Coaxial powder feeding device for broadband laser cladding and powder feeding method thereof

A technology of laser cladding and coaxial powder feeding, applied in metal material coating process, coating and other directions, can solve the problems of poor processing quality, complex system, sensitive laser cladding direction, etc. Simple structure, even powder spot spreading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

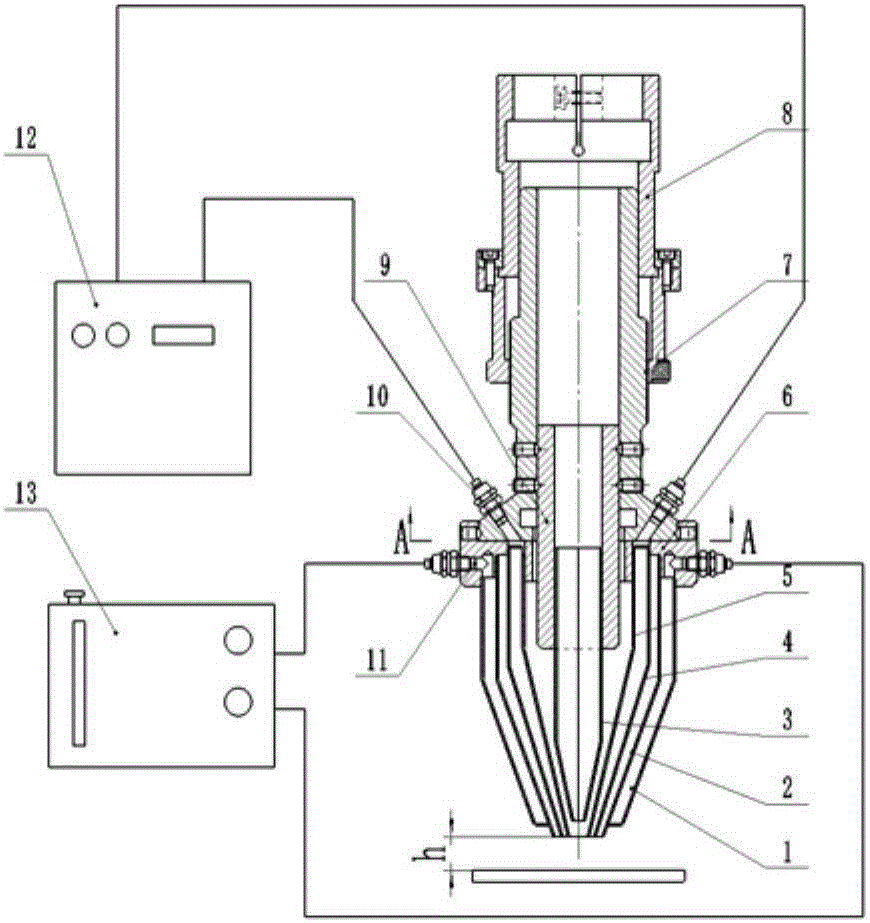

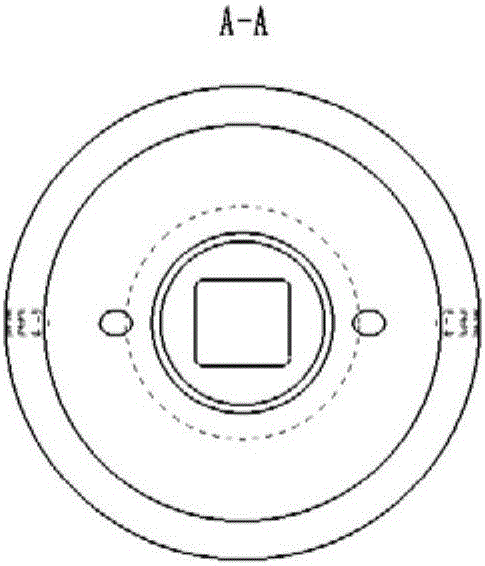

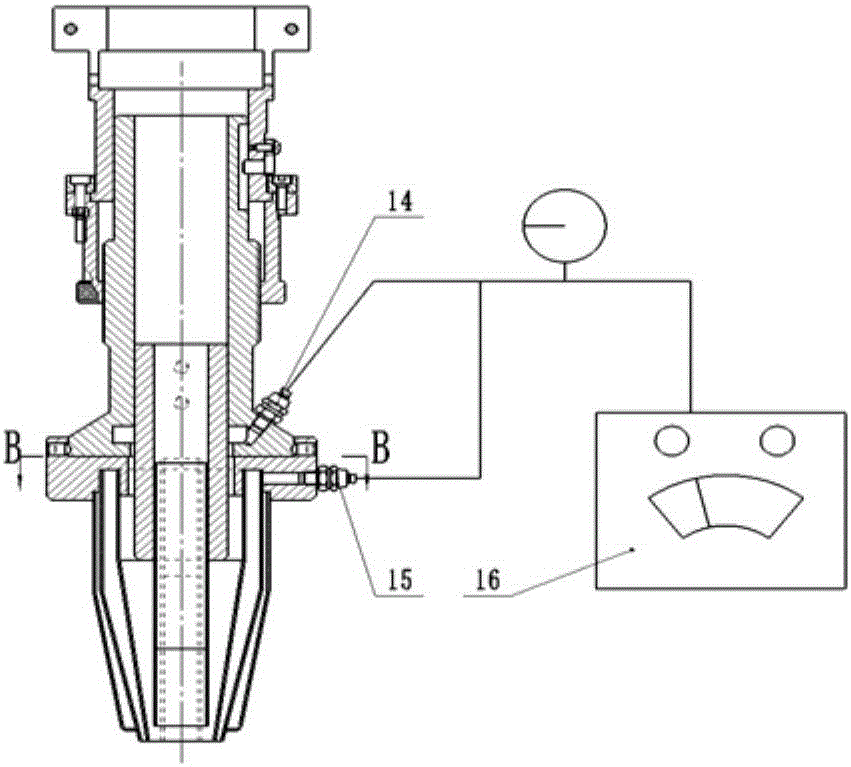

[0023] Such as figure 1 and image 3 As shown, a coaxial powder feeding device for broadband laser cladding includes a height-adjustable sleeve assembly 7 with a central through hole. The top of the sleeve assembly 7 is provided with an external piece for connecting to the laser (end lens) (connecting hoop 8), the shaft center of the bottom end of the sleeve assembly 7 is provided with a beam shield 3, and the bottom end of the sleeve assembly 7 is provided with an inner layer gas cover 5, an outer gas shield 5, and an outer layer that are sequentially placed on the beam shield 3 from the inside to the outside. Layer air cover 2 and cooling water cover 1, between the inner layer air cover 5 and the outer layer air cover 2 at the bottom of the sleeve assembly 7 are provided with two symmetrical powder feeding pipes 4 about the beam shield 3, and the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com