Non-mould multi-point forming system for plate

A moldless multi-point, plate technology, which is applied in the field of plate plastic processing and plate mold-free multi-point forming system, can solve the problems of high manufacturing cost, inability to meet engineering production needs, inability to meet efficiency, processing quality and accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

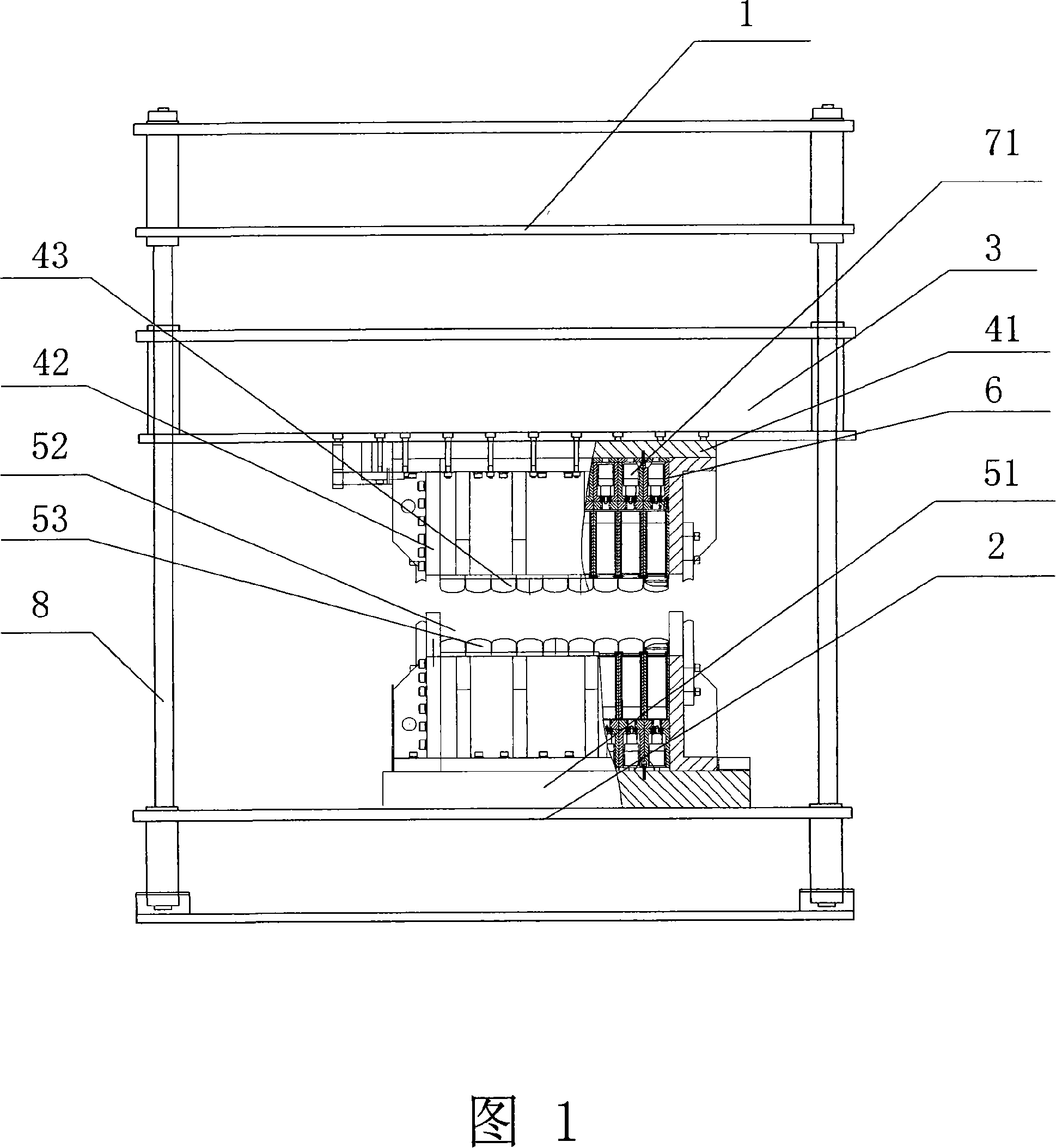

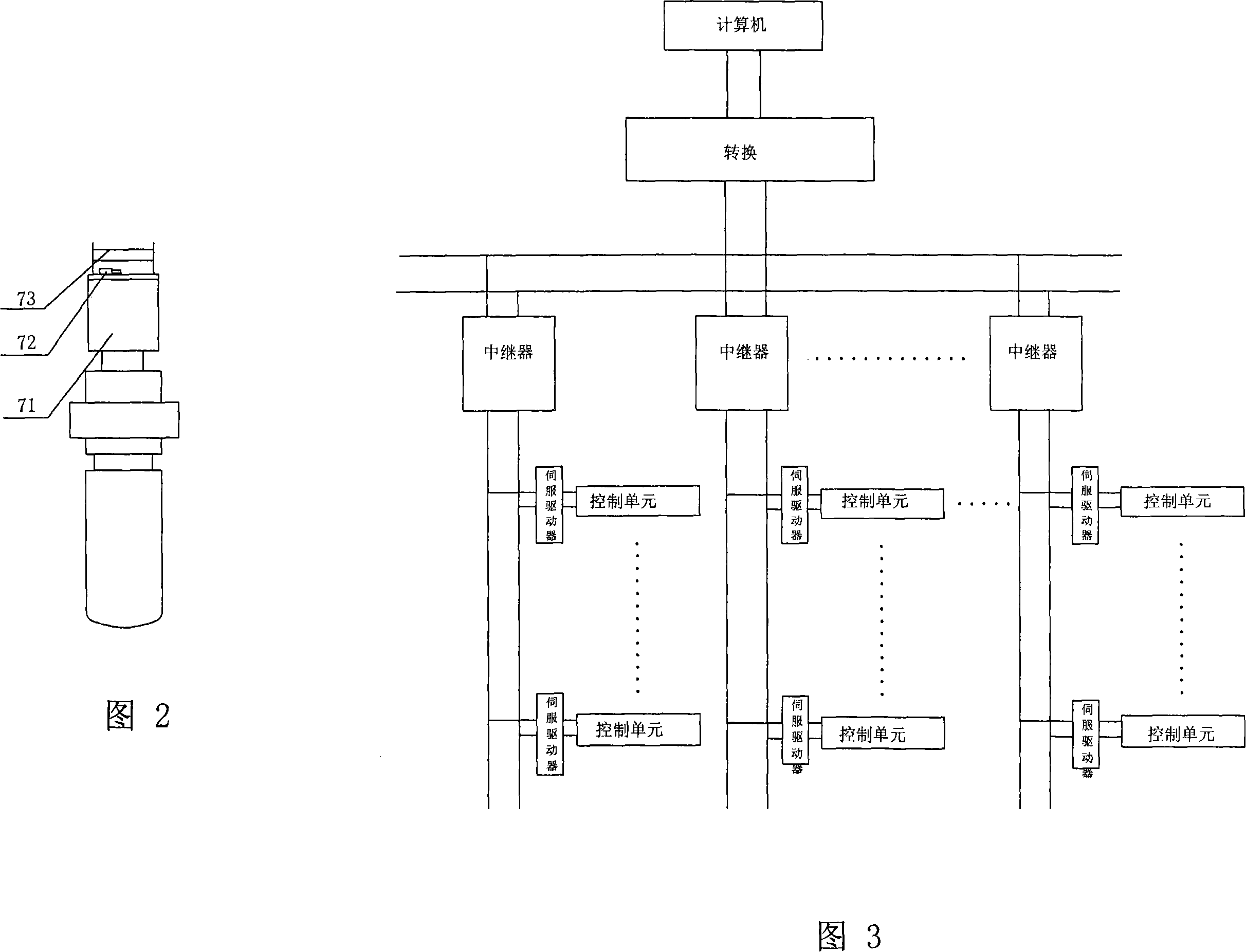

[0012] As shown in Fig. 1 and Fig. 2, the present invention includes an upper beam frame 1, a lower beam frame 2, a movable beam frame 3, an upper fixed plate 41, an upper basic body control unit group 42, a lower fixed plate 51, and a lower basic body control unit Group 52, basic body control units 43, 53, unit fixing plate 6, reduction motor 71, rotation angle detection device 72, control circuit 73, connecting rod 8. The upper beam frame 1 and the lower beam frame 2 are connected by a connecting rod 8, and a movable beam frame 3 is also connected between the upper beam frame 1 and the lower beam frame 2, and the movable beam frame 3 can slide on the connecting rod 8, and the movable beam frame 3 An upper fixed plate 41 is provided on the upper fixed plate 41, and an upper basic body control unit group 42 with an automatic adjustment mechanism is arranged on the upper fixed plate 41. The upper basic body control unit group 42 is composed of several basic body control units 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com