A saw blade rolling device capable of preventing saw blade surface scratches and center hole deformation

A hole deformation and saw blade technology, which is applied in the field of rolling equipment, can solve the problems of poor rolling quality of saw blades, achieve the effect of ingenious design, convenient operation, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

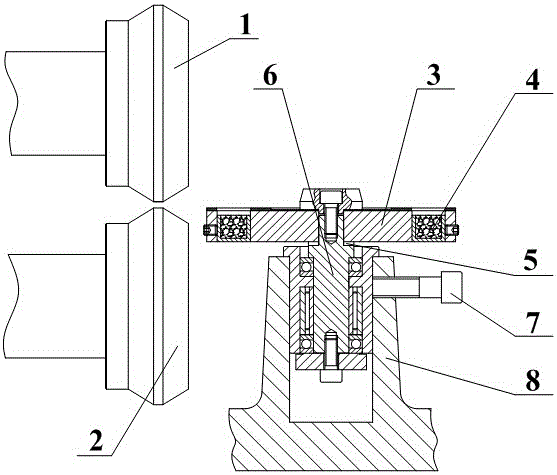

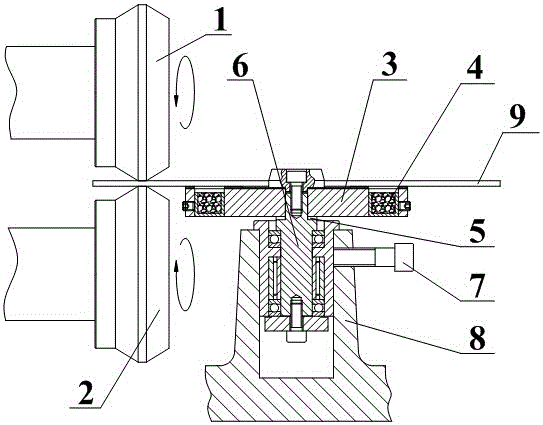

[0026] Such as figure 1 As shown, the present invention is mainly used to realize the rolling of the saw blade, which includes a driving rolling wheel 1 , a driven rolling wheel 2 , a saw blade fixing mechanism and a workbench 8 . The active rolling wheel 1 and the driven rolling wheel 2 cooperate with each other to realize the rolling and rolling of the saw blade, and the saw blade fixing mechanism is fixed on the workbench 8 for placing the saw blade that needs to be rolled. . Specifically, the saw blade fixing mechanism includes a fixed support frame 6 that is detachably connected to the workbench 8 through a locking screw 7, and is sleeved on the fixing member (in this embodiment, the fixing member is preferably a positioning pin). The positioning tray 3 fixed on the supporting frame 6 and used for placing the saw blade, and the magnets 4 arranged in the positioning tray 3 and evenly distributed around it for attracting the saw blade. In this embodiment, in order to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com