Patents

Literature

61results about How to "Play a plastic role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Building thermal insulation dry powder mortar

A building thermal insulation dry powder mortar belongs to a building thermal insulation material. The weight ratio of a dry powder to water is 1: 1.5. The dry powder is prepared by mixing 450 parts by mass of ordinary portland cement, 70 parts by mass of a calcined gypsum powder, 37.5 parts by mass of a redispersible emulsion powder, 15 parts by mass of fine xylem fibers, 13 parts by mass of polypropylene staple fibers, 10 parts by mass of slaked lime, 10 parts by mass of sierozem, 10 parts by mass of heavy calcium carbonate, 3 parts by mass of hydroxypropyl methyl cellulose, 364 parts by mass of a calcined expanded perlite and 17.5 parts by mass of a premixed auxiliary agent. The thermal insulation building dry powder mortar has the advantages of strong thermal insulation, strong bond with walls, high compressive strength, strong drawing force, excellent weather resistance, and environmental protection, and also has the advantages of fire resistance, cracking resistance, leakage resistance, moisture resistance, sliding resistance, earthquake resistance and the like.

Owner:王荣

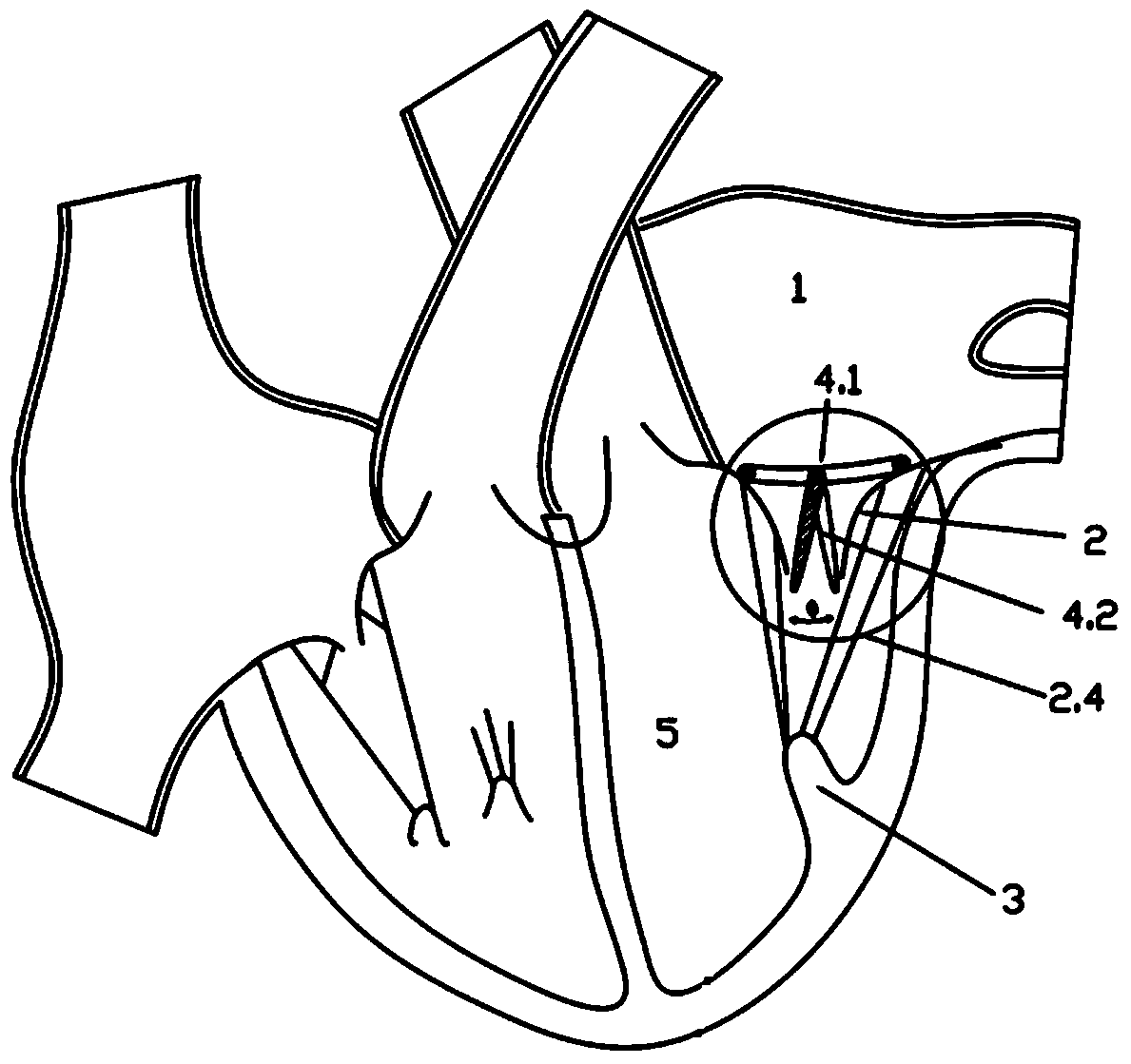

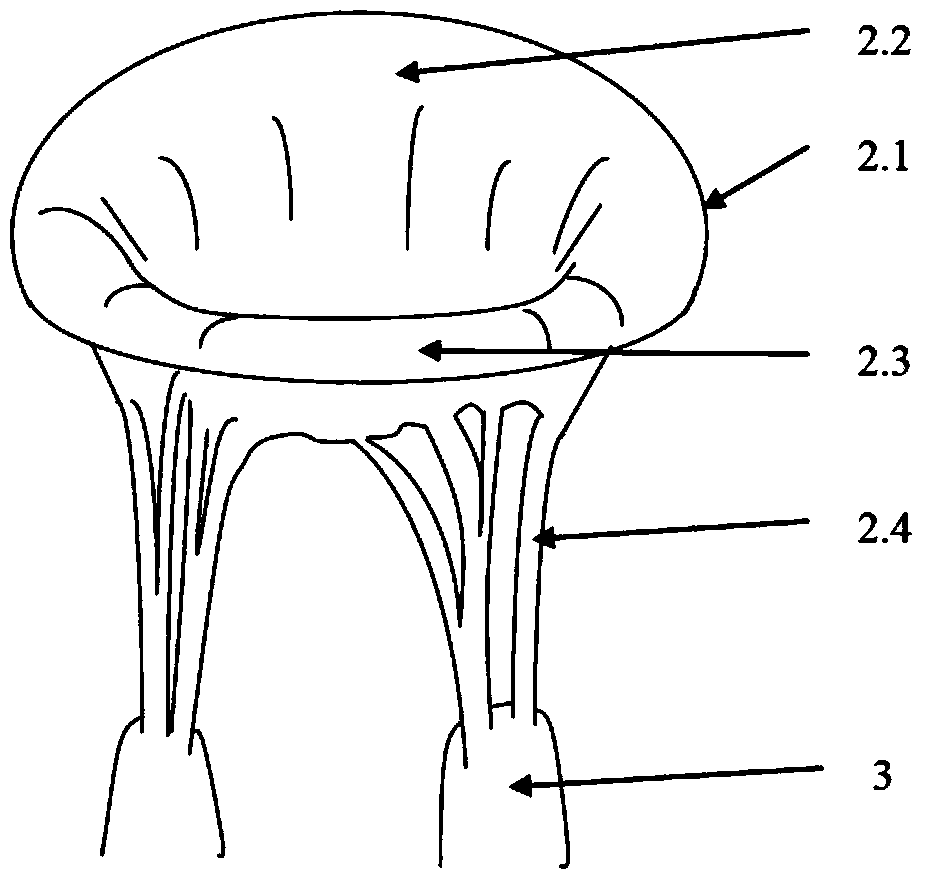

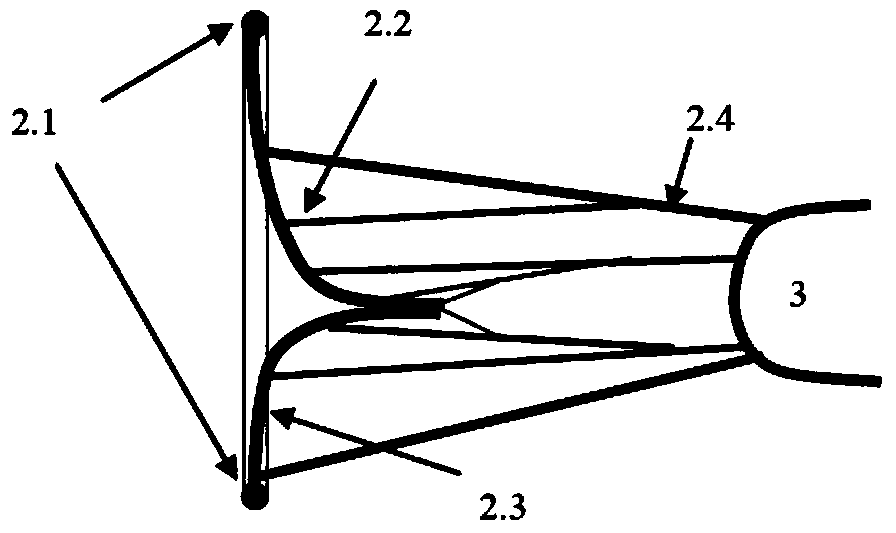

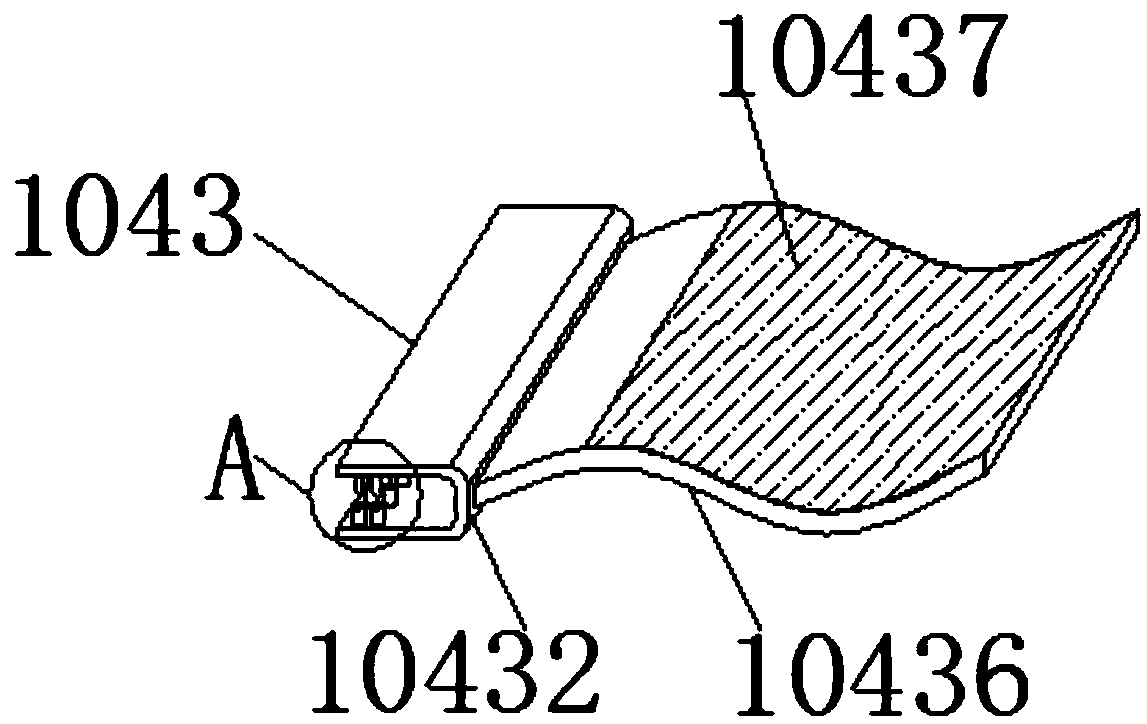

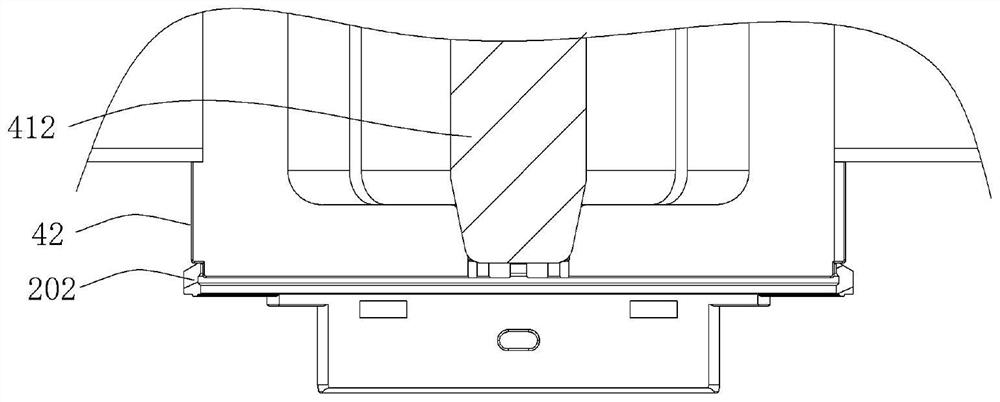

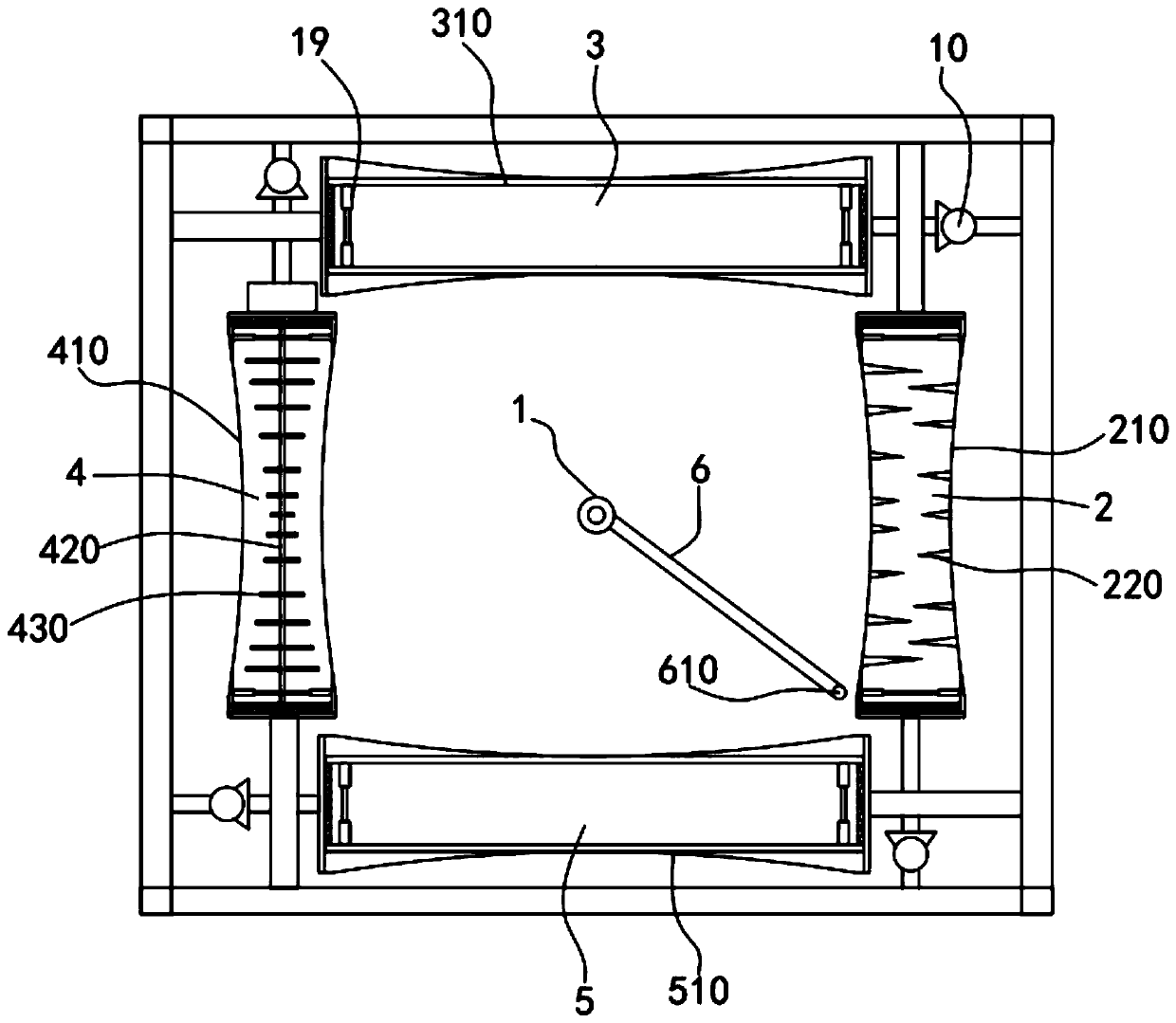

Self-adaptive locating mitral valve closing plate blocking body for repairing mitral regurgitation

ActiveCN104042359AReduce or avoid refluxPlay a plastic roleAnnuloplasty ringsMitral valve leafletSelf adaptive

The invention provides a self-adaptive locating mitral valve closing plate blocking body for repairing mitral regurgitation. The self-adaptive locating mitral valve closing plate blocking body for repairing the mitral regurgitation comprises a suture plastic ring which can be sutured on a mitral ring and a closing plate, the closing plate comprises a tongue-shaped plate and a supporting rod which is located at the top end of the tongue-shaped plate and connected with the suture plastic ring, and the closing plate can swing back and forth and can be connected to the suture plastic ring in a left-and-right twisting mode. The suture plastic ring is sutured on a valve ring of a mitral valve of a patient through a thoracotomy and an open heart surgery, a plastic function on the mitral ring which is diseased and swelled is performed, and the closing plate is supported. When a heart contracts and valve cusps are closed, the closing plate achieves self-adaptive locating of the position of the closing plate through swing and twisting of itself according to the position of regurgitation holes in the free edges of the valve cusps, the closing plate is made to be located at the position of the free edges when the two valve cusps are closed, the regurgitation holes are filled up, the closing plate is tightly attached to the free edges of the valve cusps , and the mitral regurgitation is lowered or avoided.

Owner:JIANGSU UNIV

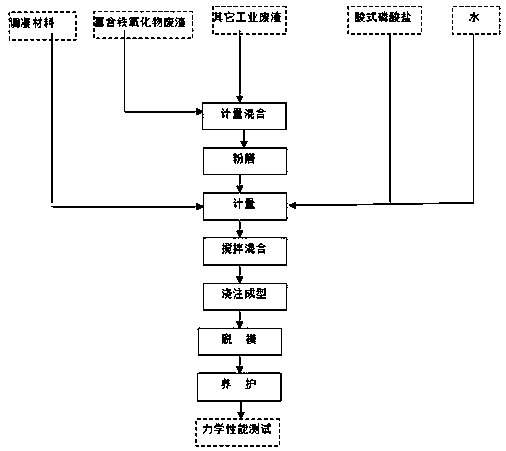

Iron phosphate cement

The invention discloses an iron phosphate cement, belonging to the technical field of building materials. The cementing material is prepared by uniformly mixing the following raw materials with the particle size of 1-100 mu m in parts by weight: 100 parts of acid phosphate, 400-800 parts of waste residue containing rich iron oxides, 3-6 parts of coagulation regulating material, 10-30 parts of other industrial waste residues and 15-200 parts of water. The iron phosphate cement has the advantages of adjustable setting time (several minutes to several hours), quick hardening, high strength, high binding property, no reduction of later strength, and the like, and can be quick hardened at normal temperature. The iron phosphate cement is simple in preparation technique, has high constructability, is suitable for quick emergency repair of defects of roads, airport pavements, bridges, tunnels, cooking ranges, dams, ditches and other engineering structures, and has wide application prospects in curing of high-risk waste residues containing rich radioelements, heavy metal elements, arsenic and the like.

Owner:KUNMING UNIV OF SCI & TECH

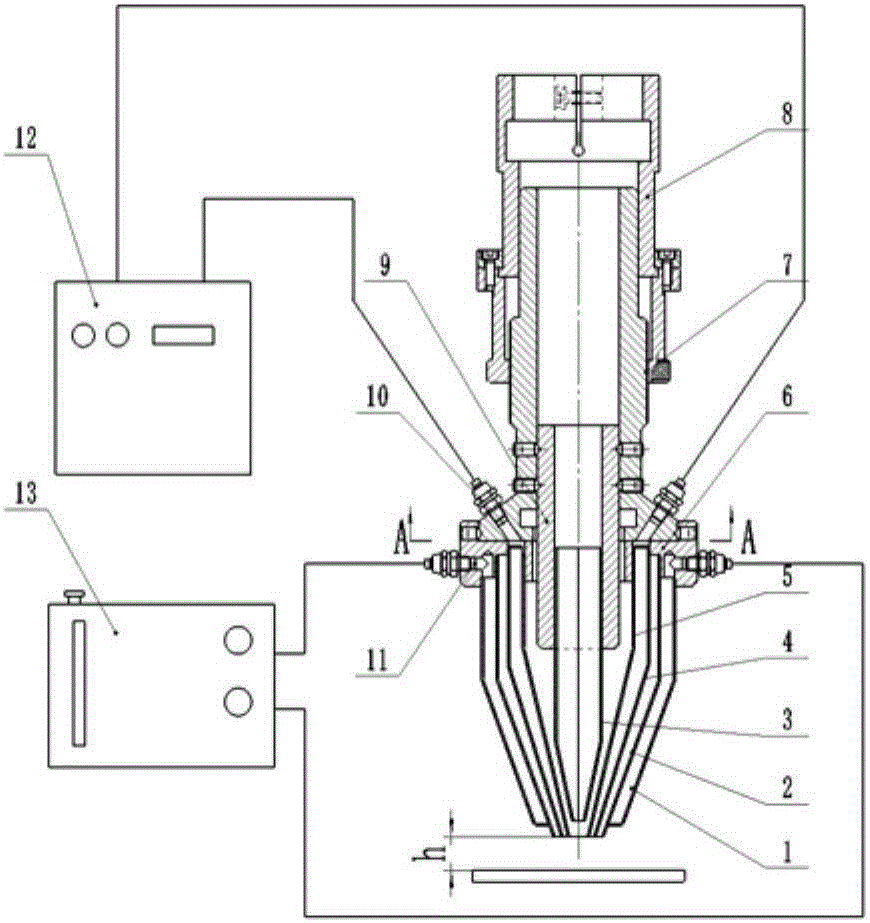

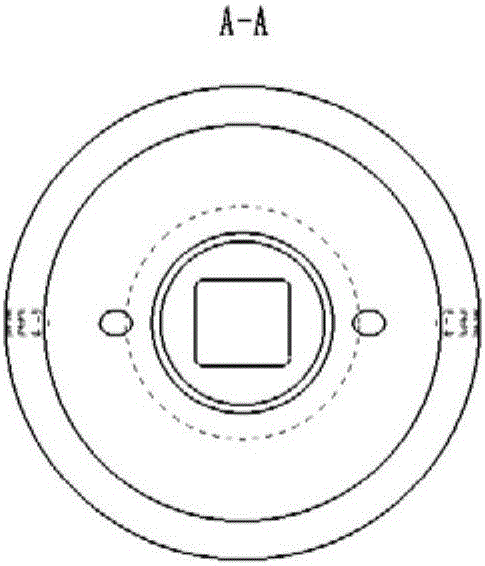

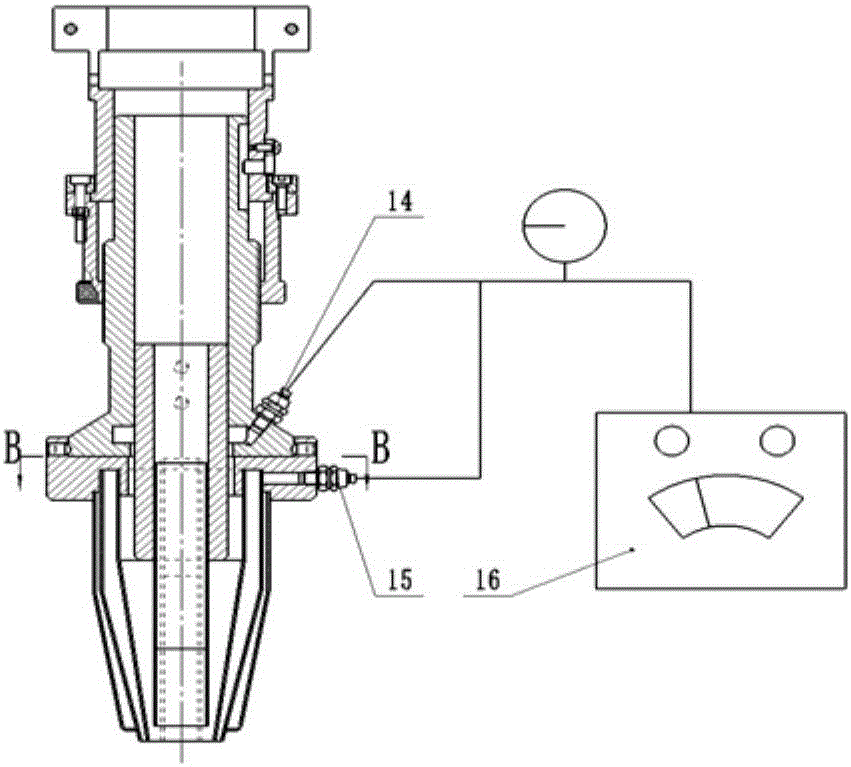

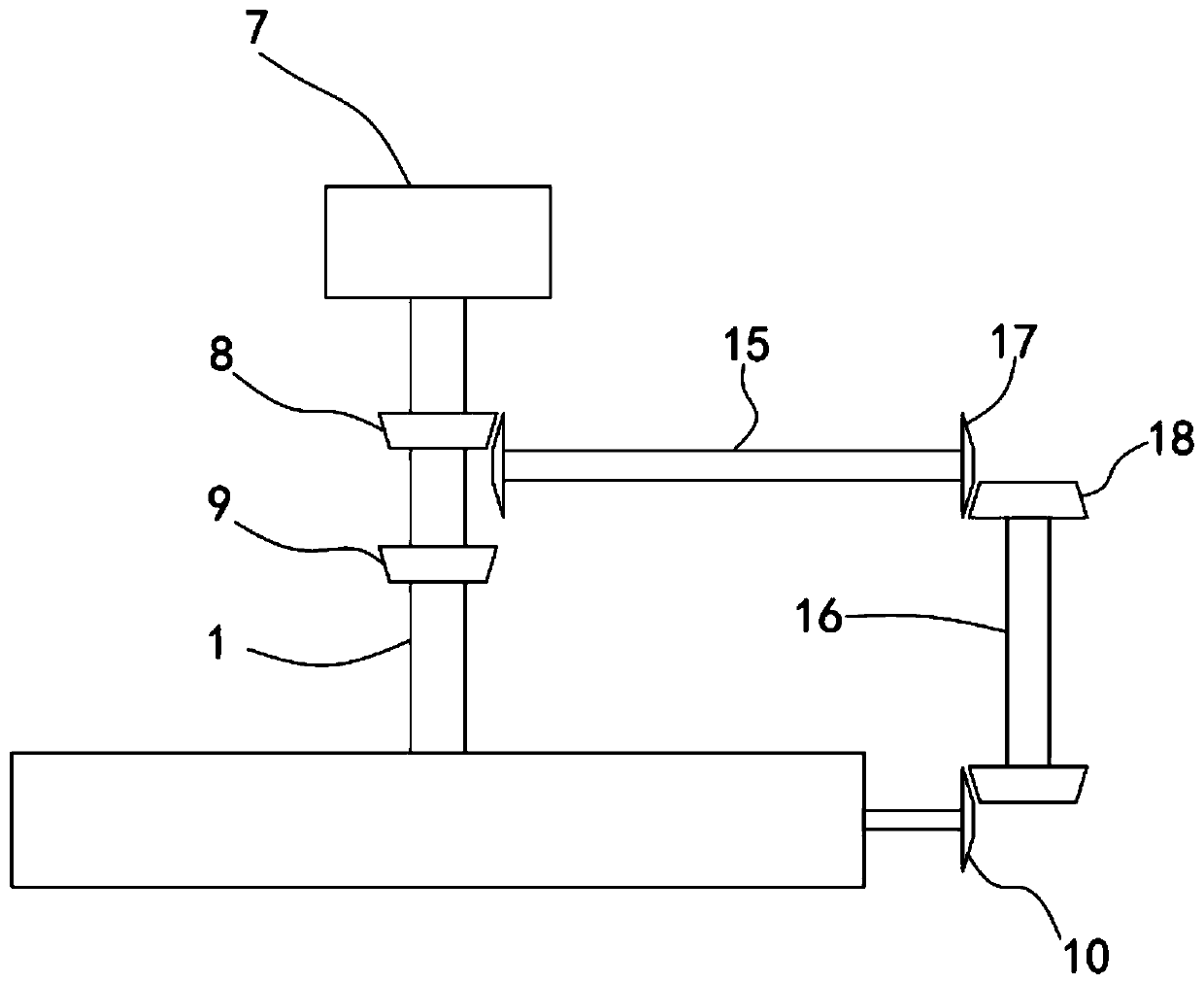

Coaxial powder feeding device for broadband laser cladding and powder feeding method thereof

ActiveCN106521485AAchieve mutual isolationPrevent surface oxidationMetallic material coating processesLight beamEngineering

The invention relates to a coaxial powder feeding device for broadband laser cladding and a powder feeding method thereof. The device comprises a sleeve module; a light beam isolation cover, and an inner-layer air cover, an outer-layer air cover and a cooling water cover for coating the light beam isolation cover in sequence from inside to outside are arranged at the bottom end of the sleeve module; two powder feeding pipes symmetrically arranged about the light beam isolation cover are arranged between the inner-layer air cover and the outer-layer air cover at the bottom end of the sleeve module; outlets of the powder feeding pipes are rectangular pipes; outlets of the light beam isolation cover, the inner-layer air cover, the outer-layer air cover and the cooling water cover at the bottoms are rectangular; and the sleeve module is provided with a water injecting port, a water outlet, an outer-layer protective gas inlet, an inner-layer protective gas inlet and a powder feeding inlet. The method comprises three steps of connection of external source equipment, powder feeding device parameter adjustment and coaxial broadband powder feeding laser cladding. The device can prevent fused metal liquid from splashing to block the outlet of the powder feeding device, can enable the powder spot pavement to become more uniform in powder spot shaping, and is simple in structure and easy to machine.

Owner:WUHAN UNIV OF TECH

Preparation method of high-toughness pressureless sintered boron carbide ceramic

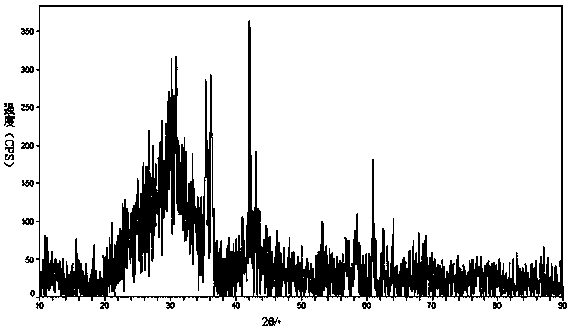

InactiveCN108911753AReduce temperature sensitivityHigh particle size concentrationBoron carbideSlurry

The invention relates to a preparation method of high-toughness pressureless sintered boron carbide ceramic. 65 to 78 wt% of boron carbide powder, 10 to 17 wt% of a sintering aid and 8-20 wt% of a ceramic additive are added into a stirring mill, and a certain amount of solvent is added, stirring ball milling-sand mill treatment-stirring ball milling process is performed, the solid content of ceramic slurry is 45 to 60 wt%, granulated powder is obtained by centrifugal spray granulation, the granulated powder is pressed into a green body, the green body is placed in a graphite sagger, graphite balls are placed around the green body, the graphite sagger is placed in a high-temperature vacuum sintering furnace for pressureless sintering, and finally the boron carbide ceramic is obtained. The low-price large-particle boron carbide powder is used as a raw material, and a multi-component eutectic non-oxide liquid phase is introduced to promote the densification of the boron carbide ceramic.

Owner:扬州北方三山工业陶瓷有限公司

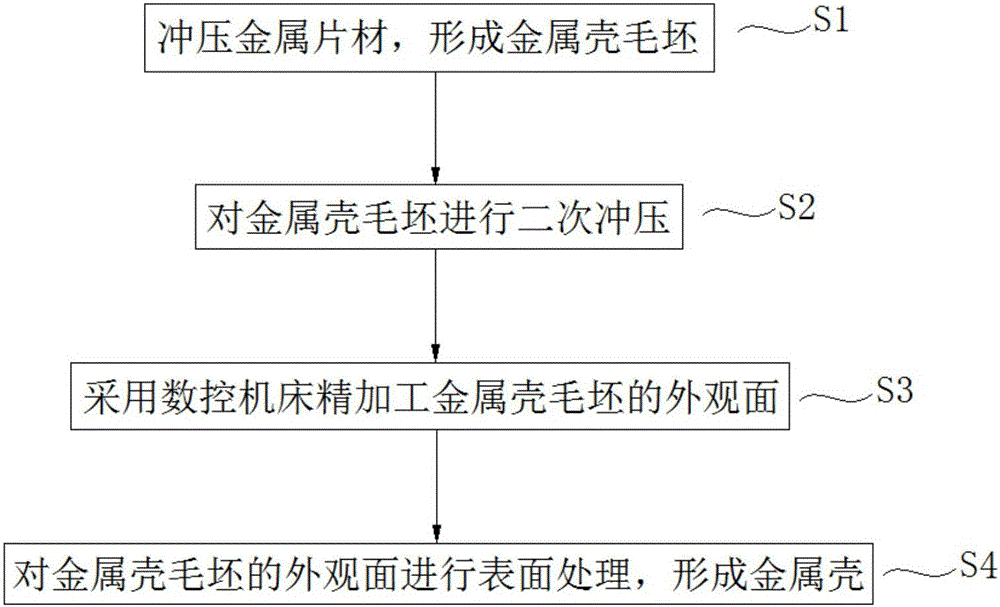

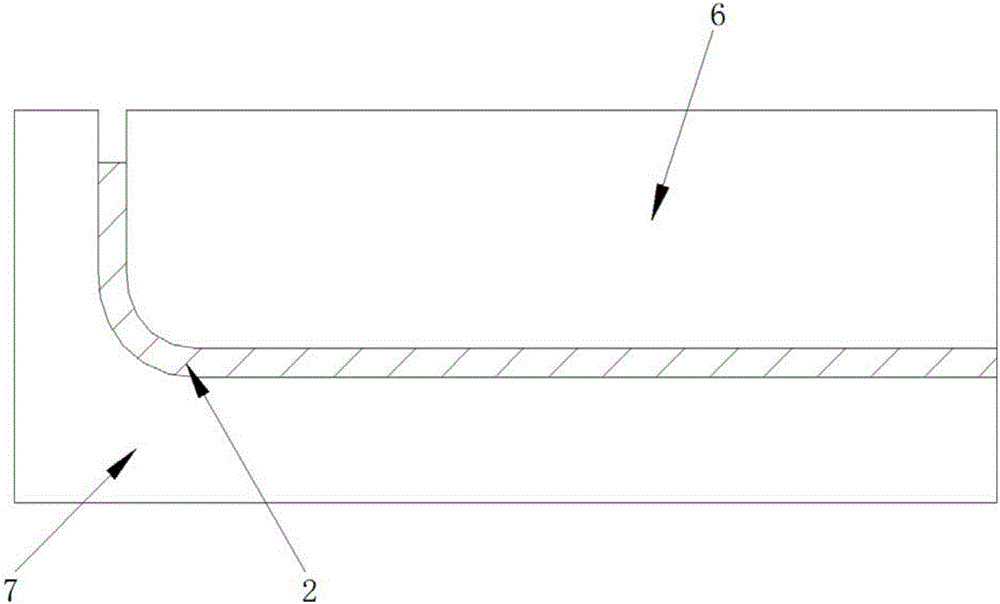

Metal shell forming process, integrated shell forming process, shell and electronic device

InactiveCN106112393APlay a plastic roleMake up for reboundCasings/cabinets/drawers detailsPunchingMetal sheet

The invention relates to the field of electronic device parts and machining methods thereof, in particular to a metal shell forming process, an integrated shell forming process, a shell and an electronic device. The metal shell forming process includes the steps that a metal sheet is stamped to form a metal shell blank; the metal shell blank is stamped for the second time; the appearance surface of the metal shell blank is subjected to finish machining; and the appearance surface of the metal shell blank is subjected to surface treatment. The integrated shell forming process includes the steps that a metal sheet is stamped to form a metal shell blank; the metal shell blank is stamped for the second time; the metal shell blank is subjected to lateral punching to form a side hole; plastic parts are formed on the metal shell blank; the appearance surface and the side hole of the metal shell blank are subjected to finish machining; and the appearance surface of the metal shell blank is subjected to surface treatment. By means of the metal shell forming process and the integrated shell forming process, precise product appearance can be obtained, and the machining time is short. The integrated shell is formed through the integrated shell forming process. The electronic device comprises the integrated shell, and the electronic device and the integrated shell have precise appearance and are short in machining time.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

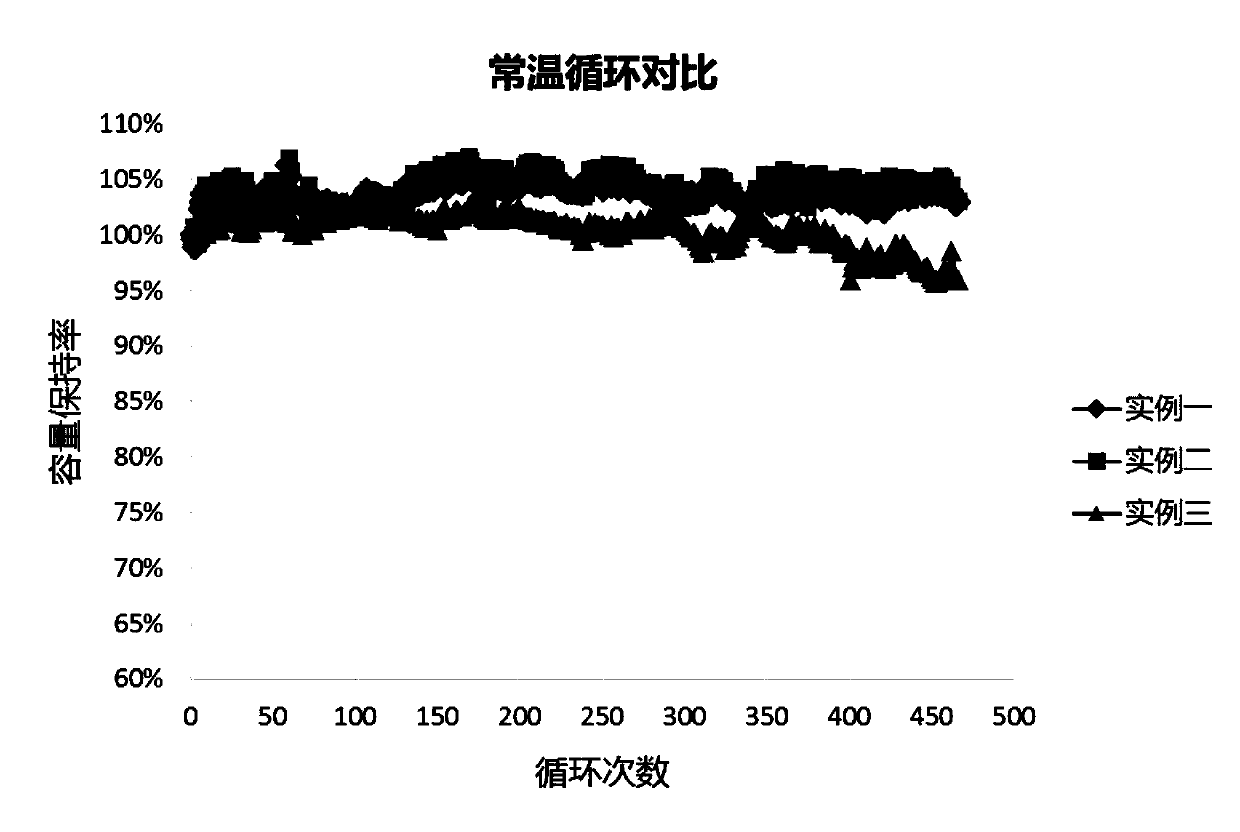

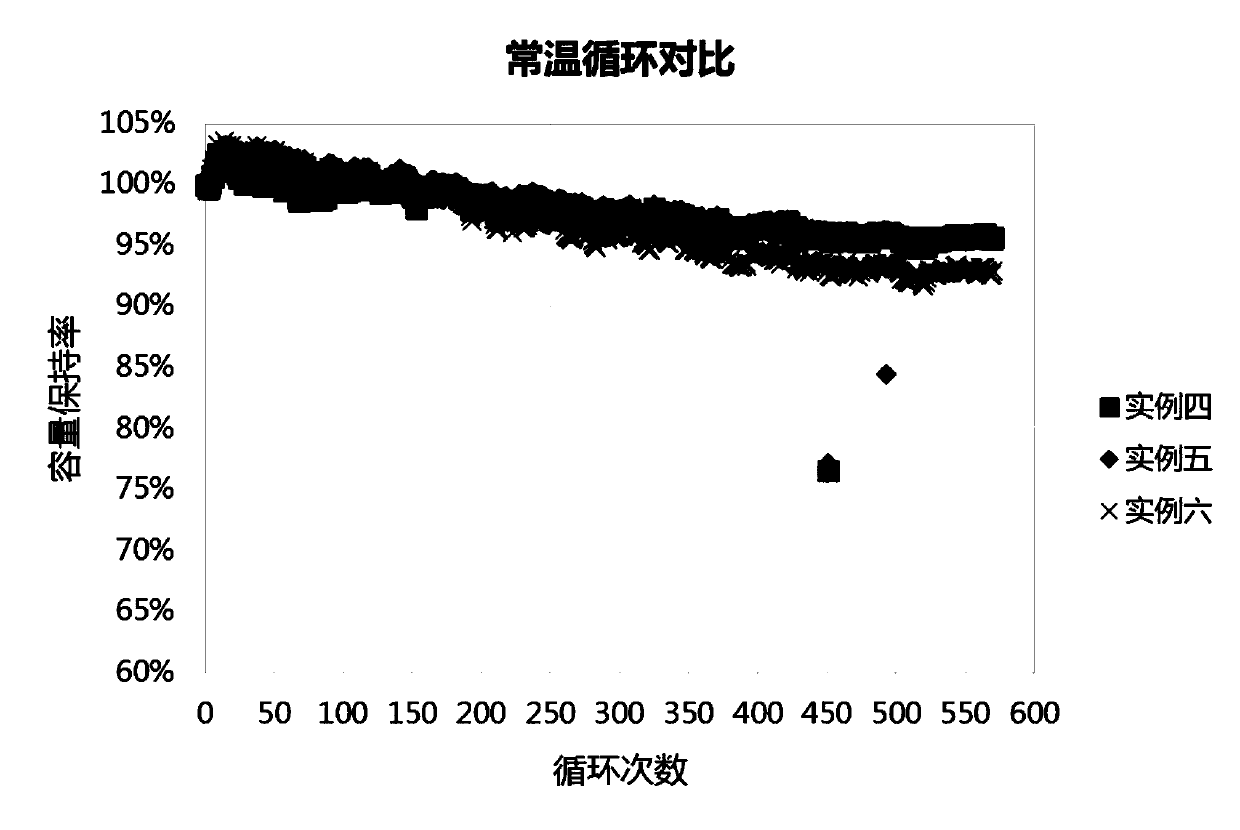

Rapid formation treatment method capable of improving cycle performance of lithium ion battery

InactiveCN107732314AExtend the production cycleShorten the production cycleFinal product manufactureElectrolyte accumulators manufactureEngineeringLithium-ion battery

The invention discloses a rapid formation treatment method capable of improving cycle performance of a lithium ion battery. The rapid formation treatment method comprises the following steps: carryingout secondary constant current charging or tertiary constant current charging on a to-be-formed main body surface of the lithium ion battery under extrusion and high temperature conditions, then directly entering a secondary sealing working procedure, wherein the extrusion condition is 1.0-1.5MPa, and the temperature condition is 45-65 DEG C. The rapid formation treatment method disclosed by theinvention has the advantages that different charging restrictions are adopted according to different lithium ion battery systems, formation time can be shortened to the utmost extent, and a uniform and compact SEI film is formed on an electrode interface, so that the cycle performance of the battery is effectively improved.

Owner:桑顿新能源科技(长沙)有限公司

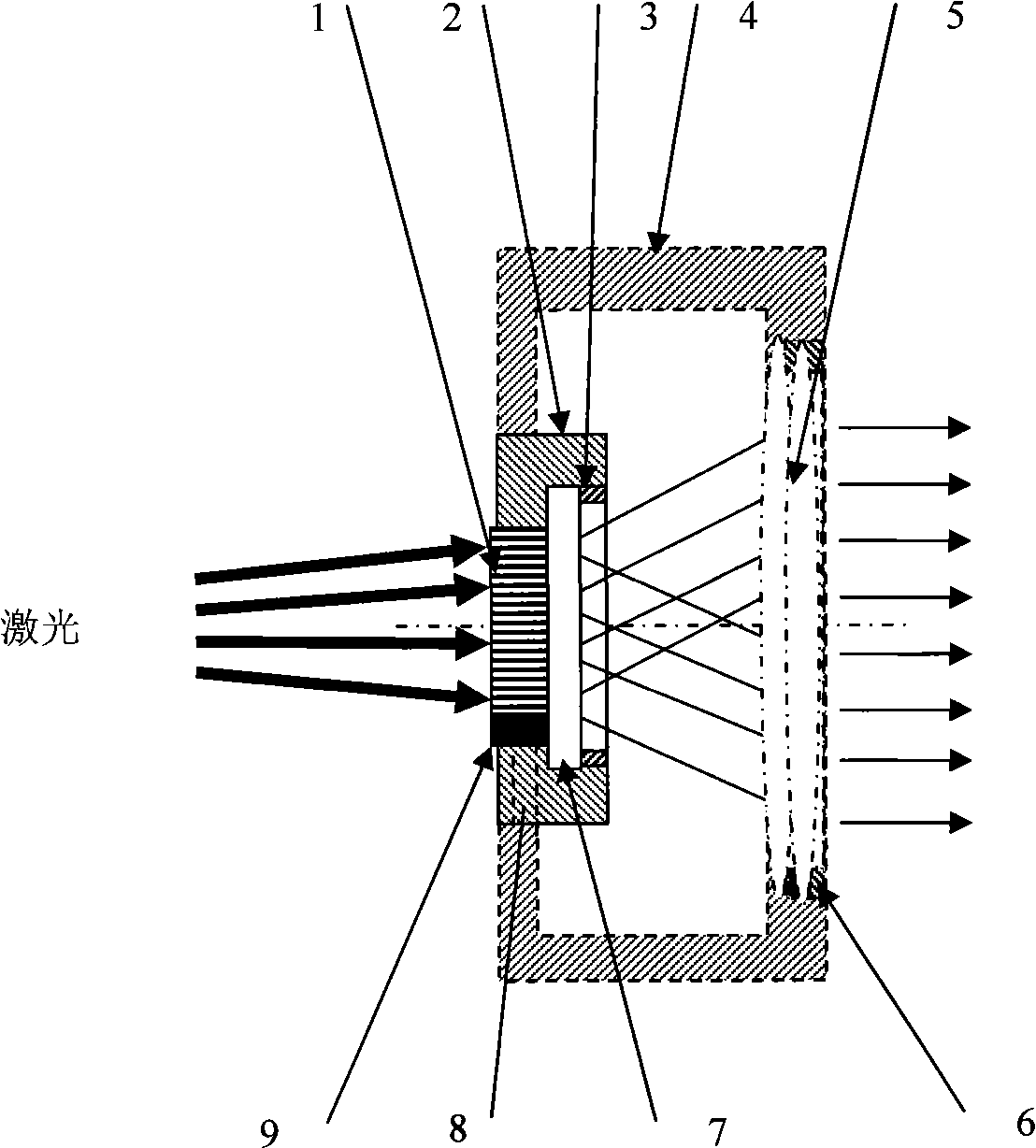

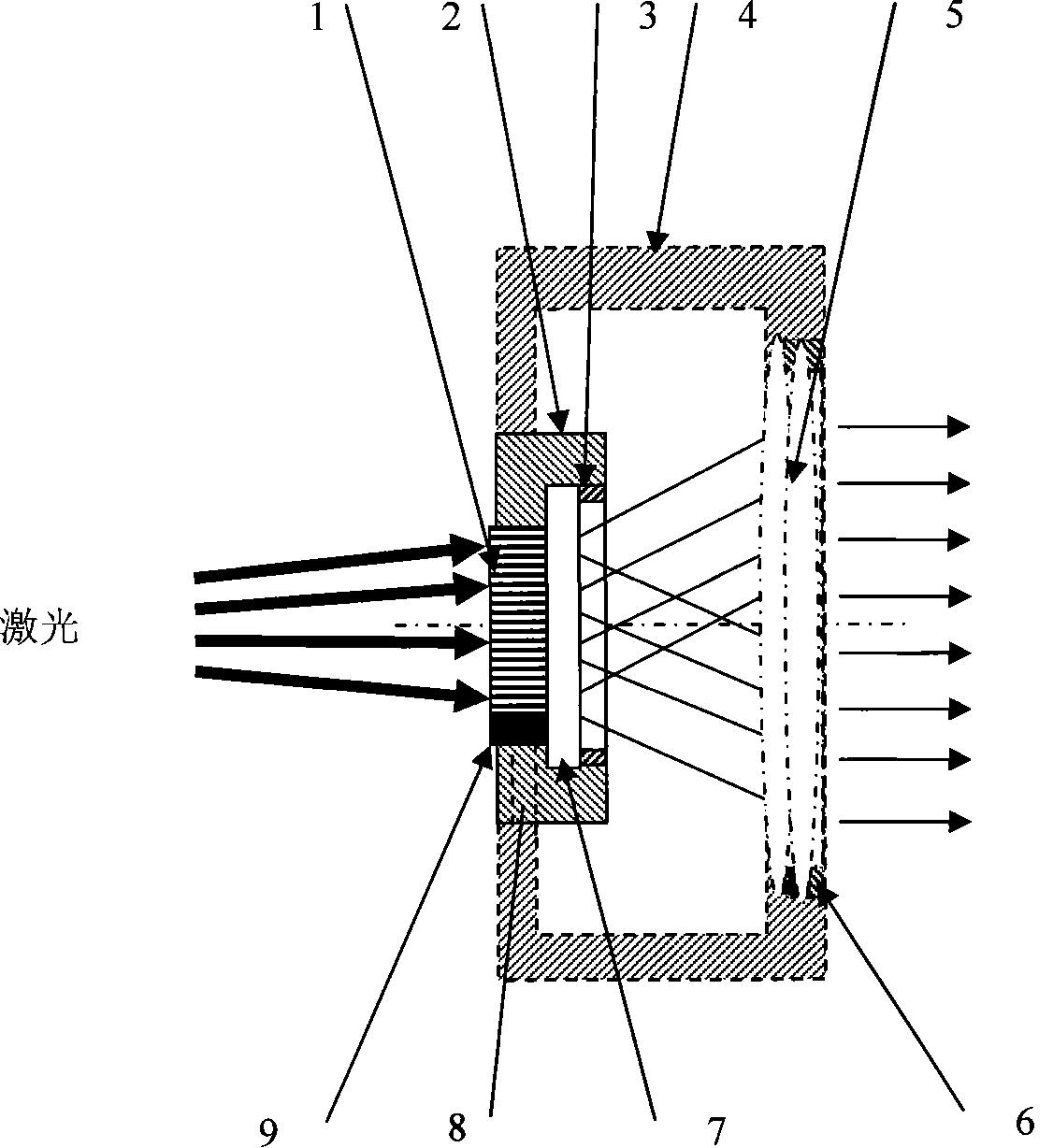

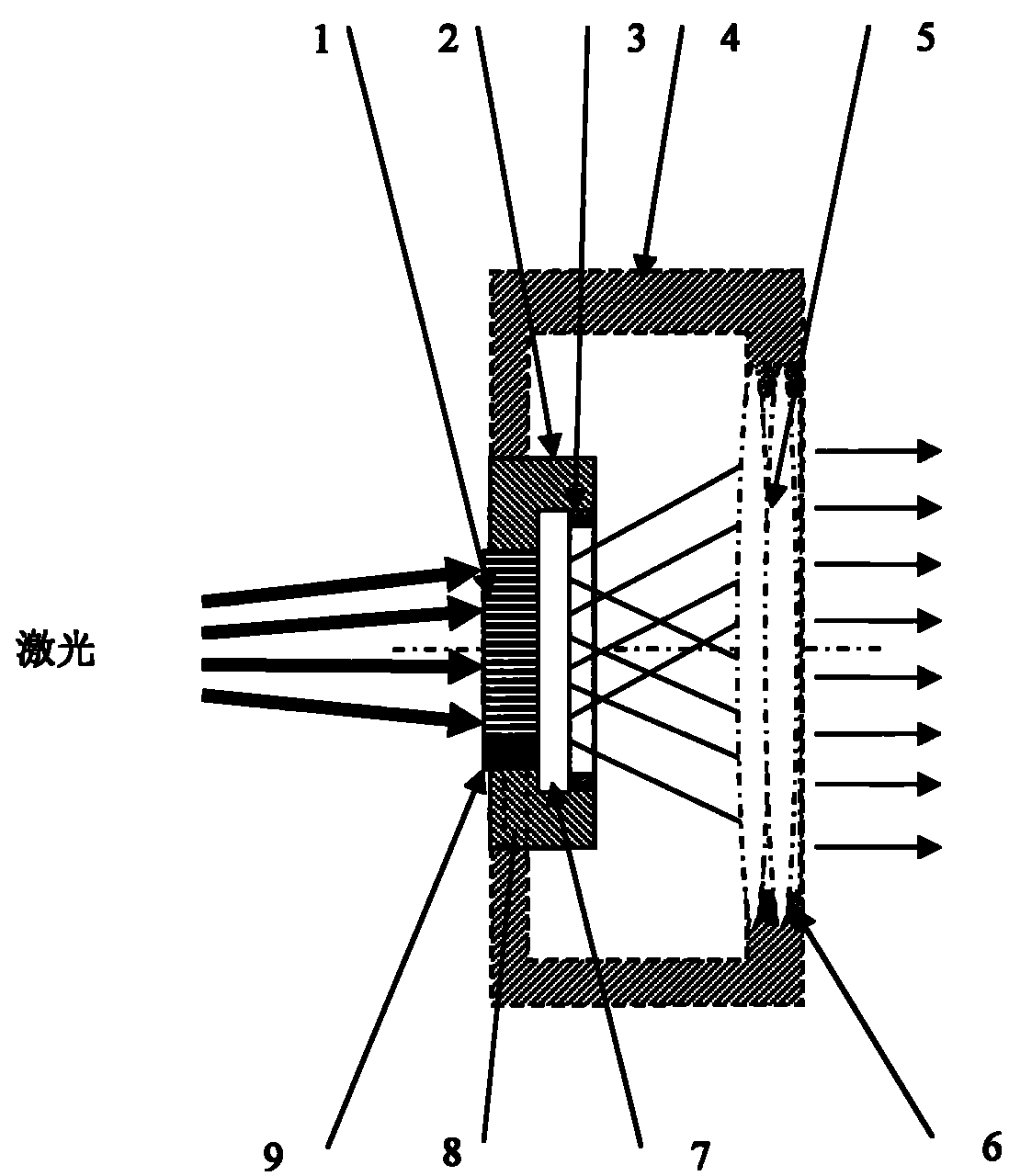

High power laser beam expander

InactiveCN101320132AReduce laser energy densityIncreased Laser Damage ThresholdCoupling light guidesHigh power lasersSingle-mode optical fiber

The invention discloses a extender lens for expanding high power laser beams, which has the main technical characteristics that a plurality of optical fiber rods with equal lengths are all tightly arranged in the cavity body of a housing and the end surfaces of the optical fiber rods respectively form input faces and output faces; the optical fiber rods are bare optical fibers and can adopt optical fibers the core diameter of which is smaller than that of single mode fiber. The invention can expand the laser beans as well as shape and stabilize the direction of the laser beans, and has the advantages of high laser induced damage threshold, simple structure and great reduction of the volume and the weight of a laser shot system.

Owner:南瑶

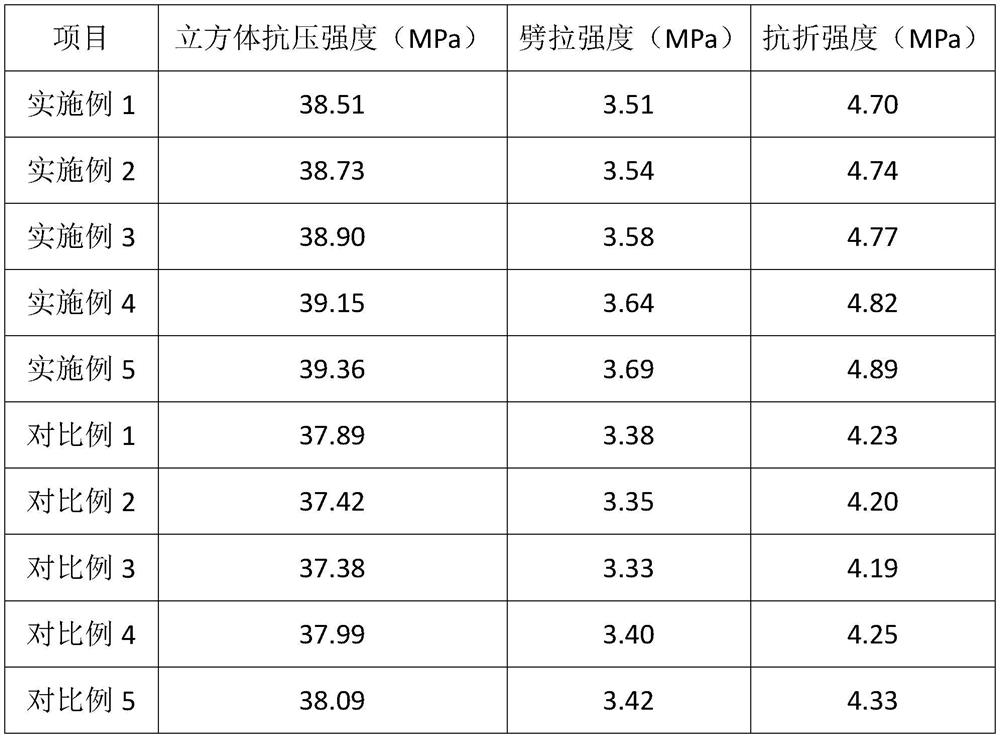

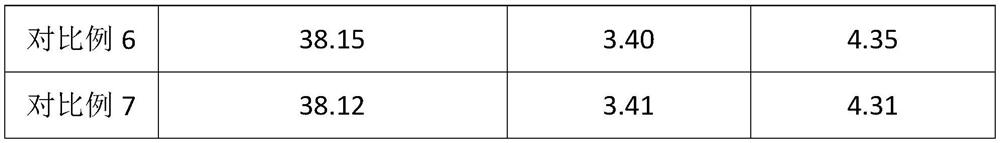

Recycled concrete and preparation method thereof

The invention discloses recycled concrete, which is characterized by being prepared from the following raw materials in parts by weight: 150-180 parts of cement, 250-300 parts of modified recycled aggregate, 400-450 parts of fine river sand, 5-10 parts of attapulgite, 1-3 parts of porous beta-cyclodextrin cross-linked polymer nanofibers, 50-65 parts of blast furnace slag, 1-3 parts of mullite fibers, 2-5 parts of diazoalkyl urea, 4-8 parts of sulfonate-terminated hyperbranched waterborne polyurethane emulsion, 2-4 parts of additives and 75-90 parts of water. The recycled concrete is prepared from the following raw materials in parts by weight: 2-4 parts of carboxyl-terminated liquid fluororubber and 1-3 parts of water-soluble hyperbranched epoxy resin. The invention also discloses a preparation method of the recycled concrete. The recycled concrete disclosed by the invention is excellent in comprehensive performance, high in strength, low in water absorption rate, good in durability and workability and good in workability.

Owner:曹均云

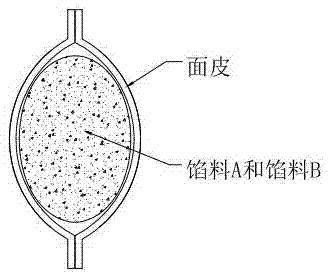

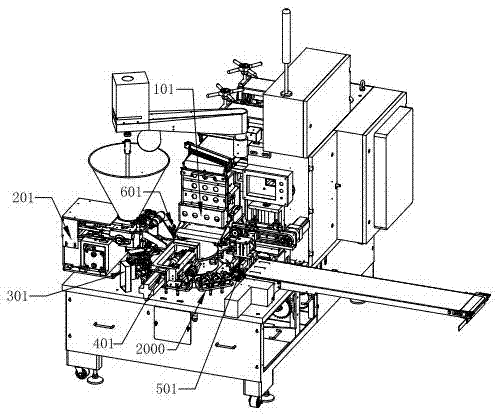

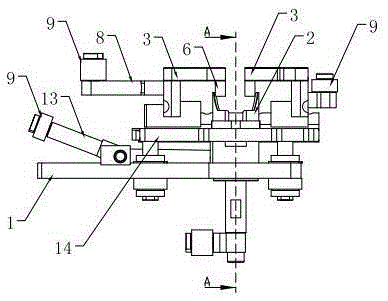

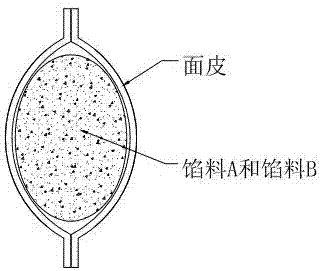

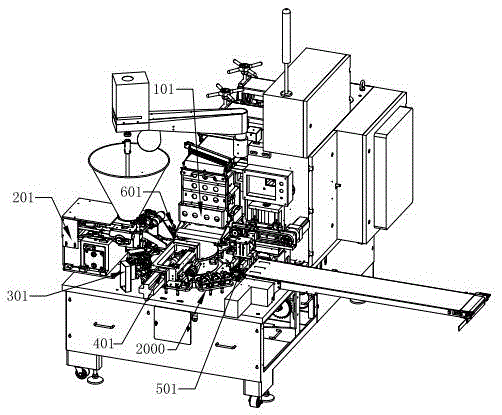

Soup dumplings

The invention belongs to the technical field of food processing and particularly relates to soup dumplings. Each soup dumpling comprises a wrapper, wherein the two side parts of the left end of the wrapper are laminated and connected through a multi-stuffing primary forming mold; the two side parts of the right end of the wrapper are laminated and connected through the multi-stuffing primary forming mold; the wrapper covers solid-state stuffing injected from a first stuffing injection device and liquid-state stuffing injected from a second stuffing injection device; the top part of the wrapper is laminated and connected through a forming device; and the whole body of the wrapper is in a sealed state. With the adoption of the soup dumplings provided by the invention, the wrappers cover the solid-state stuffing and the liquid-state stuffing after the dumplings are automatically produced; and the defect in the prior art that the liquid-state stuffing in all the soup dumplingsis frozen into a solid state and then is covered by the wrappers is overcome.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

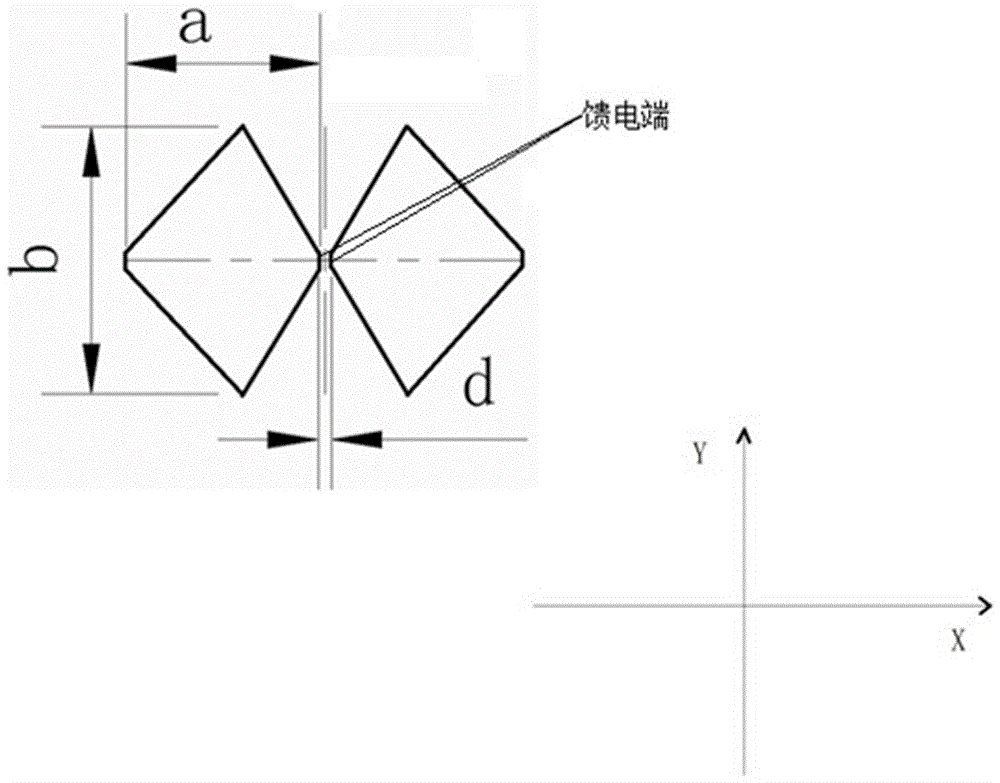

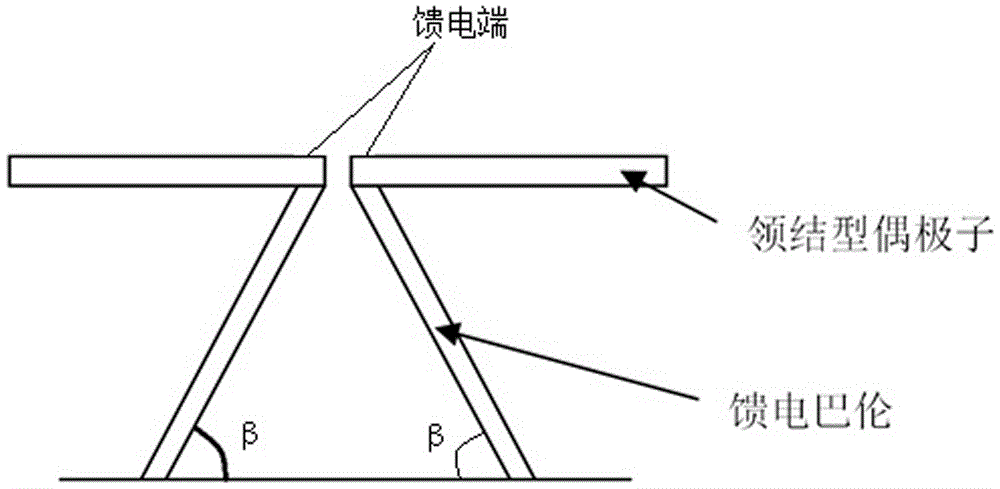

Low-frequency broadband high-efficiency low-profile back-cavity antenna

ActiveCN106549223ASmall sizeMeeting the requirements for UWB workRadiating elements structural formsAntennas earthing switches associationAntenna designSection plane

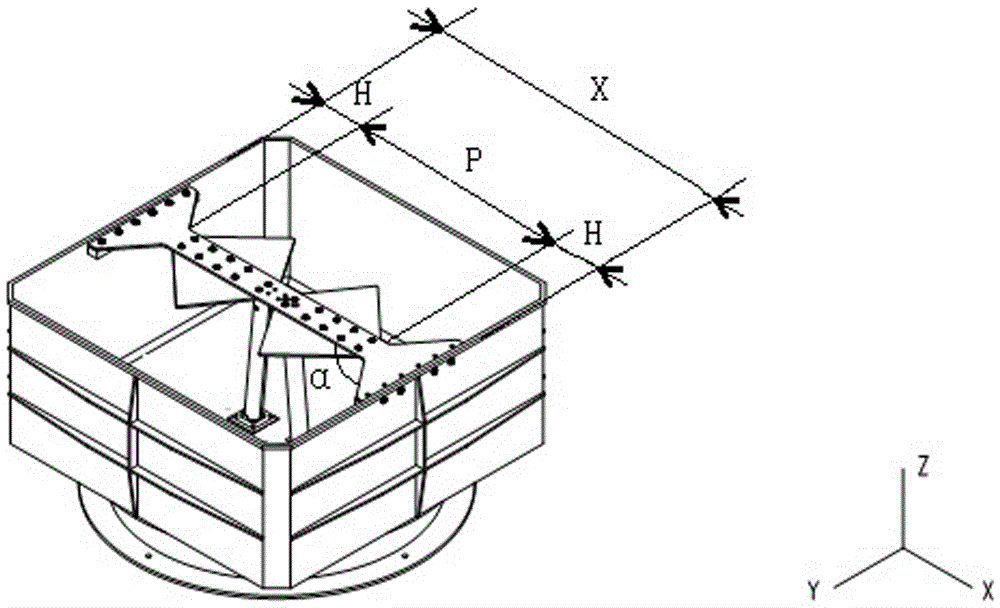

The present invention belongs to the back-cavity antenna design field and provides a low-frequency broadband high-efficiency low-profile back-cavity antenna. The objective of the invention is to solve problems in the prior art. According to the low-frequency broadband high-efficiency low-profile back-cavity antenna of the invention, a bow tie-shaped dipole and a feed Balun are arranged in a reflection cavity; the root portion of the feed Balun is connected with the bottom end surface of the reflection cavity; the top end of the feed Balun is connected with the feed end surface of the tie-shaped dipole; the other end surface of the tie-shaped dipole is connected with an H-shaped medium pull rod; the cavity connection end of the feed Balun is a connection port which is connected with the bottom end surface of the reflection cavity; the end surface of the cavity connection end of the feed Balun is parallel to the bottom surface of the reflection cavity; the dipole connection end of the feed Balun is a connection end which is infinitely closed to the feed end of the tie-shaped dipole; the end surface of the dipole connection end of the feed Balun is parallel to the bottom surface of the reflection cavity; and two ends of the H-shaped medium pull rod are respectively connected with two opposite edges of the opening end surface of the reflection cavity.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

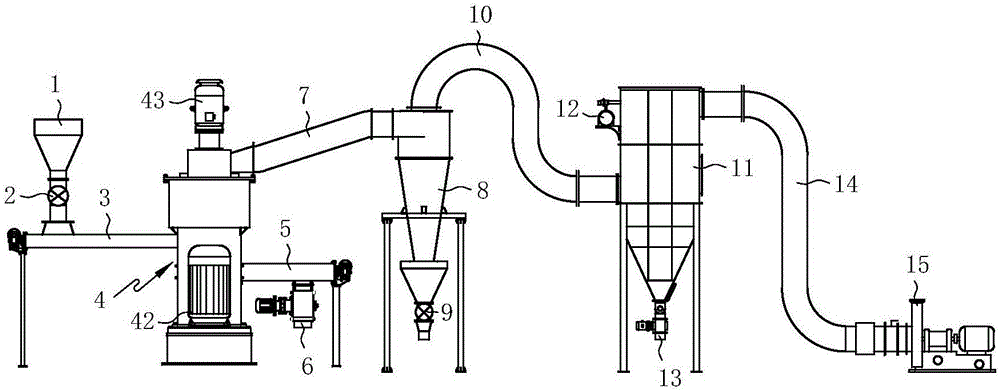

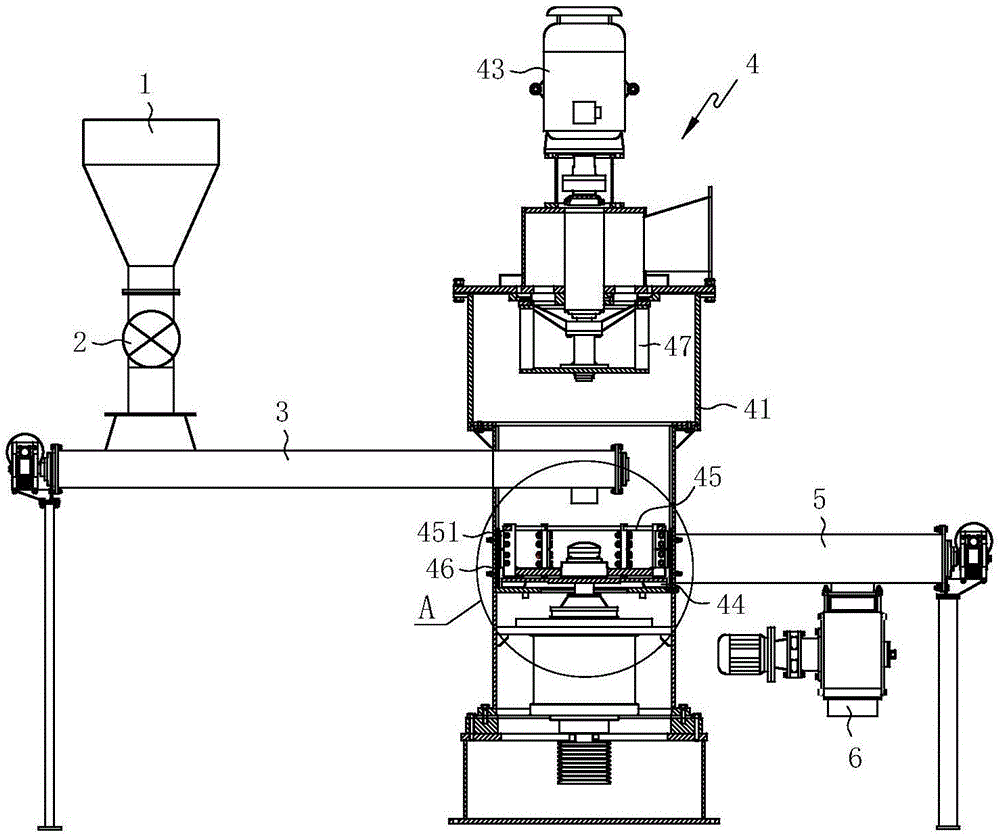

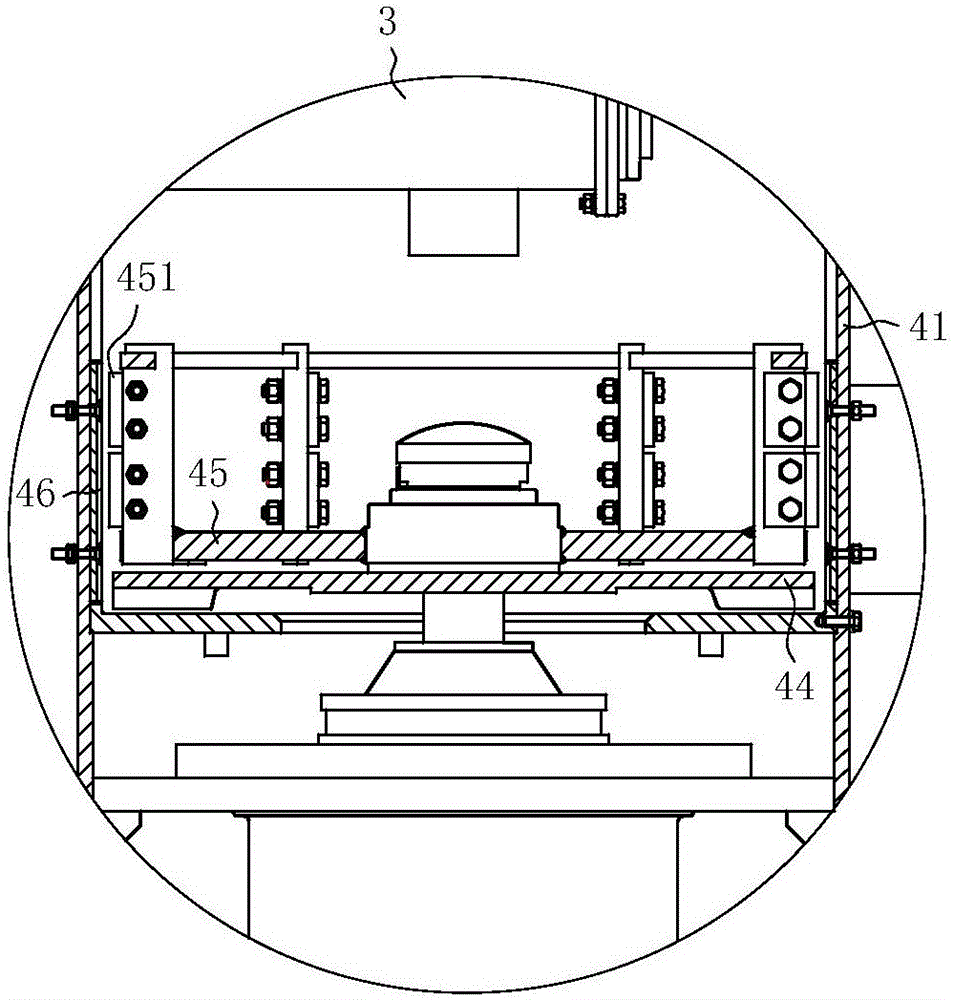

Crushing and shaping integrated production line

The invention discloses a crushing and shaping integrated production line and relates to the technical field of powder equipment. The crushing and shaping integrated production line comprises a crushing and shaping integrated machine; a crushing and shaping device and a grading device are mounted in a cylinder body of the crushing and shaping integrated machine; the crushing and shaping device comprises a wind wheel, a crushing disc and a shaping hammerhead which is fixedly arranged on the inner wall, corresponding to the crushing disc, of the cylinder body; the grading device comprises an impeller; a material inlet is formed in the cylinder body between the crushing disc and the impeller; a fine powder outlet is formed in the cylinder body between the impeller and a second power device; a coarse powder material outlet is formed in a position, corresponding to the crushing disc, on the cylinder body. The crushing and shaping integrated production line disclosed by the invention has the advantages that crushing, shaping and grading functions are simultaneously achieved; the whole crushing and shaking process is carried out in one closed equipment so that material overturning is avoided and material pollution caused by mixing other materials in the material in the overturning process is completely eliminated; product quality is improved; the crushing efficiency is enhanced.

Owner:WEIFANG ZHENGYUAN POWDER ENG EQUIP

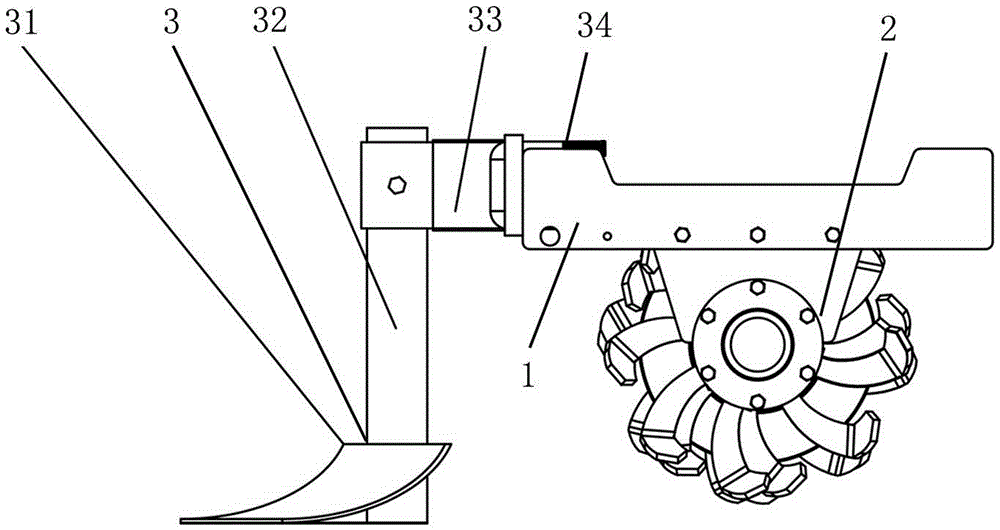

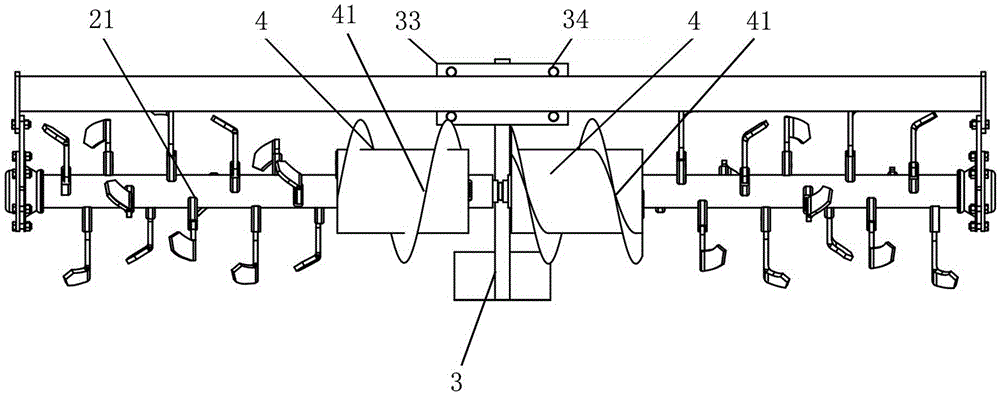

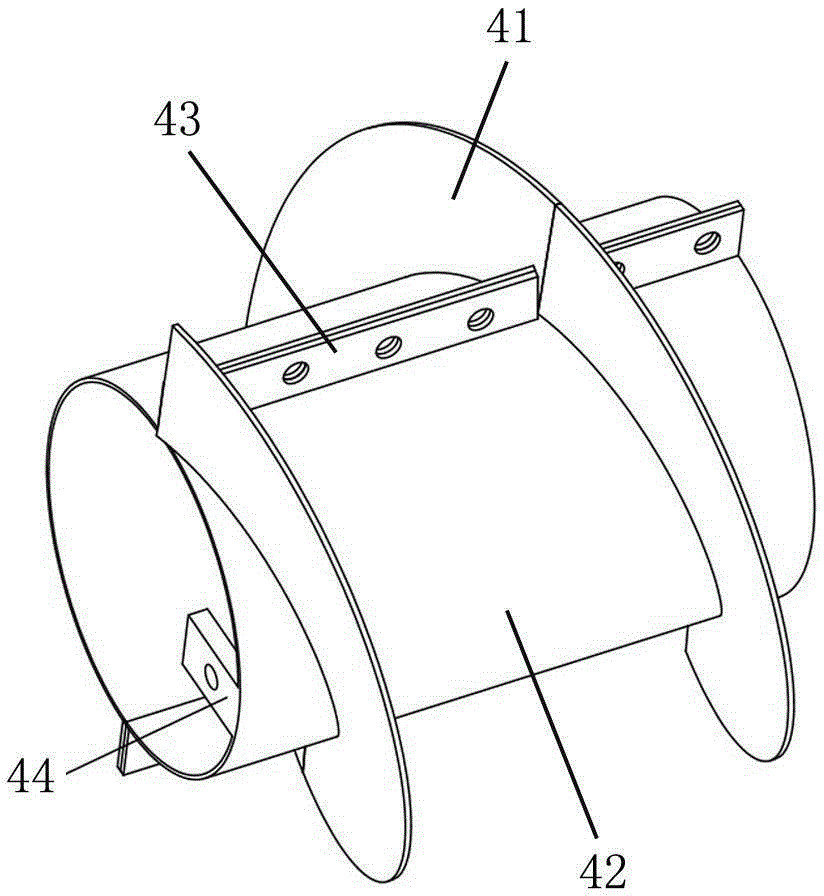

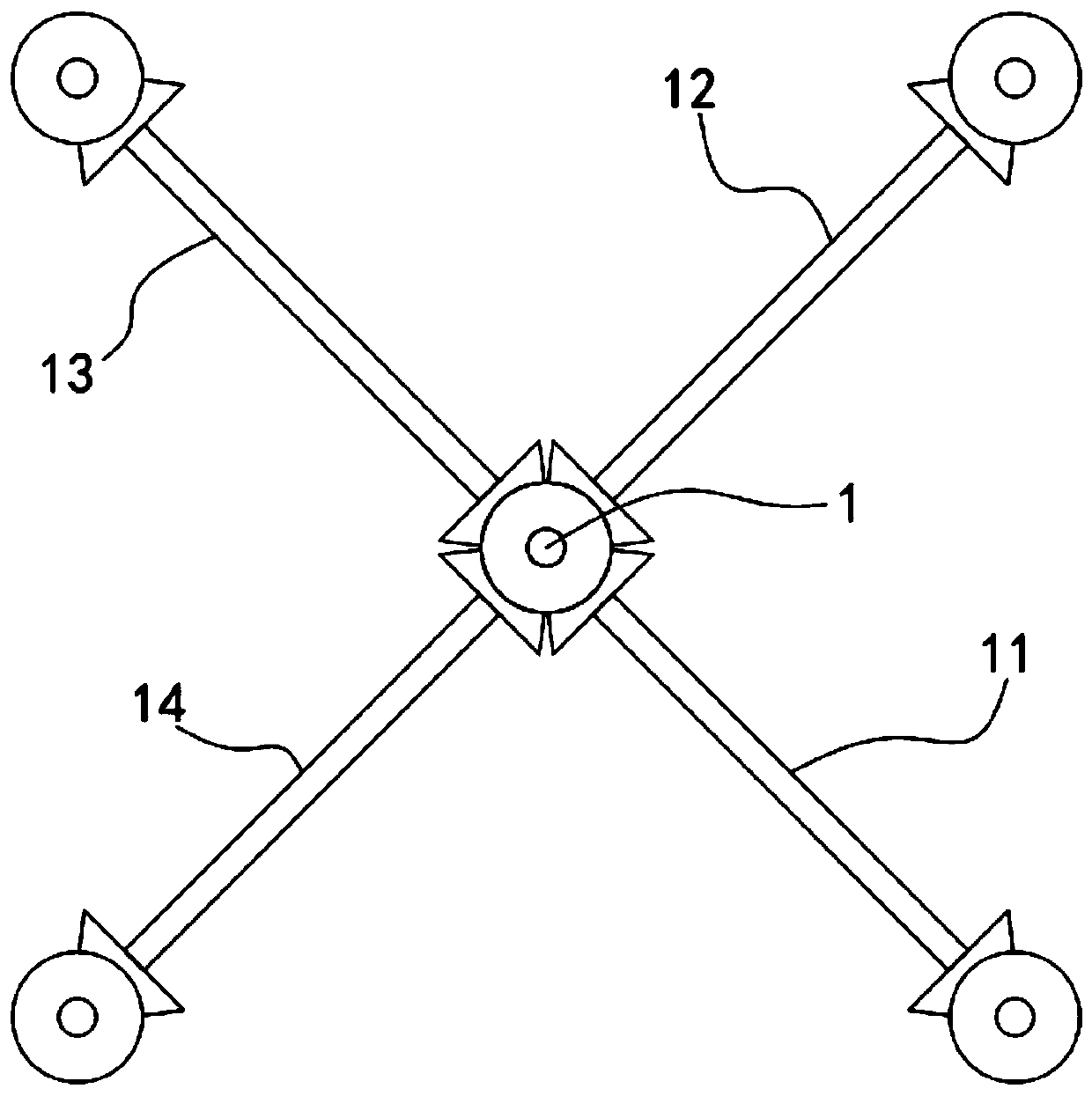

Rotary tillage and ditching device

InactiveCN105230159ASimple structureReduce manufacturing costSpadesPloughsEngineeringMechanical engineering

The invention discloses a rotary tillage and ditching device. The rotary tillage and ditching device comprises a frame and a rotary tillage mechanism arranged on the frame. A forward plough used for opening up a trench is arranged ahead of a heading direction of the rotary tillage mechanism on the frame. A rotary tillage shaft of the rotary tillage mechanism is provided with two packing auger shaping mechanisms located behind the forward plough. All the packing auger shaping mechanisms are provided with auger blades spirally rotating around the rotary tillage shaft. The packing auger blades of the two packing auger shaping mechanisms are opposite in spiral directions and push top soil subjected to soil-turning operation by the forward plough to two sides of the opened trench when performing rotary motion along with the rotary tillage shaft. The rotary tillage and ditching device is advantaged by being simple and reasonable in structure, low in manufacture cost, small in resistance of trench digging, fine in trench digging quality and low in power consumption.

Owner:HUNAN AGRICULTURAL UNIV

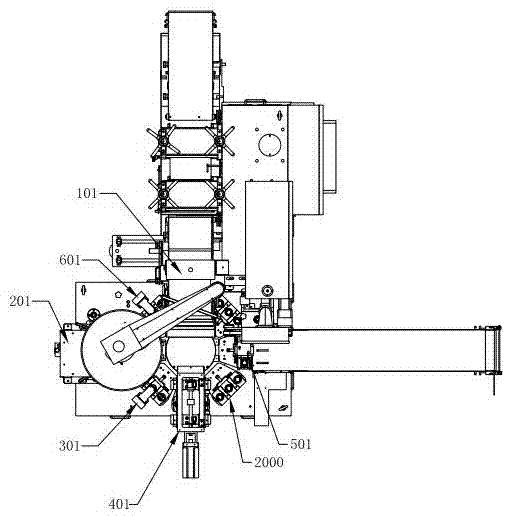

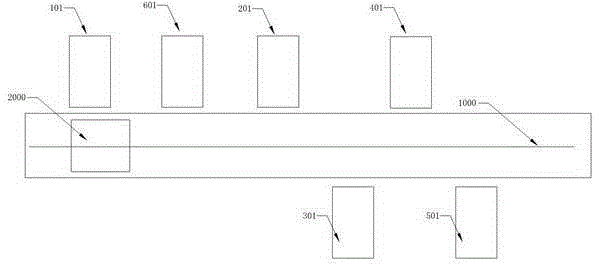

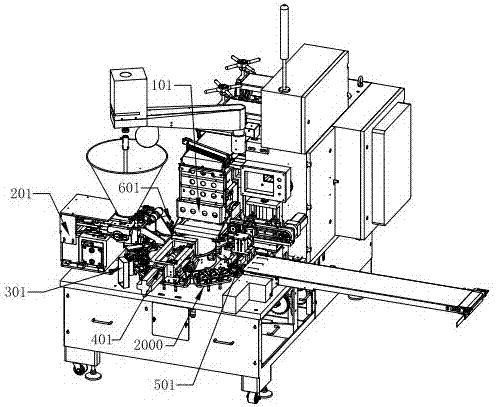

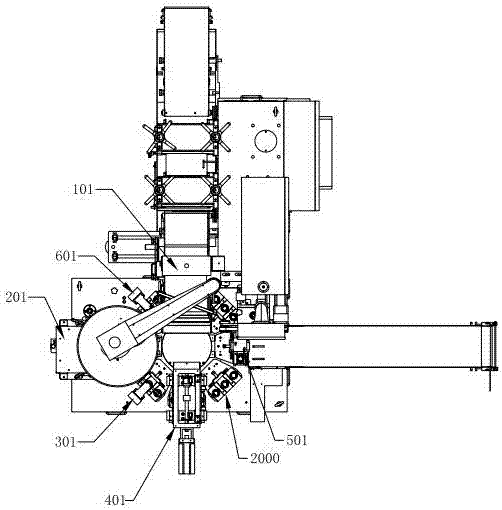

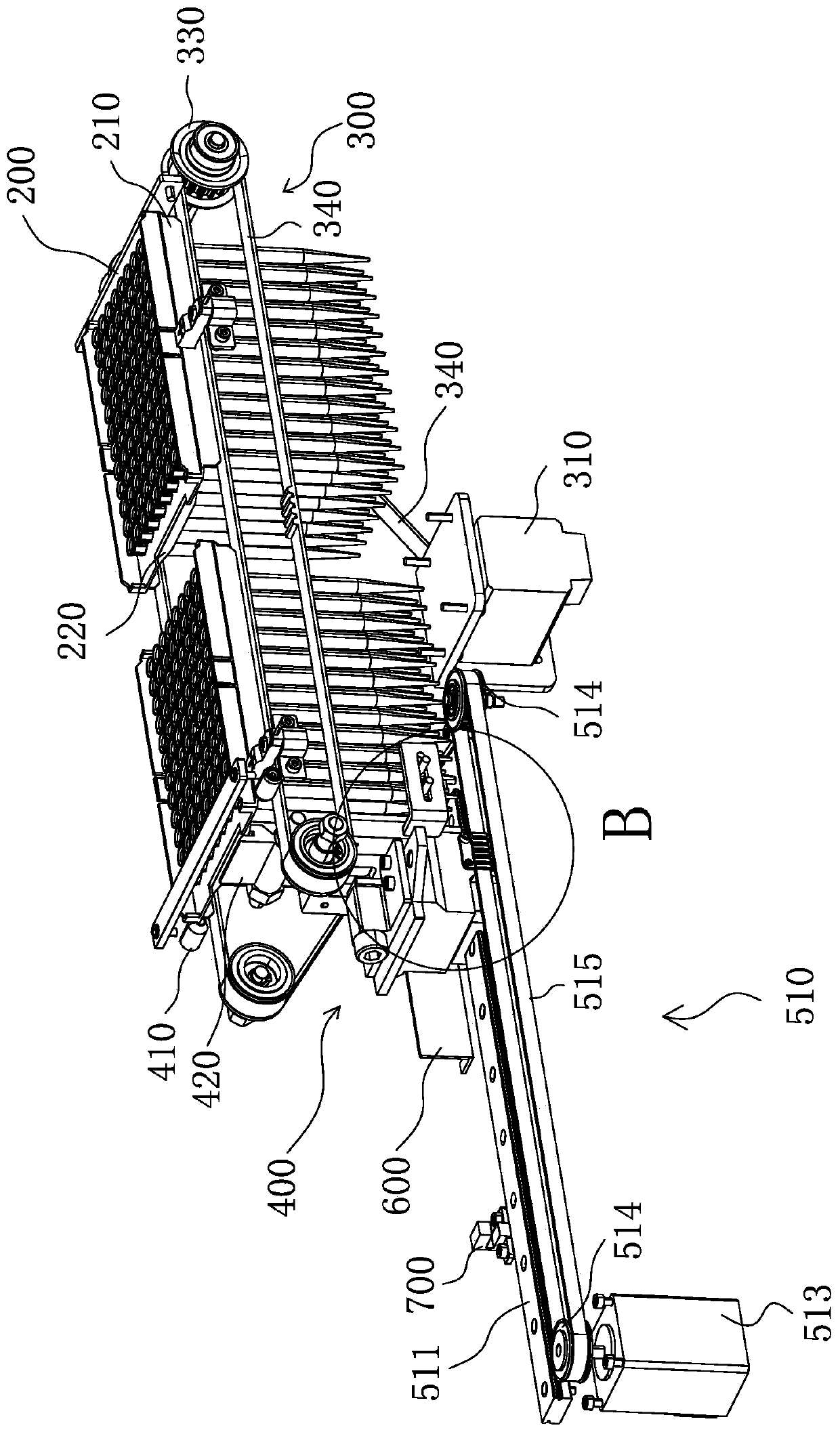

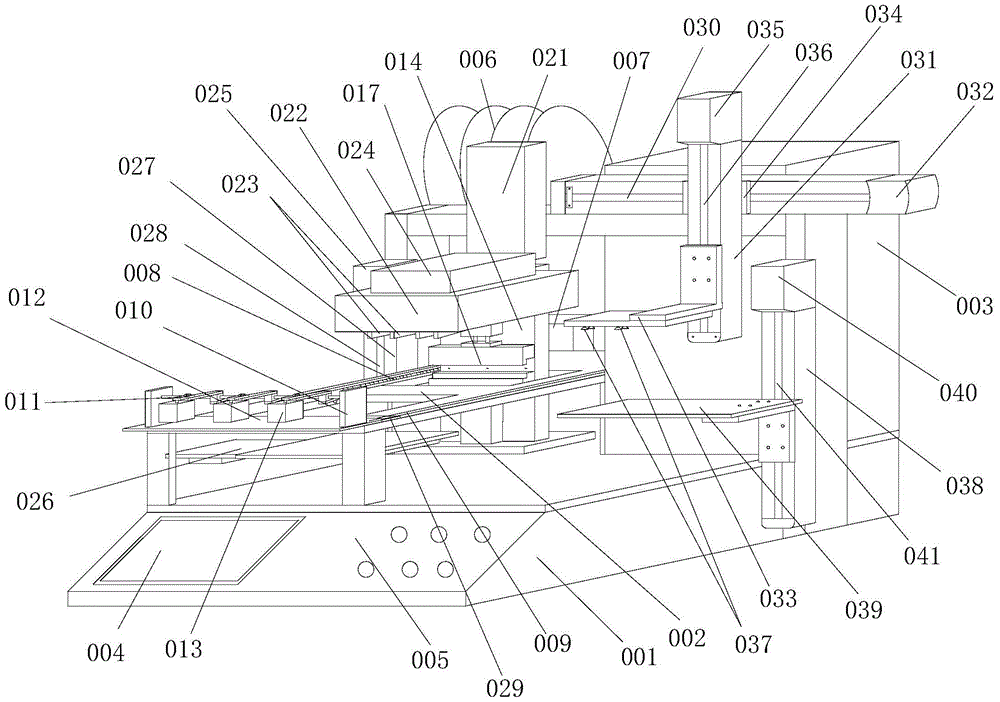

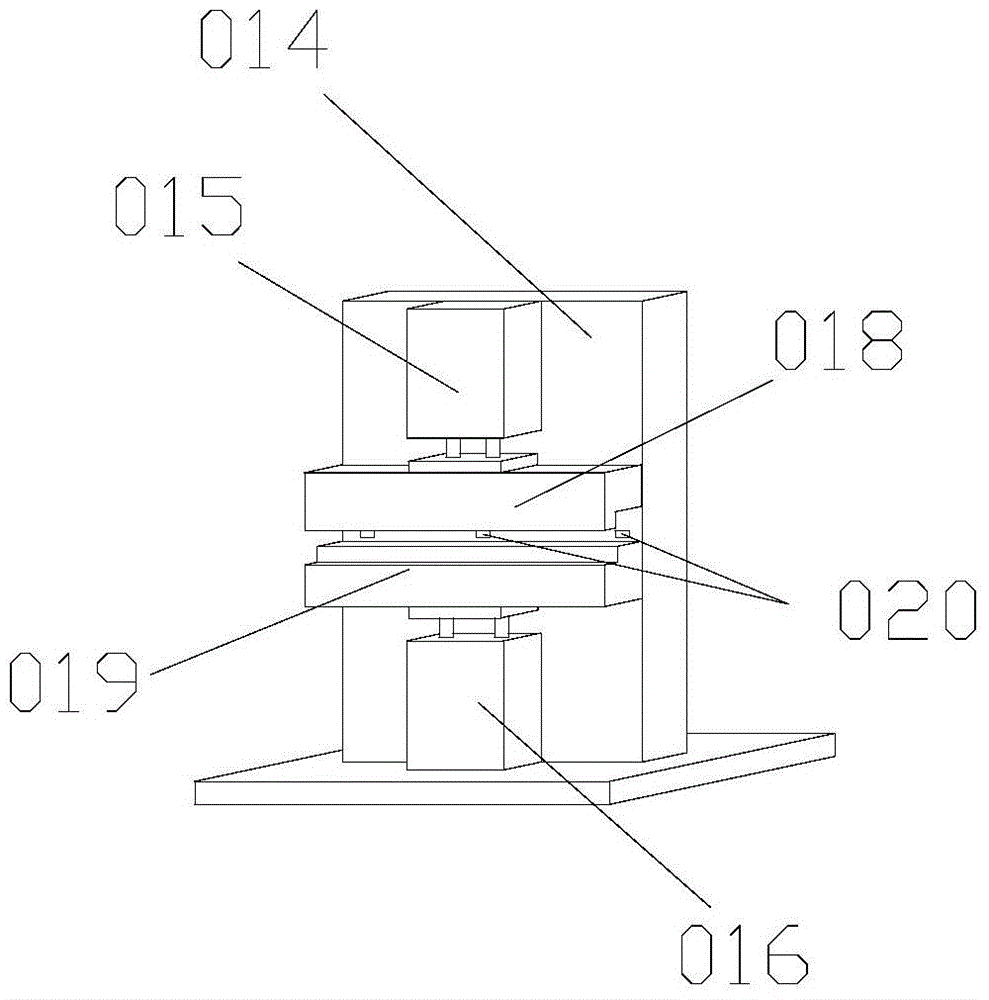

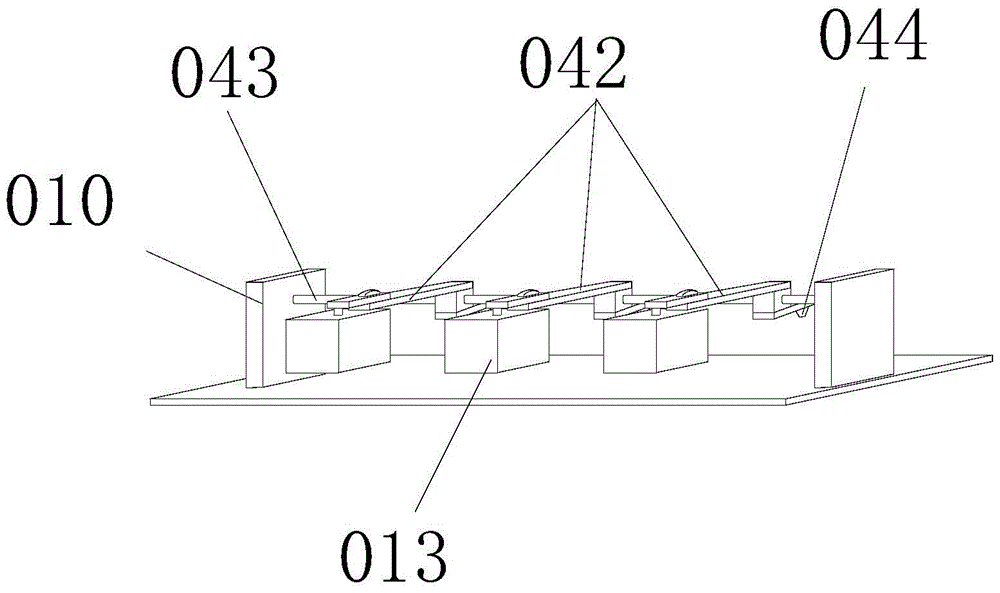

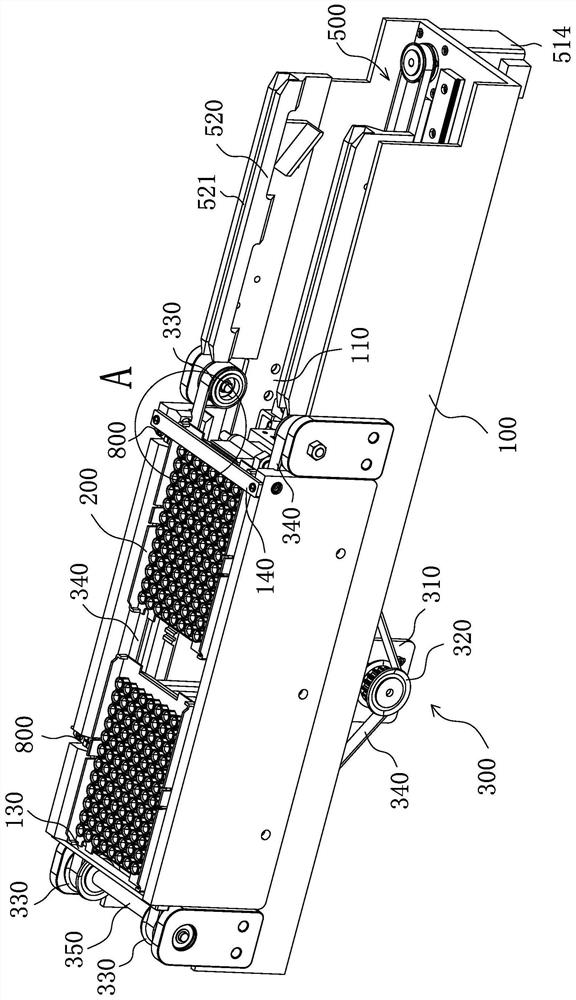

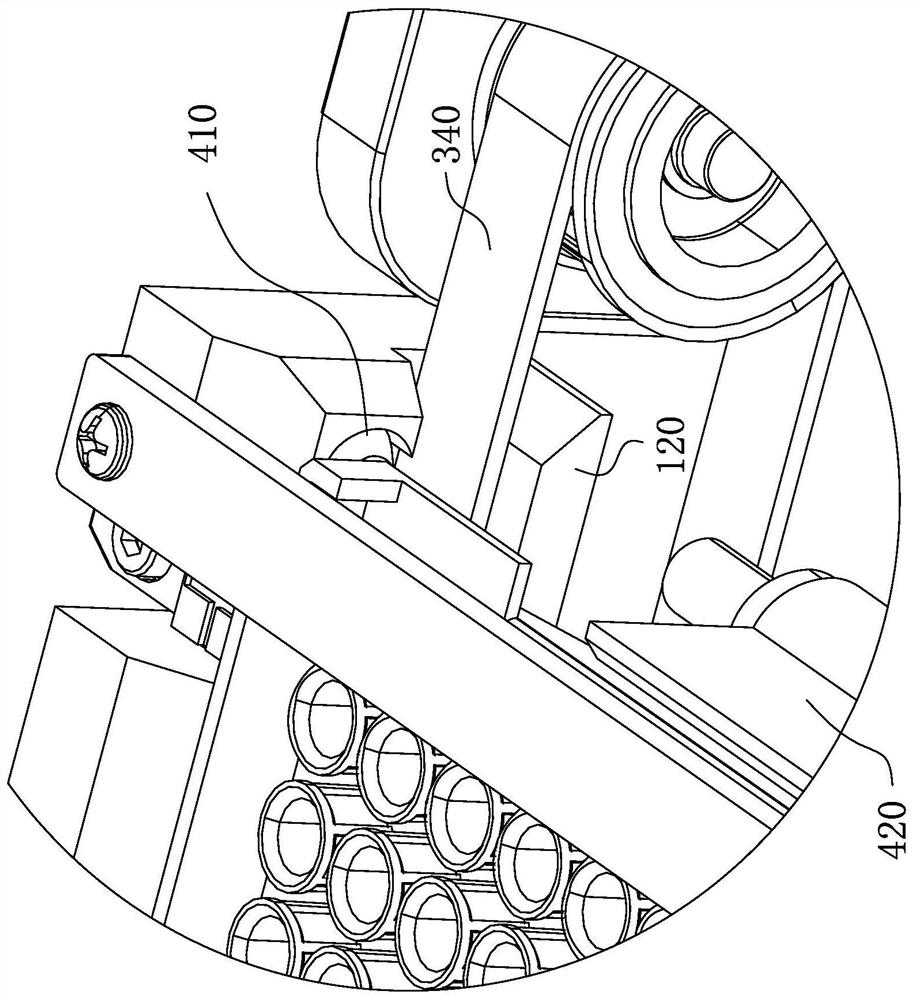

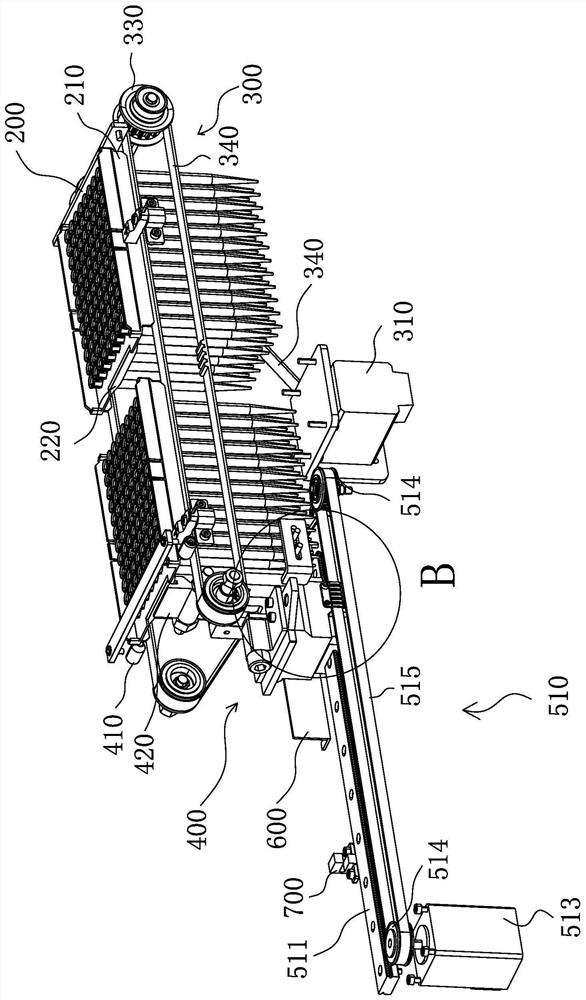

Linear station multiple stuffing forming device

The invention belongs to the technical field of food processing, and especially relates to a linear station multiple stuffing forming device. The linear station multiple stuffing forming device comprises a track, and a wrapper receiving station, a first stuffing station, a second stuffing station, a forming station and a demoulding station arranged around the track. The track is a linear track. A wrapper conveying apparatus, a first stuffing apparatus, a second stuffing apparatus, a forming device and a demoulding apparatus are respectively arranged at one side or two sides of the track. The track is the linear track, the wrapper conveying apparatus, the first stuffing apparatus, the second stuffing apparatus, the forming device and the demoulding apparatus are respectively arranged at one side or two sides of the track, so that the whole device is not restricted by the stations and can be expanded unlimitedly.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

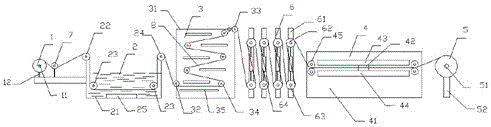

Calendaring device for label tape

InactiveCN106185419AExtended service lifeNo damageCalendersDrying machines with progressive movementsWinding machineEngineering

The invention discloses a calendaring device for a label tape. The calendaring device comprises an unwinding mechanism, a water washing mechanism, a drying mechanism, a calendaring machine and a winding machine, wherein according to the motion direction of the label tape, the water washing mechanism is in front of the drying mechanism; the drying mechanism is in front of the calendaring machine; and the winding mechanism is at the back of the calendaring machine. According to the calendaring device, the label tape calendaring efficiency is high, the surface is flat after calendaring, and the calendaring cost is reduced.

Owner:湖州领先丝带有限公司

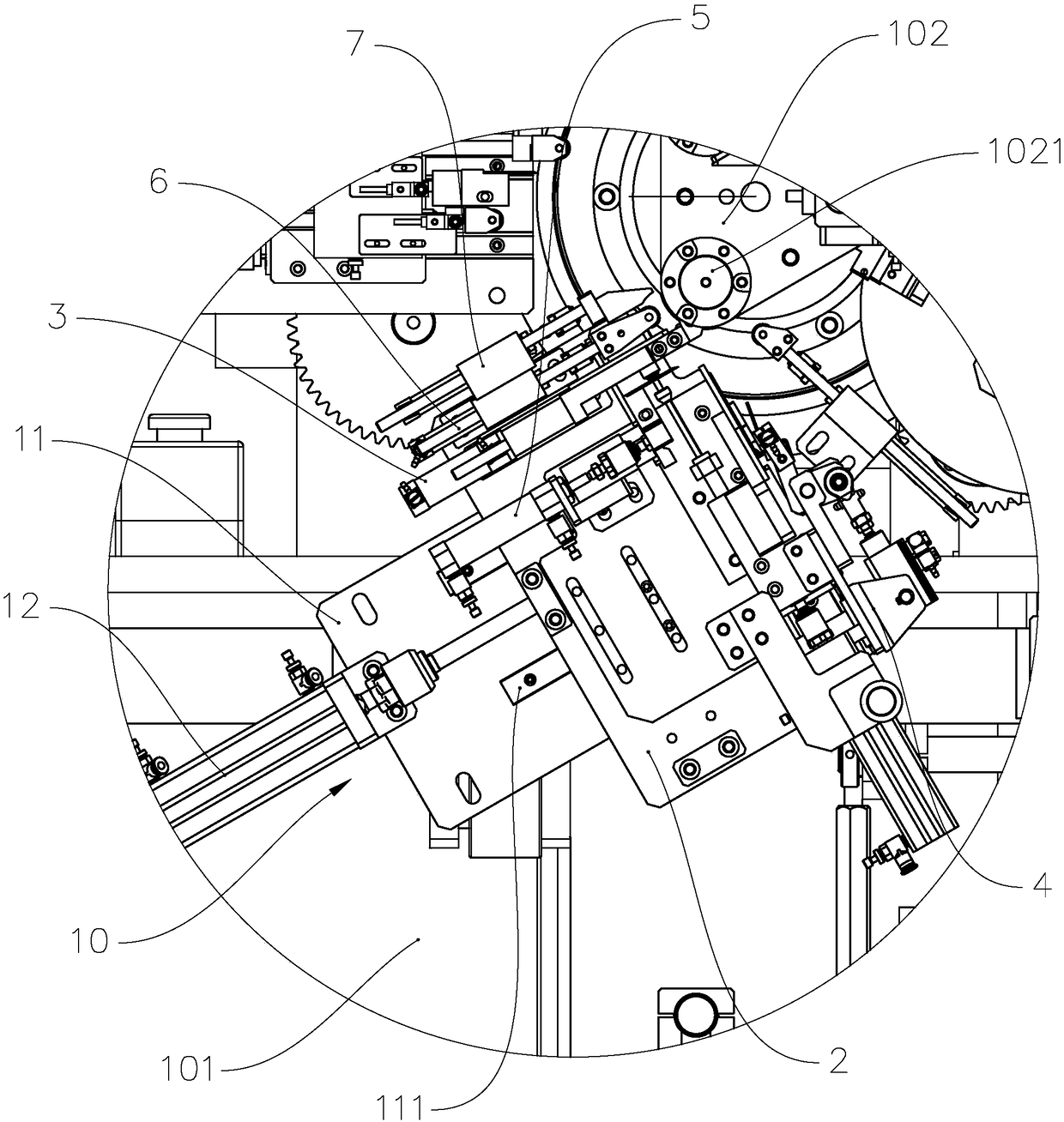

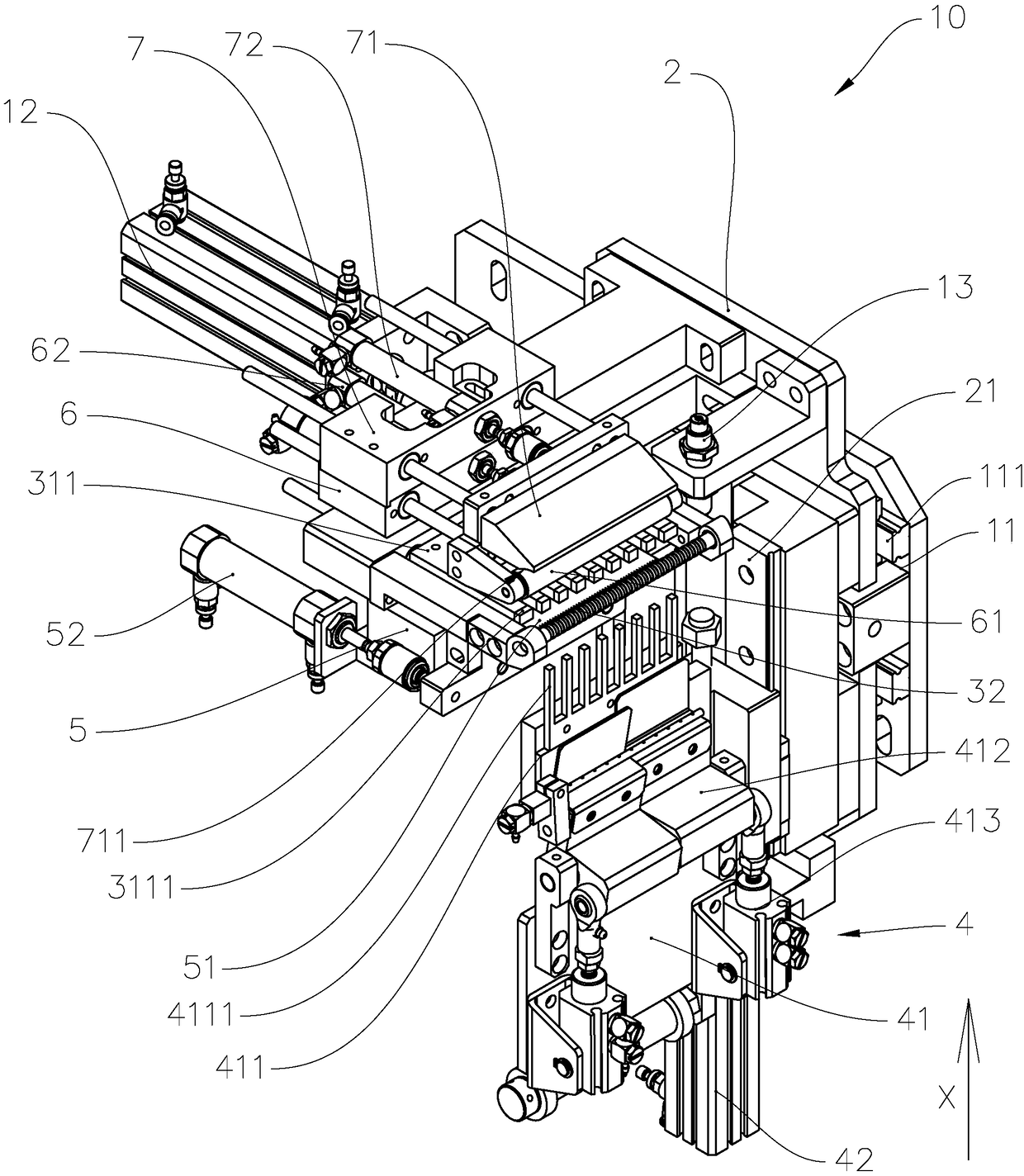

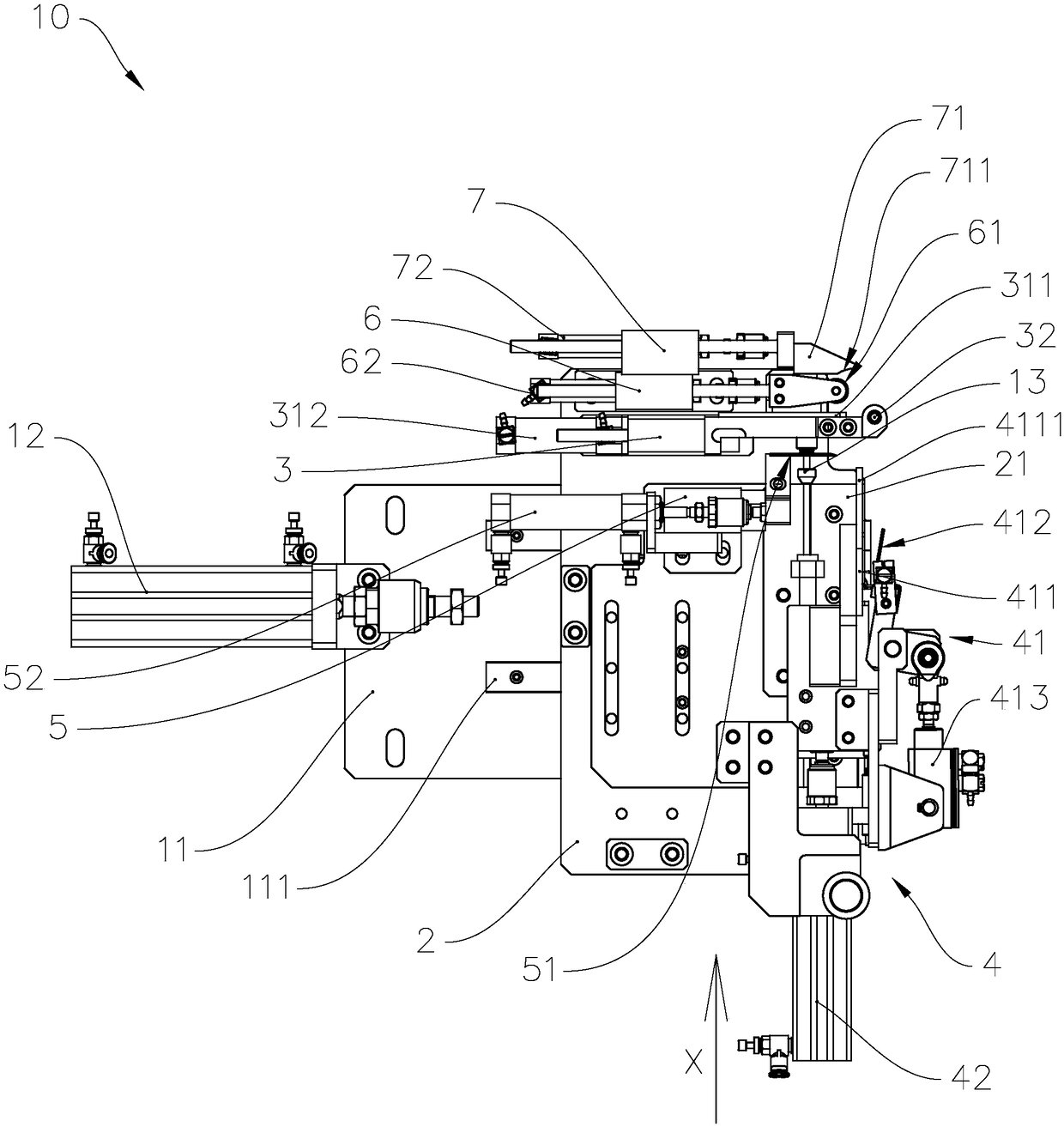

Rubberizing device and rubberizing method thereof, cylindrical battery cell flaking winding machine

ActiveCN108717984AEasy to operateGuarantee the quality of gluingFinal product manufactureNon-aqueous electrolyte cellsWinding machineEngineering

The invention provides a rubberizing device and a rubberizing method thereof, a cylindrical battery cell flaking winding machine, and the rubberizing device comprises a connecting base which is provided with a first guide rail, a glue supplying unit, and a glue preparation unit, a cutting blade unit and a rubberizing unit which are all mounted on the connection base, wherein the glue preparation unit comprises a glue preparation roller and a glue pressing mechanism of which an output end moves in the manner of being opposite to or back to the glue preparation roller; the glue supplying unit comprises a glue supplying mechanism connected with the first guide rail in the manner of sliding, and a first driving mechanism connected between the connecting base and the glue supplying mechanism; the glue supplying mechanism can move along the first guide rail to a space between the glue pressing mechanism and the glue preparation roller; and the cutting blade unit comprises a cutting blade mounted on the connecting base in the manner of sliding, and the cutting blade unit, the glue preparation unit and the rubberizing unit are orderly arranged along a feeding direction of the glue supplying unit. The rubberizing method of the rubberizing device and the cylindrical battery cell flaking winding machine are also provided, and the rubberizing device, the rubberizing method of the rubberizing device and the cylindrical battery cell flaking winding machine all have the advantages of high production efficiency and can avoid that a battery cell is compacted too tightly in a rubberizing process.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

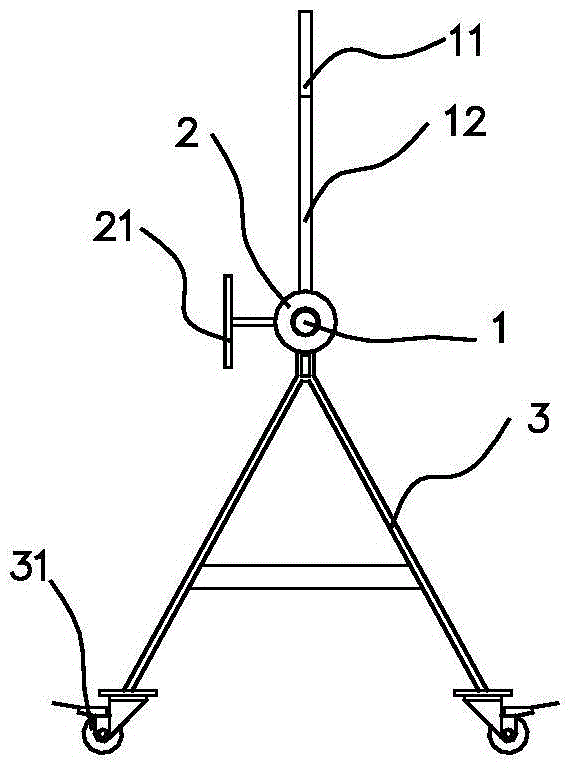

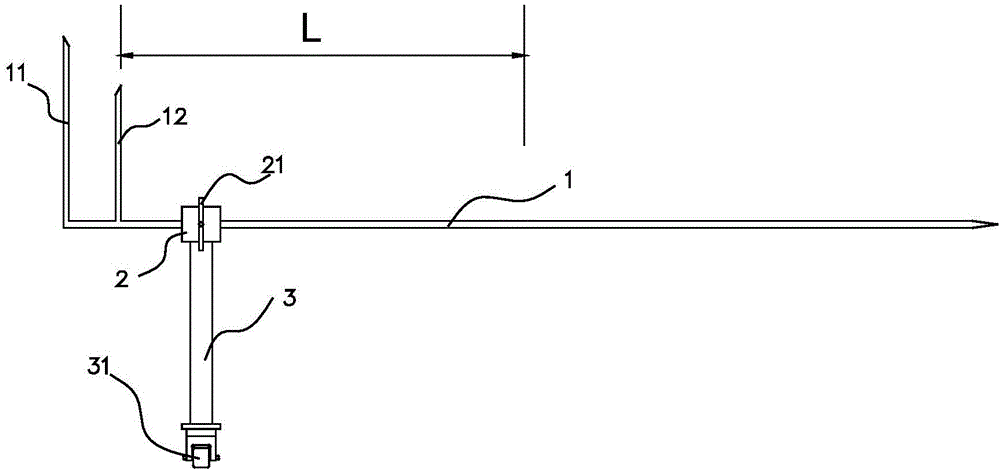

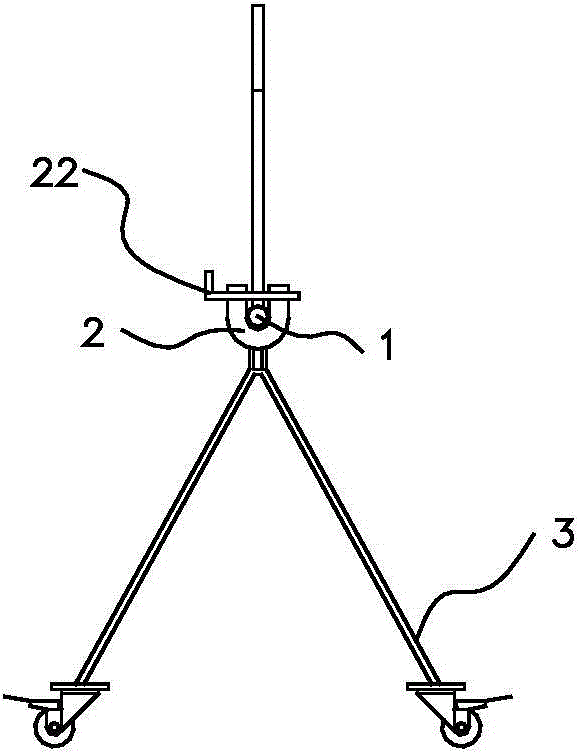

Special tool for maintenance of corrugated beam barrier of highway

InactiveCN105625218APlay a plastic rolePlay a repairing roleRoadway safety arrangementsShortest distanceEngineering

The invention discloses a special tool for maintenance of a corrugated beam barrier of a highway and relates to the technical field of barrier maintenance. By the adoption of the special tool for maintenance of the corrugated beam barrier of the highway, the situation that the barrier bounces and injures people in the dismantling process can be avoided, and a repairing function and a short-distance transferring function are achieved. The special tool for maintenance of the corrugated beam barrier of the highway comprises a main rod and a traveling support. A long cross arm and a short cross arm are arranged at the front end of the main rod, wherein the long cross arm is located at the top end of the main rod, and the short cross arm is located behind the long cross arm, in parallel to the long cross arm and is provided with a gap. A movable supporting structure is arranged at the top end of the traveling support. The main rod is provided with a supporting section. The supporting section of the main rod is arranged on the movable supporting structure. According to the special tool for maintenance of the corrugated beam barrier of the highway, the main rod is arranged to be in an F shape, and a corrugated beam protective plate right can be placed in the gap between the long cross arm and the short cross arm. During dismantling, the long cross arm at the end of the main rod is clamped on the back side of a corrugated beam, the short cross arm is clamped on the front side of the corrugated beam, and even if the barrier bounces elastically when screws are separated from the barrier and stand columns are installed, the situation that the barrier bounces and injures people is avoided under the restraint of the short cross arm. Meanwhile, a clamping opening formed by the F shape can also have shaping and repairing effects on the corrugated beam protective plate which deforms slightly.

Owner:江苏高速公路工程养护有限公司

a soup dumpling

The invention belongs to the technical field of food processing and particularly relates to soup dumplings. Each soup dumpling comprises a wrapper, wherein the two side parts of the left end of the wrapper are laminated and connected through a multi-stuffing primary forming mold; the two side parts of the right end of the wrapper are laminated and connected through the multi-stuffing primary forming mold; the wrapper covers solid-state stuffing injected from a first stuffing injection device and liquid-state stuffing injected from a second stuffing injection device; the top part of the wrapper is laminated and connected through a forming device; and the whole body of the wrapper is in a sealed state. With the adoption of the soup dumplings provided by the invention, the wrappers cover the solid-state stuffing and the liquid-state stuffing after the dumplings are automatically produced; and the defect in the prior art that the liquid-state stuffing in all the soup dumplingsis frozen into a solid state and then is covered by the wrappers is overcome.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Multistage stuffing forming device

The invention belongs to the technical field of food processing and relates to a multistage stuffing forming device. The device comprises a track, a wrapper receiving station, a first stuffing injection station, a second stuffing injection station, a forming station and a demolding station, wherein the wrapper receiving station, the first stuffing injection station, the second stuffing injection station, the forming station and the demolding station are arranged around the track, a wrapper conveying device is arranged at the position of the wrapper receiving station, a first stuffing injection device is arranged at the position of the first stuffing injection station, a second stuffing injection device is arranged at the position of the second stuffing injection station, a forming device body is arranged at the position of the forming station, and a demolding device is arranged at the position of the demolding station; a multistage stuffing preliminary forming mold moving along the track is arranged on the track, and wrappers are preliminarily formed into the pocket shape through the multistage stuffing preliminary forming mold. The two independent stuffing injection stations are arranged to conduct stuffing injection twice on the wrappers, and the wrappers are processed into the pocket shape after the first time of stuffing injection, so that the second time of stuffing injection can be conducted on the wrappers; through the two times of independent stuffing injection, stuffing materials in stuffed food are not mixed or overly mixed, and the unique tastes of different stuffing materials can be reserved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

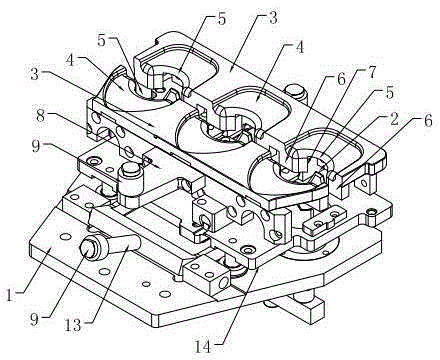

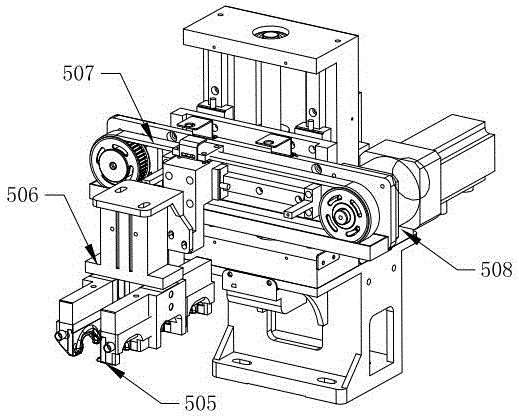

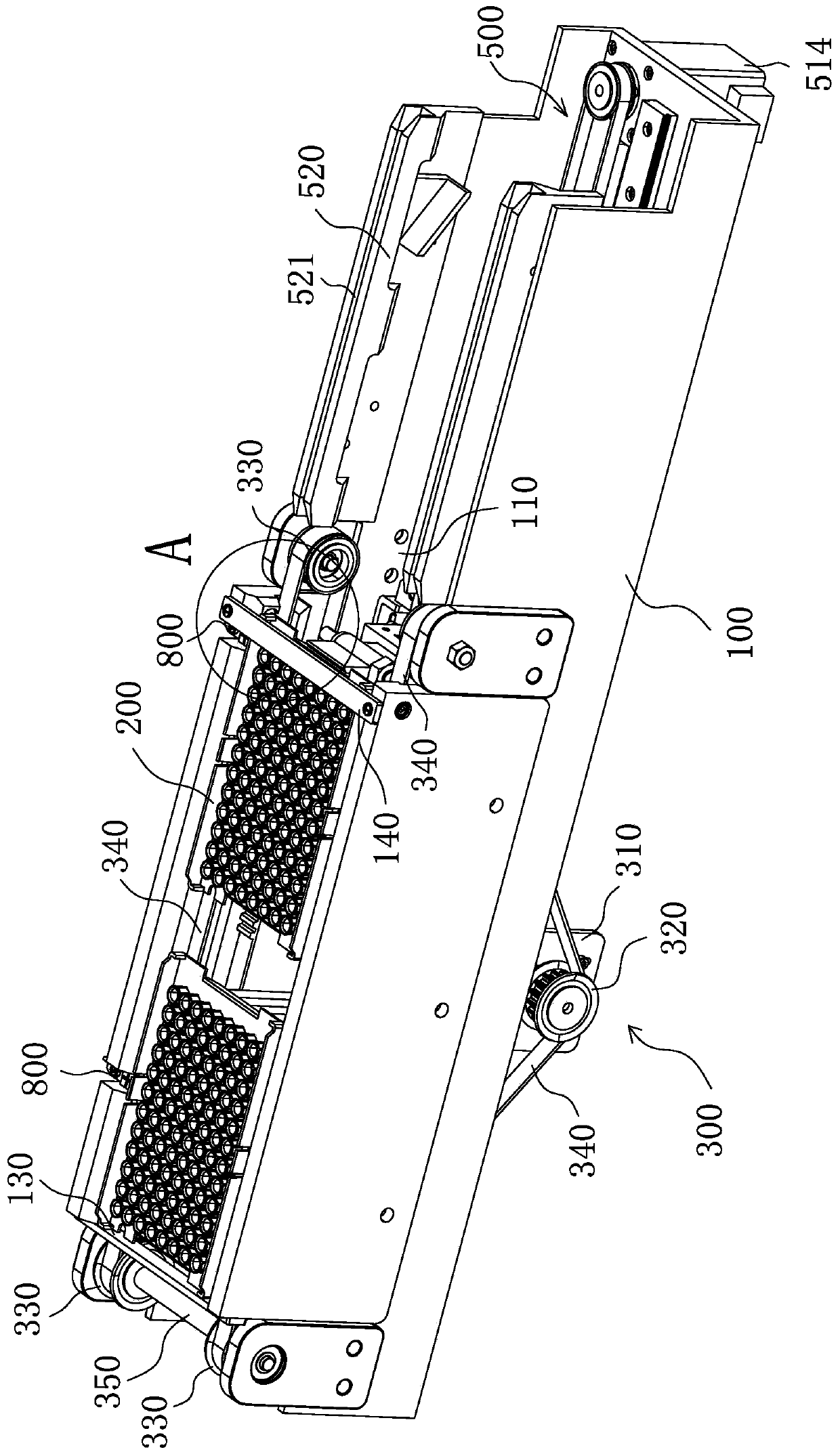

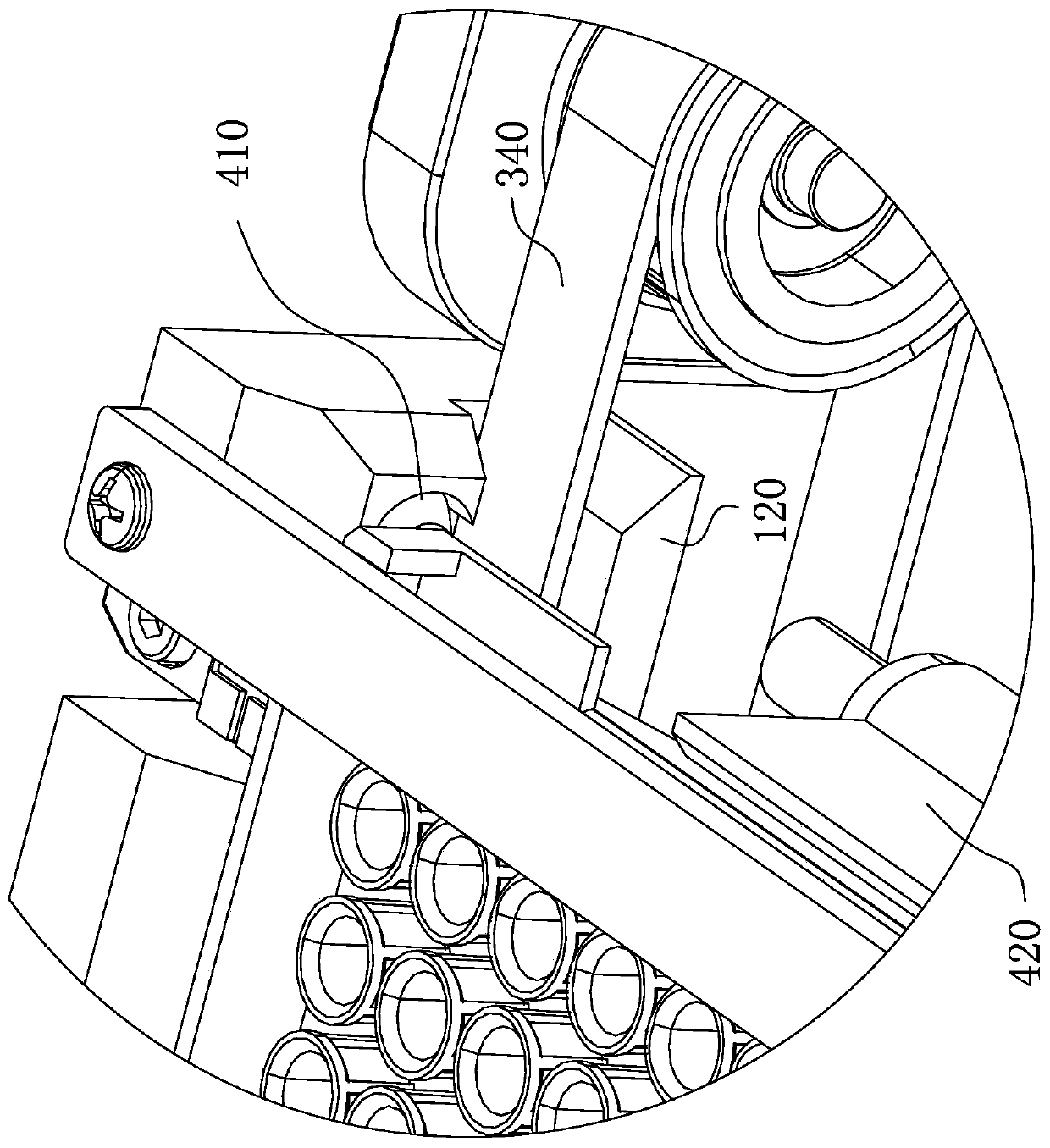

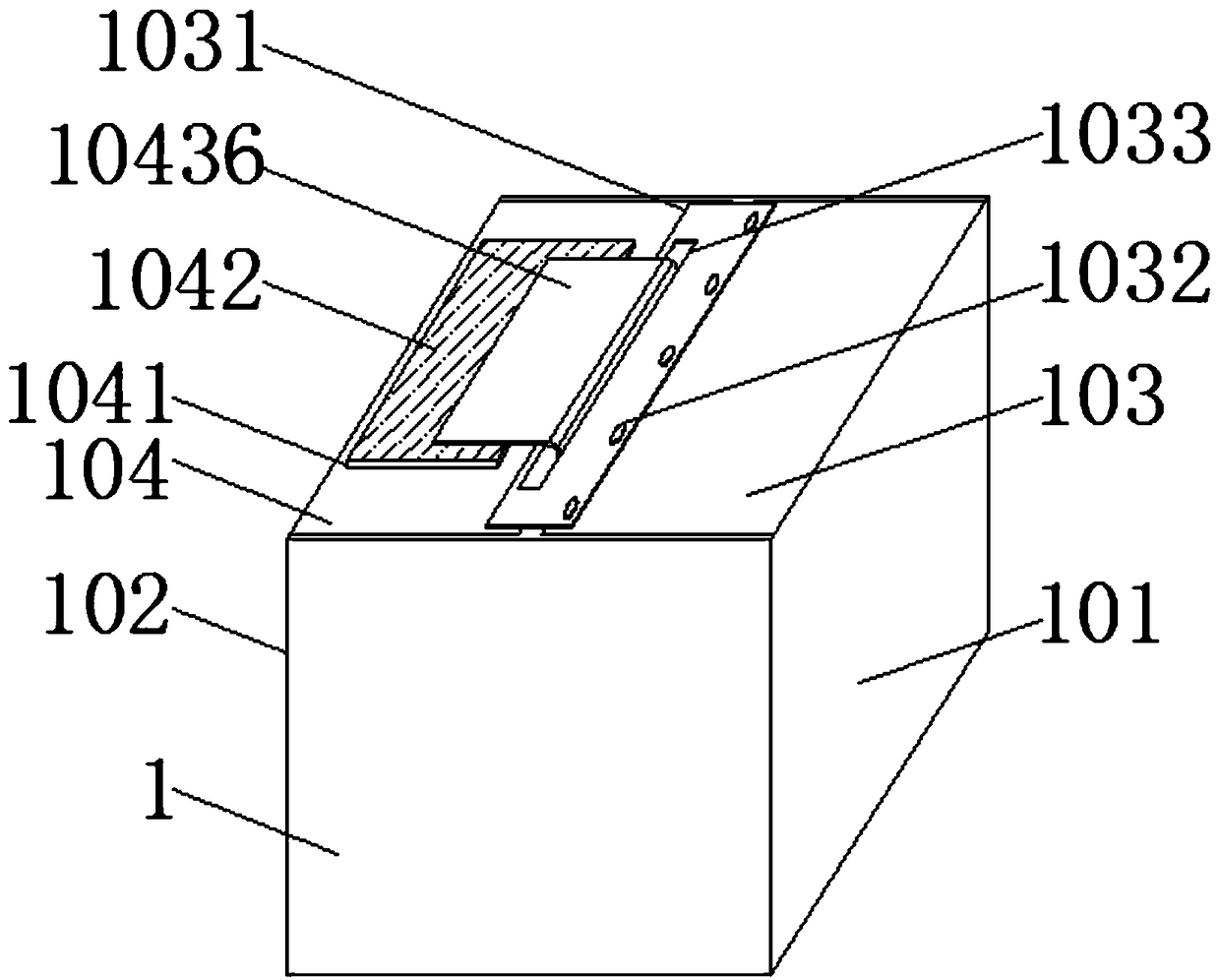

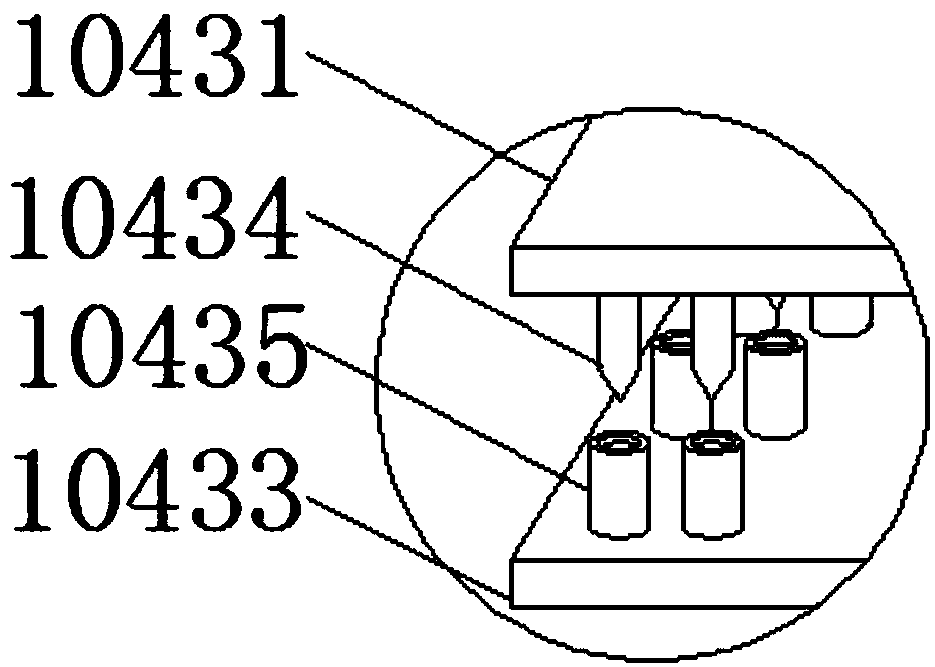

Analysis instrument consumable conveying device

ActiveCN111453274APlay a plastic roleGuaranteed positioningStorage devicesStructural engineeringMechanical engineering

The invention provides an analysis instrument consumable conveying device and belongs to the technical field of detection and analysis equipment. The analysis instrument consumable conveying device comprises a support, a consumable frame, a first translation assembly, a transfer assembly and a second translation assembly, wherein the support is provided with a conveying channel; the front side andthe rear side of the consumable frame extend downwards to be provided with supporting edges; the consumable frame is downwards embedded into the support; the first translation assembly is mounted onthe left side of the interior of the conveying channel and upwards abuts against the two supporting edges of the consumable frame; the transfer assembly comprises a blocking part arranged at the middle part of the support, a locating block and a lifting mechanism, the locating block and the lifting mechanism are arranged on the right side of the blocking part, the blocking part can extend into orextend out of the conveying channel, the locating block and the lifting mechanism are arranged on the right side of the interior of the conveying channel, and the lifting mechanism drives the locatingblock to rise and fall so as to be clamped in or separated from the consumable frame; and the second translation assembly comprises a sliding mechanism mounted on the right side of the interior of the conveying channel and two guide bars, the sliding mechanism is used for driving the locating block and the lifting mechanism to do left-right translational motion, and the top surface of each guidebar is concave downwards to form a guide groove allowing one supporting edge of the consumable frame to be embedded into.

Owner:宁波海尔施智造有限公司

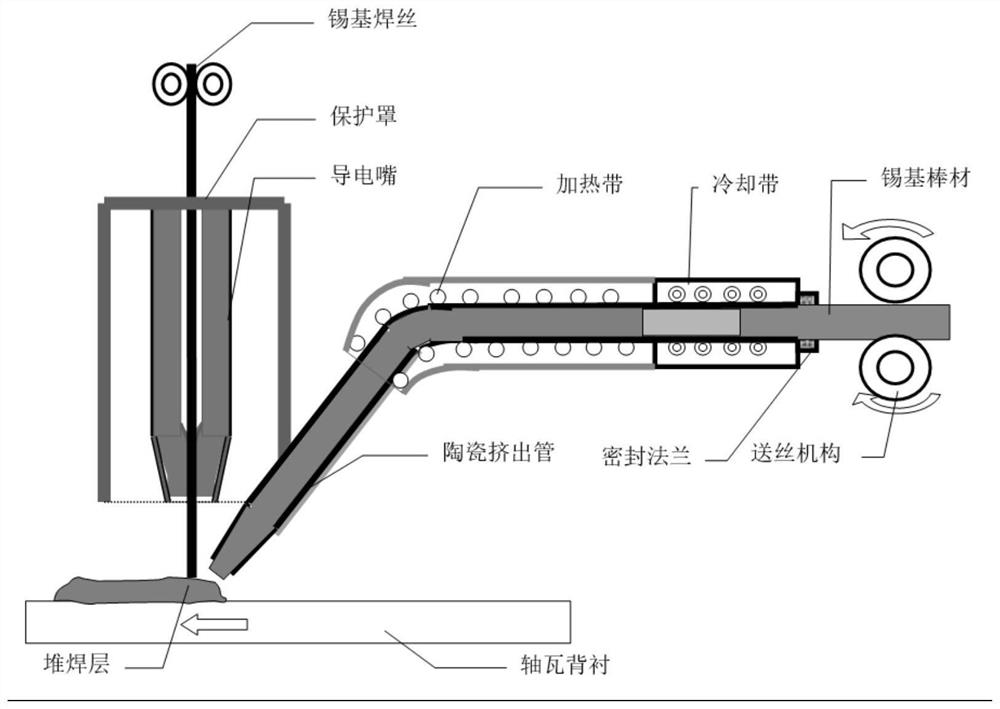

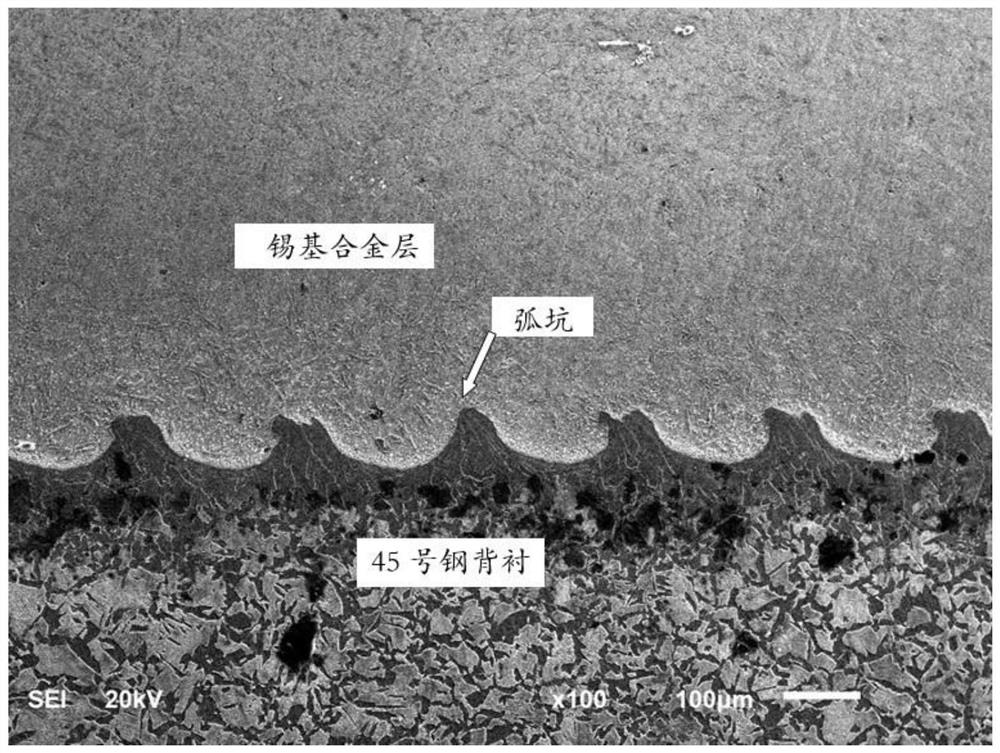

Sliding bearing bush material and preparation method thereof

ActiveCN112222575AIncrease productivityImprove bindingElectrode supporting devicesWelding accessoriesSlider bearingSemi solid

The invention discloses a sliding bearing bush material and a composite additive preparation process thereof. The bearing bush material is sequentially composed of a backing, a bonding layer and an anti-friction layer, the backing is made of medium-low carbon steel, the bonding layer and the anti-friction layer are both made of tin-based babbitt metal, and the bonding layer is made of tin-based babbitt metal with low Sb and Cu content. The bonding layer and the anti-friction layer are sequentially prepared by using a method of combining MIG welding and semi-solid extrusion. The specific preparation method comprises the steps that an MIG welding gun and a semi-solid slurry extrusion pipe keep a fixed angle, when the welding gun conducts MIG welding on the backing, the semi-solid extrusion pipe extrudes semi-solid materials to the same backing position at the same time, in this way, the bonding layer and the anti-friction layer are deposited on the surface of the backing in sequence, andtherefore the bearing bush material is prepared. The method is high in efficiency, the tool cost and the machining allowance can be greatly reduced, and good welding quality is achieved.

Owner:JIANGSU UNIV OF SCI & TECH

Packaging carton capable of being rapidly sealed and increasing reuse rate

InactiveCN109279174AIntegrity guaranteedImprove sealing efficiencyClosuresEnvironmental resistanceCardboard

The invention discloses a packaging carton capable of being rapidly sealed and increasing the reuse rate. The packaging carton comprises a front panel. The right side of the front panel is fixedly connected with a right side plate. The left side of the front panel is fixedly connected with a left side plate. The top and the bottom of the right side plate are both fixedly connected with a right topplate. The top and the bottom of the left side plate are both fixedly connected with a left top plate. According to the packaging carton capable of being rapidly sealed and increasing the reuse rate,box sealing operation is conducted on the carton through cooperation of mechanisms of the carton itself, integrity of the carton can still be ensured after unboxing while the carton sealing efficiency is improved, the repeatable use rate is increased, and the packaging carton is more economical, practical and environment-friendly. According to the packaging carton capable of being rapidly sealedand increasing the reuse rate, a clamping and fixing box and a buckle plate are connected with paperboards at the sealing position of the carton; on one hand, a sealing structure is installed; on theother hand, the carton opening hardness of the carton can also be increased; and the packaging carton is not prone to be extruded and deformed, and the carton can also be protected while goods are protected.

Owner:邵广华

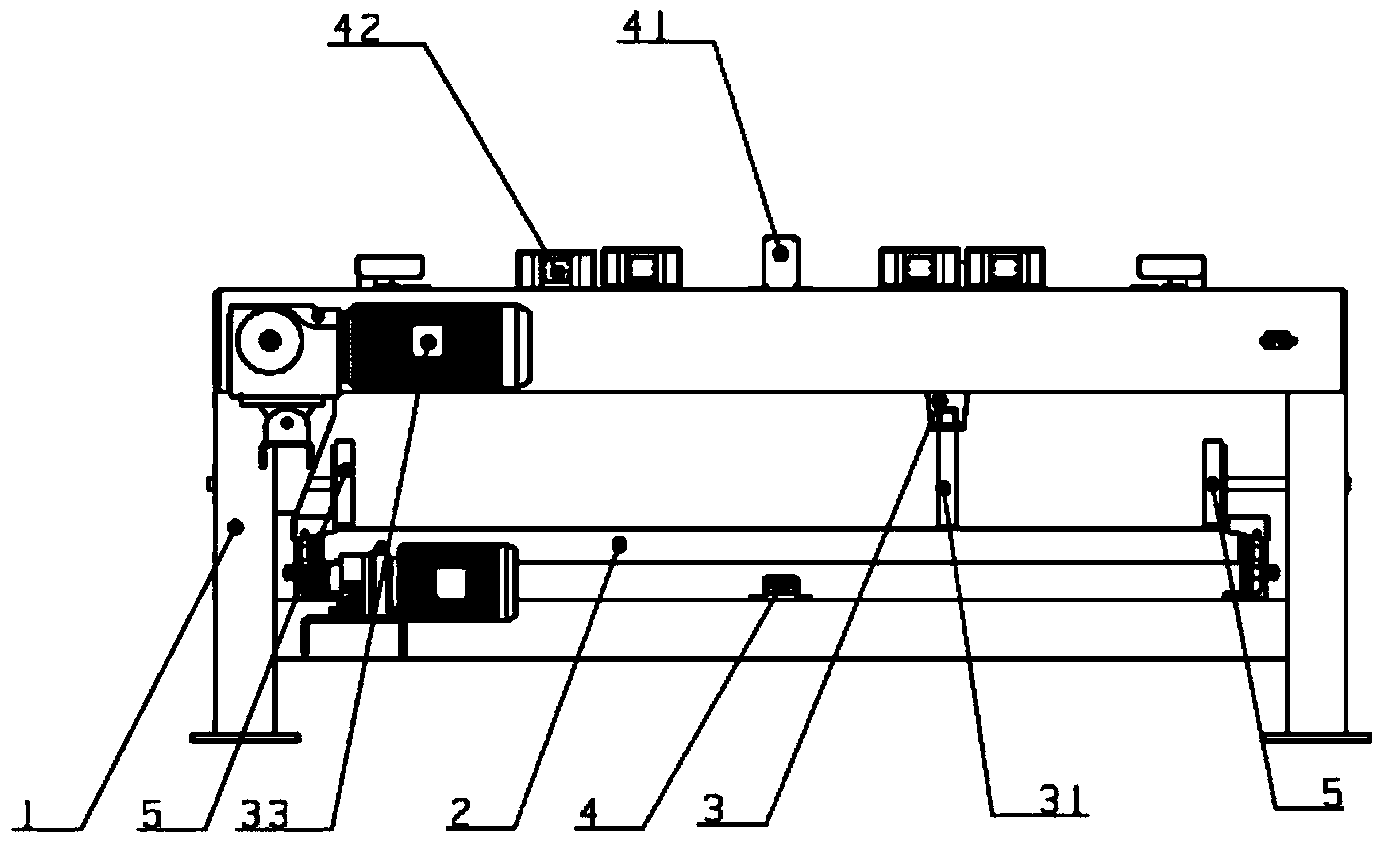

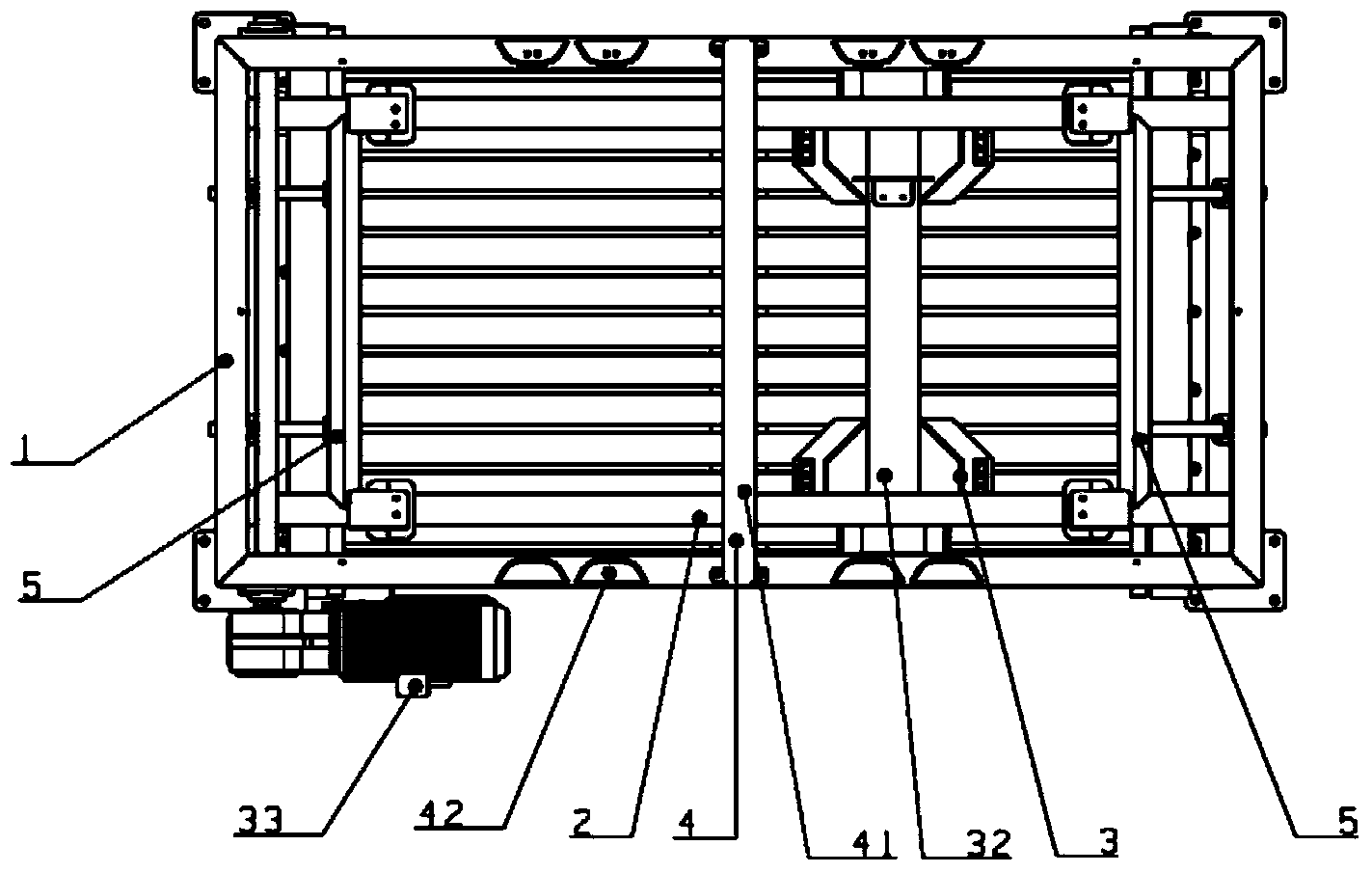

Automatic bag-packaging product conveying path splitter

ActiveCN103964185AMeet the need for high efficiencyMeet palletizing needsControl devices for conveyorsEngineeringManufacturing line

The invention relates to an automatic bag-packaging product conveying path splitter which comprises a machine frame, a conveying device and a station pushing device. The conveying device and the station pushing device are arranged on the machine frame. The station pushing device is arranged above the conveying device. In work, the station pushing device linearly moves in a left and right reciprocating mode in the direction parallel to the conveying direction of the conveying device, and conveyed bag-packaging products on the conveying device are pushed to a left branch path and a right branch path to be conveyed from the middle. The technical purpose that in the automatic stacking operation process, bag-packaging products quickly conveyed by a front production line are divided to be conveyed by two or more paths from one path is achieved.

Owner:GUANGXI LIYUANBAO SCI & TECH

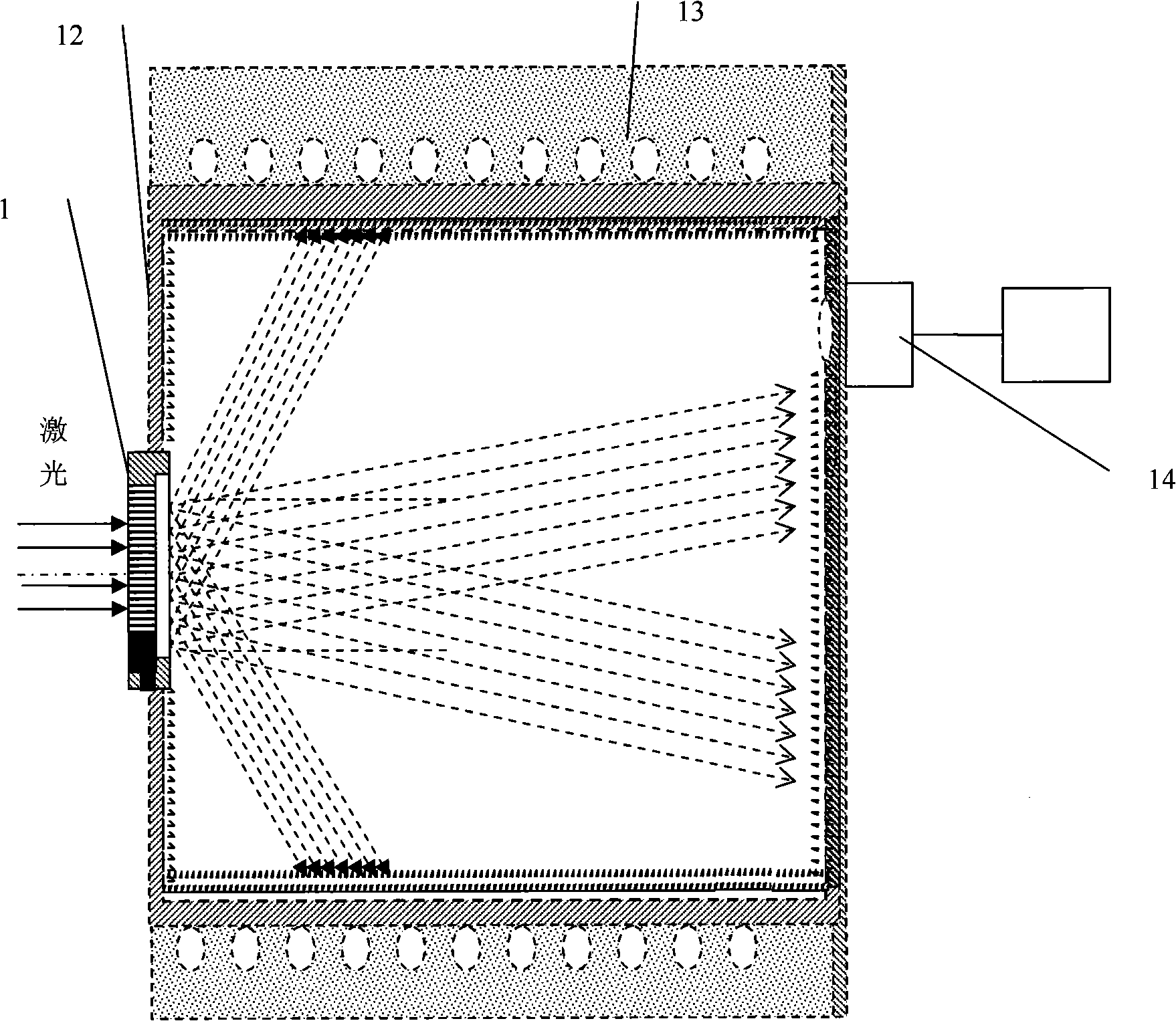

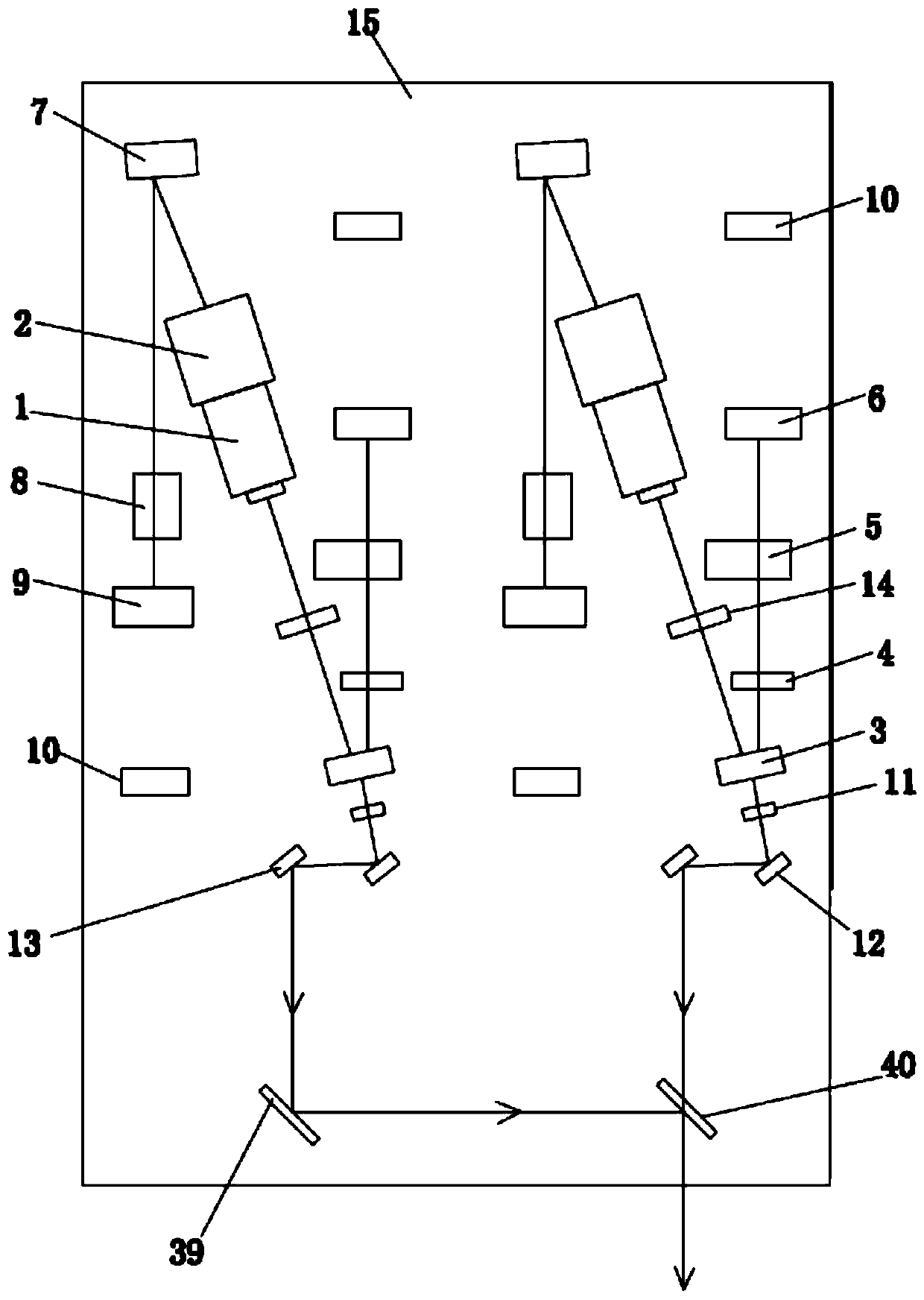

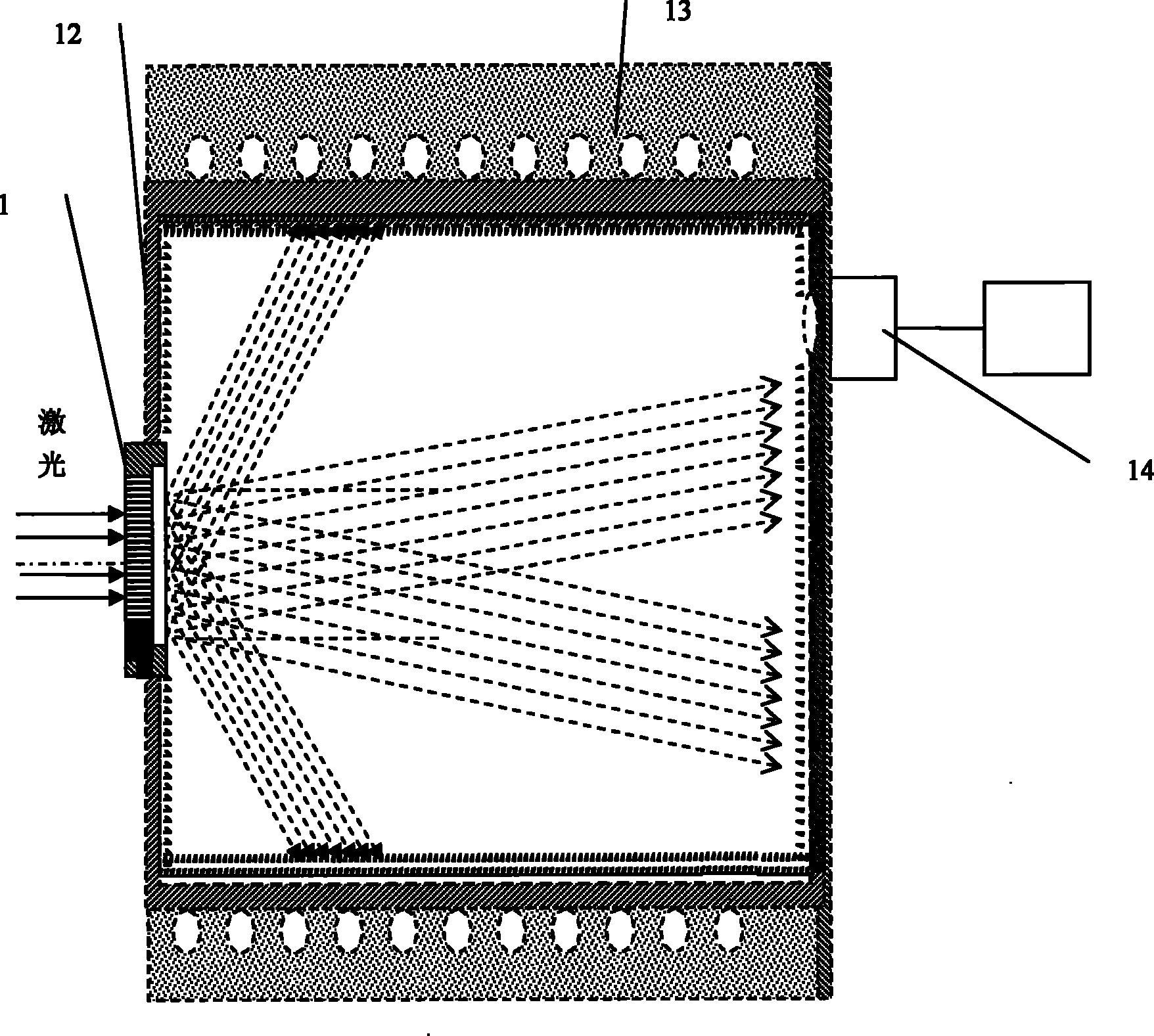

532nm parallel connection beam combination laser

PendingCN109768462AHigh beam qualityImprove cutting accuracyLaser constructional detailsSuperhard materialResonant cavity

The invention discloses a 532nm parallel connection beam combination laser, comprising two Z-shaped resonant cavities which are arranged in parallel, each Z-shaped resonant cavity comprises an acousto-optic Q switch, a 1064nm laser module and a resonant lens set which are adjacently arranged, the resonant lens set is used for converting 1064nm light into 532nm light, and a wave plate is arranged at the output end of each Z-shaped resonant cavity; and a laser beam combination mirror set is arranged at one side of the output ends of the two Z-shaped resonant cavities. The 532nm parallel connection beam combination laser provided by the invention guarantees relatively high beam quality while laser power is doubled by virtue of laser beam combination, so that cutting precision on a superhard material is improved.

Owner:广州安特激光技术有限公司

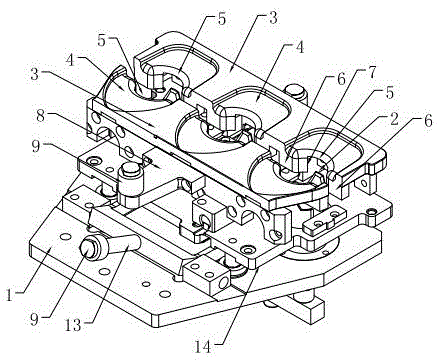

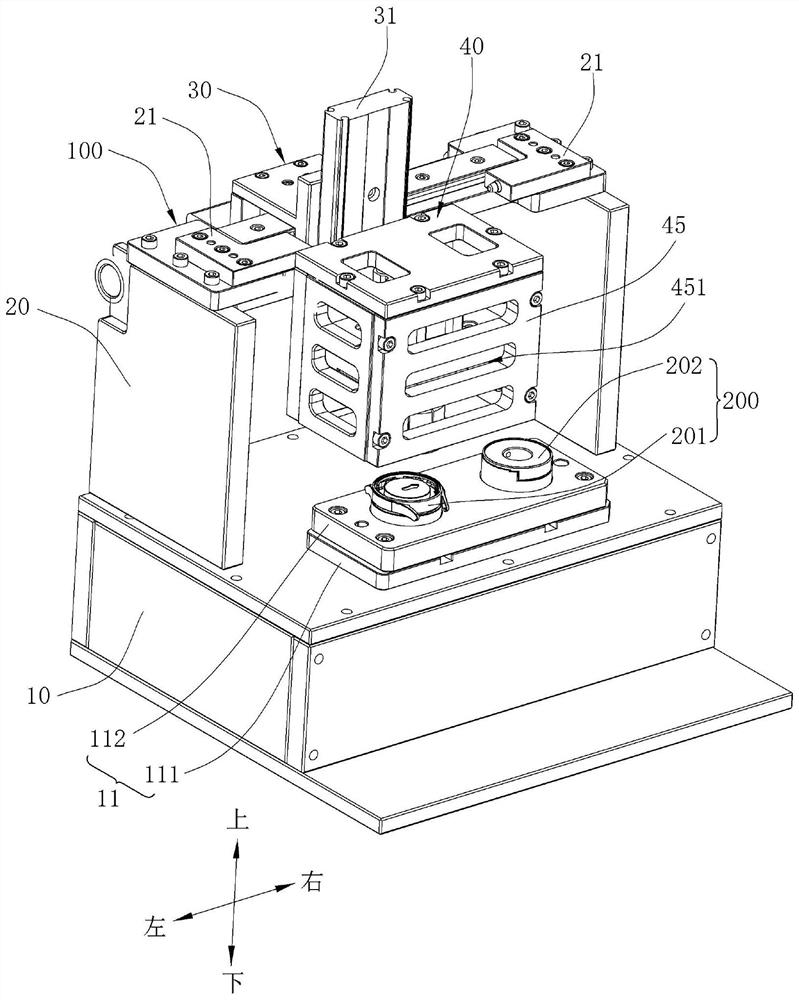

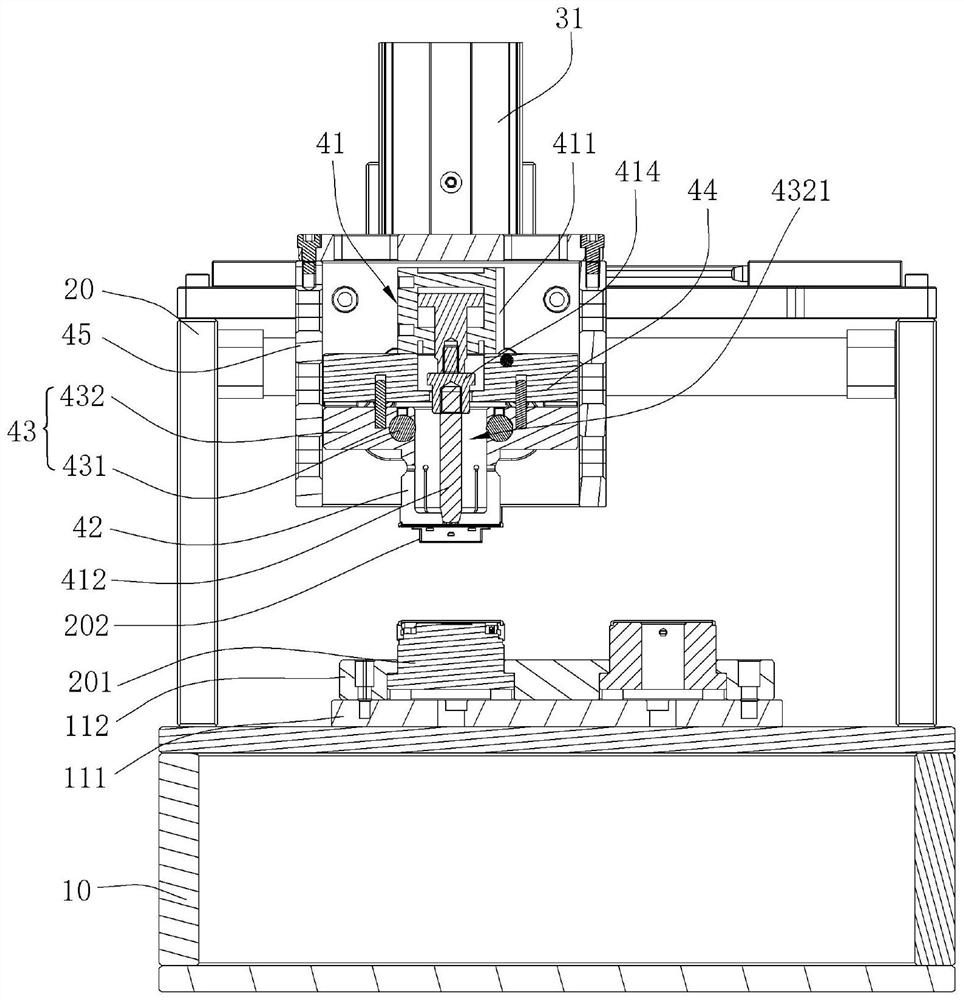

Workpiece assembling equipment

The invention discloses workpiece assembling equipment. A workpiece comprises a shell and a decorative ring; and the workpiece assembling equipment comprises a base and a assembling mechanism, wherein the base is provided with an object placing table, and the object placing table is used for placing the shell and the decorative ring; the assembling mechanism comprises a rack, a material conveying component and a material grabbing and releasing component; the rack is mounted on the base; the material conveying component is mounted on the rack; the material grabbing and releasing component is located above the object placing table; and the material conveying component is used for driving the material grabbing and releasing component to do lifting motion relative to the rack and do reciprocating motion between the shell and the decorative ring; the material grabbing and releasing component comprises a driving structure and a material supporting ring; and the driving structure is used for driving the material supporting ring to support the inner edge of the decorative ring or release the supporting of the inner edge of the decorative ring so as to grab or release the decorative ring correspondingly. According to the workpiece assembling equipment, the automatic assembling process of the shell and the decorative ring in the workpiece can be completed; the assembling speed is increased; the production efficiency is improved; and moreover, in the assembling process, the material supporting ring can play a role in shaping the decorative ring, so that deformation of the decorative ring in the assembling process is prevented, the assembling precision is guaranteed, and the product yield is improved.

Owner:东莞怡力精密制造有限公司

A fully automatic welding method for photovoltaic panels and an automatic photovoltaic panel welding machine for realizing the method

ActiveCN103692097BImprove work accuracyIncrease incomeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDelivery system

The invention discloses a full-automatic welding method of a photovoltaic panel. The method comprises the following steps of stacking a plurality of photovoltaic panels on a feeder, and mounting a solder strip on a solder strip conveying system; starting a solder strip conveying mechanism, clamping the solder strip, conveying the solder strip to a position above the feeder and tightening the solder strip; lifting the feeder, and enabling the photovoltaic panel on the top of the feeder to contact with the solder strip; dropping a welding mechanism, enabling a depression bar on the welding mechanism to contact with the solder strip, pressing the solder strip by the depression bar under the effect of gravity, clinging the solder strip to the photovoltaic panel, releasing the solder strip by the solder strip conveying mechanism, continuing dropping the welding mechanism to cover the photovoltaic panel, enabling a heating tube on the welding mechanism to work, transferring heat to a working position by a blowing mechanism, and welding the solder strip on the photovoltaic panel; after completion, cutting off the solder strip by a cutoff mechanism, resetting the welding mechanism, and automatically unloading by an unloading system. The invention provides an automatic photovoltaic panel welding machine capable of realizing the method.

Owner:东莞市开胜电子有限公司

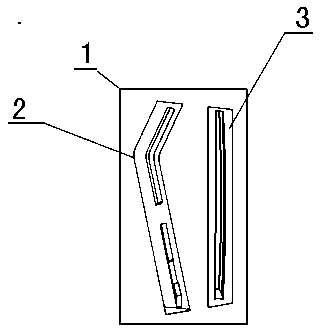

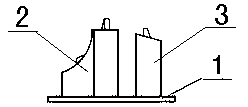

Clamp for reshaping car lamp liner frame

The invention discloses a clamp for reshaping a car lamp liner frame. The clamp is characterized in that the clamp is composed of an aluminium plate base (1), a supporting limited block I (2) and a supporting limited block II (3), wherein the supporting limited block I (2) and the supporting limited block II (3) are fixed on the aluminium plate base (1), and the relative position between the supporting limited block I (2) and the supporting limited block II (3) is arranged according to the appearance of the car lamp liner frame. According to the clamp for reshaping the car lamp liner frame provided by the invention, the car lamp liner frame is directly placed on the two supporting limited blocks after being taken from a mechanical arm of an injection molding machine, and removed after the product is completely cooled and sized, so that the role of reshaping the car lamp liner frame is played.

Owner:JIANGSU HONGCHANG SCI & TECH

High power laser beam expander

InactiveCN101320132BIncreased Laser Damage ThresholdReduce energy densityCoupling light guidesBeam expanderHigh power lasers

The invention discloses a extender lens for expanding high power laser beams, which has the main technical characteristics that a plurality of optical fiber rods with equal lengths are all tightly arranged in the cavity body of a housing and the end surfaces of the optical fiber rods respectively form input faces and output faces; the optical fiber rods are bare optical fibers and can adopt optical fibers the core diameter of which is smaller than that of single mode fiber. The invention can expand the laser beans as well as shape and stabilize the direction of the laser beans, and has the advantages of high laser induced damage threshold, simple structure and great reduction of the volume and the weight of a laser shot system.

Owner:南瑶

A consumable conveying device for an analyzer

ActiveCN111453274BPlay a plastic roleGuaranteed positioningStorage devicesStructural engineeringMechanical engineering

The invention provides a consumable conveying device for an analyzer, which belongs to the technical field of detection and analysis equipment, and includes a support, which is provided with a conveying channel; Bracket; the first translation component, which is installed on the left side of the transmission channel and up against the two supporting sides of the consumable rack; the handover component, which includes a blocking piece arranged in the middle of the bracket, a positioning block located on the right side of the blocking piece and The lifting mechanism, the blocking piece can extend into or out of the transmission channel, the positioning block and the lifting mechanism are arranged on the right side inside the transmission channel, and the lifting mechanism drives the positioning block up and down to snap in or out of the consumable rack; the second translation component, which includes The sliding mechanism and two guide bars on the right side inside the transmission channel are used to drive the positioning block and the lifting mechanism to move left and right. The top surface of the guide bar is concave to form a guide groove for a supporting edge of the consumable rack to be embedded.

Owner:宁波海尔施智造有限公司

Flat tea processing method and device

ActiveCN110178925AEvenly heatedShake green effect is goodPre-extraction tea treatmentTea extractionEngineeringGreen leaf

The invention discloses a flat tea processing method and device. The processing device comprises a spindle, a cutting box, a green-leaf rocking box, a rolling box, a shaping box, a connecting rod, a first bevel gear, a second bevel gear and a third bevel gear, wherein the cutting box and the rolling box are arranged on two sides of the spindle, and the green-leaf rocking box is arranged above thespindle. Various tea processing devices are integrated to simplify the structure of the processing apparatus.

Owner:旺苍县高阳碧峰茶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com