Refining and feeding device

A technology of feeding and conveying device, applied in the field of homogeneous feeding device, can solve problems such as uneven feeding, and achieve the effect of uniform material, convenient adjustment, and reduction of worry and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

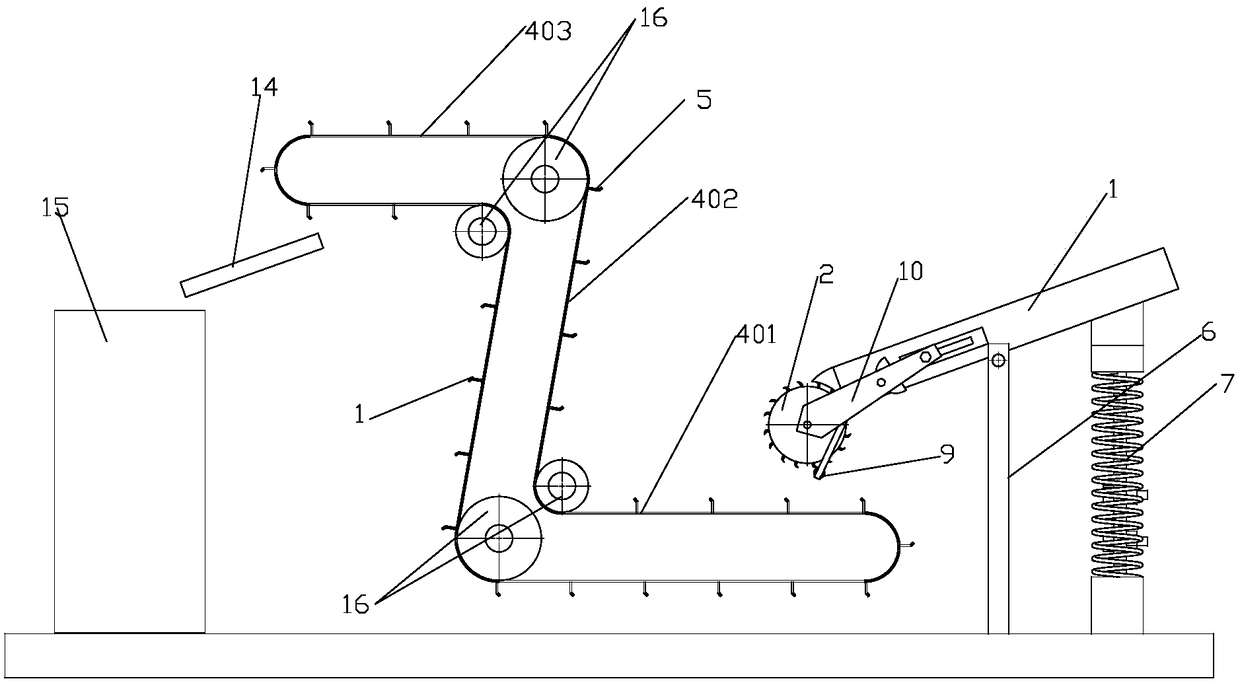

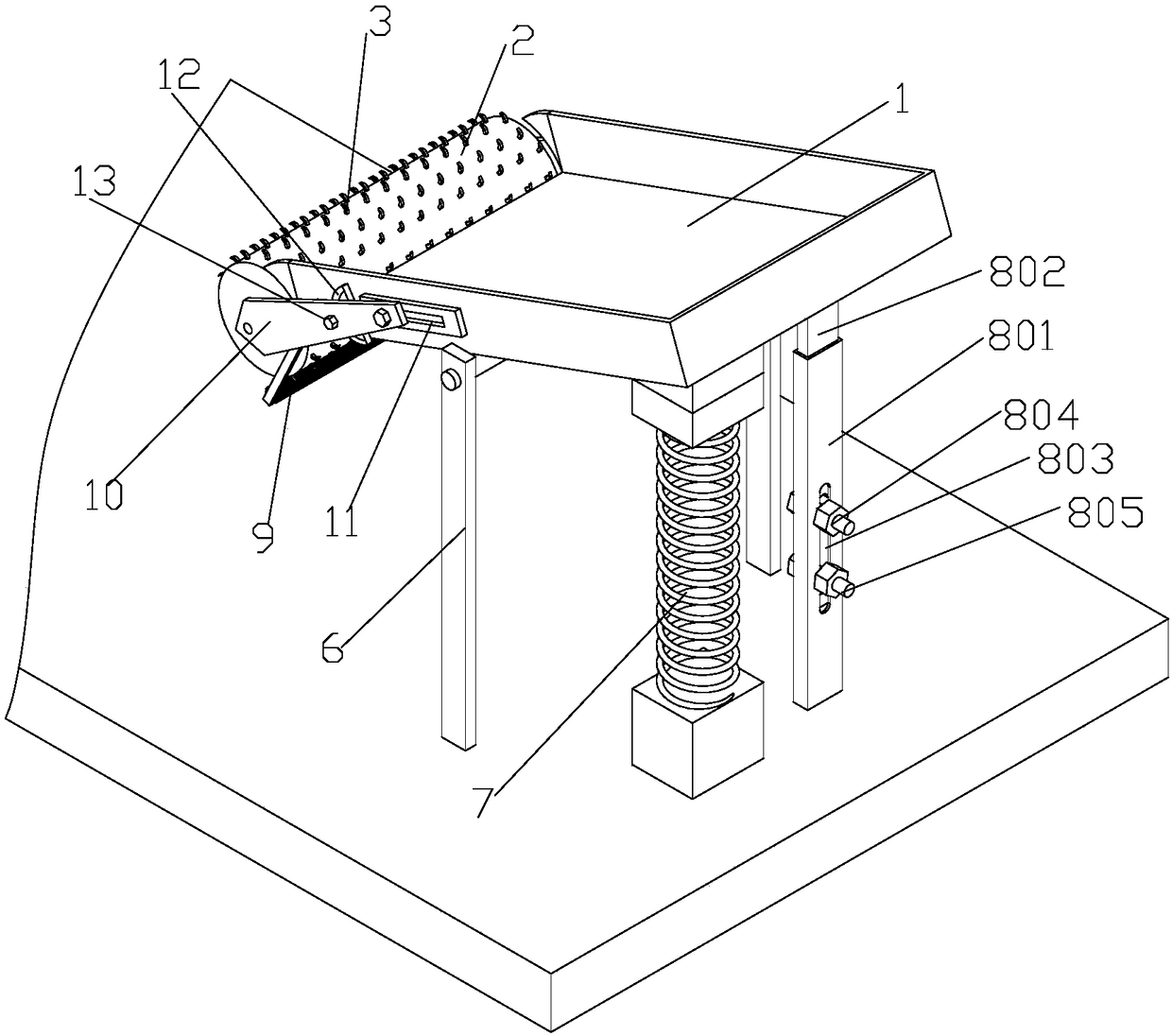

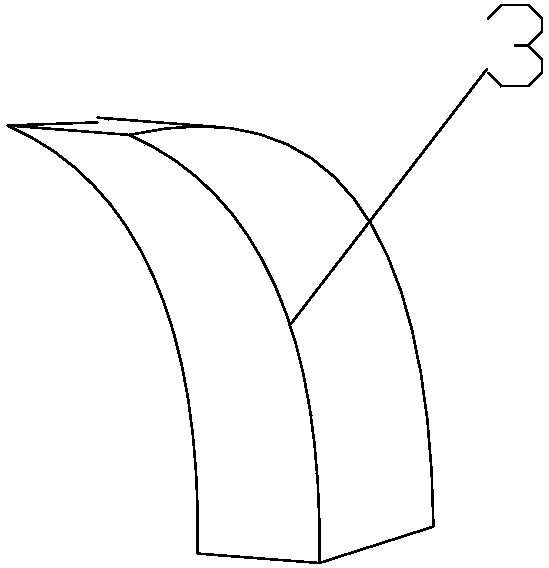

[0023] Examples such as Figures 1 to 7 As shown, a uniform material feeding device can be used for uniform material feeding of flexible materials such as tea leaves and Chinese herbal medicines. The device includes a hopper 1, and a drum 2 is arranged on the front and lower side of the discharge port of the hopper 1, and a group of comb teeth 3 are evenly dislocated on the drum 2, that is, the comb teeth 3 are evenly distributed in each row, and the upper one The row is arranged in a dislocation relative to the next row, so that the material not caught by the comb teeth 3 of the previous row can be caught by the comb teeth 3 of the next row. The bottom of the hopper 1 is provided with a hopper turret 6, the hopper turret 6 is arranged at the middle position of the hopper 1, and the hopper 1 is arranged on the hopper turret 6 and can turn back and forth around the hopper turret 6, thereby changing the hopper 1 tilt angle. Specifically, the hopper turret 6 can be flexibly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com