Rapid formation treatment method capable of improving cycle performance of lithium ion battery

A lithium-ion battery and cycle performance technology, applied in the field of lithium-ion batteries, can solve the problems of not being suitable for the lithium iron phosphate system, the uniformity and compactness of the SEI film, and the long formation time. Comprehensive treatment method, the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

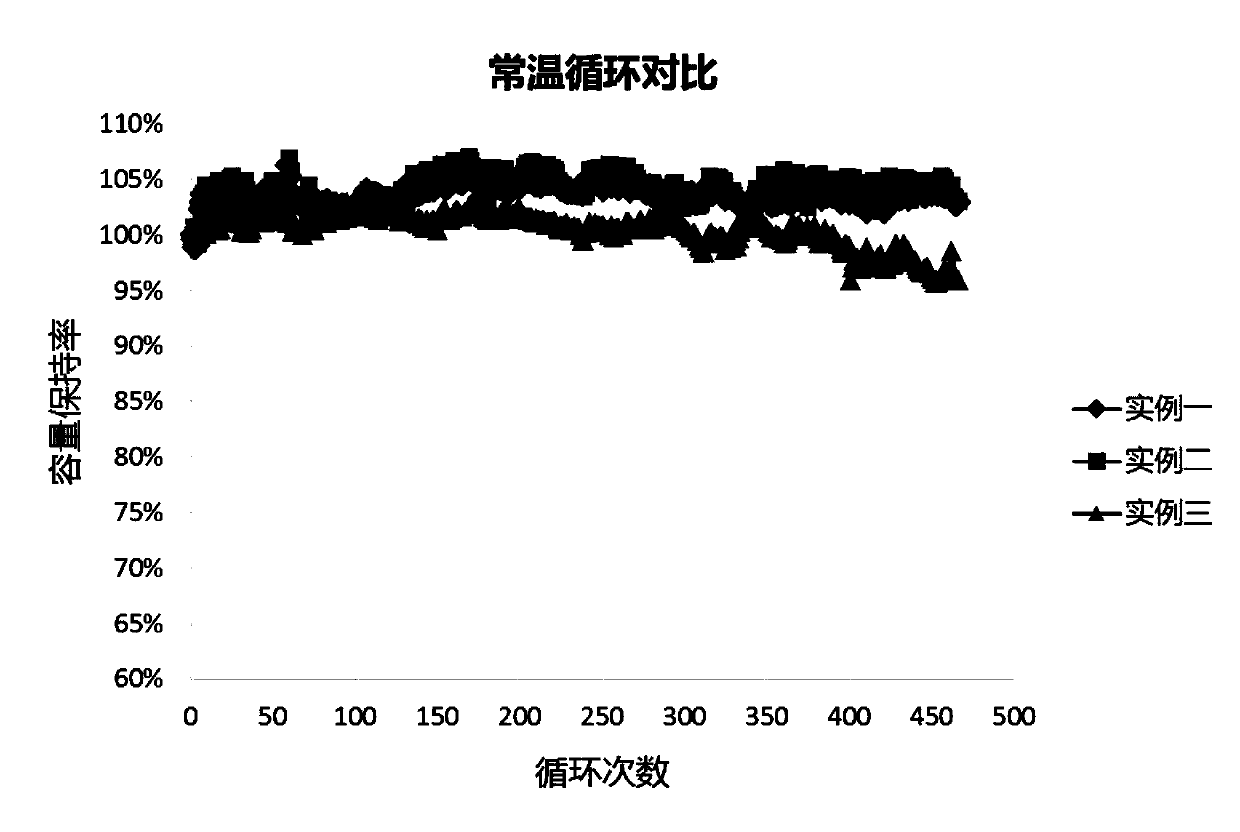

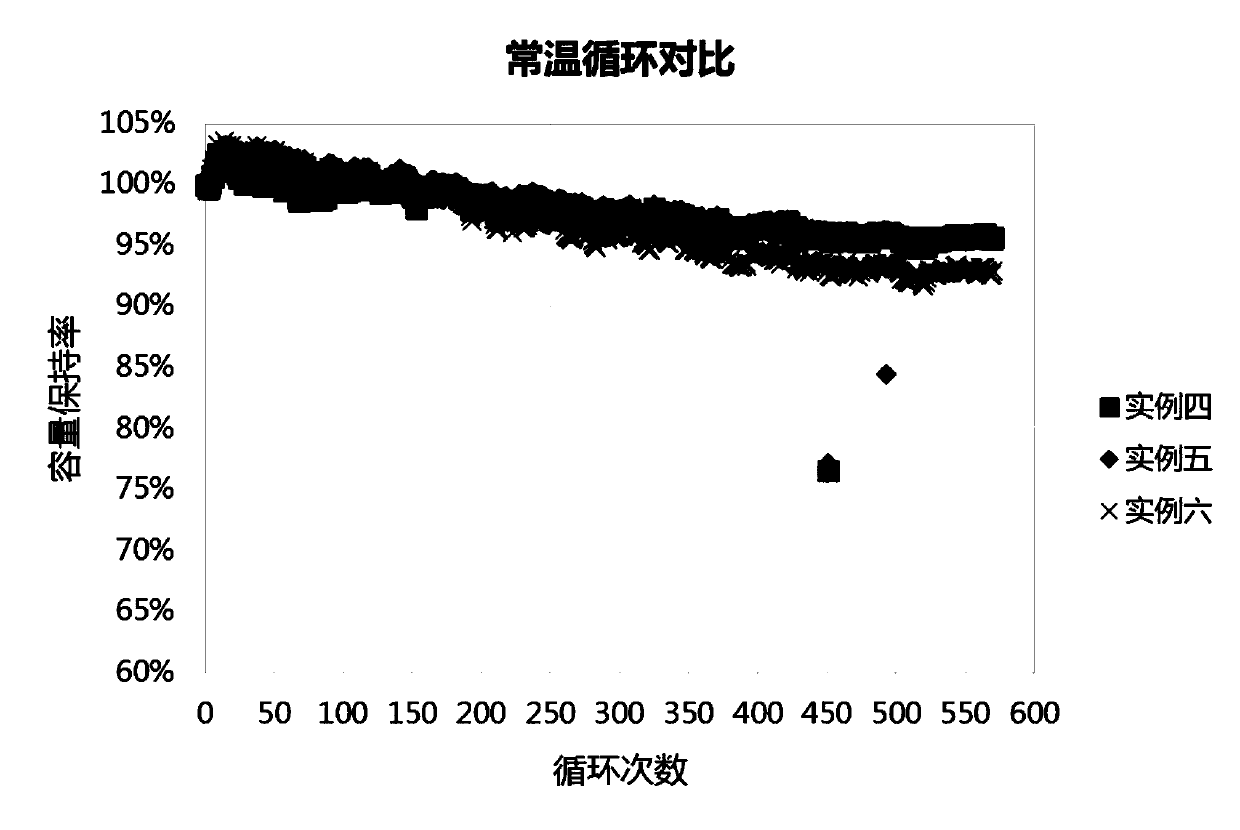

example 1

[0026] Taking the cathode material of the battery as a ternary material as an example, the specific implementation steps are as follows:

[0027] 1) Put the injected lithium-ion battery on the high-pressure and high-temperature chemical conversion equipment. The battery surface pressure set by the equipment is 1.0MPa and the battery surface temperature is 60℃. Leave it for 10 minutes to ensure that the pressure and temperature of the battery surface are consistent with each other. The equipment set value is consistent;

[0028] 2) Formed constant current charging, using 0.1C current charging, charging time is 25min, charging protection cut-off voltage is 3.85V, after charging, put it aside for 3min;

[0029] 3) Formed constant current two charge, using 0.5C current charging, charging time is 115min, charging protection cut-off voltage is 3.85V, and left for 3min;

[0030] 4) The battery cell is placed in the cabinet and directly enters the second sealing process.

example 2

[0032] Example 2 is basically the same as Example 1, except that after the battery cell is placed in the cabinet, it does not directly enter the second sealing process. Instead, it is placed at a high temperature for 12 hours before entering the second sealing process.

example 3

[0034] Example 3 is the traditional chemical conversion processing method, the specific implementation steps are as follows:

[0035] 1) Cold-pressing and shaping the cells to be formed;

[0036] 2) Put the cold-pressed and reshaped battery cells in the cabinet on the chemical conversion equipment for a first charge, charging with 0.072C current, charging time 40min, charging protection cut-off voltage 4.1V, and leaving it for 3min;

[0037] 3) Formed second charge, charged with 0.05C current, charging time is 180min, charging protection cut-off voltage is 4.1V, and left for 3min;

[0038] 4) Formed triple charge, charged with 0.1C current, charging time is 120min, charging protection cut-off voltage is 4.1V, and left for 3min;

[0039] 5) Formed four-charge, 0.2C current charging, charging time is 60min, charging protection cut-off voltage is 4.1V, and left for 3min;

[0040] 6) Put the battery cell out of the cabinet and put it at high temperature for 12 hours before entering the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com