Pipeline-laying vessel and pipeline-laying method using same

A laying method and pipeline technology, which are applied in the direction of pipeline laying and maintenance, pipe/pipe joint/pipe fittings, and pipe-laying ships, etc., can solve problems such as lengthening, structural rigidity and recovery of laying ships, and difficulty in laying operations with deep-sea pipelines, etc. , to achieve the effect of smooth laying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

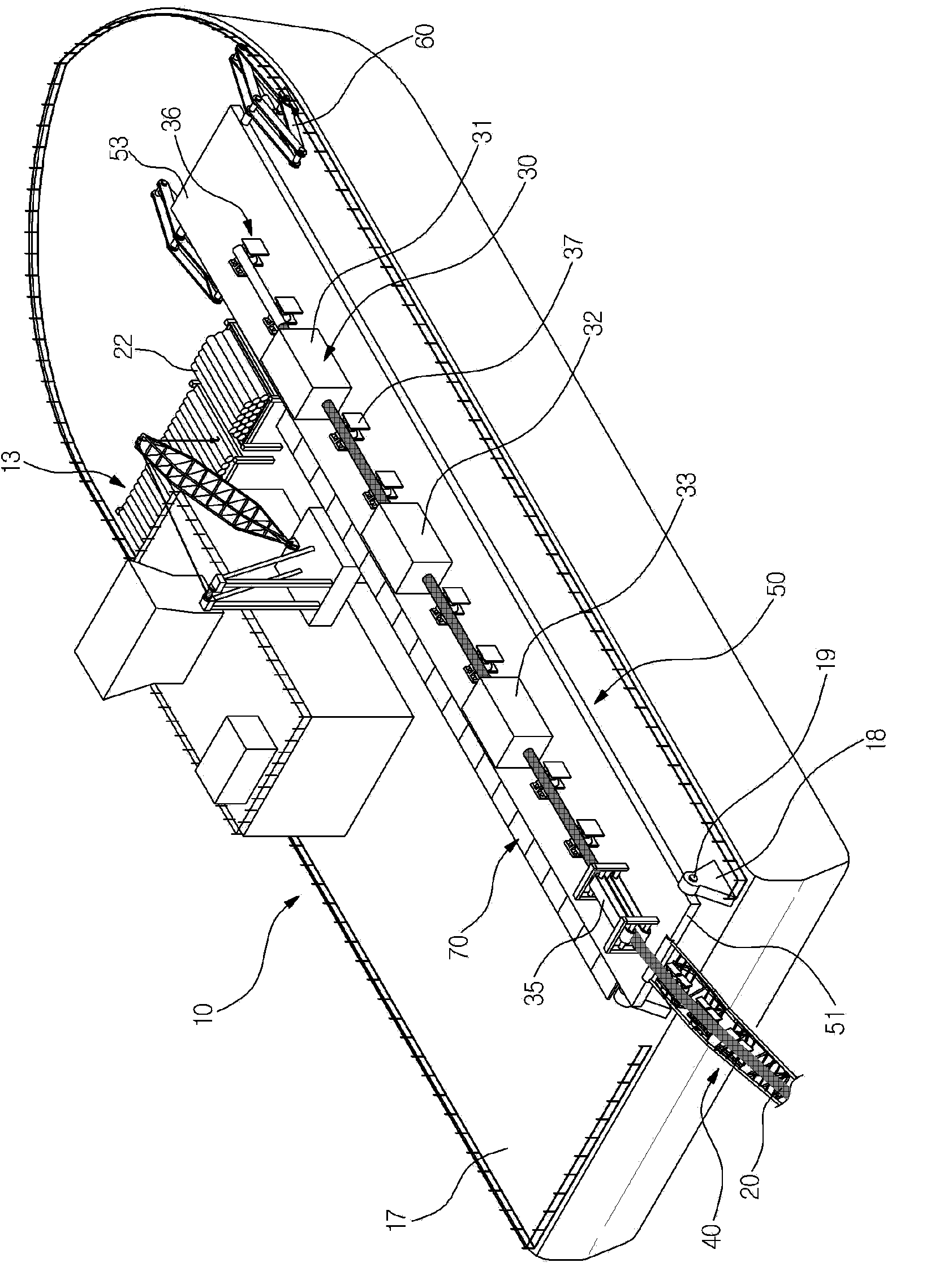

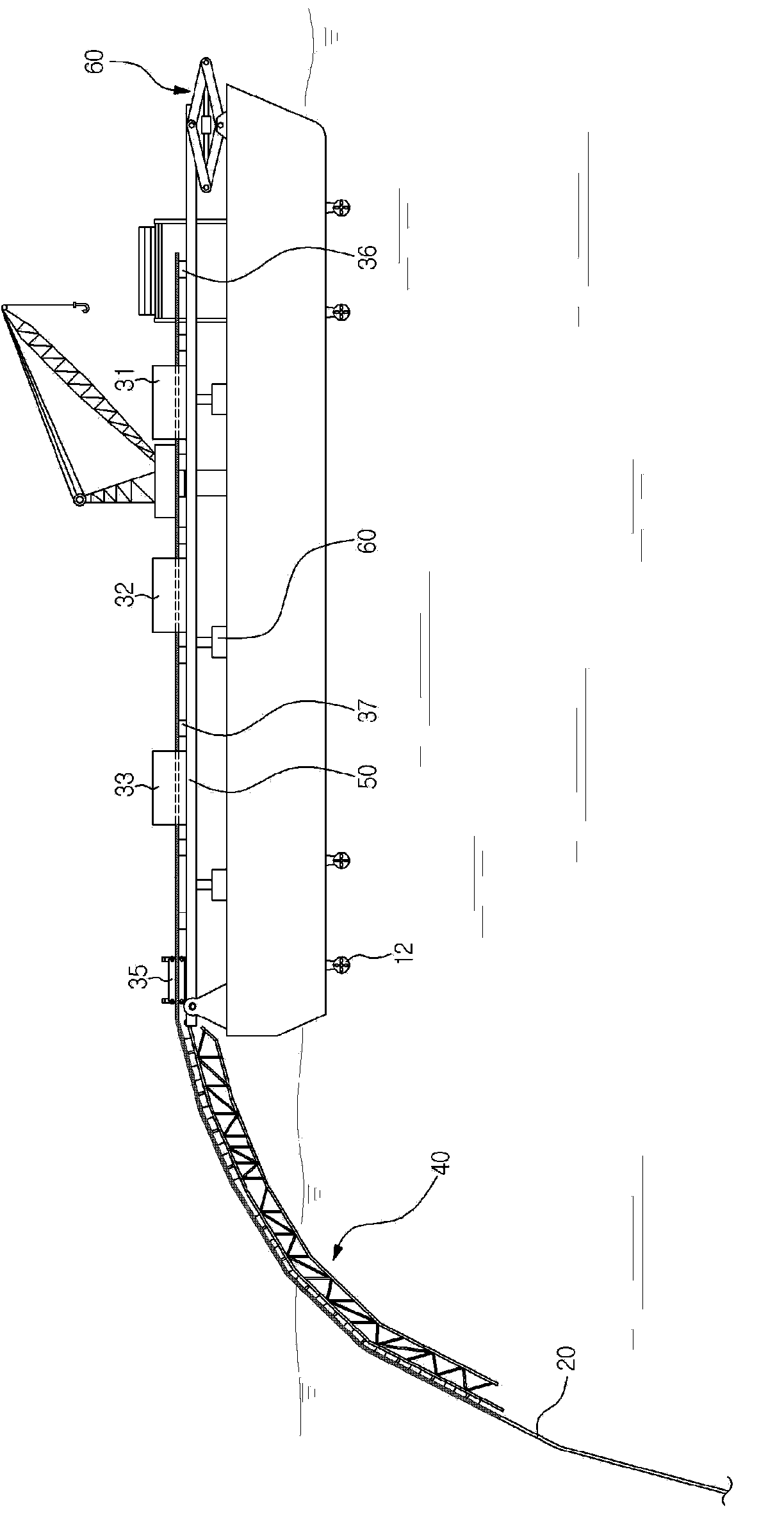

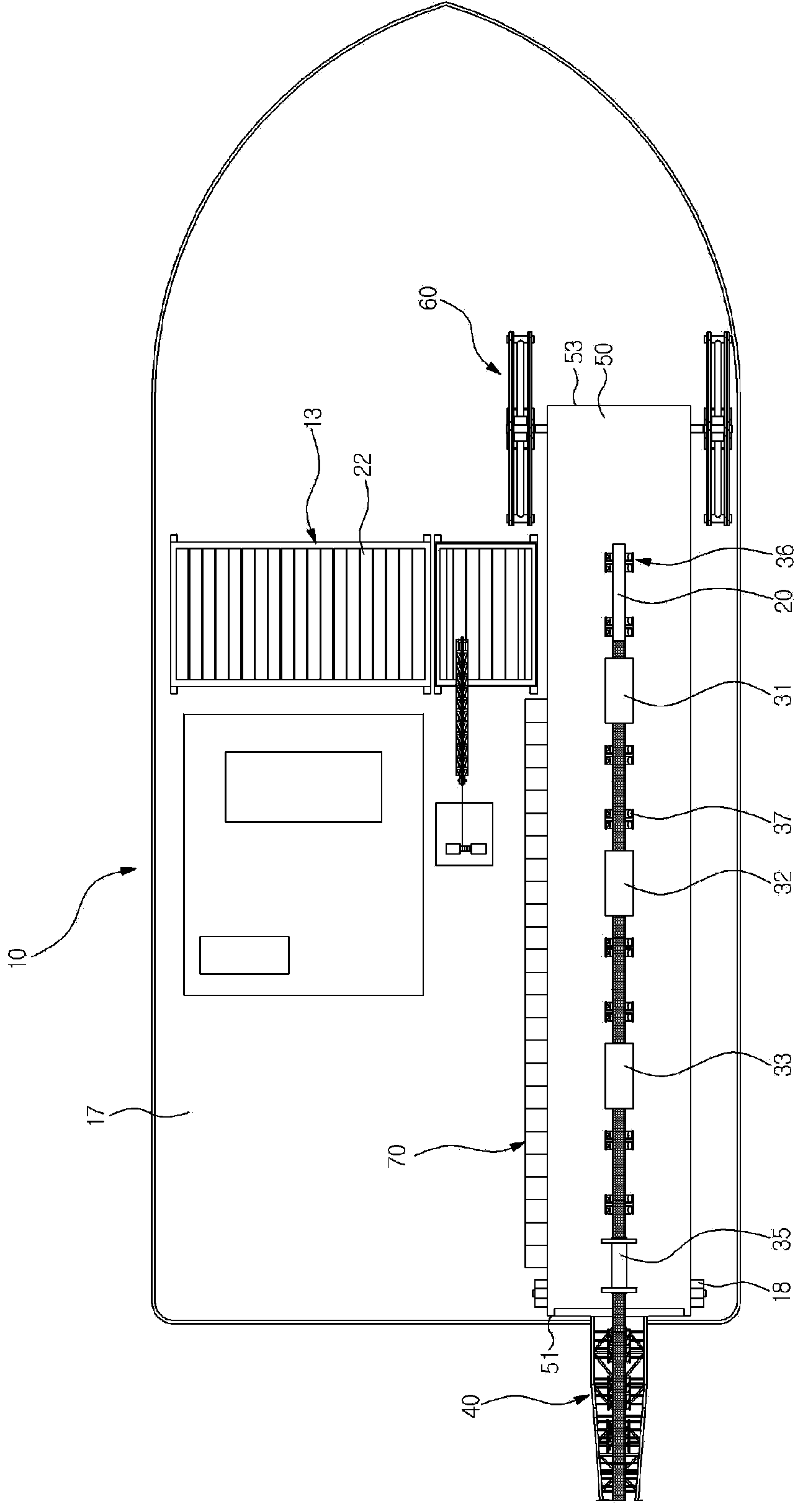

[0033] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 is a perspective view schematically showing a pipeline laying vessel according to an embodiment of the present invention, figure 2 is a top view of a pipeline laying vessel according to an embodiment of the present invention, image 3 It is a side view of the pipe-laying vessel of the embodiment of the present invention.

[0034] refer to Figure 1 to Figure 3 , the S-lay ship 10 of the present embodiment is a pipeline laying ship for laying a pipeline 20 on the seabed, and a plurality of pipeline segments 22 per unit length are supplied to the pipeline laying ship by a transport ship, and the plurality of pipeline segments 22 supplied It is lowered to the seabed while being connected by more than one operating station 30 arranged on the hull.

[0035] This laying ship 10 is moved to the position for laying the pipeline 20 by the propelling device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com