Thermosetting bonding based ceramic additive production method and equipment

A ceramic and bonding technology, which is applied in the field of ceramic additive manufacturing and equipment based on thermosetting bonding, can solve problems such as the inability to realize the additive manufacturing of silicon carbide ceramic powder, hindering the solid phase crystallization reaction of ceramic particles, and weakening the strength of the material. , to achieve wide applicability, increase strength, and reduce raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

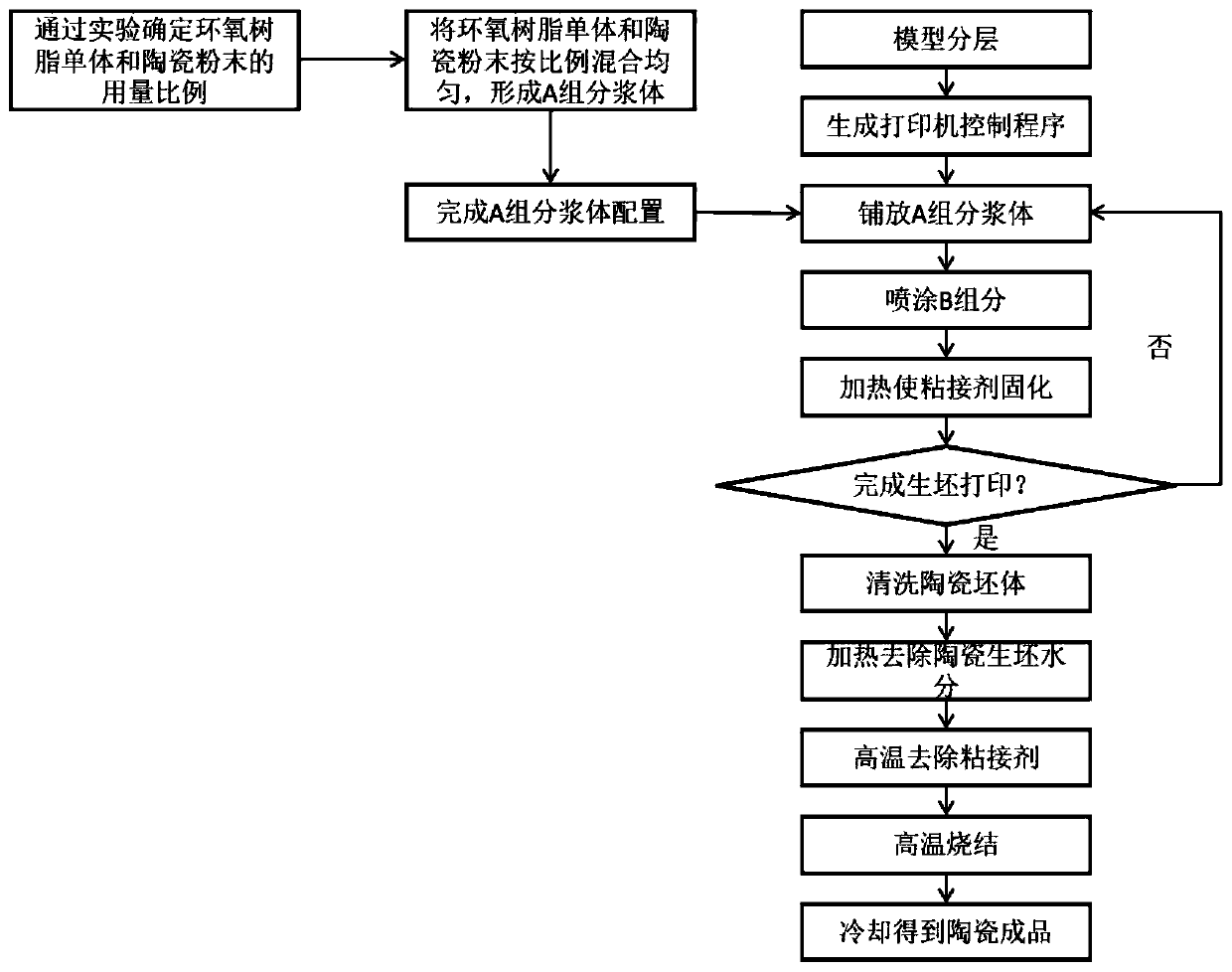

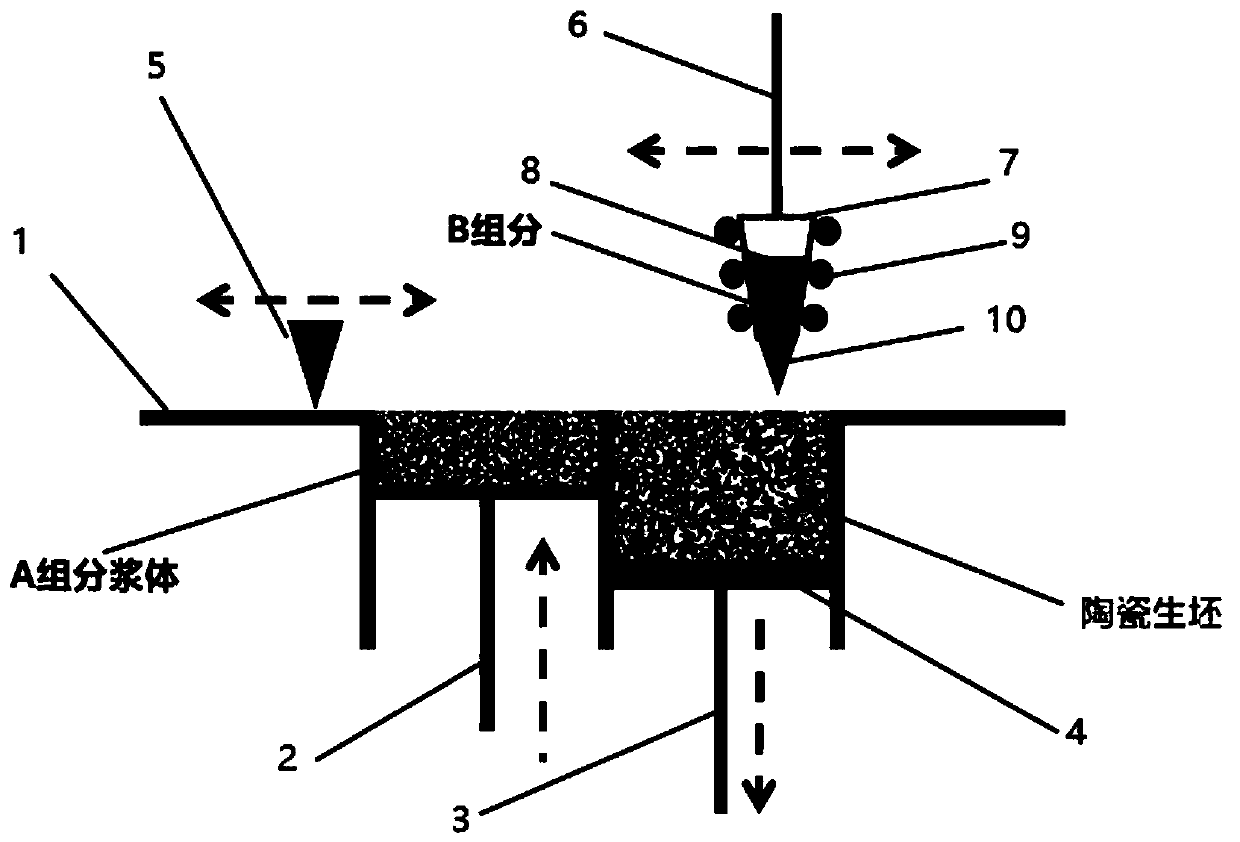

[0060] A kind of additive manufacturing method of alumina ceramics

[0061] 1) Model design and layering: Design the part model that needs to be printed, use computer software to layer, calculate the area that needs to be bonded for each layer, and generate a printer control program that includes the injection path of component B.

[0062] 2) Preparation of alumina ceramic powder raw material: select alumina ceramic powder with a particle diameter of 60 nm as the raw material.

[0063] 3) Determination of the dosage ratio of component A slurry: using bisphenol F glycidyl ether (BFDGE) as the epoxy resin monomer, it is determined through experiments that in the component A slurry, the epoxy resin monomer and alumina ceramic powder The mass ratio is 1:3.

[0064] 4) Use diethyltoluenediamine (DETDA) for component B, adjust the injection parameters of component B: the compressed gas pressure is 0.23MPa, the single compressed gas injection time is 110ms, component B is heated in ...

Embodiment 2

[0069] A kind of additive manufacturing method of silicon carbide ceramics

[0070] 1) model design and stratification: same as embodiment 1;

[0071] 2) Preparation of silicon carbide ceramic powder raw materials: mix β-SiC powder with a particle size of 100nm and trace C and B powders in a ratio of 100:3:1 as raw materials;

[0072] 3) Determination of the dosage ratio of component A slurry: use bisphenol F glycidyl ether (BFDGE) as the epoxy resin monomer, and determine through experiments, in the component A slurry, epoxy resin monomer and silicon carbide ceramic powder raw materials (The mixture prepared by step 2) has a mass ratio of 1:2.5.

[0073] 4) Use diethyltoluenediamine (DETDA) for component B, adjust the injection parameters of component B: the compressed gas pressure is 0.20MPa, the single compressed gas injection time is 110ms, component B is heated in the storage syringe The temperature is 80°C, and the diameter of a single droplet of component B ejected ac...

Embodiment 3

[0078] A kind of additive manufacturing method of ferrite ceramics

[0079] 1) The model design and layering, the calculation ratio of the adhesive, and the printing process can refer to Examples 1 and 2.

[0080] 2) Preparation of ferrite ceramic powder raw material: Manganese-zinc ferrite powder with brand PC40 was used as raw material.

[0081] 3) According to the aforementioned method, after the ceramic green body is printed and cleaned, the ceramic green body is placed in a sintering furnace, heated to 140°C, and kept for 3 hours to remove the moisture contained in it; then heated to 600°C in an air environment ℃, keep warm for 6 hours to remove the binder components; finally, heat to 1200 ℃ in an inert gas environment, keep warm for 5 hours, so that the manganese zinc ferrite powder is sintered into finished solid ceramic parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com