Method for preventing proppants in water-base fracturing fluid from settling in transfer process

A water-based fracturing and proppant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as proppant settlement that is not completely solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of this organic zirconium crosslinking agent comprises the steps:

[0047] 1) Warm up deionized water to 50-90°C, add zirconium trichloride, sodium chloride, and ammonium chloride in sequence, and stir at a speed of 20-40 rpm to obtain transparent liquid A;

[0048] 2) Add ethylene glycol into the transparent liquid A and stir at a speed of 20-40 rpm to obtain the transparent liquid B;

[0049] 3) Add lactic acid to the transparent liquid B to react, and drop lye to adjust the pH value to 4-8;

[0050] 4) React at constant temperature for 45min-480min to obtain a colorless and transparent organic zirconium crosslinking agent.

Embodiment 1

[0053] formula:

[0054] Deionized water: 40 parts;

[0055] 4 parts of zirconium trichloride;

[0056] 13 parts of ethylene glycol;

[0057] 6 parts of lactic acid;

[0058] Sodium chloride 0.1 part;

[0059] 0.01 parts of ammonium chloride.

[0060] The preparation steps are: heat 40 parts of deionized water to 50°C, add 4 parts of zirconium trichloride, 0.1 part of sodium chloride, and 0.01 part of ammonium chloride in sequence, stir at a speed of 20-40 rpm, and wait for the trichloride to After the zirconium is completely dissolved, add 13 parts of ethylene glycol and stir at a speed of 20-40 rpm. After fully dissolving, continue to add 6 parts of lactic acid, and then drop in 20% sodium hydroxide lye to adjust the pH value to 6. React at constant temperature for 480 minutes to obtain a colorless and transparent organic zirconium crosslinking agent.

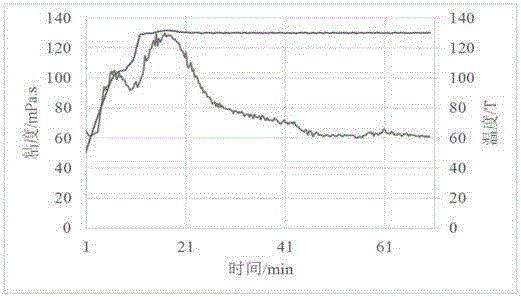

[0061] Performance evaluation: the effect of using the above organic zirconium crosslinking agent in water-based fractu...

Embodiment 2

[0063] formula:

[0064] Deionized water: 70 parts;

[0065] 5 parts of zirconium trichloride;

[0066] 12 parts of ethylene glycol;

[0067] 6 parts of lactic acid;

[0068] Sodium chloride 0.1 part;

[0069] 0.01 parts of ammonium chloride.

[0070] The preparation steps are: heat 70 parts of deionized water to 50°C, add 5 parts of zirconium trichloride, 0.1 part of sodium chloride, and 0.01 part of ammonium chloride in sequence, stir at a speed of 20-40 rpm, and wait for the trichloride to After the zirconium is completely dissolved, add 12 parts of ethylene glycol and stir at a speed of 20-40 rpm. After fully dissolving, continue to add 6 parts of lactic acid, and then drop in 20% sodium hydroxide lye to adjust the pH value to 4. React at a constant temperature for 480 minutes to obtain a colorless and transparent organic zirconium crosslinking agent.

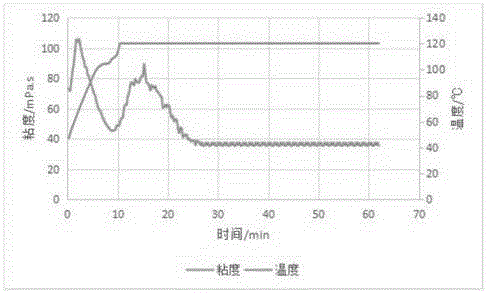

[0071] Performance evaluation: the effect of using the above organic zirconium crosslinking agent in water-based fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com