Charge self-adapted dissipation basin-type insulator

A basin-type insulator, self-adaptive technology, applied in the direction of insulators, supporting insulators, circuits, etc., can solve problems such as stop simulation analysis, and achieve the effect of improving stable operation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment technical scheme of the present invention is described in detail as follows:

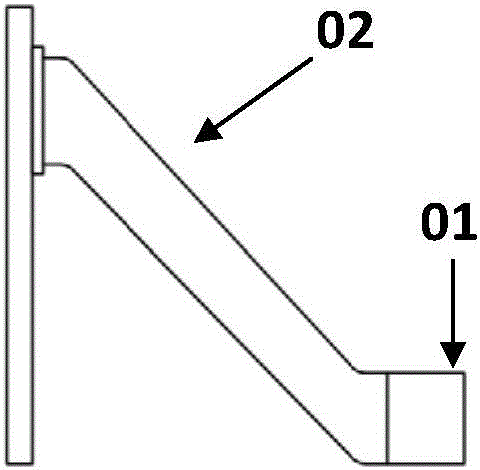

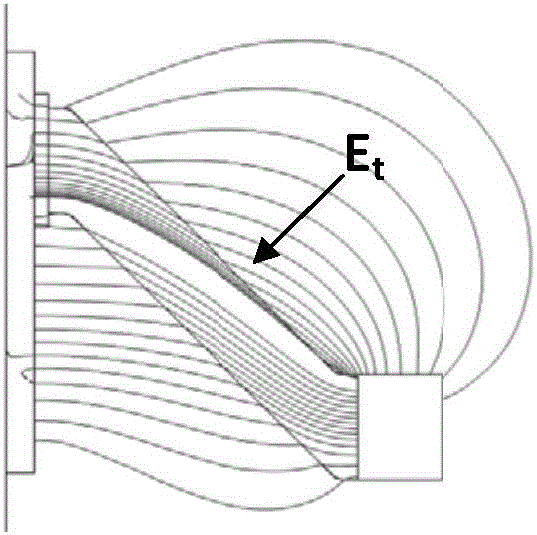

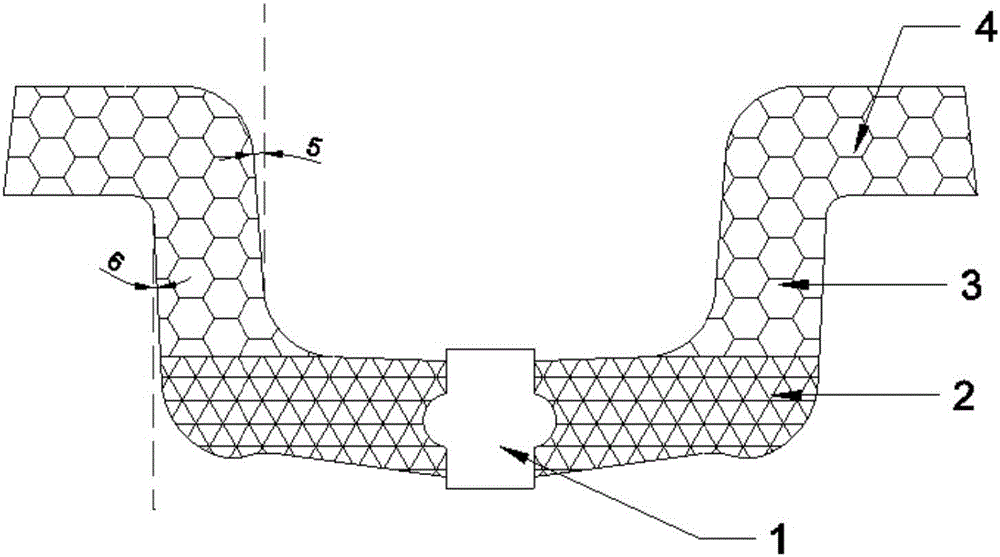

[0017] The present invention proposes a self-adaptive charge dissipating pot-type insulator, which is an integrated structure with a U-shaped cross-section, as shown in Figure 1, including a central insert 1 and symmetrically arranged on both sides of the central insert The insulating area, the insulator is an integral structure with a U-shaped cross-section, the insulating area is composed of an insulator area 2, an adaptive sub-area 3 and an edge flange 4, the central insert 1 and the insulator area 2, the adaptive sub-area 3. The edge flanges 4 respectively constitute the bottom (1, 2), side wall (3) and top (4) of the U-shaped structure; wherein, the insulator area 2 is made of a mixture of epoxy resin, aluminum oxide, and curing agent The self-adaptive sub-area 3 is made by mixing epoxy resin, alumina doped with nonlinear mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com