Unreeling frame

The technology of a pay-off rack and a pay-off shaft, which is applied in the field of pay-off racks, can solve the problems of affecting the quality stability of twisted wires, difficulty in ensuring the quality of twisted wires, and increased production costs of cables. smooth line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

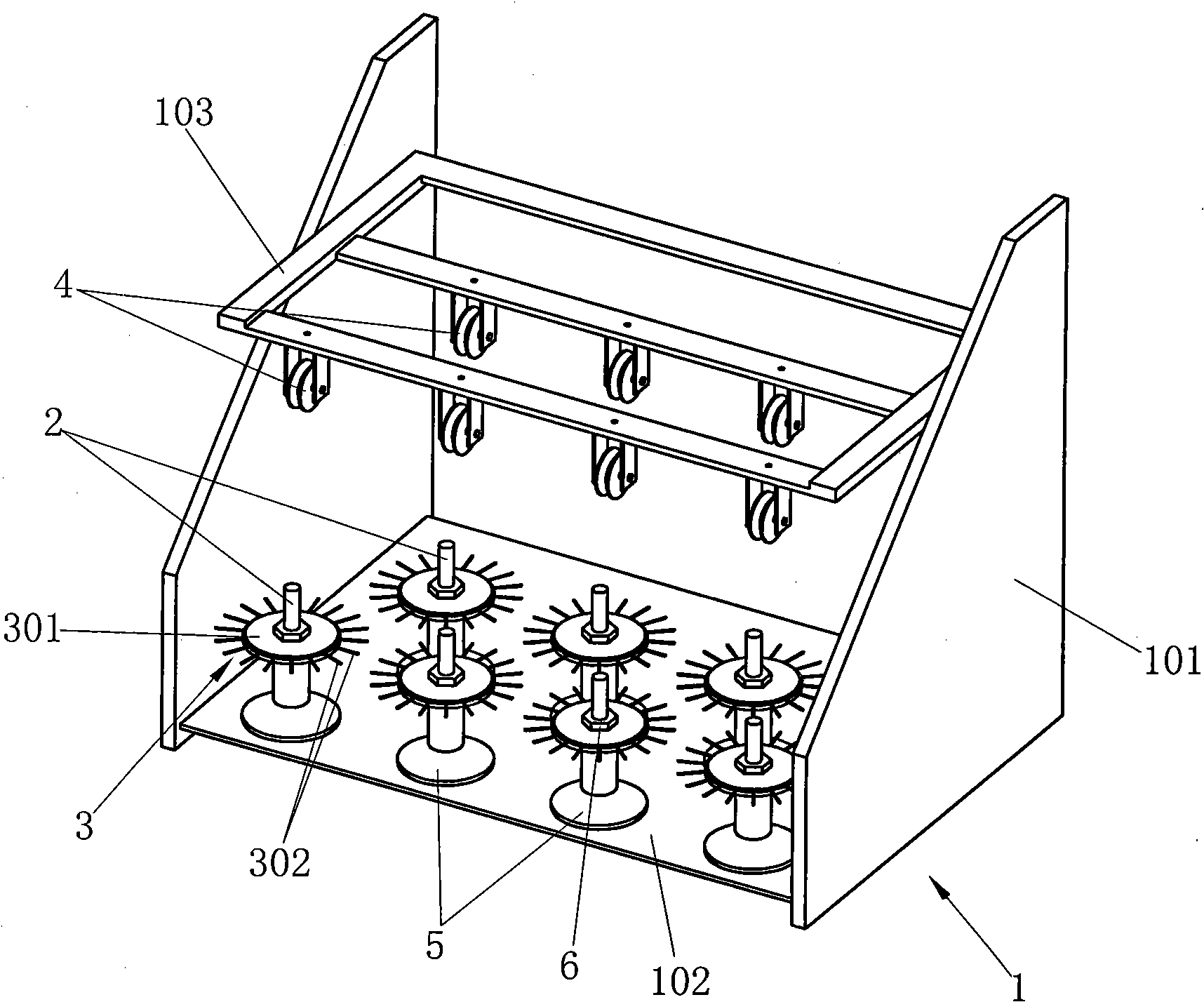

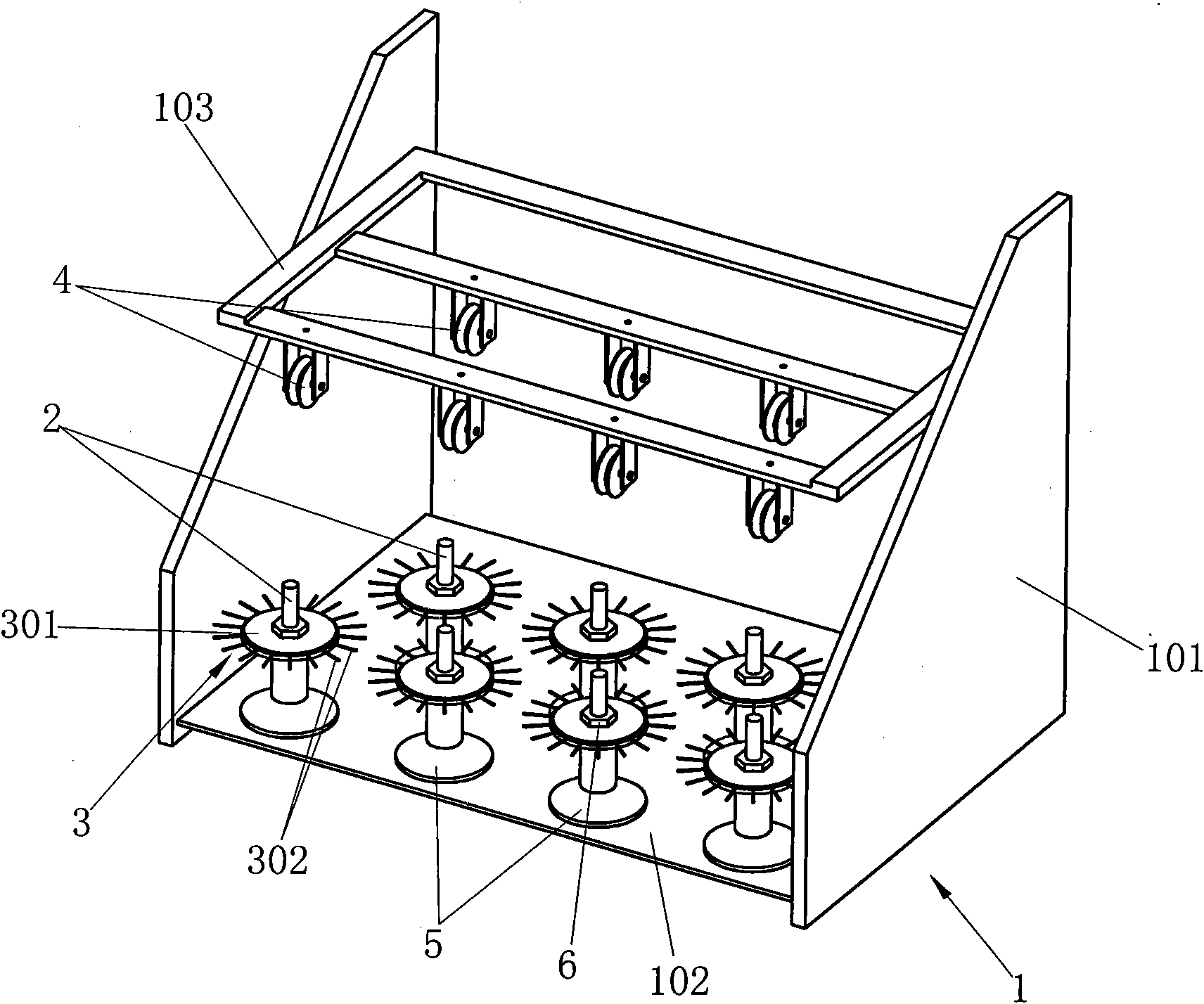

[0012] Such as figure 1 As shown, the present invention includes a frame body 1, a bottom plate 102 is welded between two side plates 101 of the frame body 1, a guide wheel bracket 103 is welded between the two side plates above the bottom plate 102, and the bottom plate 102 is provided with 7 vertical pay-off shafts 2, the number of pay-off shafts 2 can be determined according to actual needs. When paying off, the winding rubber shaft 5 is set on the winding shaft 2, and the brush pad 3 is installed on the winding rubber shaft 5 On the upper end, the brush pad 3 and the winding rubber shaft 5 are fixed together with the base plate 102 by the nut 6 on the pay-off shaft 2, and the brush pad 3 and the winding rubber shaft 5 are fixed when paying off. The brush pad 3 includes a backing plate 301, the backing plate 301 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com