Wire length measuring and feeding device

A technology for feeding devices and electric wires, which is applied in the field of electric wire length measuring and feeding devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

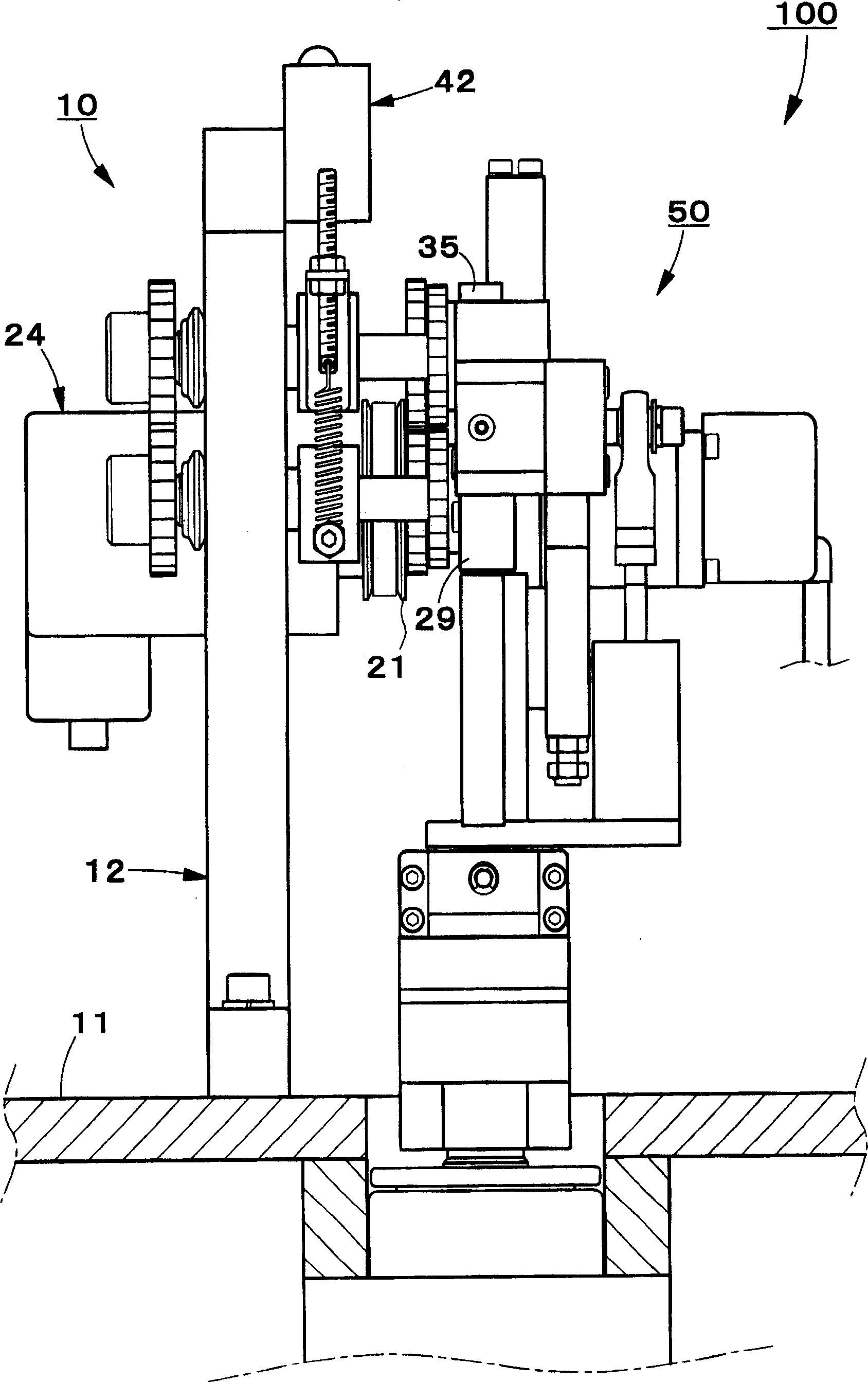

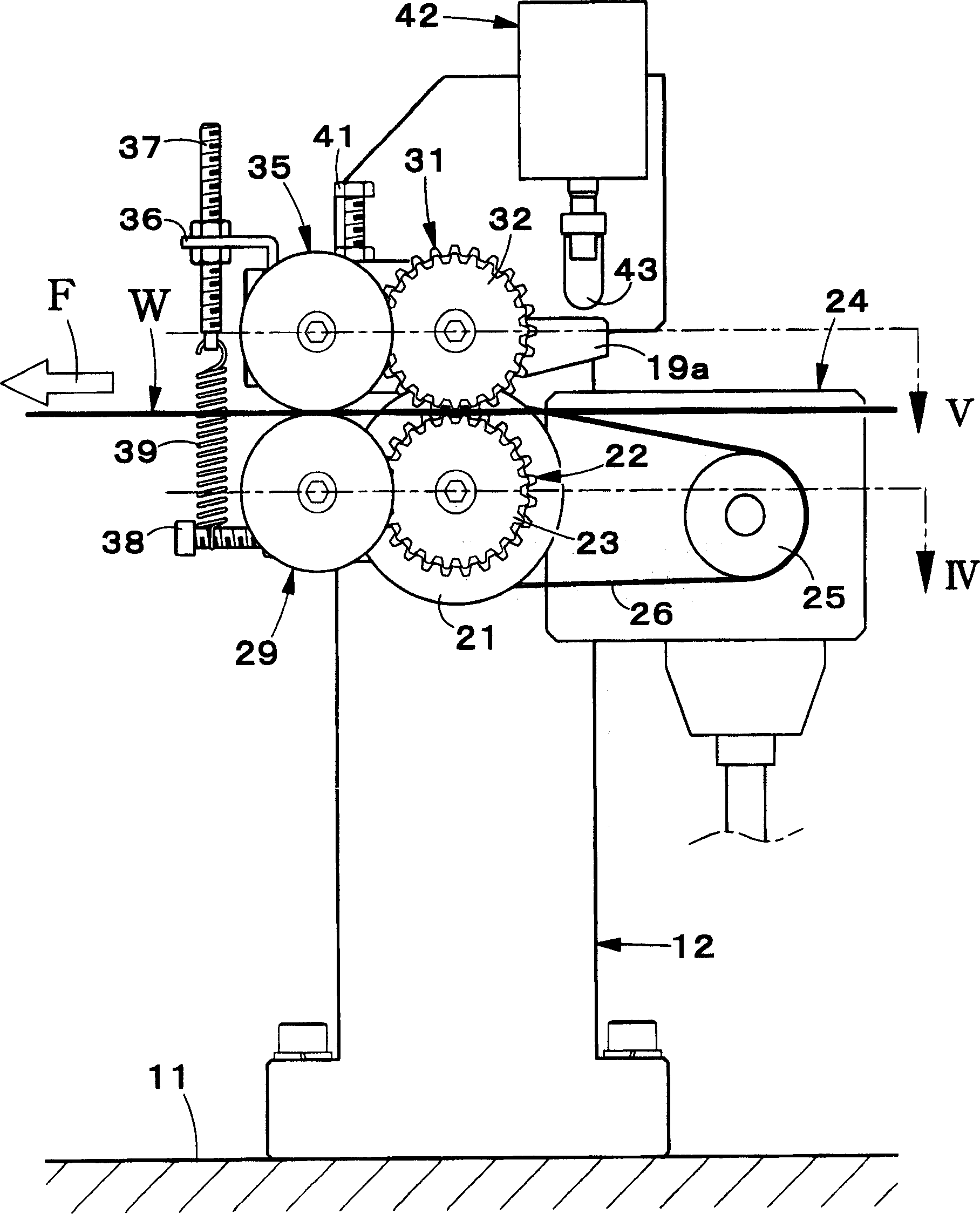

[0042] Below, refer to Figure 1 ~ Figure 1 1 An embodiment of the wire length measuring and feeding device of the present invention will be described in detail. In addition, in the following description, the direction in which the wires are fed toward the wire processing device is referred to as the front-rear direction, the vertical direction is referred to as the up-down direction, and the direction perpendicular to these directions is referred to as the left-right direction.

[0043] First, the initial reference figure 1 The wire length measuring and feeding device 100 of this embodiment is a combination of a feeding mechanism 10 fixed on a base 11 and a length measuring and swinging mechanism 50 that can swing freely on the base 11. The length measuring and swinging mechanism 50 is A structure that swings around a swing axis extending in the up and down direction.

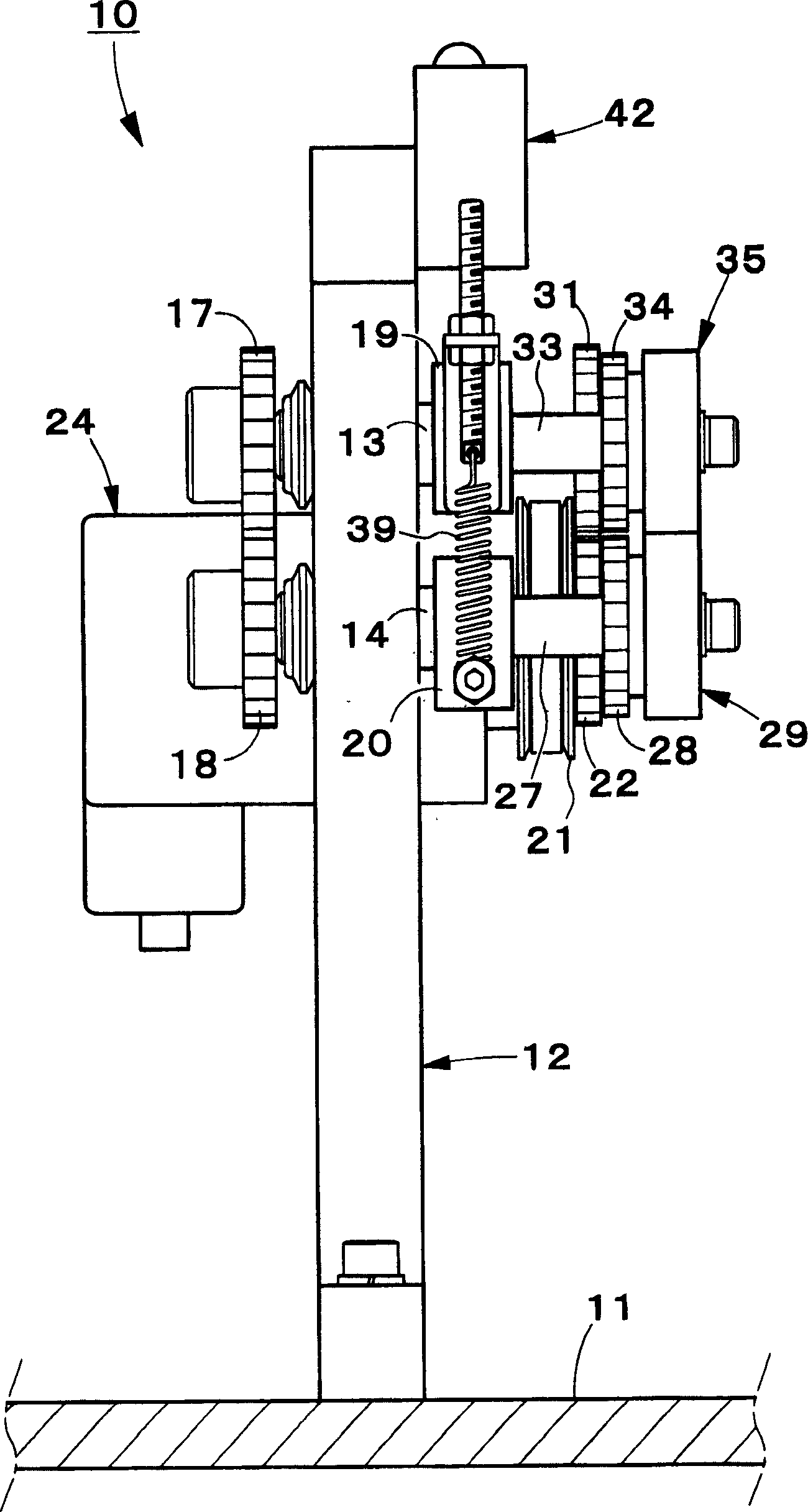

[0044] Feeding mechanism 10 such as figure 2 -As shown in FIG. 6, it has the original plate-shaped bracket (su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com