Fracturing design method for optimizing uniform spreading concentration

A design method and laying technology, applied in earthwork drilling, production fluid, wellbore/well components, etc., can solve the problem that the pump injection program does not meet the objective requirements of oilfield production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A fracturing design method for optimizing the uniform laying concentration, taking the injection of cross-linked guar gum liquid as an example, is implemented according to the following four steps.

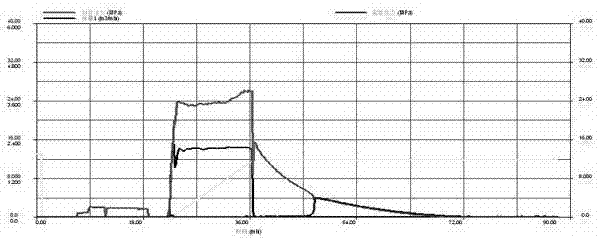

[0022] Such as figure 1 As shown, in step one, the liquid efficiency η is determined by the small-scale test fracturing of cross-linked guar gum, and the cross-linked guar gum liquid efficiency η is 24.5%, which belongs to low liquid efficiency. .

[0023] Step 2, according to the glue liquid efficiency η that obtains in step 1 is 24.5%, η is brought in formula one and formula two,

[0024] …………………………………… (Formula 1)

[0025]

[0026] ………………………………… (Formula 2)

[0027] Calculated prefluid volume ν is 85m 3 , the test fracture interpretation permeability is 1.1×10 -3 μm 2 .

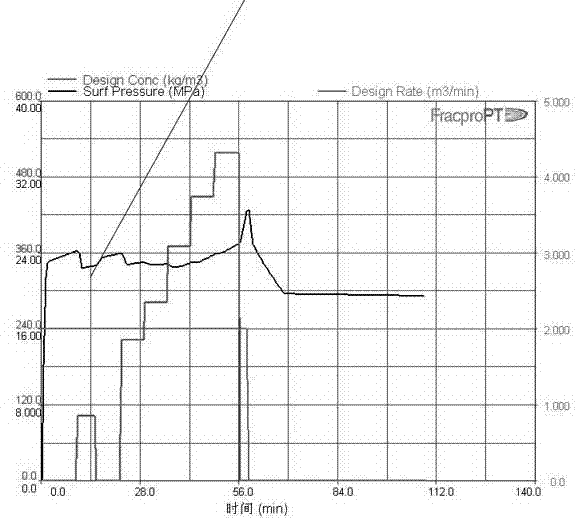

[0028] Such as figure 2 Shown, step 3, in conjunction with step 1, cross-linked guar gum liquid efficiency η is 24.5% and step 2, and in step 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com