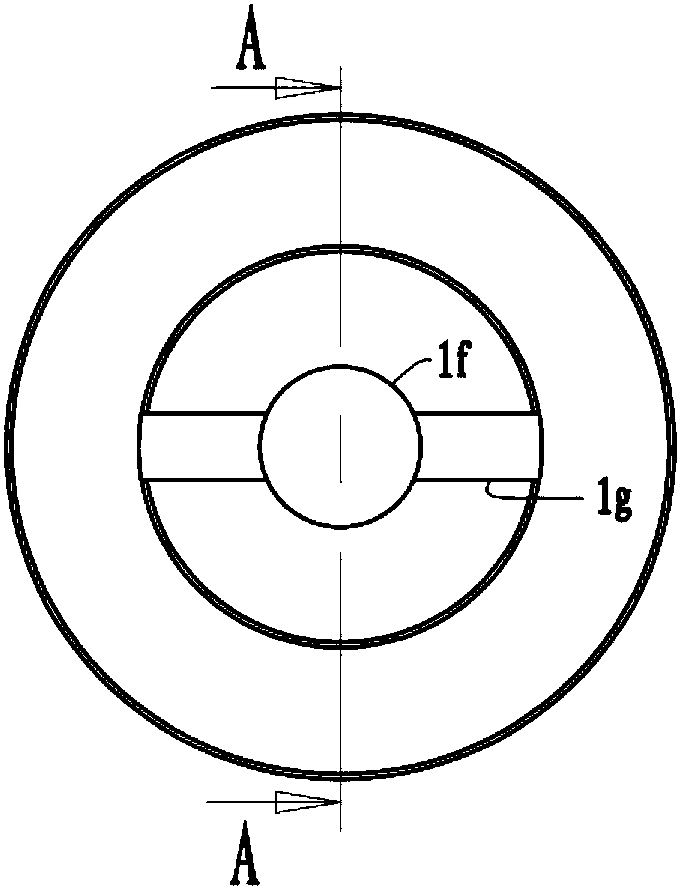

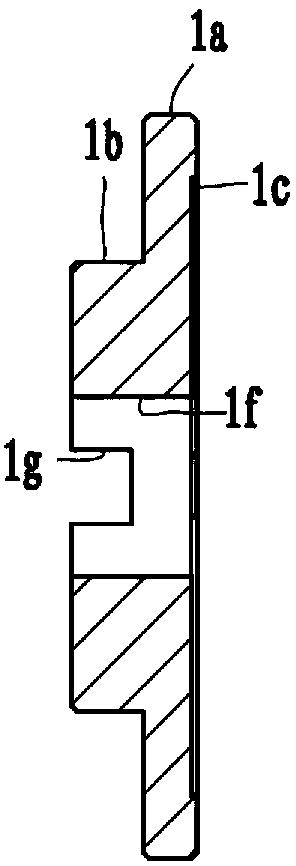

[0022] Example 1. The test fixture for paper-based friction material of the present invention includes a fixture main body 1 , a positioning spline 2 , a magnet 3 and a core plate 4 . The fixture main body 1 is a metal disc structure. The sample clamping part 1a on the fixture main body 1 is used for clamping and positioning the paper-based friction material 5. The right end surface is processed with a sample clamping groove 1c, a sample dismounting groove 1d and The magnet installation hole 1e, the fixture installation part 1b has a spline groove 1g for connection with the friction testing equipment, the axis of the fixture main body 1 has a A process hole 1f, which is used to reduce the weight of the fixture; the sample clamping part 1a is guaranteed Under the premise of fixture strength and rigidity, reduce the thickness as much as possible to reduce the weight of the fixture. The thickness is preferably 5-10mm; The outer diameter of the friction material 5 is 10-20mm larg...

Embodiment 2

[0023] Example 2. The method for testing the paper-based friction material by using the paper-based friction material test jig in Example 1, the specific steps are as follows.

[0024] 1) Bond the paper-based friction material 5 to be tested to one side of the core plate 4, and ensure the concentricity of the paper-based friction material 5 and the core plate 4 during bonding.

[0025] 2) Assemble the fixture, assemble the positioning spline 2 in the sample clamping groove 1c by welding, ensure that the B process hole 2b and the A process hole 1f are concentric, and assemble the magnet 3 on the magnet installation with an interference fit. Inside hole 1e.

[0026]3) Assemble the core plate 4 bonded with the paper-based friction material 5 into the sample clamping groove 1c, with the side with the paper-based friction material 5 on the outside.

[0027] 4) Assemble the friction material testing fixture on the friction testing machine to test the friction performance of the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com