Patents

Literature

729results about "Supporting insulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

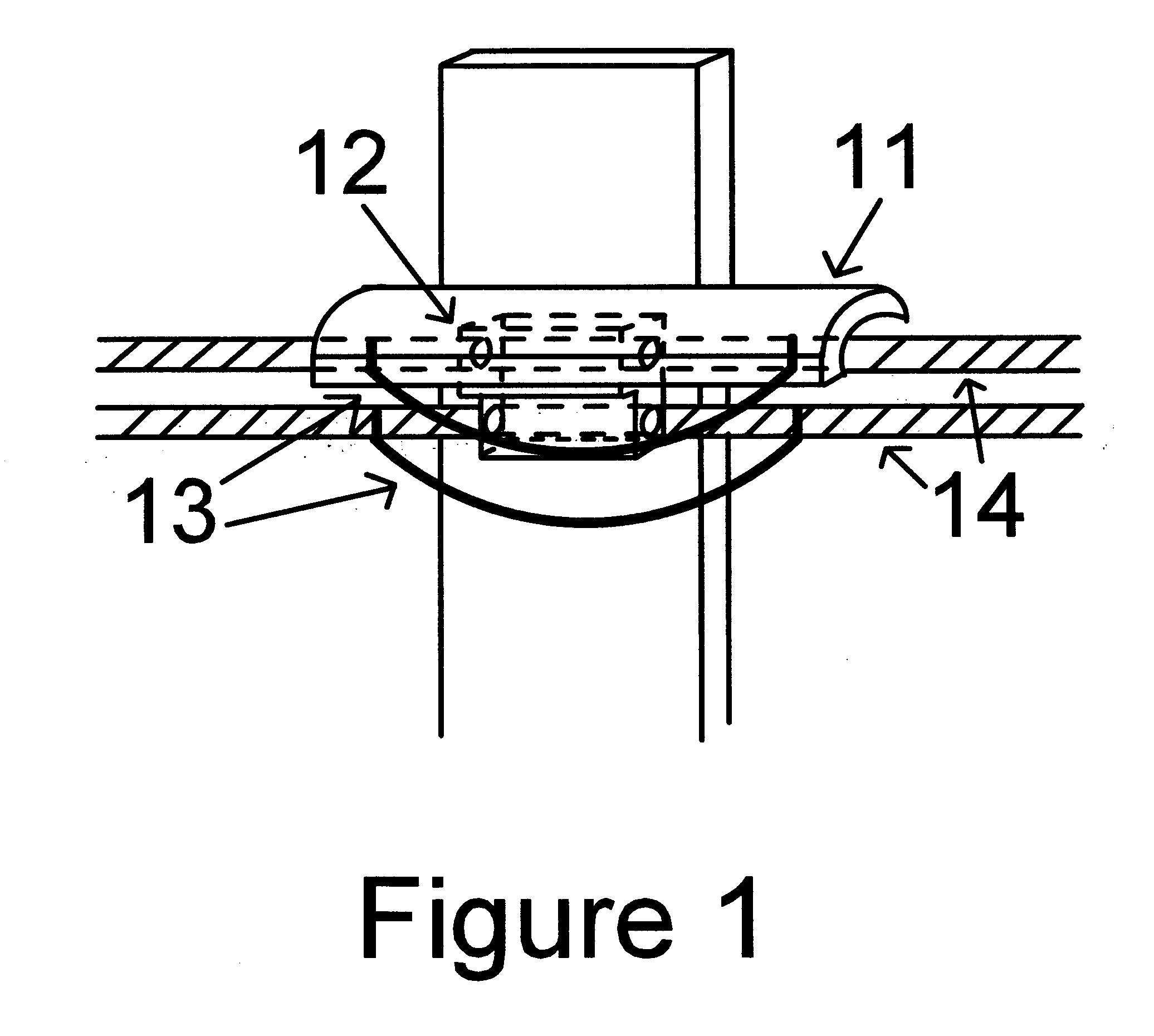

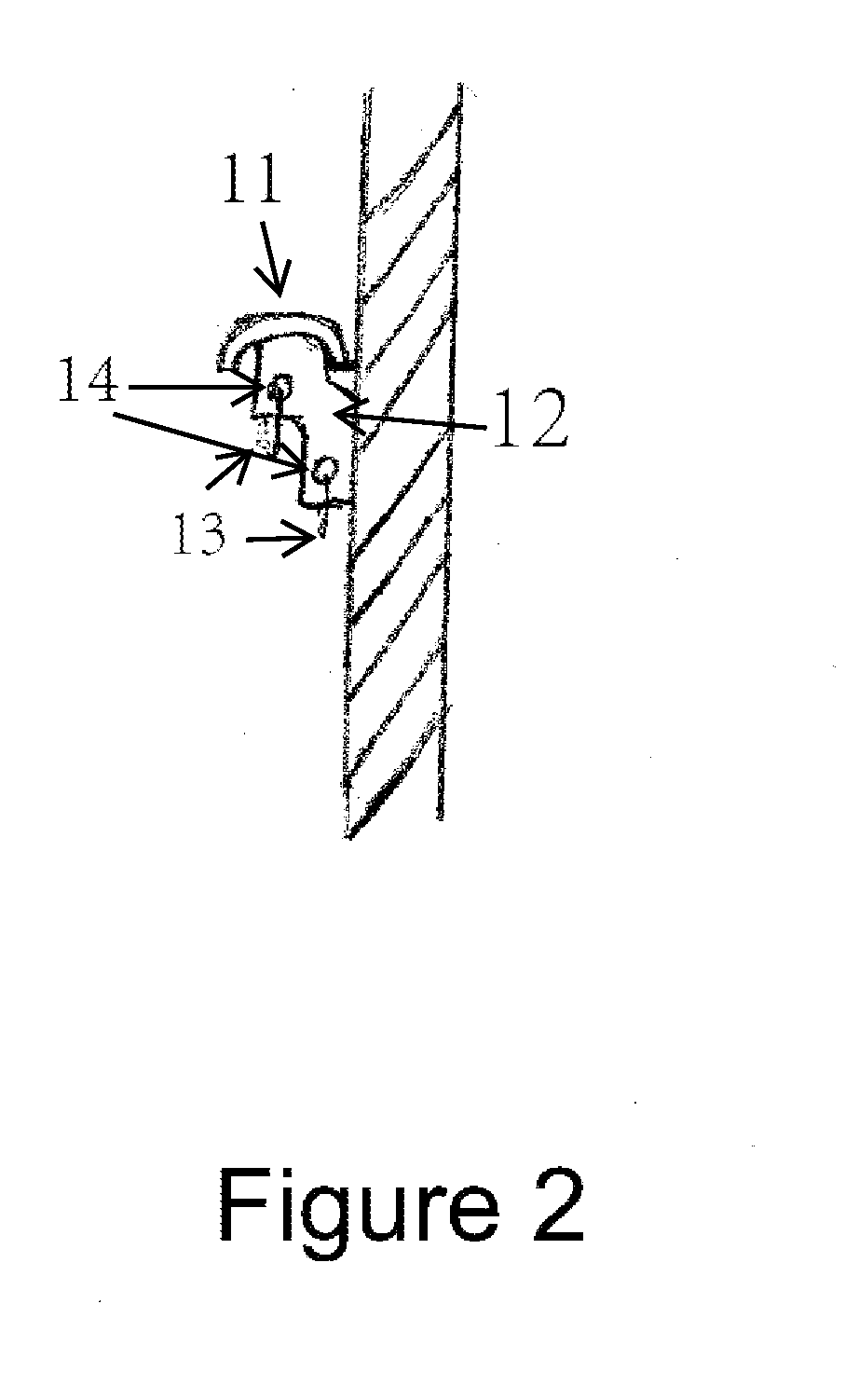

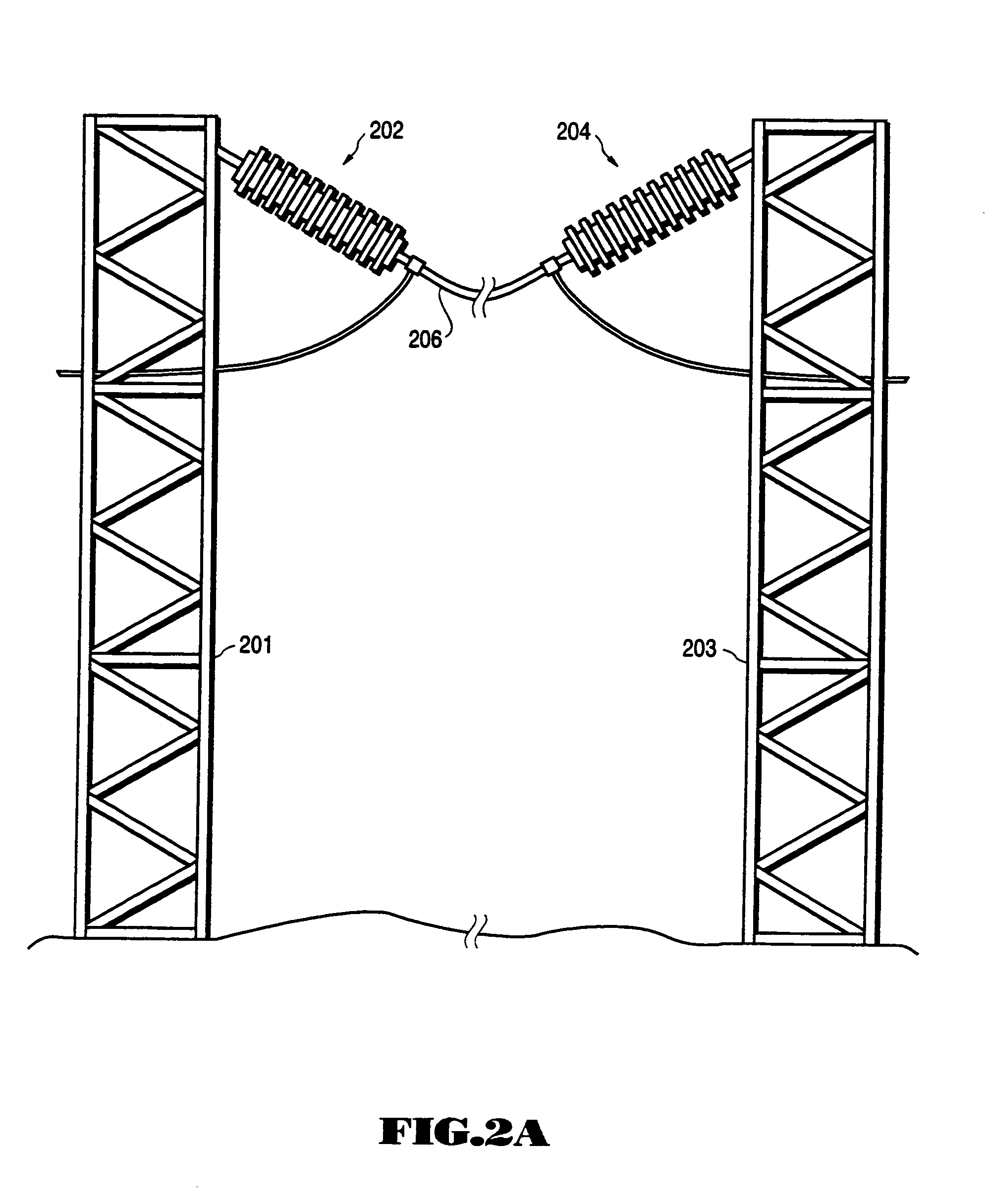

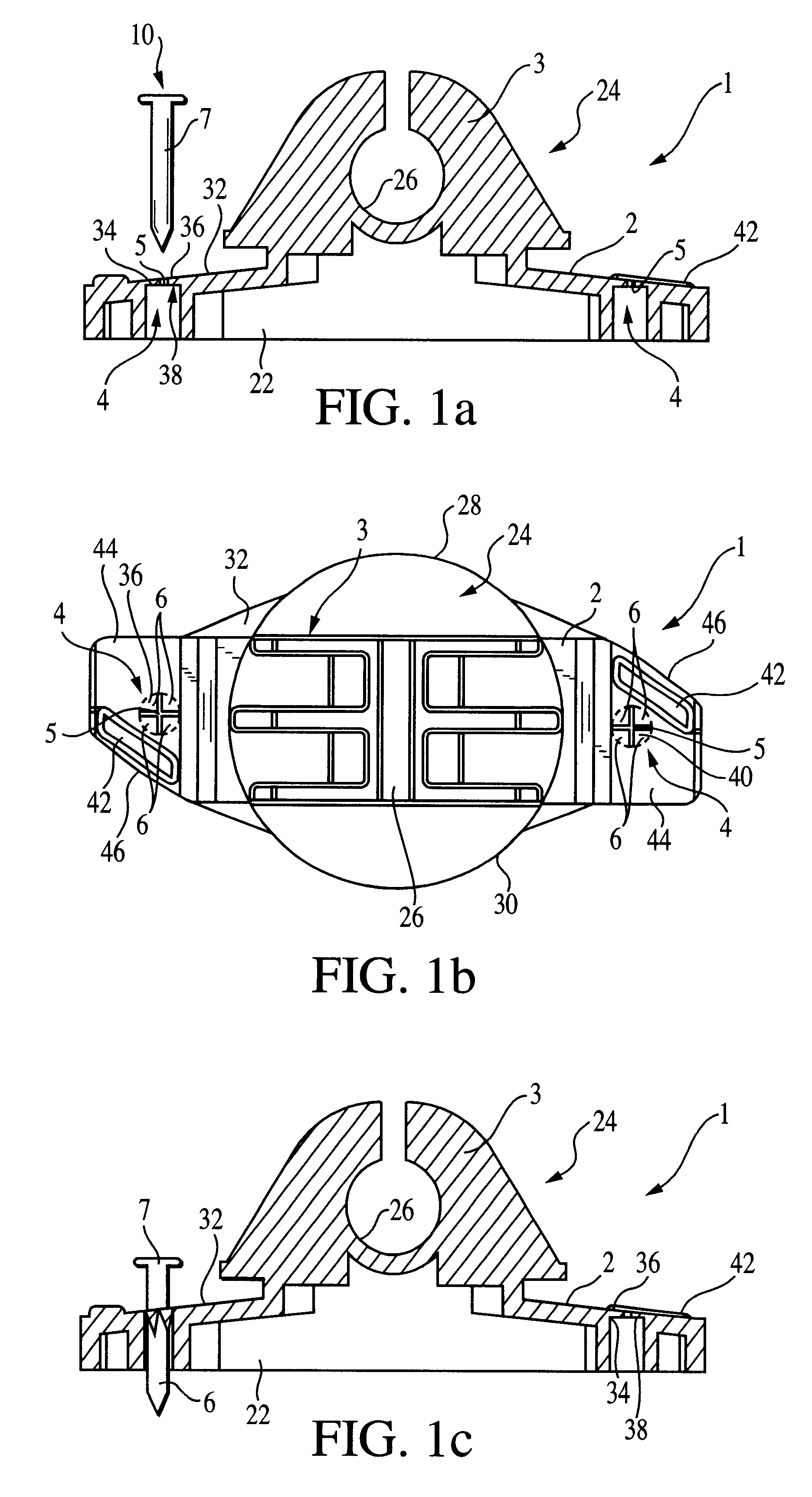

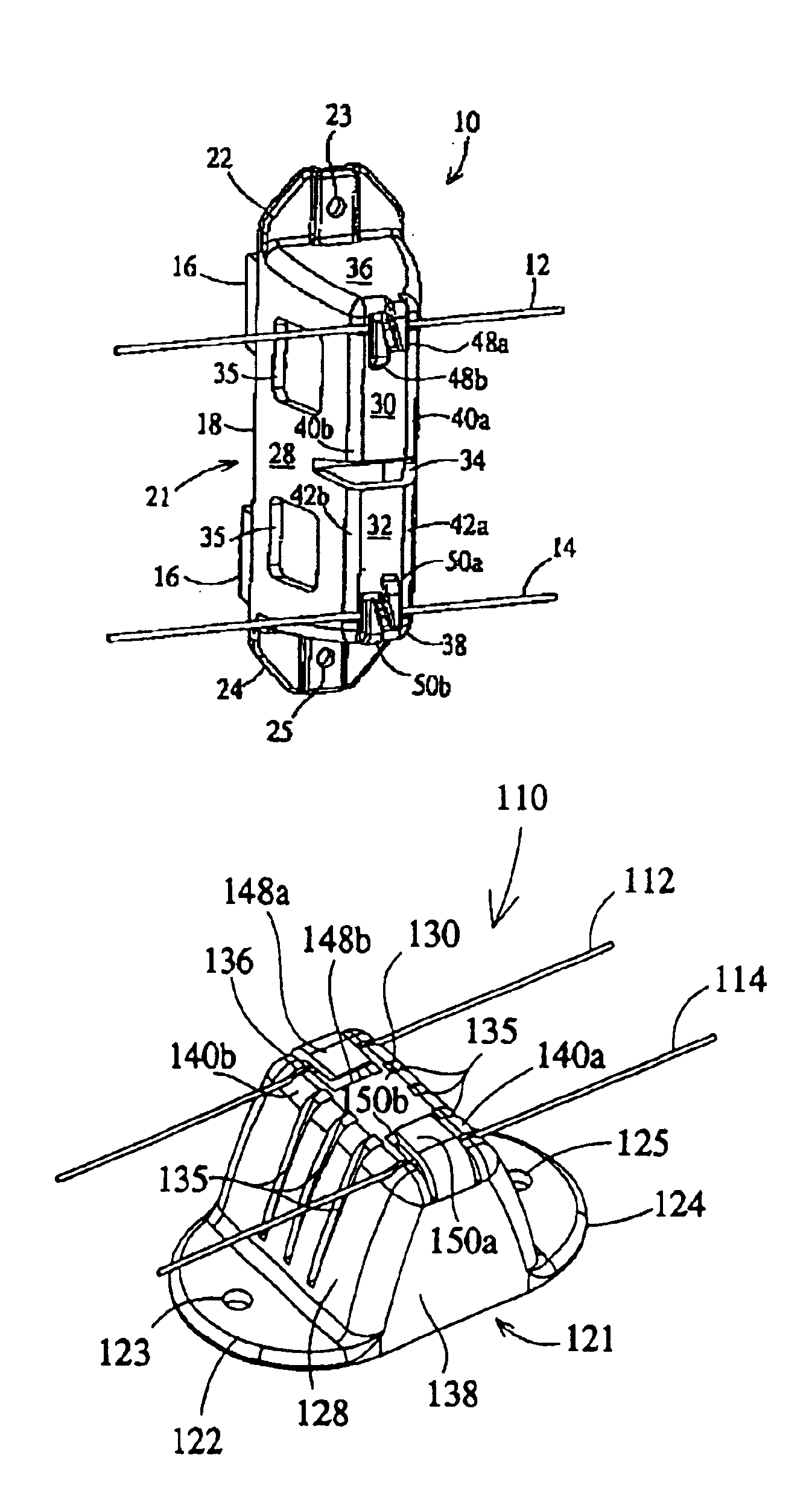

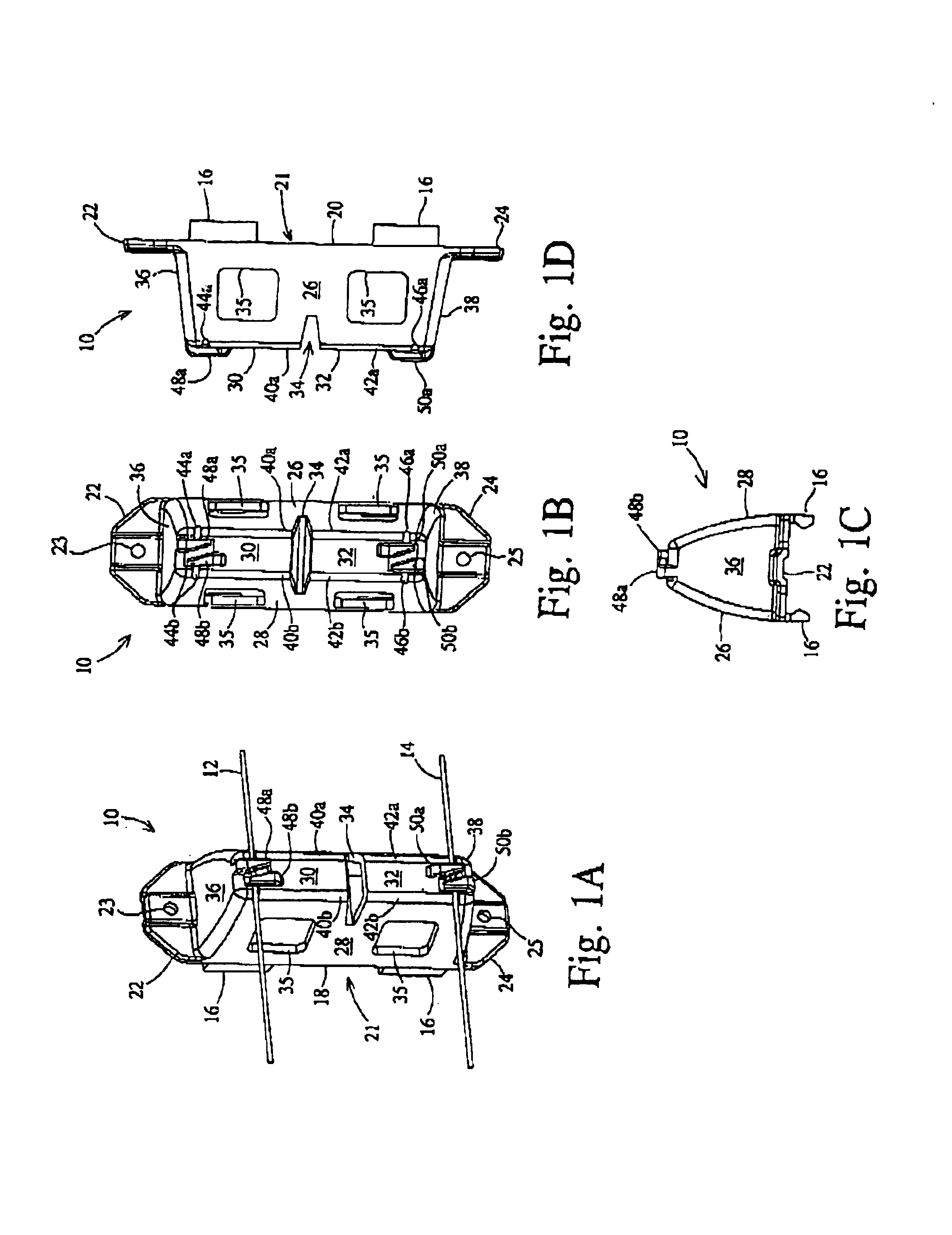

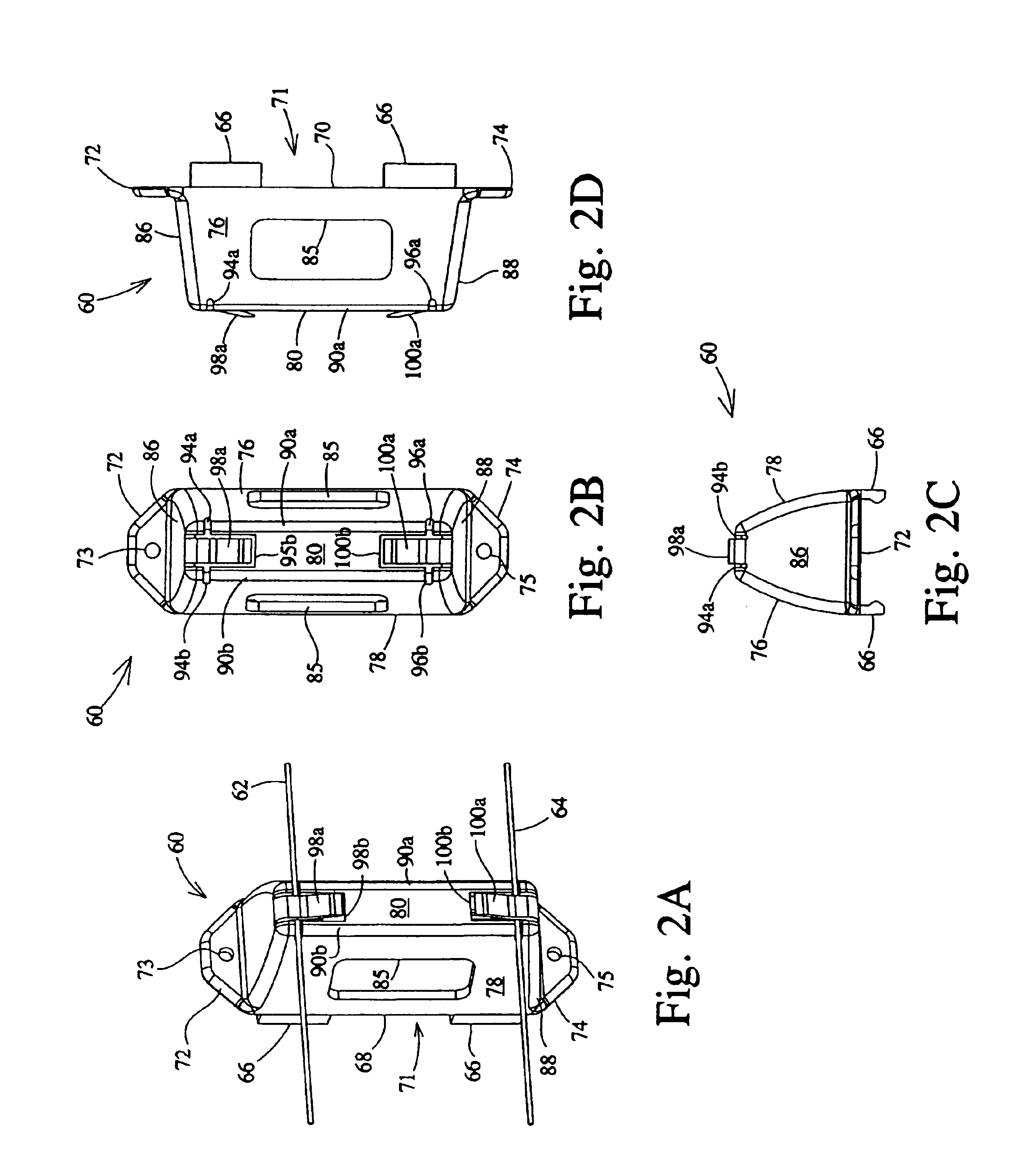

Apparatus and methods for transmission line based electric fence insulation

InactiveUS20120181258A1Avoid flowPrevent short-circuitingOhmic-resistance heatingSupporting insulatorsElectricityEngineering

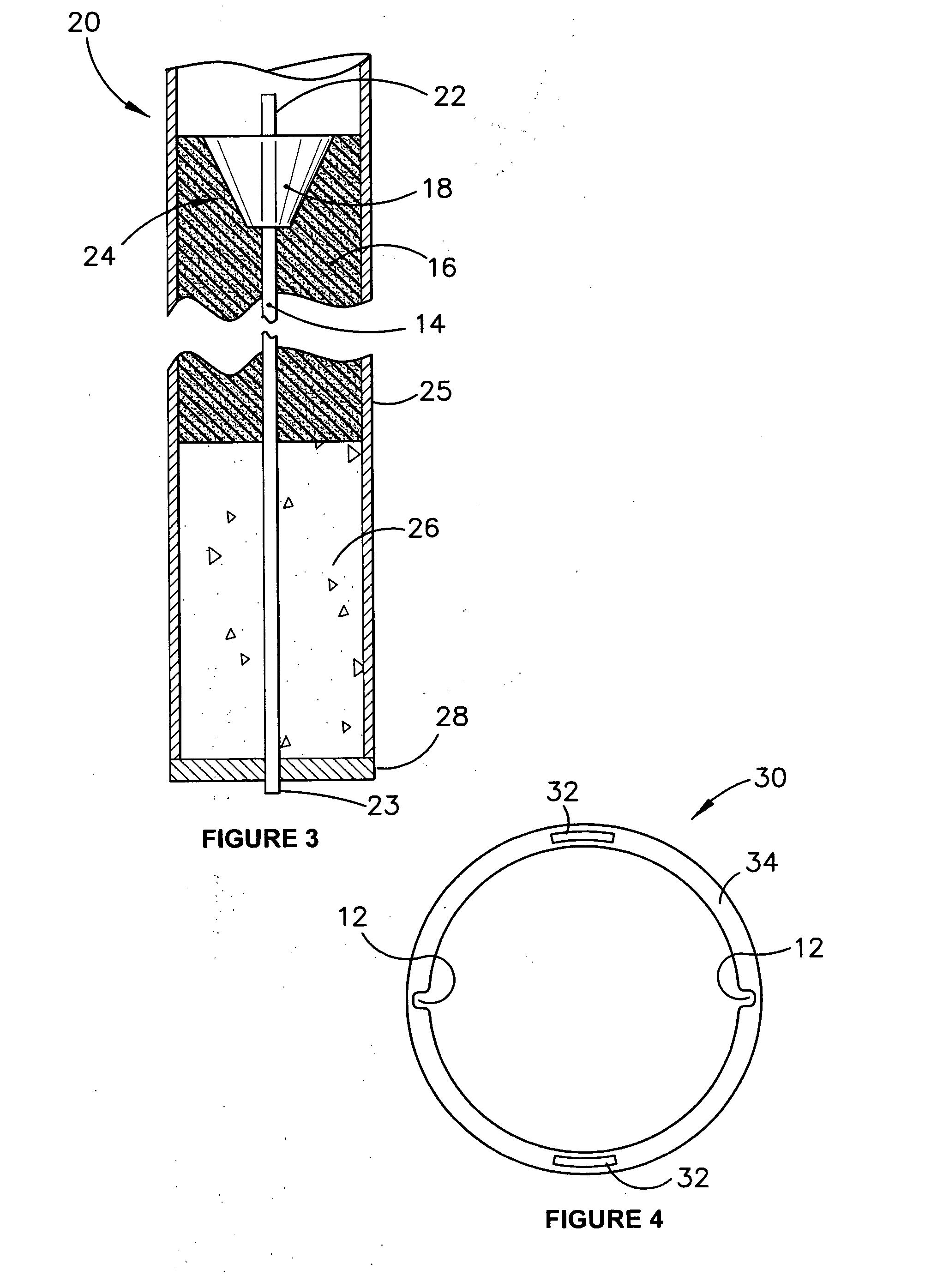

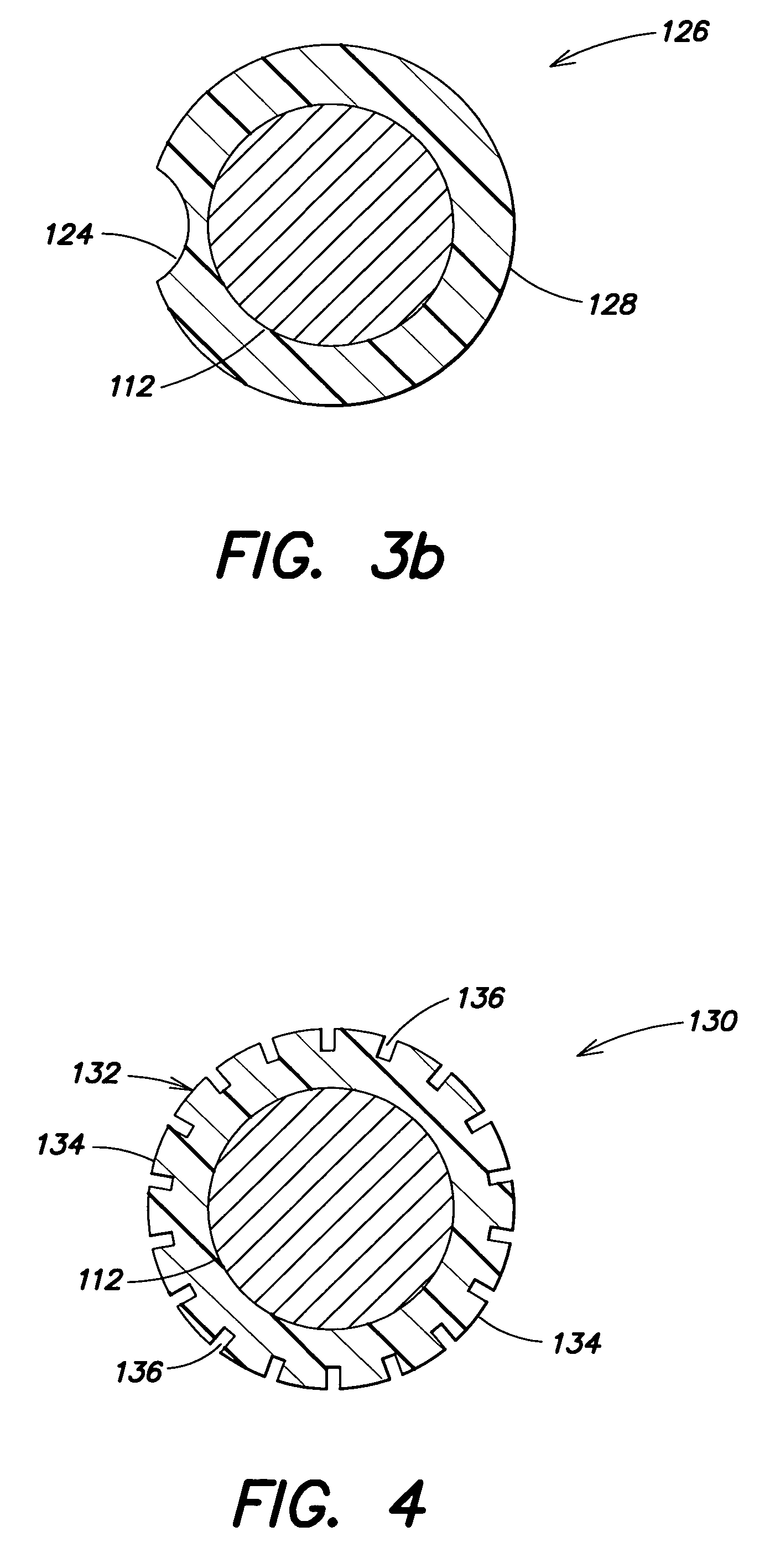

Apparatus and methods for wire insulation in transmission line based electric fence are described in this invention. An insulator holds a wire pair that form the transmission line in its wire clamps. The insulator has a rain shed that sheds the wire clamps from getting wet by rain water. The insulator also has a pair of rain water divert guides that guide rain water accumulated on the wire to flow to the guide instead of to the wire clamps. This invention also describes a wire heating method that uses electric current to heat the fence wires such that the wire / wire clamp contact point will be kept dry and ice, snow accumulated on fence wires will be melted. Performance of the transmission line based electric fence can thus be greatly improved in advert weather conditions.

Owner:SHAN XUEKANG +1

Wildlife guard cover

InactiveUS6291774B1Minimum of effort and timeEasy to install and removeOverhead installationNutsWildlifeField conditions

A wildlife guard for electrical power distribution equipment has two hingedly mounted sections which close together to form a protective cover at the top of an insulator bushing on electrical equipment. The wildlife guard is adapted by its structure to fit a range of bushing sizes and yet provide structural integrity and reliable protection once in place. The wildlife guard also accommodates passage of conductive members such as electrical conductors and sparkgap bars through the cover at locations governed by actual field conditions. The wildlife guard has a cover locking mechanism allowing its easy removal when desired.

Owner:RELIANT ENERGY

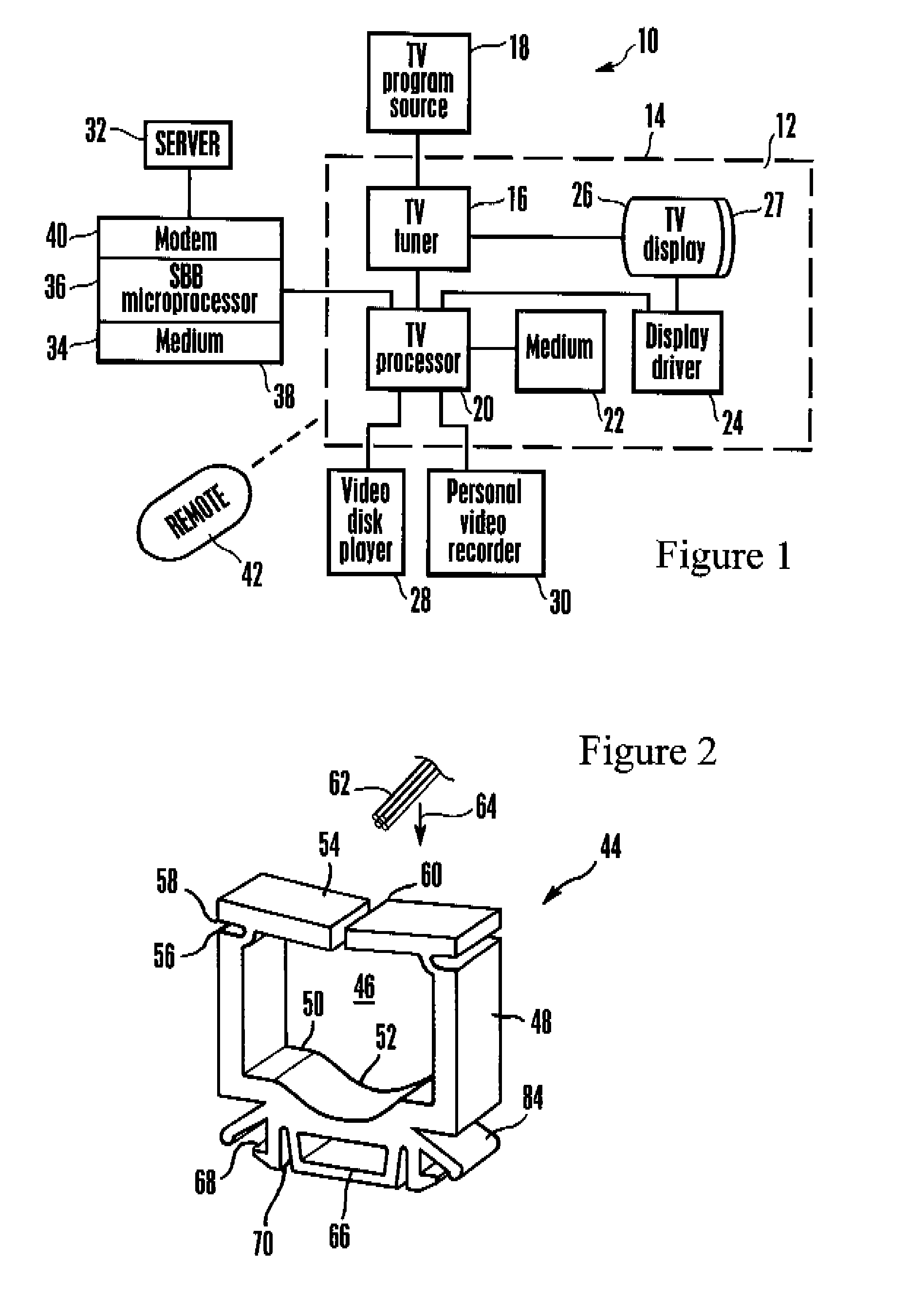

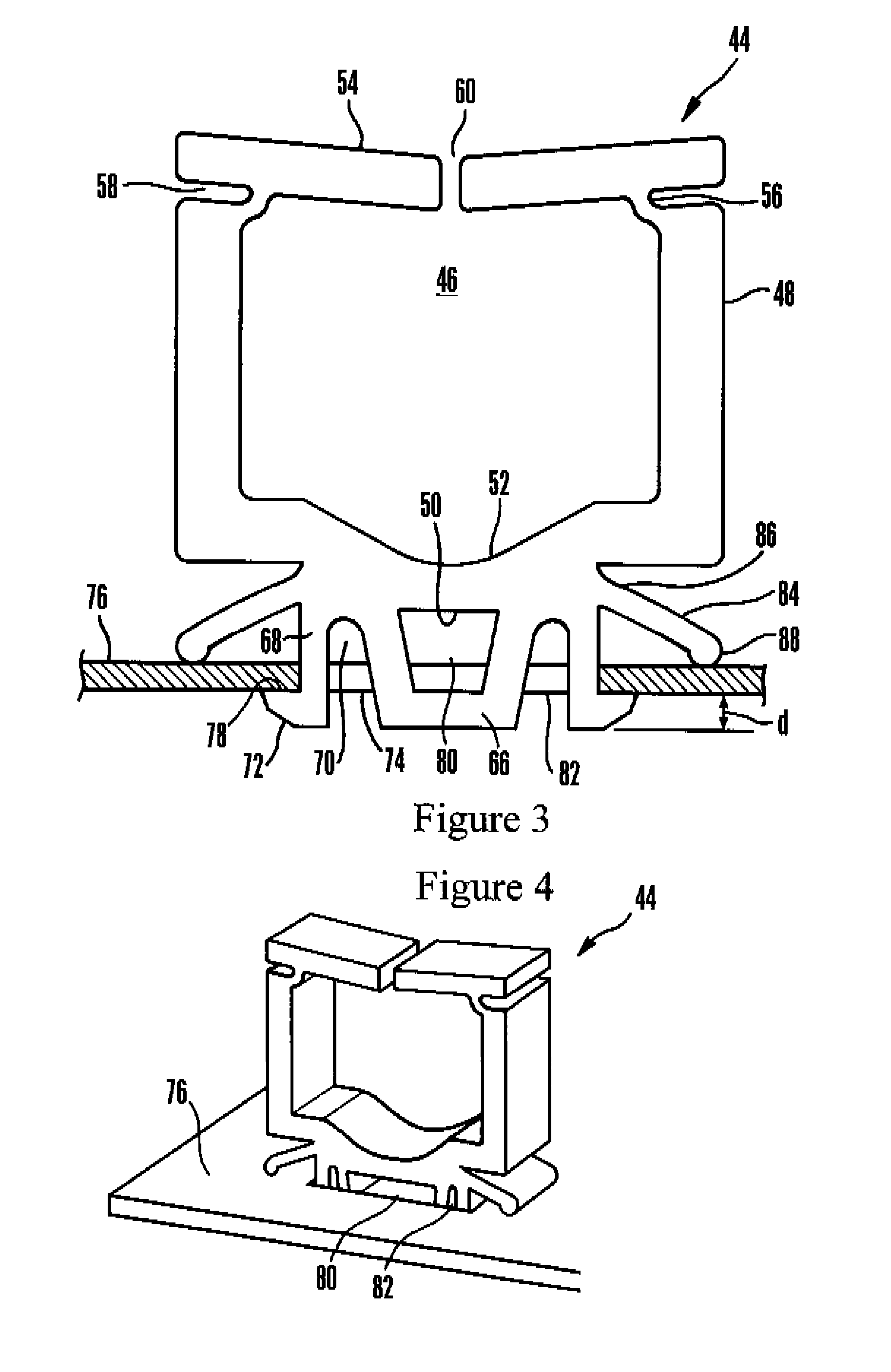

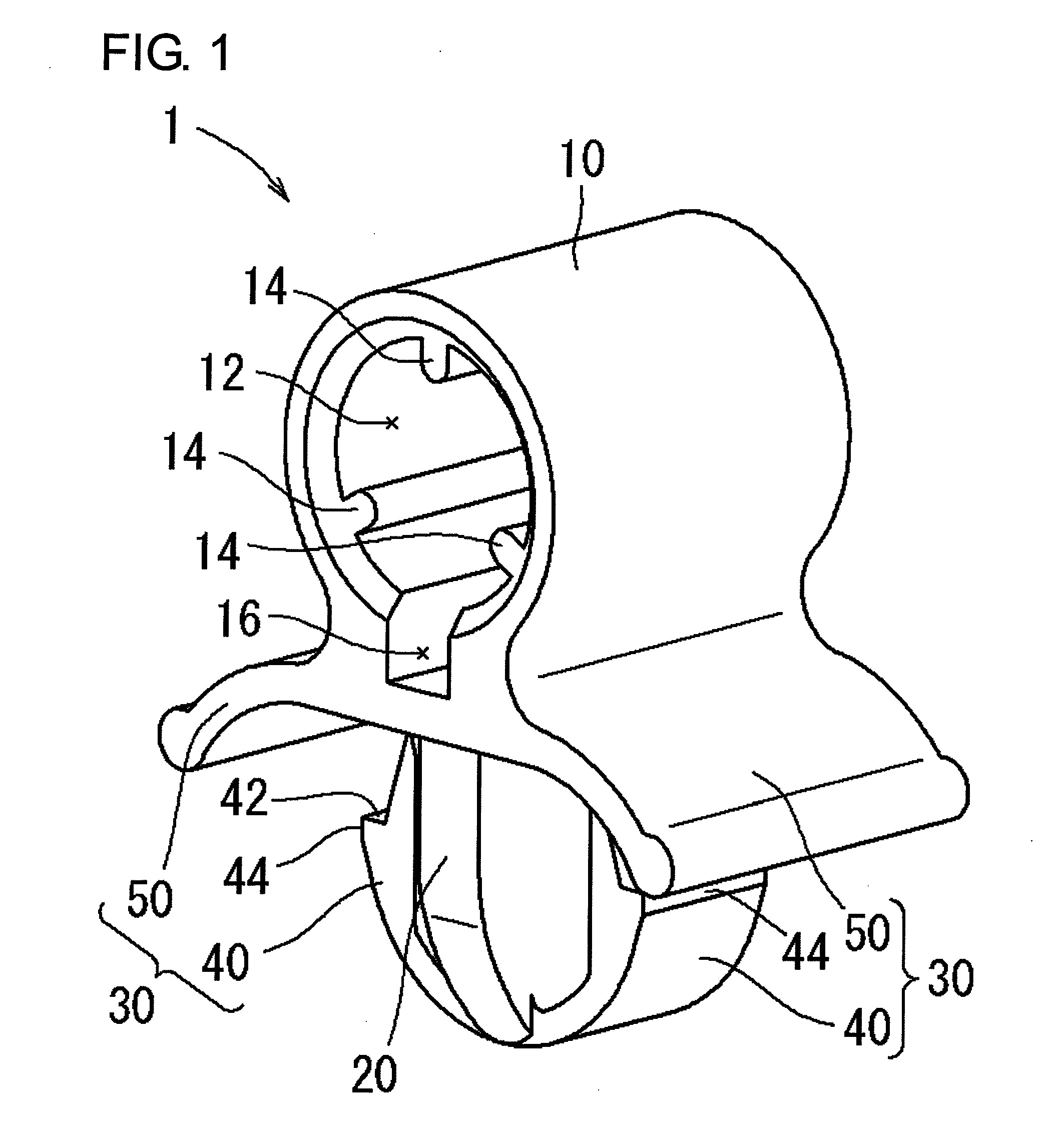

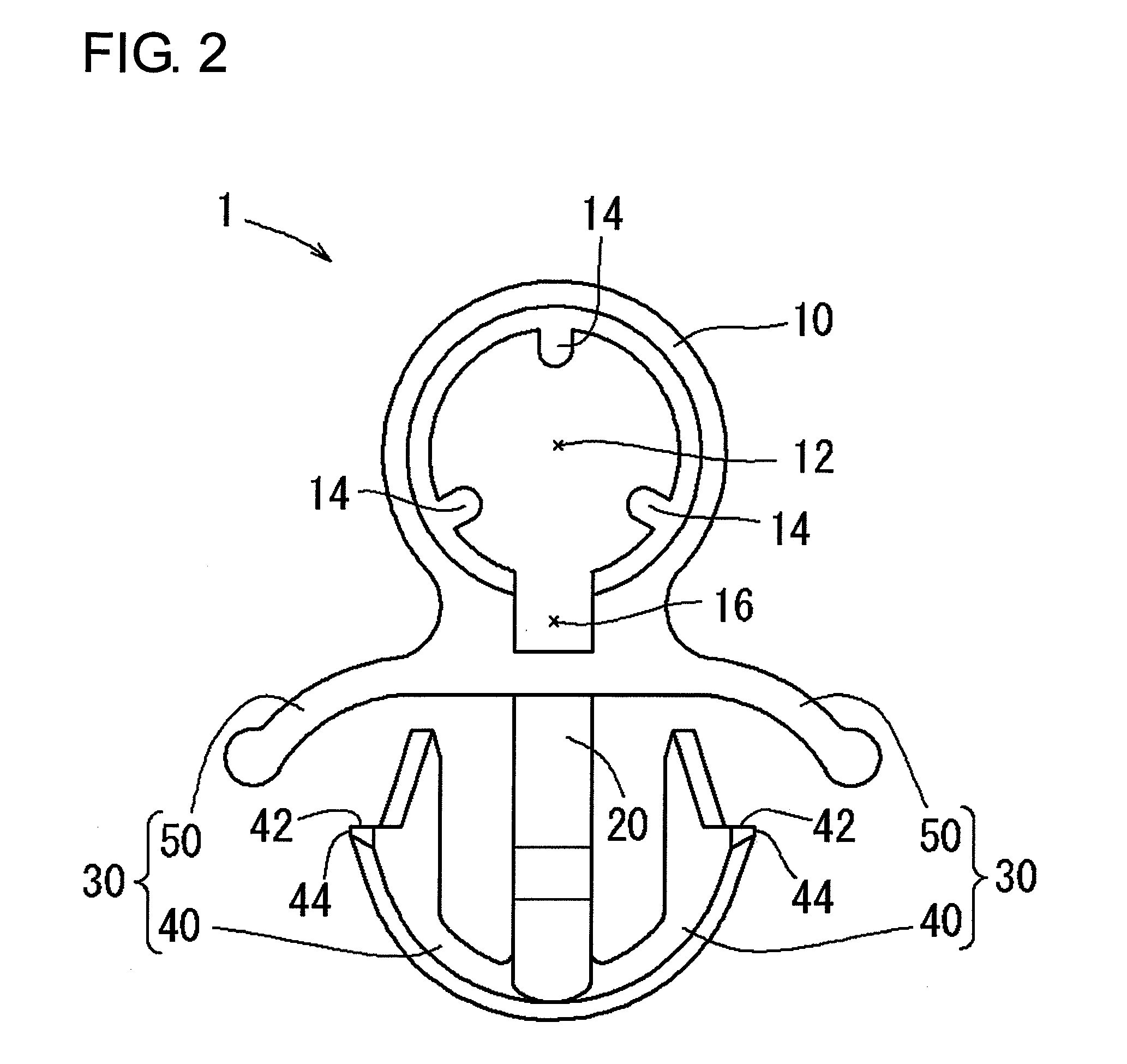

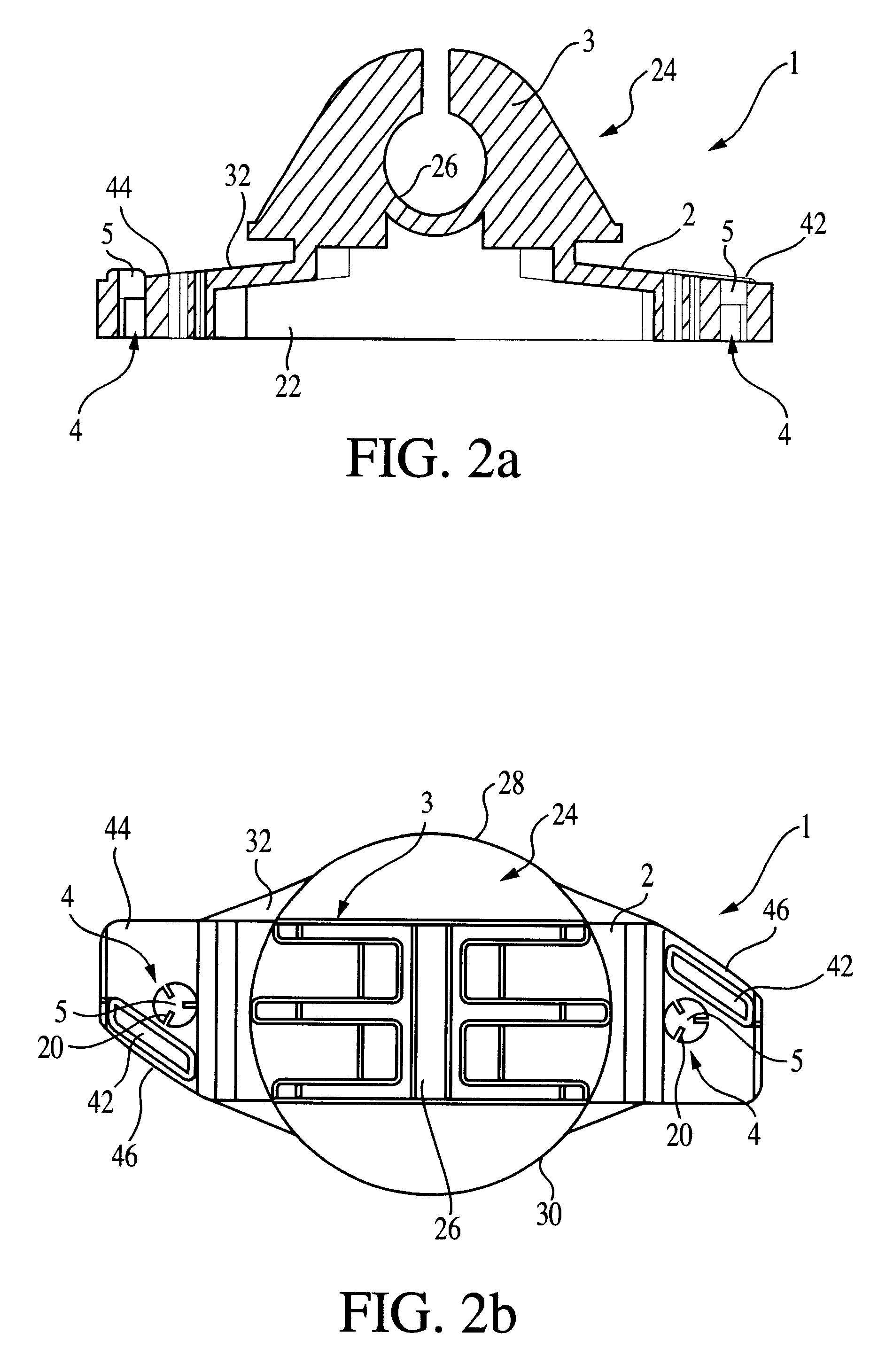

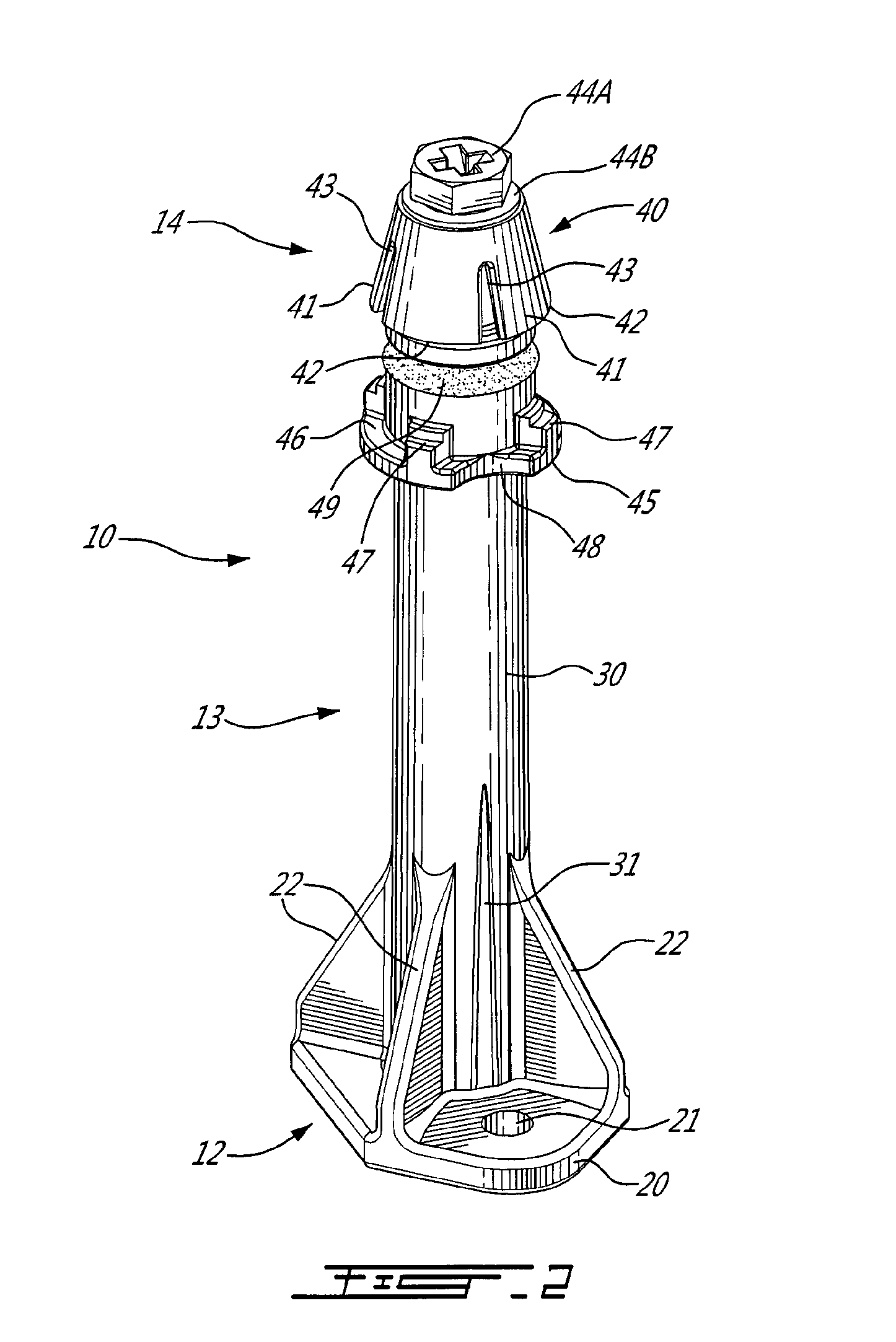

Wire holder with single step installation into T-shaped hole in support substrate

A new wire holder design. The holder is installed into a T-shaped or L-shaped hole in substrate such as a sheet metal, printed wiring board, etc. using only a single installation motion. The holder holds wires in place. Because it requires only a single installation motion the holder is easily installed and furthermore cannot rotate once installed. The holder protrudes only about a millimeter below the substrate.

Owner:SONY CORP +1

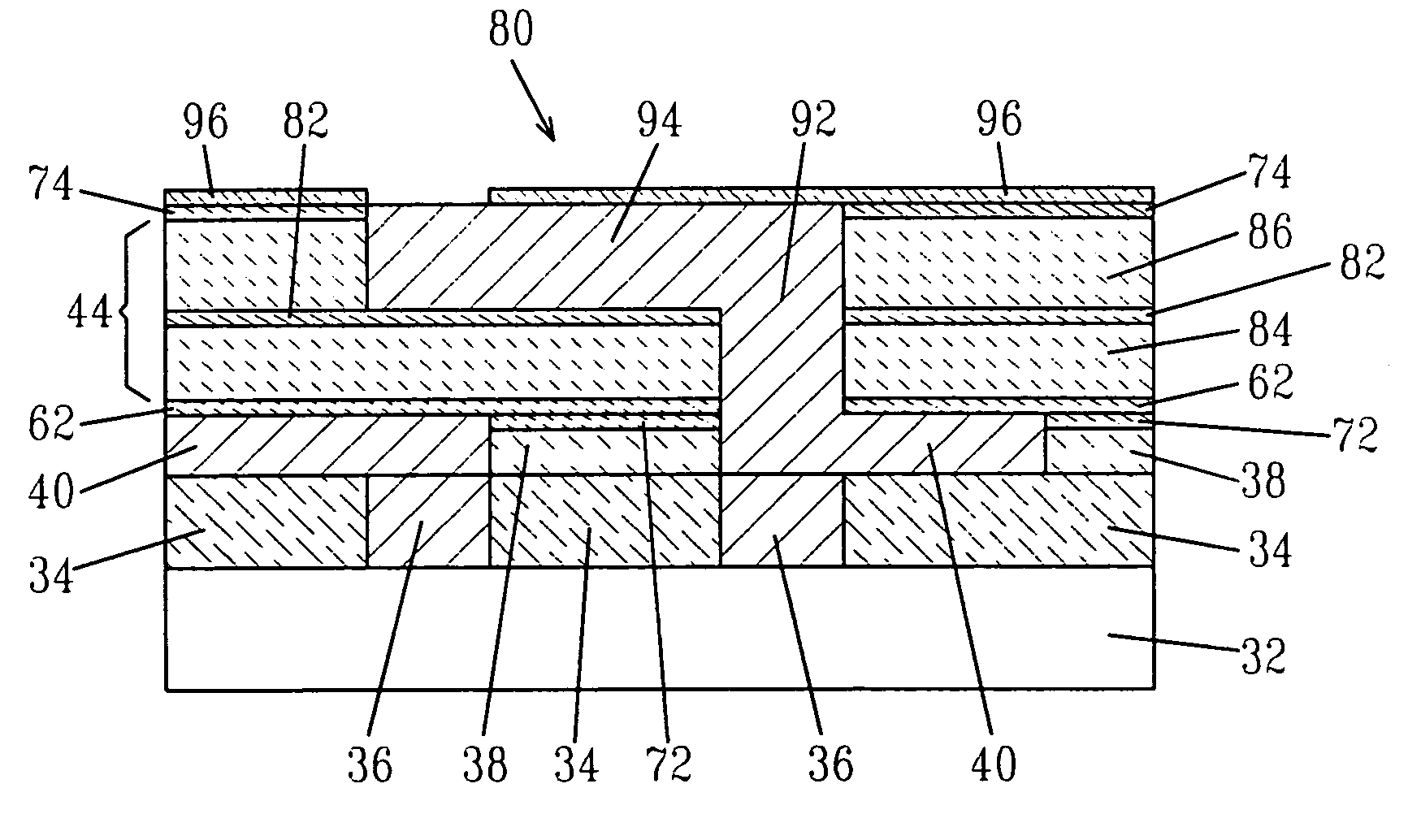

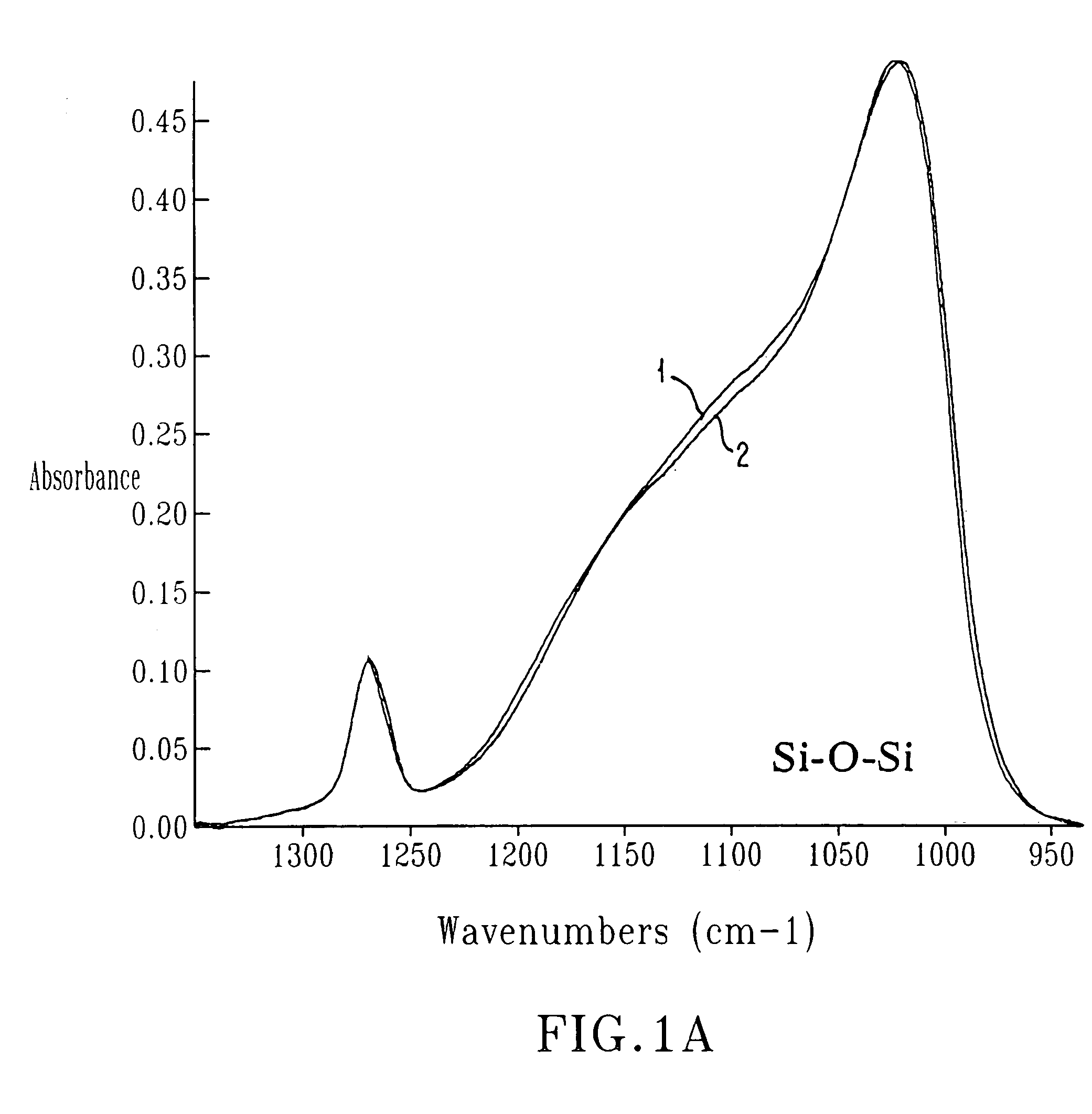

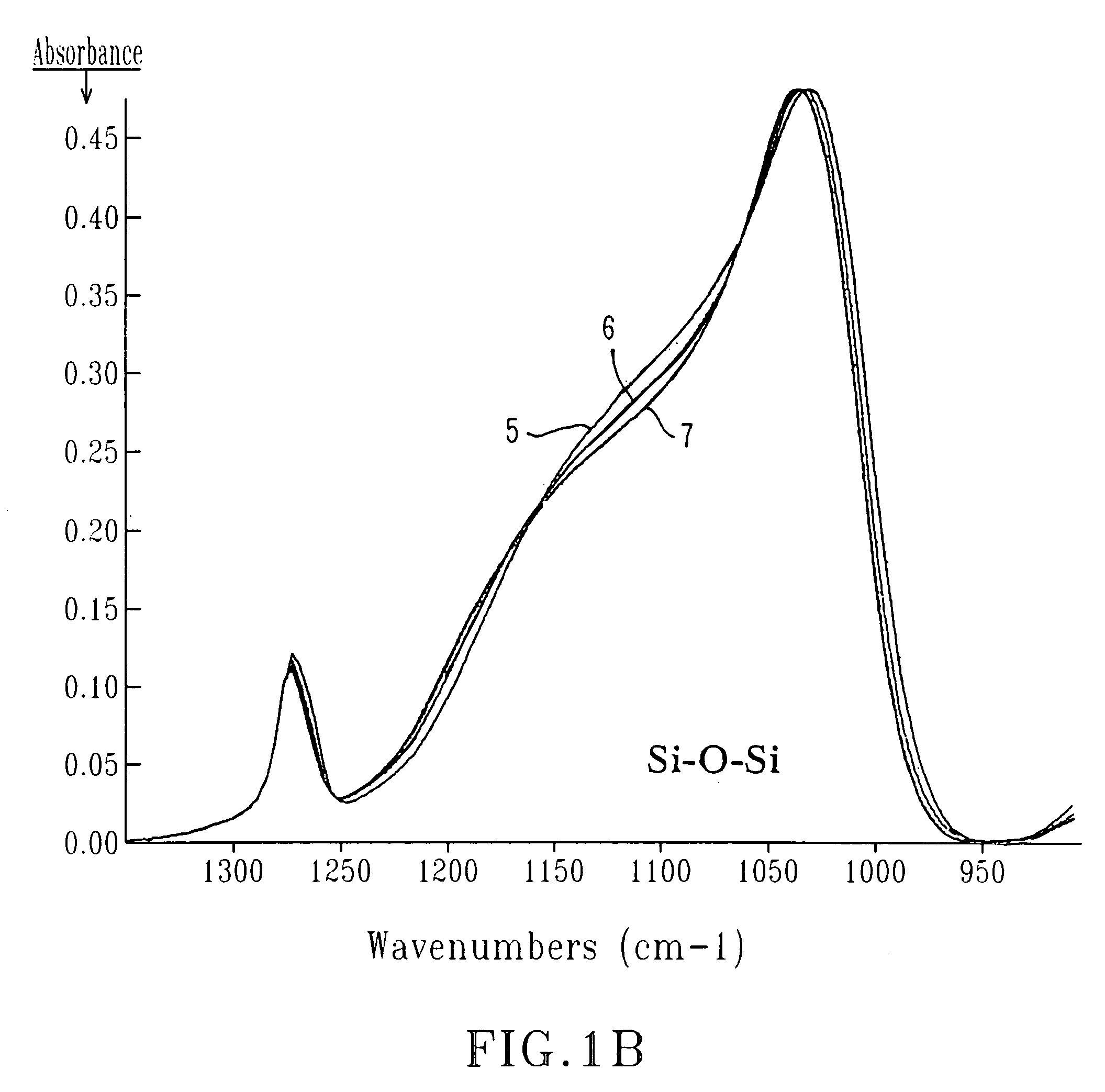

Low k and ultra low k SiCOH dielectric films and methods to form the same

Dielectric materials including elements of Si, C, O and H having specific values of mechanical properties (tensile stress, elastic modulus, hardness cohesive strength, crack velocity in water) that result in a stable ultra low k film which is not degraded by water vapor or integration processing are provided. The dielectric materials have a dielectric constant of about 2.8 or less, a tensile stress of less than 45 MPa, an elastic modulus from about 2 to about 15 GPa, and a hardness from about 0.2 to about 2 GPa. Electronic structures including the dielectric materials of the present invention as well as various methods of fabricating the dielectric materials are also provided.

Owner:GLOBALFOUNDRIES U S INC

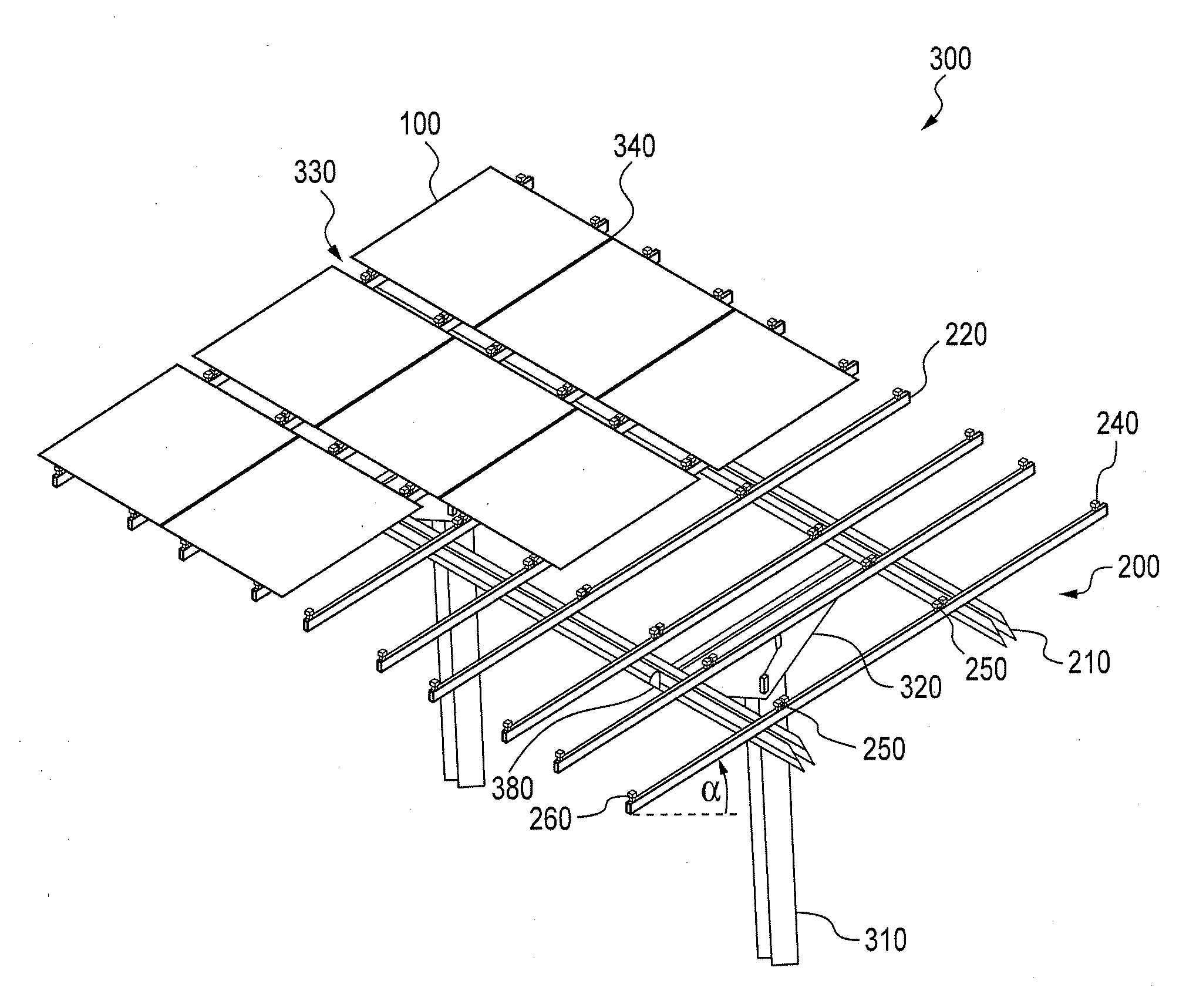

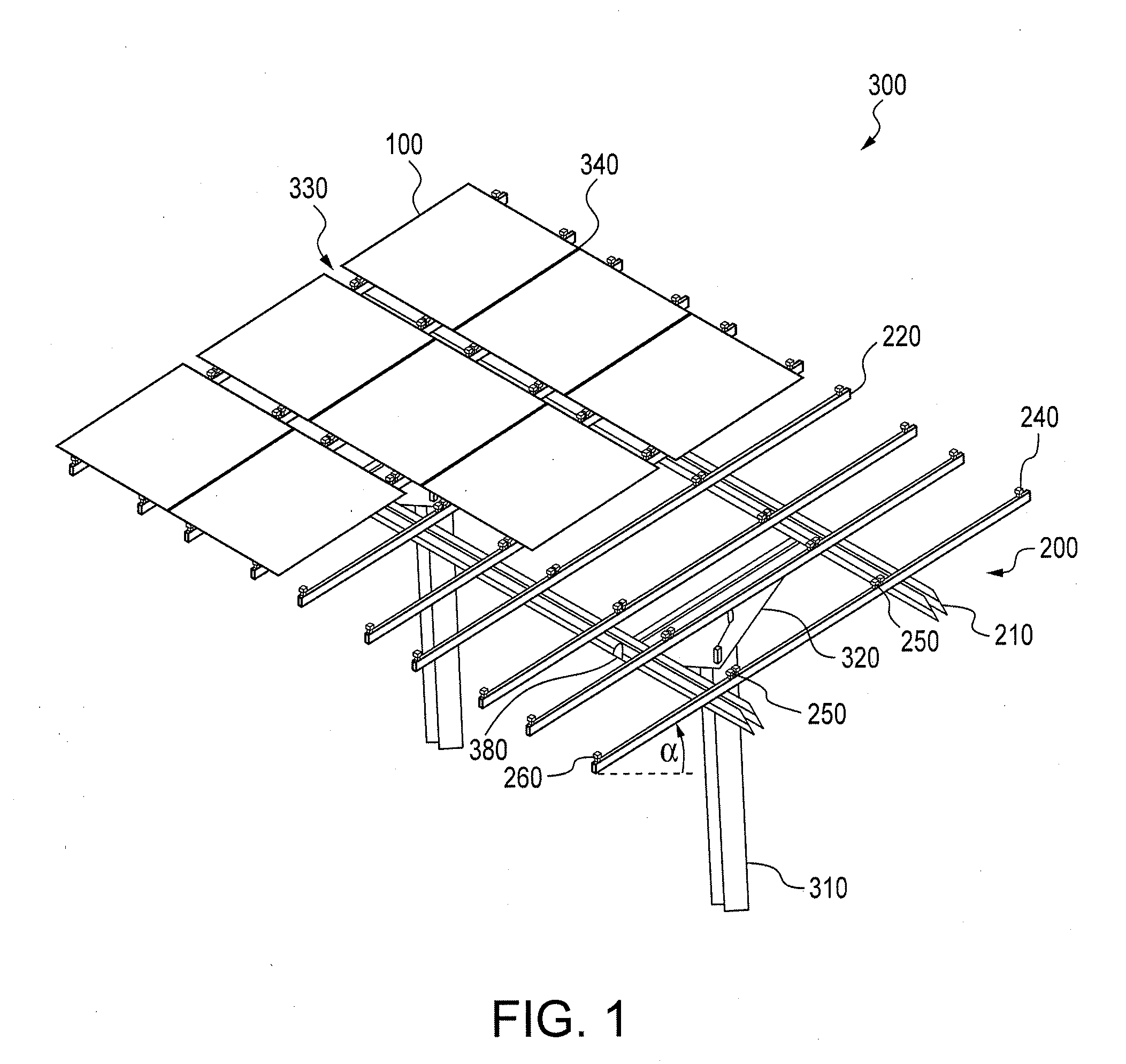

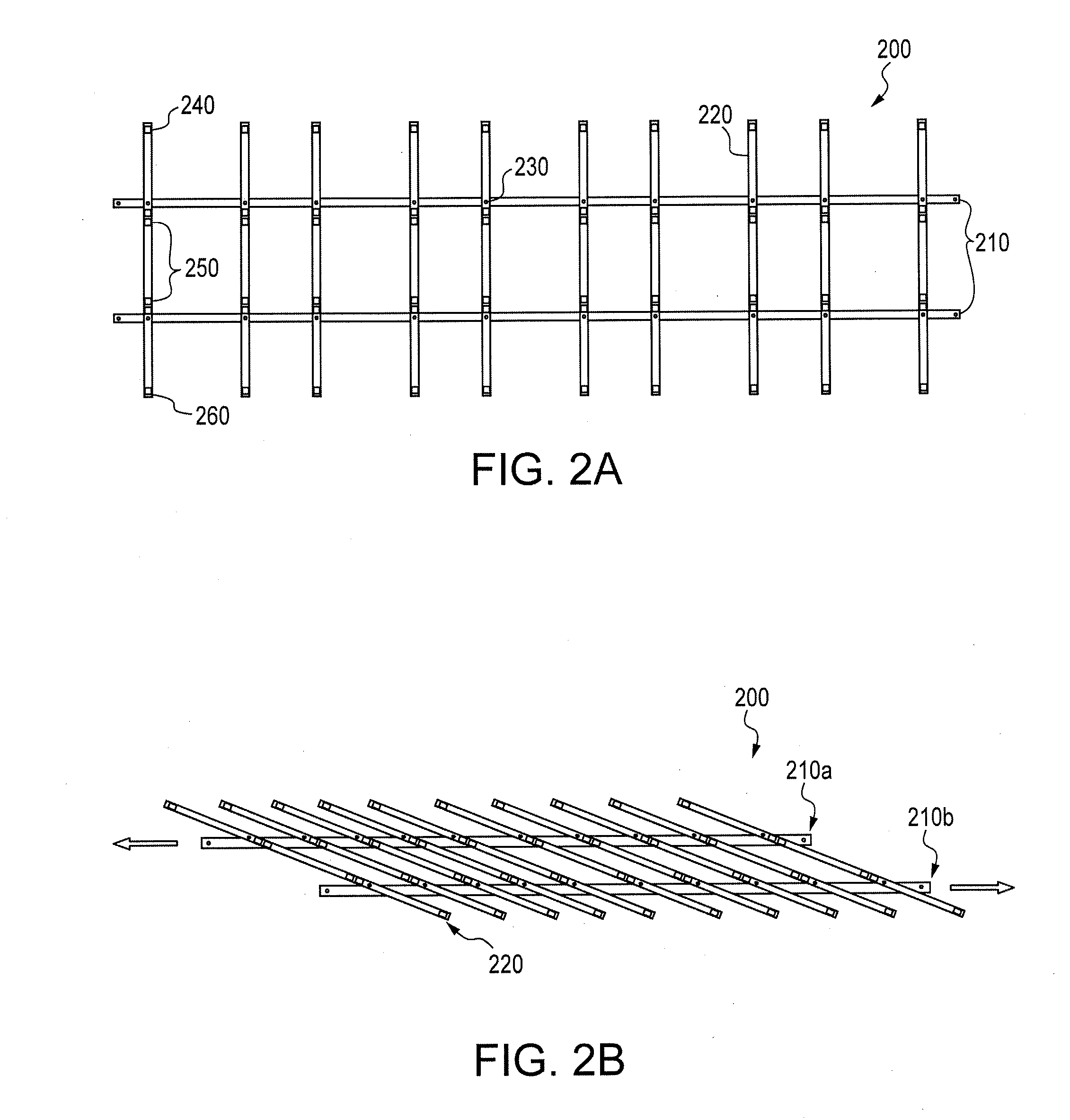

Slider clip and photovoltaic structure mounting system

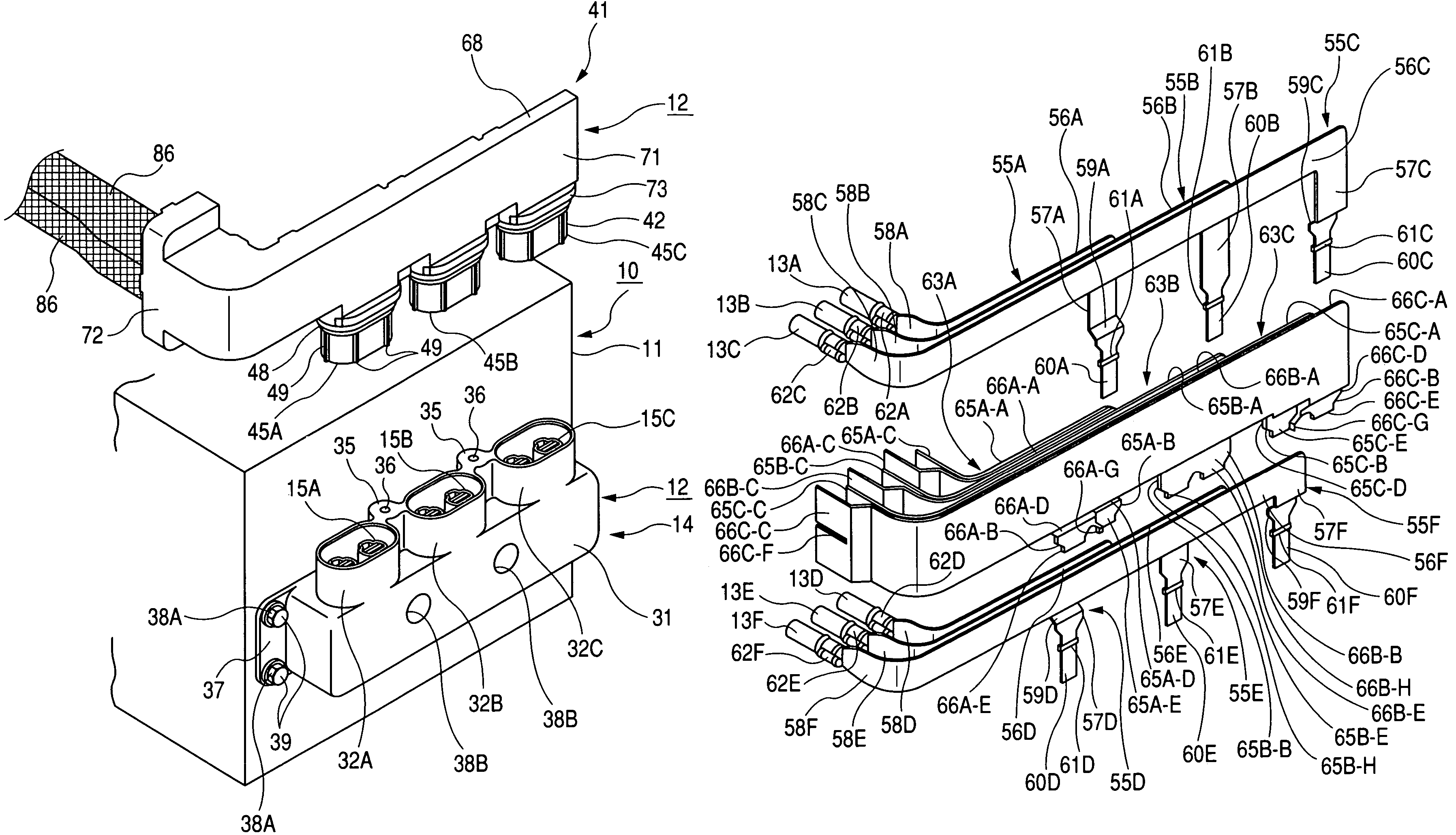

ActiveUS20110068244A1Easy to installEasy to insertSolar heating energyCandle holdersTilt tablesElectrical and Electronics engineering

Described herein is a mounting system and slider clips that support simplified installation of photovoltaic structures. The mounting system comprises a support structure which can be mounted to support columns via an optional tilt table. The support structure comprises a plurality of parallel spaced beams and a plurality of parallel spaced rails that are mounted approximately perpendicular to the beams. Disclosed embodiments describe a collapsible support structure in which the rails are pivotally mounted to the beams. Rails are preassembled with prefabricated slider clips for holding edge portions of the photovoltaic structures. Rails can also be integrally formed with slider clips. Described herein are also methods of installing one or more photovoltaic structures using the mounting system and methods for manufacturing slider clips and a photovoltaic structure mounting system.

Owner:JPMORGAN CHASE BANK NA

Indicators for early detection of potential failures due to water exposure of polymer-clad fiberglass

A composite insulator containing means for providing early warning of impending failure due to stress corrosion cracking, flashunder, or destruction of the rod by discharge activity conditions is described. A composite insulator comprising a fiberglass rod surrounded by a polymer housing and connected with metal end fittings on either end of the rod is doped with a dye-based chemical dopant. The dopant is located around the vicinity of the outer surface of the fiberglass rod. The dopant is formulated to possess migration and diffusion characteristics, and to be inert in dry conditions and compatible with the insulator components. The dopant is positioned within the insulator such that upon the penetration of moisture through the housing to the rod through a permeation pathway in the outer surface of the insulator, the dopant will become activated and will leach out of the same permeation pathway or diffuse through the housing. The activated dopant then creates a deposit or stain on the outer surface of the insulator housing. The dopant comprises an oil-soluble dye, an indicator, or a stain compound that can either be visually identified, or is sensitive to radiation at one or more specific wavelengths. The dopant could also be formulated by a nanoparticle enabled material. Deposits of activated dopant on the outer surface of the insulator can be detected upon imaging of the outer surface of the insulator by appropriate imaging instruments or the naked eye.

Owner:ELECTRIC POWER RES INST INC

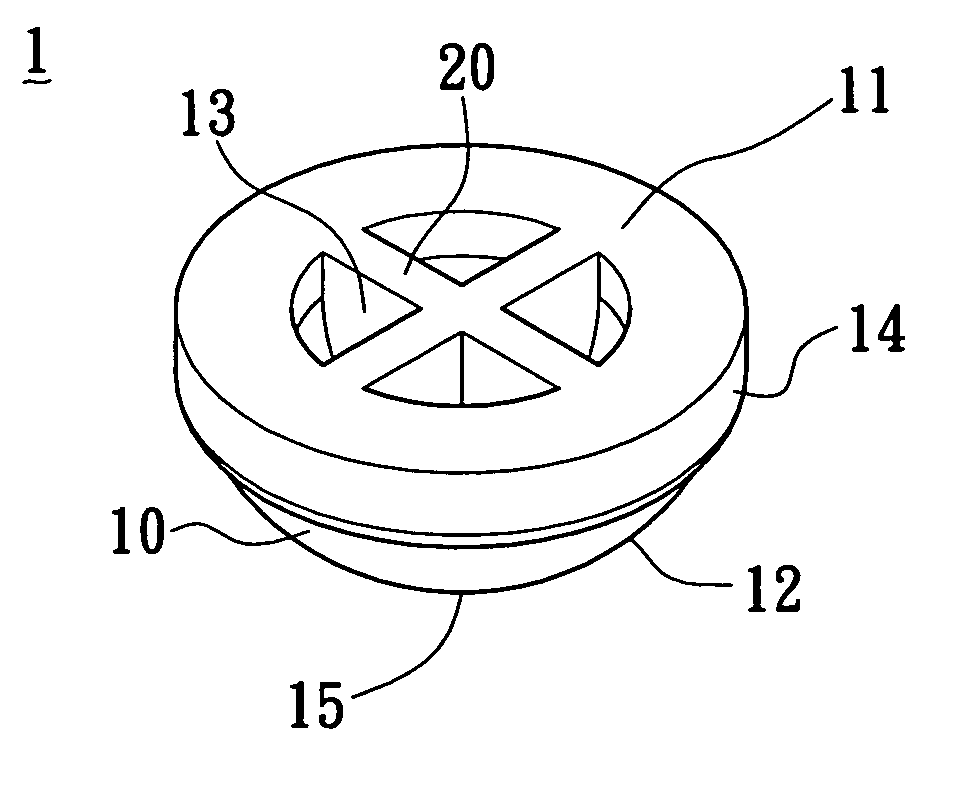

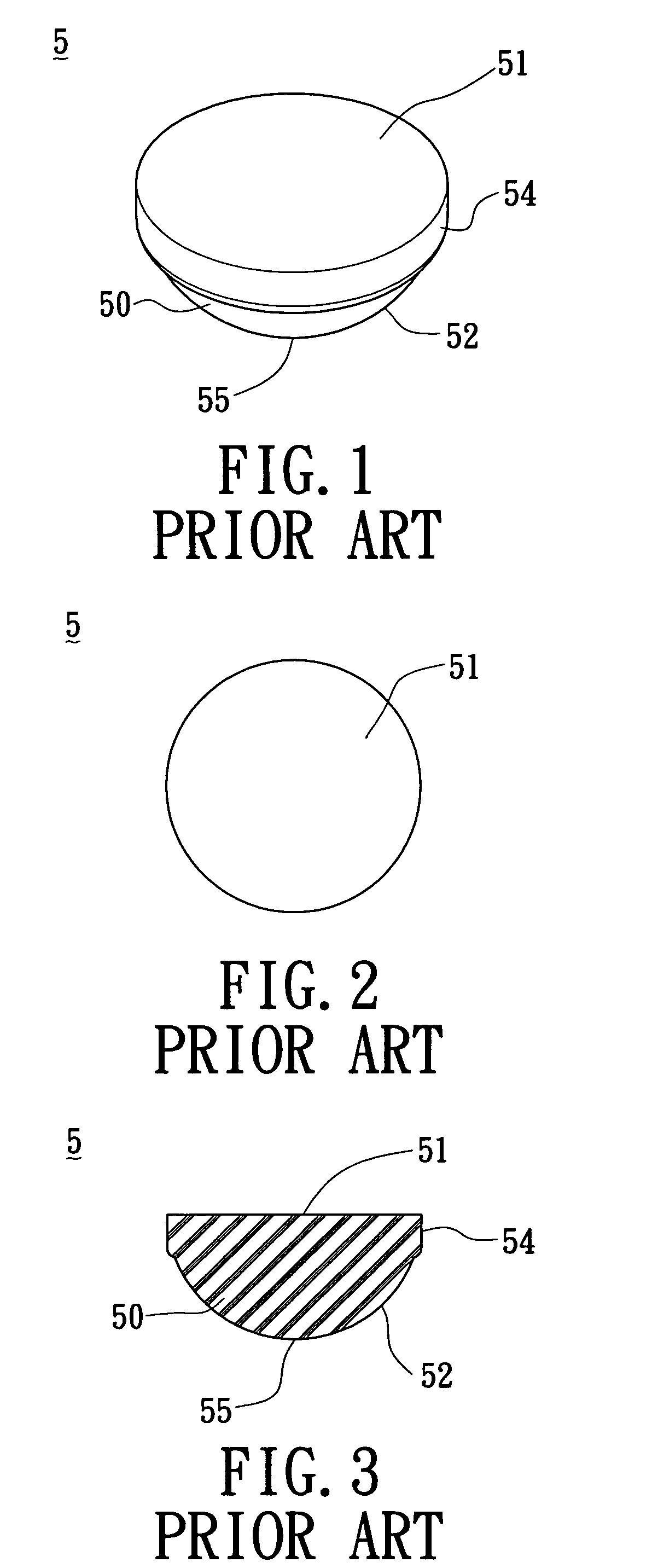

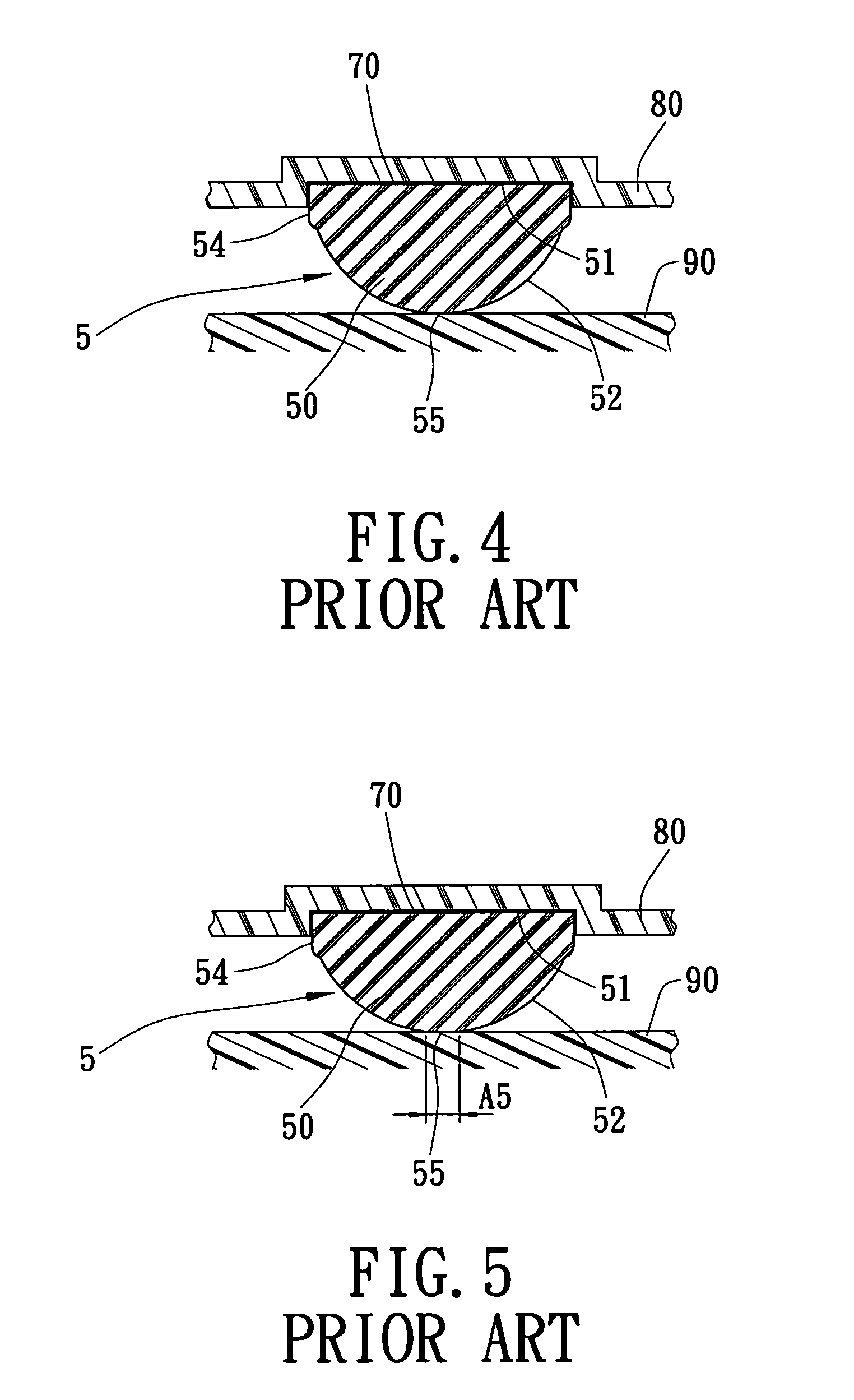

Foot pad

InactiveUS6979778B2Good effectIncrease elasticityPortable framesInstallation of lighting conductorsSupport surfaceConical surface

A foot pad has an elastic conical body and at least one elastic rib. The elastic conical body defines a connecting surface and an outer conical surface. The connecting surface defines a hollow portion, and the elastic rib integrally connects to the elastic conical body at a surface of the hollow portion. The outer conical surface has a root portion connecting with an outer edge of the connecting surface. A thickness of the elastic conical body at the root portion of the outer conical surface is greater than a thickness of the elastic conical body at other portions of the outer conical surface. Elasticity of the foot pad is thereby increased so as to enlarge a contact area contacting an outer supporting surface, so that an anti-skid effect is improved and the foot pad is capable of absorbing a deformation of an electronic product.

Owner:LITE ON TECH CORP

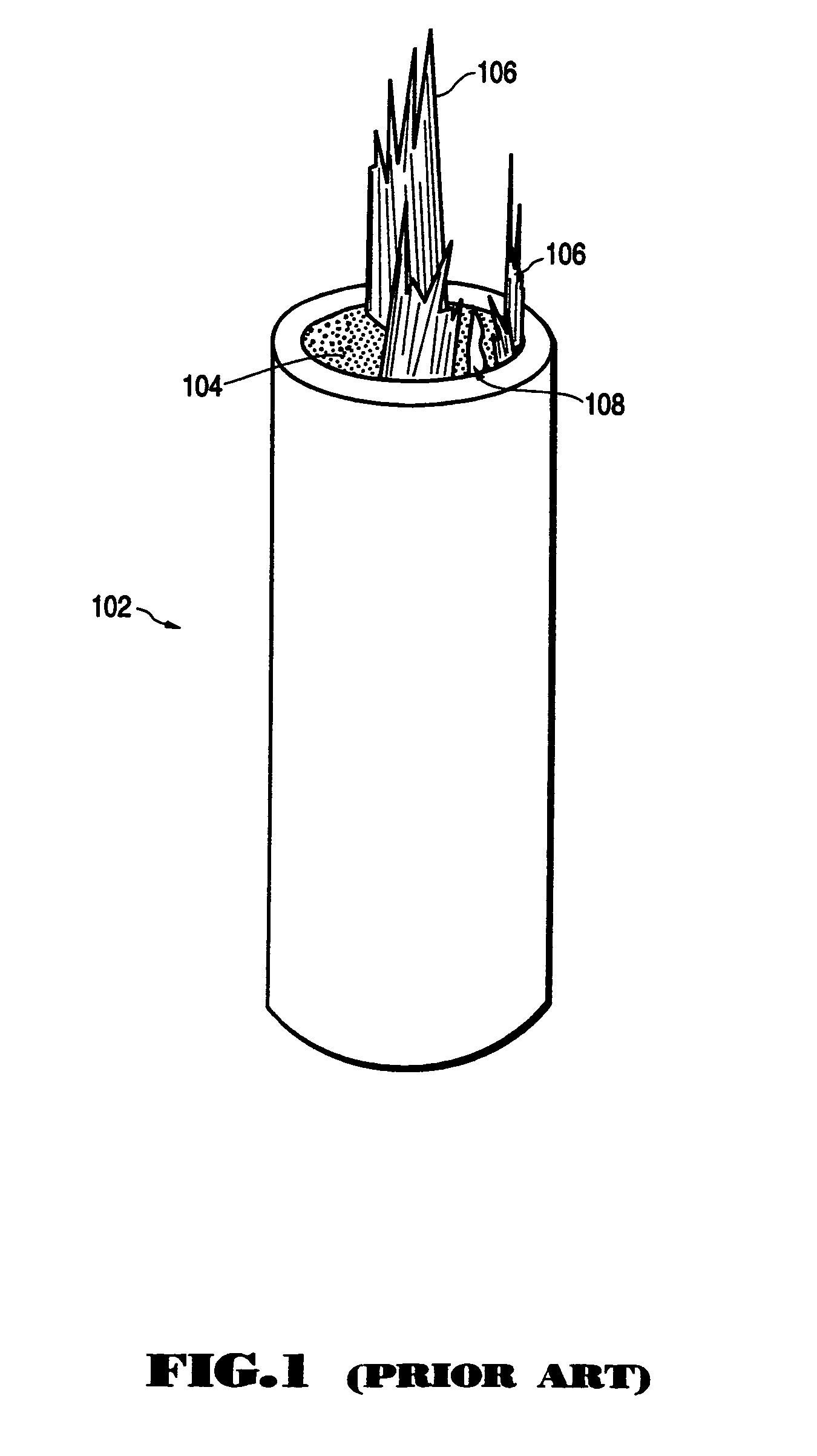

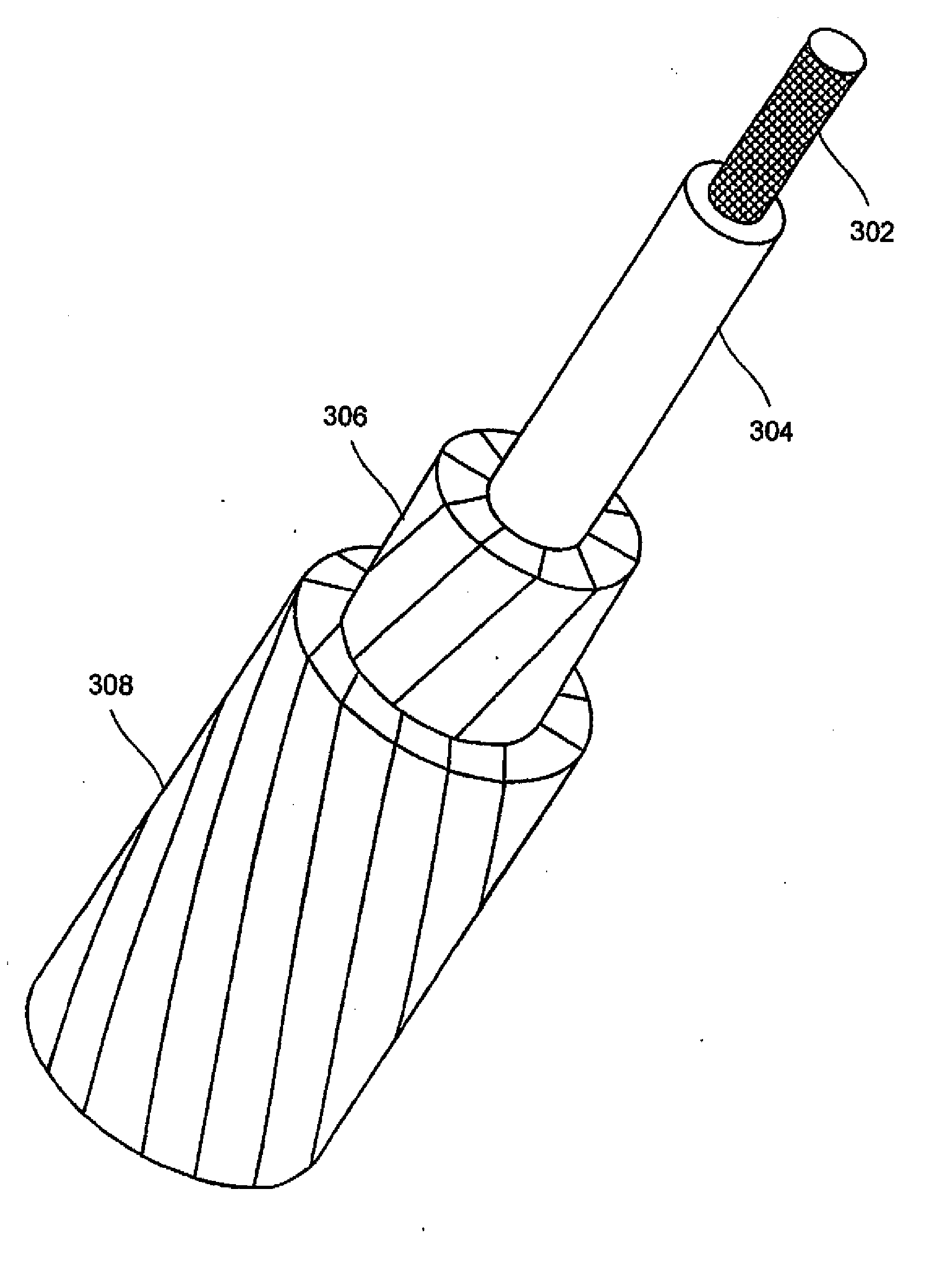

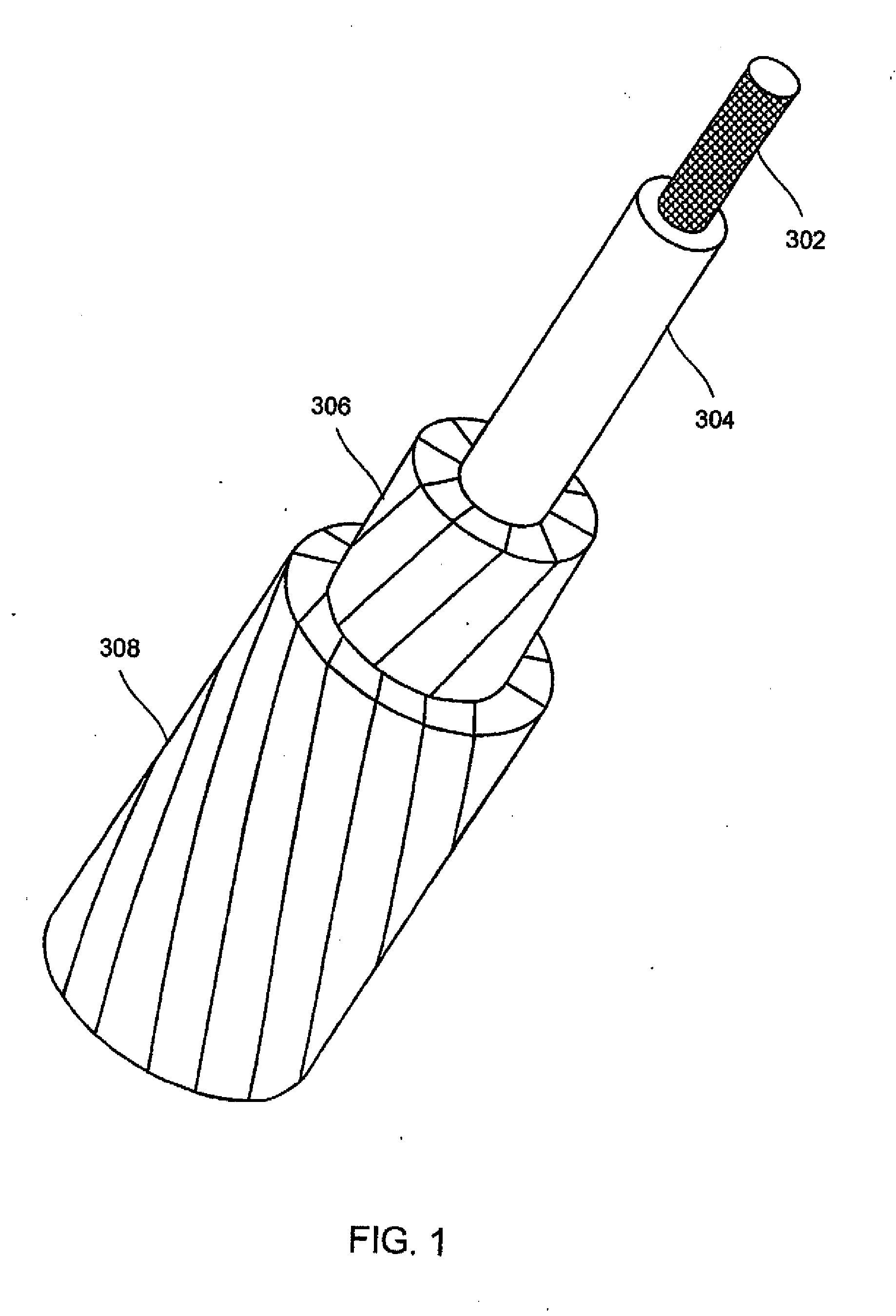

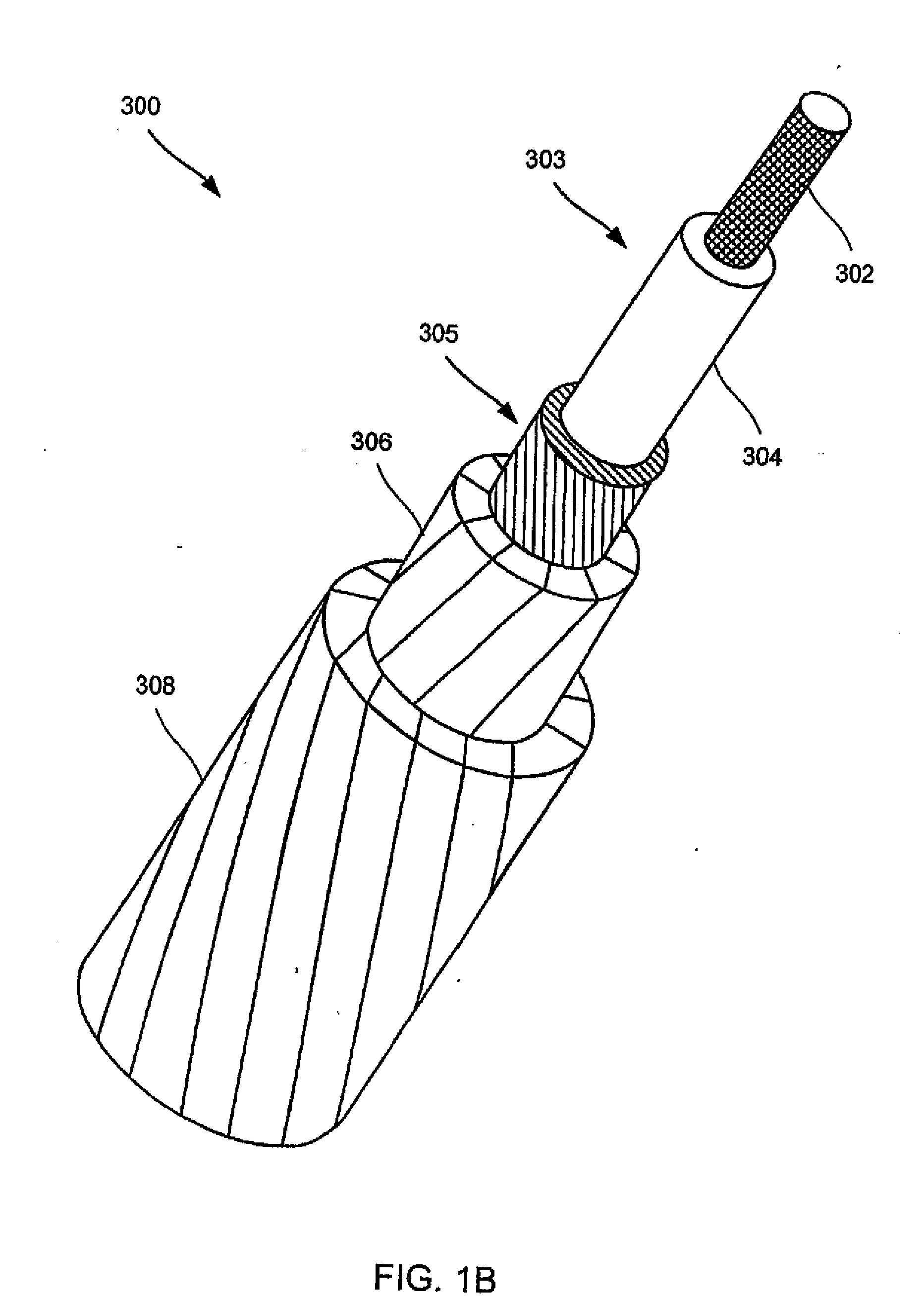

Composite core for an electrical cable

InactiveUS20100163275A1Change in weightMaintain stable propertiesMaterial nanotechnologyNon-insulated conductorsProduction rateElectrical conductor

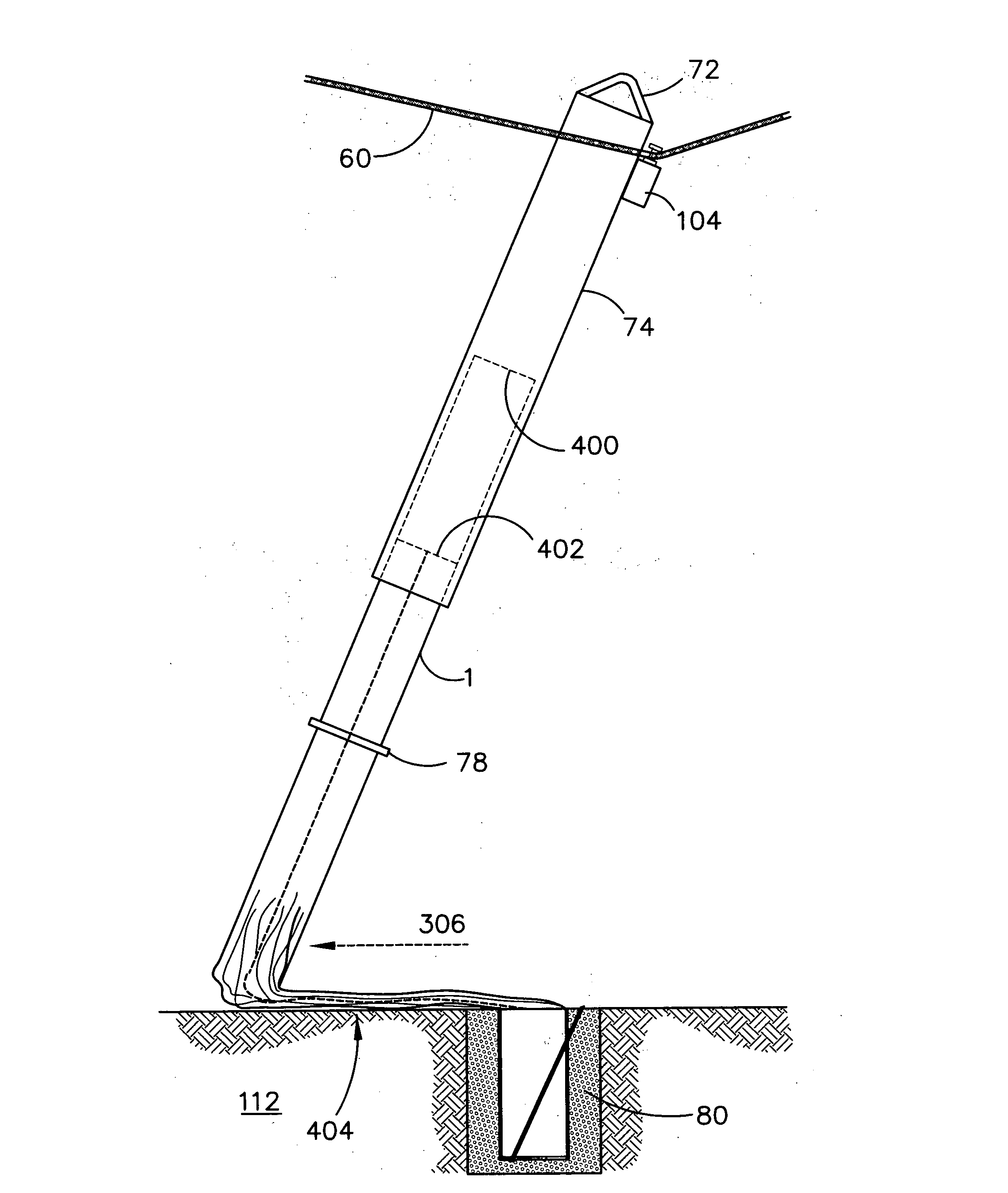

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable (300) has a composite core and at least one layer of aluminum conductor (306). The composite core (303) comprises a plurality of fibers from at least one fiber type in one or more matrix materials. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

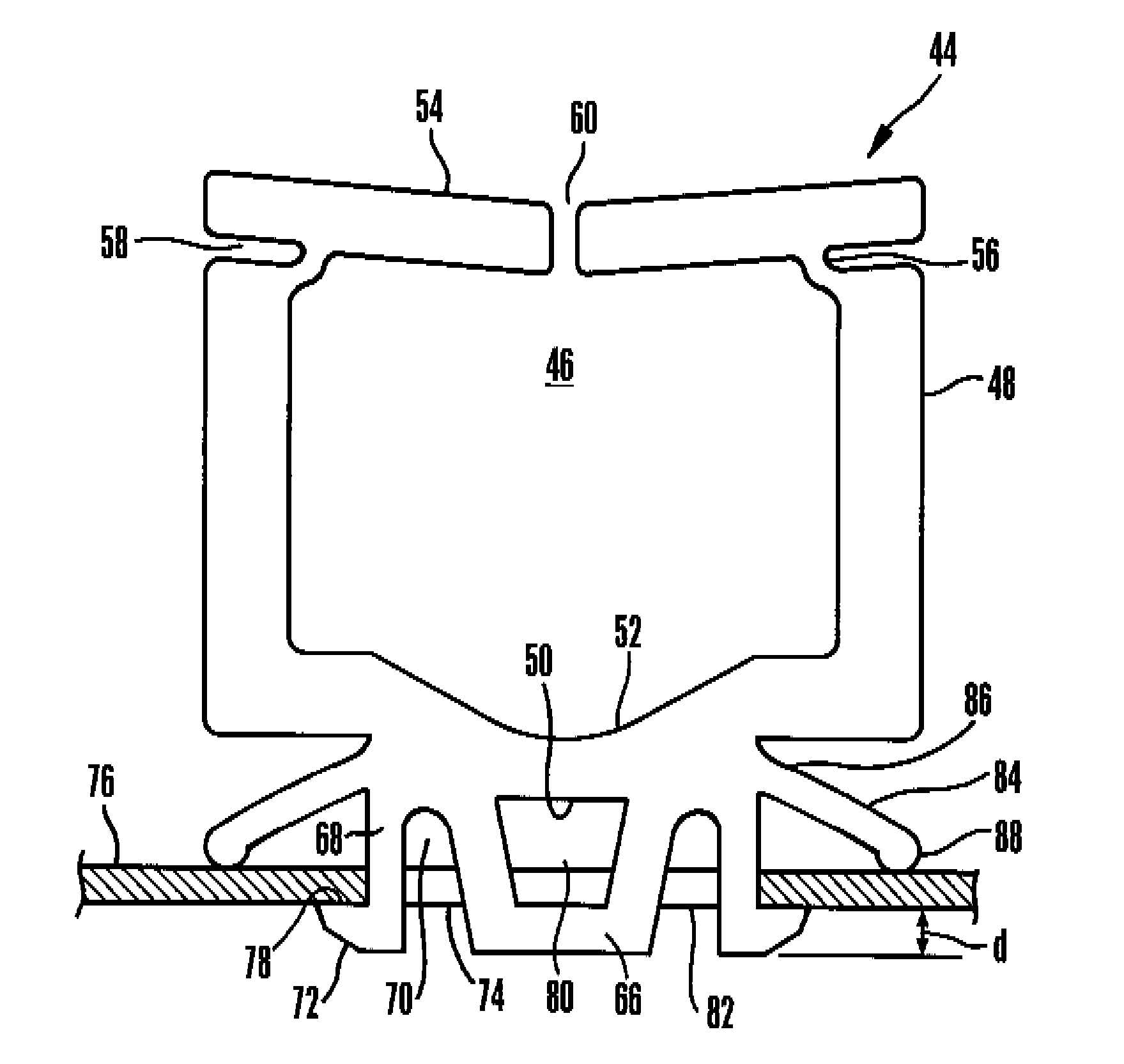

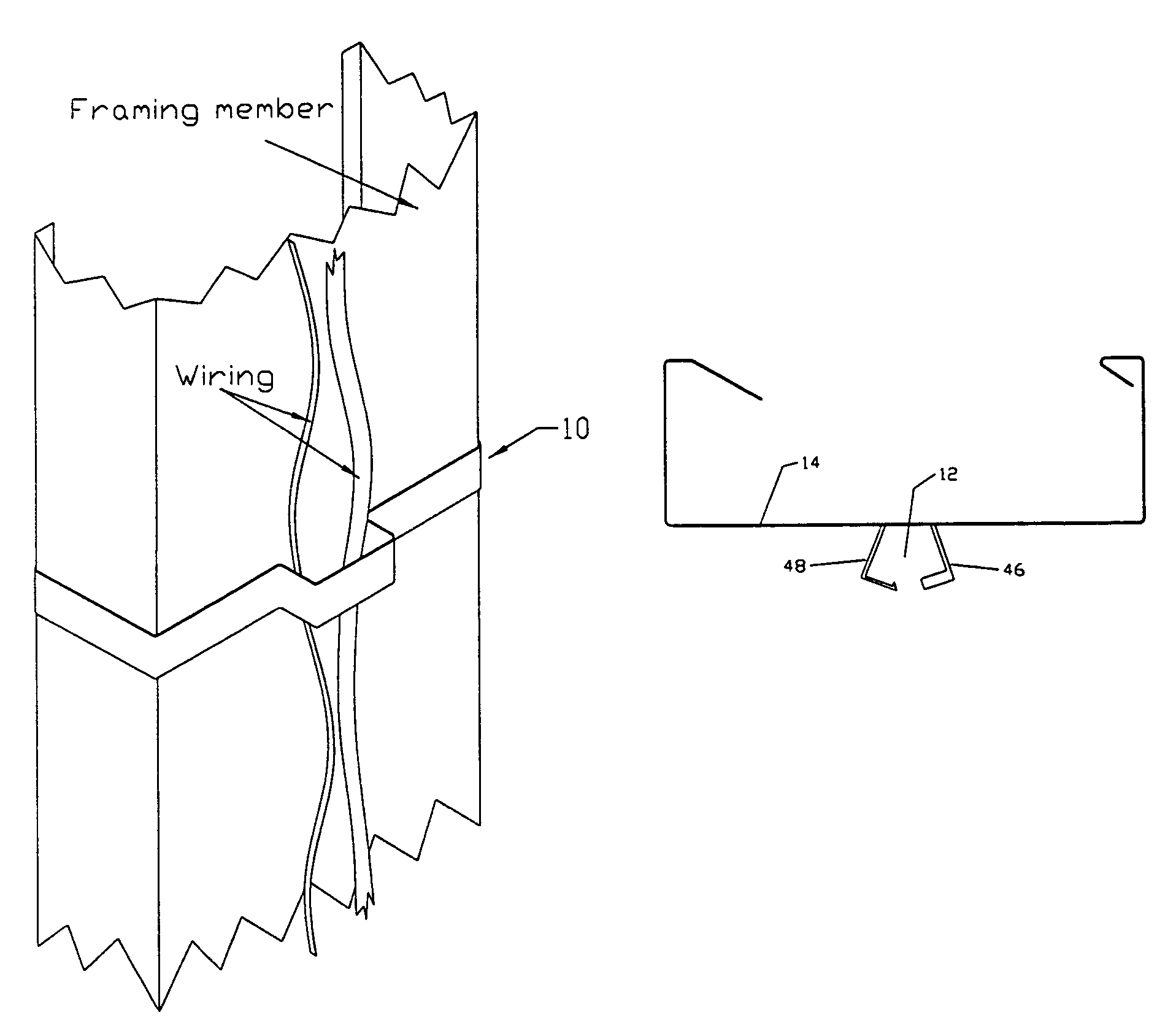

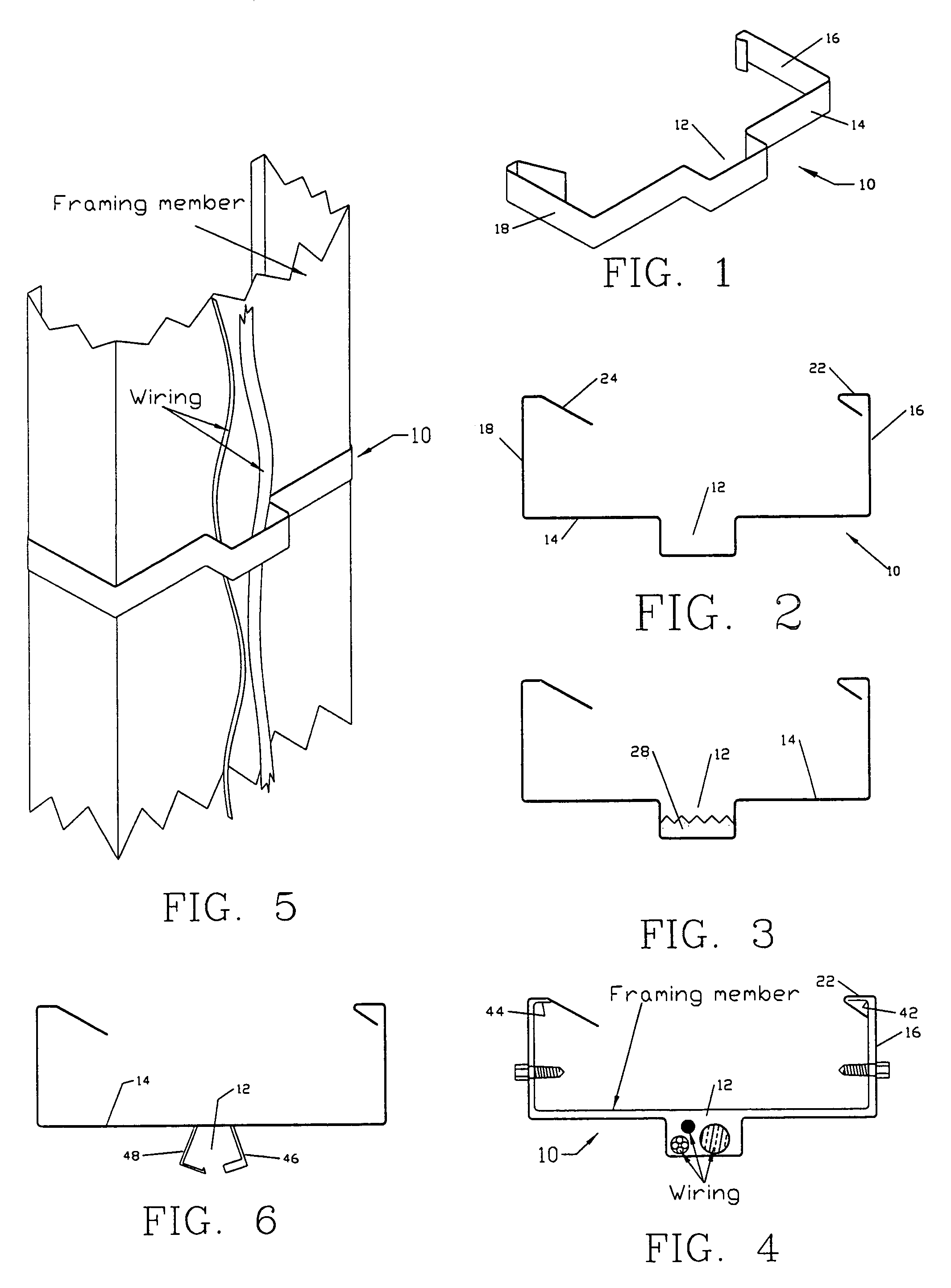

Wiring clip securing electrical wiring to a framing member

A wiring clip for securing electrical wiring to metal framing members. In a specific embodiment, the subject clip can secure the wiring a required distance from the nearest edge or face of the metal framing member to which a wall board is to be secured. The wire clip generally resembles an open frame having a wire receiving area formed in the main body, where the wire receiving area is centrally located within the main body. The wire clip is generally of U-shaped configuration, with two arms being joined to the main body. The end of the first arm is bent to form a J-hook, such that the J-hook can be hooked about a first inner edge of a metal stud. The end of the second arm comprises a clip, such that the clip can be removable, secured about the second inner edge of the metal stud. The arms, as well as the main body, are resilient, such that the arms and the main body will embrace the metal stud.

Owner:COLLETT DENISE MARIE

Mounting apparatus for printed circuit board

Owner:HON HAI PRECISION IND CO LTD

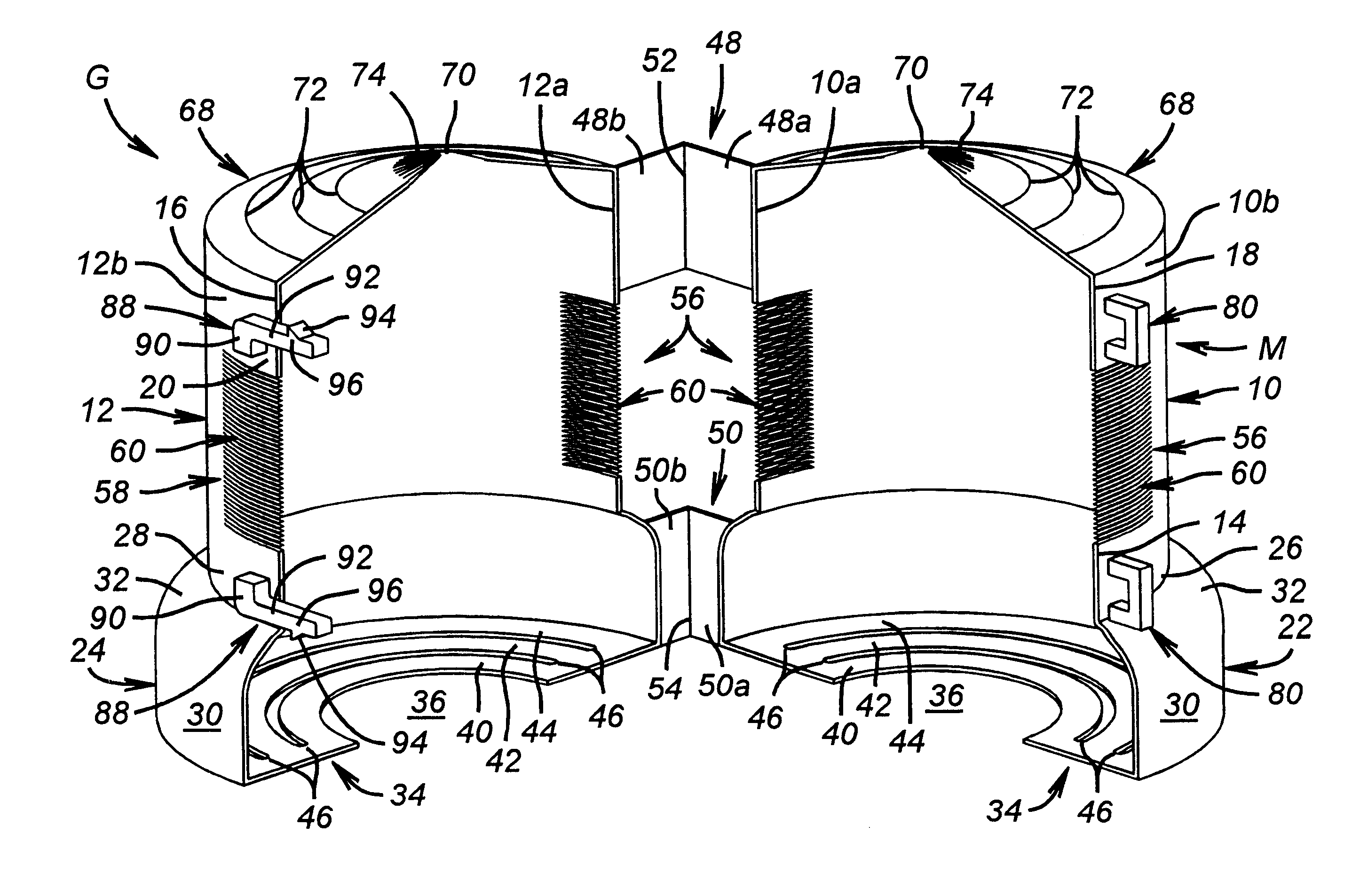

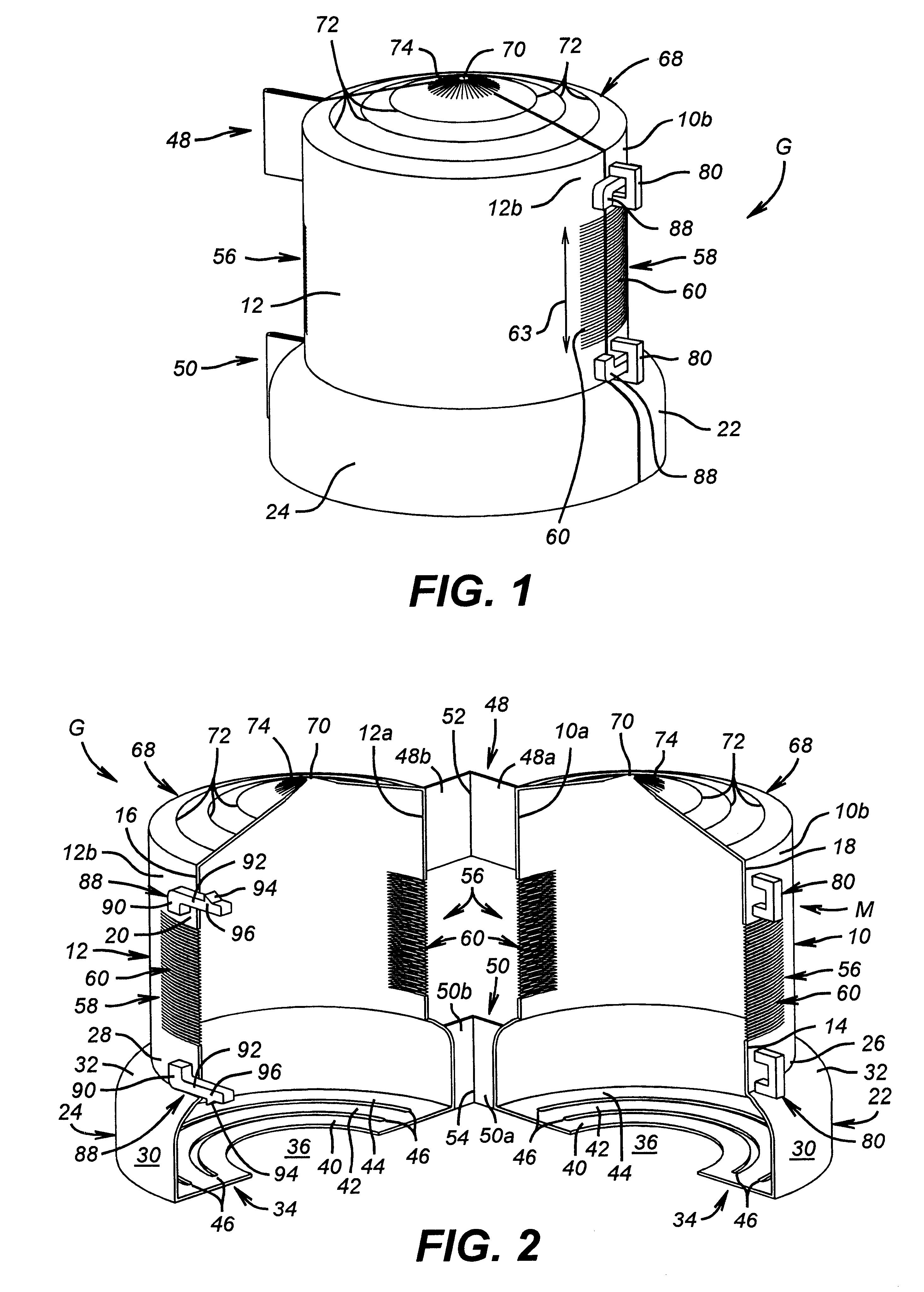

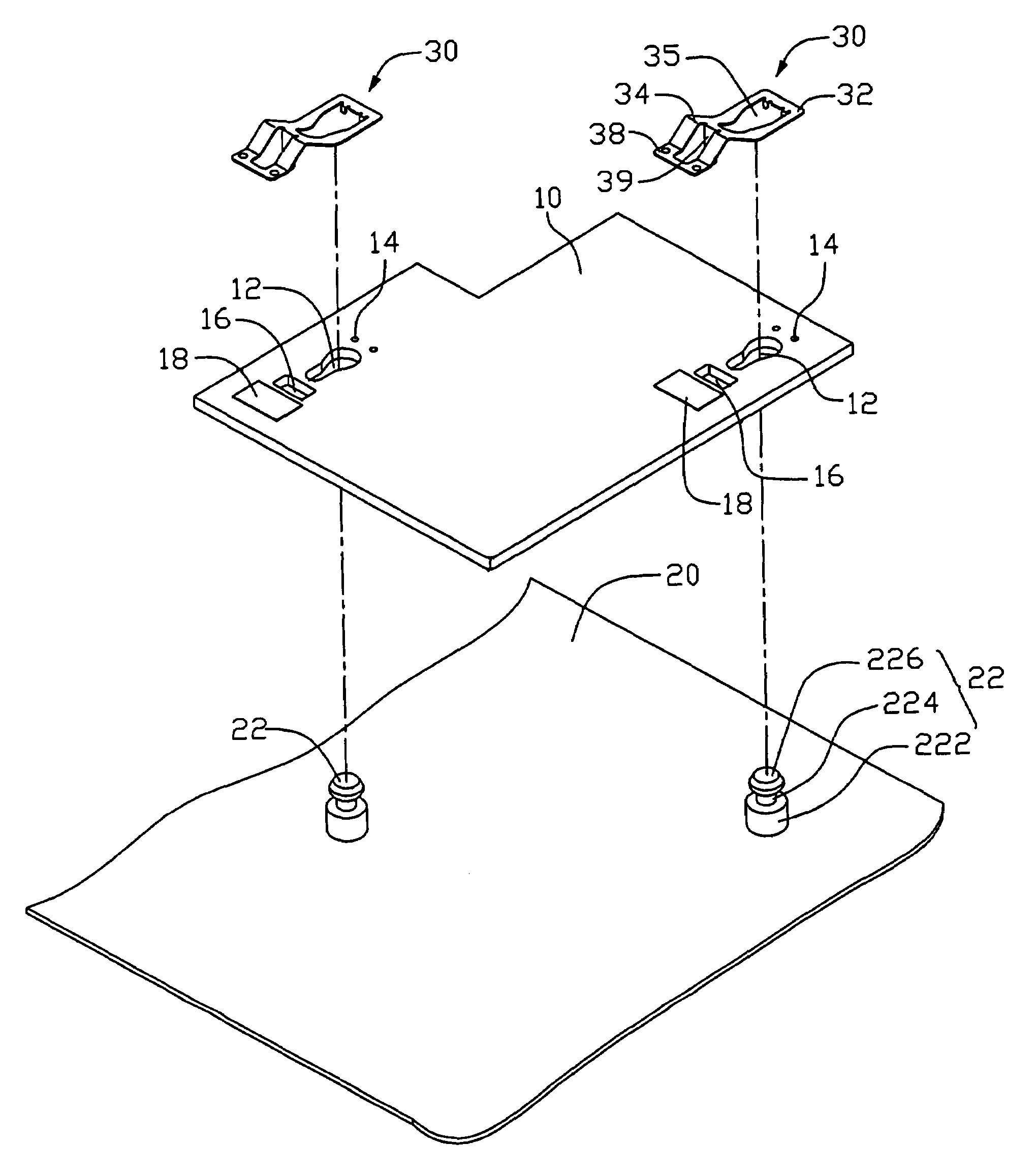

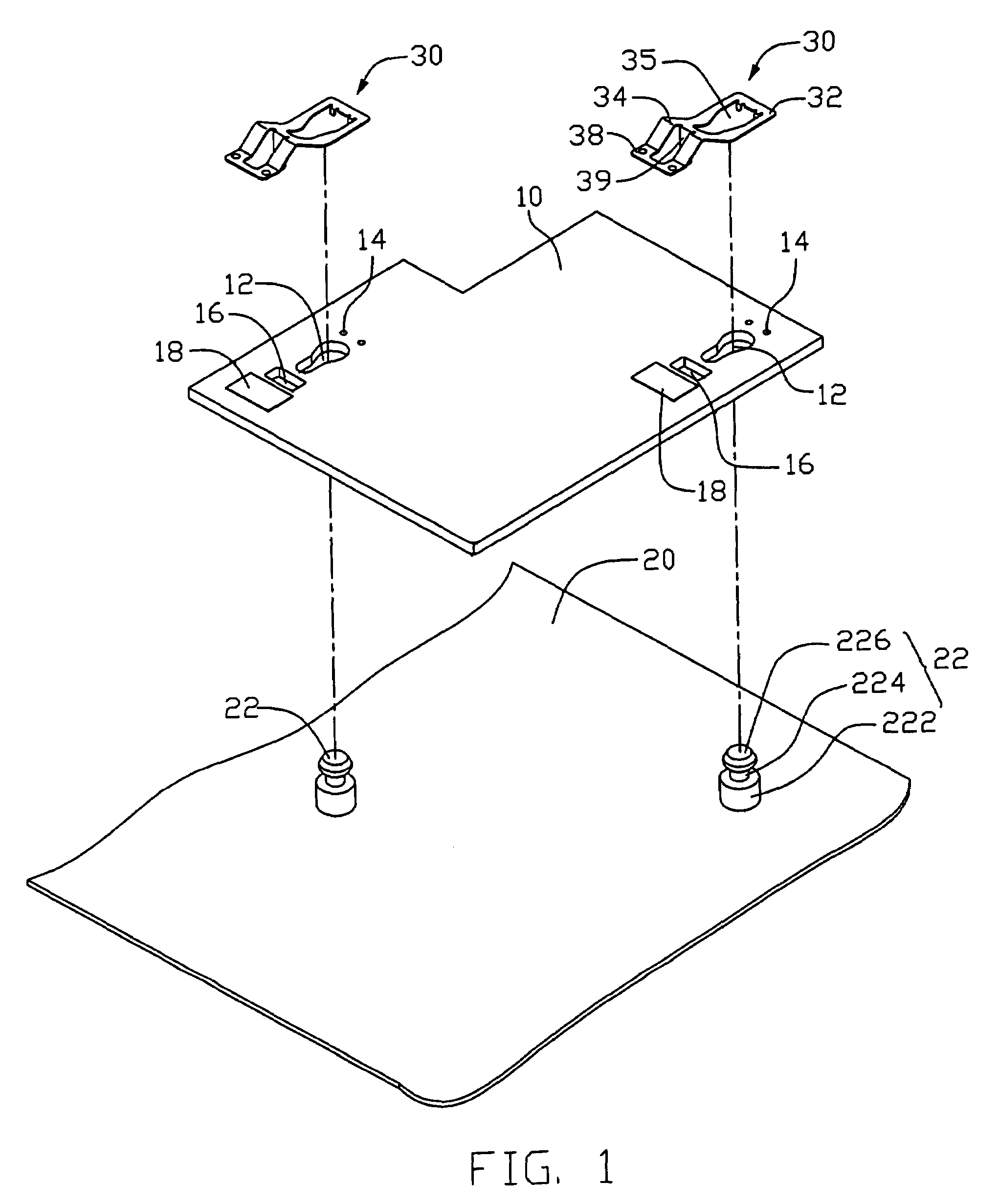

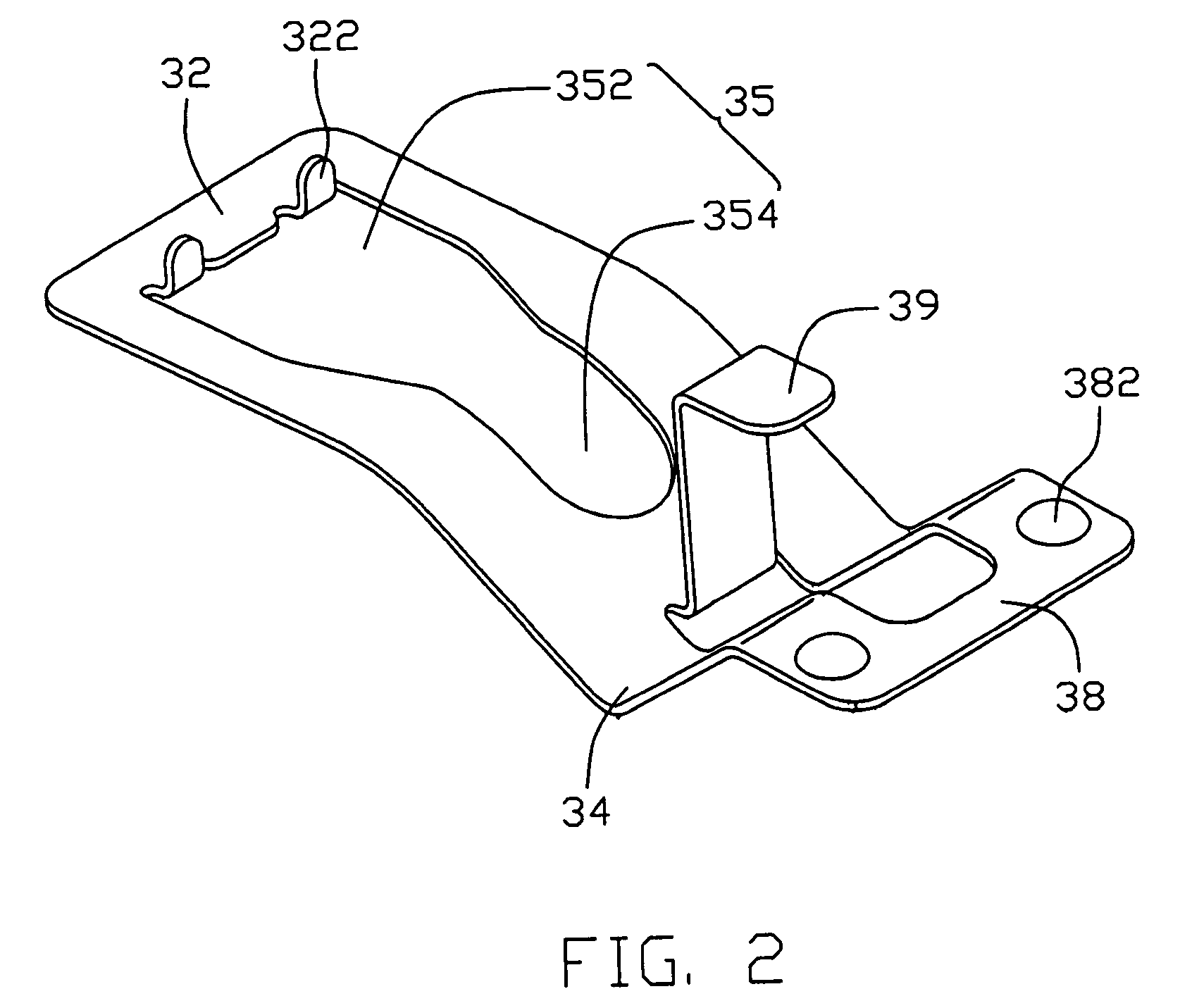

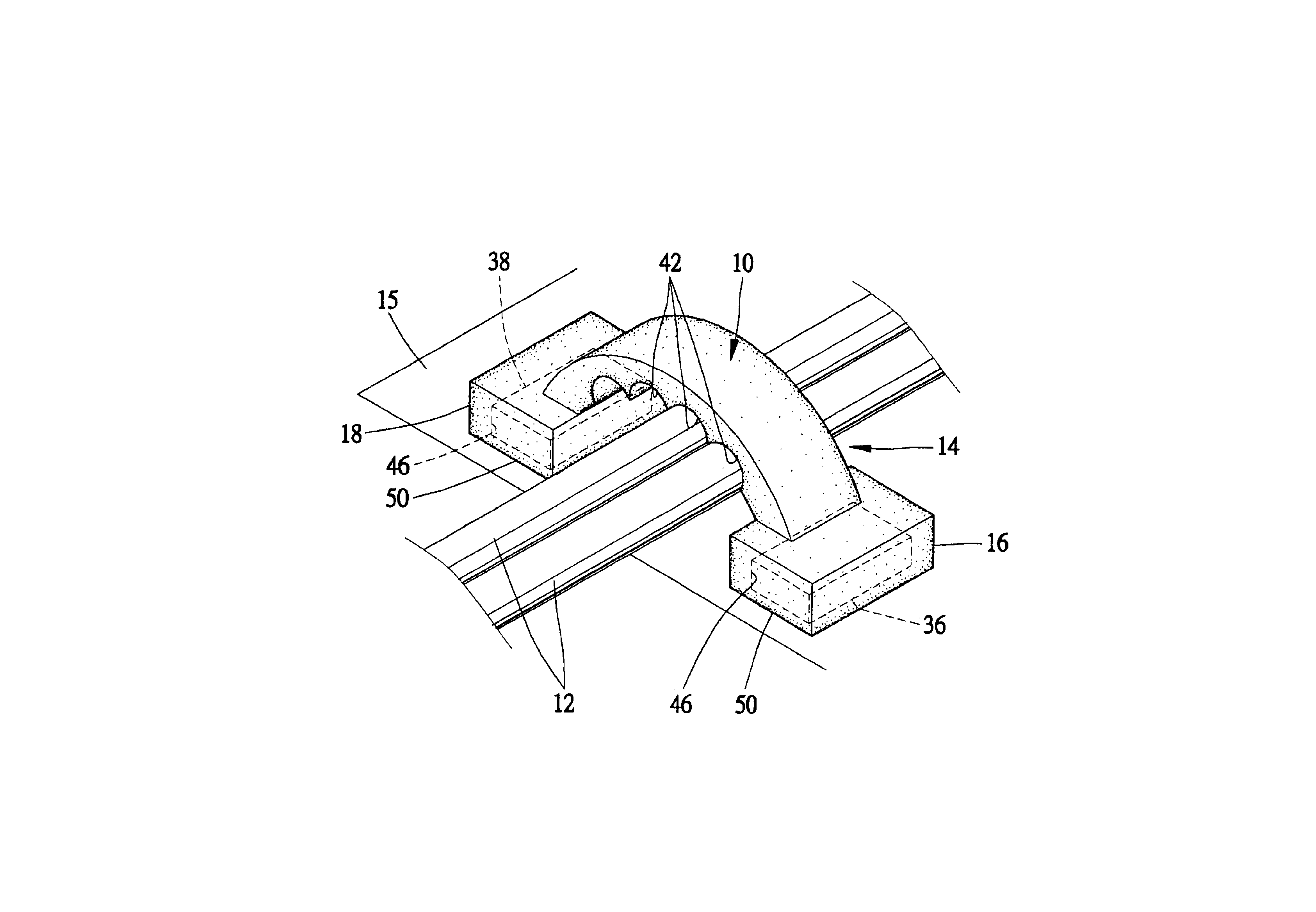

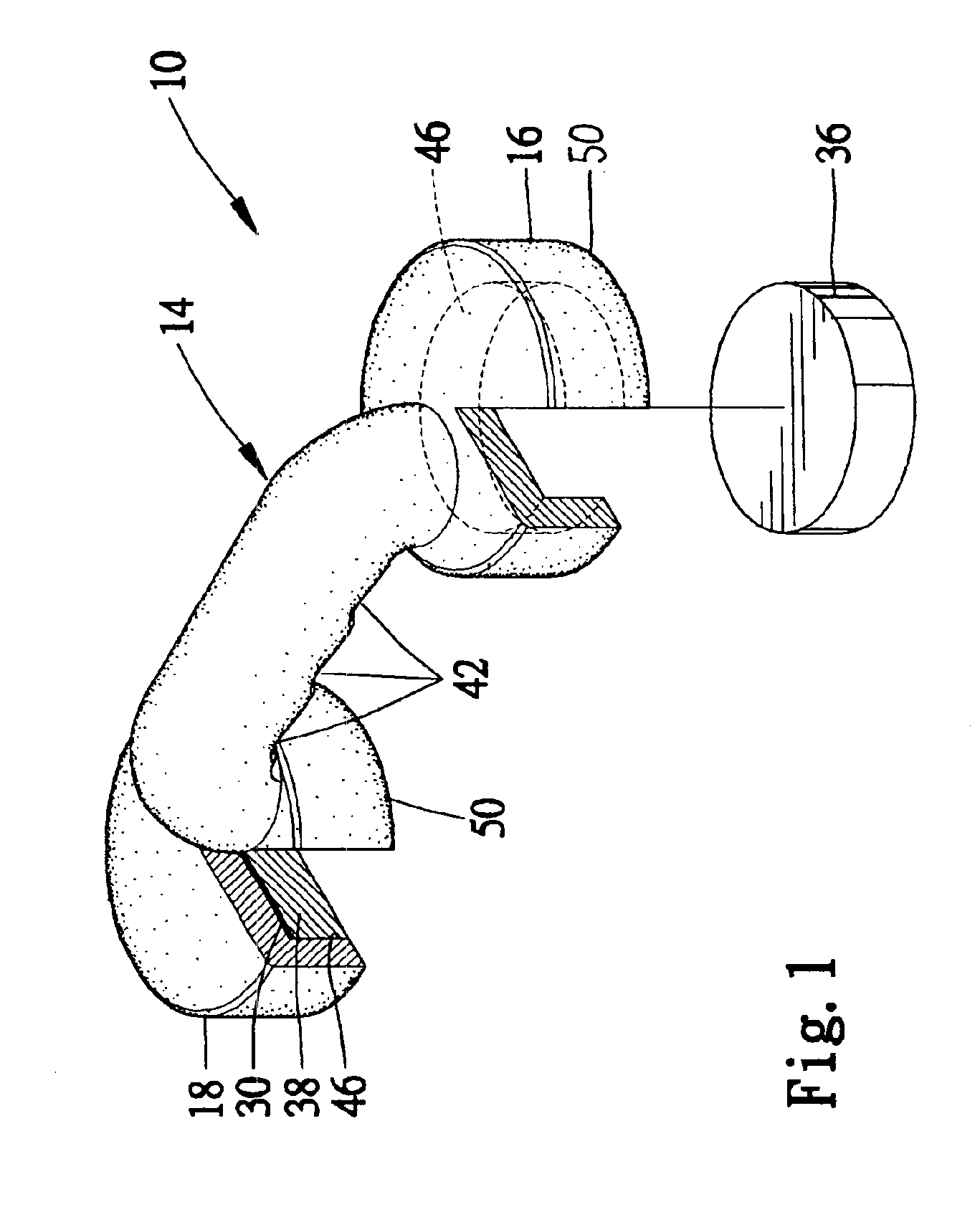

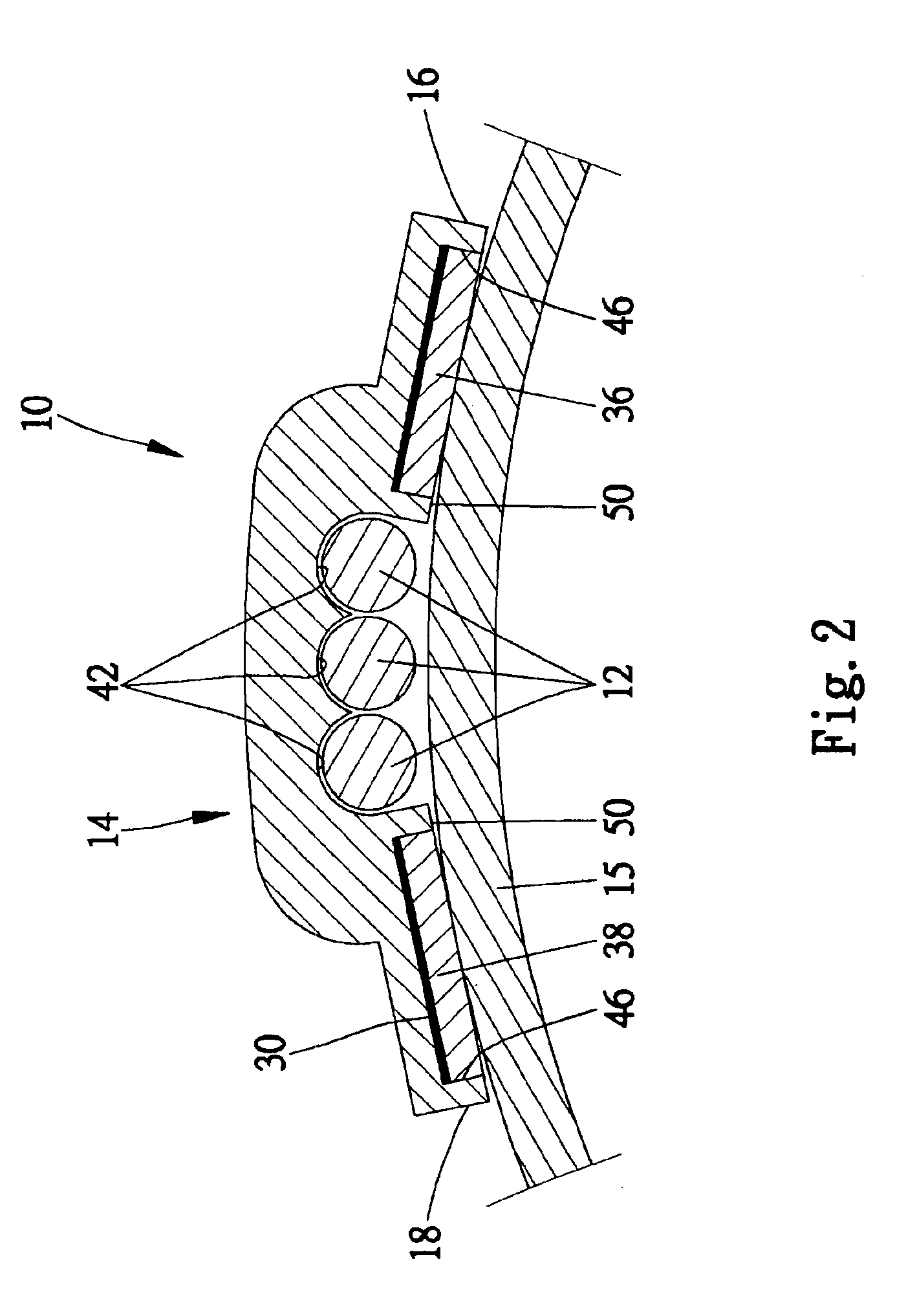

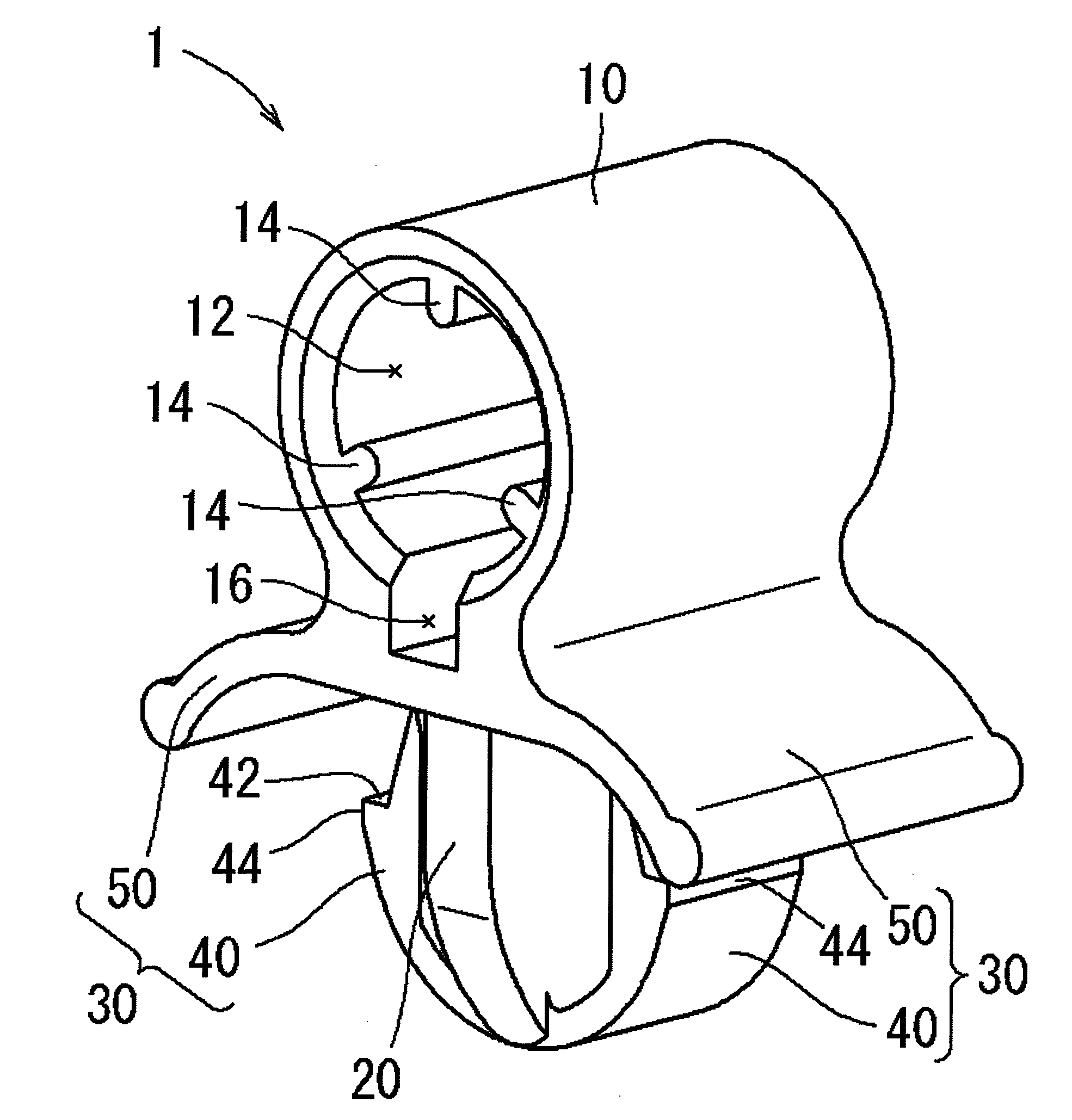

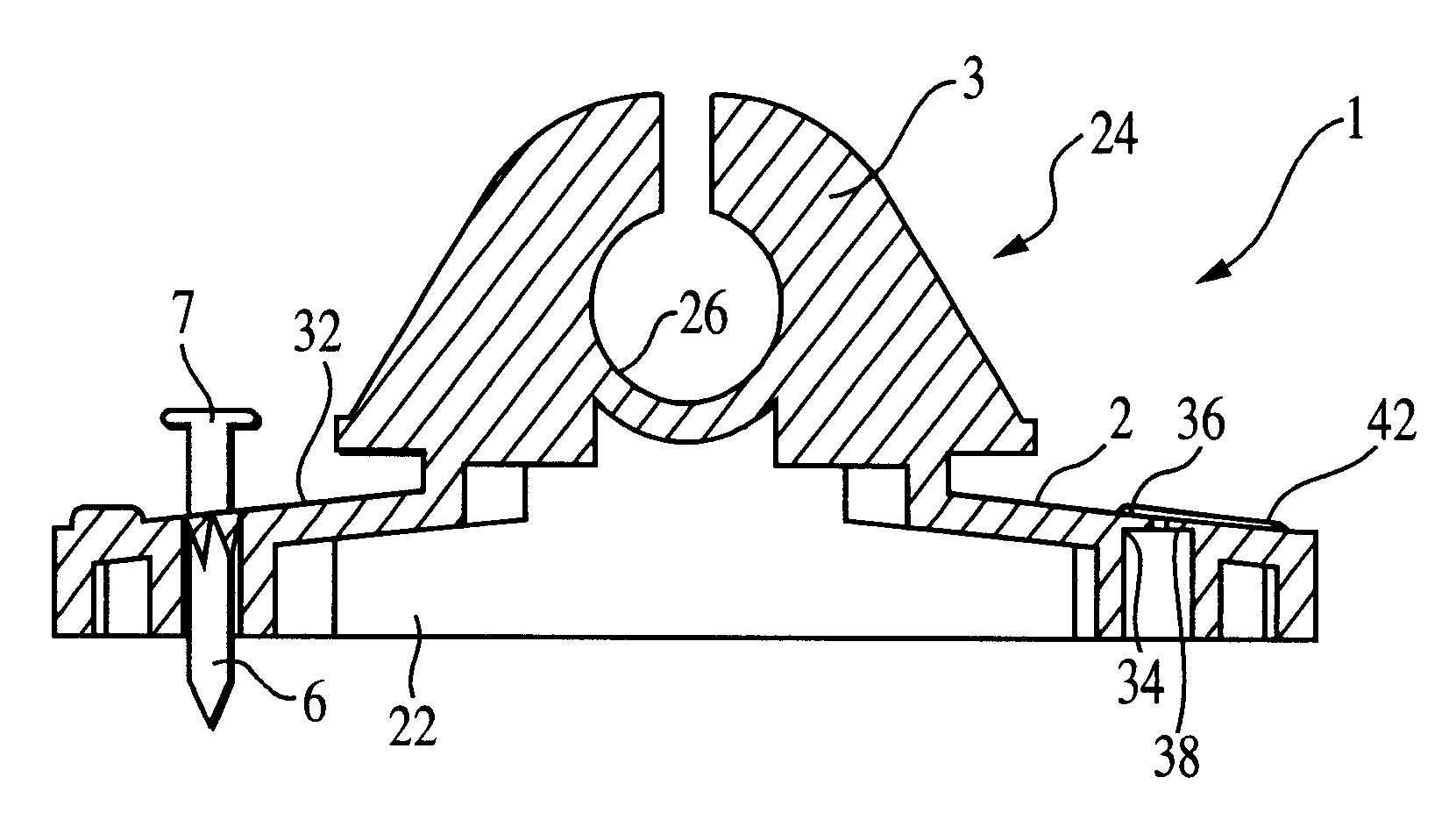

Brackets and methods for holding wires utilizing magnetic force

ActiveUS6855890B1Easy to installEasy to removePicture framesDomestic mirrorsPlastic materialsEngineering

A bracket (10) holds a wire (12) adjacent a magnetic surface (15). The bracket (10) includes a retaining member (14) with a magnetic attracting end (16) and a retaining end (18). The retaining member (14) is shaped to accept the wire (12) between the magnetic attracting end (16) and the retaining end (18) while holding the wire (12) adjacent the magnetic surface (15) when the retaining member (14) is held to the magnetic surface (15). The retaining member (14) is formed of a plastic material that is flexible to form a plurality of holding shapes and sturdy to retain one of the plurality of holding shapes to correspond to the magnetic surface (15) of a planar or non-planar configuration. The magnetic attracting end (16) and the retaining end (18) can each include a cavity (46) to receive and fit magnetic attractors (36, 38). The magnetic attractors (36, 38) can each have a length longer than a width and have elongated magnetic forces which are generally perpendicular to an axis extending between the magnetic attracting end (16) and the retaining end (18) of the retaining member (14). In other aspects, the wire (12) is held on a nonmagnetic surface by placing the wire (12) adjacent to the nonmagnetic surface and to first and second magnet attractive fasteners (22, 24) that have been attached to the nonmagnetic surface. While constraining the wire (12) within the bracket (10), the first and second magnetic attractors (36, 38) are attached to the first and second magnet attractive fasteners (22, 24), respectively, thereby holding the wire (12) adjacent the nonmagnetic surface.

Owner:R & B ENTERPRISES

Clip

A clip for attaching a wire member to a panel member is provided. The clip includes a head part provided with a wire insertion hole capable of holding the wire member a main part supporting the head part and locking means for fitting the main part to a fitting hole of the panel member. The main part is a single body. An inside and an outside of the wire insertion hole are not communicated with each other in a radial direction thereof.

Owner:TOYOTA BOSHOKU KK

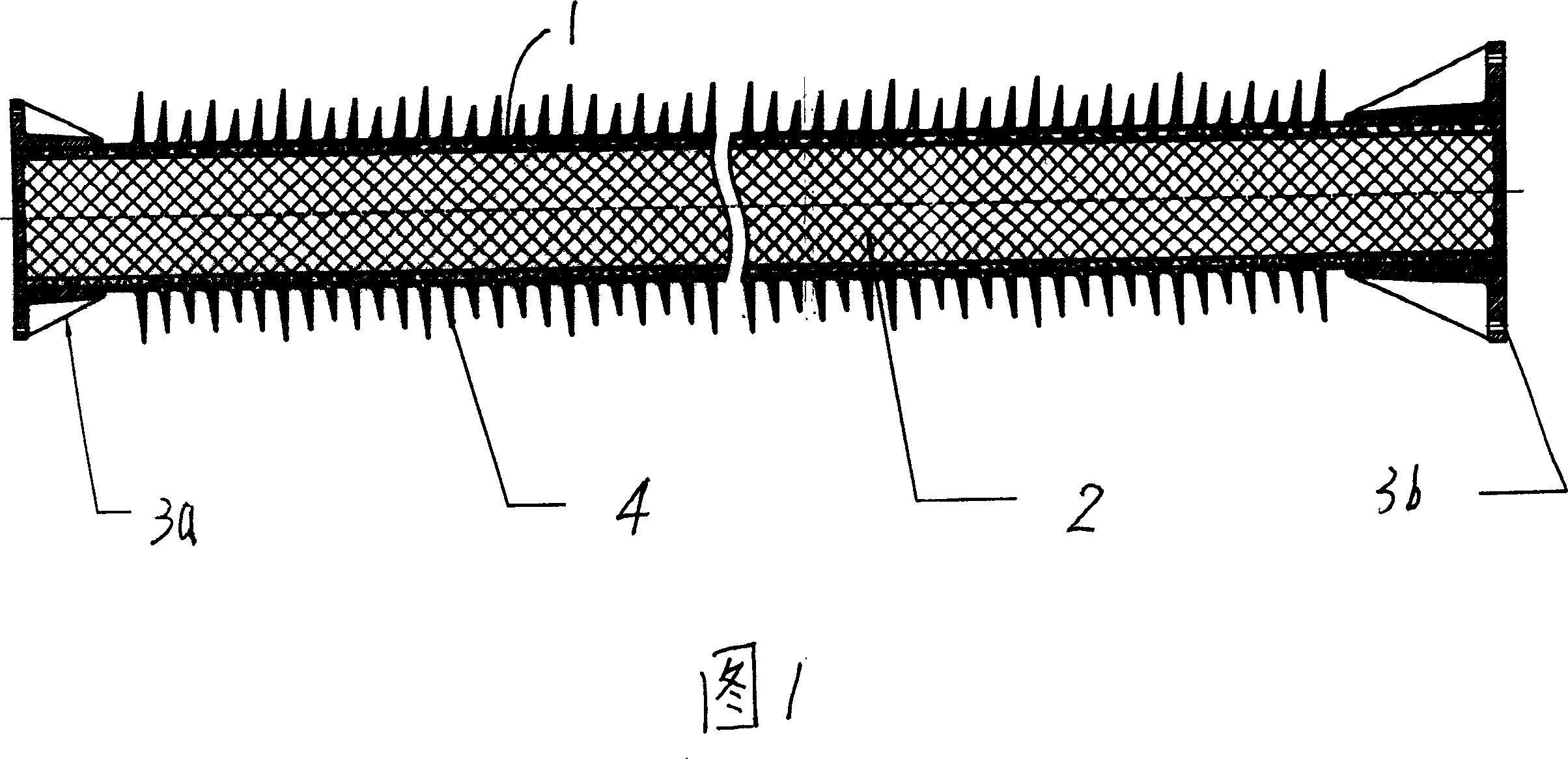

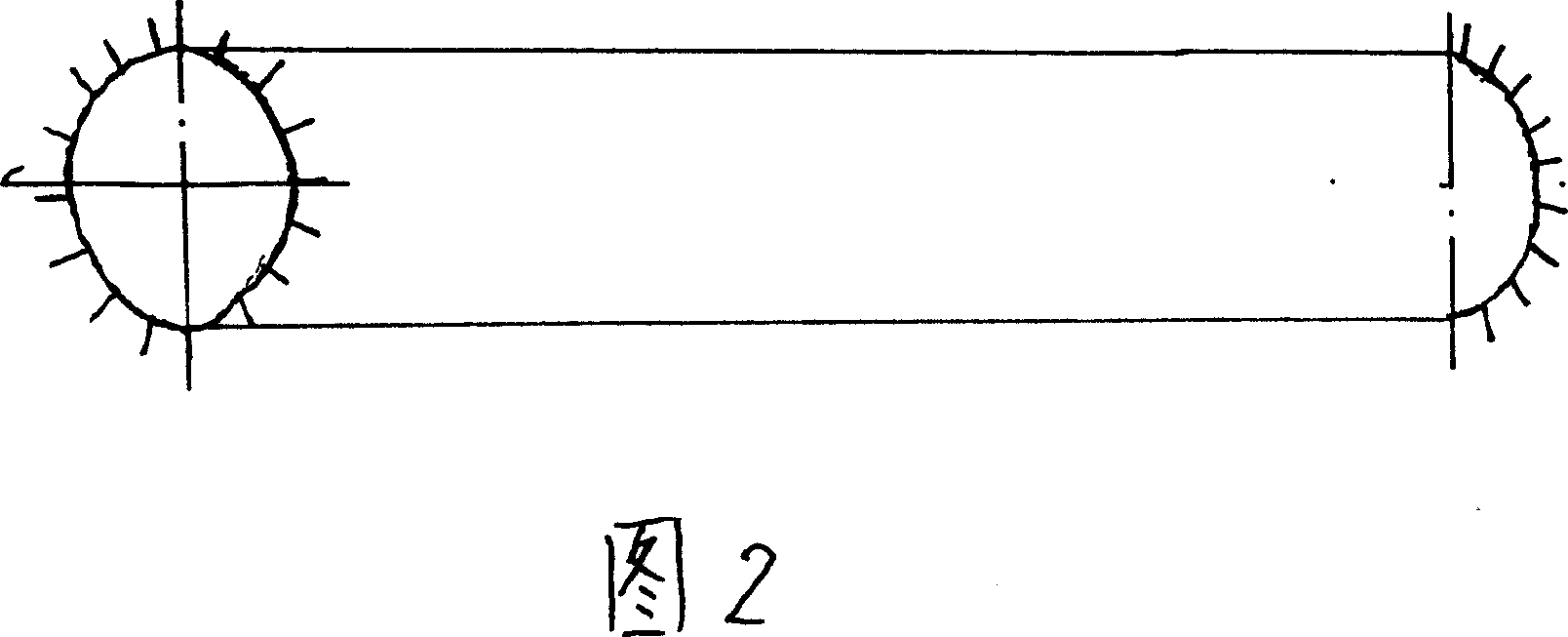

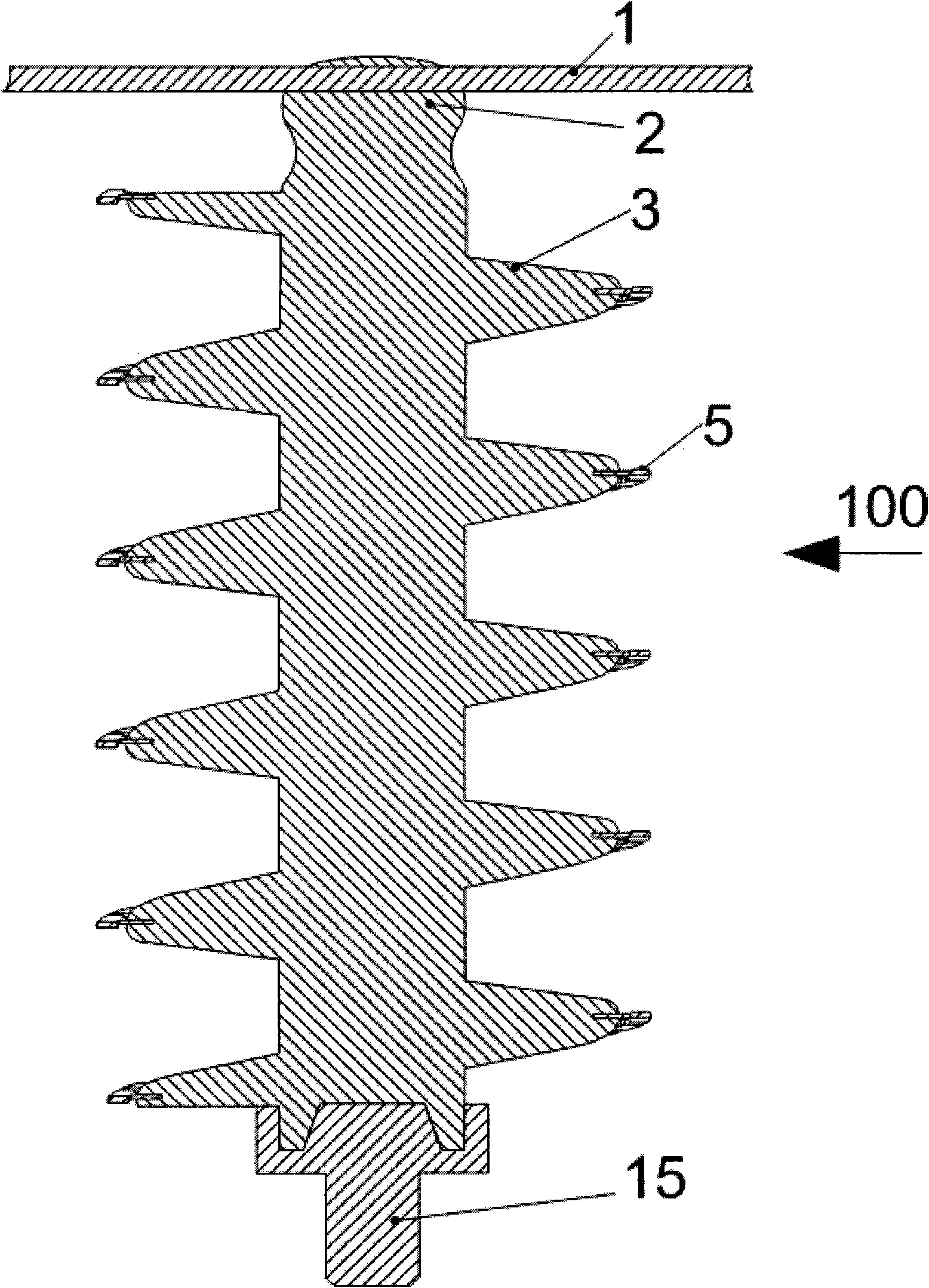

A compound supporting pole insulator with extrusion bar as internal core and its making method

The invention relates to a composite column insulator with a pulltrusion rod as the inner core, which is used in power transformation and transmission in power industry, and a producing method of the insulator. The invention consists of a winding tube, a core stick, end connecting parts and an umbrella part. The end connecting parts are separately stuck on the two ends of the winding tube. The invention is characterized in that: the winding tube is arranged at the periphery of the core stick, the integrated umbrella is stuck on the out side of the winding tube, and the umbrella is an injecting-formed part made of high-temperature vulcanization silicon rubber; the winding tube is made of epoxy resin adhesive emerged glass roving which is wound and solidified; the pulltrusion rod is used as the inner core of the insulator, so the problem of hollow insulator leakage is avoided; the high strength pulltrusion rod as the inner core of the winding tube greatly increases mechanical performance of the insulator; when producing the winding tube, a track is first simulated, and then pins are fixed on both ends of the core stick. When winding, a tension mechanism with even and constant tensile force is used for control, thus realizing even paving of the glass fiber.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

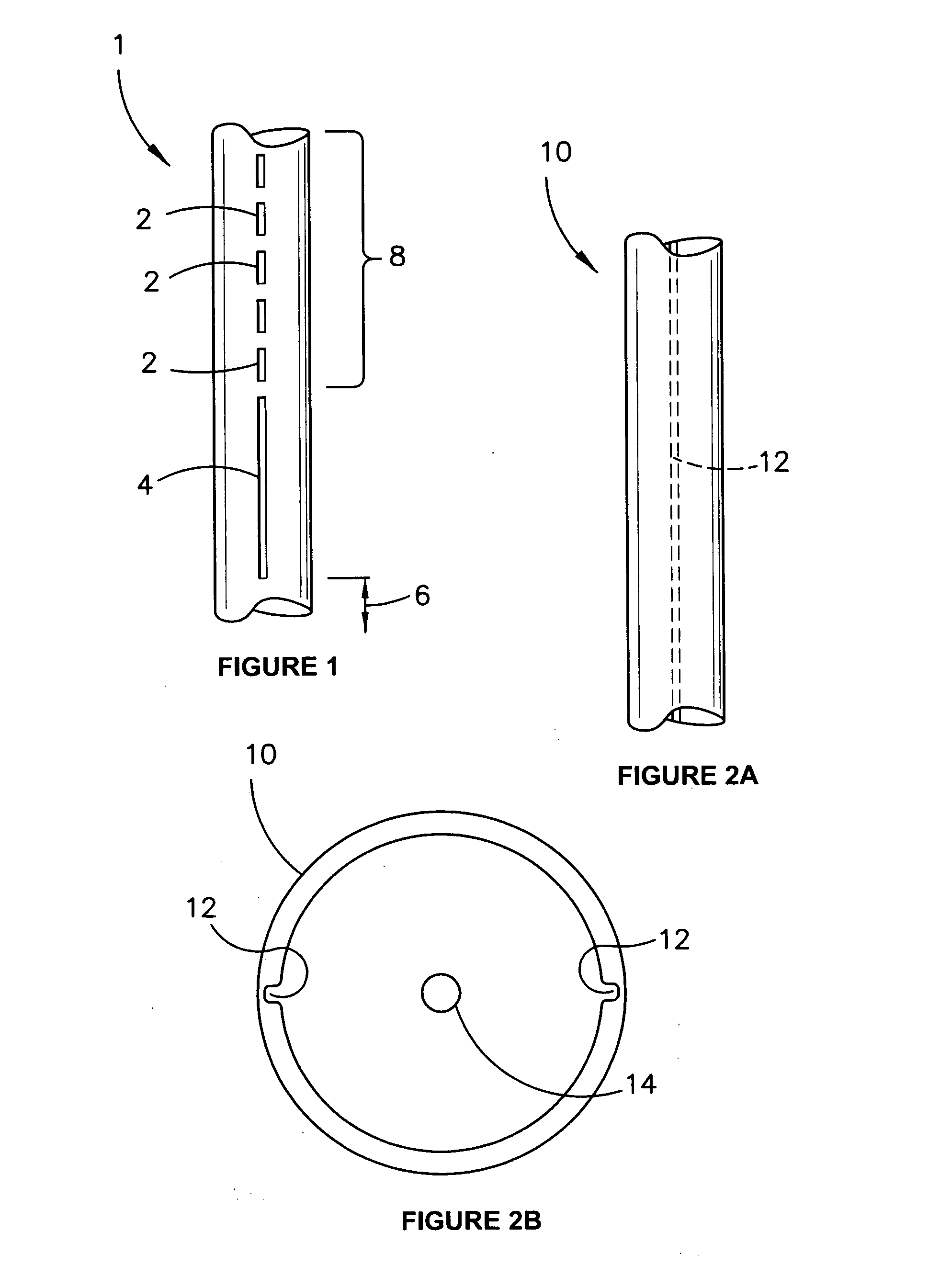

Utility pole

A utility pole comprises a hollow elongate body (1) formed from a composite material including reinforcing fibres embedded in a matrix material and an energy-absorbing region comprising at least one elongate weakened zone (2, 4, 12) formed in the hollow elongate body (1), the at least one weakened zone promoting delamination of the fibres and the matrix material if a vehicle strikes the utility pole.

Owner:GRIFFITHS MICHAEL +1

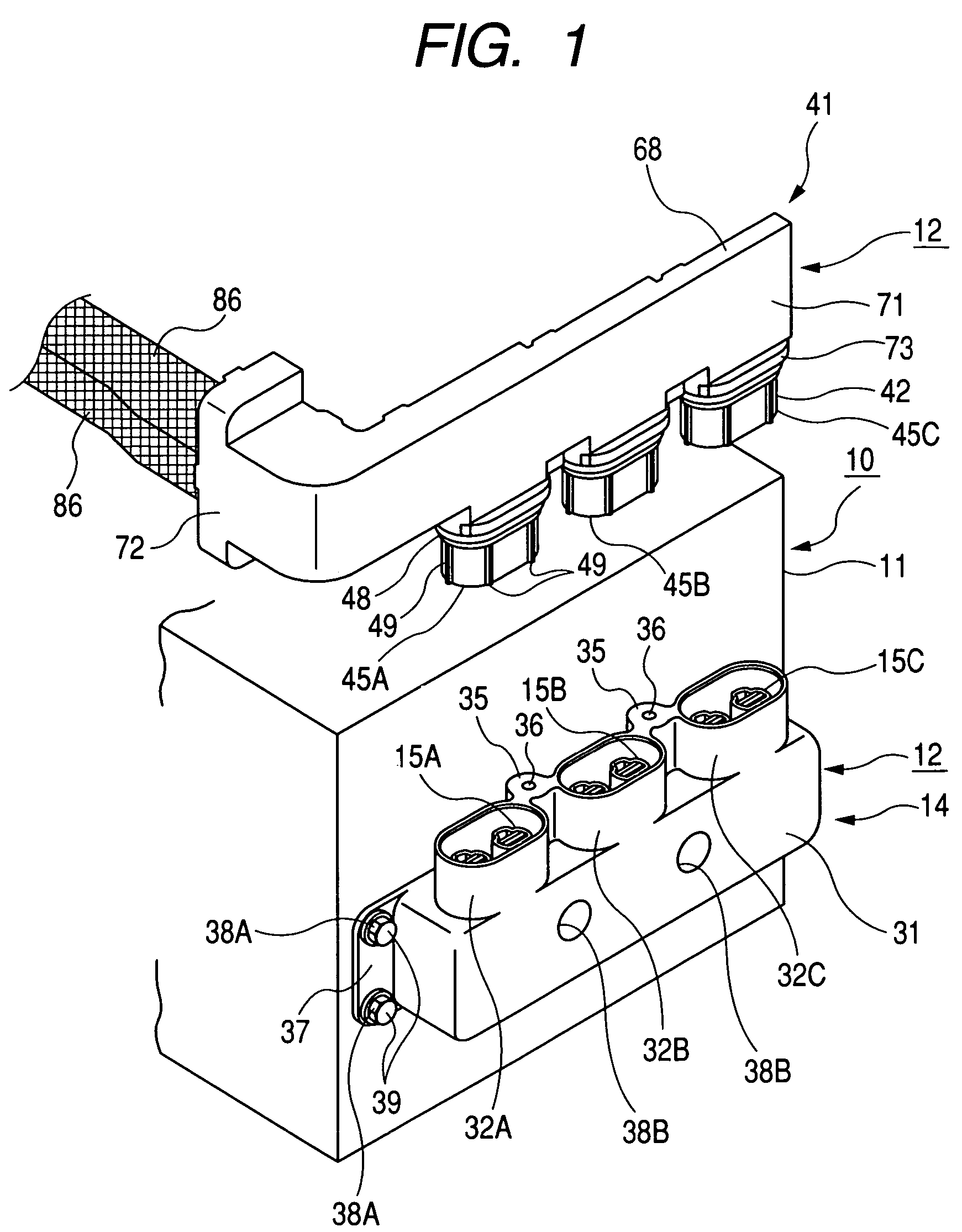

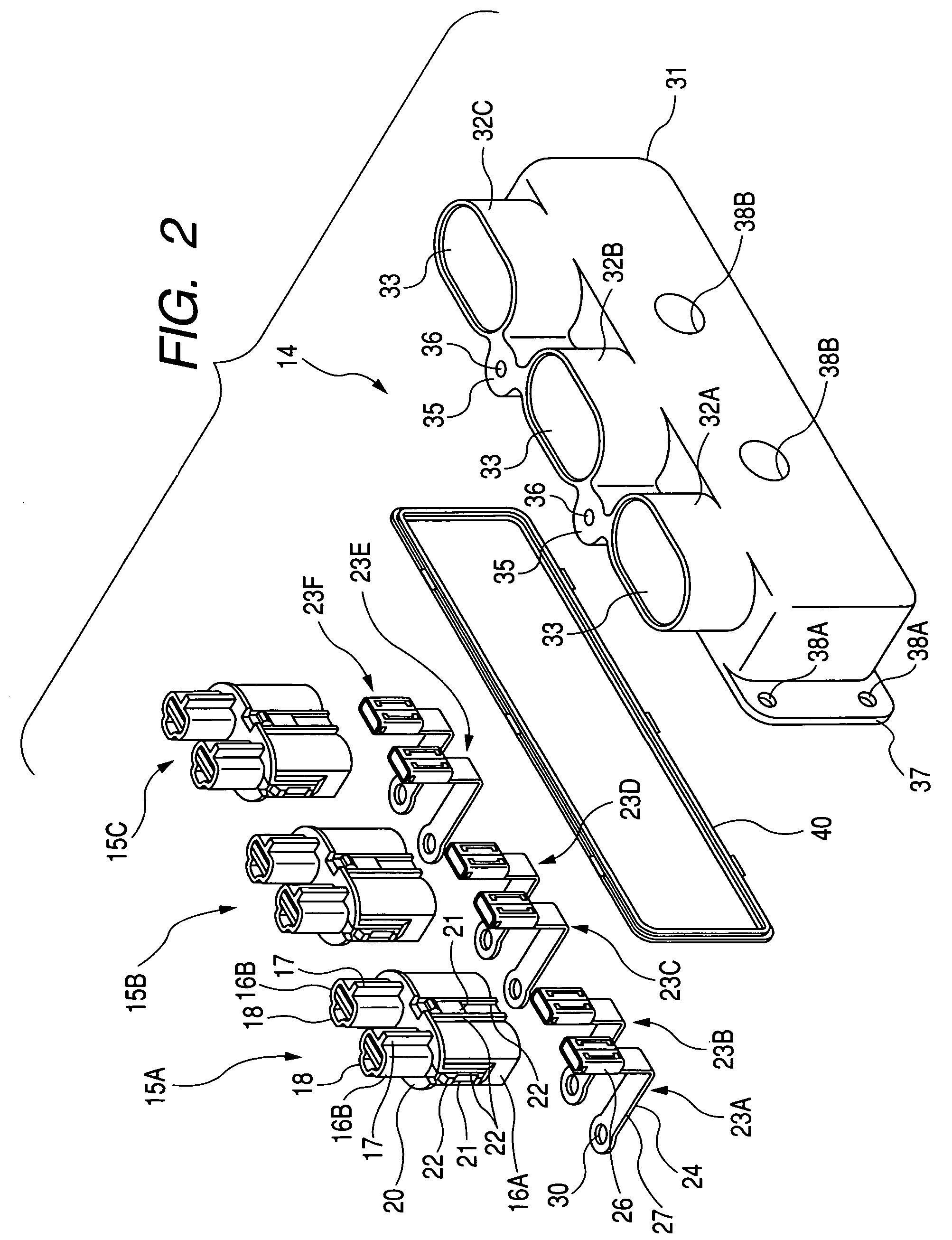

Connector for inverter

InactiveUS7268300B2Large capacityNot easy to bendRelieving strain on wire connectionNutsFrequency changerMating connection

A connector includes an apparatus-side connector housing attached to a casing of an inverter. The apparatus side-connector housing has a plurality of busbars. Each of the busbars has on one end portion a terminal fitting portion where a mating connector of the apparatus-side connector housing is connected and on the other portion an inverter-side terminal portion where an output terminal of the inverter main circuit board is connected. The busbars are divided and arranged into groups respectively corresponding to the U, V and W phases with respect to the inverter-side terminal portion. The busbars are arranged into groups respectively including the U, V and W three-phases for connection to each of the three-phase loads, with respect to the terminal fitting portion. A wire connecting inverter with a plurality of there phase loads can be arranged with respect to each of three phase loads with small space.

Owner:AUTONETWORKS TECH LTD +2

Insulator retainer

InactiveUS6489569B1Less fiddly to undertakeLess timeRemovable ornamentalStaplesElectrical conductorEngineering

An insulator capable of supporting the conductor of an electric fence including at least one retaining portion capable of retaining at least one fixing element to the insulator prior to the insulator being fixed to a support structure with the fixing element.

Owner:GALLAGHER ELECTRONICS LTD CO

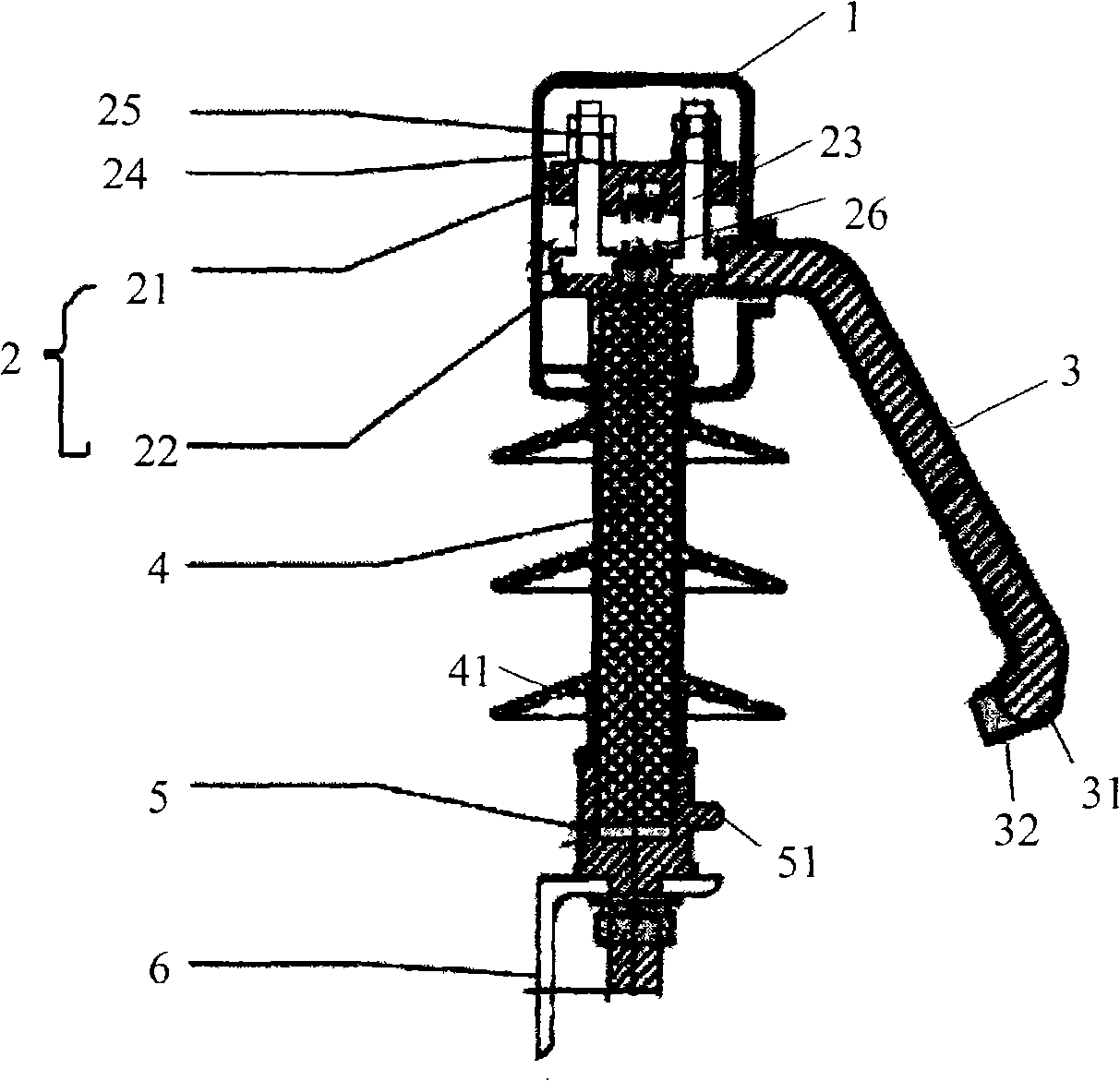

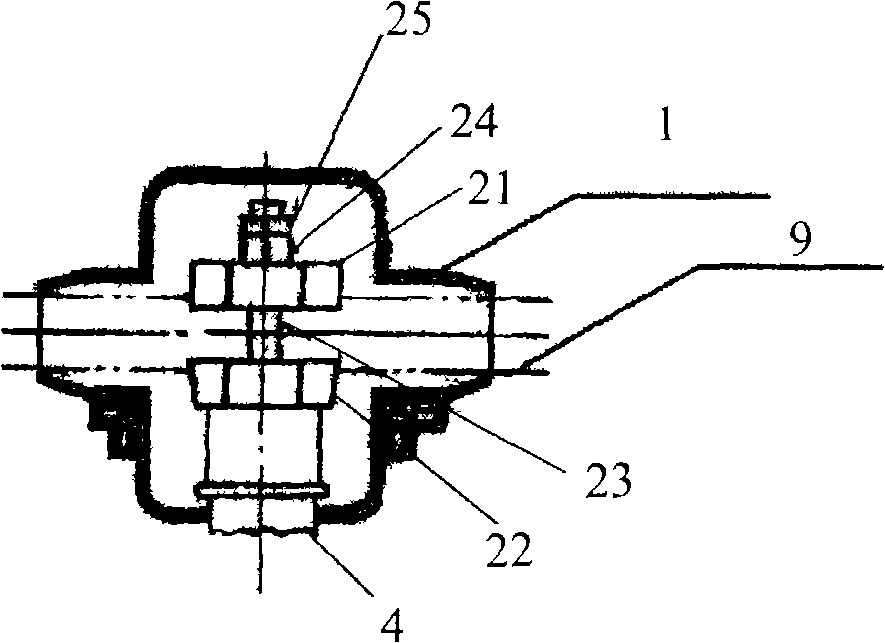

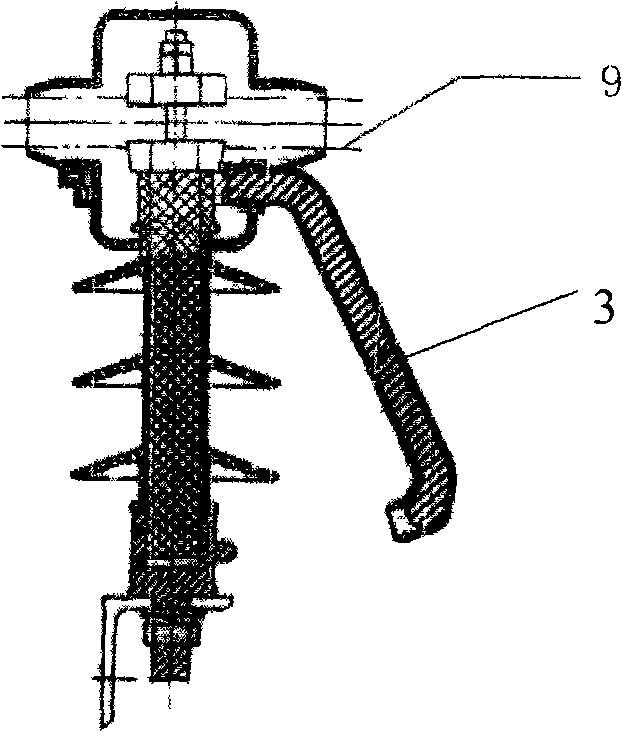

Lightning protection post insulator

ActiveCN101325104AImprove insulation performanceIncrease creepage distanceSupporting insulatorsLightningEngineering

The invention discloses a lightning protection support insulator, which comprises an insulating hood and a wire clipping hardware fitting which is arranged inside the insulating hood and is composed of an upper pressing block and a lower pressing block. The lightning protection support insulator is characterized in that the lightning protection support insulator also comprises a starting rod connected with the side end of the wire clipping hardware fitting, a insulator with both ends being respectively connected with the lower end of the wire clipping hardware fitting and a cross arm, and a lower steel pin arranged inside the insulator and close to one end of the cross arm. The lightning protection support insulator achieves the combination of the support insulator and an arc protection hardware fitting, and has the characteristics of insulation, conducting wire supporting, arc protection, simplified circuit, low fabricating cost and reusability.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Electric fence insulators

Owner:WOODSTREAM CORP

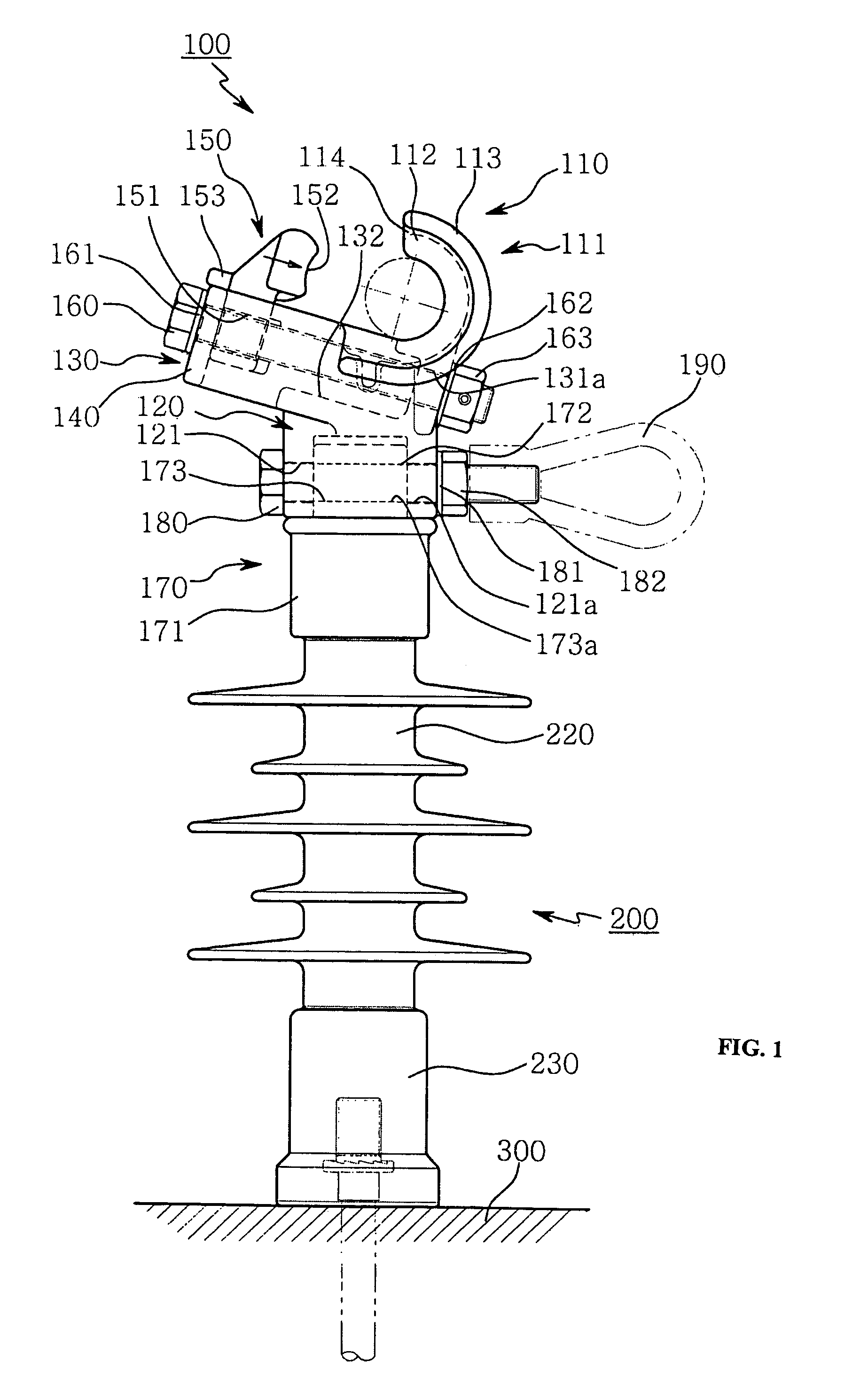

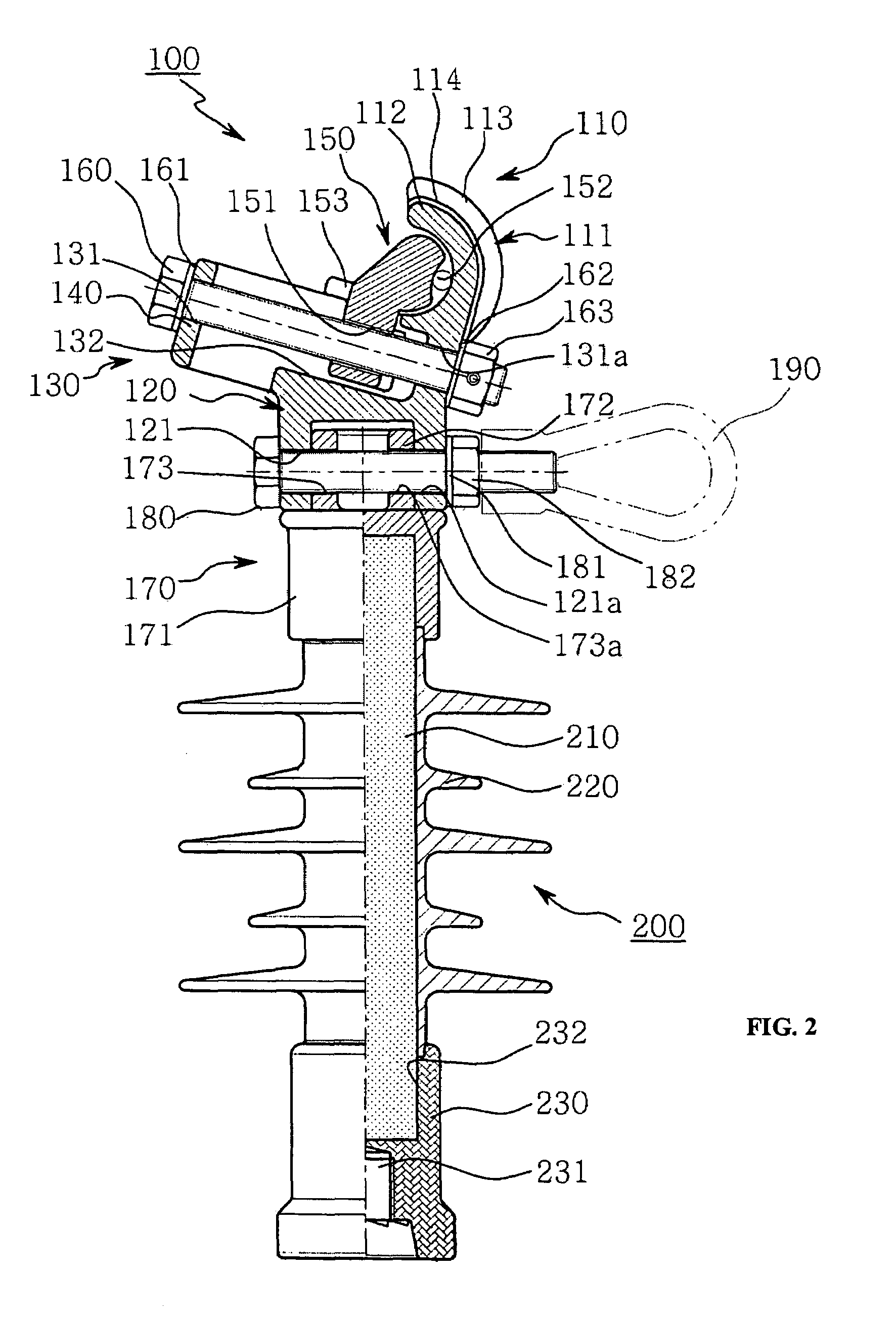

Electrical power line insulator with end clamp

Owner:KIM BONG JOO

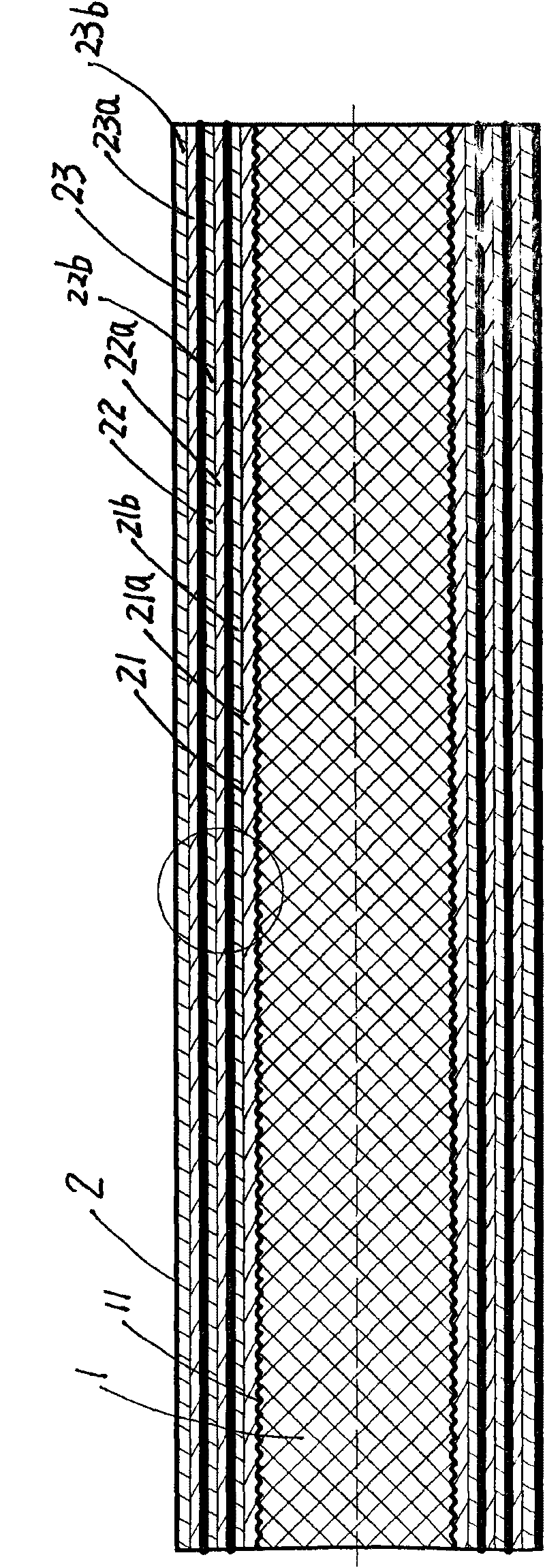

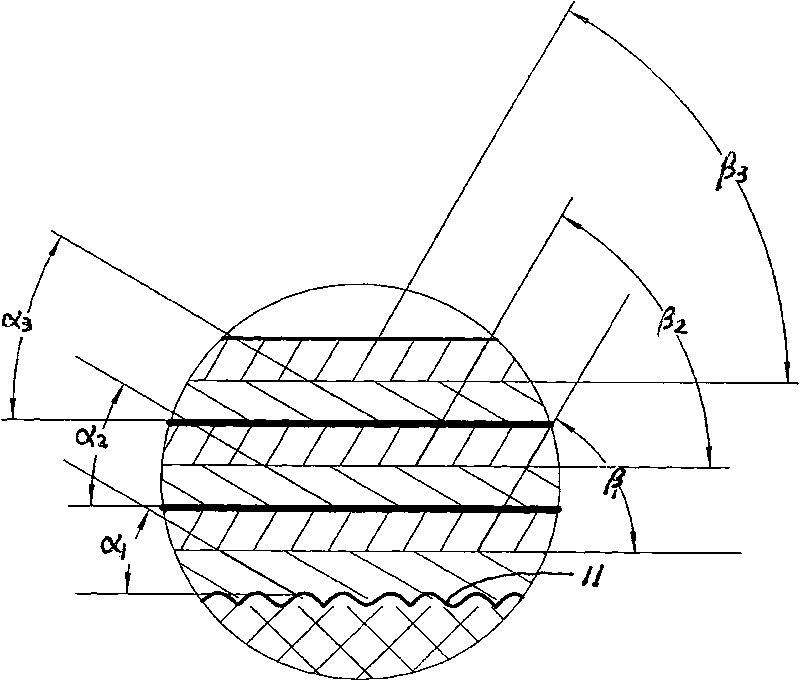

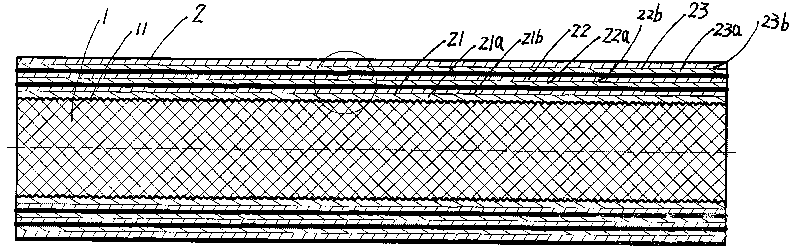

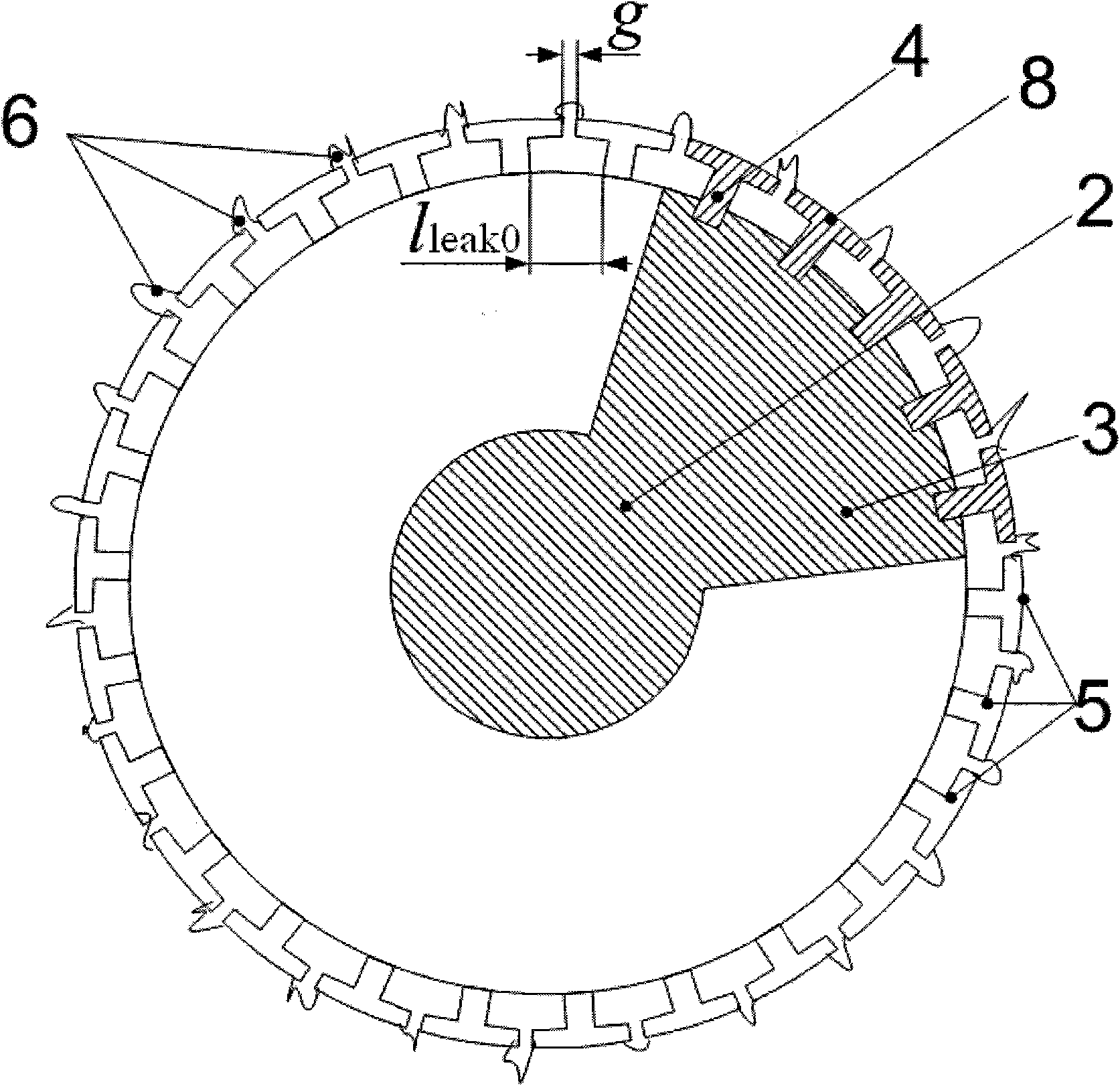

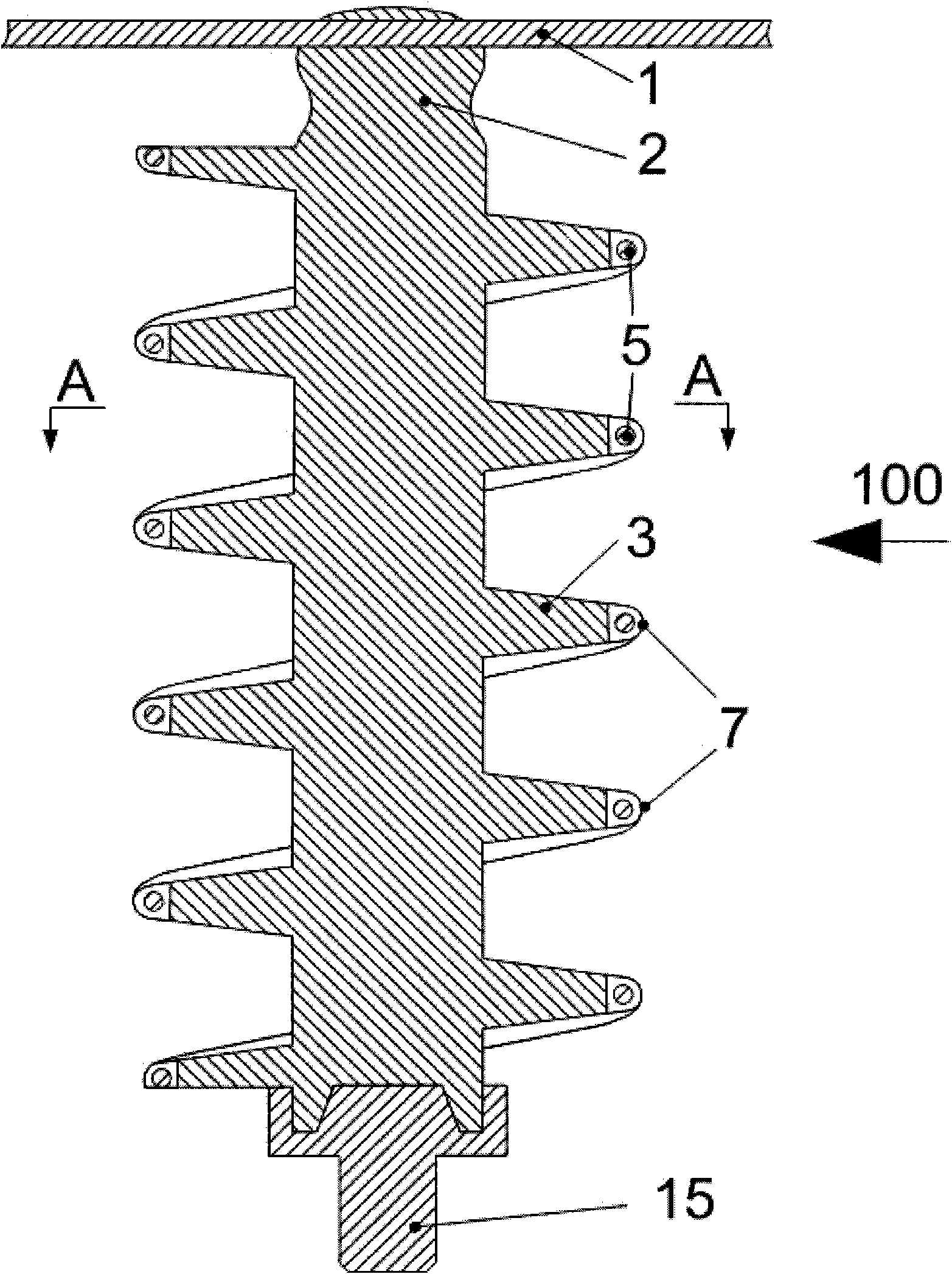

Core rod of ultra-high-voltage post composite insulator and manufacturing method thereof

The invention relates to a core rod of an ultra-high-voltage post composite insulator used for power transmission and transformation in the power industry and a manufacturing method thereof. The core rod consists of a rod core and a winding tube, wherein the winding tube is arranged on the periphery of the rod core and is a tube made by winding and curing a glass fiber yarn dipped with epoxy resin glue. The core rod is characterized in that the rod core is a core body with a damping slot on the surface thereof, and the winding tube consists of a layer I, a layer II and a layer III, and the three layers are respectively formed by winding and curing a glass fiber yarn dipped with epoxy resin glue. Since the pultrusion rod is used as an inner core, and the damping slot is processed on the surface of the rod core, the connection between the rod core and the winding tube is more reliable; and since the winding tube consists of multiple layers and forms a large-diameter core rod through laminated winding and curing, the invention improves the performance of the winding tube, is applicable to the ultra-high-voltage condition and greatly improves the wind resistance and bending resistance of the post composite insulator.

Owner:南方电网技术研究中心 +1

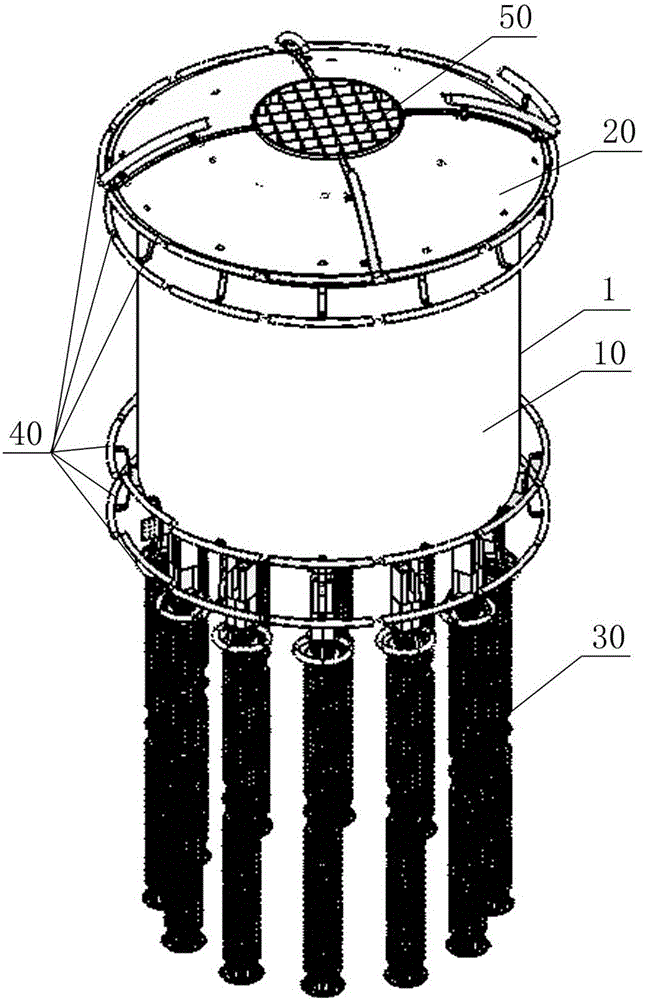

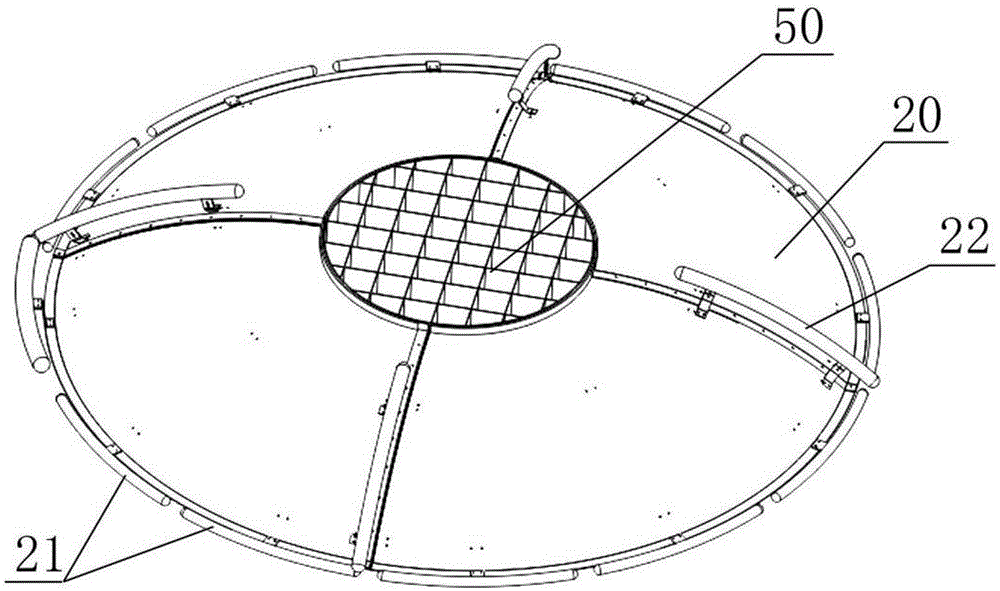

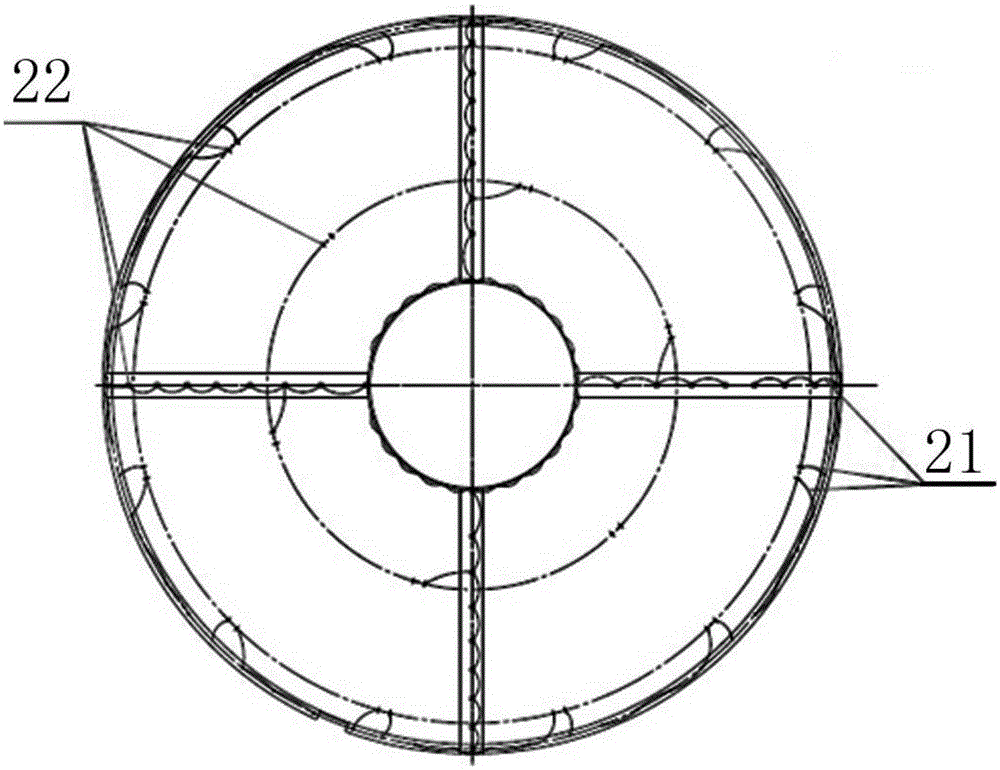

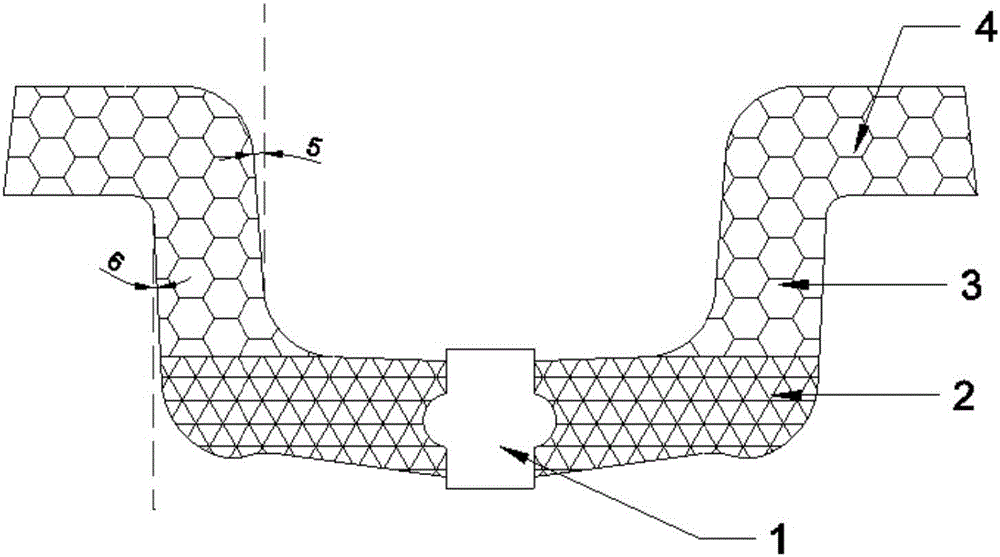

High-voltage and ultrahigh-voltage dry-type air-cored current limiting reactor

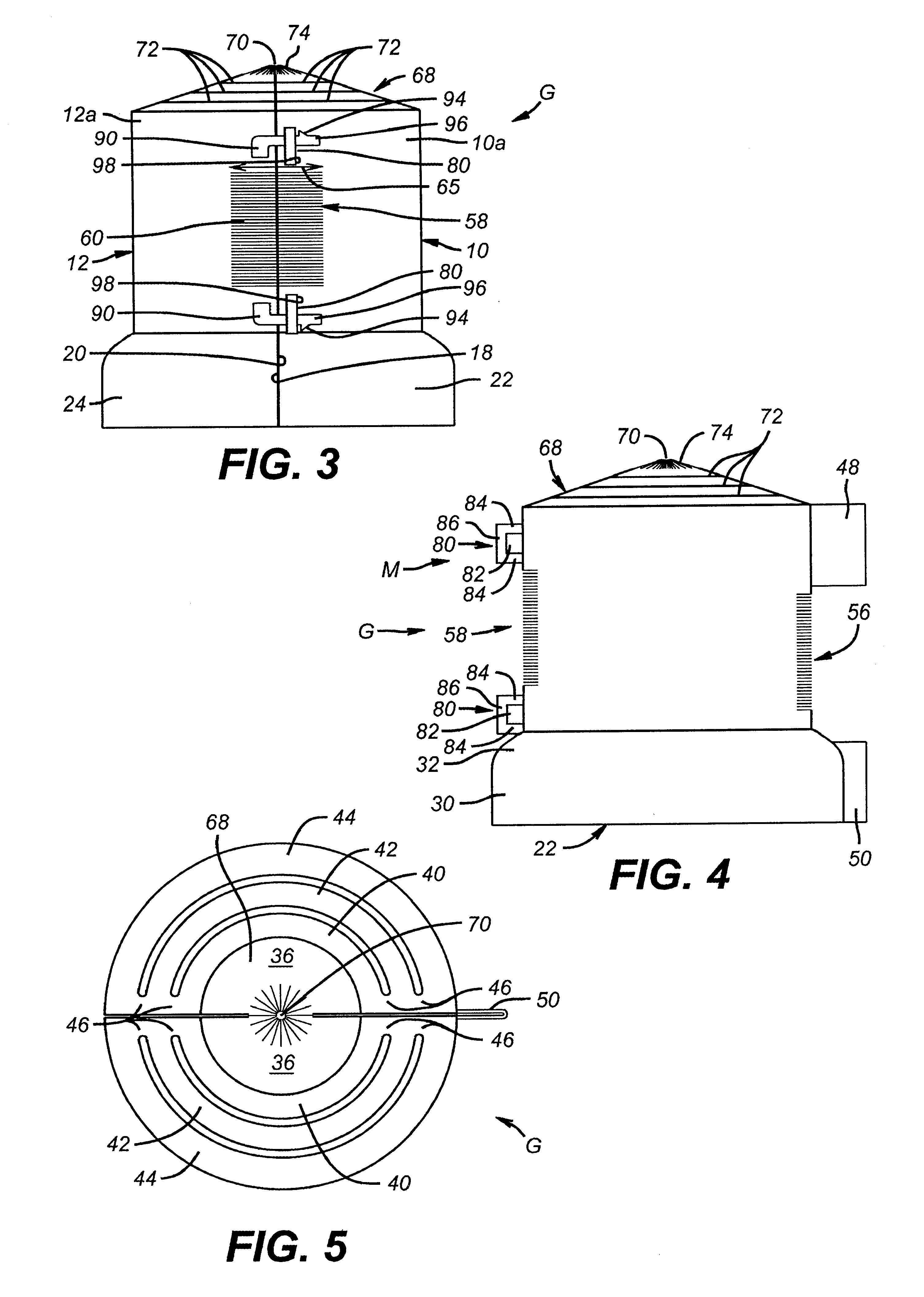

ActiveCN105047361AReduce lossImprove mechanical propertiesTransformers/reacts mounting/support/suspensionSuspension/strain insulatorsCurrent distributionCorona ring

The invention relates to a high-voltage and ultrahigh-voltage dry-type air-cored current limiting reactor. A main reactor body (1) comprises a coil (10), a rain hat (20) and a combined lazy arm (11), wherein the main reactor body (1) is supported by an insulated support post (30); electric field shielding parts (40) are arranged at the upper part and the bottom part of the main reactor body (1); and each electric field shielding part (40) comprises an upper main reactor body corona ring (41) and a lower main reactor body corona ring (42) to solve the problem of power generation of the main reactor body and accessories at high voltage. The insulated support post (30) comprises a support post insulator (31) and a metal bracket (33); and the metal bracket (33) is connected with a support post insulator (31) through an epoxy flat plate (73) and insulated bolts. According to the high-voltage and ultrahigh-voltage dry-type air-cored current limiting reactor, the requirements on the ground insulation level and support are met; leakage flux is reduced; the requirements on the temperature of accessories are reduced; and the reactor provided by the invention can meet the requirements of power grids of 220kV and 500kV on voltage and current distribution, insulation level and short-time current.

Owner:BEIJING POWER EQUIP GRP

Support device

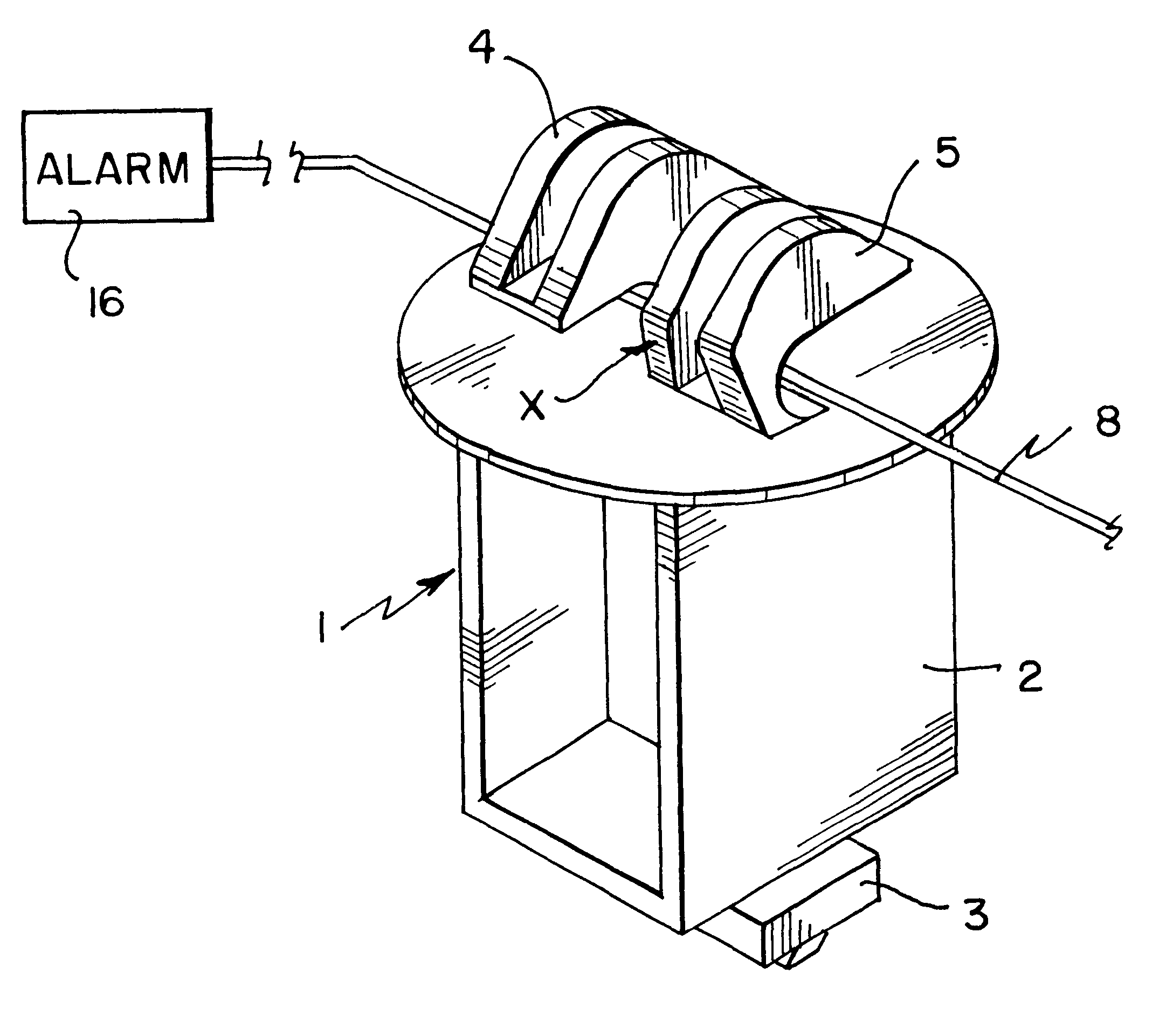

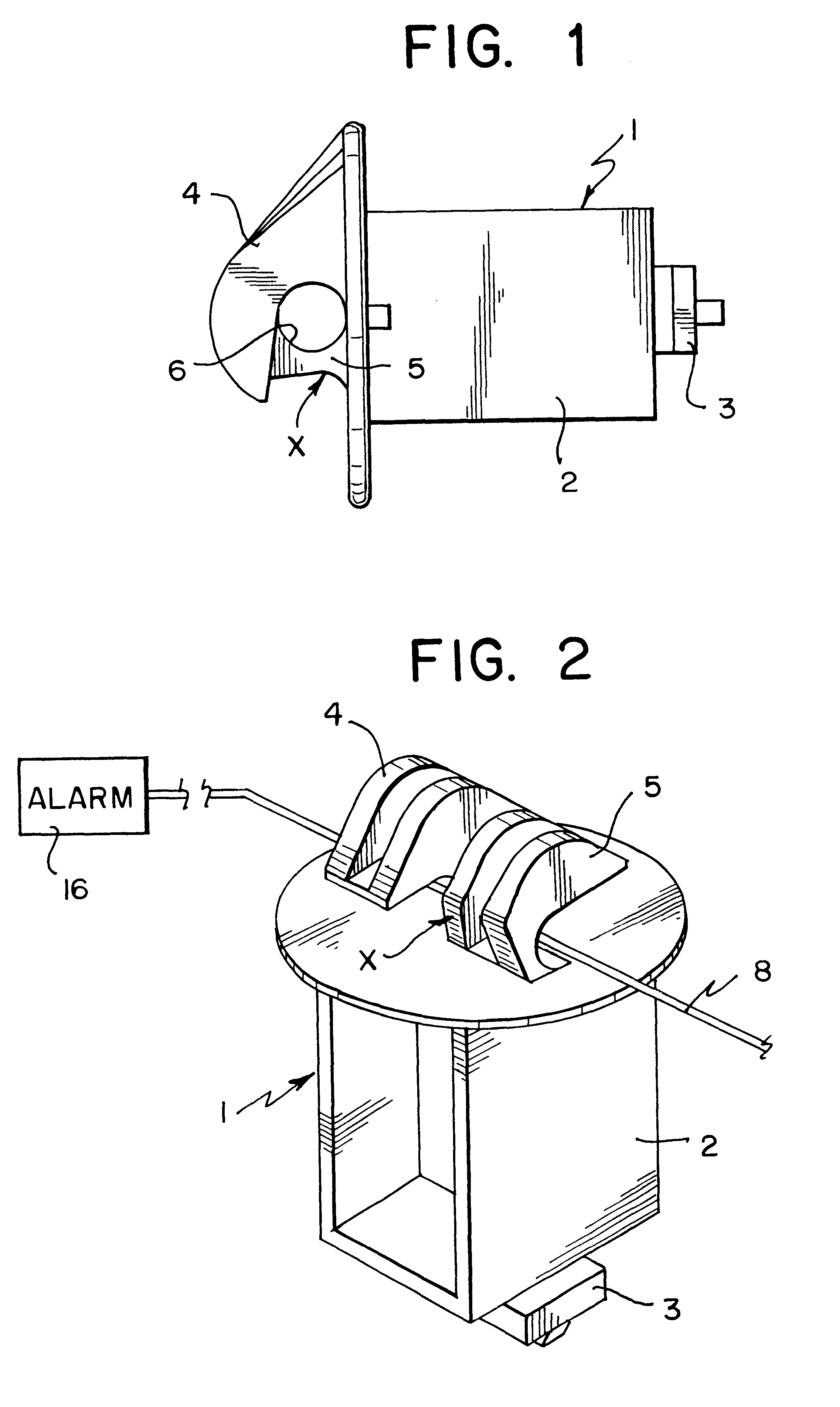

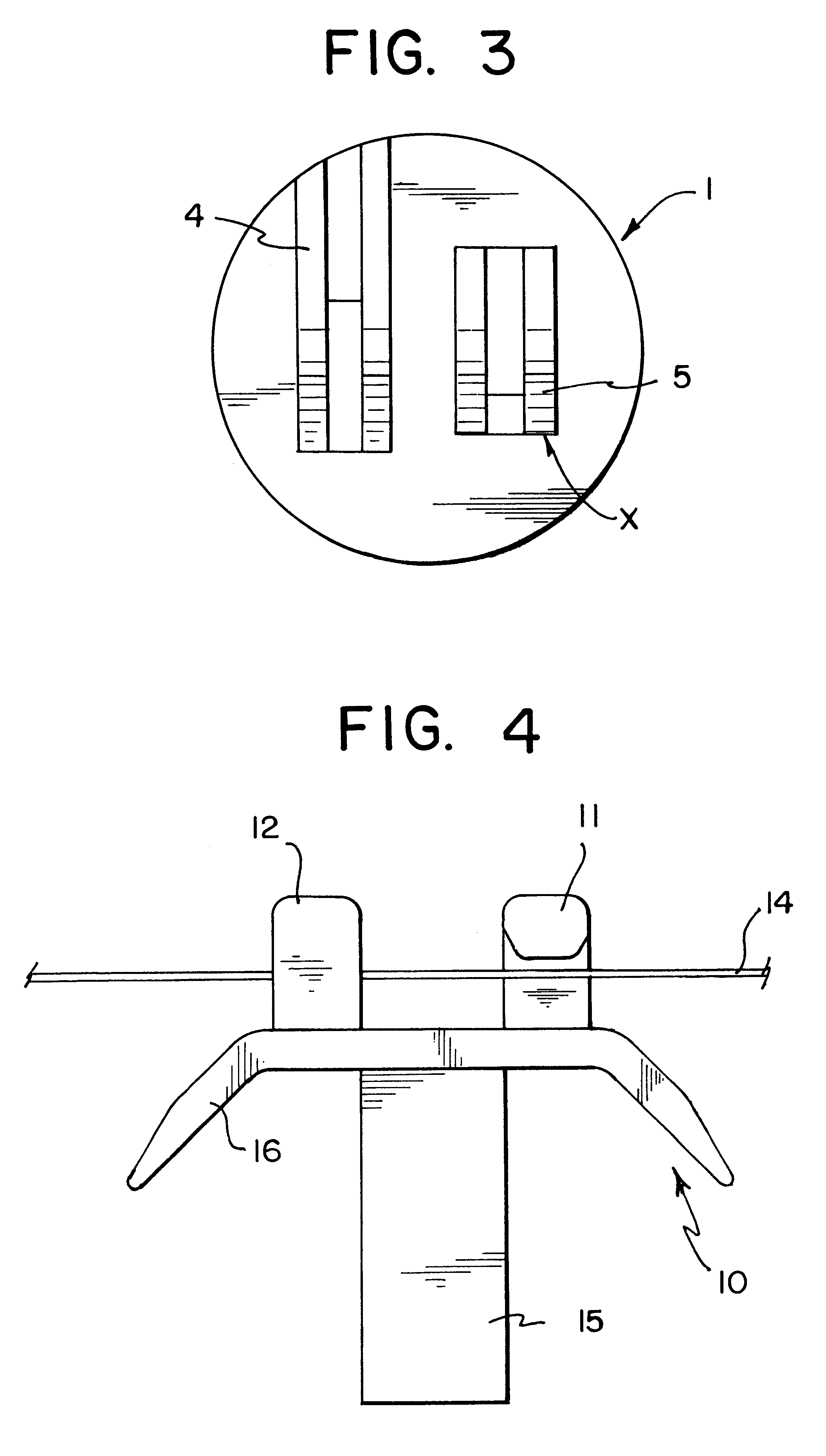

InactiveUS6290190B1Reduce tooling costsReduce supportPipe supportsPasturing equipmentMechanical engineeringInitial load

A support device (1) for supporting a length of material (8) wherein the support device includes: at least one support finger (4,5) for supporting the length of material (8) which applies an initial load to the support finger (5); the support device characterised in that the support finger (5) no longer supports the length of material (8) when the support finger is placed directly or indirectly under a load substantially greater than the initial load.

Owner:GALLAGHER ELECTRONICS LTD CO

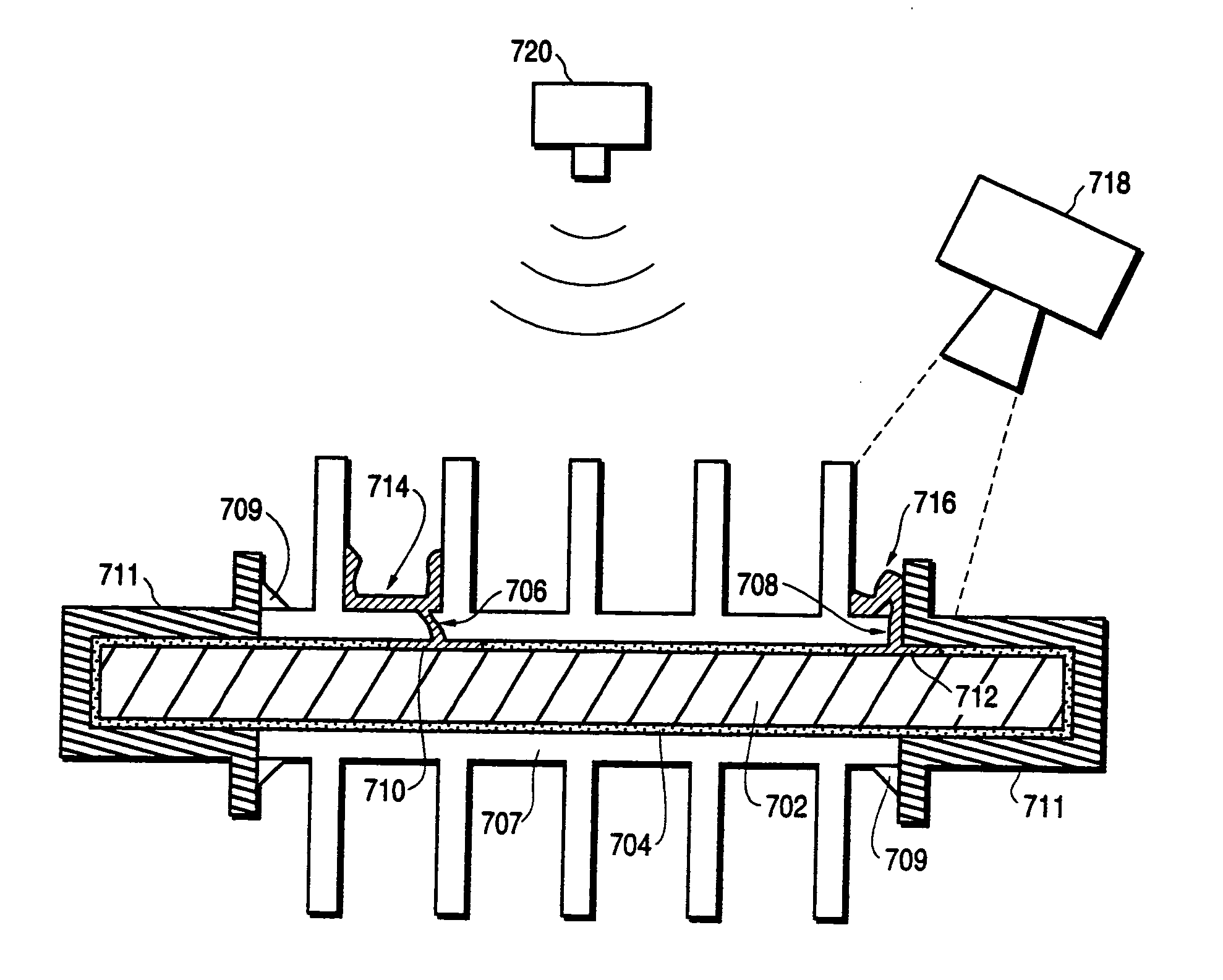

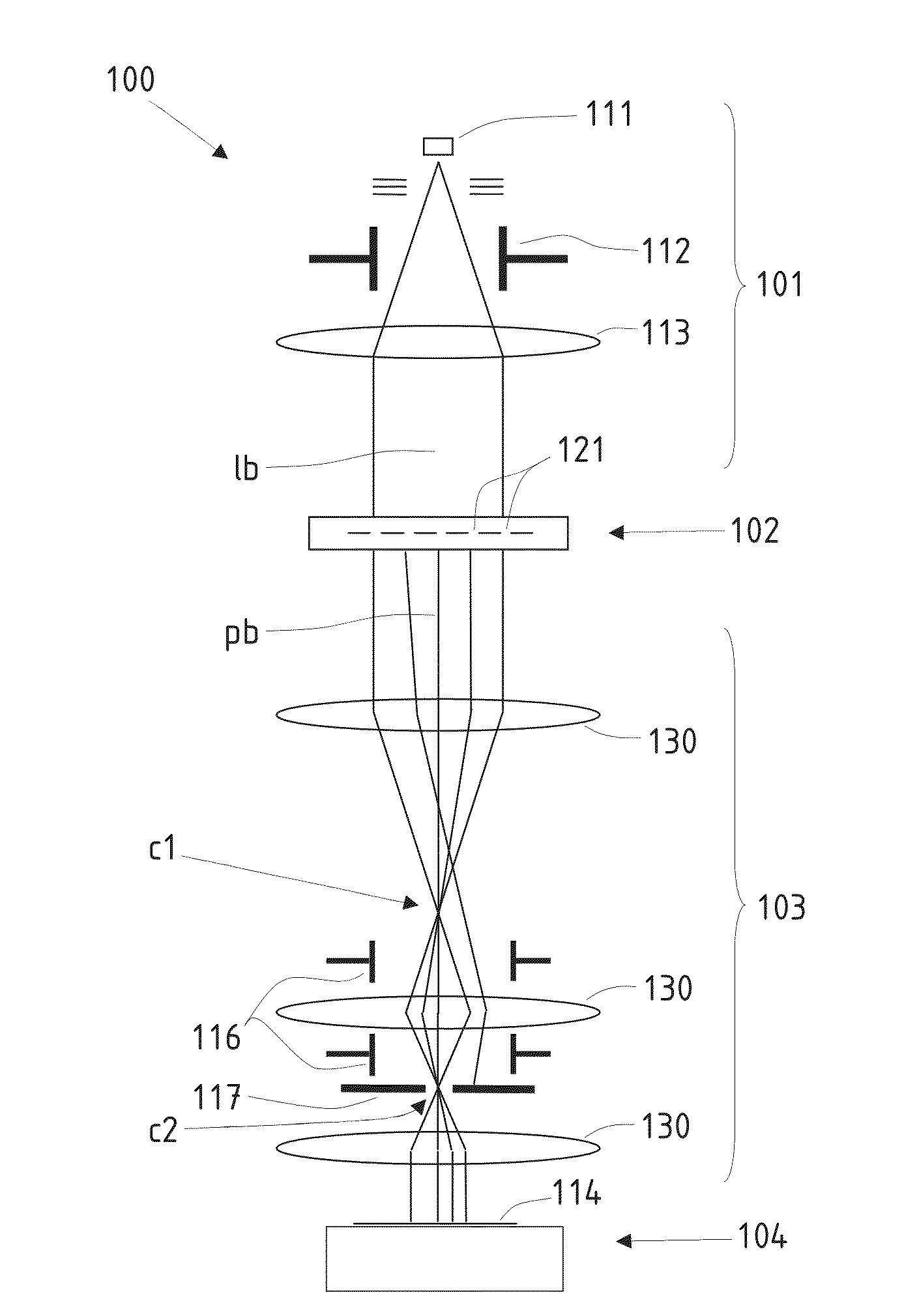

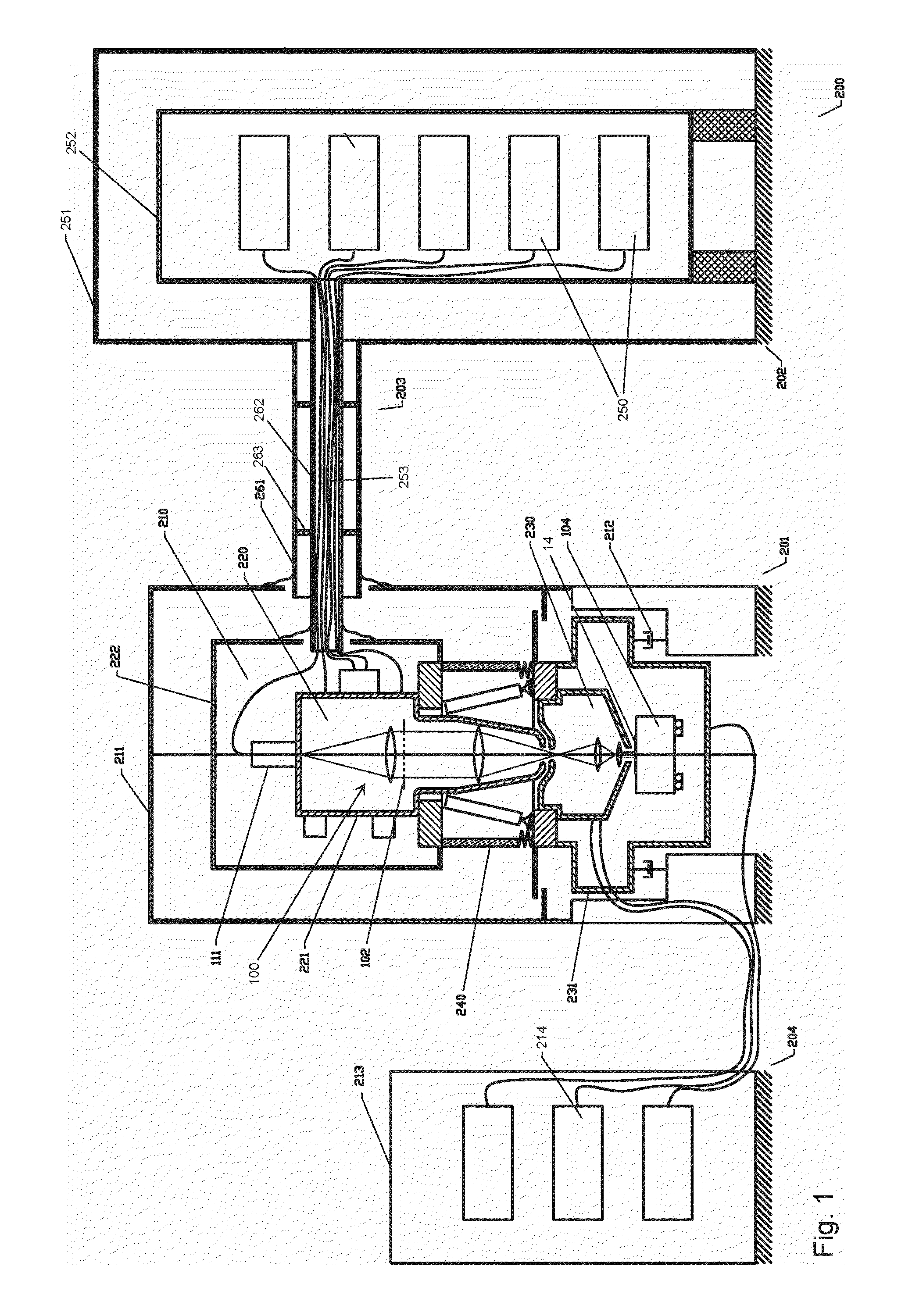

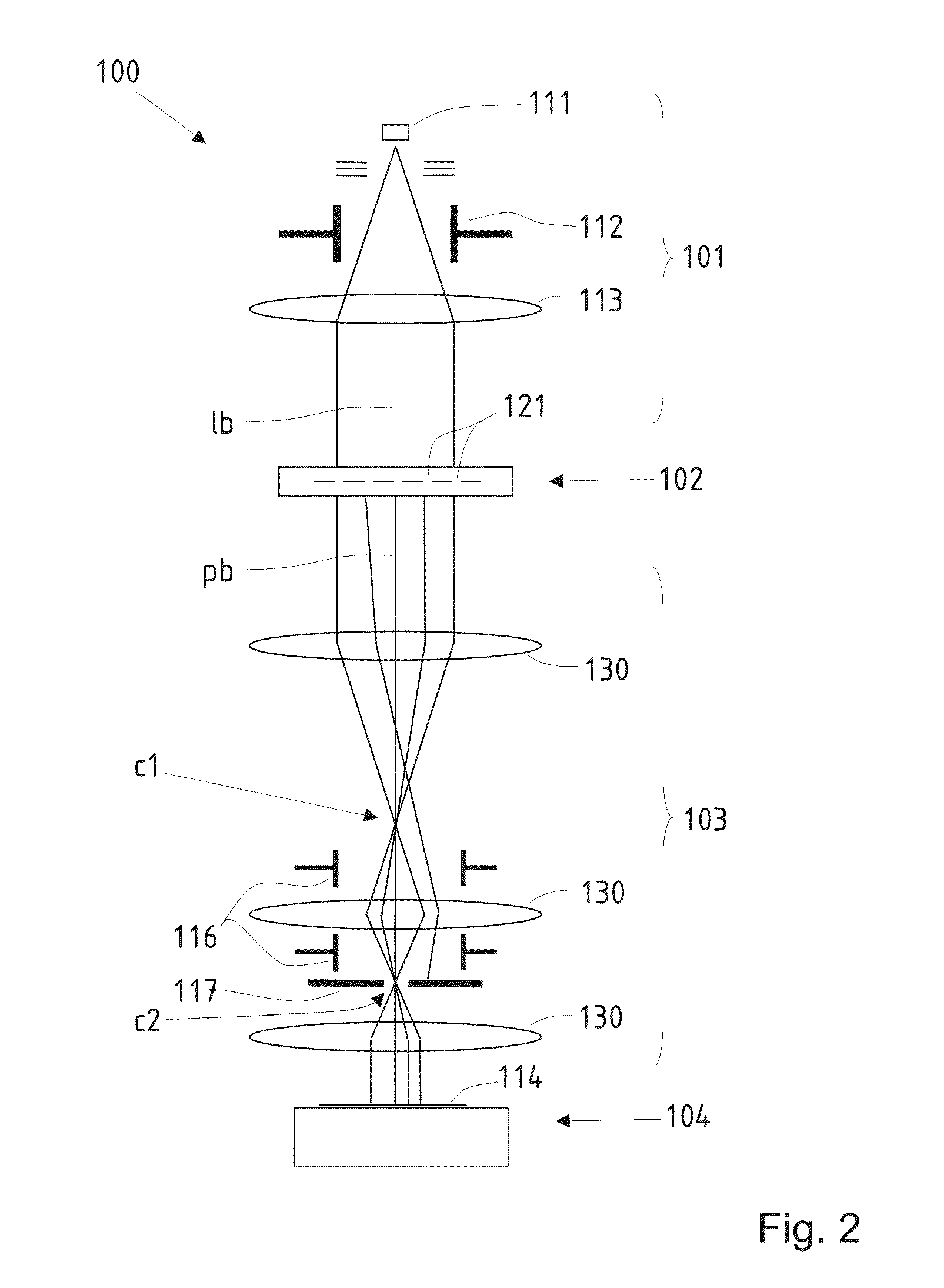

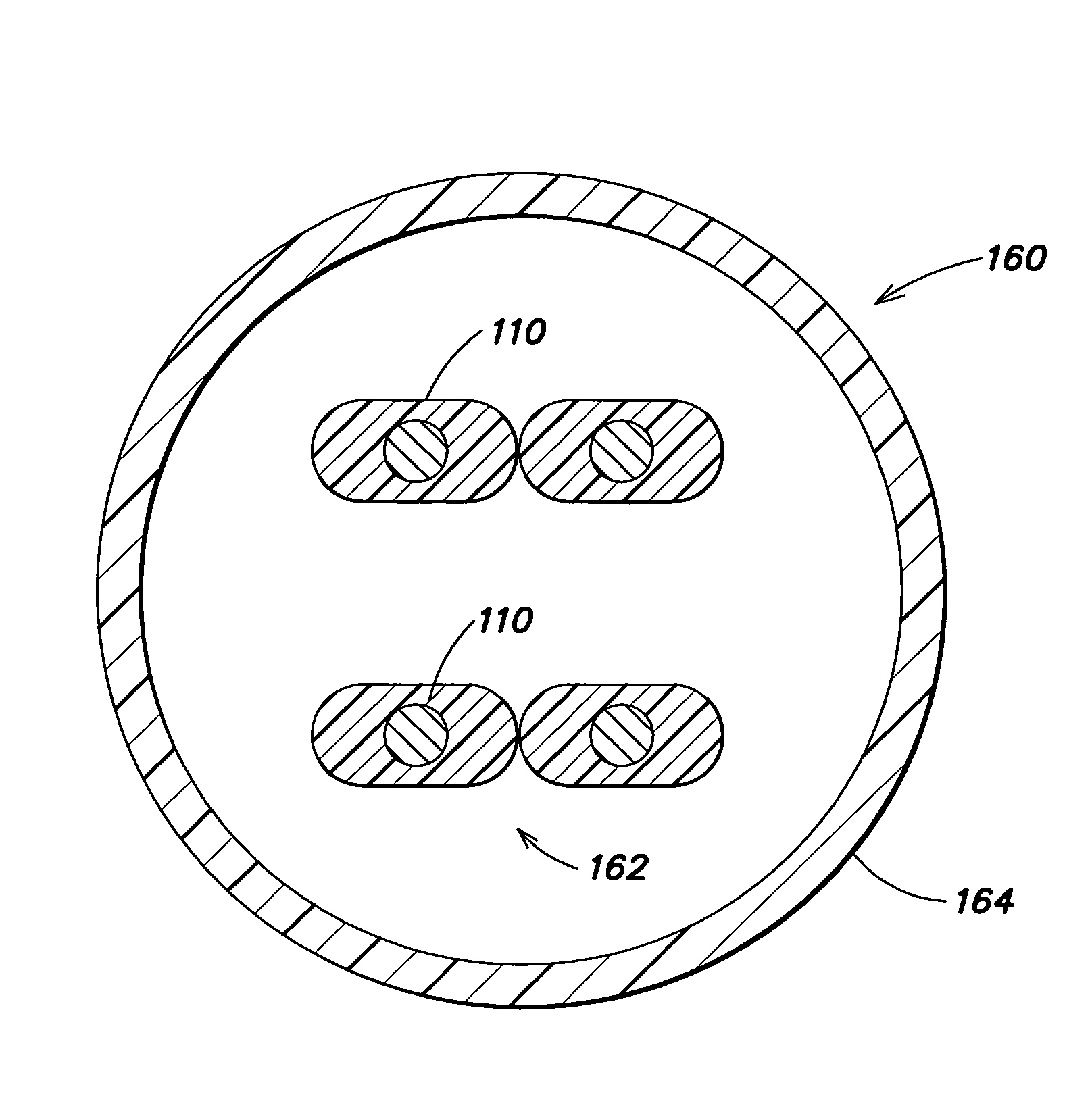

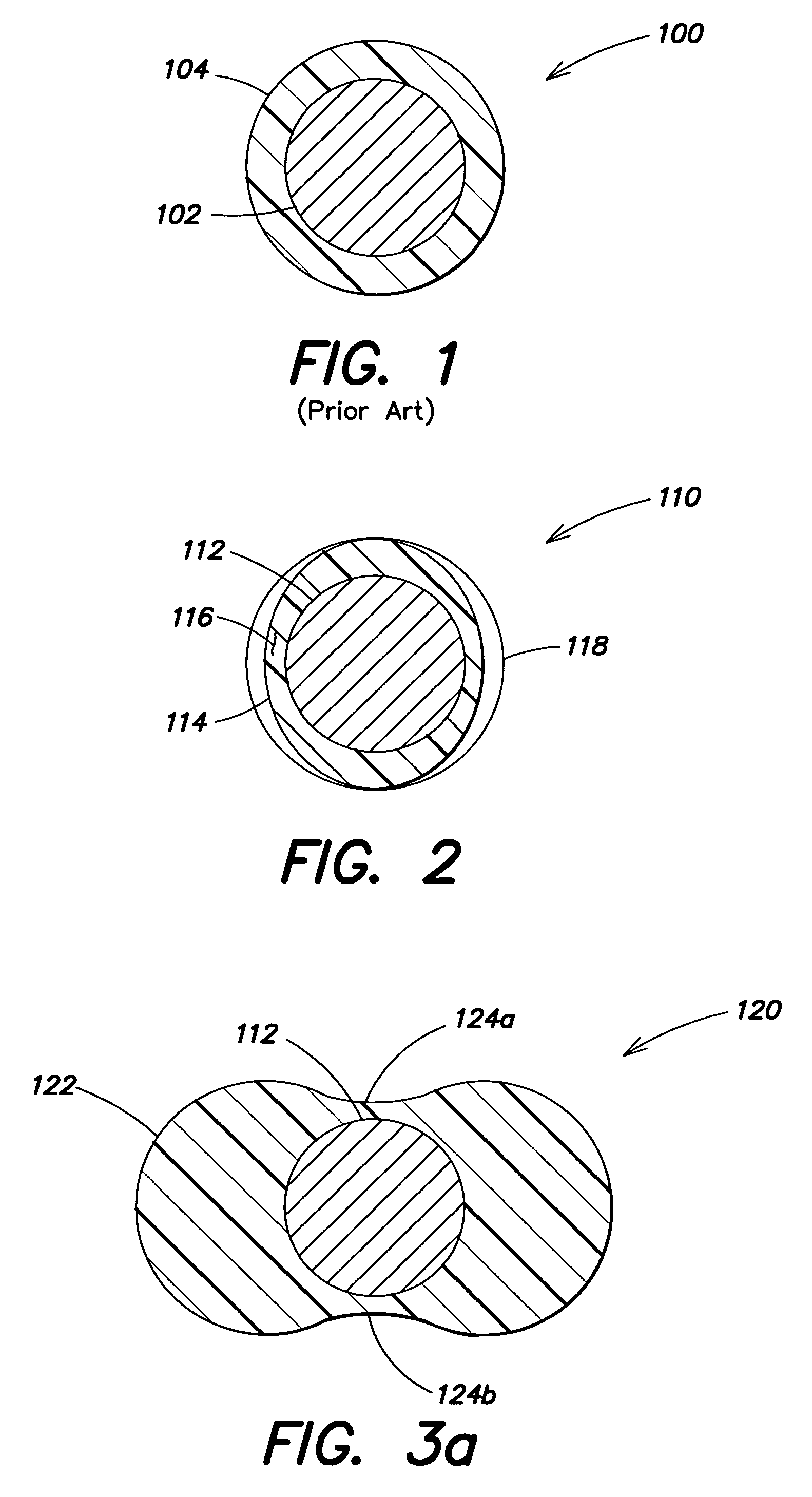

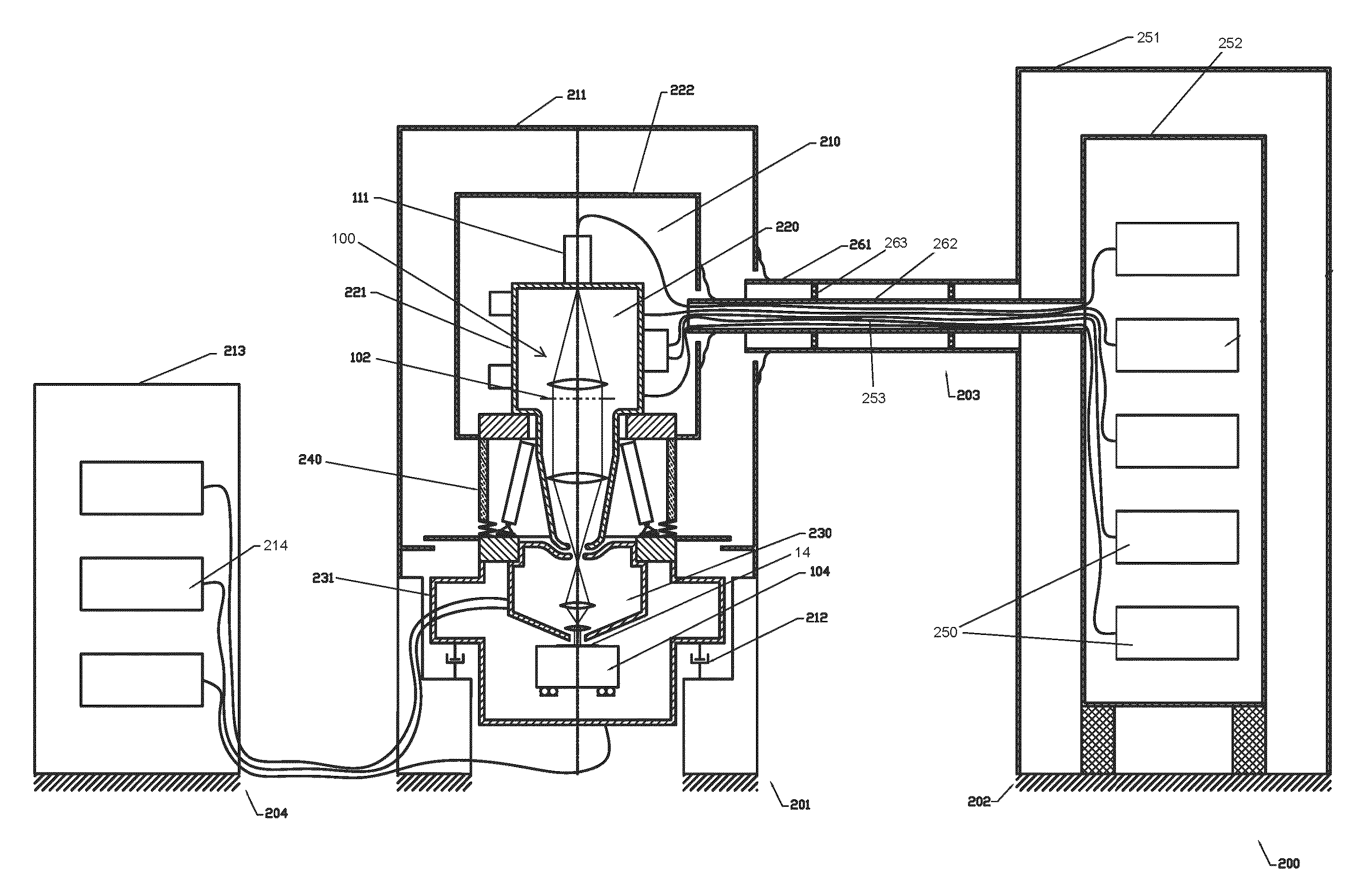

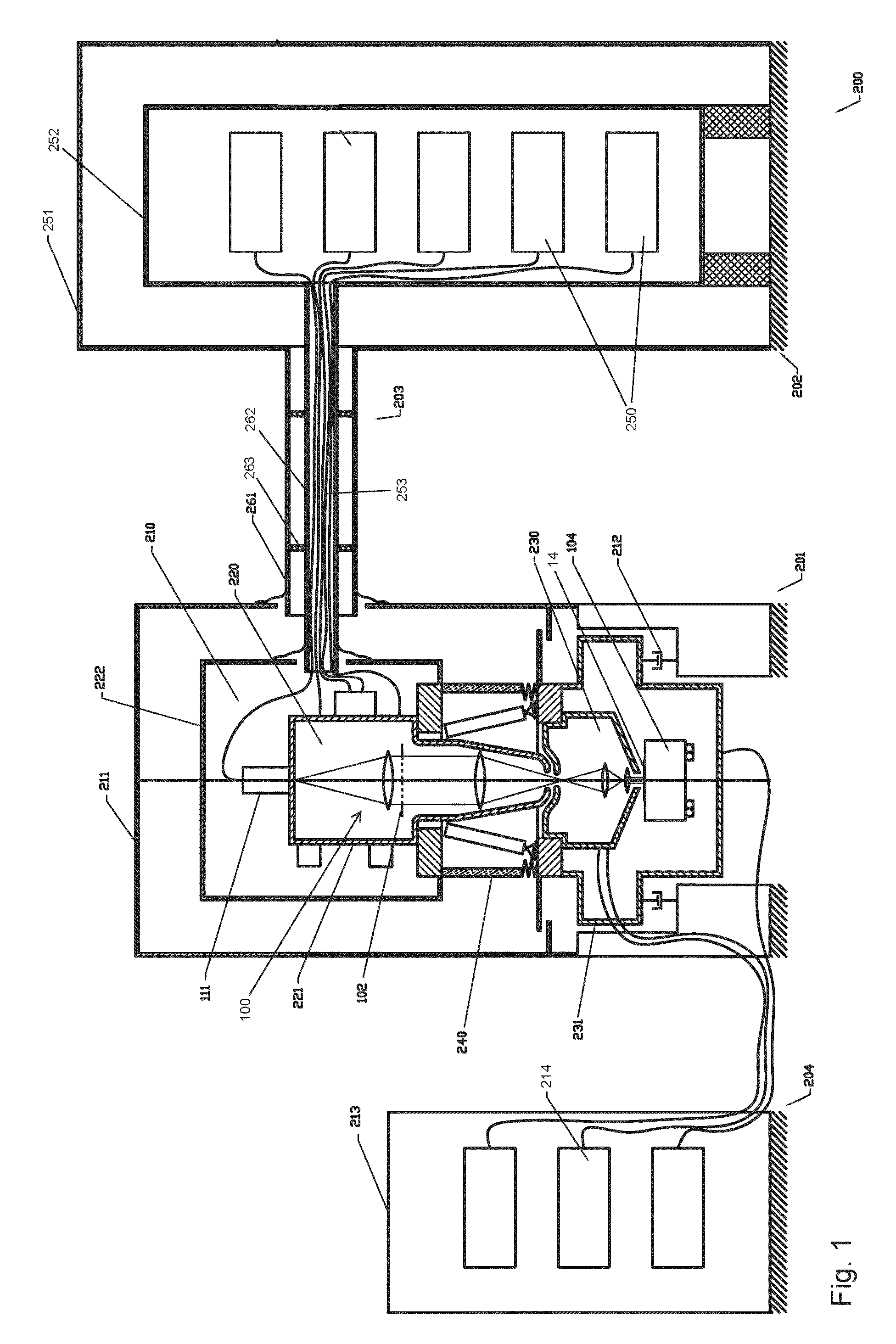

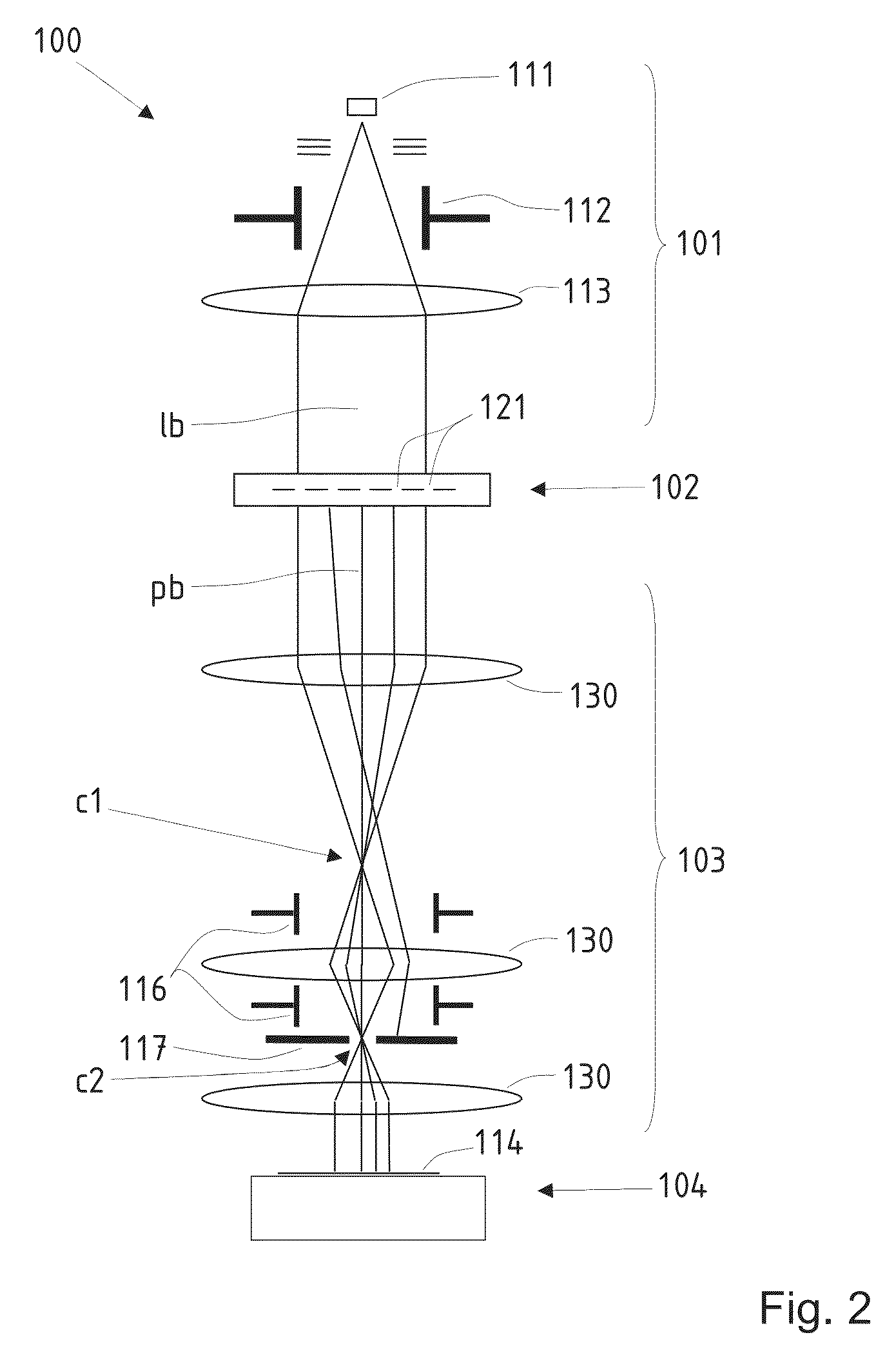

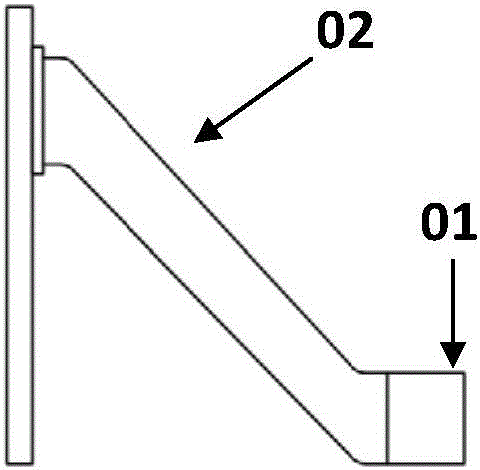

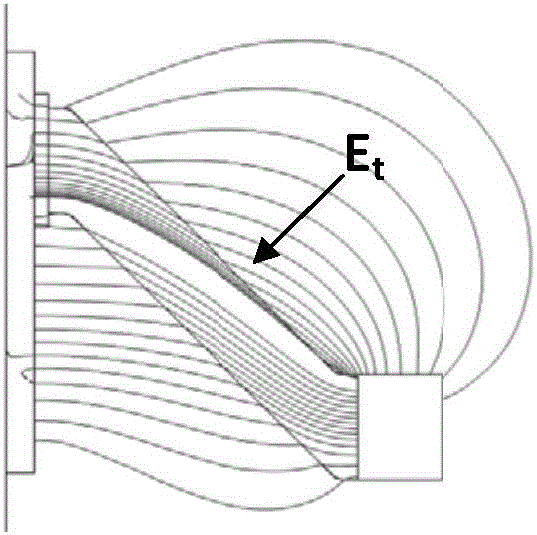

High-voltage insulation device for charged-particle optical apparatus

ActiveUS20140197327A1Improve insulation performanceSimplify the assembly processStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsEngineeringOptical instrument

A high-voltage insulation device (300) for use in a charged-particle optical apparatus comprises a plurality of rigid pillars (320) made of electrically insulating material. These pillars (320) are arranged around a central passage (310) which traverses the insulating device along its longitudinal axis (L), and the two ends of each pillar are configured to be respectively fixed to two separate electrostatic housings (221, 231) of the charged-particle optical apparatus by means of two respective end plates (311, 312), with the pillars (320) being oriented at an angle so as to be inclined with regard to said longitudinal axis (L). Advantageously, the pillars are mechanically adjustable with regard to their effective length, and each pillar (320) is arranged outside the central passage with its two ends at either of the first and second end plates (311,312), preferably in a zig-zag arrangement.

Owner:IMS NANOFABTION

Electrical cable comprising geometrically optimized conductors

Owner:BELDEN TECHNOLOGY INC

High-voltage insulation device for charged-particle optical apparatus

ActiveUS9093201B2Reduce weightImprove mechanical stabilityElectric discharge tubesNanoinformaticsElectricityEffective length

A high-voltage insulation device (300) for use in a charged-particle optical apparatus comprises a plurality of rigid pillars (320) made of electrically insulating material. These pillars (320) are arranged around a central passage (310) which traverses the insulating device along its longitudinal axis (L), and the two ends of each pillar are configured to be respectively fixed to two separate electrostatic housings (221, 231) of the charged-particle optical apparatus by means of two respective end plates (311, 312), with the pillars (320) being oriented at an angle so as to be inclined with regard to said longitudinal axis (L). Advantageously, the pillars are mechanically adjustable with regard to their effective length, and each pillar (320) is arranged outside the central passage with its two ends at either of the first and second end plates (311, 312), preferably in a zig-zag arrangement.

Owner:IMS NANOFABTION

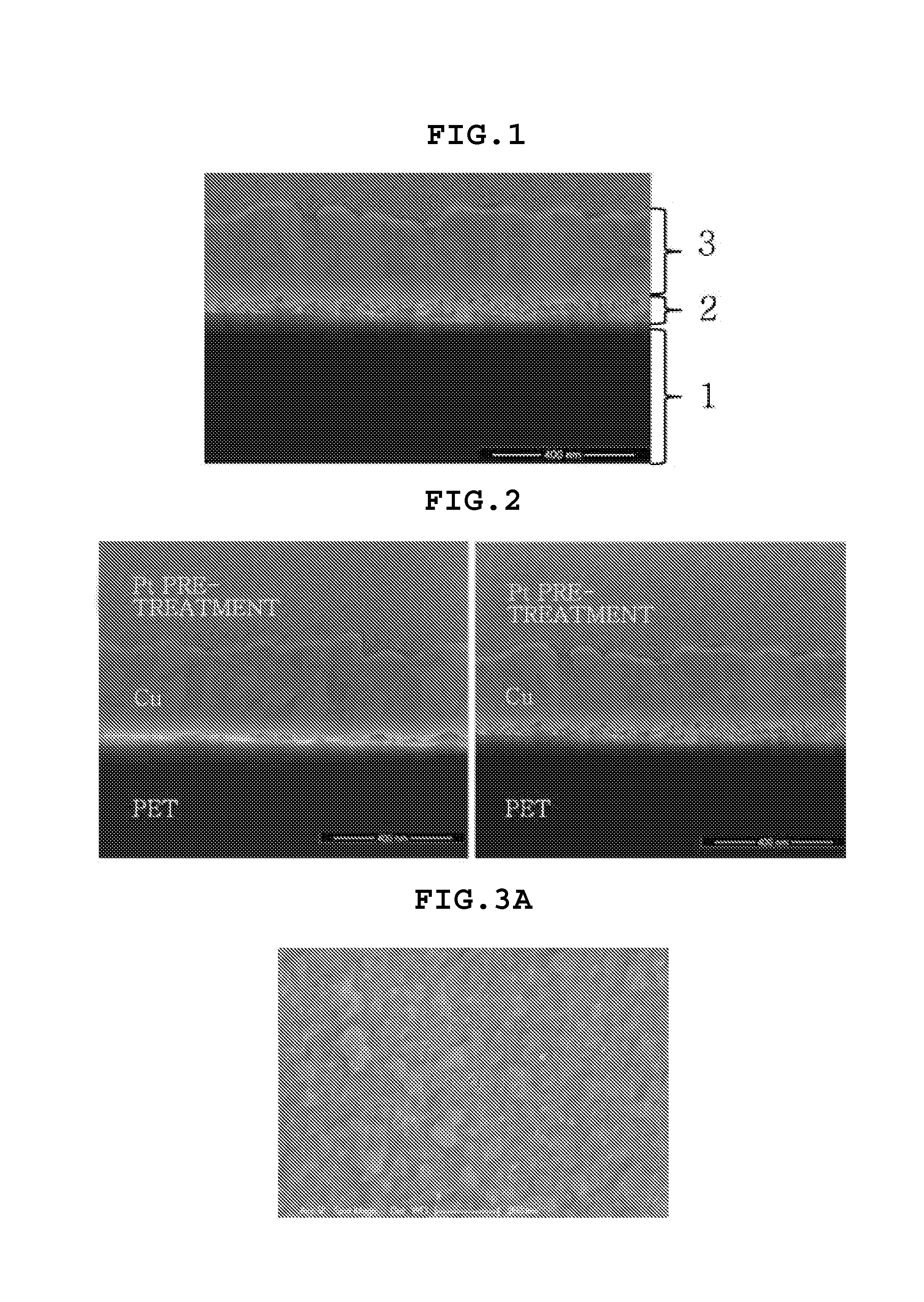

Insulating base plated with metal layer, plating method thereof, and transparent electrode including insulating base

InactiveUS20140017508A1Improve adhesionLiquid/solution decomposition chemical coatingSupporting insulatorsInterface layerElectroplating

Disclosed herein are an insulating base plated with a metal layer, a plating method thereof, and a transparent electrode including the insulating base. During the manufacture of a polymer layer, a structure of an interface layer between a surface of the polymer layer and a metal layer is modified, adhesion with metal is excellent and the polishability of the interface layer is reduced, and thus, the reflectivity of the metal layer is reduced and particular color impression of metal is reduced to obtain black-oxide treated properties. When the metal layer formed on the insulating base is used in a mesh-type transparent electrode having a fine pattern, sufficient adhesion with metal for forming a pattern is obtained and the reflectivity of an adhesion layer of the metal layer is reduced, thereby increasing the visibility. Accordingly, the insulating base may be suitable for products such as transparent electrodes or touch panels.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

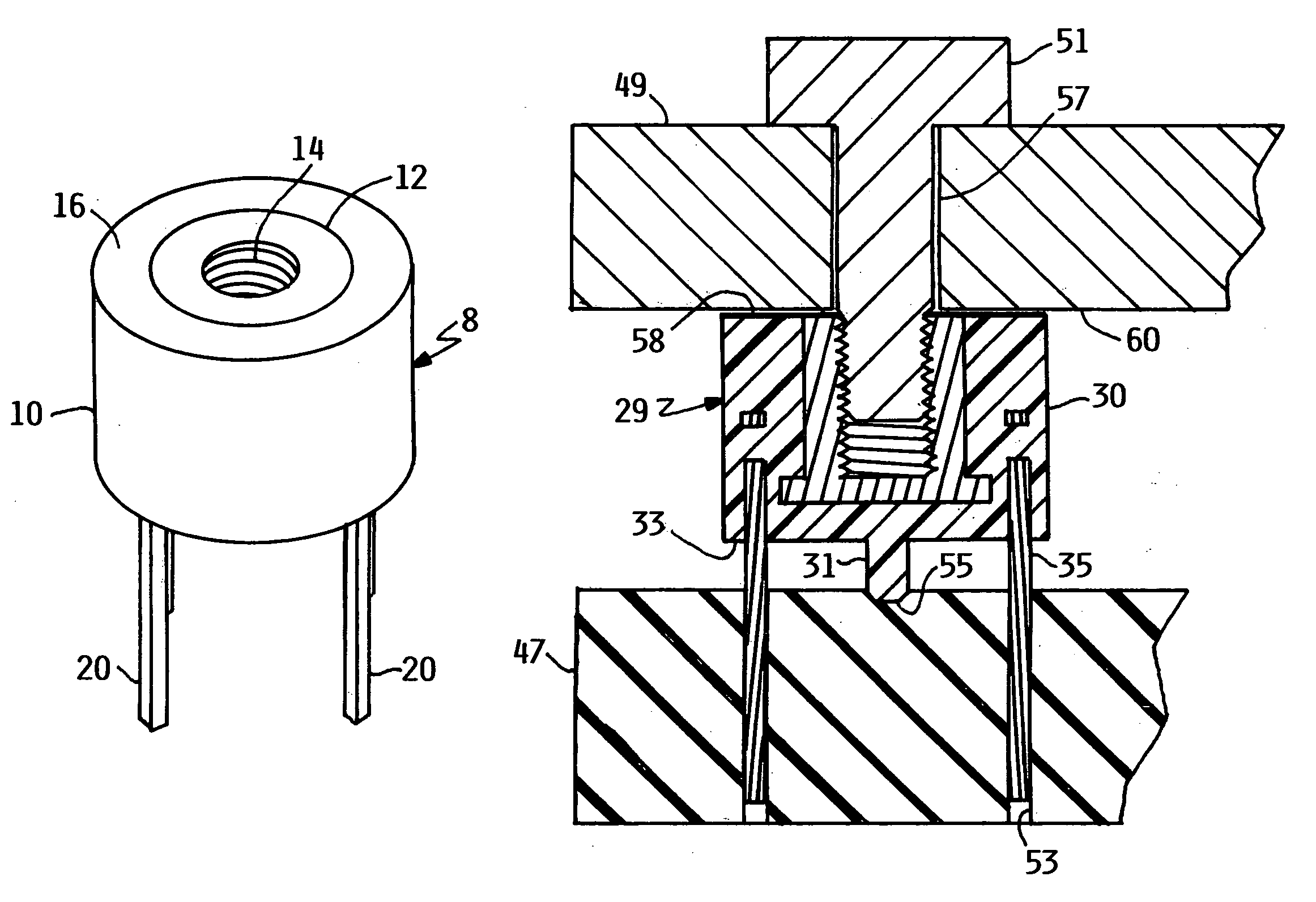

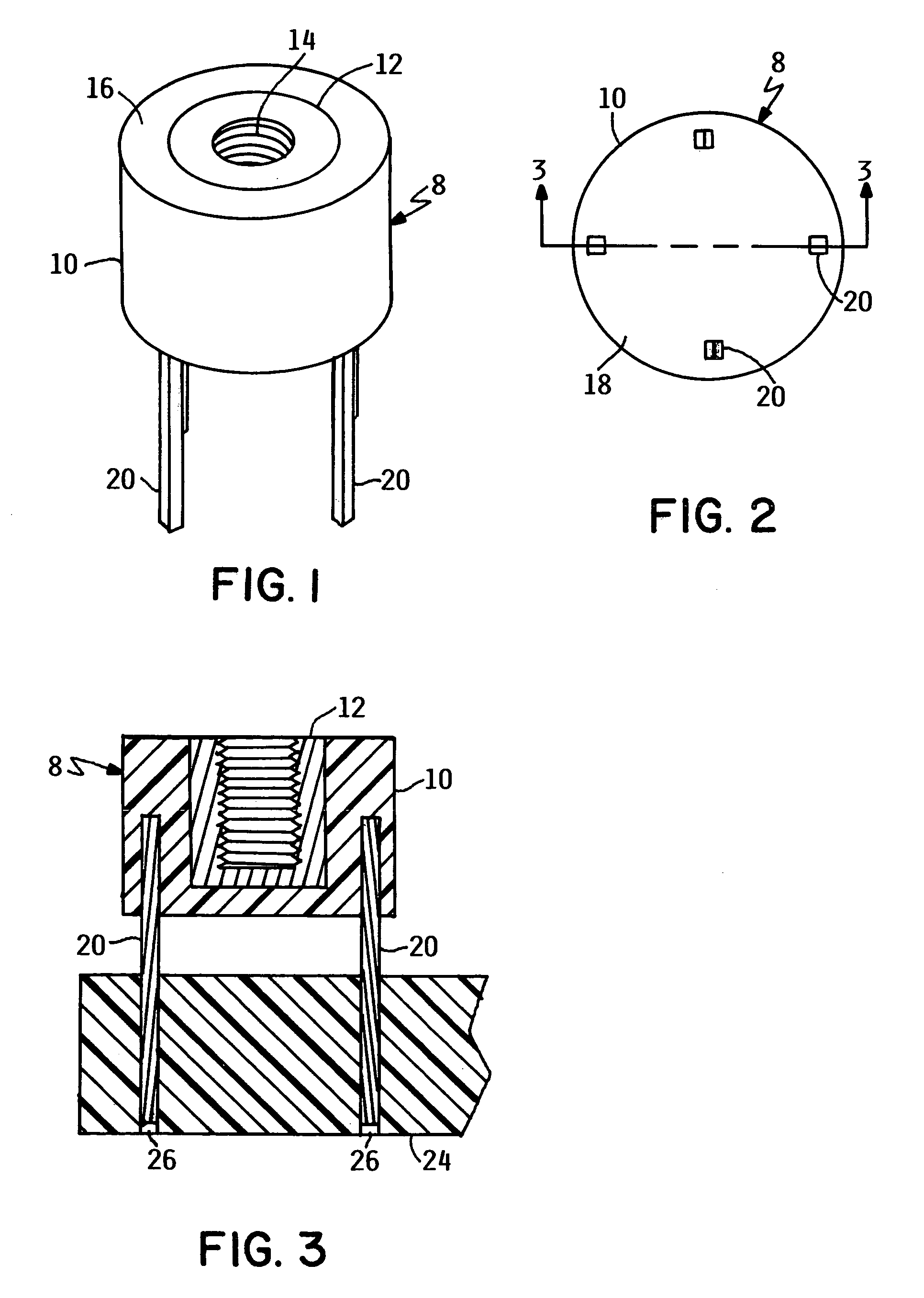

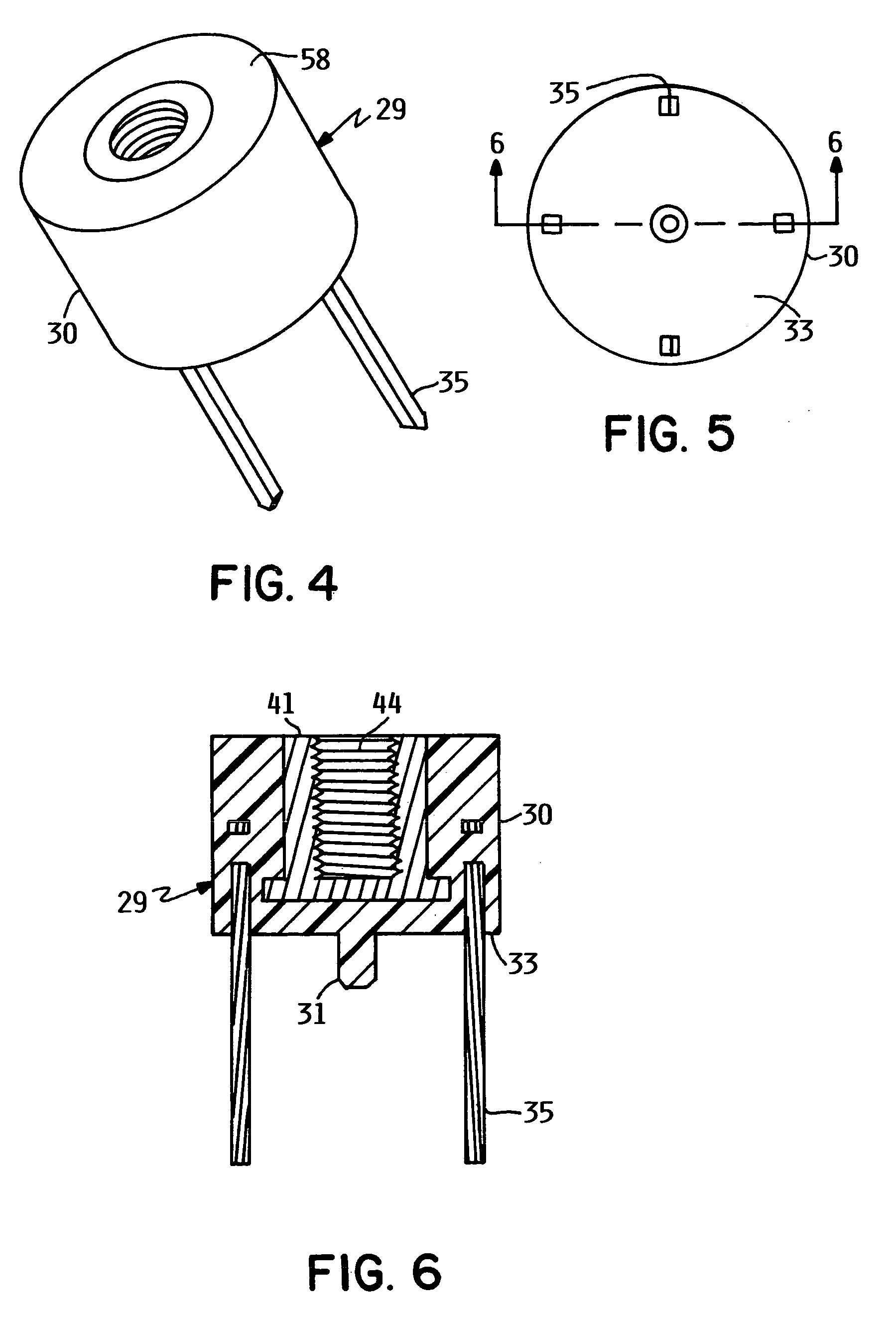

Pin mounted circuit board retainer

InactiveUS6863562B1Printed circuit assemblingSubstation/switching arrangement detailsEngineeringPrinted circuit board

A connector for attaching a printed circuit board to other apparatus is formed as a separate connector body with a plurality of pins projecting from one end surface that are attached to the printed circuit board by being secured in vias through the board and a threaded opening at the end surface opposite the one end surface from which the pins project. When a bolt is received in the connector threaded opening and drawn tight to secure the printed circuit board to other apparatus, the stresses and material deformation induced by the securing bolt are isolated from the printed circuit board. Further, the attachment of the pins to the printed circuit board rather than the use of screws extending through holes in the circuit board reduces the size of ‘keep out’ zones that must be avoided by the wiring paths on each wiring surface of the printed circuit board through which mounting holes extend. Fabrication of the connector and assembly of the connector to the printed circuit board are facilitated by providing a pair of parallel side surfaces on the connector body which can be gripped by a tool. The connector can also be used to electrically insulate or provide a current path by the selection of the polymer that forms the connector body portion.

Owner:IBM CORP

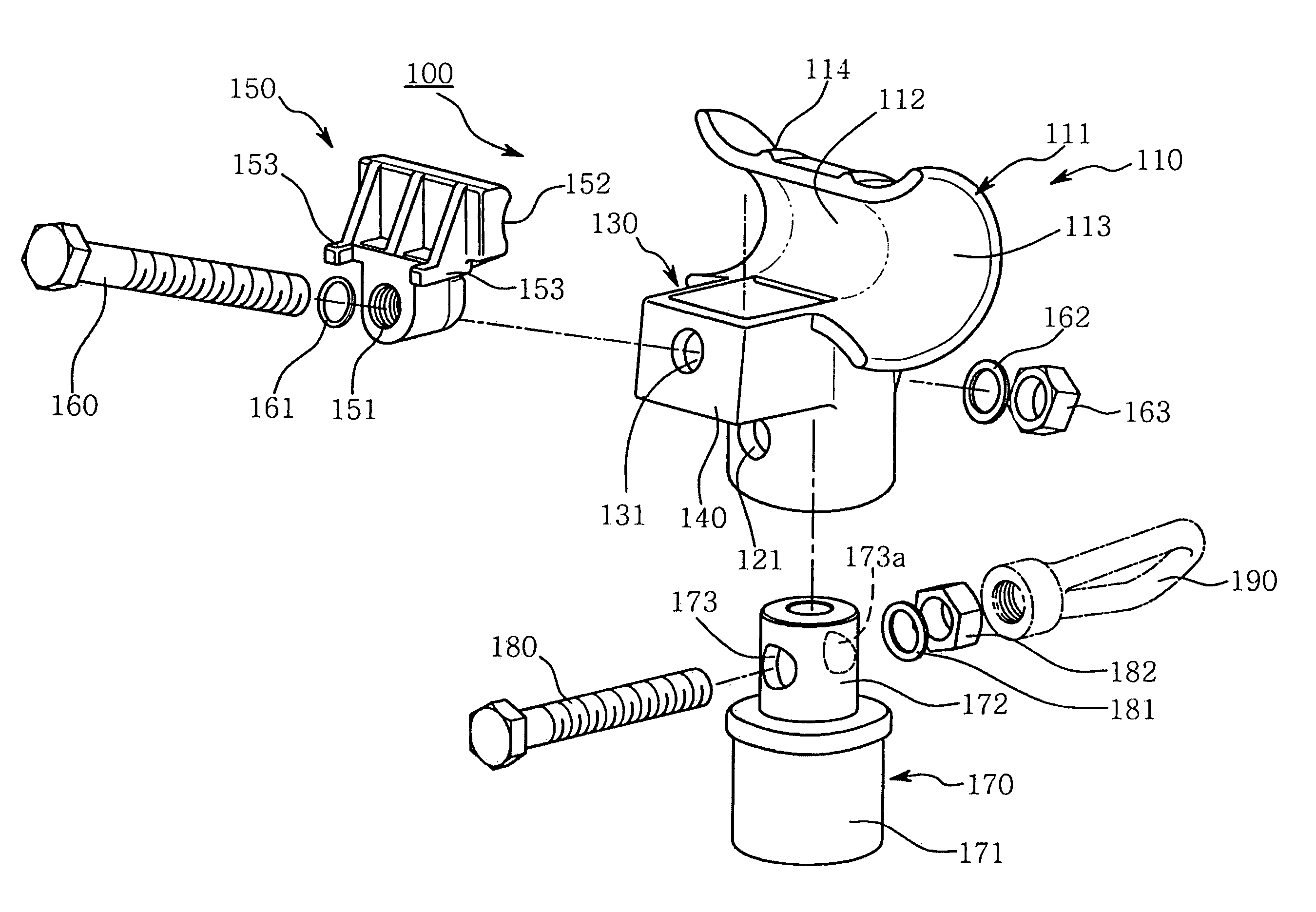

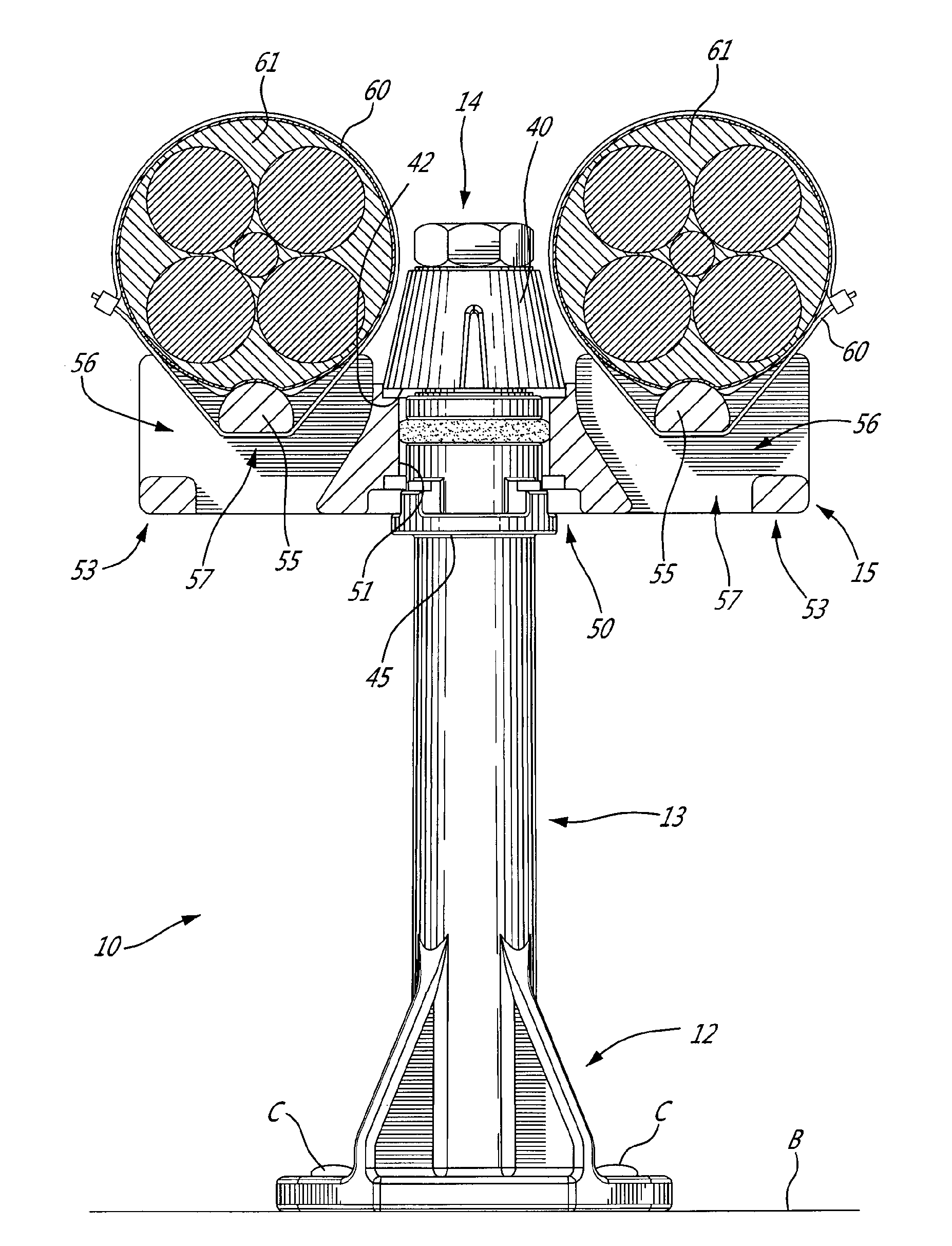

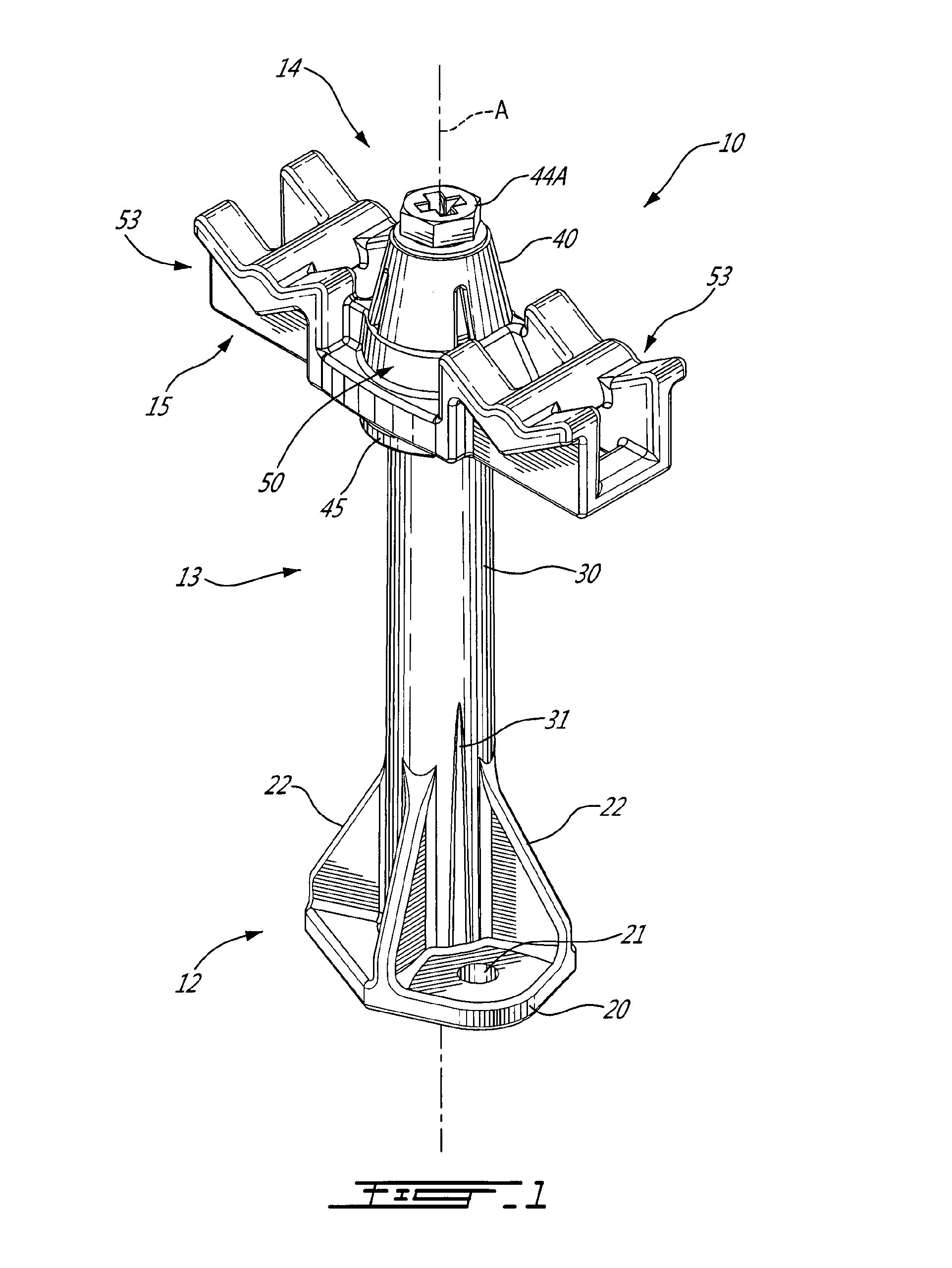

Standoff device and method of installation of harness

A device connects a wire harness to a structure. A fixation portion of the device is secured to the structure. A spacing portion is connected to the fixation portion and to a connector portion. A retaining clip on the connector portion deforms when a wire harness connector component moves axially toward the fixation portion. The clip opposes an abutment edge against the component into engagement position when the component is past the clip to prevent it from moving back onto the clip. An abutment surface contacts another portion of the component in engagement position to prevent further axial movement of the component toward the fixation portion. The component is held captive between the edge and the abutment surface. Also provided are a cable support for connecting the wire harness to the device, a method for connecting and disconnecting the wire harness to a structure with the device, and an aircraft.

Owner:BOMBARDIER CORP

High-voltage insulator and a high-voltage electric power line using said insulator

ActiveCN101981633ASimple designHigh working reliabilitySupporting insulatorsEmergency protective arrangements for limiting excess voltage/currentElectrical conductorElectric discharge

Owner:SIMRAY ELECTRIC CO LTD

Charge self-adapted dissipation basin-type insulator

The invention relates to a charge self-adapted dissipation basin-type insulator and belongs to the technical field of power transmission and distribution devices. The insulator is an integral formed structure with a U-shaped cross section and comprises a central insert and insulation zones symmetrically arranged on two sides of the central insert, wherein the insulation zones are composed of insulation subzones, self-adapting subzones and edge flanges, and the central insert and the insulation subzones, the self-adapting subzones and the edge flanges respectively form the bottom, side wall and top of the U-shaped structure, the insulation subzones are prepared by mixing epoxy resin, aluminum oxide and a curing agent, the self-adapting subzones are prepared by mixing epoxy resin, aluminum oxide doped with a nonlinear material and a curing agent, and the edge flanges are made from the same material adopted by the self-adapting subzones or are metal flanges. The insulator can adjust surface charge accumulation itself in the operating process in a self-adapted mode, limit the surface charge quantity in a safety range and accordingly ensures safe and stable operation of a device.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com