Double-powder quick molding and uniform spreading device

A technology of metal powder and powder spreading device, which is applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., and can solve the problems that cannot satisfy the adjustable additive manufacturing of various material components, and do not have multi-component adjustable functions. , to achieve the effect of even laying, reducing time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

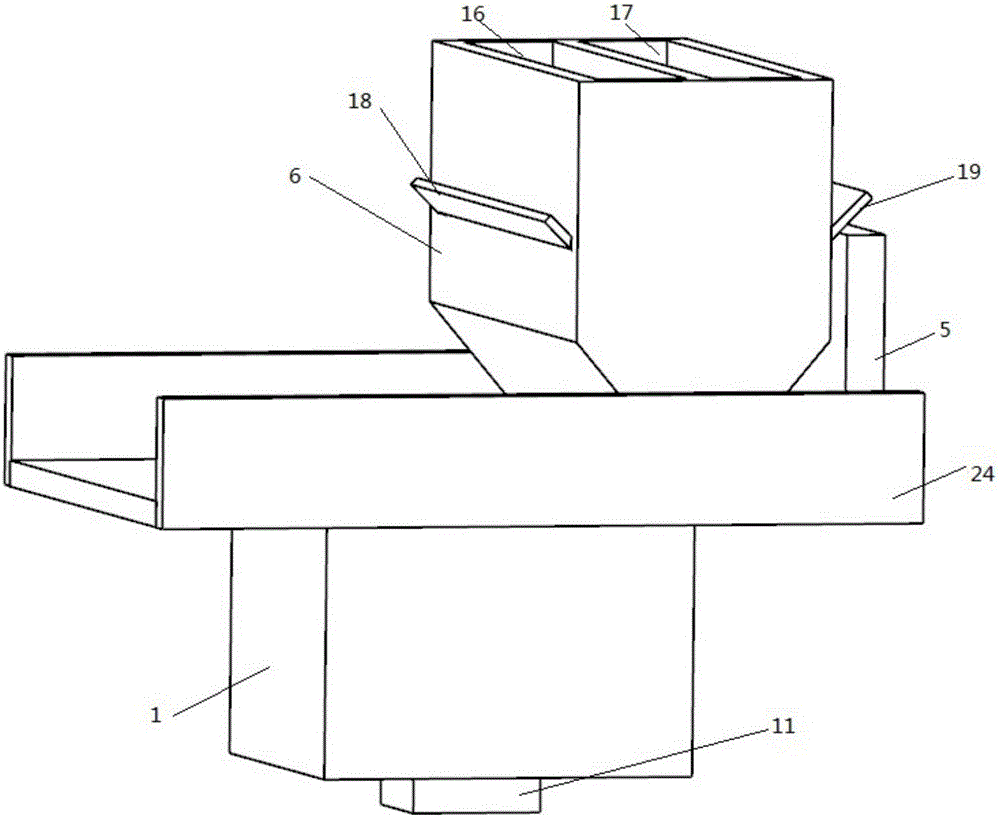

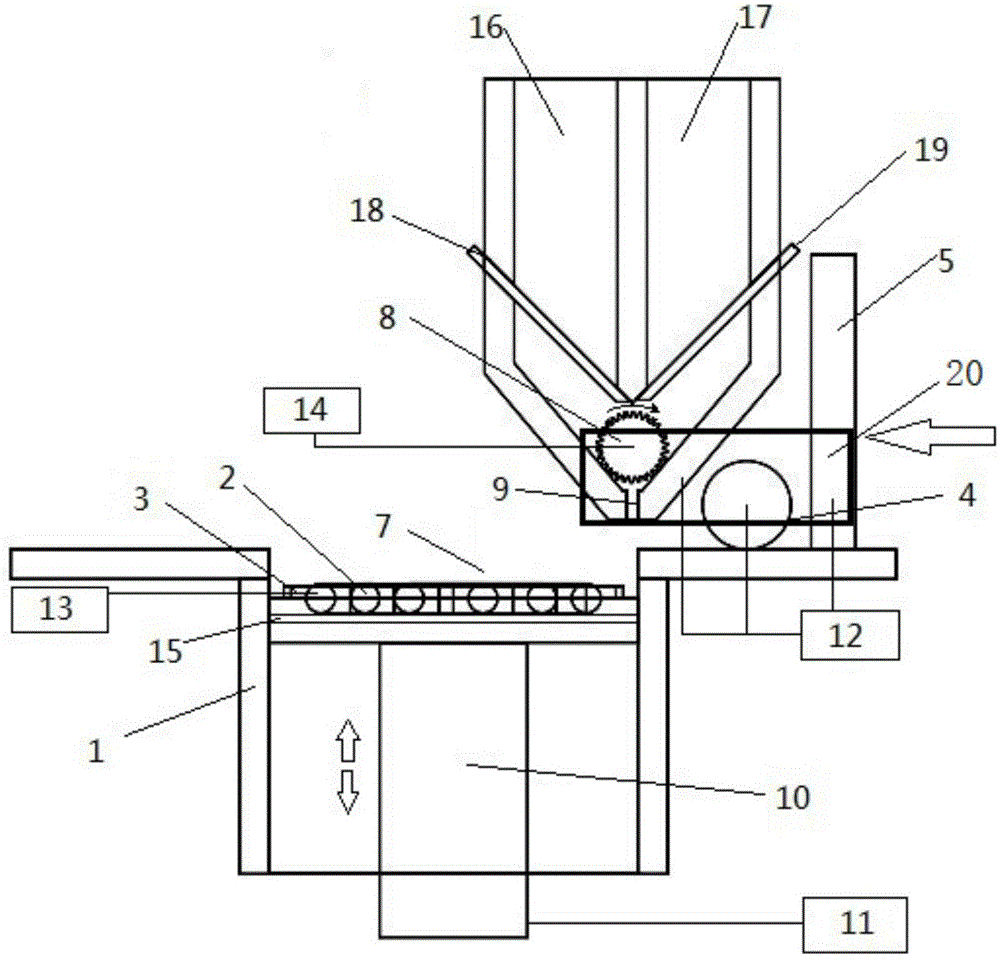

[0031] Embodiment 1, select a kind of powder a to carry out additive manufacturing, as Figure 3a As shown, the specific additive manufacturing steps are as follows:

[0032] Step 1, using a two-chamber powder supply box, and putting powder a into the first chamber 6 according to the determined powder material.

[0033] Step 2, preparation before spreading powder. Place the target substrate 15 with a thickness of d1 on the lifting platform 10 at a height parallel to the worktable, turn on the heating system, and heat the target substrate 15 to a predetermined temperature T1, which is controlled by feedback from the temperature monitoring system.

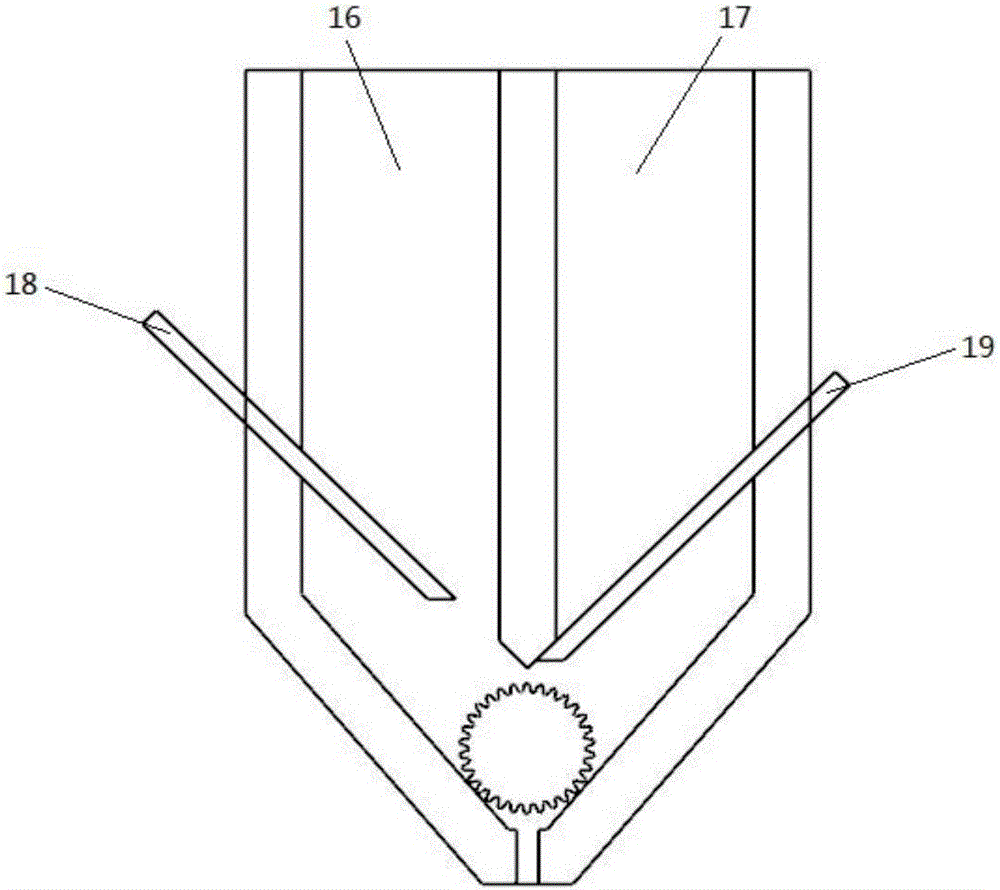

[0034] Step 3, open the first chamber switch 18, and pre-lay a layer of powder material with a thickness of D 0 .

[0035] Step 4, first spread powder, such as Figure 4a shown. Determine to select powder for use, open switch 18, select powder a for use, select the automatic control button, then press the start button. In the m...

Embodiment 2

[0040] Example 2, two kinds of powders a and b are selected for additive manufacturing, as shown in Figures 3 and 4, and the specific additive manufacturing steps are as follows:

[0041] Step 1, using a two-chamber powder supply box, according to the determined powder material, put powder a into the first chamber 16 and put powder b into the second chamber 17 .

[0042] Step 2, preparation before spreading powder. Place the target substrate 15 with a thickness of d1 on the lifting platform, the height is parallel to the worktable, turn on the heating system, and heat the target substrate 15 to a predetermined temperature T1, which is controlled by the feedback of the temperature monitoring system.

[0043] Step 3, turn on the first chamber switch 18 and the second chamber switch 19, mix the powder e according to a certain ratio, and pre-lay a layer of powder material with a thickness of D 0 ,

[0044] Step 4, first spread powder, such as Figure 4a shown. Determine to sel...

Embodiment 3

[0049] Embodiment 3, select three kinds of powder a, b, c to carry out additive manufacturing, as Figure 5a -d, the specific additive manufacturing steps are as follows:

[0050] Step 1, using a two-chamber powder supply box, according to the determined powder material, put powder a into the first chamber 16, powder b into the second chamber 17, and powder c into the third chamber 25 .

[0051] Step 2, preparation before spreading powder. Set the thickness to d 1 The target substrate 15 is placed on the lifting platform, the height is parallel to the worktable, the heating system is turned on, and the target substrate 15 is heated to a predetermined temperature T 1 , controlled by the temperature monitoring system feedback.

[0052] Step 3, open the first chamber switch 18, and pre-lay a layer of powder material with a thickness of D 0 .

[0053] Step 4, first spread powder, such as Figure 4a shown. Determine to select powder for use, open switch 19, select powder b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com