A compound supporting pole insulator with extrusion bar as internal core and its making method

A pillar insulator and inner core technology, applied in the direction of supporting insulators, insulators, electrical components, etc., can solve the problems of affecting the electrical performance and life of the product, brittle fracture, easy to break, etc., to avoid the leakage of the inner filling medium and improve the mechanical performance , laying uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

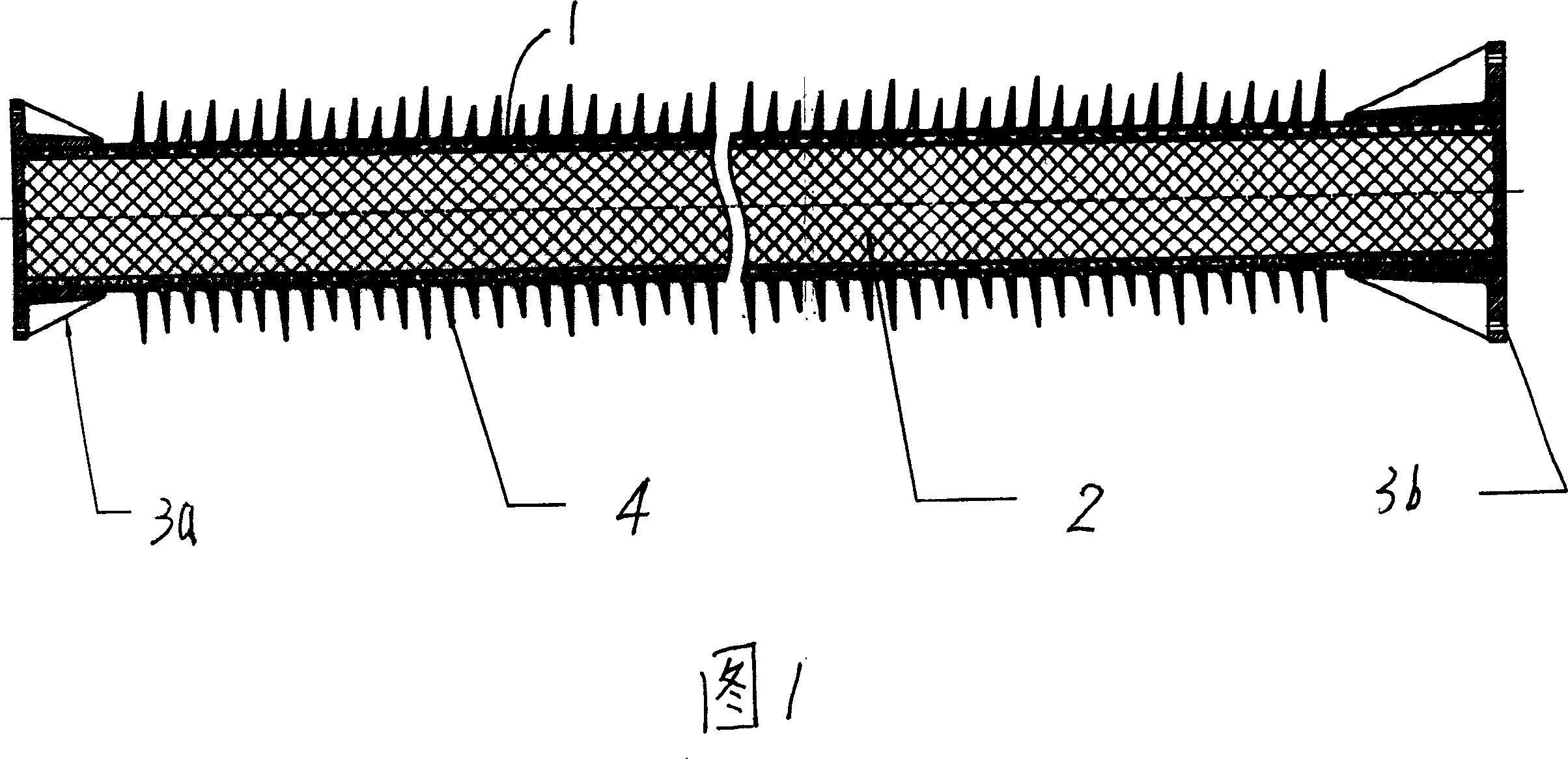

[0033] The umbrella body 4 is made of high-temperature vulcanized silicone rubber, and its components by weight are: 28% methyl vinyl silicone rubber, 34% white carbon black, 34% aluminum hydroxide, 3% silicone oil, and 1% vulcanizing agent.

[0034] Manufacturing steps:

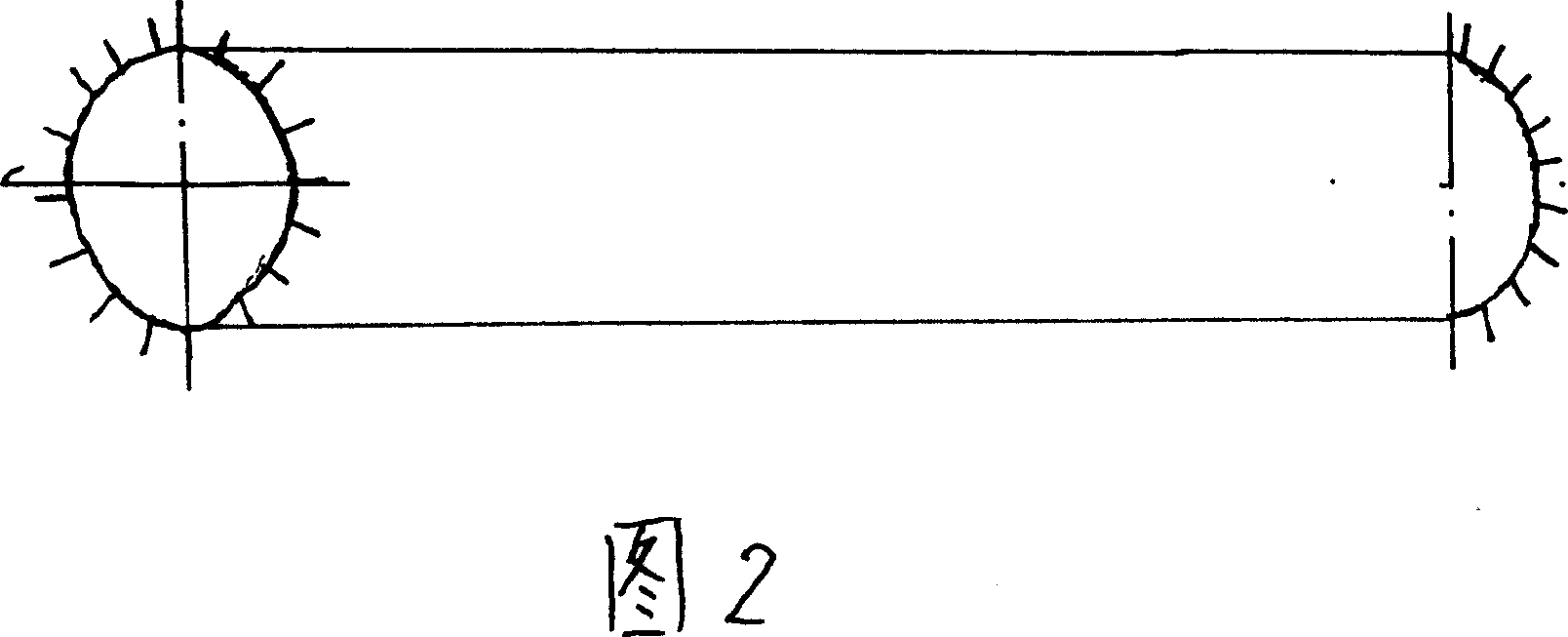

[0035] ① Clamp the pultrusion rod to be wound as the inner core with a special fixture, and fix the pins at both ends of the axis of the simulated trajectory;

[0036] ② Treat the surface of the mandrel in step ① and grind it rough;

[0037] ③ On the mandrel in step ②, use a constant tension control mechanism to evenly wind the glass fiber yarn impregnated with epoxy resin glue on the mandrel to a preset thickness;

[0038] ④ Send the coiled tube string in step ③ into an oven for high-temperature curing, so that the coiled tube and mandrel are solidified into one;

[0039] ⑤ Machining the wound pipe string in step ④;

[0040] ⑥Apply the coupling agent evenly on the outer wall of the wound pipe made in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com