Patents

Literature

399results about How to "Lay evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

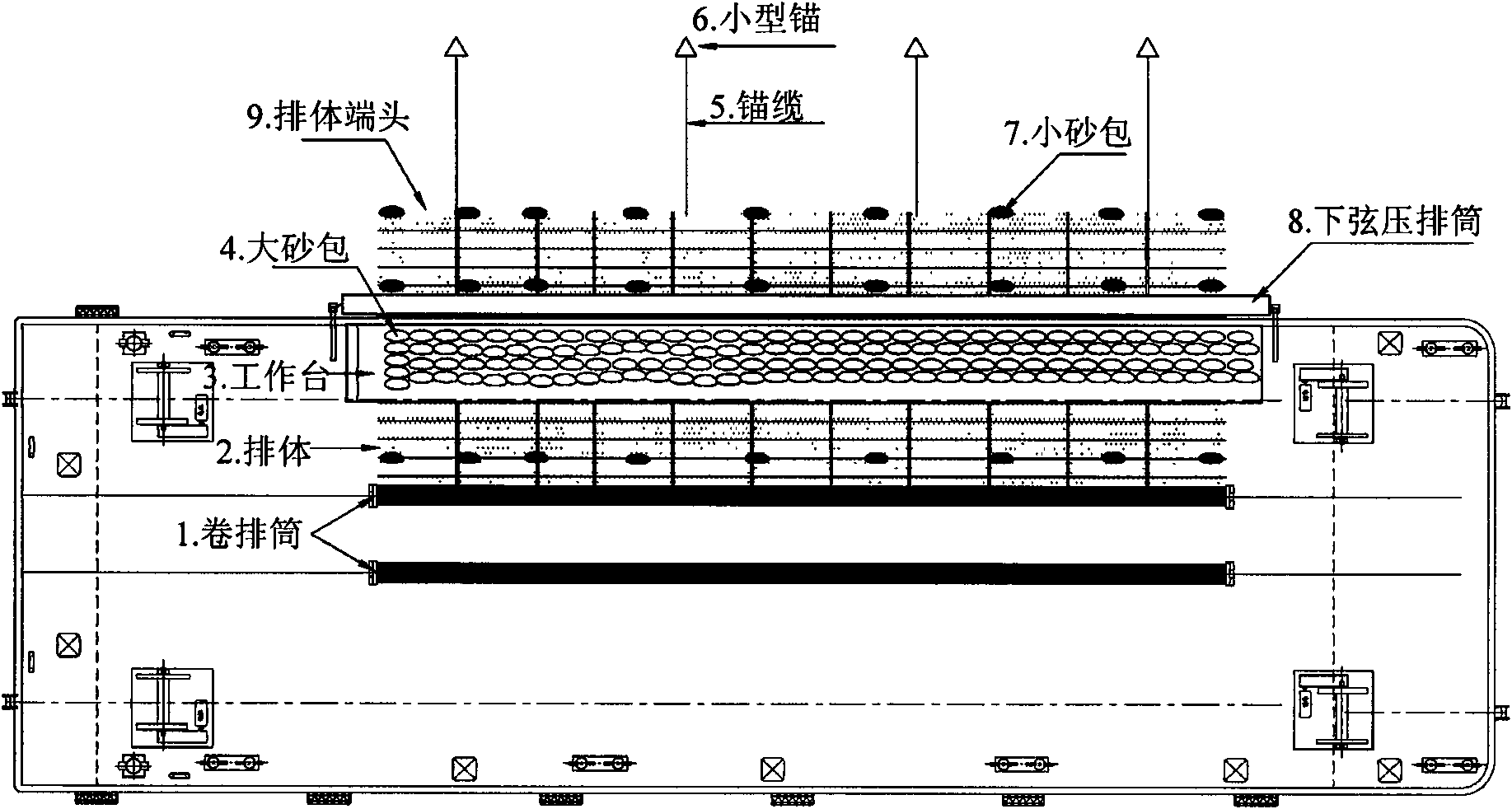

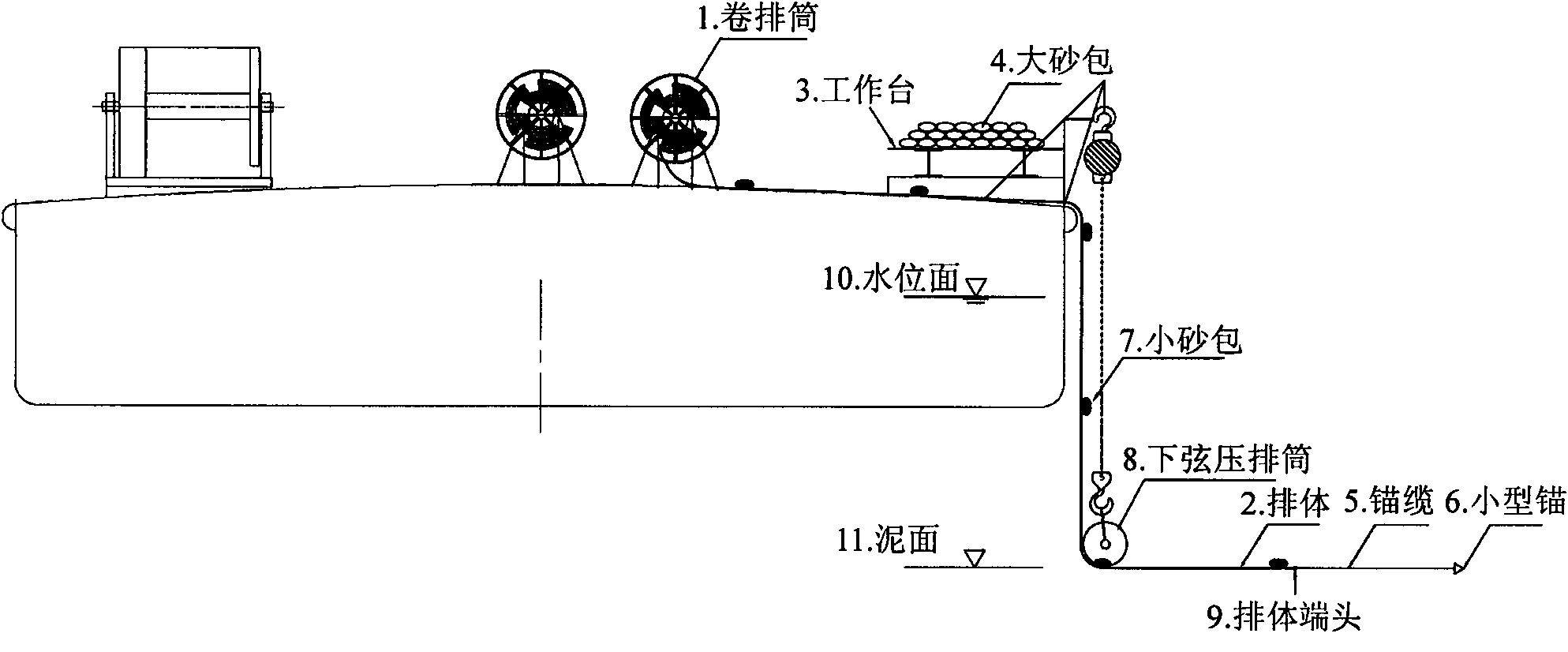

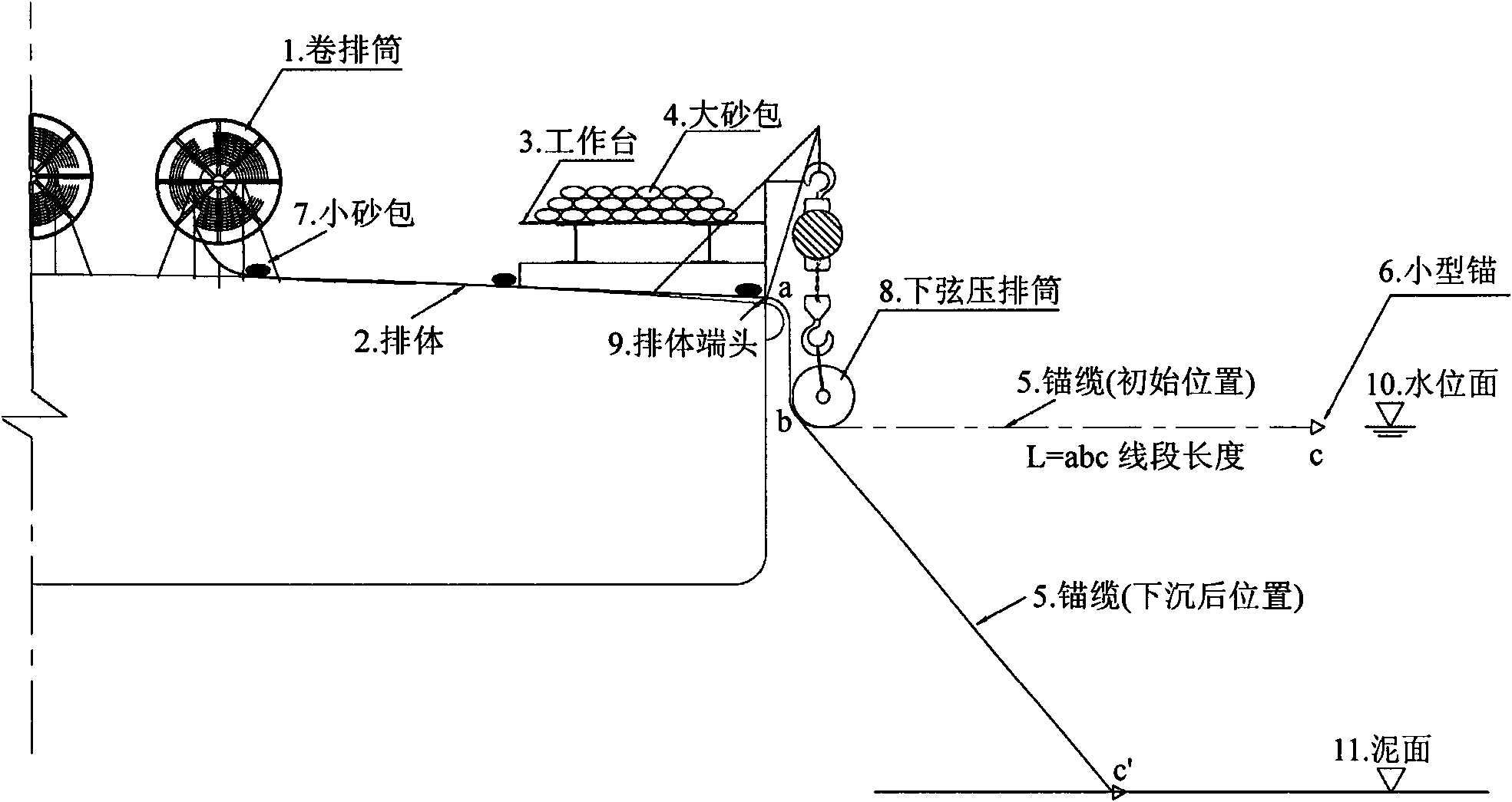

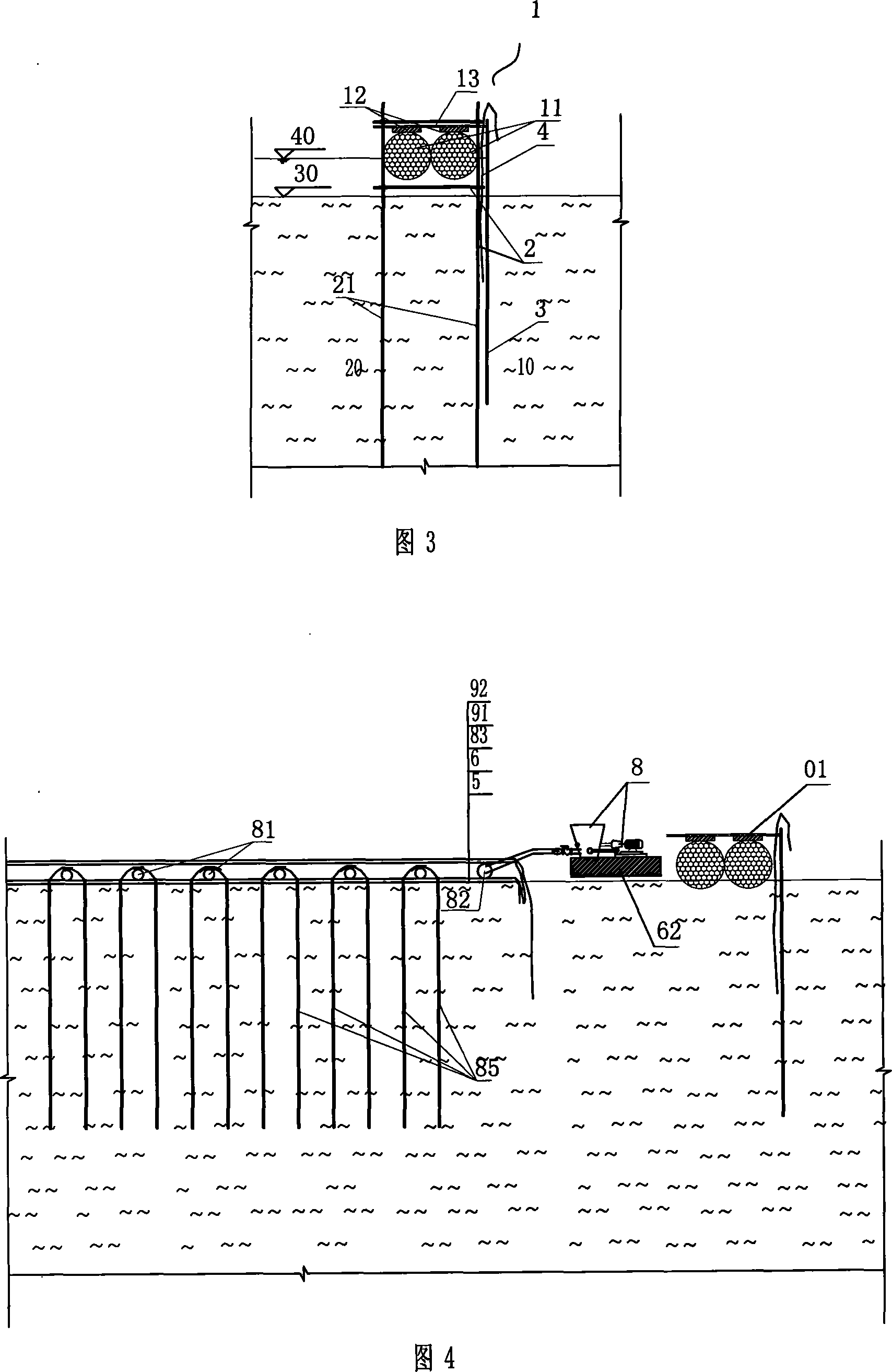

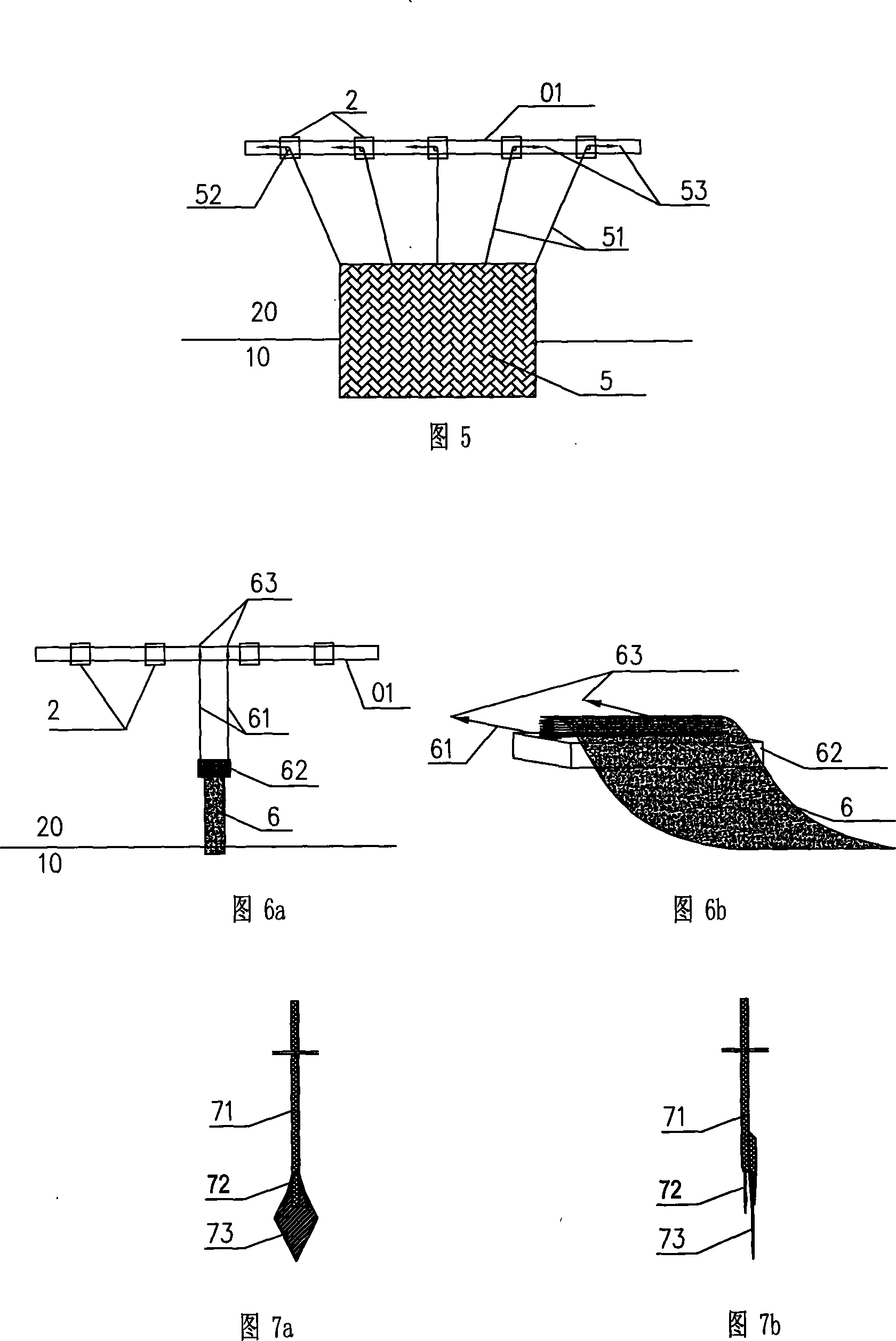

A Fast and Reliable New Technology for Underwater Laying

The invention relates to underwater arrangement, in particular to arrangement of a geotextile-geogrid complex which can play a role in isolating soil, reinforcing and reducing soil body deformation in soft foundation treatment projects such as reclamation projects and the like. In channel improvement projects, the novel technology is mainly used for protecting riverbed bottom matters in an arrangement range from being eroded by water to fulfill the aims of protecting the bottom and feet, preventing downcutting and protecting the engineering foundation. The conventional underwater arrangement lacks a key technology, so that the arrangement range and the axis deflection are difficult to control accurately, even phenomena of geo-mattress torsion, floating and the like occur, and the foundation stability and engineering quality cannot be ensured. The invention provides a novel quick and reliable underwater arrangement technology. In the technology, four important procedures, i.e., positioning, tiling, ironing and ballasting of the geo-mattress are combined organically by using the principles of tip anchoring, lower board arrangement barrel ironing and binding and throwing combination ballasting, so that the influences of load effects of wind, waves and the like and tide rise and fall on the construction during offshore operation are eliminated effectively, the geo-mattress can be quickly and accurately tiled on a coating surface, and the working efficiency is increased manifold.

Owner:CCCC FOURTH HARBOR ENG INST +3

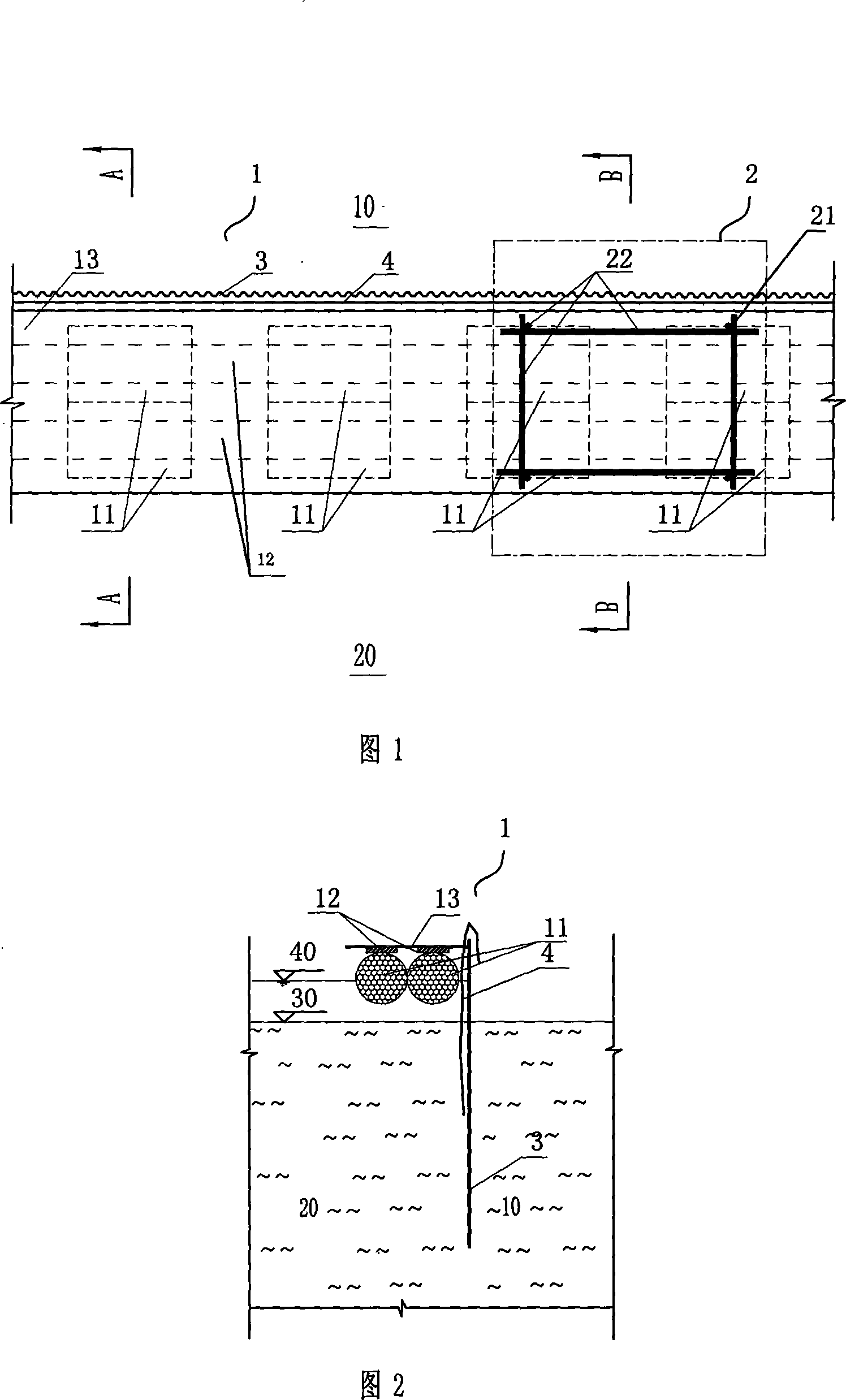

Method for rapidly reinforcing ultra-soft soil superficial zone and packaged technology

The invention discloses a fast strengthening method for ultra-soft earth, comprising the following steps: (1) arranging the separation curtains to divide a plurality of construction areas in the area of waiting for strengthening; pouring water at the field; using the device of artificial inserting plate to insert and arrange the short plastic drainage plate; arranging the horizontal drainage pipeline and then paving a layer of sealing film on the pipeline; forming the strengthening device for shallow layer of ultra-soft earth through the vacuum pumping equipment connected with the pipeline; (2) vacuuming the strengthening device for shallow layer of ultra-soft earth; (3) integrally strengthening the foundation of the device. The fast strengthening method for ultra-soft earth has the advantages that the method can rapidly and effectively solve the problem of strengthening the ultra-soft foundation on the shallow layer, so as to supply the favorable conditions for the construction, such as drainage sand cushion, plastic drainage board or bag sand-well, and supply an advanced art used for strengthening rapidly the foundation on silt or ultra-soft foundation on the filled silt with saving costs greatly.

Owner:CCCC FOURTH HARBOR ENG CO LTD +3

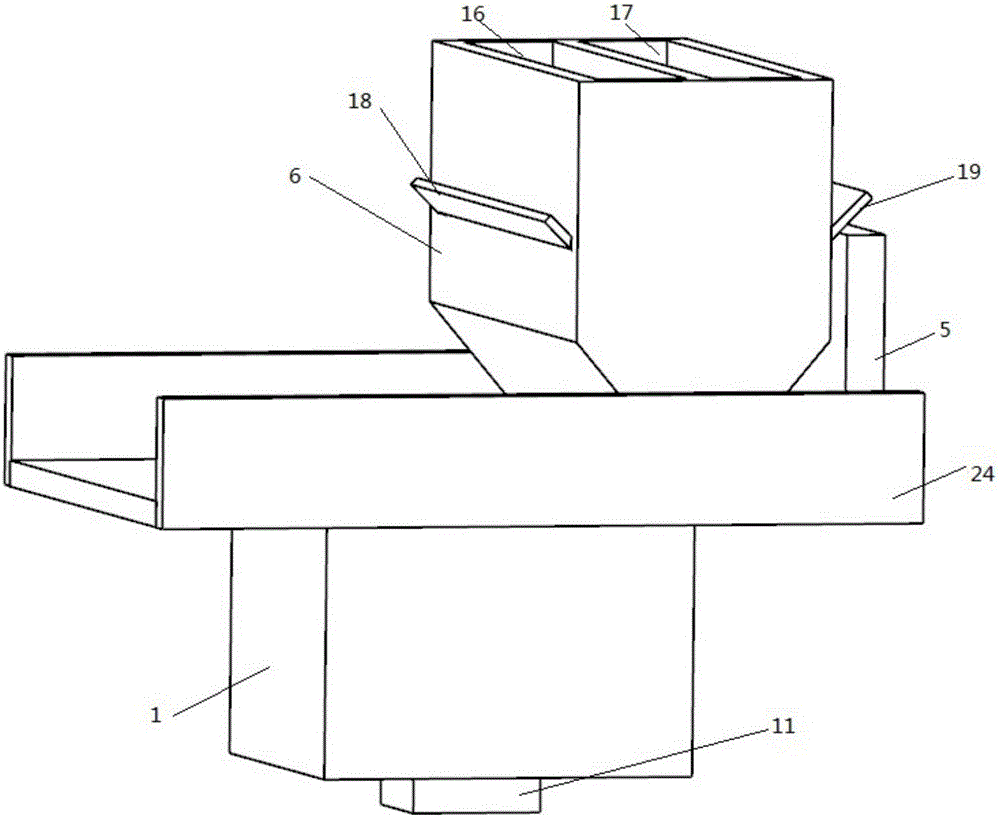

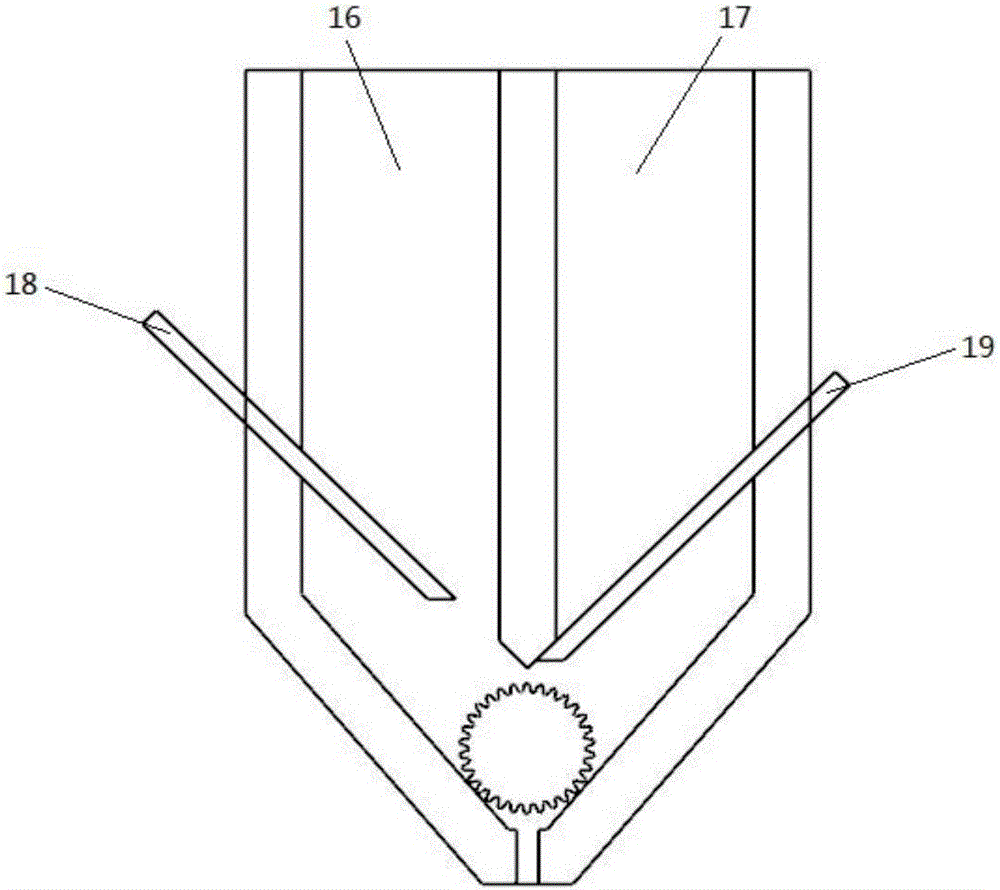

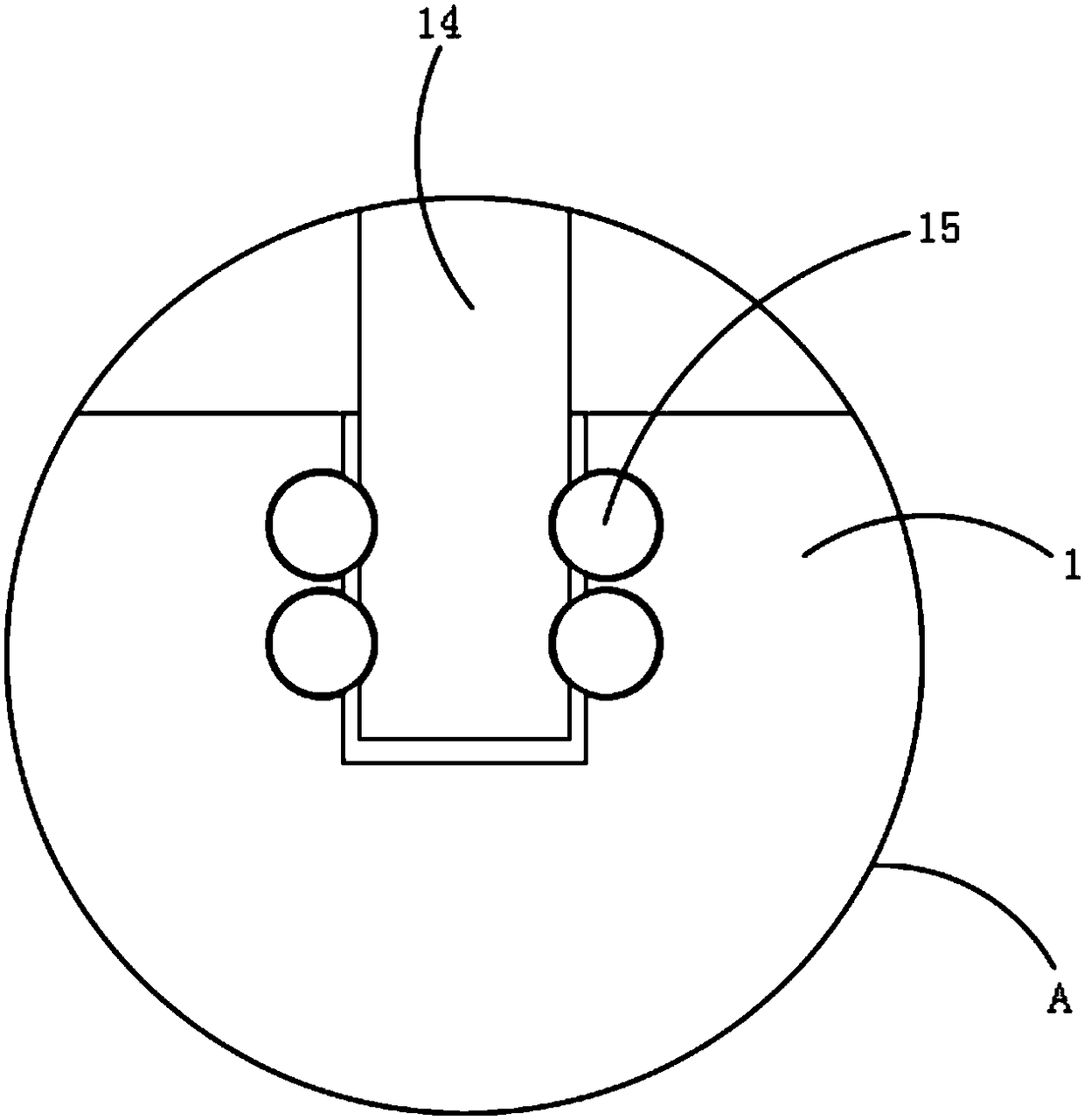

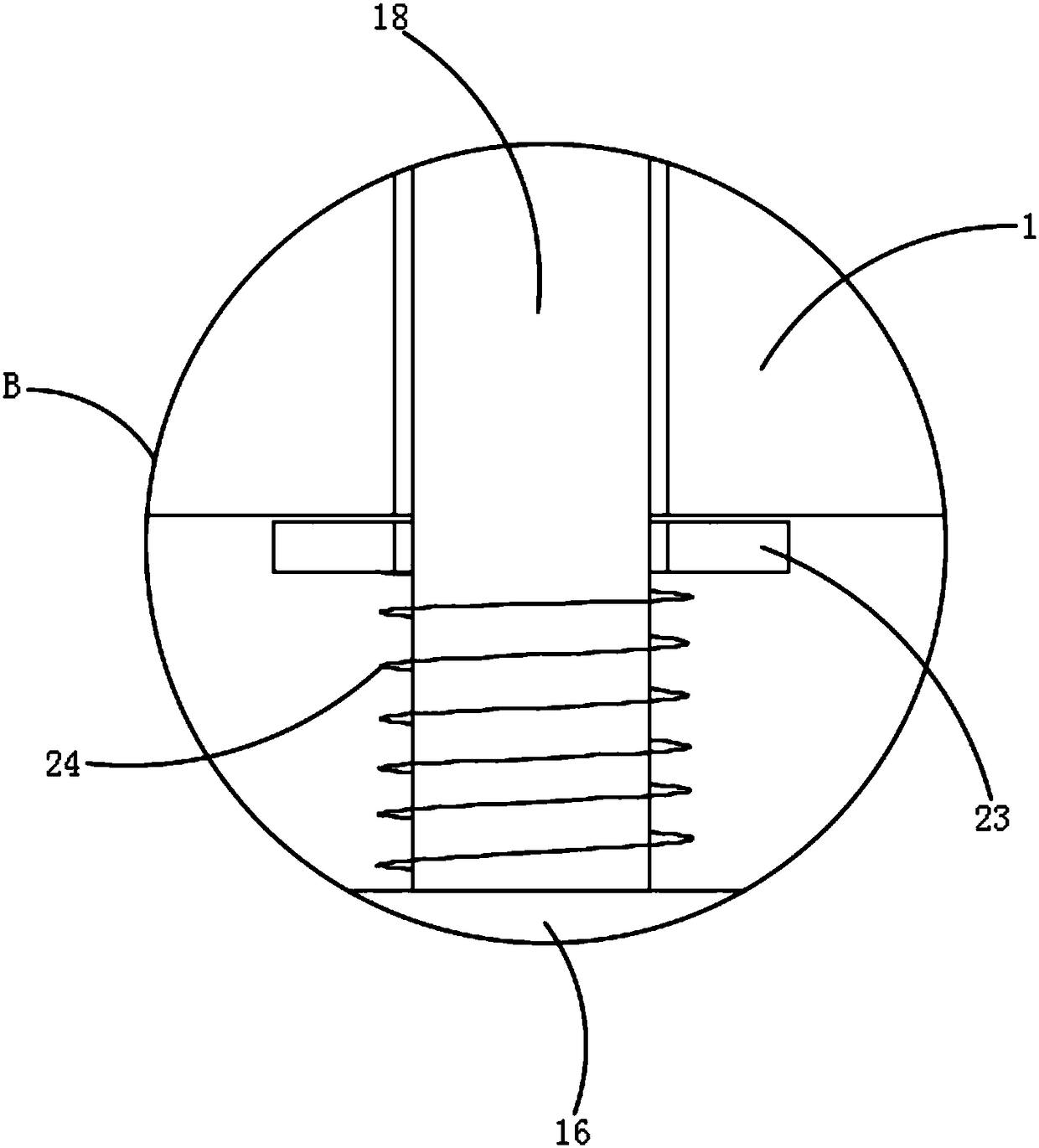

Double-powder quick molding and uniform spreading device

InactiveCN105728721ALay evenlyRealize rapid prototypingAdditive manufacturing apparatusIncreasing energy efficiencyHigh energyEngineering

The invention aims to provides a double-powder quick molding and uniform spreading device which comprises a lifting working platform, a linear module fixedly connected with the lifting working platform, a powder pressing roller arranged on a linear module sliding block, a powder scraper, a powder supply body, a lifting platform arranged in a working platform molding cylinder and a heating device arranged on the lifting platform, wherein a baffle is arranged in the powder supply box to divide the powder supply box into a plurality of chambers with the same volume; a switch for controlling the falling of a powder is arranged at a powder outlet part of each chamber; a powder supply shaft with a gear-shaped section is arranged at a powder outlet of the powder supply box; and the powder supply shaft is tangent to a wedged edge of the powder outlet of the powder supply box. The double-powder quick molding and uniform spreading device realizes quick molding of two powders at any ratio on each layer according to a two-dimensional diagram, ensures that all layers of a molded part have gradient differences, and thus reduces time waste caused by the reason that only one powder can be used in one cycle. The double-powder quick molding and uniform spreading device can uniformly heat the powders that a high energy density beam acts on, detect a temperature field and control interpass temperature, thus reducing residual stress caused by nonuniform temperature.

Owner:NANJING UNIV OF SCI & TECH

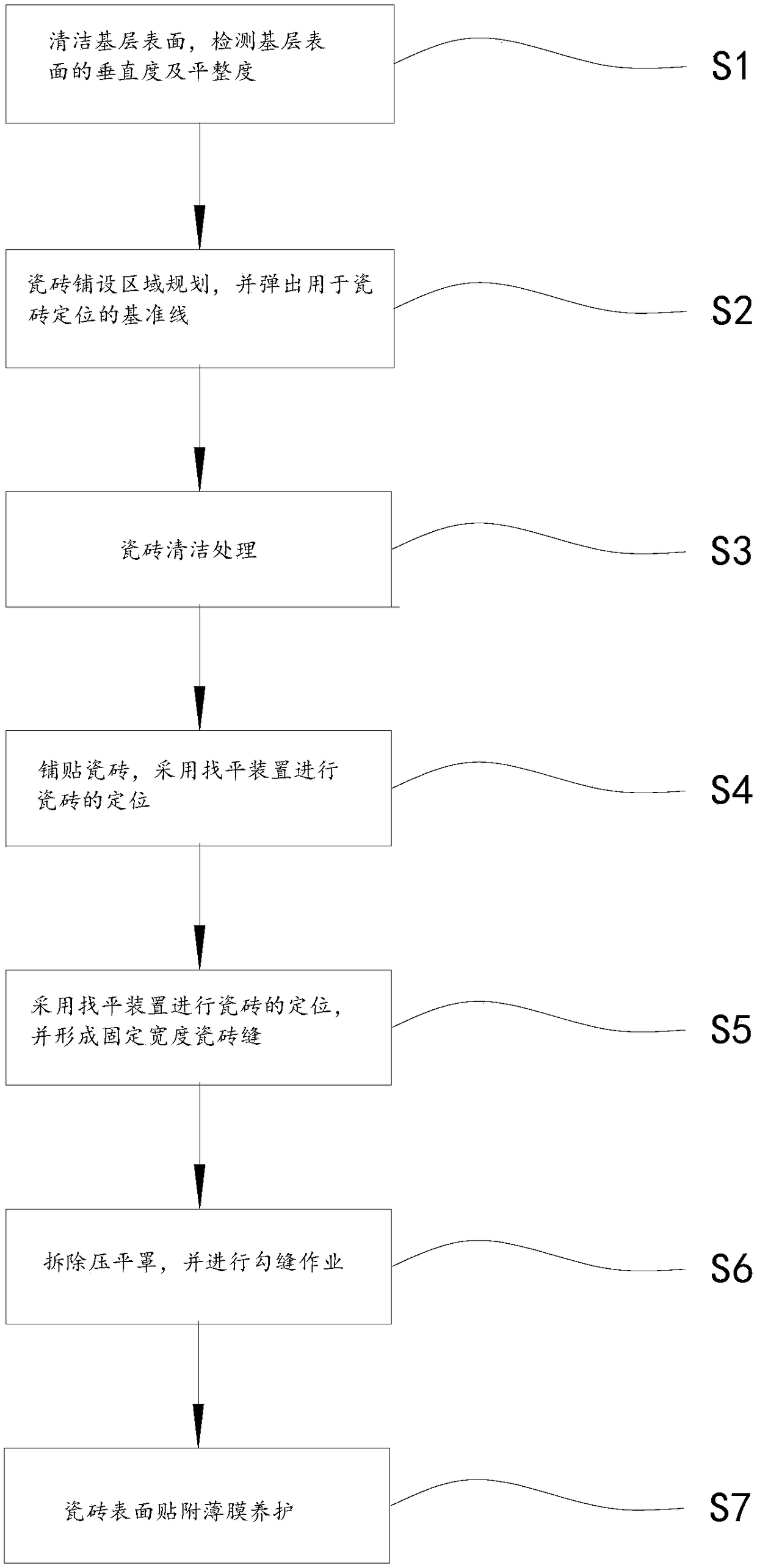

Tile paving method

InactiveCN108222450AAvoid misalignmentGuaranteed aestheticsBuilding constructionsDislocationCivil engineering

The invention provides a tile paving method. The tile paving method comprises the following steps that the base surface is cleaned, and the perpendicularity and flatness of the base surface are detected; planning is carried out according to an area needed to be tiled, and the vertical and horizontal datum lines used for tile positioning are popped up; tiles are cleaned, and it is ensured that corners and the two surfaces of the tiles are free of oil fouling; the tiles are paved, the tiles are positioned using a leveling device, the tiles are leveled using the leveling device, and the tile seamwidth formed between every two adjacent tiles is 1.5-3 mm; after mortar is solidified, a flattening cover is removed, and pointing operation is carried out; and after the pointing is completed, a thin film is attached to the surface of the tiles after paving for conserving for 5-10 days. According to the tile paving method, dislocation phenomenon of the tiles is avoided during leveling, gaps between the tiles are controlled to be reasonable, and the beauty and practicability of the tiles after paving are enhanced.

Owner:广州炬隆卫浴制品有限公司

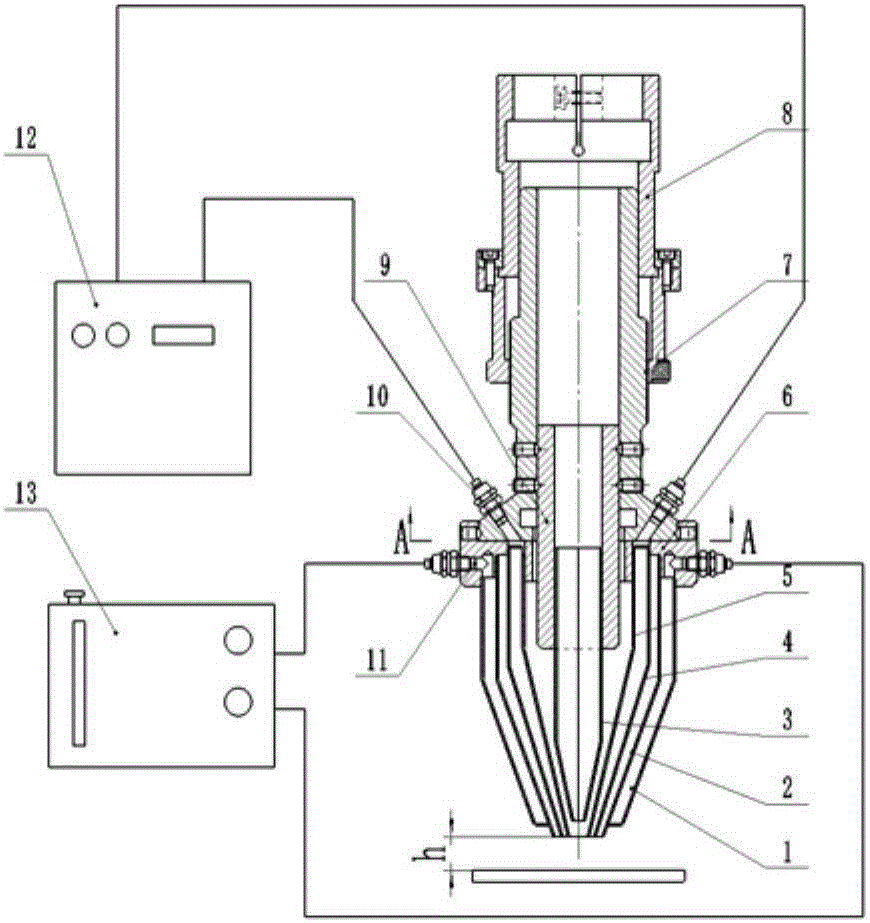

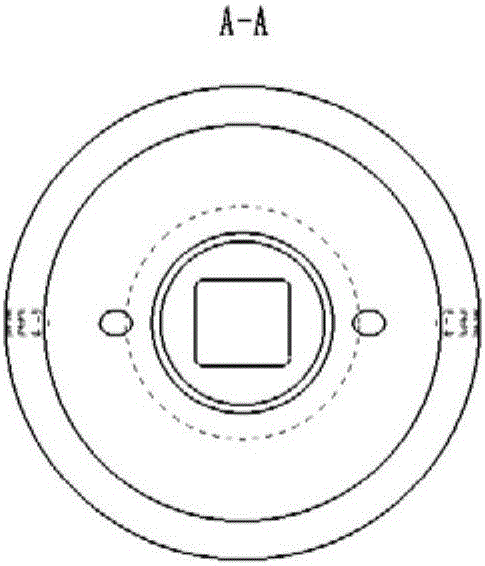

Coaxial powder feeding device for broadband laser cladding and powder feeding method thereof

ActiveCN106521485AAchieve mutual isolationPrevent surface oxidationMetallic material coating processesLight beamEngineering

The invention relates to a coaxial powder feeding device for broadband laser cladding and a powder feeding method thereof. The device comprises a sleeve module; a light beam isolation cover, and an inner-layer air cover, an outer-layer air cover and a cooling water cover for coating the light beam isolation cover in sequence from inside to outside are arranged at the bottom end of the sleeve module; two powder feeding pipes symmetrically arranged about the light beam isolation cover are arranged between the inner-layer air cover and the outer-layer air cover at the bottom end of the sleeve module; outlets of the powder feeding pipes are rectangular pipes; outlets of the light beam isolation cover, the inner-layer air cover, the outer-layer air cover and the cooling water cover at the bottoms are rectangular; and the sleeve module is provided with a water injecting port, a water outlet, an outer-layer protective gas inlet, an inner-layer protective gas inlet and a powder feeding inlet. The method comprises three steps of connection of external source equipment, powder feeding device parameter adjustment and coaxial broadband powder feeding laser cladding. The device can prevent fused metal liquid from splashing to block the outlet of the powder feeding device, can enable the powder spot pavement to become more uniform in powder spot shaping, and is simple in structure and easy to machine.

Owner:WUHAN UNIV OF TECH

Method for producing ceramic brick decorated with aperture

The invention relates to a manufacturing method of ceramic brick with decorative effect of hole, which is mainly characterized in that foaming material is combined by external imposing on the blanks. The foaming material is one organic or inorganic material or combination of run of mine ore material, industrial material, industrial waste and the like which can dissociate and oxidation react after calcining with high temperature. The manufacturing method is characterized in that the surface of the produced ceramic brick and the hearth layer are all equipped with natural-hole effect, simultaneously, the texture of the multicolor pattern on the surface is very natural and the stereo perception is appeared, which is much similar with natural-hole stone. Compared with the product pressed and molded by concave-convex mold in the prior art, the patterns of the product employing the manufacturing method is more natural and abundant, the stereo perception is more remarkable and the patterns are not stupid and rigid but changeable, simultaneously, the variety and size are abundant, the weight of the brick is reduced and the product is environment friendly, which belongs to high-grade architectural decorative material.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Petroleum asphalt coiled material laying equipment

ActiveCN108222384AEasy to attachImprove firm performanceRoof toolsRoads maintainencePetroleumAsphalt

The invention discloses petroleum asphalt coiled material laying equipment which comprises a mounting plate. Travel mechanisms are mounted at four corners of the lower side of the mounting plate, a cleaning mechanism is mounted on a side of the upper end of the mounting plate, a support frame is arranged on the upper side of the mounting plate, a feed roller is rotationally connected onto the support frame by a first rotary shaft, a discharge through opening is formed in the mounting plate, a guide plate which corresponds to the discharge through opening is arranged on the lower side of the mounting plate, a gas exhaust mechanism is mounted on the lower side of the mounting plate, the end, which is far away from the mounting plate, of the guide plate faces the gas exhaust mechanism, and aflattening mechanism is arranged on the side, which is far away from the guide plate, of the gas exhaust mechanism. The petroleum asphalt coiled material laying equipment has the advantages that the surfaces of laid locations can be cleaned by the cleaning mechanism, so that petroleum asphalt coiled materials can be conveniently attached to the laid locations, and the coiled material laying firmness can be improved; bubble between the coiled materials and the surfaces of the laid locations can be squeezed out by the gas exhaust mechanism, the petroleum asphalt coiled materials can be flattenedby the flattening mechanism, and accordingly the petroleum asphalt coiled material laying smoothness can be improved.

Owner:江苏东和循环科技有限公司

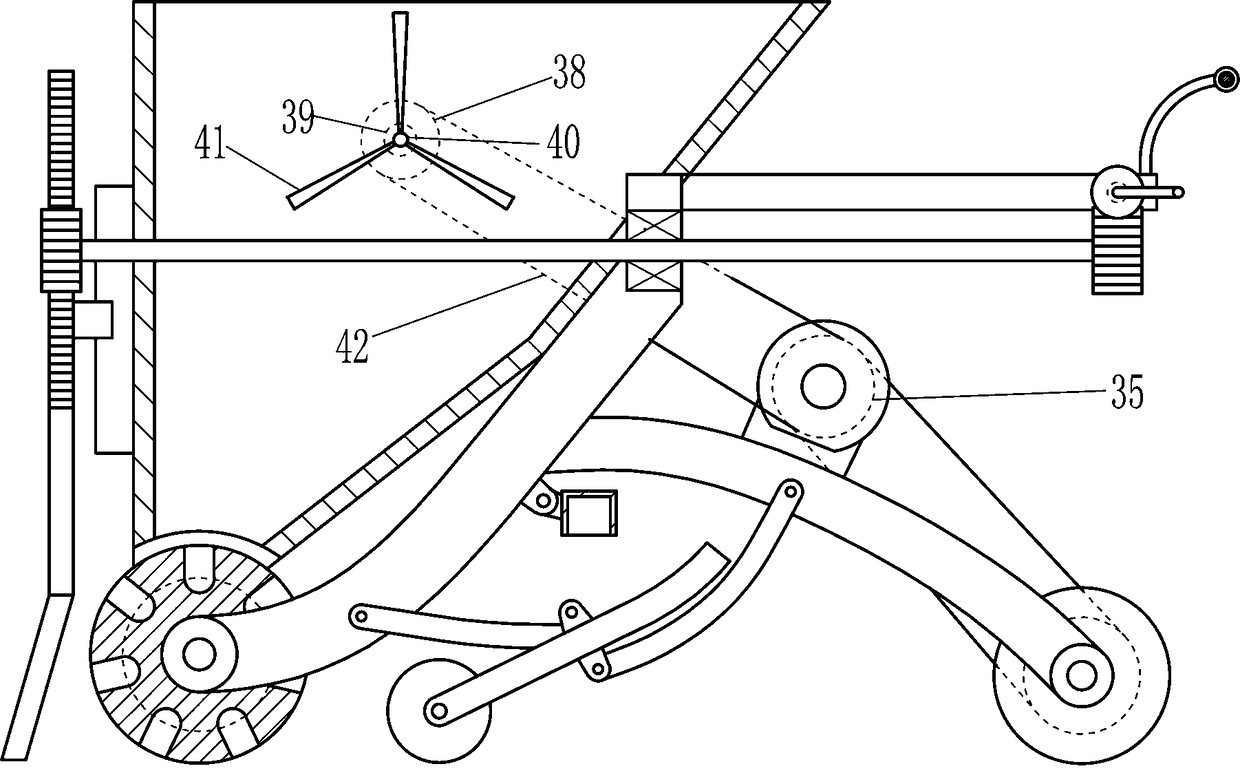

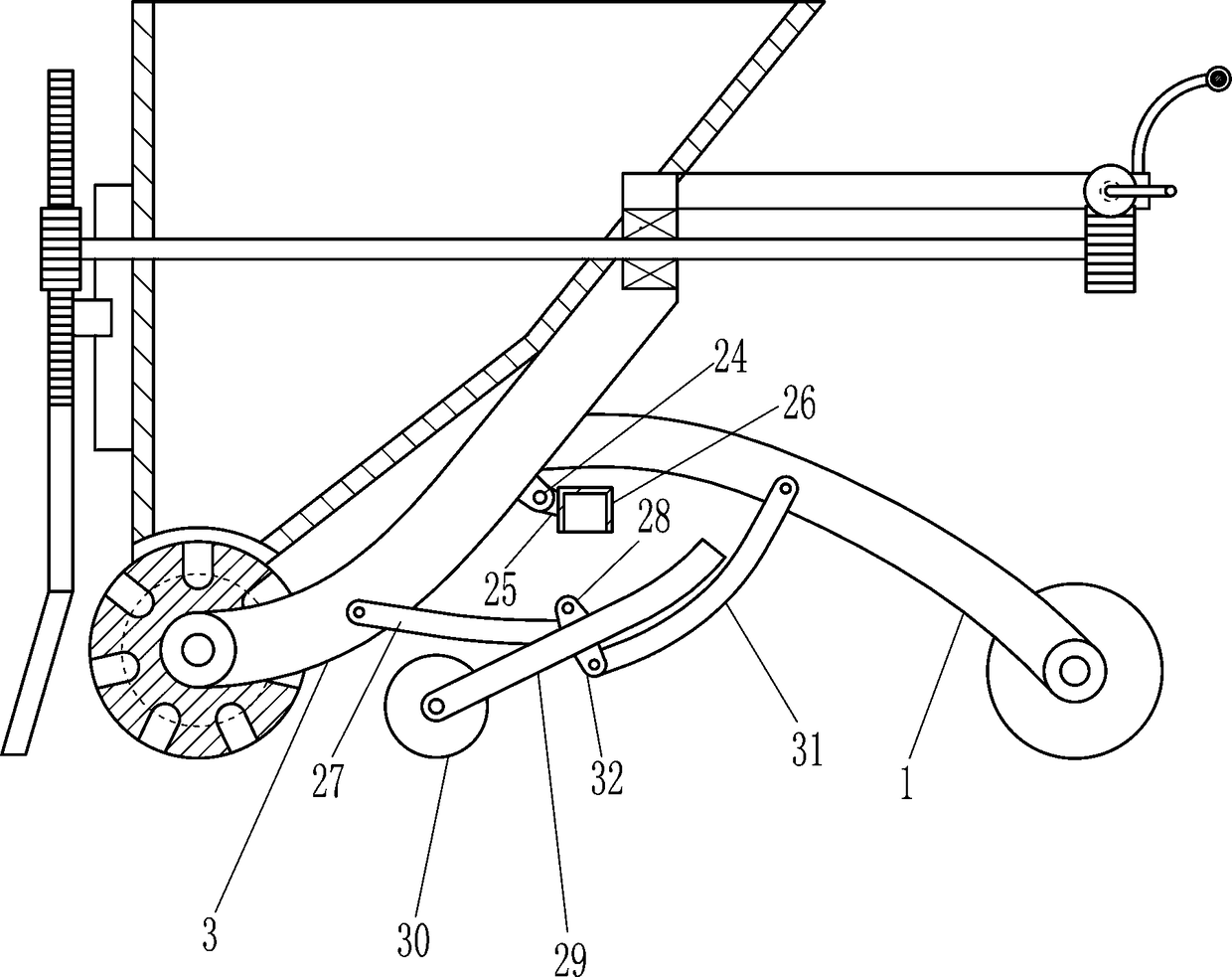

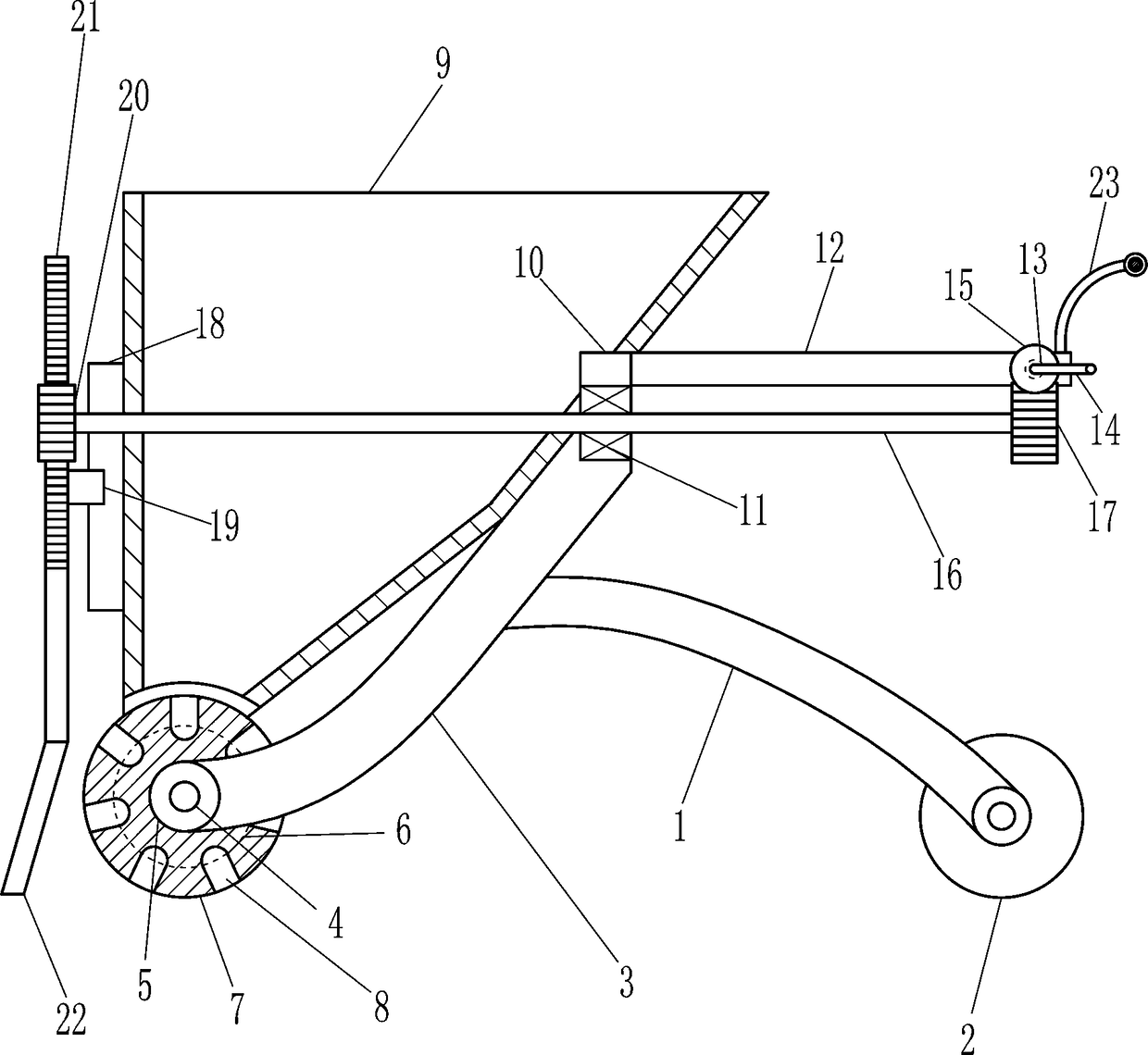

Asphalt laying device convenient for laying thickness adjustment

The invention discloses an asphalt laying device convenient for laying thickness adjustment. The asphalt laying device comprises a fixing frame, a front wheel, a rolling roll, a tank body and a discharging port; a drive motor is fixedly connected with the outer side wall of a rear fixing frame; the tank body is mounted in the middle of the fixing frame; a stirring motor is fixedly connected with the top of the tank body; a stirring shaft is fixedly connected with the shaft extending end of the stirring motor; a feeding tube is fixedly connected with the lower surface of the tank body, a connecting rod is hinged to the lower surface of the feeding tube; a laying plate is hinged to the lower end of the connecting rod. The asphalt laying device disclosed by the invention has the benefits thatasphalt is stirred by utilizing the stirring rod; the asphalt adhered onto the inner wall of the tank body is scraped by utilizing a scraping plate, so that raw materials are saved, and the waste isavoided; the asphalt at the bottom of the tank body is stirred by utilizing a spiral plate so as to be overturned upwards, so that the stirring effect is improved; the asphalt is pushed to move leftwards by utilizing a screw rod and is uniformly discharged from the discharging port; the asphalt is flatly struck off by utilizing the laying plate so as to be more uniformly laid; through adjusting the distance between the laying plate and the ground, the laying thickness can be conveniently adjusted.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

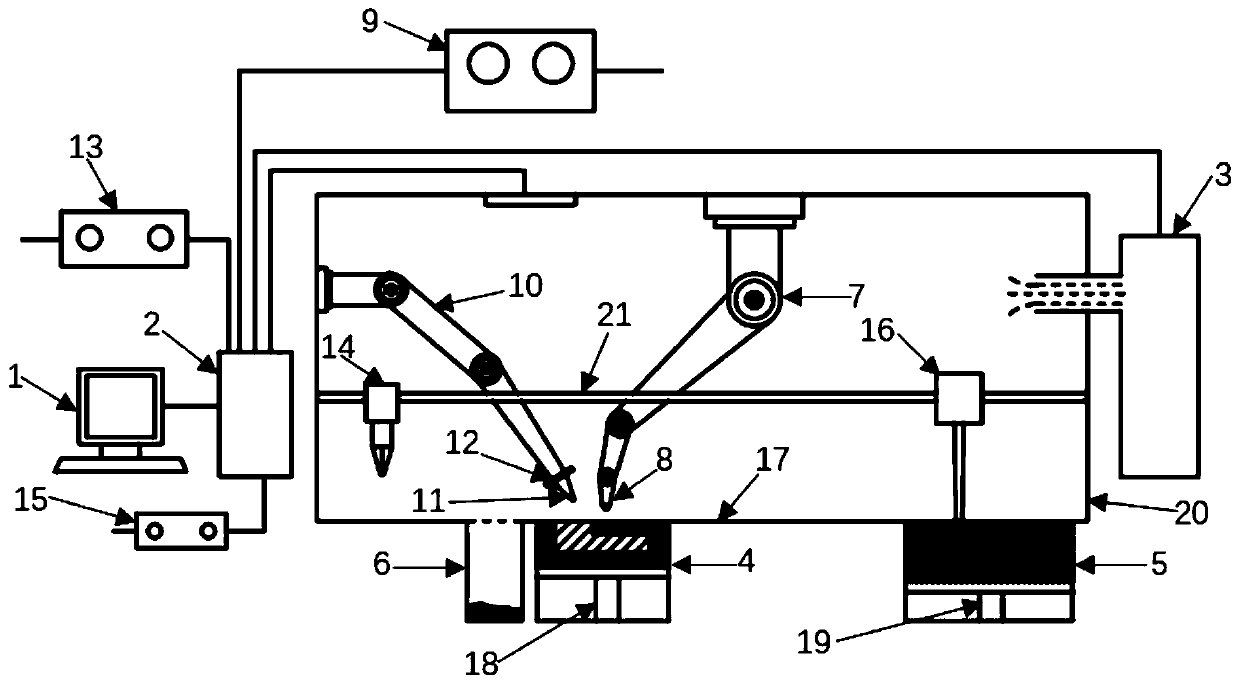

Part additive composite manufacturing device and method

InactiveCN110976869AAvoid processing powerIncreased efficiency in high-quality molding processesAdditive manufacturing apparatusIncreasing energy efficiencyLaser transmitterFemto second laser

The invention discloses a part additive composite manufacturing device and method. The part additive composite manufacturing device comprises a forming chamber, a controlling device, a laser melting mechanical arm, a laser shot blasting mechanical arm, a femtosecond laser transmitter and a forming cylinder, wherein the bottom face of an inner cavity of the forming chamber serves as a working tabletop, the top of the forming cylinder is connected with the bottom of the working table top, a bottom plate of the forming cylinder is connected with a first lifting device, the laser melting mechanical arm and the laser shot blasting mechanical arm are both arranged on the inner wall of the forming chamber, a laser melting nozzle is arranged at the tail end of the laser melting mechanical arm, alaser shot blasting nozzle is arranged at the tail end of the laser shot blasting mechanical arm, an electric linear reciprocating mechanism is arranged in the inner cavity of the forming chamber, thefemtosecond laser transmitter is connected to the electric linear reciprocating mechanism, and the movement direction of the electric linear reciprocating mechanism is parallel to the working table top. The effect that three machining devices do not affect one another is realized, the comprehensive performance of produced parts is greatly improved, and meanwhile secondary machining is avoided.

Owner:CHANGAN UNIV +1

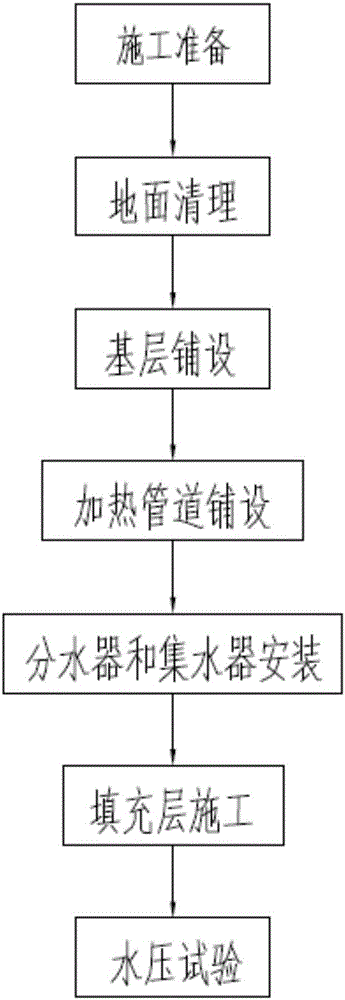

Indoor floor heating construction method

ActiveCN106402987AGood technical effectReduce laying costsLighting and heating apparatusFluid distribution meansWhole bodyEngineering

The invention discloses an indoor floor heating construction method. The indoor floor heating construction method comprises the following steps: (a) preparing for construction; (b) cleaning floor; (c) laying a base layer; (d) laying heating pipes; (e) mounting a water distributor and a water collector; (f) constructing a filling layer; (g) performing a water pressure test. According to the indoor floor heating construction method, the quality of clamping blocks can be checked to improve the construction of the clamping blocks; when the clamping blocks are spliced, the clamping blocks are fixed to steel wire mesh pieces by using iron wires; the steel wire mesh pieces are spliced into a whole body in advance, so that the clamping blocks are stably fixed to the steel wire mesh pieces, the heating pipes can be laid smoothly, and the heating pipes are prevented from winding with one another; therefore, the heating pipes are laid orderly; reworking phenomena are reduced; the heating pipe pavement efficiency is improved; four sections of inner layer heating pipes are arranged between outer layer heating pipes at two ends; the heating pipe pavement area is increased; the temperature on the floor is increased uniformly after the construction of a floor heating system.

Owner:HANGZHOU GOUJIA NETWORK TECH CO LTD

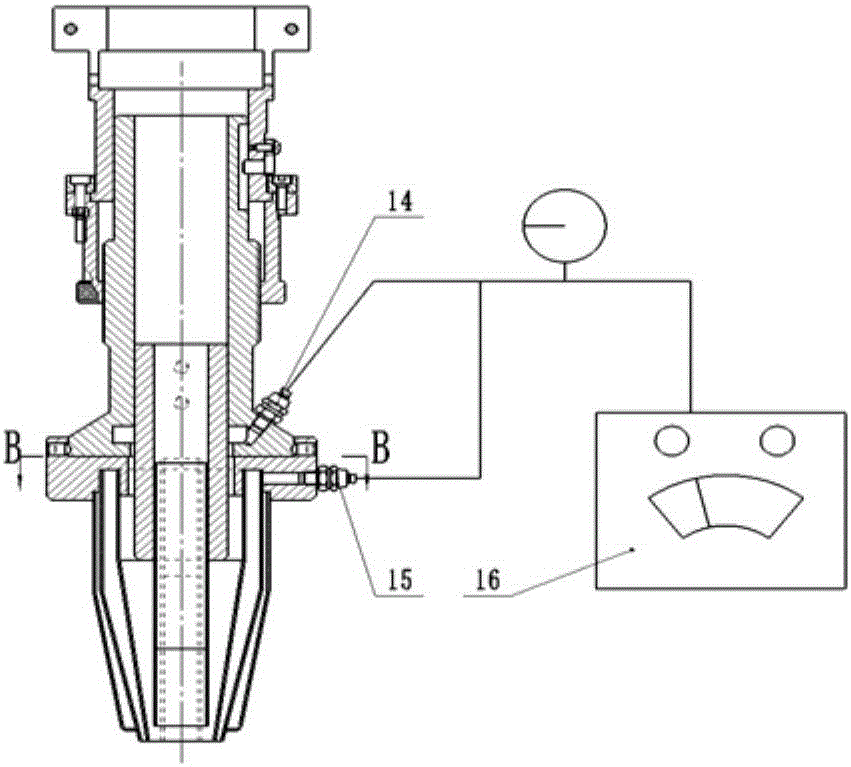

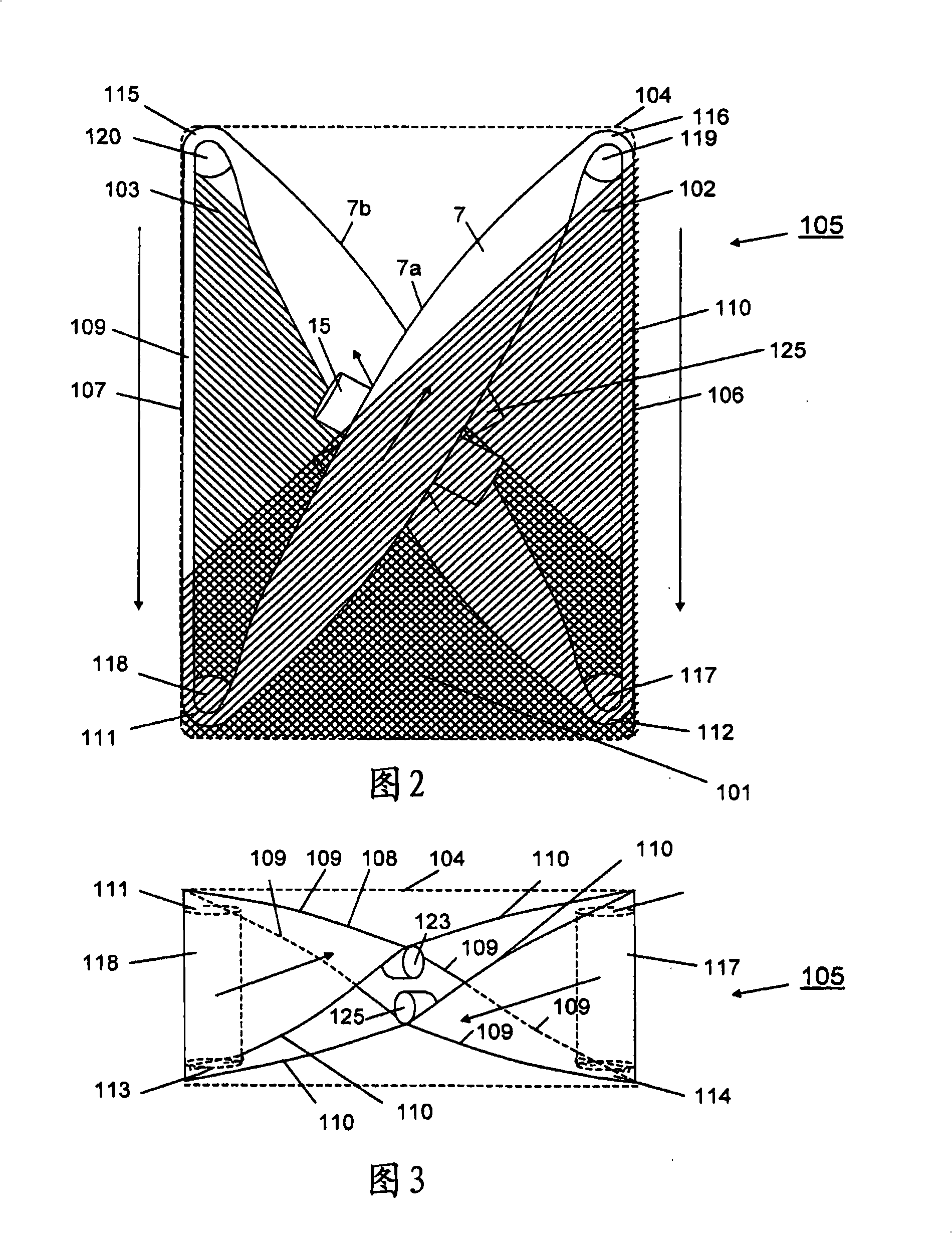

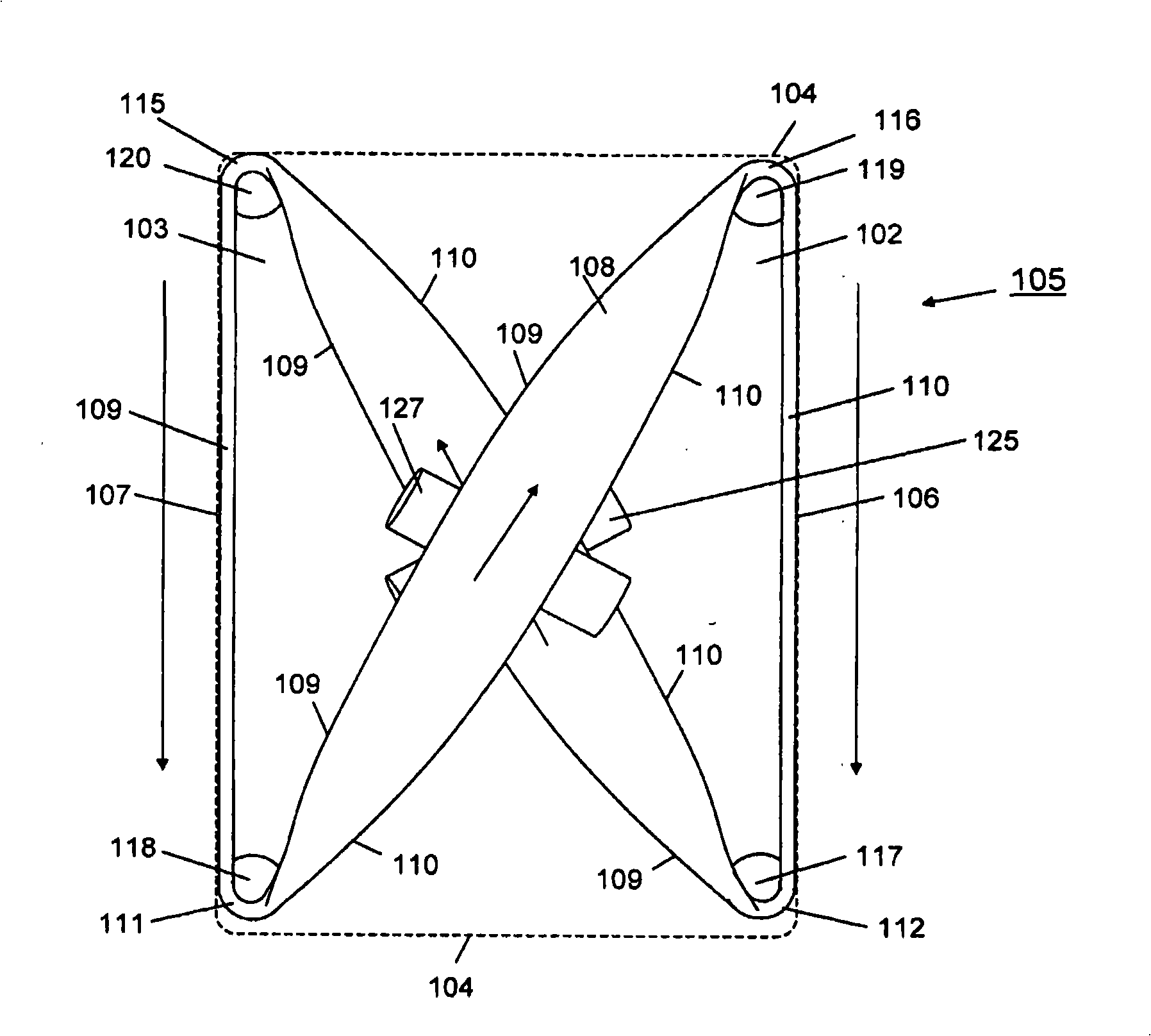

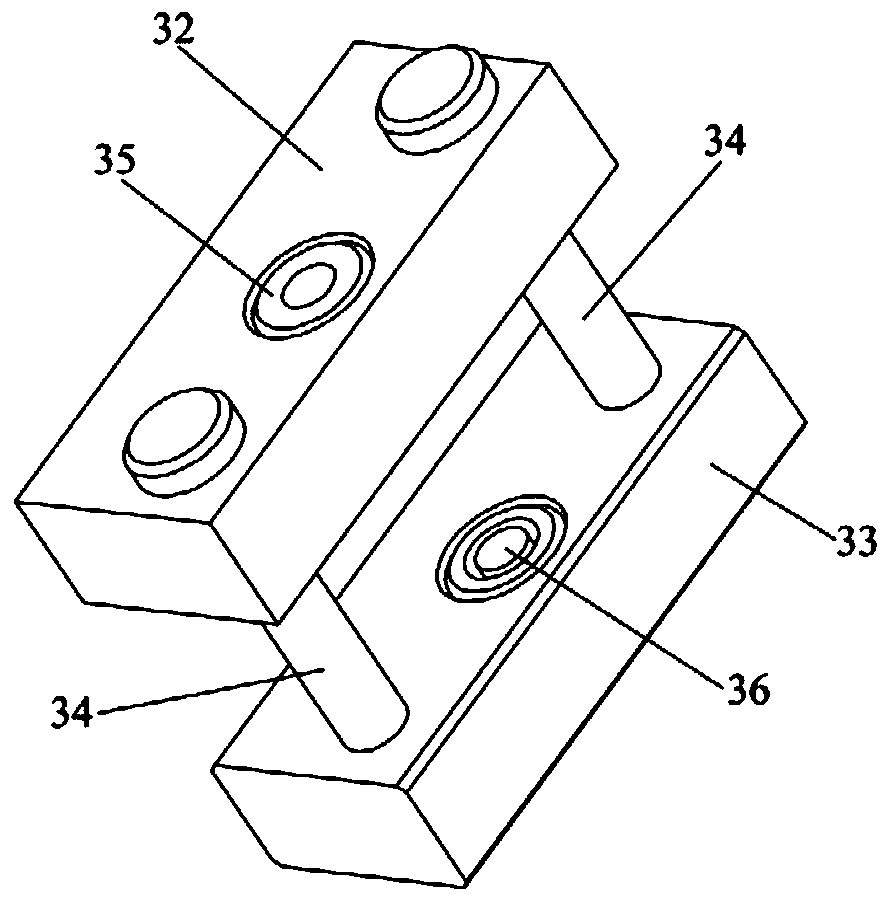

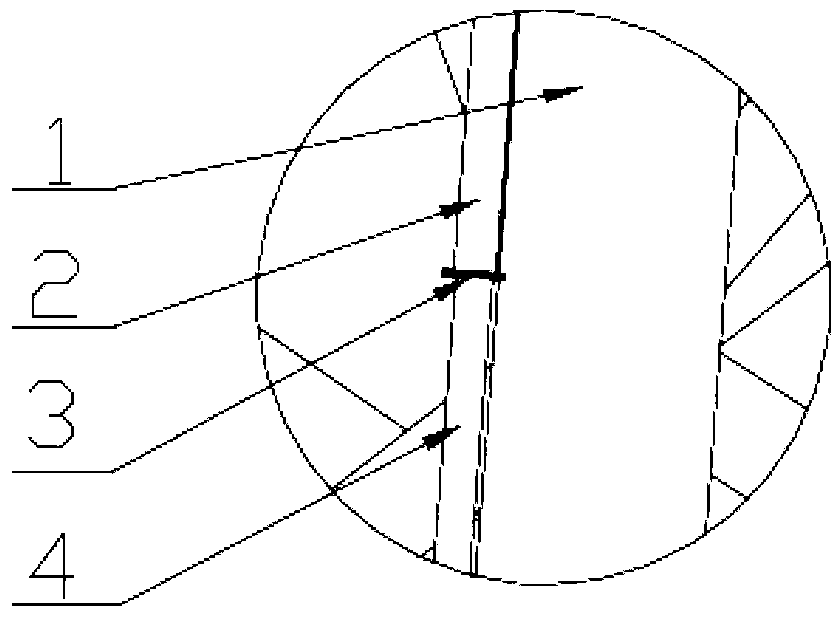

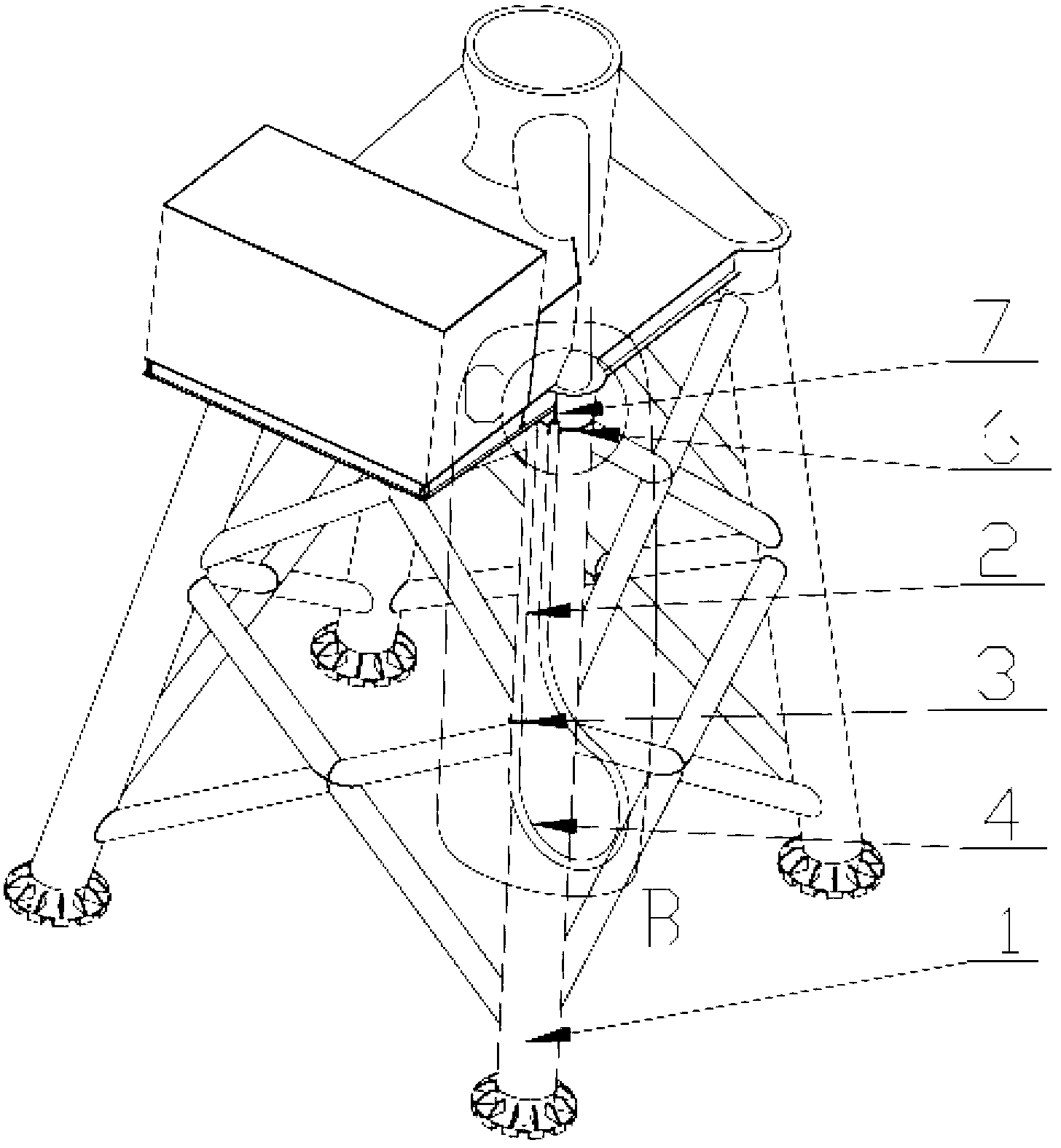

Method for the continuous production of a multiaxial contexture web

ActiveCN101516612AEasy to operateNo adhesionLayered productsNon-woven fabricsEngineeringFrictional resistance

The invention relates to a method for the continuous production of a multiaxial contexture web, in which a uniaxial contexture (4, 102, 103, 302, 303, 402, 403) is shaped to form a multiaxial contexture (5, 101, 301, 401) by winding about a plane (104, 306, 406), and to a corresponding apparatus for carrying out the method according to the invention. According to the invention, in order to accelerate the production method and for improved handling of the contextures (4, 5, 101, 102, 103, 301, 302, 303, 401, 402, 403) during the production process, there is provision for clamping elements (6, 7) to be used as delimitation of a plane (104, 306, 406), around which the uniaxial contexture (4, 102, 103, 302, 303, 402, 403) is wound. Furthermore, in order to reduce the friction during the production of the multiaxial contextures (5, 101, 301, 401), there is provision for at least one belt or band drive (105) to be used which runs along two side edges (106, 107) which lie opposite one another. Furthermore, there is provision according to the invention for a unidirectional contexture (4, 102, 103, 302, 303, 402, 403) to be wound at an angle around a plate (201) to form a reel, wherein the plate (201) is provided with an apparatus for compensating for friction and the reel (245) is pulled off from the plate (201). In addition, it is proposed to set the winding plane (104, 306, 406) in mechanical oscillation during the winding operation, in order to pull off the multiaxial contexture (5, 101, 301, 401) from the winding plane (104, 306, 406) with a low frictional resistance as a result of the oscillations. Furthermore, it is proposed to select an oblique position of the longitudinal axis (407) of the winding plane (104, 306, 406) in relation to the direction of gravity (408).

Owner:费伯拉弗斯股份公司

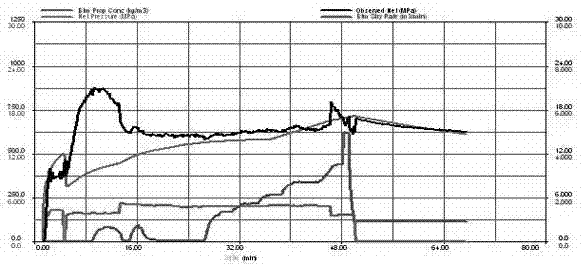

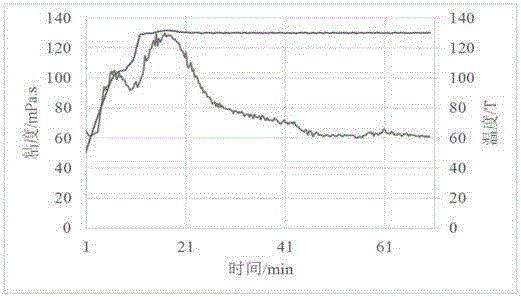

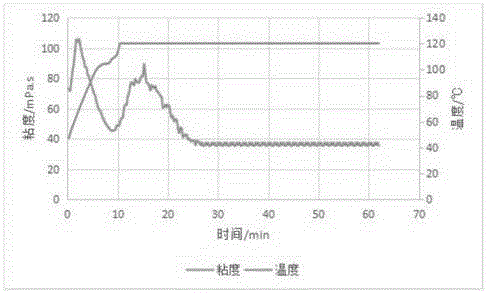

Oil and gas reservoir fracturing sand adding method

The invention provides an oil and gas reservoir fracturing sand adding method, which comprises a fracturing crack forming stage and a sand adding stage. A multi-scale complex crack system is formed inthe fracturing crack forming stage, fracturing fluid with different viscosities and propping agents with different particle sizes are injected in the sand adding stage to adapt to the multi-scale crack system, and the crack system is filled and supported from far to near. According to the method provided by the invention, by optimizing and adjusting the construction parameters and adjusting and controlling the accumulation height of the proppant in the fracture, the effective support of the proppant in the fracture height direction is improved, the filling degree of a multi-scale complex fracture system is improved, the volume fracturing complex fracture sand adding technology is perfected and improved, and finally, the effects of increasing the yield after pressing and stabilizing the yield are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

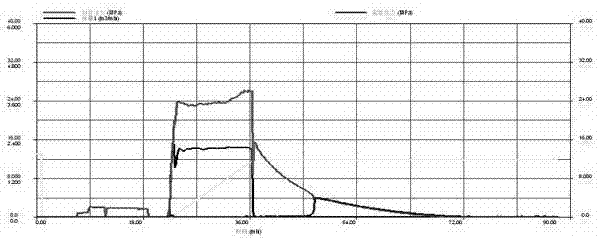

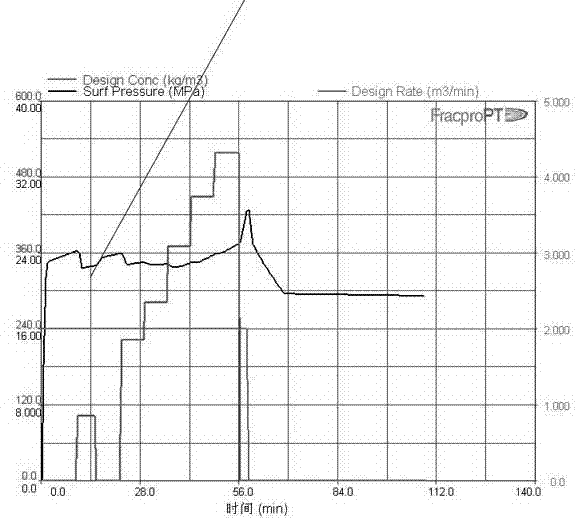

Fracturing design method for optimizing uniform spreading concentration

The invention relates to a method for oil extraction in oilfields, namely a method for optimizing a conventional fracturing sand adding program in underground operation, in particular to a fracturing design method for optimizing uniform spreading concentration. The method is implemented by adding leading liquid and then uninterruptedly adding sand mixed liquid. The method is characterized by comprising the following four steps: 1, determining the efficiency eta of the liquid; 2, determining the volume nu of the leading liquid; 3, determining the sand adding gradient; and 4, performing a uniform spreading concentration pumping program, adding the leading liquid of which the volume nu is determined in the step 2, and then uninterruptedly adding the sand mixed liquid according to the sand adding gradient designed in the 3. By the method, the conventional simple pumping method based on the construction experience is changed; and by adopting the uniform spreading concentration sand adding program of different sand-liquid ratio raising speeds at different stages, the effectiveness of fracturing design and the transformation degree of a reservoir are improved on the premise that the pumping safety is ensured.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

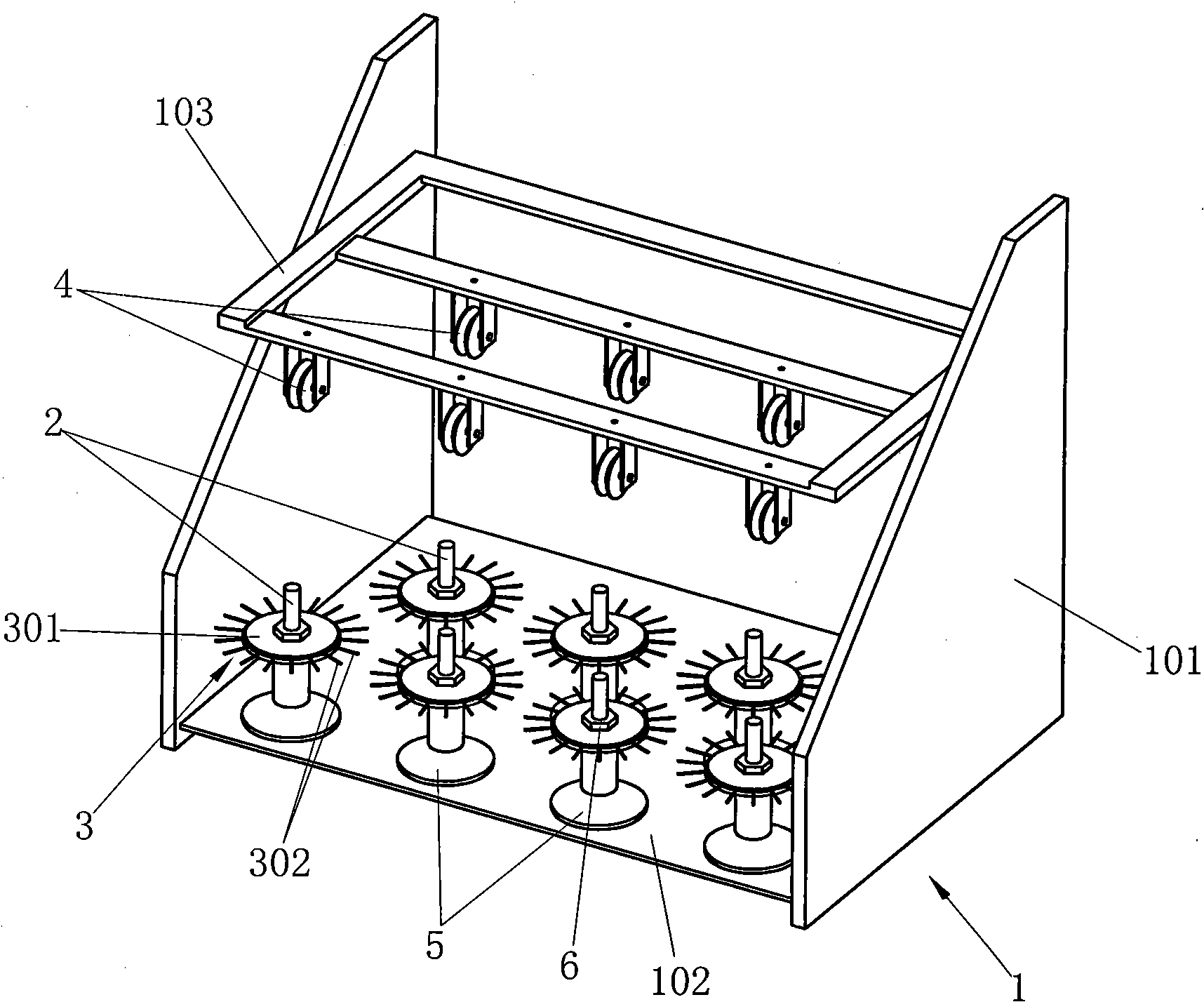

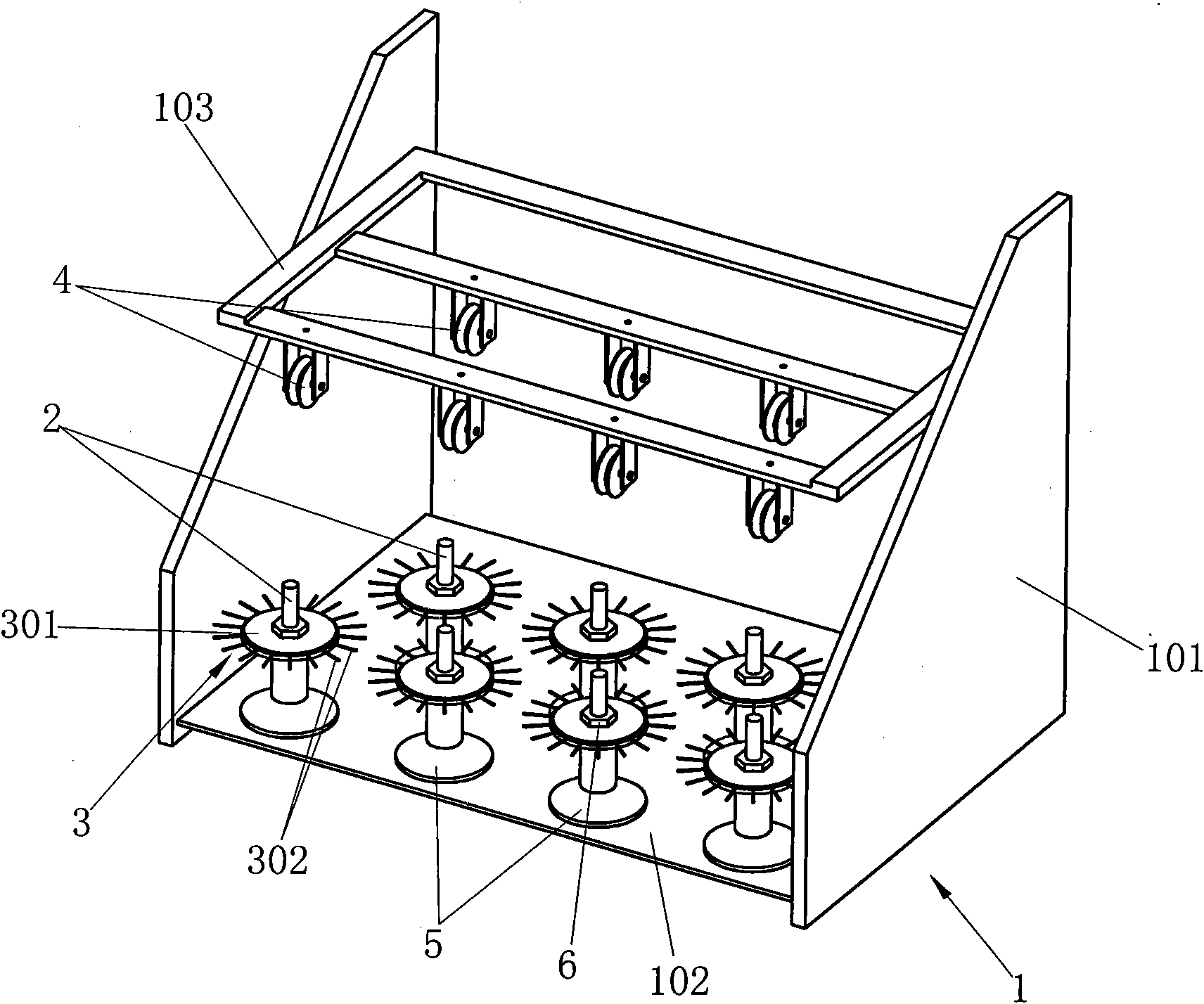

Unreeling frame

The invention relates to an unreeling frame which is characterized by comprising a frame body. A soleplate is arranged below two lateral plates of the frame body, a guide wheel bracket is arranged between the two lateral plates above the soleplate which is provided with at least three perpendicular unreeling shafts, a winding rubber shaft is sleeved on each unreeling shaft, a brush gasket is mounted at the upper end of each winding rubber shaft and fixed together with the winding rubber shaft and the soleplate with screws, the brush gasket comprises a backing plate, a plurality of radially distributed elastic brush bristles are symmetrically arranged on the periphery of the backing plate, and guide wheels in the same number as the unreeling shafts are arranged on the guide wheel bracket. The invention has simple and compact structure, convenient use and stable and smooth unreeling, is particularly suitable for unreeling ultrafine enameled wires and keeping the constant tension of the enameled wires between the winding rubber shaft and a wire twisting machine by the elasticity of the elastic brush bristles to avoid breaking the enameled wires, guarantee the qualities of twisted wires, improve the pass rate of products and decrease the production costs of wires.

Owner:无锡巨丰复合线有限公司

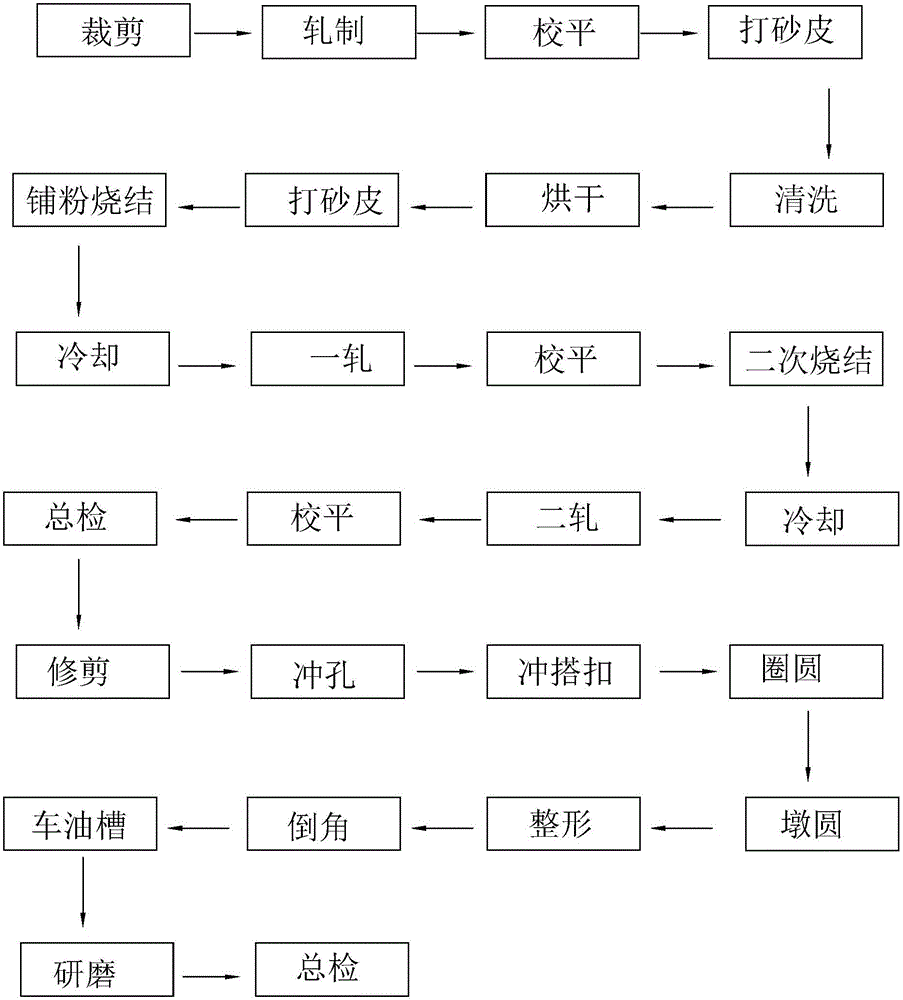

Wrapped bearing bush processing method

The invention discloses a wrapped bearing bush processing method. A big steel plate is cut into multiple small blank plates, anti-rust oil on the blank plates is removed by means of a JQ-107 cleaning agent through ultrasonic cleaning, the cleaned blank plates are dried and then polished with sand paper, unleaded copper powder is spread on the polished blank plates, then the blank plates are placed in a sintering furnace to be sintered at 920-940 DEG C, and the rotating speed of a mesh belt in the furnace is 350-400 mm / min; the blank plates after primary sintering are rolled by 0.05-0.1 mm, and the leveled blank plates are placed in the furnace again for secondary sintering at 940-950 DEG C for 20-40 min, and the rotating speed of the mesh belt in the furnace is 350-400 mm / min; secondary rolling is conducted on the blank plates after secondary sintering by 0.02-0.04 mm, the blank plates after secondary rolling are punched, and the punched blank plates are rolled into the shape of a bearing bush. The wrapped bearing bush produced with the method is stable in structure, and the service life of the wrapped bearing bush is prolonged greatly.

Owner:浙江凯蒂滑动轴承有限公司

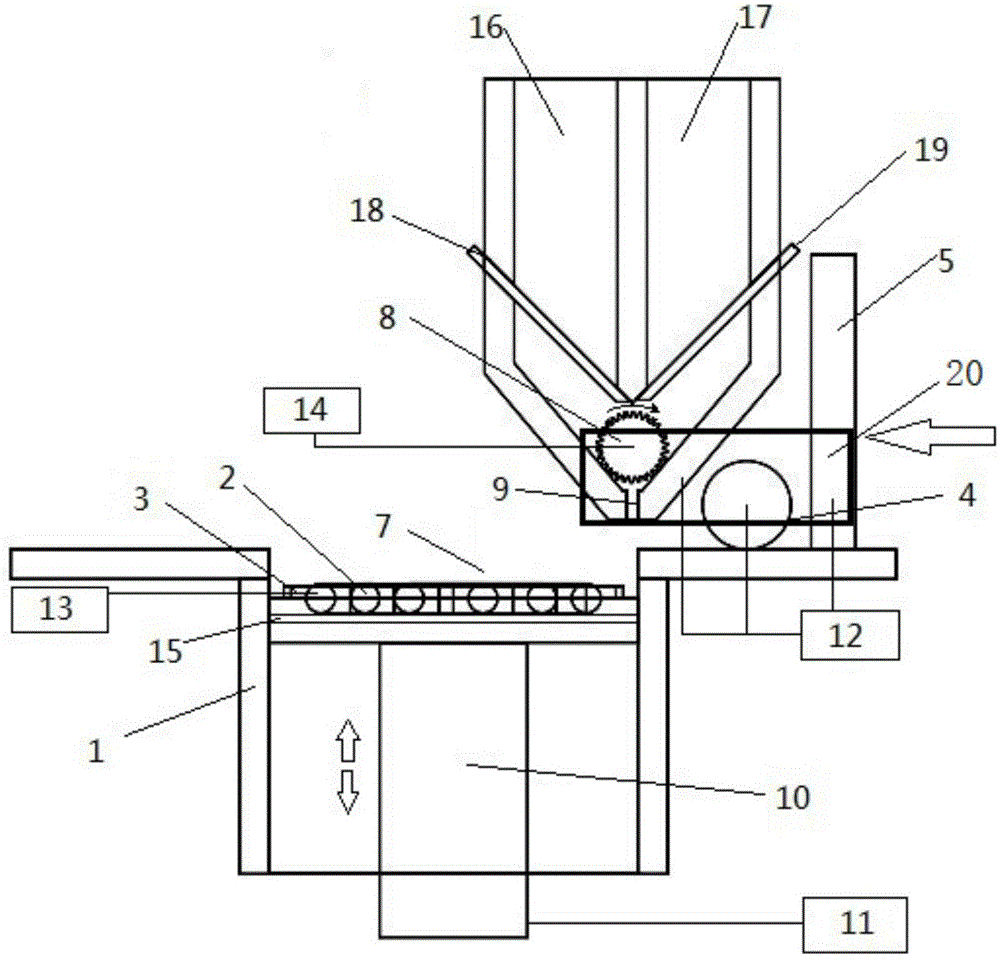

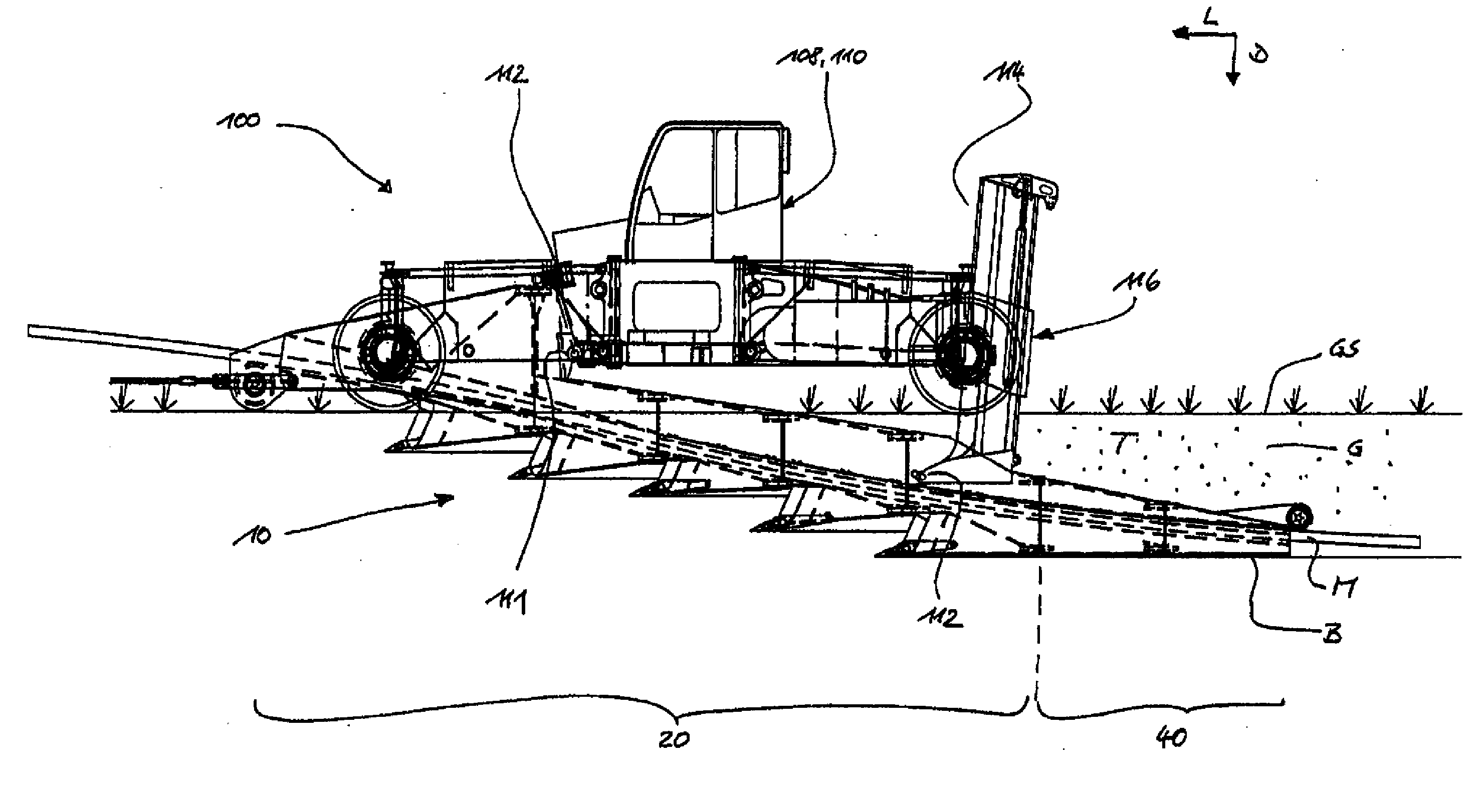

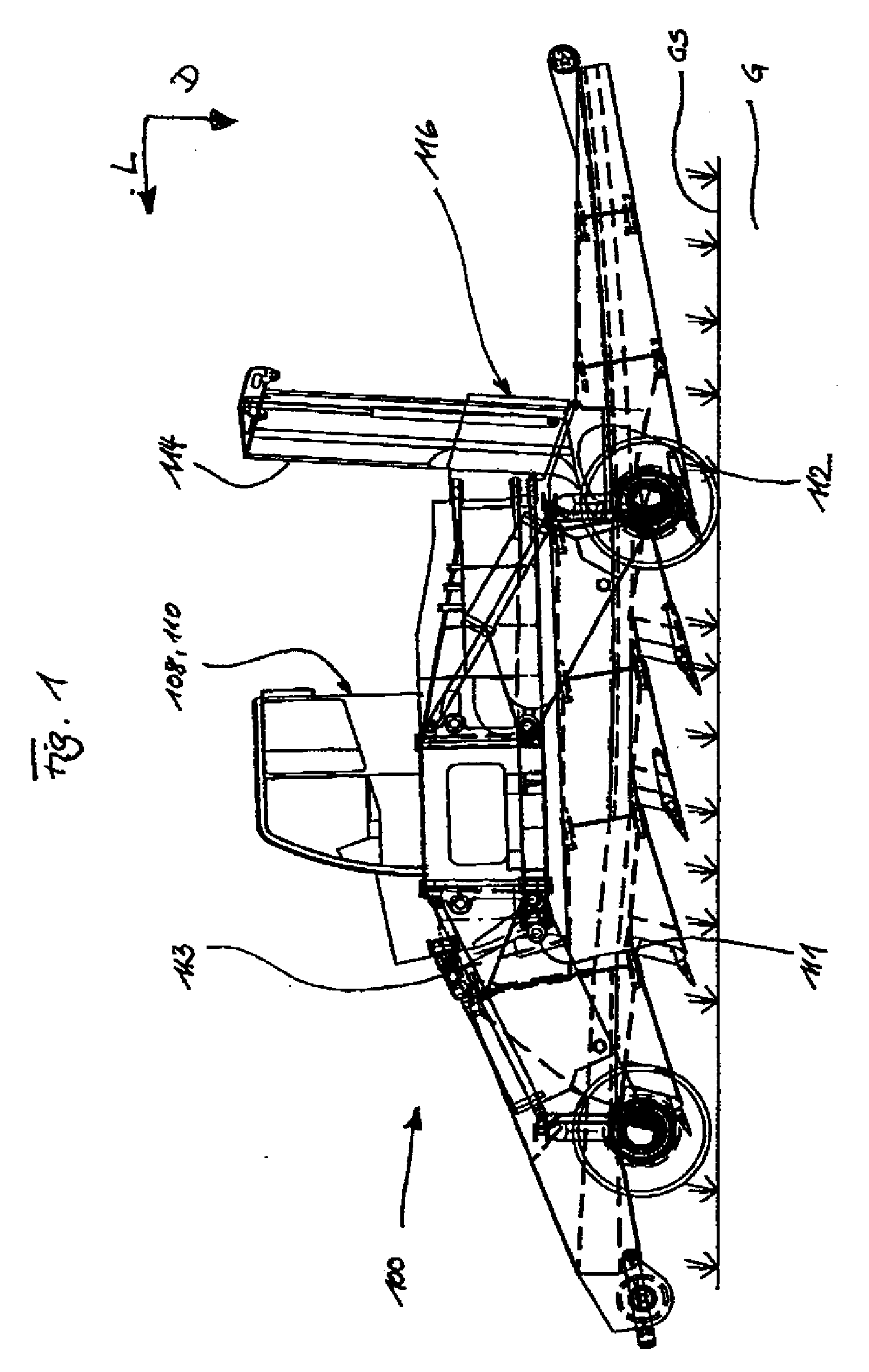

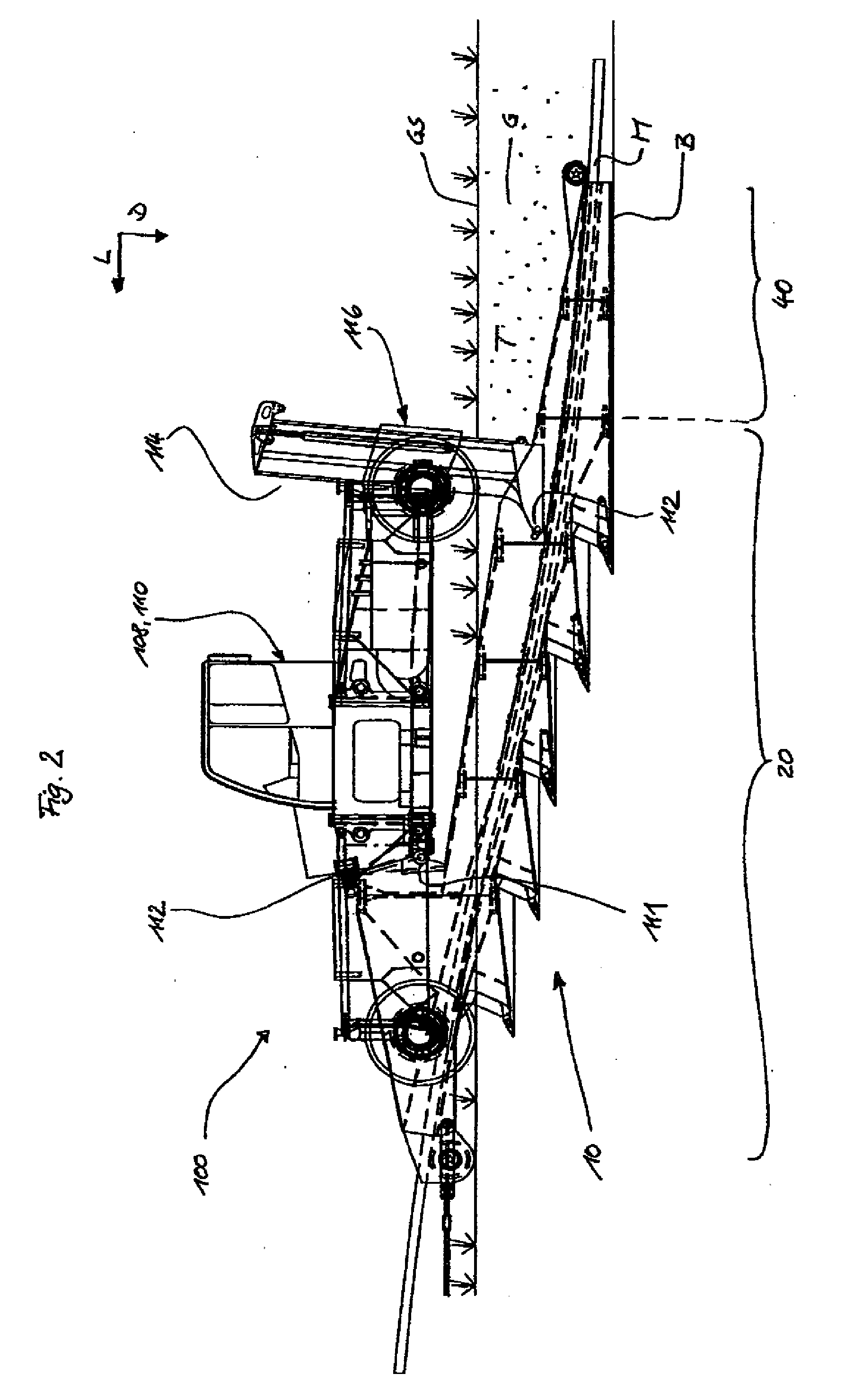

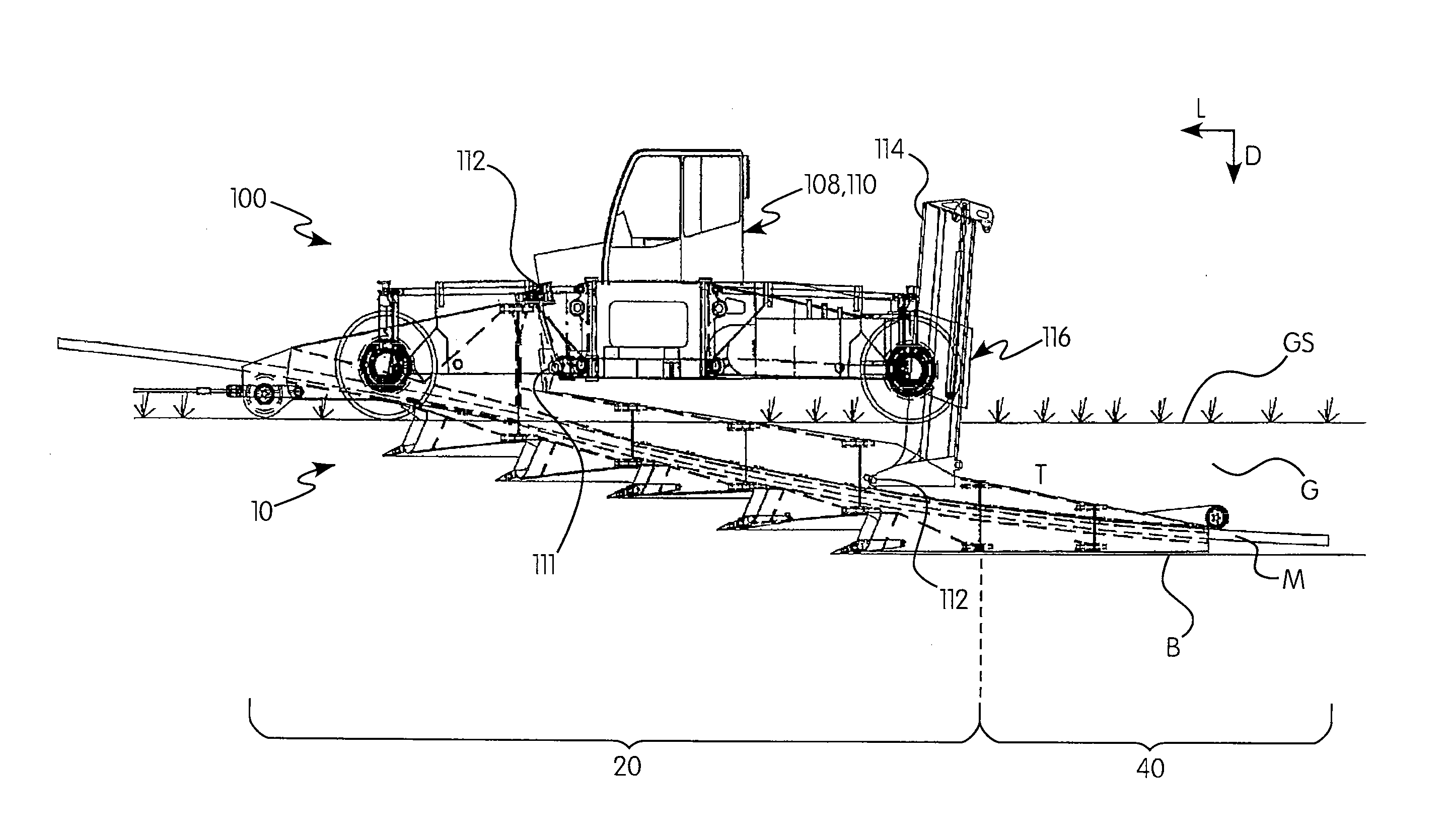

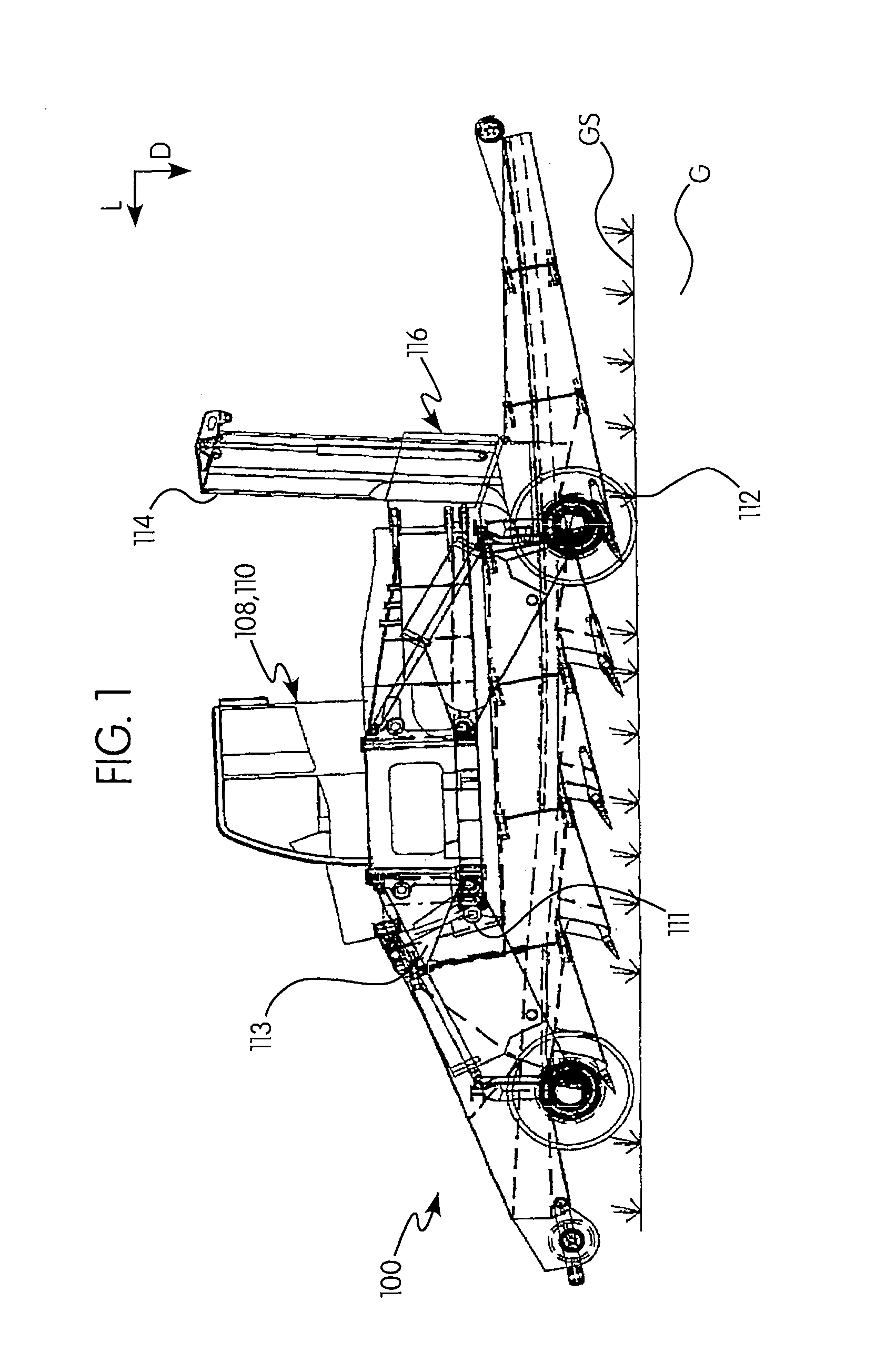

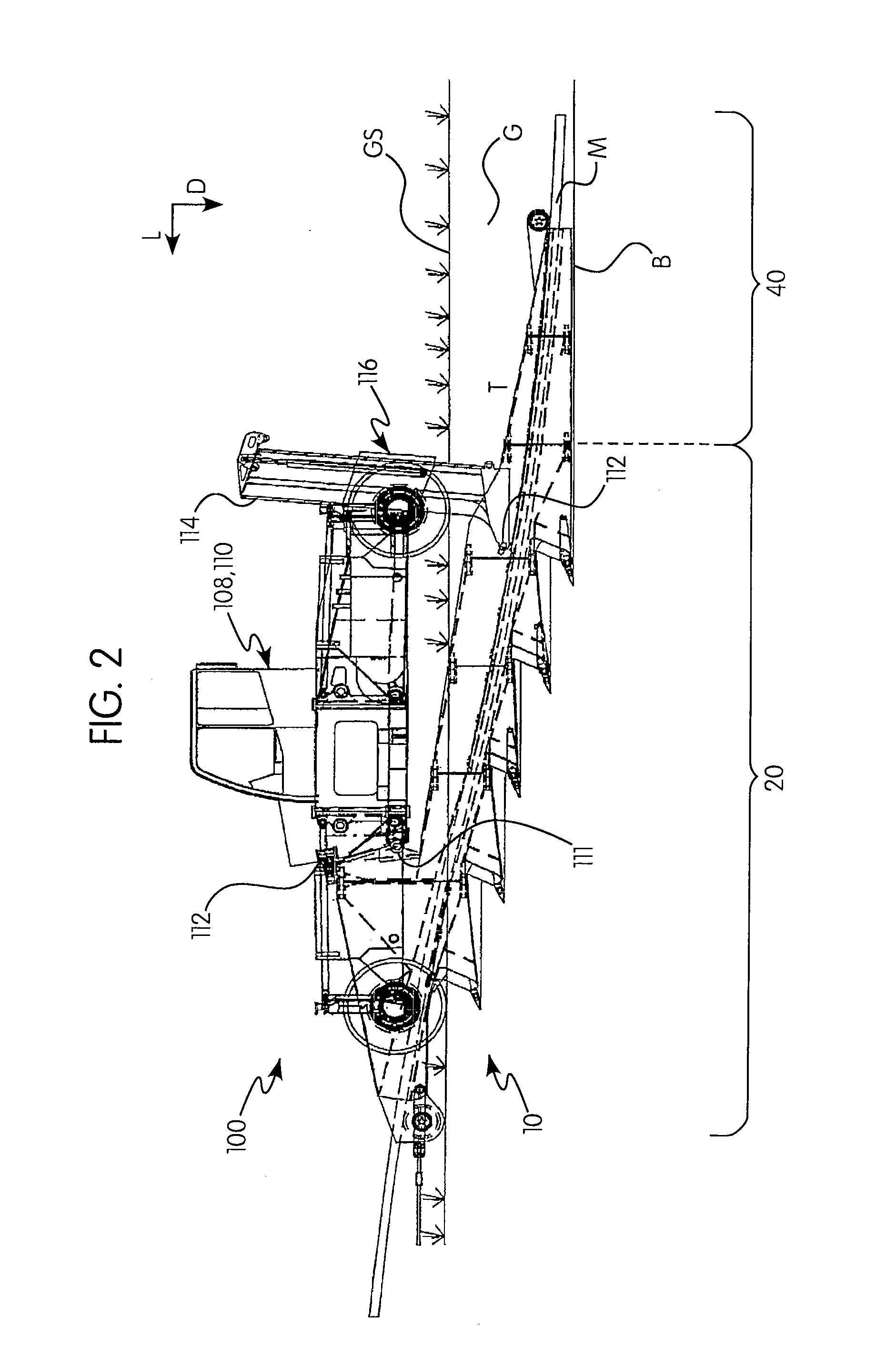

Strand-like material laying device for cutting the ground and inserting strand-like material into the ground

ActiveUS20090010716A1Smoothly feedSmooth feedingPipe laying and repairWaterborne vesselsSteel tubeEngineering

A strand-like material laying device for an appliance for laying any kind of strand-like material into the ground is disclosed. The strand-like material laying device is designed to lay a more rigid strand-like material such as steel pipes into the ground, and assures that the strand-like material to be laid can smoothly be fed into a trench formed in the ground without risking that a bending radius thereof falls below a minimum allowable bending radius which depends on the type of the strand-like material to be laid. The strand-like material laying device can also be immersed into the ground to form a subterranean trench while being moved in a longitudinal direction.

Owner:FOCKERSPERGER JR WALTER

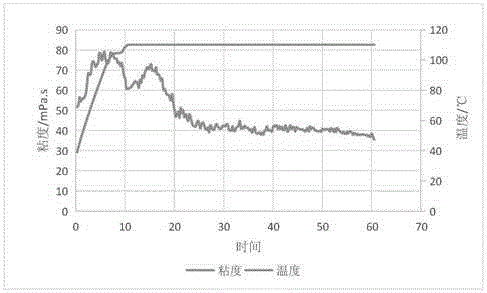

Method for preventing proppants in water-base fracturing fluid from settling in transfer process

InactiveCN105670597AAvoid destructionDestruction will notDrilling compositionActive agentCross linker

The invention discloses a method for preventing proppants in water-base fracturing fluid from settling in a transfer process. By enhancing the strength of a spatial network structure, the spatial network structure cannot be destroyed in a proppant transfer process, and the proppants always maintain a suspension state instead of settling in the fluid. Technical measures for enhancing the strength of the spatial network structure are as follows: crosslinking agents are used for being crosslinked with polyacrylamide polymers, wherein the crosslinking agents comprise a crosslinking agent A and a crosslinking agent B, the crosslinking agent A is an organic zirconium crosslinking agent, and the crosslinking agent B is a conventional crosslinking agent; the crosslinking agent B and the polyacrylamide polymers are subjected to physical crosslinking, and surfactant hydrophobic groups in the crosslinking agent B and hydrophobic groups in the polymers are subjected to a hydrophobic effect, so that the strength of the system spatial network structure is enhanced; the crosslinking agent A and the polyacrylamide polymers are subjected to chemical crosslinking, organic zirconium is subjected to hydration, hydrolysis and olation in a solution, and mutinuclear olation complex ions are formed and crosslinked with amide groups in the polymers, accordingly, the strength of the spatial network structure is further enhanced.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

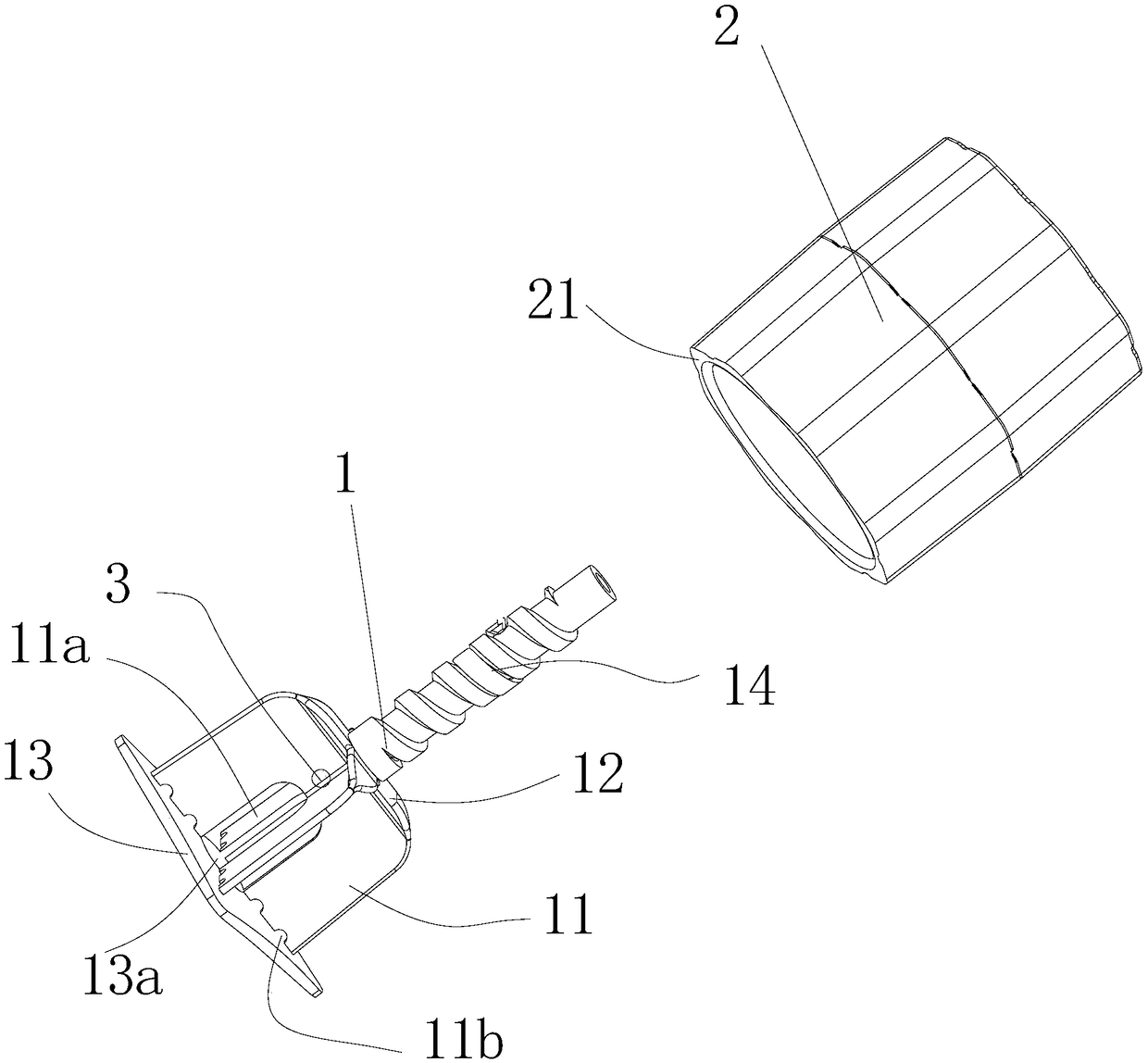

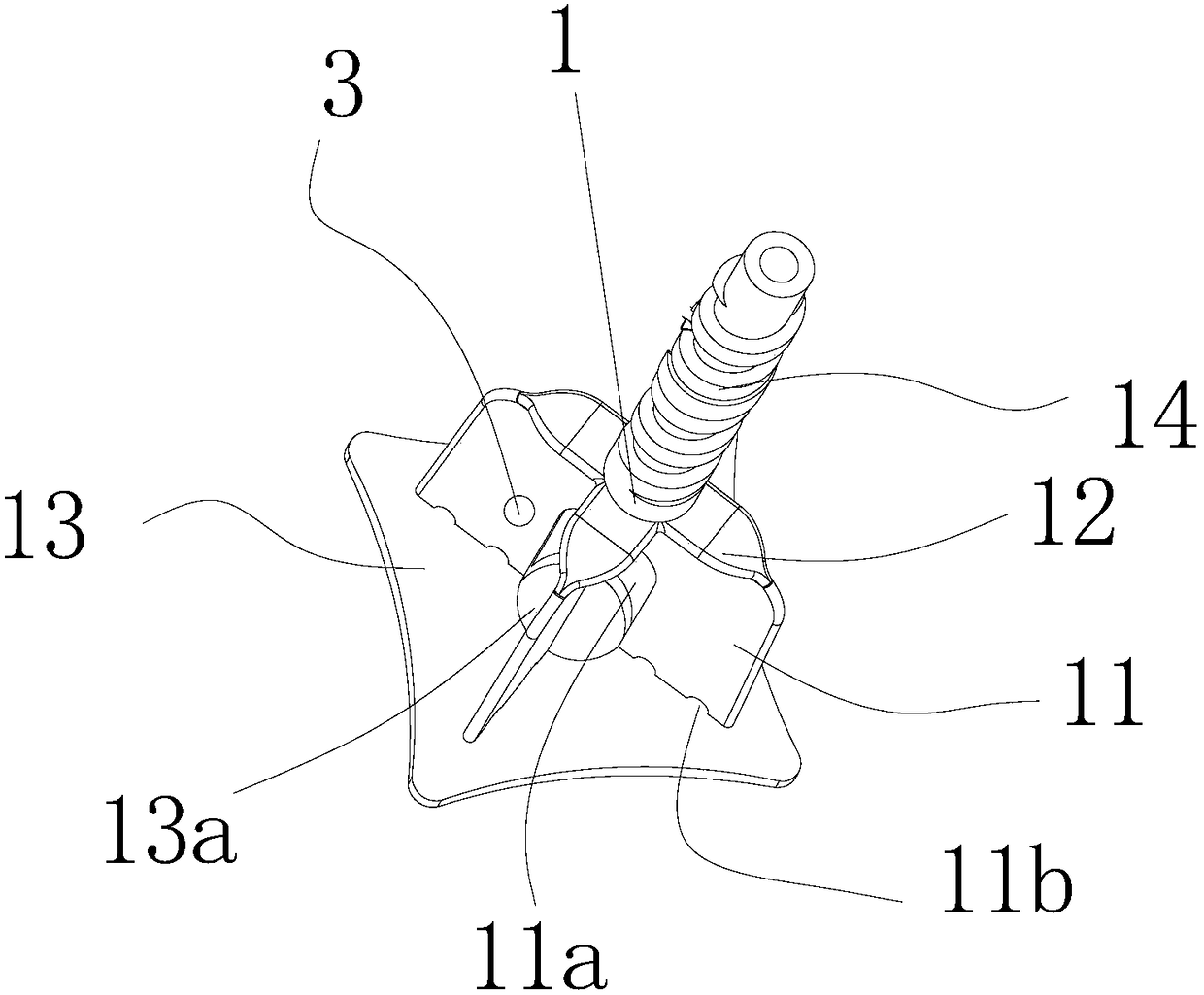

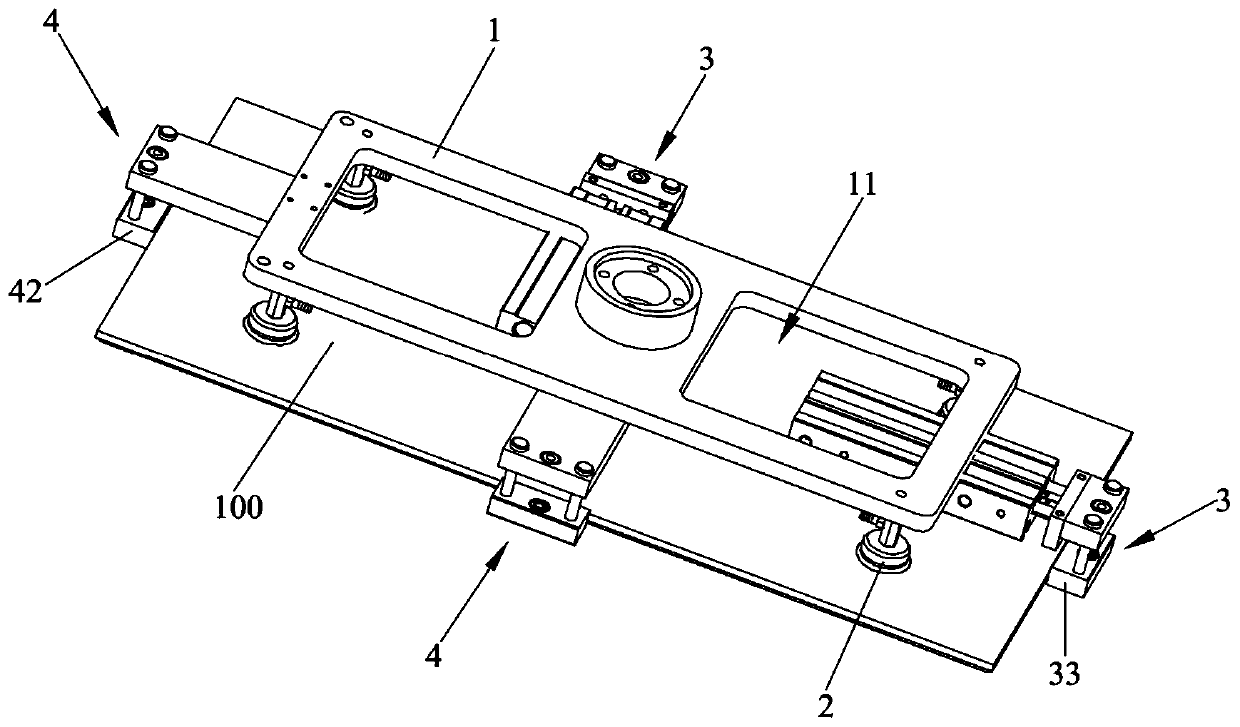

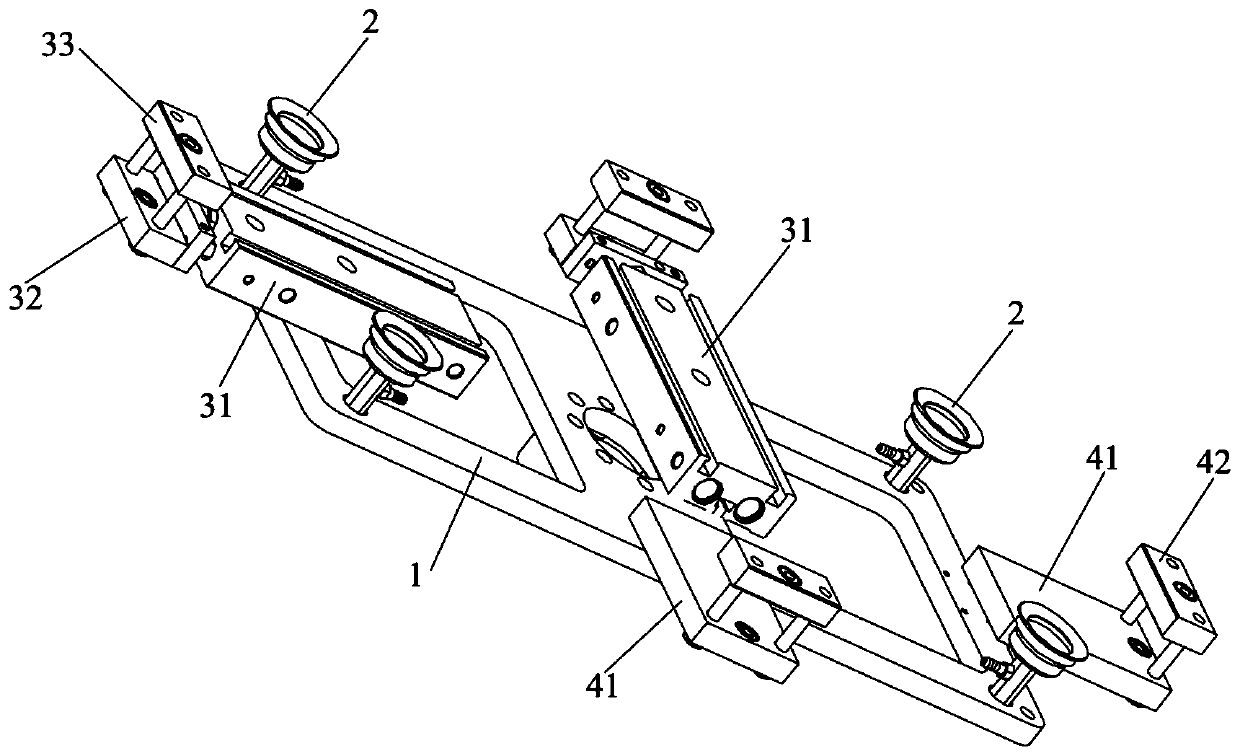

Ceramic tile clamping mechanism and ceramic tile laying robot

ActiveCN110905177AImprove laying accuracyPrevent slidingGripping headsBuilding constructionsCeramic tilesEngineering

The invention relates to the technical field of construction machinery, and discloses a ceramic tile clamping mechanism and a ceramic tile laying robot. According to the tile clamping mechanism provided by the invention, a sucking disc, a first clamping assembly and a second clamping assembly are arranged, and therefore, a tile can not only be sucked by the sucking disc, but also can be clamped bya first clamping piece and a second clamping piece, and the tile can be effectively prevented from sliding relative to the sucking disc through the cooperation of the first clamping piece and the second clamping piece, and accordingly the laying precision is improved advantageously; in addition, by arranging the first clamping piece and the second clamping piece to be liftable in the thickness direction of a mounting plate, that is, the first clamping piece and the second clamping piece can be moved in the thickness direction of the tile, the first clamping piece and the second clamping piececan be moved away from the tile in the direction close to the mounting plate when the tile is clamped in the laying position; and therefore, when tiles are laid, the first clamping piece and the second clamping piece are prevented from being inserted into gaps between adjacent tiles, and interference with tiles already laid beside is avoided.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

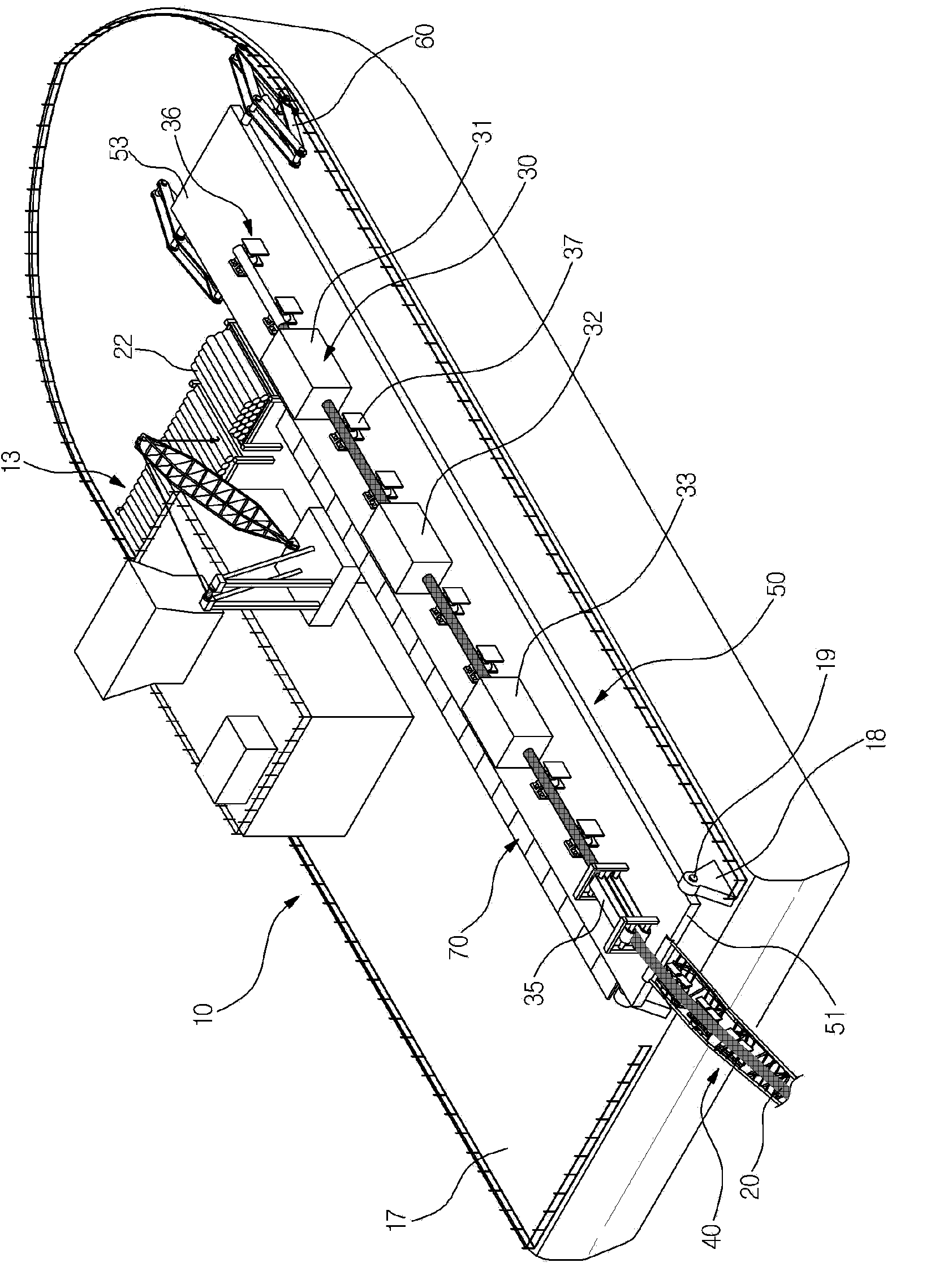

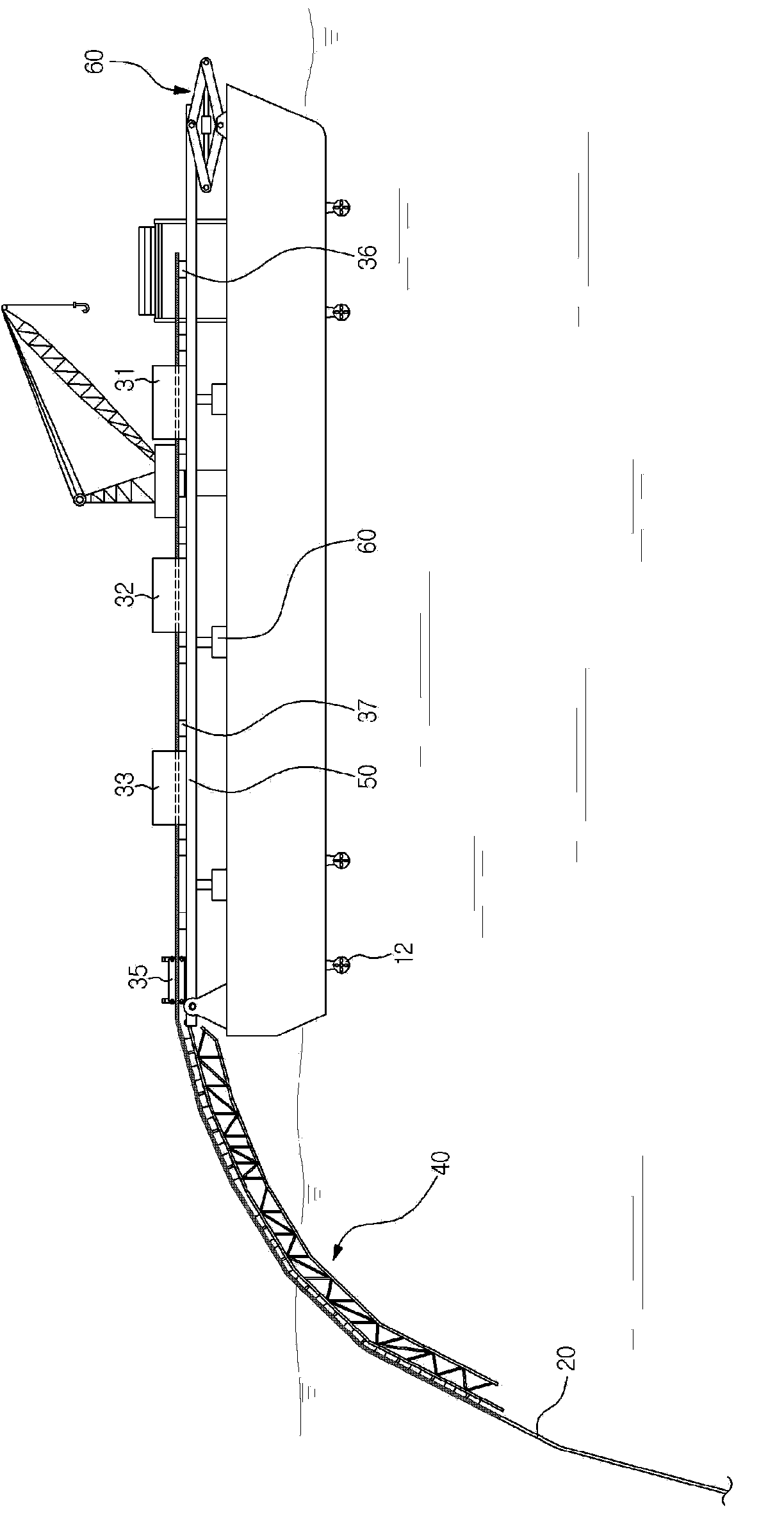

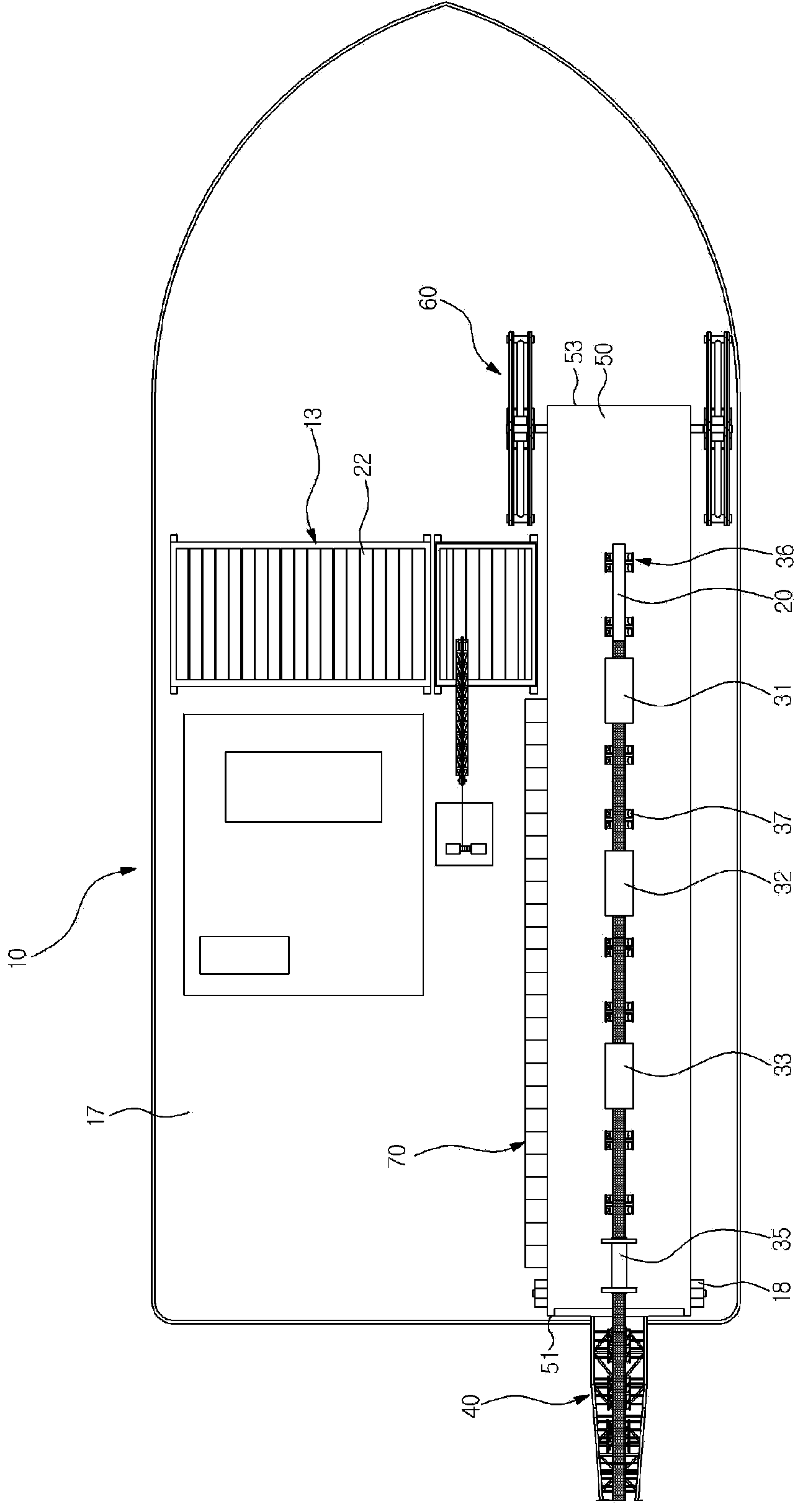

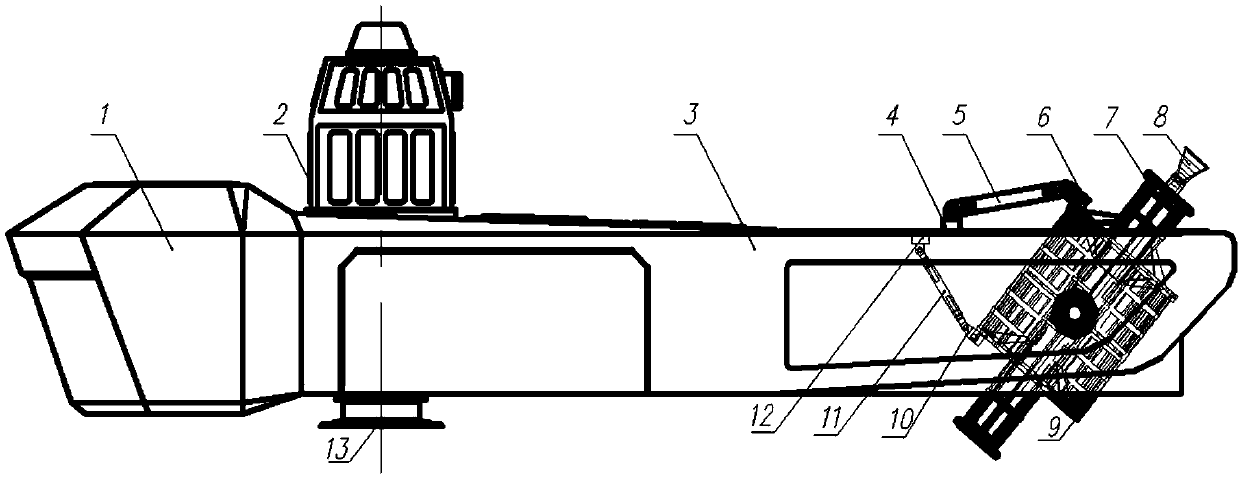

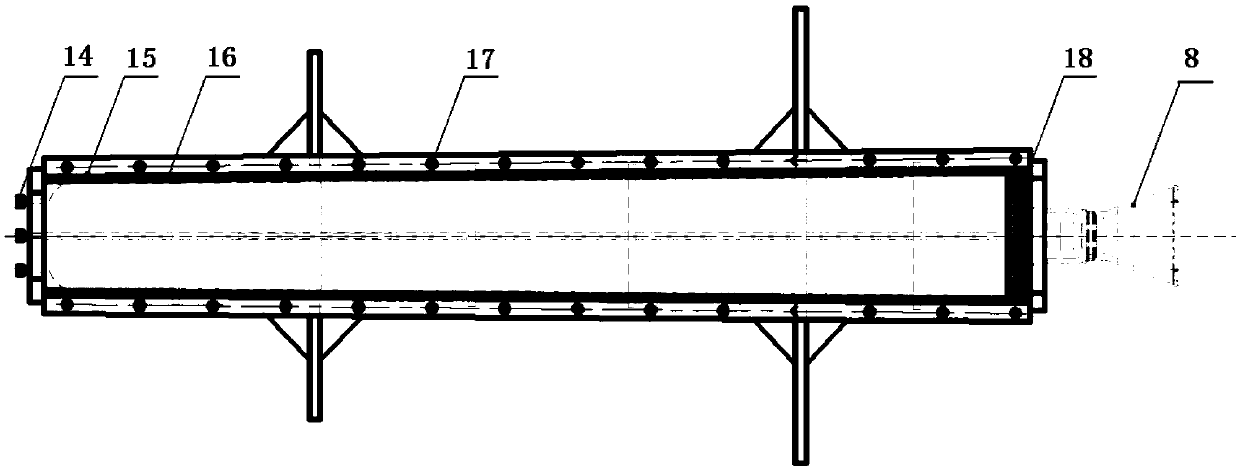

Pipeline-laying vessel and pipeline-laying method using same

ActiveCN104125915ASmooth layingLay evenlyPipe laying and repairPipe-laying vesselsMarine engineeringActuator

Disclosed are a pipeline-laying vessel and a pipeline-laying method using same. According to one embodiment, the pipeline-laying vessel comprises: a platform which is provided along the pipeline-laying route and on which is placed one or more work stations where pipeline assembly is carried out; a stringer which is connected near to one end of the platform and guides the pipeline to the sea floor; and a raising-and-lowering actuator which adjusts the angle of inclination of the platform.

Owner:SAMSUNG HEAVY IND CO LTD

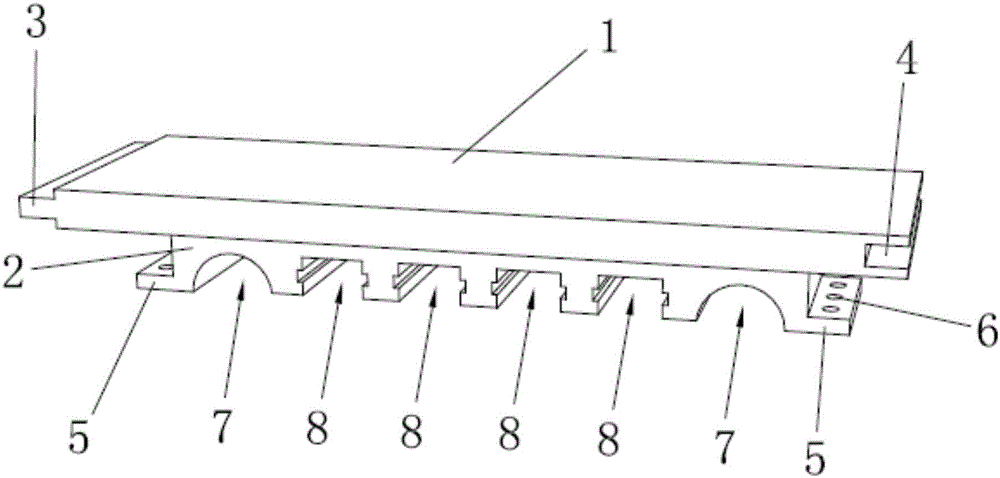

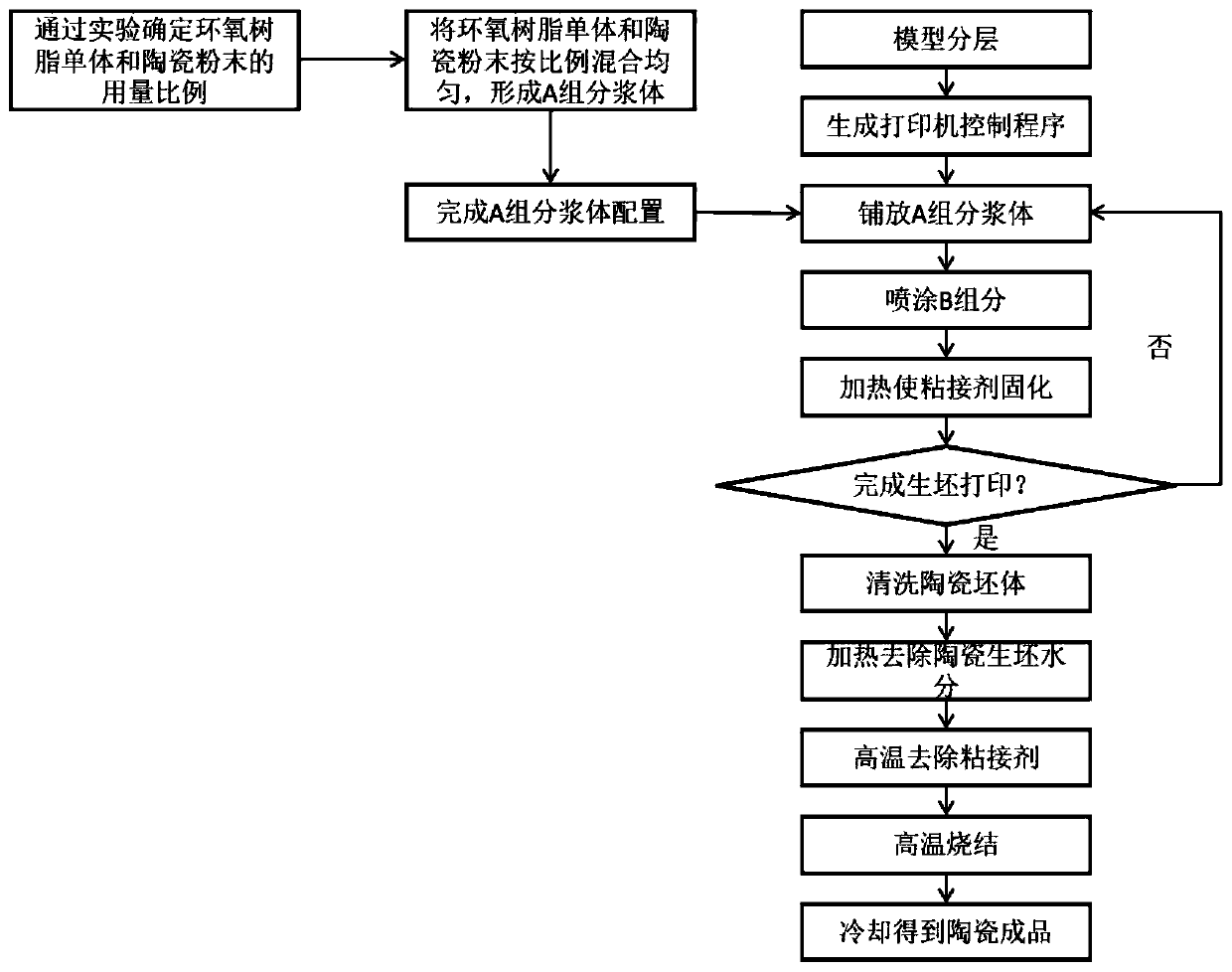

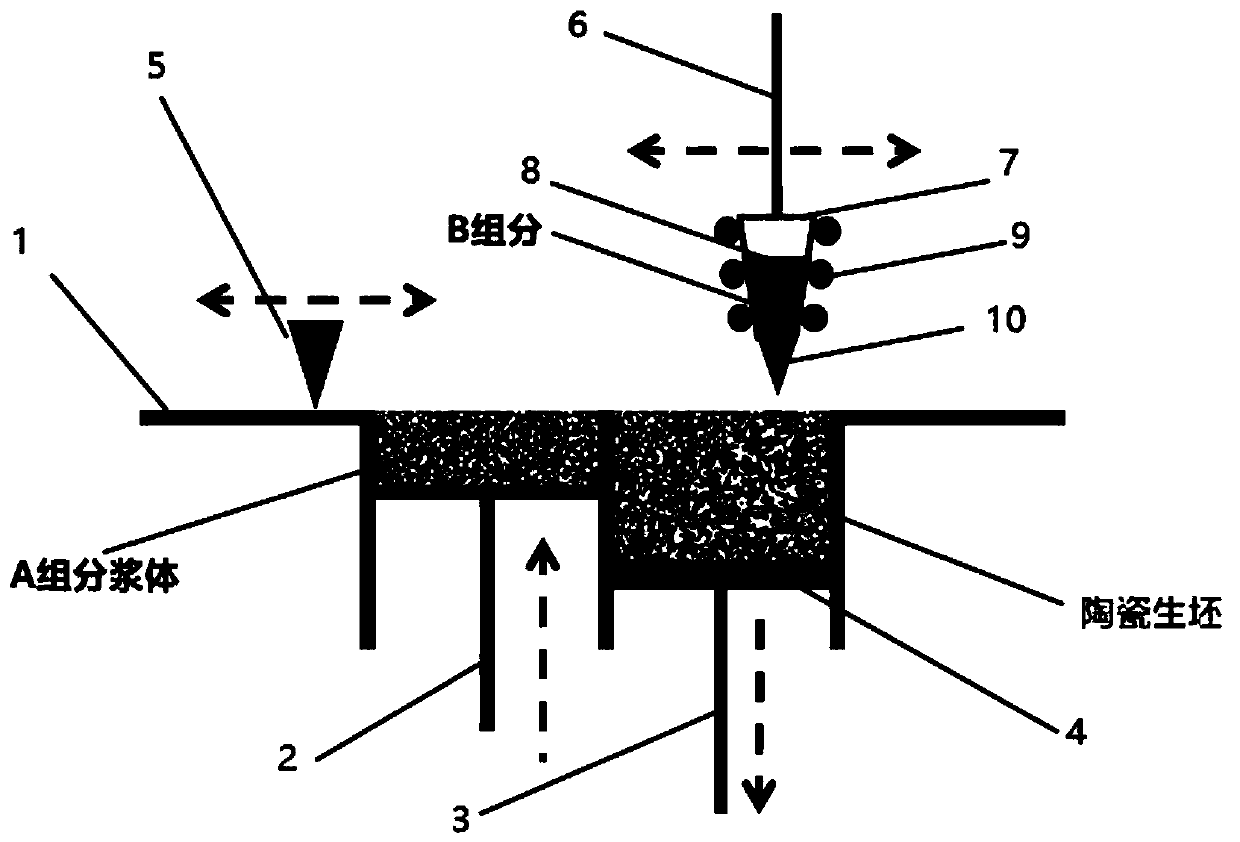

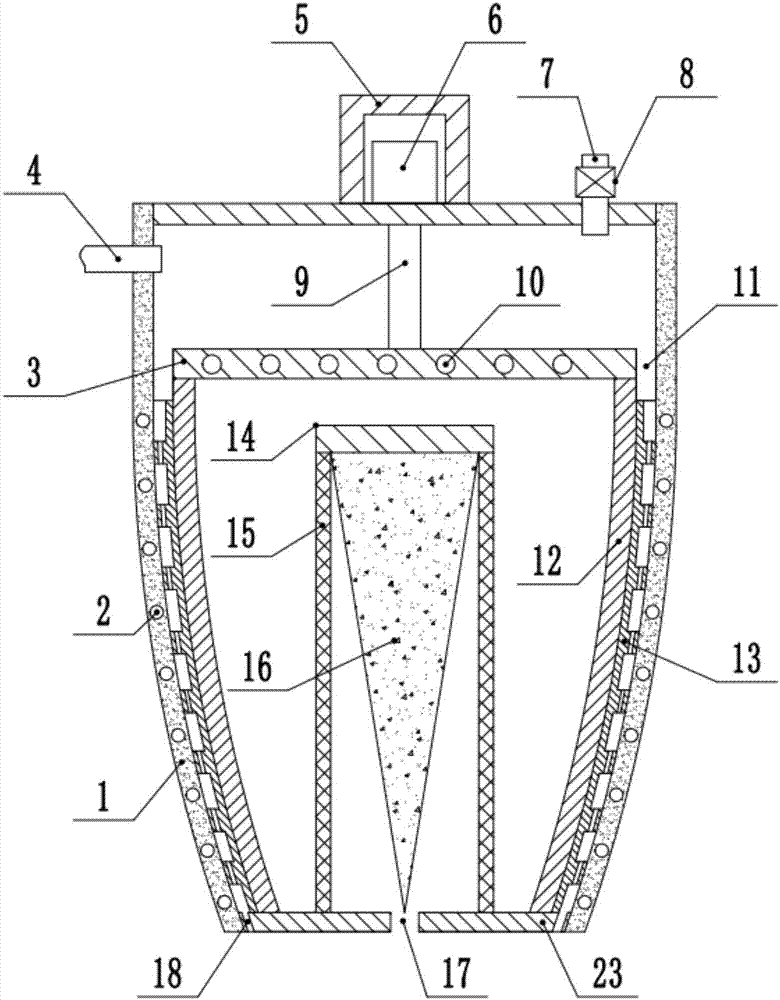

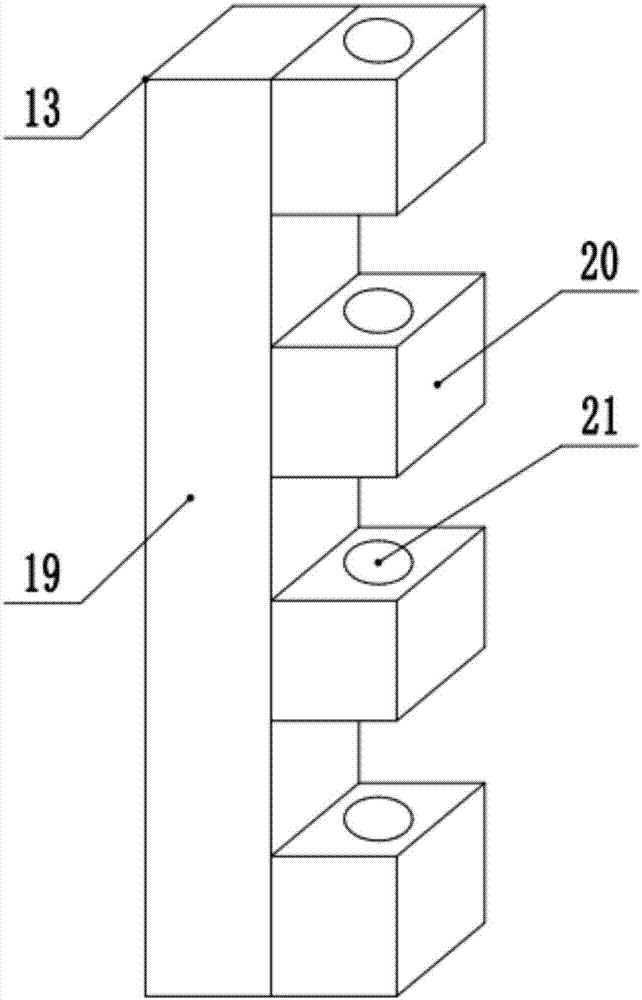

Thermosetting bonding based ceramic additive production method and equipment

PendingCN110240485ASmall molecular weightReduce stickingAdditive manufacturing apparatusCeramic shaping apparatusEpoxyMetallurgy

The invention relates to a thermosetting bonding based ceramic additive production method. The method comprises the steps: layering a mold for ceramic parts required to be printed, determining an area required to be bonded of each layer, and creating a printer control program; uniformly mixing an epoxy resin monomer with ceramic powder to form slurry with relatively good fluidity as component A slurry, wherein for a consumption ratio of the epoxy resin monomer and the ceramic powder, the proportion of the ceramic powder in the component A slurry should be as high as possible on the premise of meeting the requirements on fluidity so as to achieve that a final ceramic finished product is high in compactness and low in shrinking percentage; laying a layer of component A slurry on a working tray; spraying a hardener of epoxy resin as a component B to the area required to be bonded of the corresponding layer with a sprayer according to the program; heating the ceramic powder of the corresponding layer with a heating device; carrying out printing layer by layer until a complete ceramic green body is formed; carrying out washing clean; and carrying out high-temperature calcination. The invention simultaneously provides equipment achieving the method, i.e., a ceramic powder bonding printer.

Owner:TIANJIN UNIV

Scraper type molecular distillation device

The invention discloses a scraper type molecular distillation device, which comprises a body and a condenser; the body is provided with a partition, the partition is disc-shaped, and the partition divides the interior of the body into an upper cavity and a lower cavity; Two strip-shaped scrapers are installed symmetrically on the left and right sides of the bottom of the partition. The scraper is composed of a mounting plate and a number of scraping blocks, and the scraping blocks are fixed on the outer surface of the scraper through the mounting plate; The scrapers are equidistantly arranged, and the scrapers are close to the inner wall of the body, and the corresponding positions of each scraper are provided with through holes that can communicate with each other; the condenser is fixedly installed inside the lower cavity, and the condenser It consists of a filter screen and a condensation funnel. In the present invention, a scraper with several scrapers is arranged on the scraper, and each scraper is provided with a through hole that can communicate with each other at the corresponding position, so as to reduce the flow velocity of the mixed solution and make the mixed solution evenly spread on the device. On the inner wall, the distillation effect is improved.

Owner:惠安县泉联智能设备技术开发有限公司

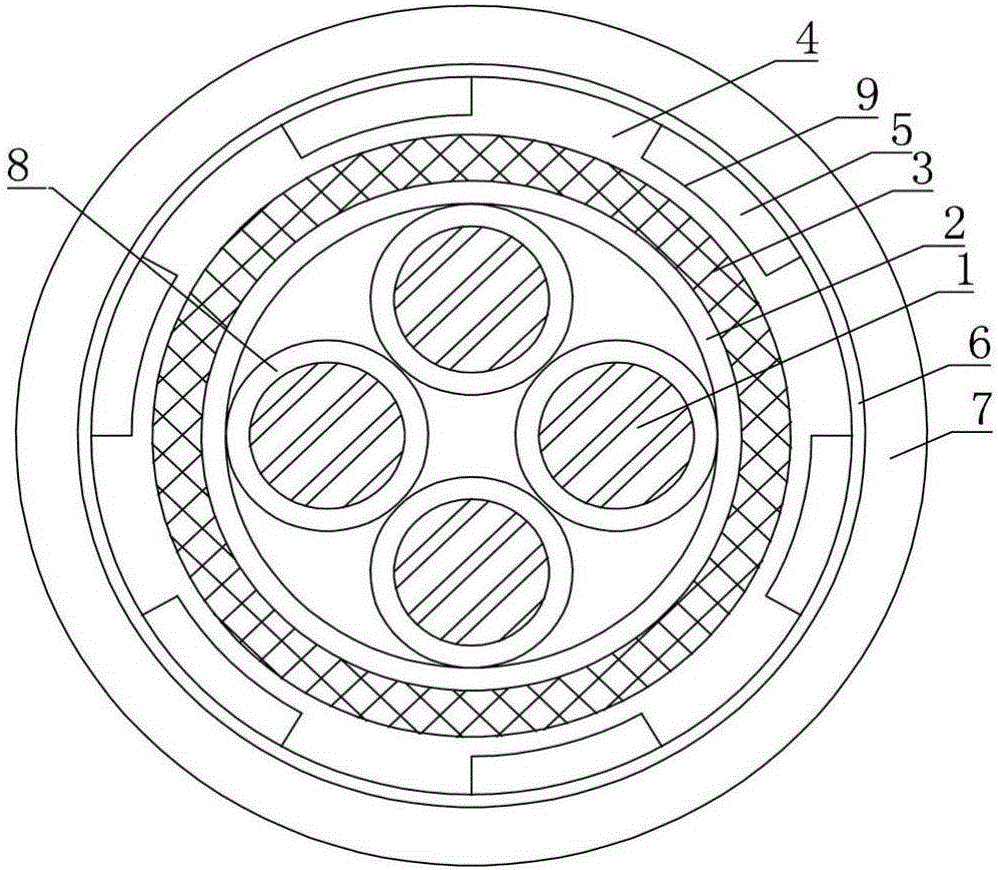

Isolated type fireproof cable

InactiveCN106098226AGood waterproof and explosion-proof effectLay evenlyClimate change adaptationInsulated cablesEngineeringElectrical conductor

The invention discloses an isolated type fireproof cable, belongs to the wire and cable field, and solves the problems that the laying effect of a fireproof layer is bad and the explosion-proof effect is bad for the existing cable. The isolated type fireproof cable comprises a conductor, an outer insulating layer at an outer side of the conductor, an isolated sleeve tube arranged at an outer side of the outer insulating layer, a tooth form sleeve arranged out of the isolated sleeve tube, a fireproof layer arranged at an outer side of the tooth form sleeve, a halogen-free flame retardant band arranged at an outer side of the fireproof layer, and a low-smoke halogen-free sheath arranged out of the halogen-free flame retardant band. The conductor is formed by twisting conductive wires. An inner insulating layer is arranged out of each conductive wire and formed by a mineral compound. The outer insulating layer is formed by a mineral compound. The isolated sleeve tube is a metal sleeve tube. The fireproof layer is laid more evenly through the tooth form sleeve, and the explosion-proof performance of the cable is improved. The machinery damage of the conductor is avoided by arranging the isolated sleeve tube. The fireproof layer can cool and dilute the flame during the combustion and quench the flame.

Owner:CHONGQING CITY SOUTH FLAME RETARDANT WIRE & CABLE CO LTD

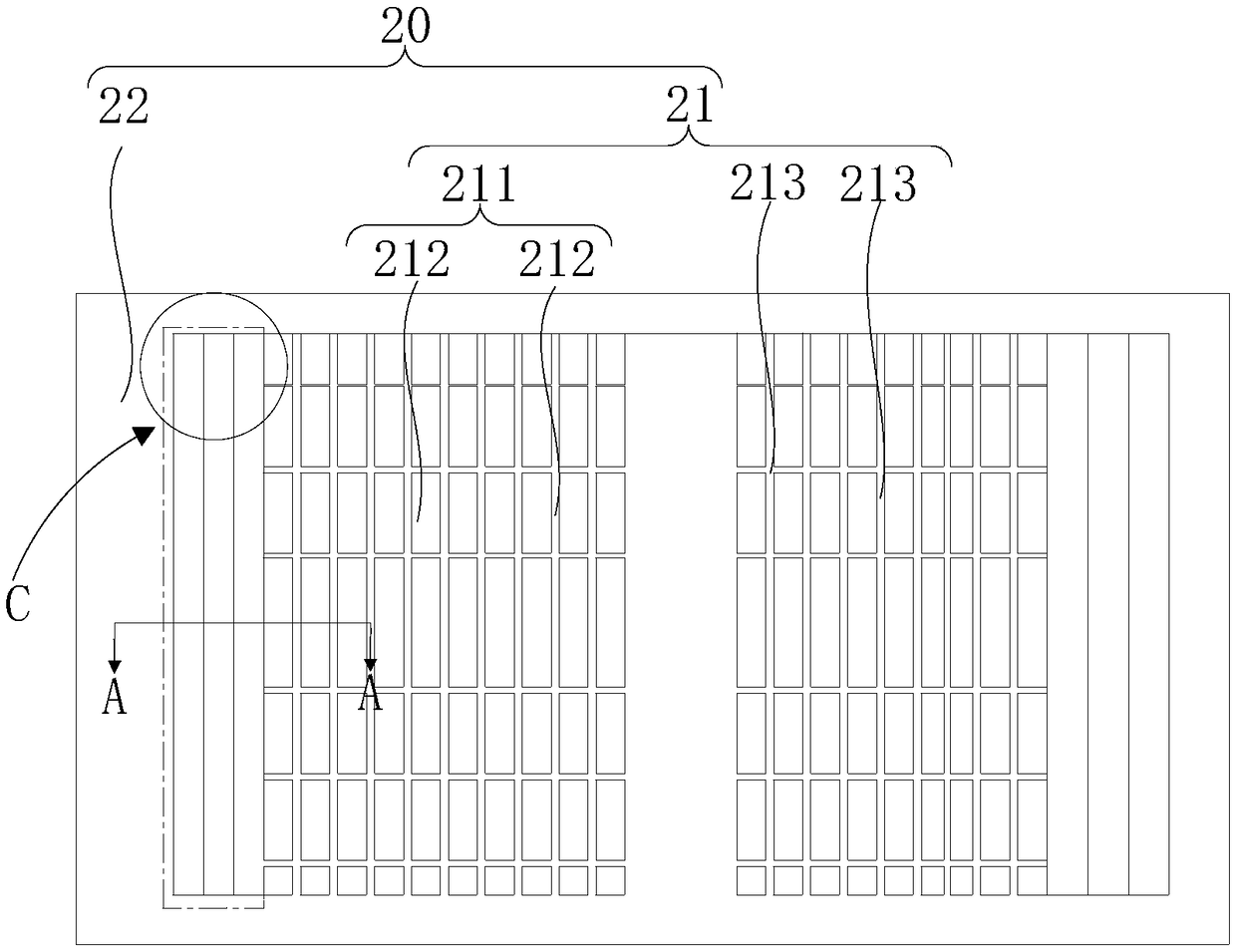

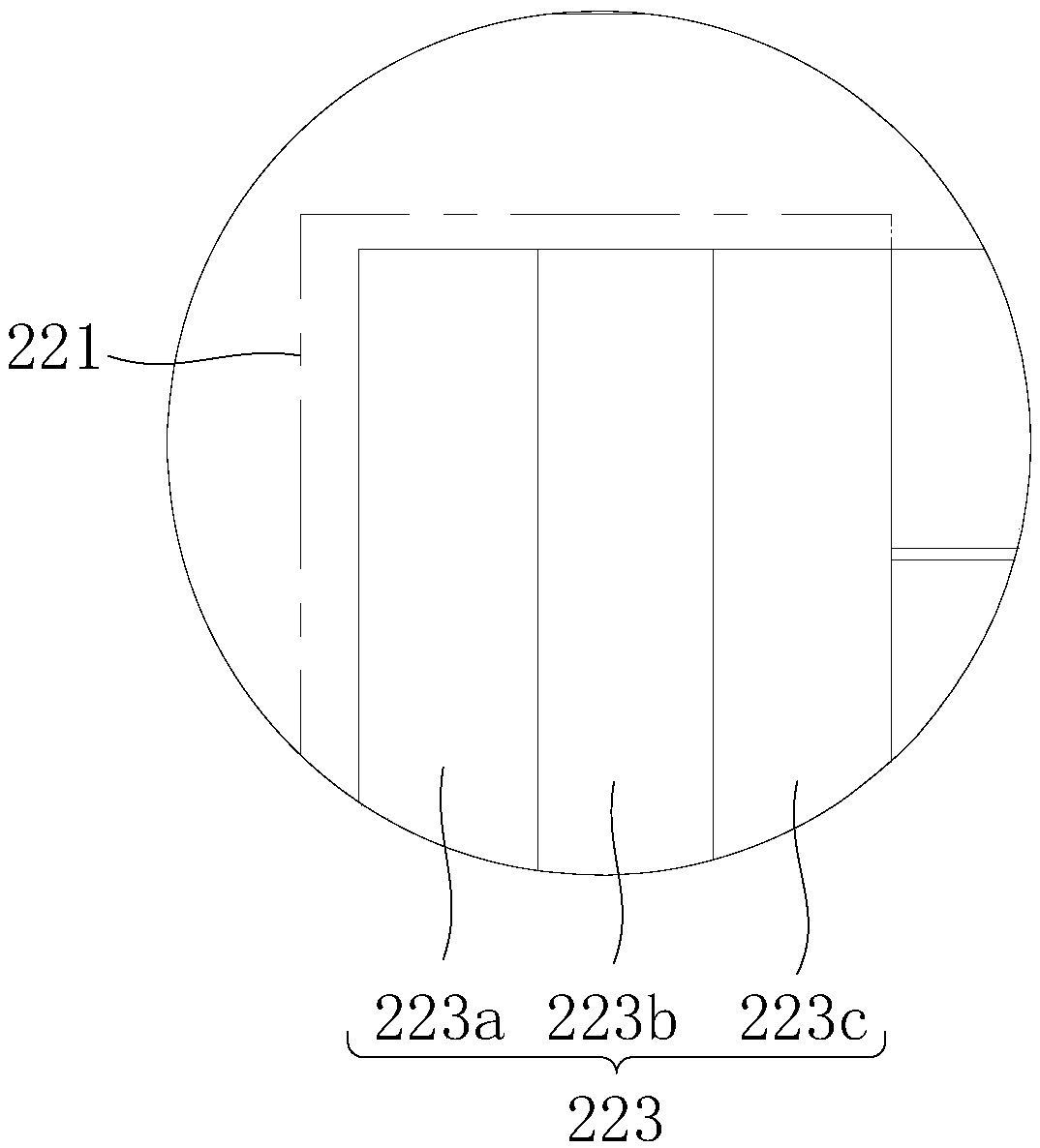

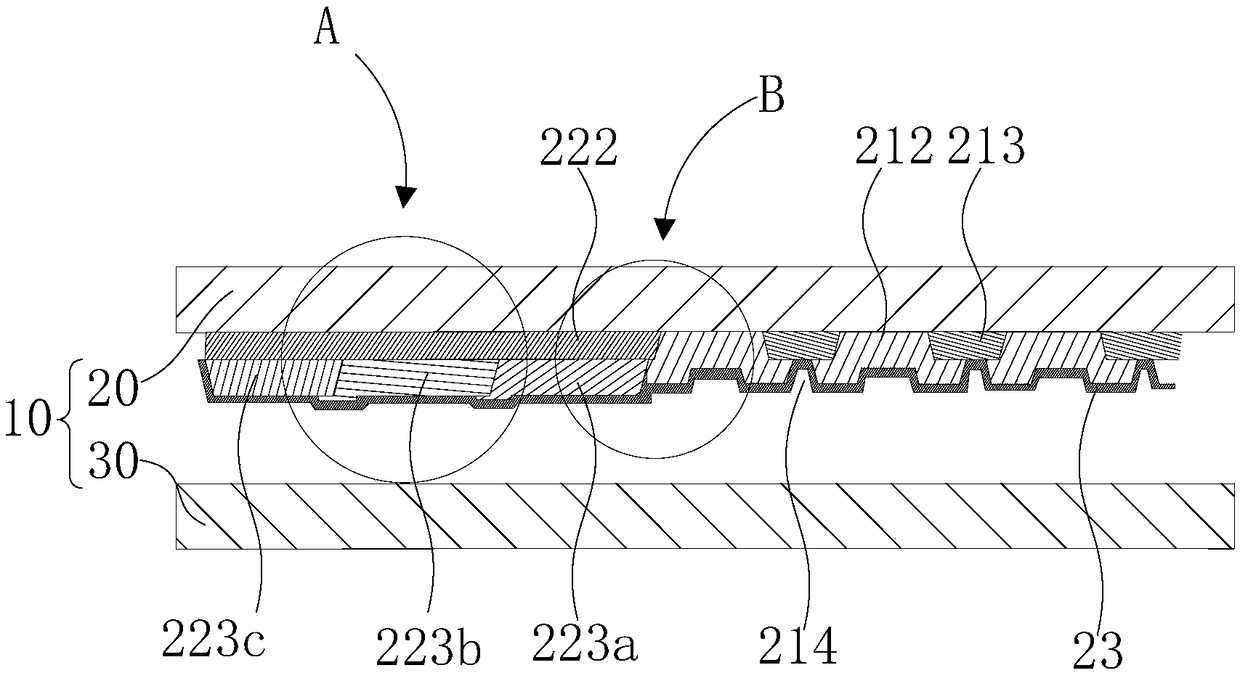

Display panel, processing method thereof and display device

ActiveCN109239963AAvoid inconsistent widthImprove flatnessNon-linear opticsOptical elementsDisplay deviceComputer science

The invention discloses a display panel, a processing method thereof and a display device. The display panel comprises a first substrate and a second substrate, and a color resistor is arranged on thefirst substrate; the first substrate comprises a display area and a non-display area arranged on the outer side of the display area, wherein the display area comprises a display color resistor area;the non-display area comprises a dummy color resistor area, a dummy color resistor is arranged on the dummy color resistor area, and the surface evenness of the dummy color resistor of the non-displayarea is higher than that of the display color resistor area of the non-display area; the outer surface of the display color resistor area and the outer surface of the dummy color resistor form an alignment film, the surface evenness of the dummy color resistor surface of the dummy color resistor area is higher than that of the display color resistor area of the display area, and the alignment film is conveniently uniformly and completely paved on the outer surface of the display color resistor area and can be dispersed onto the dummy color resistor.

Owner:CHONGQING HKC OPTOELECTRONICS TECH CO LTD +1

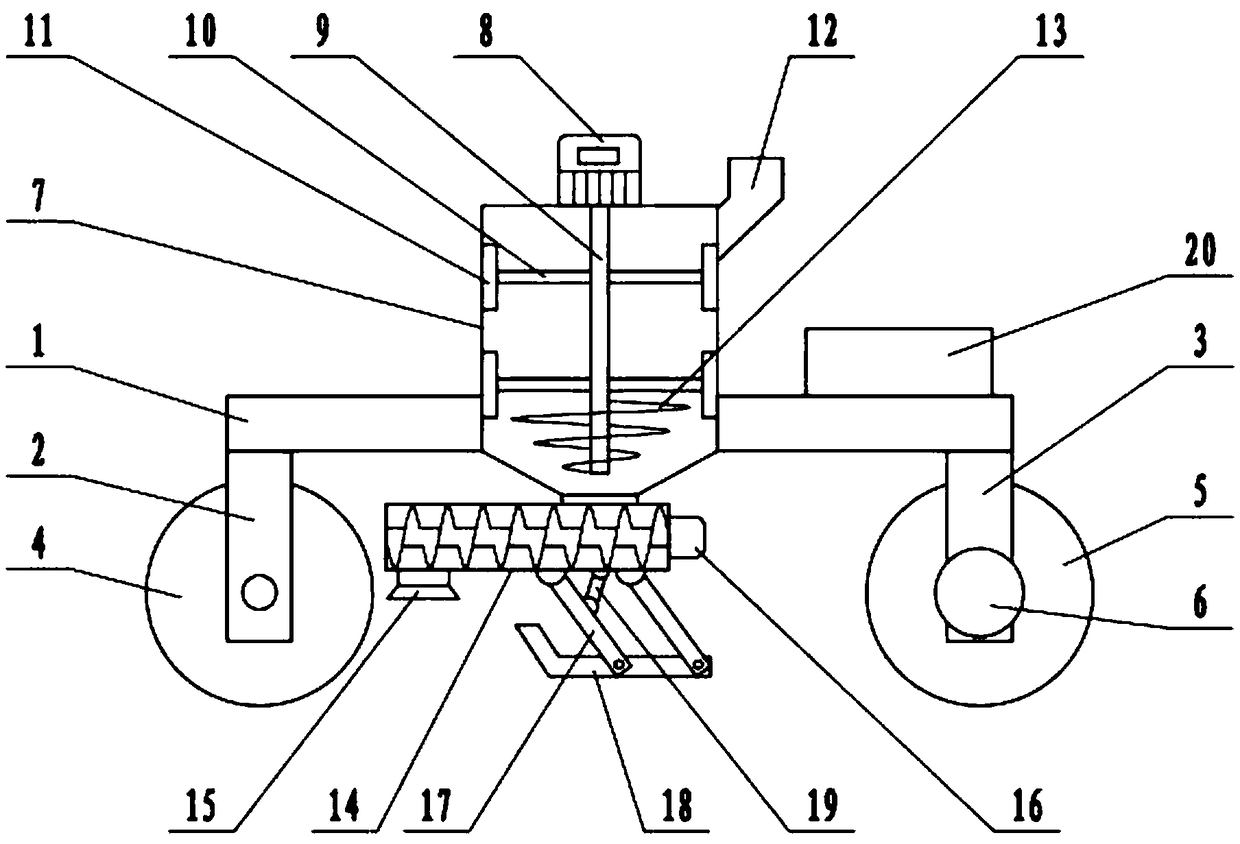

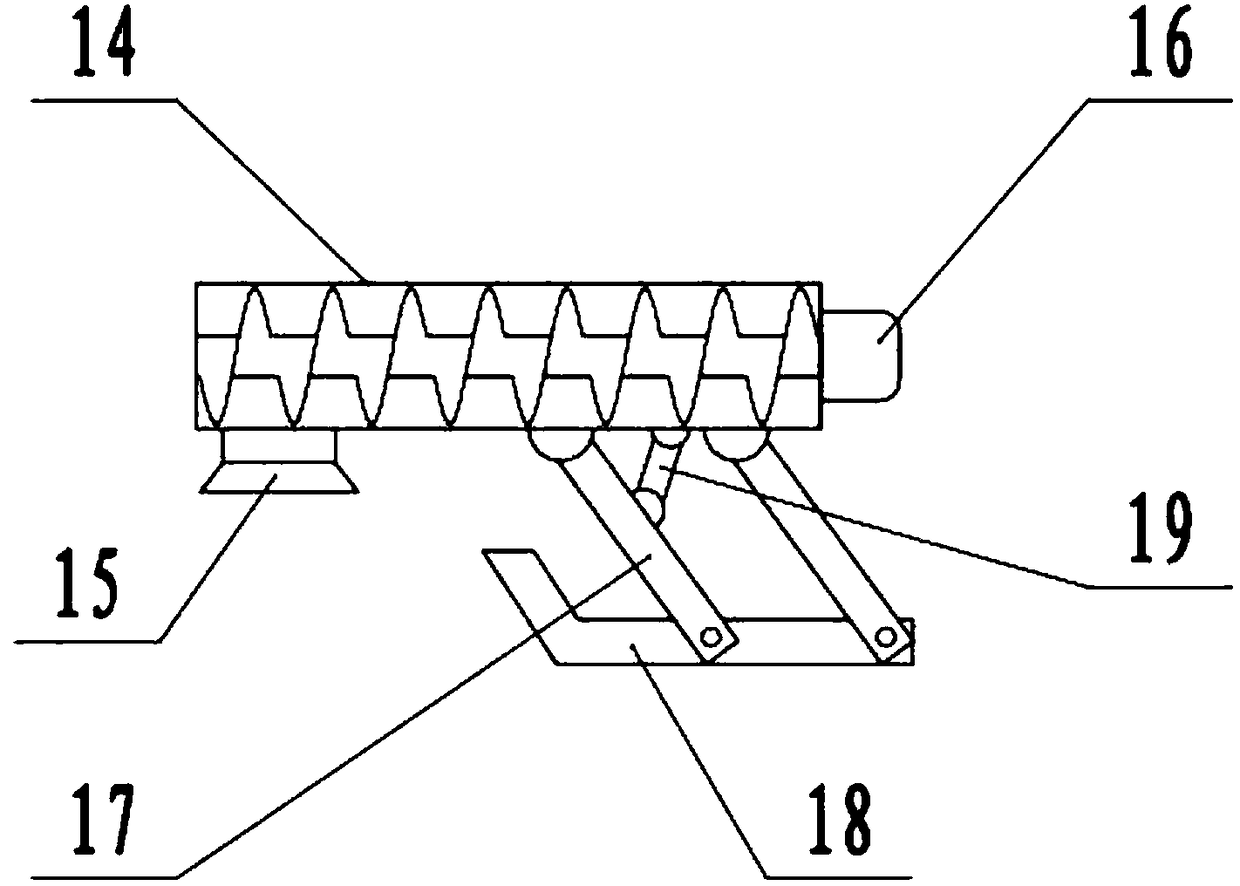

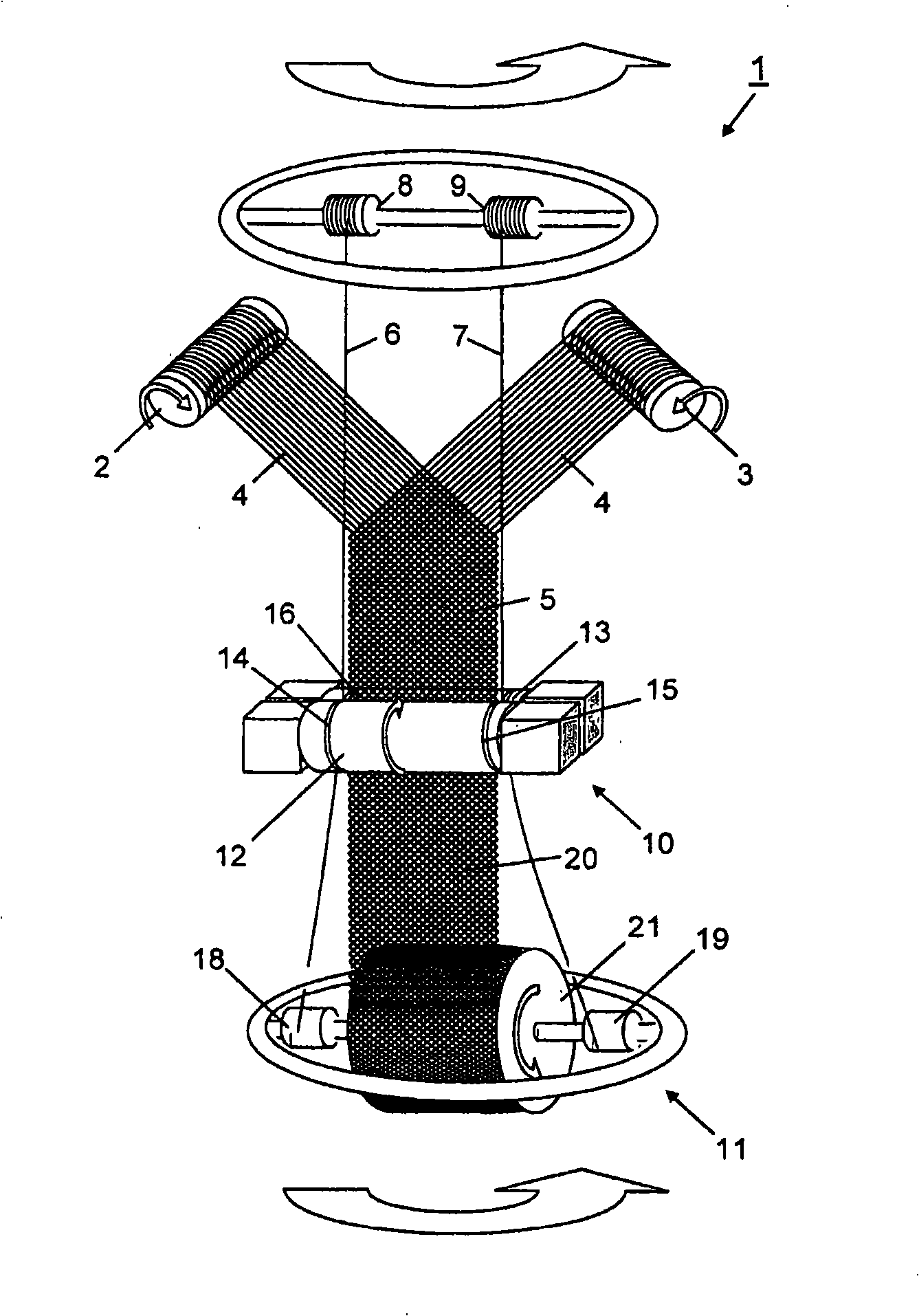

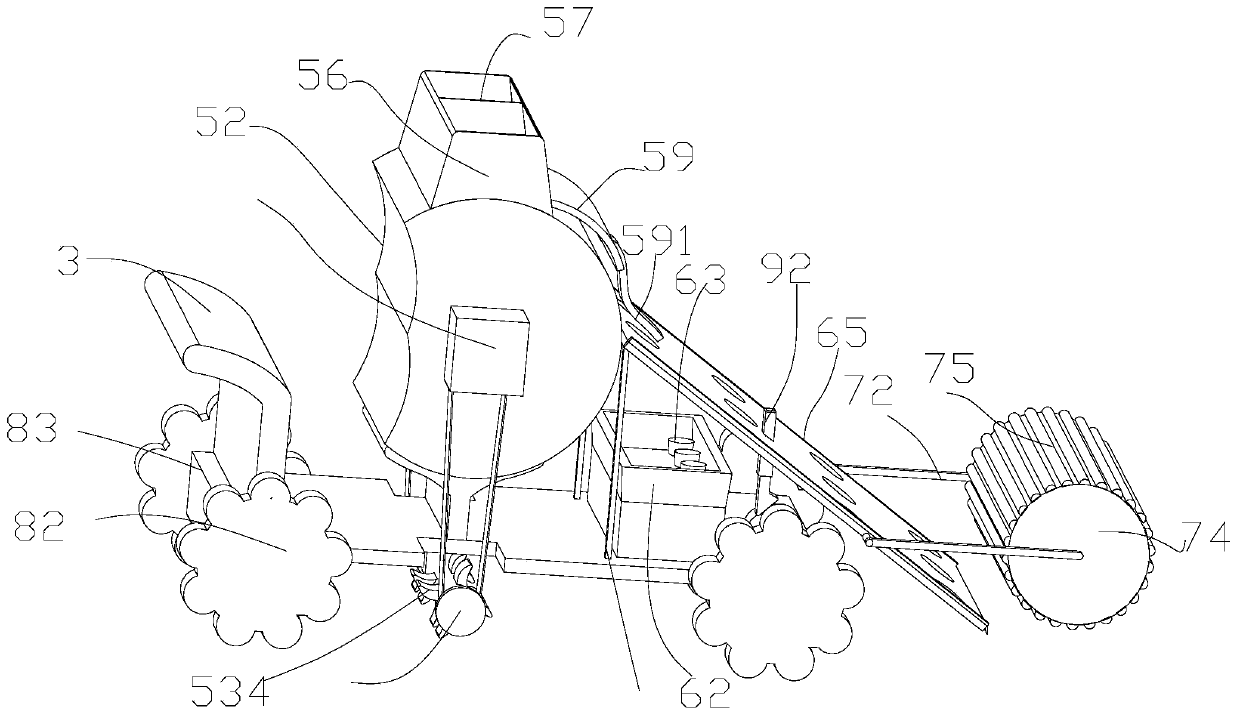

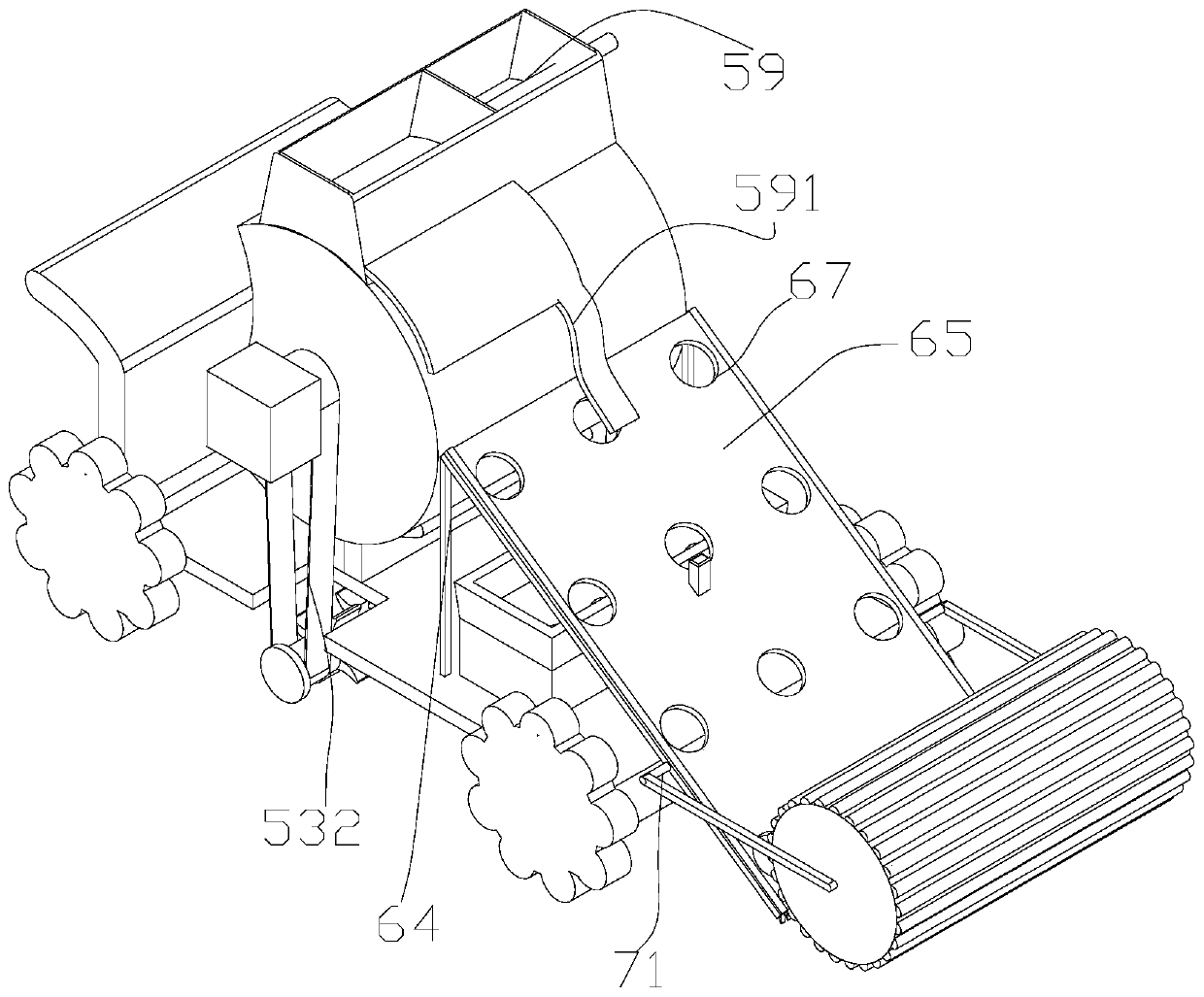

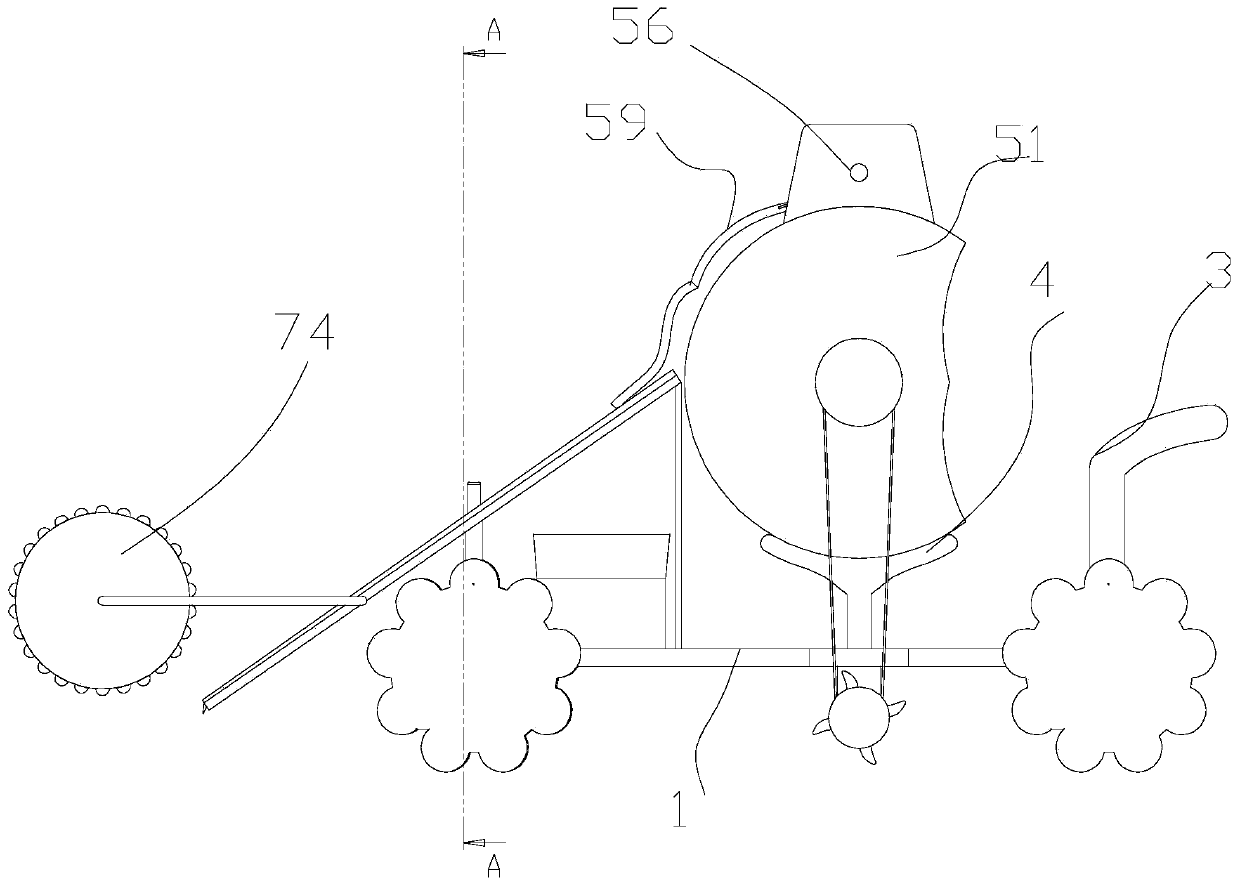

Garden grass spreader

InactiveCN111328644AUniform speedWide range of adaptationSpadesHops/wine cultivationAgricultural engineeringBiology

The invention discloses a garden grass spreader. The garden grass spreader comprises a baseplate, rolling parts disposed on the left and right sides of the baseplate, a handle disposed on the left rolling part, a Y-shaped bracket disposed on the left side of the upper end of the baseplate, a feeding mechanism disposed on the upper end of the Y-shaped bracket, a water-spaying mechanism disposed onthe right side of the upper end of the baseplate, a compacting mechanism disposed on the right side of the water-spaying mechanism. The feeding mechanism comprises a roller, a groove disposed on the left side of the roller, a shearing mechanism disposed below the roller, a first rotating shaft through the inner of the roller, a motor disposed on the front of the first rotating shaft, a feeding boxdisposed above the roller, a pushing plate disposed the inner of the feeding box, a pushing rod disposed on the rear of the pushing plate, wherein the pushing rod can move forward and backward in thefeeding box, an arc plate disposed on the right side of the outside of the feeding box and a limiting bar disposed on the rear of the lower end of the arc plate. According to the invention, turf is transported by the roller, then slides down through the net board, and is laid on the ground. A cam can drive the top block to move up and down, and the turf is intermittently transported. The garden grass spreader has the advantages of faster laying speed, time and labor saving, and convenience and efficiency.

Owner:孙利成

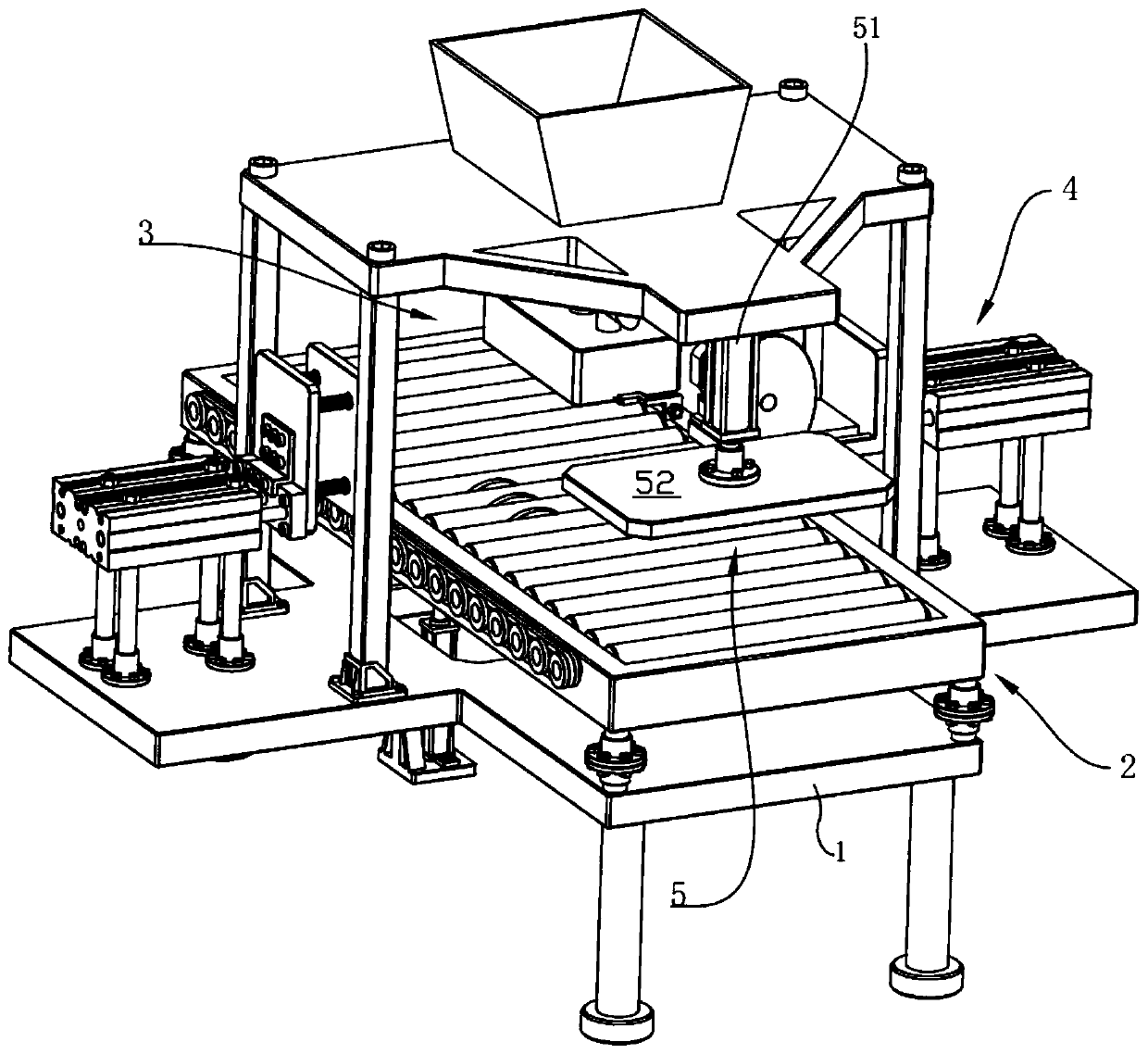

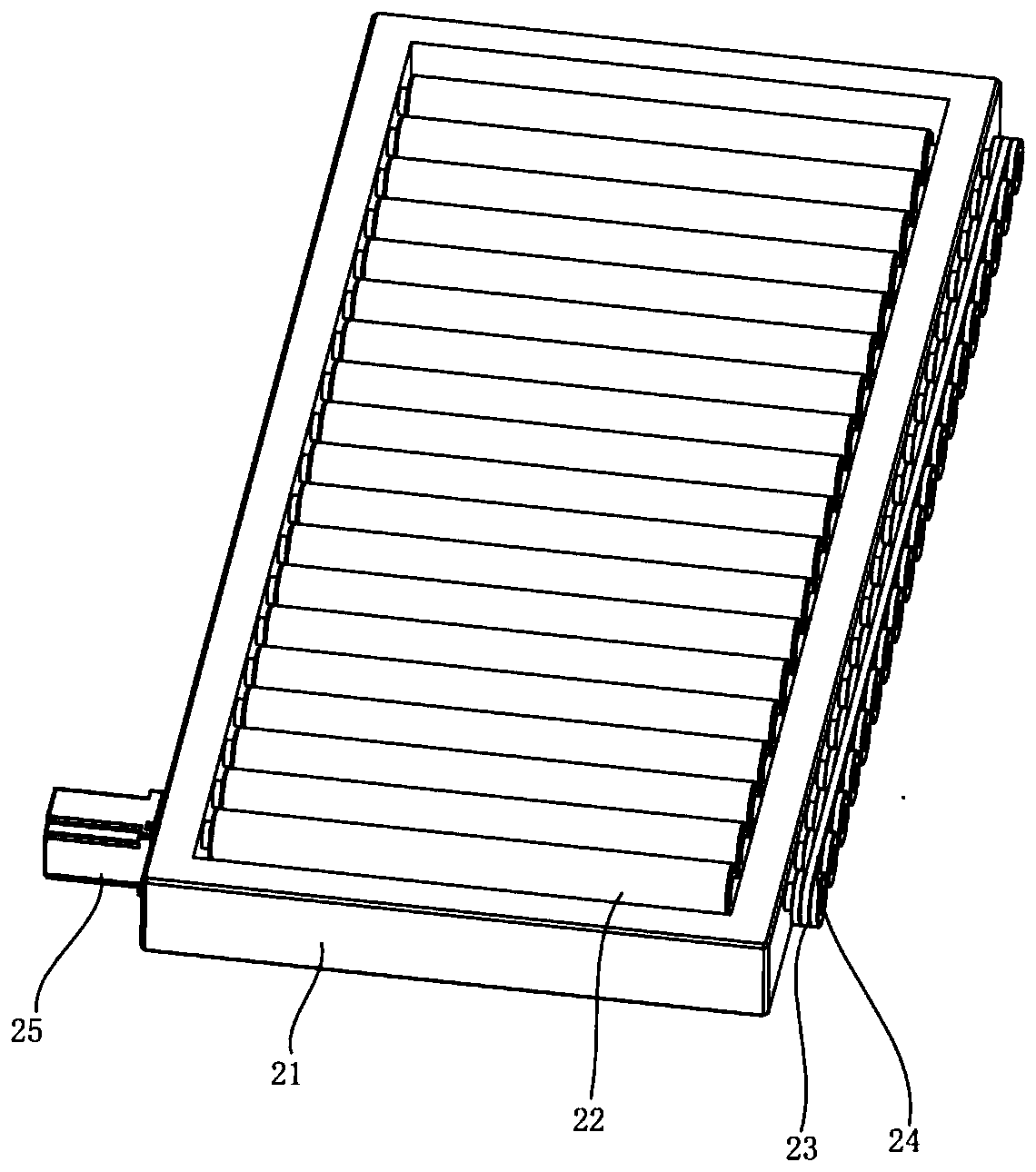

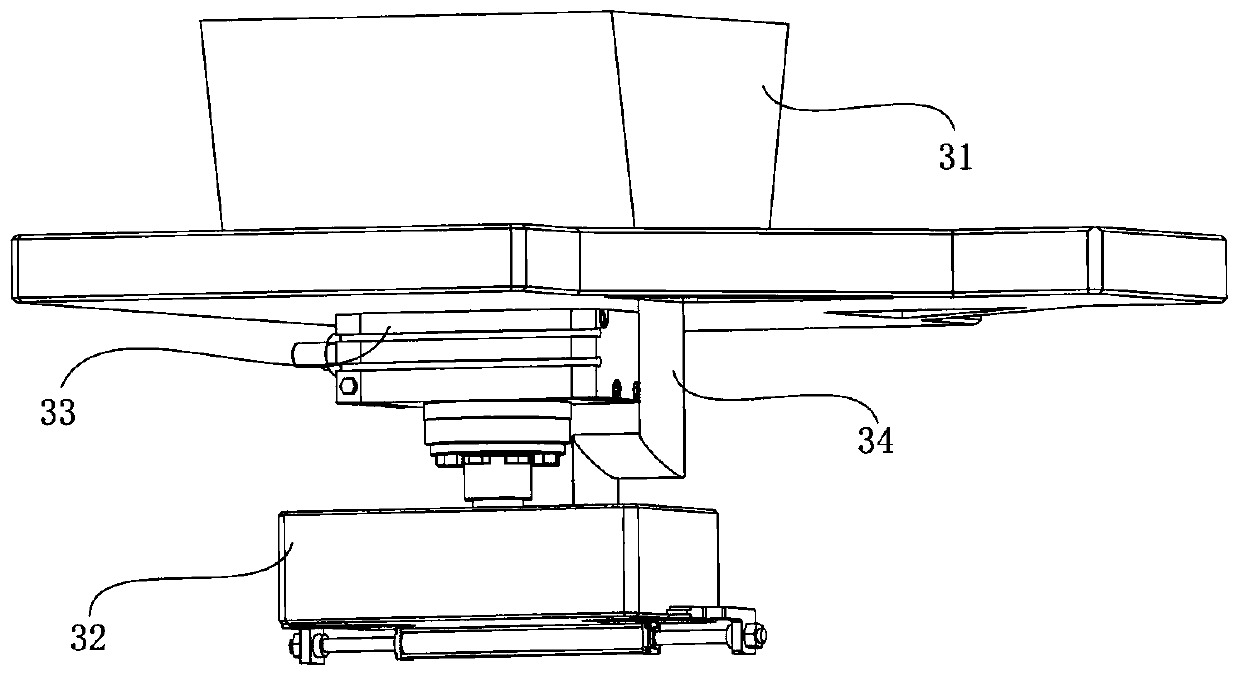

Forming device for sand casting cavity

The invention provides a forming device for a sand casting cavity. The forming device comprises a machine frame, a conveying mechanism, a sand discharging mechanism, a material shaking mechanism and acompacting mechanism; the sand discharging mechanism comprises a feeding hopper, a discharging box, a rotary cylinder, an elastic hose, two drawing plates and a dual-direction cylinder, the discharging box is installed on the upper layer plate of the machine frame through the rotary cylinder, the discharging box communicates with the feeding hopper through the elastic hose, the two drawing platesare separately installed at the bottom of the discharging box in a movable mode, discharging holes are formed in the drawing plates; and the ends, provided with the discharging holes, of the drawingplates extend into the discharging box, the two drawing plates are correspondingly and fixedly connected to power output ends at the two ends of the dual-direction cylinder, and the material shaking device is installed on the machine frame. The discharging box is driven to rotate back and forth by the rotary cylinder, the drawing plates are driven to move back and forth by the dual-direction cylinder, so that when discharging is performed, the positions of the discharging holes relative to the side edge of the discharging box are changed constantly, forming sand are uniformly laid in a sand box when sand discharging is performed, and the forming sand is enabled to be more tight.

Owner:LINYI TIANKUO CASTING CO LTD

Strand-like material laying device for cutting the ground and inserting strand-like material into the ground

ActiveUS7841802B2Smooth feedingIncrease working depthPipe laying and repairWaterborne vesselsEngineeringBend radius

A strand-like material laying device for an appliance for laying any kind of strand-like material into the ground is disclosed. The strand-like material laying device is designed to lay a more rigid strand-like material such as steel pipes into the ground, and assures that the strand-like material to be laid can smoothly be fed into a trench formed in the ground without risking that a bending radius thereof falls below a minimum allowable bending radius which depends on the type of the strand-like material to be laid. The strand-like material laying device can also be immersed into the ground to form a subterranean trench while being moved in a longitudinal direction.

Owner:FOCKERSPERGER JR WALTER

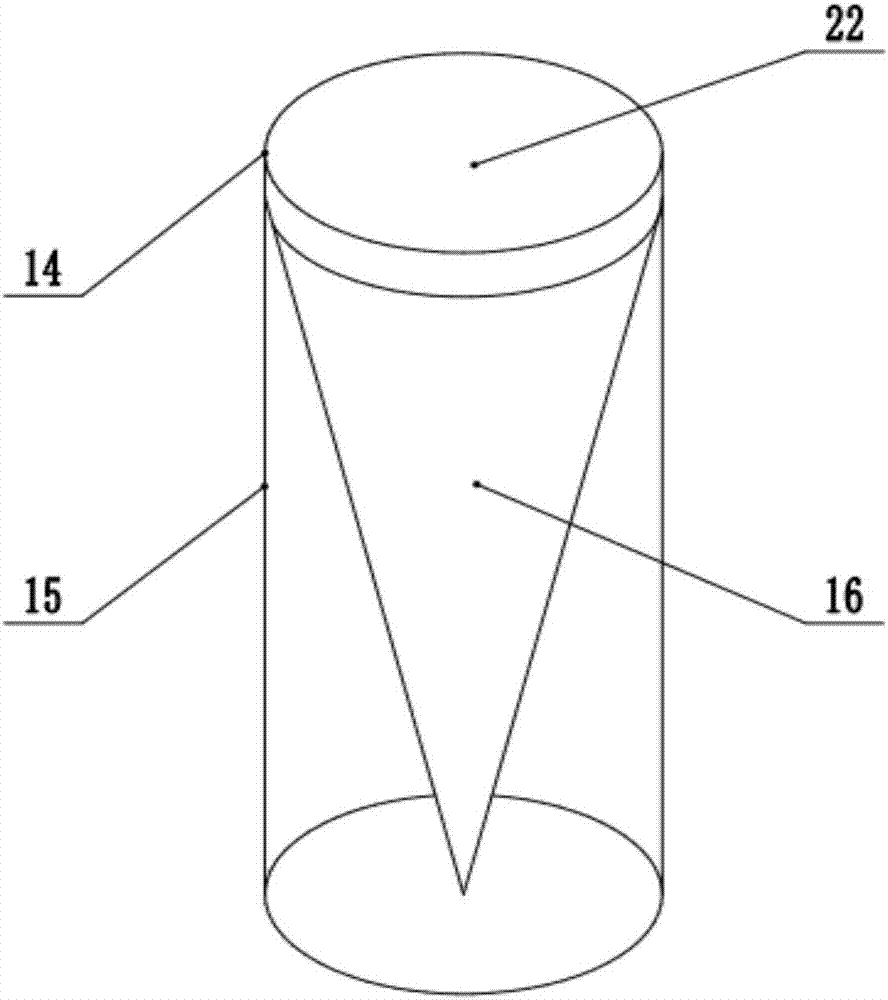

Solid rocket engine dynamic centrifugal overload ignition testing device and method

InactiveCN109578169ARealize dynamic adjustmentAccurate installation and positioningRocket engine plantsSpokeInstrumentation

The invention provides a solid rocket engine dynamic centrifugal overload ignition testing device and method. The device comprises a centrifugal machine transmission system, a centrifugal machine rotating arm system, a balance weight cabin, an instrument cabin and a rotating cabin. The rotating cabin is arranged in a hollow structure at the outer end of a rotating arm. The side face of the rotating cabin is connected with the rotating arm through a rotating shaft. The rotating cabin is further hinged to the rotating arm through a screw type adjusting device. The length of the screw type adjusting device is adjusted so that the rotating cabin can be driven to rotate around the rotating shaft connected with the rotating arm. A solid rocket engine is installed in the rotating cabin through aspoke type fastening device. The spoke type fastening device comprises a conical cylinder, and the conical cylinder is formed by combining two semi-arc seats with the axial taper through a connectingbolt. A radial expansion-preventing soft cushion is stuck and fixed to the inner surface of the conical cylinder. A front end plate and a rear end plate are arranged at the two ends of the conical cylinder, an axial adjusting bolt is installed in the front end plate, and a circle of ring-shaped rubber block is stuck to the inner side face of the rear end plate. By means of the solid rocket enginedynamic centrifugal overload ignition testing device and method, the installing and debugging problem of a cone-structure whole-size solid rocket engine centrifugal overload test is solved.

Owner:XIAN AEROSPACE PROPULSION TESTING TECH RES INST

Indoor cement laying device for construction

InactiveCN109138389ALay evenlyAdjustable thicknessBuilding constructionsInterference fitArchitectural engineering

The invention relates to a laying device, in particular to an indoor cement laying device for construction and with cement laying thickness adjusting and uniform laying. According to the technical scheme, the indoor cement laying device for construction comprises a first supporting plate, wheels, a second supporting plate, a first bearing seat, a first rotating shaft, a servo motor, a feeding rotating disc and the like. The wheels are arranged at the bottom of the first supporting plate. The second supporting plate is fixedly connected to the left end of the first supporting plate. The first bearing seat is embedded in the bottom of the second supporting plate. The first rotating shaft is connected into the first bearing seat in an interference fit mode. The function of indoor cement laying is achieved. Cement laying is more uniform. The function of cement stirring is achieved as well as cement laying thickness adjusting, and therefore the cement does not solidify. The indoor cement laying device has the characteristics of cement laying thickness adjusting, uniform laying and cement stirring to enable the cement not to solidify.

Owner:浙江年代建设工程有限公司

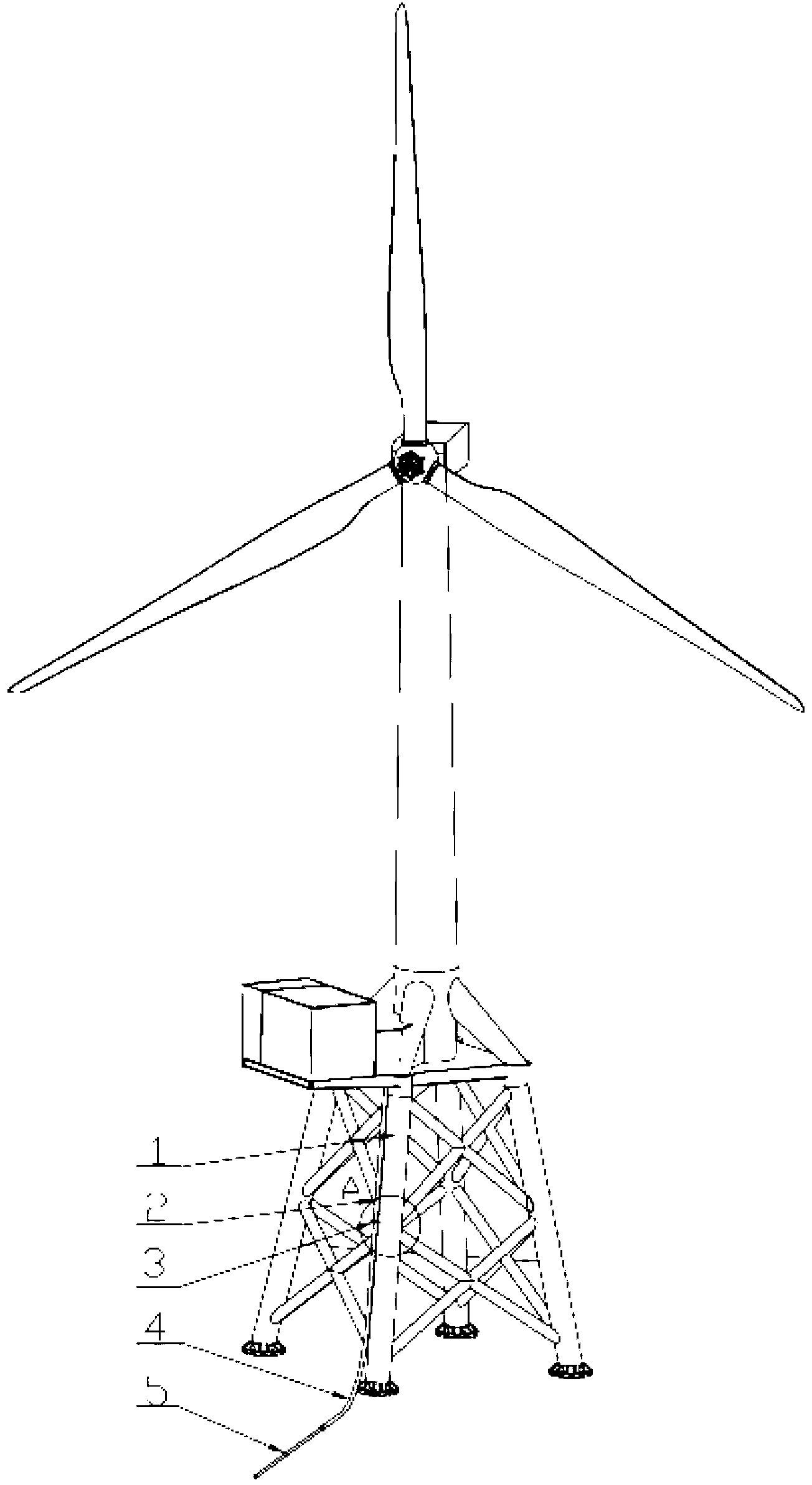

Submarine cable laying and protection method and guiding device for offshore wind turbine foundation

The invention discloses a submarine cable laying and protection method and a guiding device for an offshore wind turbine foundation. The method comprises the steps that firstly, the guiding device is made on a pile leg of the wind turbine foundation, and a cable traction line passes through a guide channel on the guiding device, wherein one end of the guide channel is disposed in an appliance placement room which is arranged on a deck of the wind turbine foundation, while the other end of the guide channel stretches out of the water to be fixed on the wind turbine foundation through a tube holder; and secondly, with the use of a laying vessel or deck pulling equipment, submarine cables are laid in place by the cable traction line, and then the end portion of the guide channel detaches from the tube holder and is laid into the seabed along the submarine cable laying direction. The submarine cable laying and protection method and the guiding device for the offshore wind turbine foundation can not only effectively protect the submarine cables, but also reduce or cancel underwater robot operations or diver's underwater operations, and thus, operating efficiency for the foundation laying of the submarine cables is effectively improved, working time is reduced, and project cost is saved.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

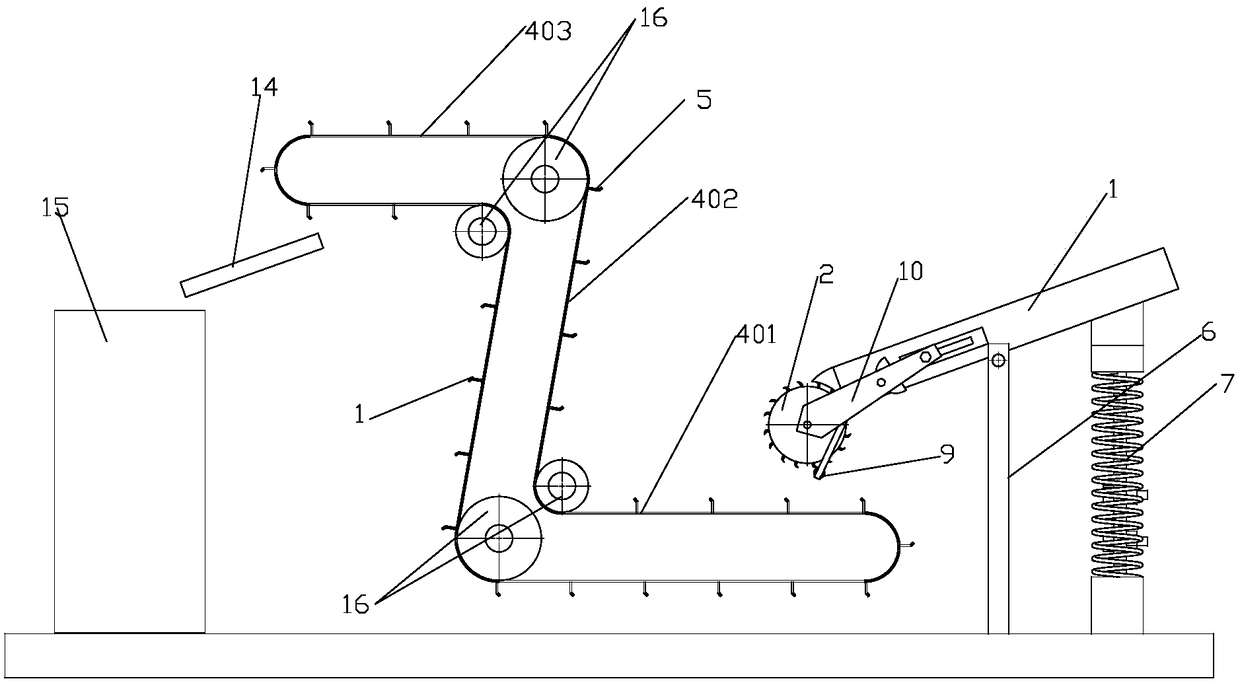

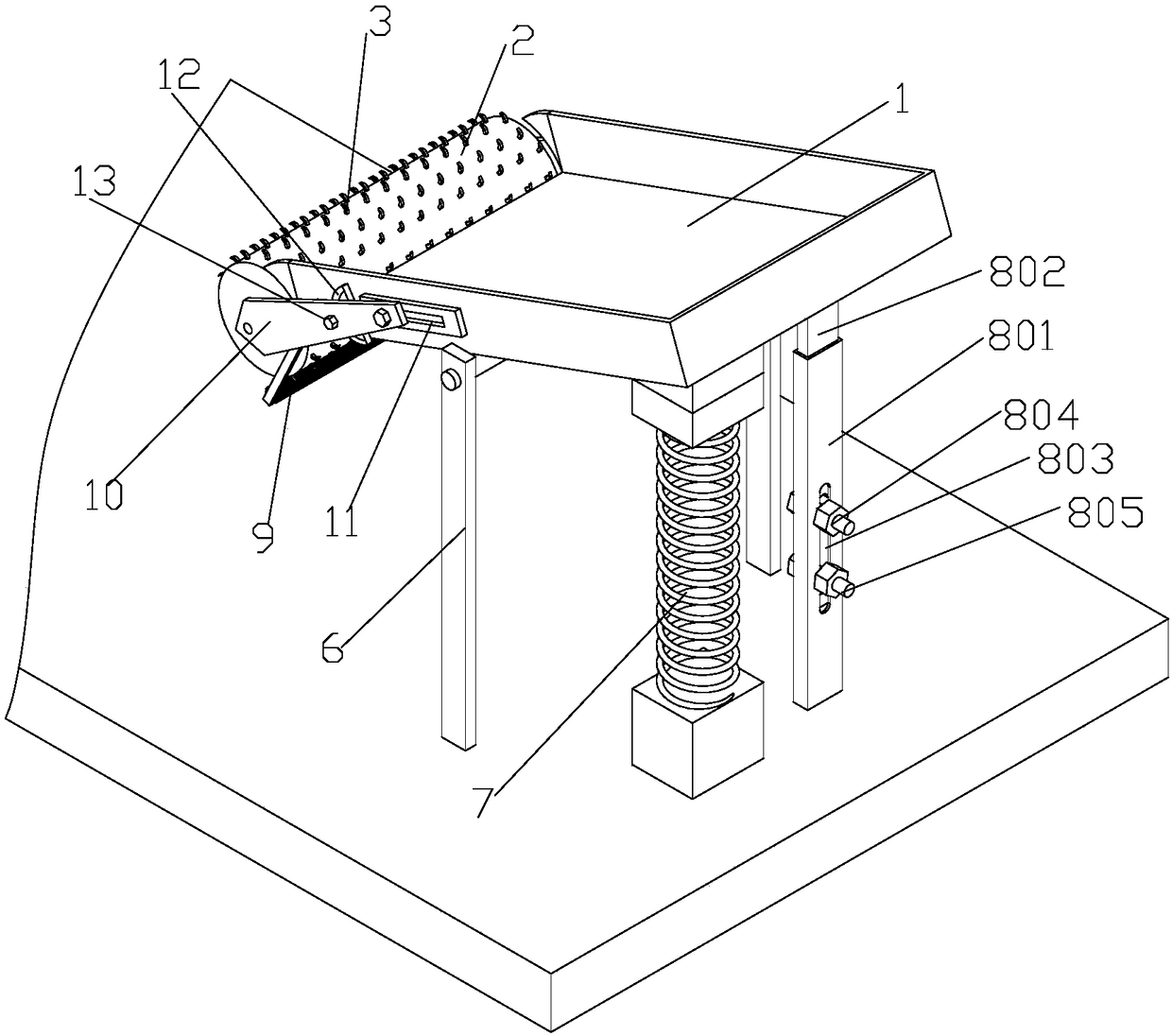

Refining and feeding device

ActiveCN108529266AUniform materialReduce distractions and injuriesConveyorsLoading/unloadingJoint actionMaterial distribution

The invention discloses a refining and feeding device. The refining and feeding device comprises a hopper and a conveying device, and a hopper rotating frame is arranged below the hopper. A roller isarranged on the front lower part of a discharge hole of the hopper, and a set of material combing teeth are arranged on the roller. An elastic support and a hopper overturn limiting structure are arranged at the end, away from the discharge hole, of the hopper. The conveying device at least includes a first horizontal conveying section located below the roller, a lifting section which is connectedwith the first horizontal conveying section in an engagement mode, and a second horizontal conveying section located after the lifting section, and the lifting section is inclined and arranged at anacute angle relative to the first horizontal conveying section. The refining and feeding device has a simple structure, skillfully utilizes the joint action of the hopper, the roller and various typesof comb teeth disposed on the roller for refining, and further refines materials by using the lifting section of the conveying device, so that the material distribution is more uniform, and the refining and feeding device can be widely used in the fields of tea processing and feeding and refining processing of agricultural and sideline products and other materials.

Owner:刘才林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com